Carbon-Negative Scenarios in High CO2 Gas Condensate Reservoirs

Abstract

:1. Introduction

2. Materials and Methods

- —amount of produced CO2, kg

- V—(flaring) gas volume, m3

- molar volume conversion—conversion from molar volume to mass (23.685 m3/kgmole)

- —molecular weight of carbon dioxide, g/mol

- zi—molar fraction of component i, fraction

- Cc—carbon content of the mixture:

- wi—weight fraction of component i,

- —carbon content of (hydrocarbon) component i (mass part of unit):

- MC—molecular weight of carbon (MC = 12 g/mol)

- x—stoichiometric coefficient for carbon (number of carbon atoms in a molecule)

- Mi—molecular weight of component, g/mol

3. Results and Discussion

4. Conclusions

- all CO2 injection scenarios result with lower total pure (hydrocarbon) gas production than base case (without CO2 injection)

- lower cumulative hydrocarbon productions should be attributed to the fact that one production well is converted to CO2 injection well, causing instantaneous production rate decrease.

- lower cumulative hydrocarbon productions can also be attributed to CO2 breakthrough from injection to production wells and it can be connected to the fact that later start of CO2 injection (EGR2 cases) results in higher cumulative production

- also, higher pure hydrocarbon cumulative production is observed for cases with lower CO2 injection pressure (consequently, lower CO2 injection rate)

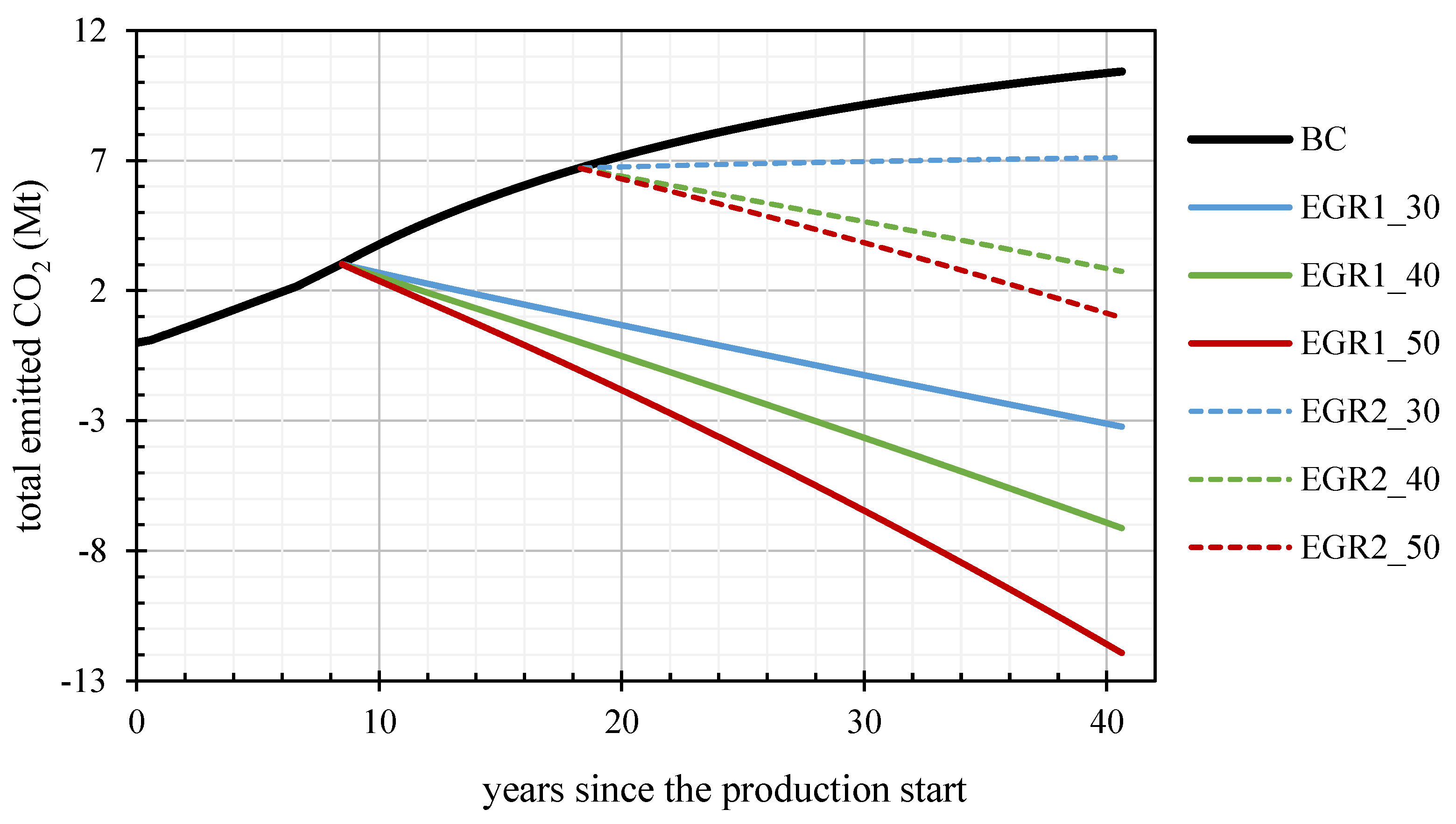

- the increase in CO2 production after breakthrough is smaller than CO2 retention—the difference between injected and produced CO2 is so large, that, from the beginning of CO2 injection, all EGR case, except EGR2_30 become carbon negative (negative slope of EGR cases shown in the last figure)

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Orr, F.M. Carbon Capture, Utilization, and Storage: An Update. SPE J. 2018, 23, 2444–2455. [Google Scholar] [CrossRef]

- Majumdar, A.; Deutch, J. Research Opportunities for CO2 Utilization and Negative Emissions at the Gigatonne Scale. Joule 2018, 2, 805–809. [Google Scholar] [CrossRef] [Green Version]

- Rojas, G.; Ali, S.M.F. Scaled Model Studies of Carbon Dioxide/Brine Injection Strategies for Heavy Oil Recovery from Thin Formations. J. Can. Pet. Technol. 1986, 25. [Google Scholar] [CrossRef]

- Blunt, M.; Fayers, F.J.; Orr, F.M. Carbon dioxide in enhanced oil recovery. Energy Convers. Manag. 1993, 34, 1197–1204. [Google Scholar] [CrossRef]

- Holm, L.W. Status of CO2 and Hydrocarbon Miscible Oil Recovery Methods. J. Pet. Technol. 1976, 28, 76–84. [Google Scholar] [CrossRef]

- Bealessio, B.A.; Alonso, N.A.B.; Mendes, N.J.; Sande, A.V.; Hascakir, B. A review of enhanced oil recovery (EOR) methods applied in Kazakhstan. Petroleum 2021, 7, 1–9. [Google Scholar] [CrossRef]

- Pittaway, K.R.; Hoover, J.W.; Deckert, L.B. Development and Status of the Maljamar CO2 Pilot. J. Pet. Technol. 1985, 37, 537–544. [Google Scholar] [CrossRef]

- Kane, A.V. Performance Review of a Large-Scale CO2-WAG Enhanced Recovery Project, SACROC Unit Kelly-Snyder Field. J. Pet. Technol. 1979, 31, 217–231. [Google Scholar] [CrossRef]

- Carcoana, A.N. Enhanced Oil Recovery in Rumania; Society of Petroleum Engineers: Tulsa, OK, USA, 1982. [Google Scholar] [CrossRef]

- Ormiston, R.M.; Luce, M.C. Surface Processing of Carbon Dioxide in EOR Projects. J. Pet. Technol. 1986, 38, 823–828. [Google Scholar] [CrossRef]

- Adams, G.H.; Rowe, H.G. Slaughter Estate Unit CO2 Pilot—Surface and Downhole Equipment Construction and Operation in the Presence of H2S. J. Pet. Technol. 1981, 33, 1065–1074. [Google Scholar] [CrossRef]

- Oldenburg, C.; Stevens, S.; Benson, S. Economic feasibility of carbon sequestration with enhanced gas recovery (CSEGR). Energy 2004, 29, 1413–1422. [Google Scholar] [CrossRef] [Green Version]

- Sim, S.S.K.; Turtata, A.T.; Singhal, A.K.; Hawkins, B.F. Enhanced Gas Recovery: Factors Affecting Gas-Gas Displacement Efficiency. J. Can. Pet. Technol. 2009, 48, 49–55. [Google Scholar] [CrossRef]

- Kalra, S.; Wu, X. SPE-169578-MS CO2 Injection for Enhanced Gas Recovery. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 15–18 April 2014; Society of Petroleum Engineers: Richardson, TX, USA; pp. 16–18. [Google Scholar] [CrossRef]

- Ping, G.; Shasha, J.; Caizhen, P. Technologies and countermeasures for gas recovery enhancement. Nat. Gas Ind. B 2014, 1, 96–102. [Google Scholar] [CrossRef] [Green Version]

- Carpenter, C. Enhanced Gas Recovery by CO2 Sequestration vs. Refracturing Treatment. J. Pet. Technol. 2015, 67, 125–127. [Google Scholar] [CrossRef]

- Baek, S.; Akkutlu, I.Y. Enhanced Recovery of Nanoconfined Oil in Tight Rocks Using Lean Gas (C2H6 and CO2) Injection. SPE J. 2021, 26, 2018–2037. [Google Scholar] [CrossRef]

- Van der Meer, B. Carbon dioxide storage in natural gas reservoir. Oil Gas Sci. Technol. 2005, 60, 527–536. [Google Scholar] [CrossRef]

- Khan, C.; Amin, R.; Madden, G. Carbon dioxide injection for enhanced gas recovery and storage (reservoir simulation). Egypt. J. Pet. 2013, 22, 225–240. [Google Scholar] [CrossRef] [Green Version]

- Khan, C.; Amin, R.; Madden, G. Effects of CO2 and acid gas injection on enhanced gas recovery and storage. J. Pet. Explor. Prod. Technol. 2013, 3, 55–60. [Google Scholar] [CrossRef] [Green Version]

- Narinesingh, J.; Alexander, D. CO2 Enhanced Gas Recovery and Geologic Sequestration in Condensate Reservoir: A Simulation Study of the Effects of Injection Pressure on Condensate Recovery from Reservoir and CO2 Storage Efficiency. Energy Procedia 2014, 63, 3107–3115. [Google Scholar] [CrossRef] [Green Version]

- Full, J.; Merseburg, S.; Miehe, R.; Sauer, A. A New Perspective for Climate Change Mitigation—Introducing Carbon-Negative Hydrogen Production from Biomass with Carbon Capture and Storage (HyBECCS). Sustainability 2021, 13, 4026. [Google Scholar] [CrossRef]

- Borowski, P.F. Significance and Directions of Energy Development in African Countries. Energies 2021, 14, 4479. [Google Scholar] [CrossRef]

- Lai, Y.-T.; Shen, C.-H.; Tseng, C.-C.; Fan, C.-H.; Hsieh, B.-Z. Estimation of Carbon Dioxide Storage Capacity for Depleted Gas Reservoirs. Energy Procedia 2015, 76, 470–476. [Google Scholar] [CrossRef] [Green Version]

- Peng, D.-Y.; Robinson, D.B. A New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Stryjek, R.; Vera, J.H. PRSV: An improved peng-Robinson equation of state for pure compounds and mixtures. Can. J. Chem. Eng. 1986, 64, 323–333. [Google Scholar] [CrossRef]

- Soave, G. Equilibrium constants from a modified Redlich-Kwong equation of state. Chem. Eng. Sci. 1972, 27, 1197–1203. [Google Scholar] [CrossRef]

- Vulin, D.; Saftić, B.; Macenić, M. Estimate of dynamic change of fluid saturation during CO2 injection—Case study of a regional aquifer in Croatia. Interpretation 2018, 6, SB51–SB64. [Google Scholar] [CrossRef]

- Loizzo, M.; Lecampion, B.; Bérard, T.; Harichandran, A.; Jammes, L. Reusing O&G-Depleted Reservoirs for CO2 Storage: Pros and Cons. SPE Proj. Facil. Constr. 2010, 5, 166–172. [Google Scholar] [CrossRef]

- Al-Abri, A.; Hiwa, S.; Robert, A. Experimental investigation of the velocity-dependent relative permeability and sweep efficiency of supercritical CO2 injection into gas condensate reservoirs. J. Nat. Gas Sci. Eng. 2009, 1, 158–164. [Google Scholar] [CrossRef]

- Hamza, A.; Hussein, I.A.; Al-Marri, M.J.; Mahmoud, M.; Shawabkeh, R.; Aparicio, S. CO2 enhanced gas recovery and sequestration in depleted gas reservoirs: A review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Zhang, L.; Niu, B.; Ren, S.; Zhang, Y.; Yi, P.; Mi, H.; Ma, Y. Assessment of CO2 Storage in DF1-1 Gas Field South China Sea for a CCS Demonstration. J. Can. Pet. Technol. 2010, 49, 9–14. [Google Scholar] [CrossRef]

- Trivedi, J.J.; Babadagli, T.; Lavoie, R.G.; Nimchuk, D. Acid Gas Sequestration During Tertiary Oil Recovery: Optimal Injection Strategies and Importance of Operational Parameters. J. Can. Pet. Technol. 2007, 46. [Google Scholar] [CrossRef]

- Sidiq, H.; Amin, R. The Impact of Pore Pressure on CO2-Methane Displacement. Pet. Sci. Technol. 2012, 30, 2531–2542. [Google Scholar] [CrossRef]

- Honari, A.; Zecca, M.; Vogt, S.J.; Iglauer, S.; Bijeljic, B.; Johns, M.L.; May, E.F. The impact of residual water on CH4-CO2 dispersion in consolidated rock cores. Int. J. Greenh. Gas Control 2016, 50, 100–111. [Google Scholar] [CrossRef]

- Kashefi, K.; Pereira, L.M.C.; Chapoy, A.; Burgass, R.; Tohidi, B. Measurement and modelling of interfacial tension in methane/water and methane/brine systems at reservoir conditions. Fluid Phase Equilib. 2016, 409, 301–311. [Google Scholar] [CrossRef]

- Sedlar, D.K.; Vulin, D.; Jukić, L.; Smajla, I. Possibility of decreasing CO2 emissions from flaring on a mature oil field. J. Pet. Sci. Eng. 2018, 171, 1302–1308. [Google Scholar] [CrossRef]

| Component | %mol |

|---|---|

| N2 | 1.98 |

| CO2 | 48.95 |

| C1 | 45.41 |

| C2 | 1.66 |

| C3 | 0.36 |

| iC4 | 0.13 |

| nC4 | 0.22 |

| iC5 | 0.07 |

| nC5 | 0.07 |

| C6 | 0.16 |

| C7 | 0.15 |

| C8 | 0.11 |

| C9 | 0.10 |

| C10+ | 0.63 |

| total | 100.00 |

| EGR Scenario | Timing | PM (iBHP = PM∙pr) |

|---|---|---|

| EGR1_30 | 0.75∙pi | 1.3 |

| EGR1_40 | 1.4 | |

| EGR1_50 | 1.5 | |

| EGR2_30 | 0.5∙pi | 1.3 |

| EGR2_40 | 1.4 | |

| EGR2_50 | 1.5 |

| Component | yi (%) |

|---|---|

| N2 | 3.88 |

| CO2 | 0.00 |

| C1 | 88.95 |

| C2 | 3.25 |

| C3 | 0.71 |

| iC4 | 0.24 |

| nC4 | 0.42 |

| iC5 | 0.14 |

| nC5 | 0.14 |

| C6 | 0.32 |

| C7 | 0.29 |

| C8 | 0.22 |

| C9 | 0.19 |

| C10+ | 1.24 |

| Σ | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jukić, L.; Vulin, D.; Kružić, V.; Arnaut, M. Carbon-Negative Scenarios in High CO2 Gas Condensate Reservoirs. Energies 2021, 14, 5898. https://doi.org/10.3390/en14185898

Jukić L, Vulin D, Kružić V, Arnaut M. Carbon-Negative Scenarios in High CO2 Gas Condensate Reservoirs. Energies. 2021; 14(18):5898. https://doi.org/10.3390/en14185898

Chicago/Turabian StyleJukić, Lucija, Domagoj Vulin, Valentina Kružić, and Maja Arnaut. 2021. "Carbon-Negative Scenarios in High CO2 Gas Condensate Reservoirs" Energies 14, no. 18: 5898. https://doi.org/10.3390/en14185898