Carbon-Negative Hydrogen Production (HyBECCS) from Organic Waste Materials in Germany: How to Estimate Bioenergy and Greenhouse Gas Mitigation Potential

Abstract

:1. Introduction

2. Basics

2.1. Organic Waste Classification in Germany

- Further use of the substance or object is certain;

- The substance or object can be used directly without any further processing other than normal industrial practice;

- The substance or object is produced as an integral part of a production process;

- Further use is lawful, i.e., the substance or object fulfills all relevant product, environmental, and health protection requirements for the specific use and will not lead to overall adverse environmental or human health impacts [(1),§4, KrWG].

2.2. Biohydrogen Production and the HyBECCS Approach

2.2.1. Biohydrogen Technologies

2.2.2. The HyBECCS Approach

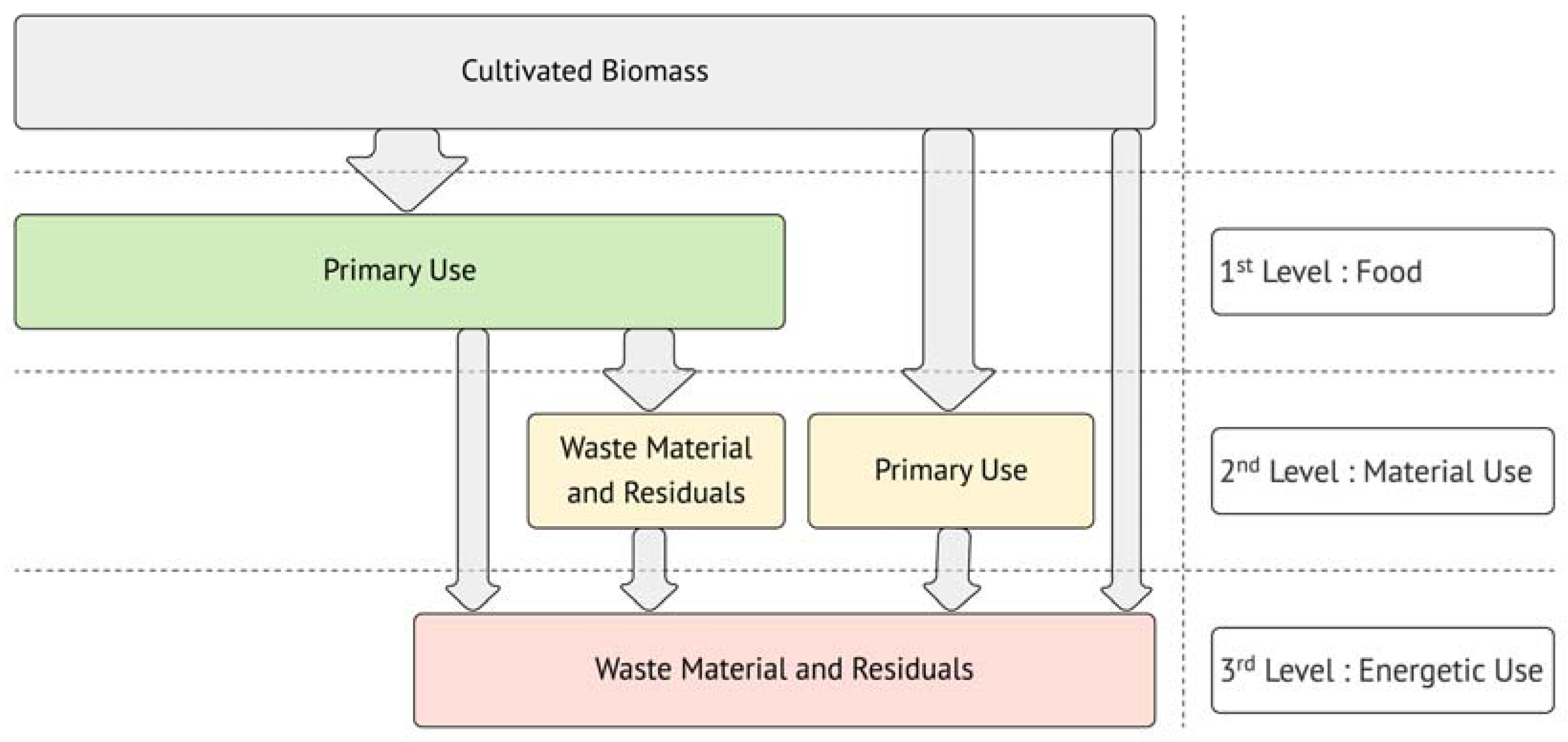

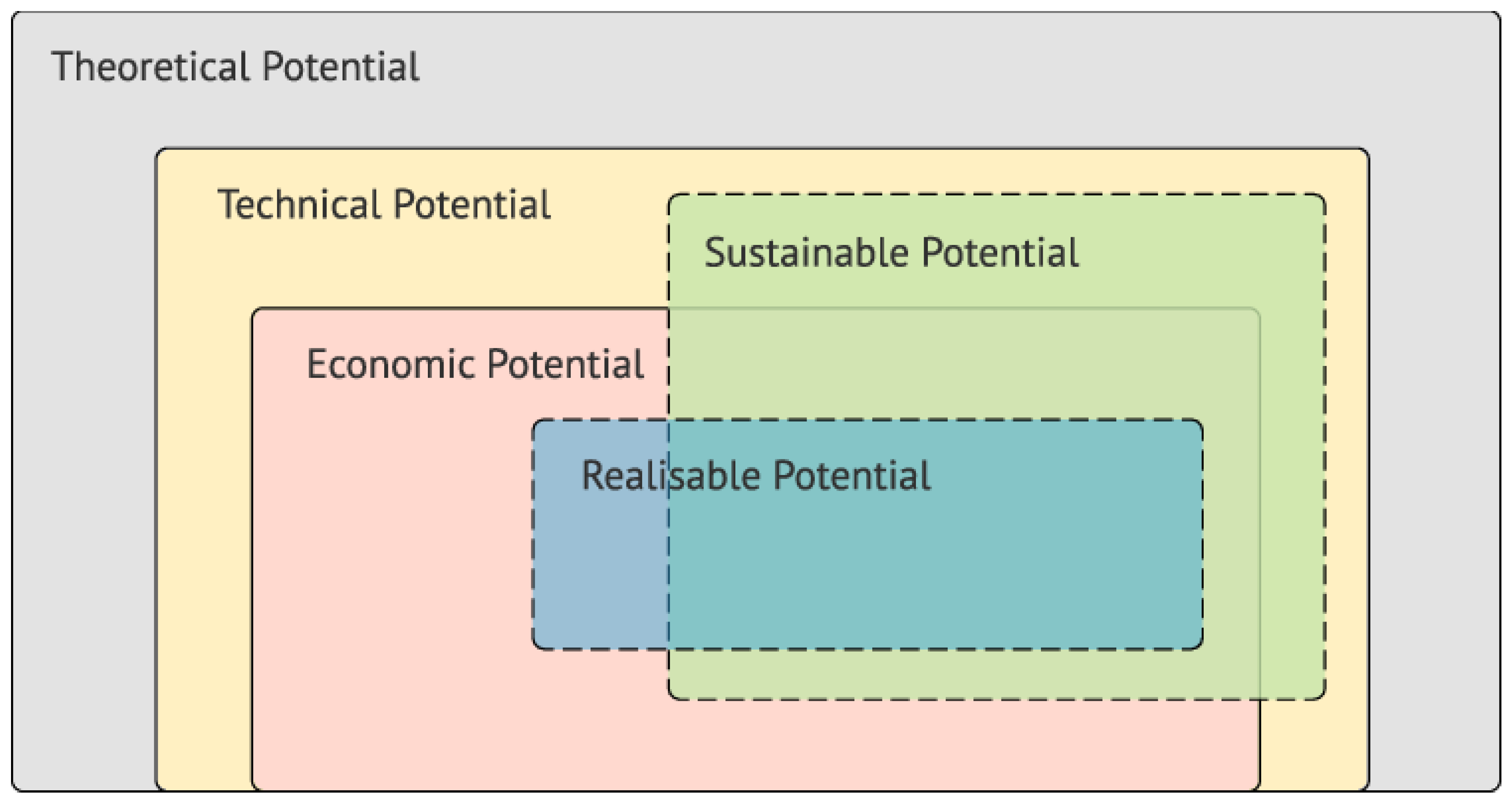

2.3. Terminology and System Boundaries

- Societal variables (as general agreement whether certain feedstock should receive a generally preferred form of utilization).

- Technical variables (cultivation, harvest, recovery, and conversion technology).

- Demand for food and material utilization.

- Ecological/environmental variables (legal requirements to ensure a sustainable resource base).

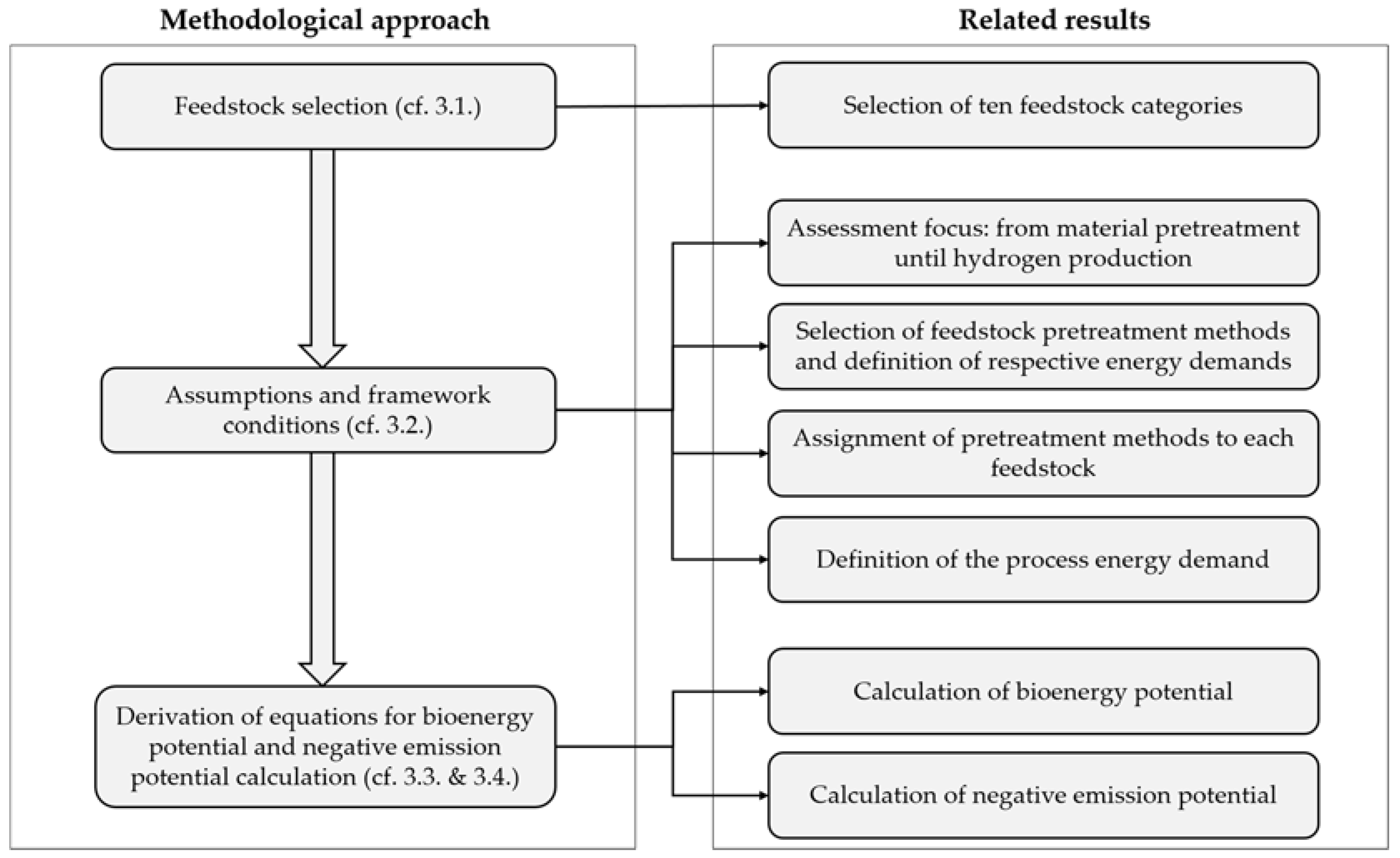

3. Methodological Approach

3.1. Feedstock Selection

- -

- Step 1 Data validity, utilization pathways, and classification issues: According to Brosowski et al., data and information are inconsistent for 16 biomass categories (BCs) and no technical potential is presented for eight categories. Those classes are sorted out in this step. Moreover, many food industry wastes, such as coffee or tobacco residues, must be disposed of according to special regulations. Other biomass flows, such as residues from convenience food production, are highly heterogeneous and assumed not to contain large amounts of relevant contents [42] (Chapter 2). Thus, it is not possible to make reasonable assumptions about the composition and such material flows should not be considered for utilization. In this case, 32/93 BCs can be discarded in this step.

- -

- Step 2 Lignocellulosic biomass: Biomass categories containing wood or wood-like waste, straw, stalk, or other green waste are currently not suitable for some biotechnological processes, as they need to be readily biodegradable by microorganisms. Wood essentially consists of cellulose, hemicellulose, and lignin, which are poorly biodegradable without extensive pretreatment. Hence, they are rather unsuitable for fermentative processes [20] (p. 53); 28/93 BCs match this criterion and should be sorted out.

- -

- Step 3 Wastes of animal origin: Such wastes should not be considered for alternative use because of the potentially contagious material and an established industry for efficient utilization of animal origin wastes. Gaida et al. describe the utilization of this biomass as already optimized. For instance, animal skin is processed to leather, and protein-rich residues are processed into tankage or fertilizer. Other potential pathways are biodiesel production and utilization as substances in the oleochemical industry [42] (pp. 22, 24). However, if a special suitability can be derived for specific biohydrogen process options, a comparison with the respective reference processes might be of interest. If not, 2/93 BCs match this criterion and should be sorted out.

- -

- Step 4 Oils and fats: In a comprehensive evaluation of utilization pathways for this category, Fehrenbach et al. found that biodiesel production might be superior to other means of utilization [22] (pp. 112, 179). A comparison of the biohydrogen process under consideration with this form of use is therefore to be initiated. If the comparison is decided in favor of biodiesel production, another 2/93 BCs are sorted out in this step.

- -

- Step 5 Waste material untypical for fermentation: Some waste types can be considered as biomass, but are not readily biodegradable, such as textiles or packaging material. These must also be subjected to a special test to determine their suitability for biohydrogen production. If this test is negative, 2/93 BCs match this criterion and have to be sorted out.

- -

- Step 6 Animal feed or low sugar content: According to Section 2.1., material use of biomass should be preferred over energetic use in the case of animal feed, for instance. Hence, plenty of different process residues from the food industry cannot be seen as waste and are consequently not considered in this estimation of potential. Usage competition can arise if such materials are utilized energetically. Residues from the sugar industry would be perfectly suitable for fermentative biohydrogen processes, due to their sugar content. However, this material is widely used as animal feed, in the yeast industry, or in distilleries. The work of Gaida et al. indicates high-value material use for most food industry residues at present [42] (Section 2). However, dairy industry residues, which mostly consist of whey [42] (p. 40), are excluded from this step. The amount currently fed to pigs is found to be better used for human consumption, which mainly consists of the contained whey protein [43] (p. 271). The contained lactose, which is a substrate for homolactic fermentation, remains in the permeate after protein extraction, hence it can be considered. Other biomass categories, such as residues from alcohol production, must first be checked as to whether they contain significant amounts of utilizable substances for biohydrogen production. Finally, 17/93 BCs could be excluded in this step.

3.2. Definition of Assumptions and Framework Conditions

3.2.1. Substrate Pretreatment

- electric: Wel = 2.5 kWh/t ≙ 9 MJ/t (Wel = 2.1–2.3 kWh/m3 [45] (p. 105); assumed substrate density 1000 kg/m3);

- thermal: Wth = 18 kWh/t ≙ 64.8 MJ/t.

3.2.2. Process Energy Demand

3.2.3. Logistics, Substrate Storage, and Handling of Residues

3.2.4. Produce Gas Separation

3.3. Calculation of Energy Potential

3.4. Negative Emission Potential Estimation

4. Discussion

5. Summary and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021; In Press. [Google Scholar]

- BMWi. The National Hydrogen Strategy, Federal Ministry for Economic Affairs and Energy, Berlin. 2020. Available online: https://www.bmwi.de/Redaktion/DE/Publikationen/Energie/die-nationale-wasserstoffstrategie.html (accessed on 4 March 2021).

- Juhrich, K. CO2 Emission Factors for Fossil Fuels. 2016. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1968/publikationen/co2_emission_factors_for_fossil_fuels_correction.pdf (accessed on 26 March 2021).

- Full, J.; Merseburg, S.; Miehe, R.; Sauer, A. A new perspective for climate change mitigation–introducing carbon-negative hydrogen production from biomass with carbon capture and storage (HyBECCS). Sustainability 2021, 13, 4026. [Google Scholar] [CrossRef]

- Agentur für Erneuerbare Energien. Bundesländer-Übersicht zu Erneuerbaren Energien (Overview Renewable Energies). Renewable Energies Agency (AEE). 2019. Available online: https://bit.ly/3s3ws6s (accessed on 4 March 2021).

- Schmid, C.; Horschig, T.; Pfeiffer, A.; Szarka, N.; Thrän, D. Biogas upgrading: A review of national biomethane strategies and support policies in selected countries. Energies 2019, 12, 3803. [Google Scholar] [CrossRef] [Green Version]

- Weide, T.; Feil, F.; Kamphus, S.; Peitzmeier, J.; Brügging, E. Bio-H2 aus Organischen Reststoffen Mittels Dunkler Fermentation in Deutschland und den Niederlanden. 2020. Available online: http://www.biohydrogen.eu/wp-content/uploads/2020/09/2020-09-18-Wasserstoff-Potential-DE-NL_final.pdf (accessed on 4 March 2021).

- Thomassen, G.; van Dael, M.; van Passel, S.; You, F. How to assess the potential of emerging green technologies? Towards a prospective environmental and techno-economic assessment framework. Green Chem. 2019, 21, 4868–4886. [Google Scholar] [CrossRef]

- Naqvi, S.; Ali, I.; Nasir, S.; Taqvi, S.A.A.; Atabani, A.E.; Chen, W. Assessment of agro-industrial residues for bioenergy potential by investigating thermo-kinetic behavior in a slow pyrolysis process. Fuel 2020, 278. [Google Scholar] [CrossRef]

- Thrän, D.; Bauschmann, M.; Dahmen, N.; Erlach, B.; Heinbach, K.; Hirschl, B.; Hildebrand, J.; Rau, I.; Majer, S.; Oehmichen, K.; et al. Bioenergy beyond the German “Energiewende”–Assessment framework for integrated bioenergy strategies. Biomass Bioenergy 2020, 142, 105769. [Google Scholar] [CrossRef]

- Long, H.; Li, X.; Wang, H.; Jia, J. Biomass resources and their bioenergy potential estimation: A review. Renew. Sustain. Energy Rev. 2013, 26, 344–352. [Google Scholar] [CrossRef]

- Fu, T.; Ke, J.H.; Zhou, S.; Xie, G.H. Estimation of the quantity and availability of forestry residue for bioenergy production in China. Resour. Conserv. Recycl. 2020, 162, 104993. [Google Scholar] [CrossRef]

- Batidzirai, B.; Smeets, E.M.W.; Faaij, A.P.C. Harmonising bioenergy resource potentials—Methodological lessons from review of state of the art bioenergy potential assessments. Renew. Sustain. Energy Rev. 2012, 16, 6598–6630. [Google Scholar] [CrossRef]

- Bharti, A.; Paritosh, K.; Mandla, V.R.; Chawade, A.; Vivekanand, V. GIS Application for the Estimation of Bioenergy Potential from Agriculture Residues: An Overview. Energies 2021, 14, 898. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). EU Bioenergy Potential from a Resource-Efficiency Perspective; EEA: Brussels, Belgium, 2013; Volume 6, ISBN 9789-2921-3397-9.

- Winkler, B.; Lemke, S.; Lewandowski, I. IREPA-Biomass for Bioenergy Potential Assessment by a Holistic and Participatory Approach. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Vienna, Austria, 4 June 2015; pp. 273–281. Available online: https://doi.org/10.5071/23rdEUBCE2015-1CV.3.21 (accessed on 17 November 2021).

- BMWi. Gesetz zur Änderung des Erneuerbare-Energien-Gesetzes und Weiterer Energierechtlicher Vorschriften. 2021. Available online: https://www.bmwi.de/Redaktion/DE/Artikel/Service/gesetz-zur-aenderung-des-eeg-und-weiterer-energierechtlicher-vorschriften.html (accessed on 1 April 2021).

- Umweltbundesamt. Waste Statistics. 2016. Available online: https://www.umweltbundesamt.de/en/topics/waste-resources/waste-management/waste-statistics (accessed on 1 April 2021).

- Thrän, D.; Adler, P.; Brosowski, A.; Fischer, E.; Herrmann, A.; Majer, S.; Oehmichen, K.; Pfeiffer, D.; Schmersahl, R.; Schröder, T.; et al. Method Handbook-Material Flow-Oriented Assessment of Greenhouse Gas Effects. 2015. Available online: https://www.energetische-biomassenutzung.de/fileadmin/media/6_Publikationen/04_MHB_en_web.pdf (accessed on 25 March 2021).

- Köppel, W.; Erler, R.; Senner, J.; Kiefer, J. Einsatz Von Industriellen Und Kommunalen Abfallstoffen für die Biogaseinspeisung. 2014. Available online: https://www.dvgw.de/medien/dvgw/forschung/berichte/g1_08_10.pdf (accessed on 9 March 2021).

- Brosowski, P.; Adler, G.; Erdmann, W.; Stinner, D.; Thrän, U.; Mantau, C.; Blanke, B.; Mahro, T.; Hering, G. Reinholdt, Biomassepotenziale von Rest- und Abfallstoffen- Status quo in Deutschland. 2015. Available online: https://mediathek.fnr.de/band-36-biomassepotenziale-von-rest-und-abfallstoffen.html (accessed on 9 March 2021).

- Fehrenbach, H.; Giegrich, J.; Köppen, S.; Wern, B.; Pertagnol, J.; Baur, F.; Hünecke, K.; Dehoust, G.; Bulach, W.; Wiegmann, K. BioRest: Verfügbarkeit und Nutzungsoptionen biogener Abfall- und Reststoffe im Energiesystem (Strom-, Wärme- und Verkehrssektor). 2019. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2019-09-24_texte_115-2019_biorest.pdf (accessed on 9 March 2021).

- Knappe, F.; Vogt, R.; Turk, T.; Hüttner, A.; Dehoust, G.; Schneider, T. Hochwertige Verwertung von Bioabfällen-Ein Leitfaden. 2015. Available online: https://pudi.lubw.de/detailseite/-/publication/94776 (accessed on 2 April 2021).

- Scholwin, F.; Grope, J.; Clinkscales, A.; Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Stinner, W.; Richter, F.; Raussen, T.; Kern, M.; et al. Thomas and Reinhold, Aktuelle Entwicklung und Perspektiven der Biogasproduktion aus Bioabfall und Gülle. 2019. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2019-04-15_texte_41-2019_biogasproduktion.pdf (accessed on 11 March 2021).

- Mühlenhoff, J.; Dannemann, B. Biogene Rest- und Abfallstoffe-Flexibler Baustein der Energiewende. Renews Spez. 2017, 81, 18. [Google Scholar]

- Knappe, F.; Vogt, R.; Lazar, S.; Höke, S. Optimierung der Verwertung Organischer Abfälle. 2012. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4310.pdf (accessed on 12 March 2021).

- Zeller, V.; Gröngröft, A.; Kirsten, C.; Weller, N.; Schenker, M.; Wedwitschka, H.; Wagner, B.; Deumelandt, P.; Reinicke, F.; Vetter, A.; et al. Basisinformationen Für Eine Nachhaltige NUTZUNG von Landwirtschaftlichen Reststoffen zur Bioenergiebereitstellung. 2012. Available online: https://www.energetische-biomassenutzung.de/fileadmin/user_upload/Downloads/Ver%C3%B6ffentlichungen/02_Basisinformationen_Reststoffe_web.pdf (accessed on 12 March 2021).

- BMU. Abfallwirtschaft in Deutschland 2020-Fakten, Daten, Grafiken. 2020. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Pools/Broschueren/abfallwirtschaft_2020_bf.pdf (accessed on 18 March 2021).

- Destatis. Waste Balance 2018. 2020. Available online: https://www.destatis.de/EN/Themes/Society-Environment/Environment/Waste-Management/Tables/liste-brief-overview-waste-balance.html (accessed on 10 March 2021).

- BMBF. Eine Kleine Wasserstoff-Farbenlehre. 2020. Available online: https://bit.ly/3mJz07R (accessed on 12 April 2021).

- Pandey, A.; Chang, J.-S.; Hallenbeck, P.C.; Larroche, C. (Eds.) Biohydrogen-Biomass, Biofuels, Biochemicals, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780-4446-4203-5. [Google Scholar]

- Poullikkas, A.; Al-Assaf, Y.; Kalamaras, C.M.; Efstathiou, A.M. Hydrogen production technologies: Current state and future developments. Conf. Pap. Energy 2013, 690627, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yin, Y. Biohydrogen Production from Organic Wastes; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9789-8110-4675-9. [Google Scholar]

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrog. Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Kapdan, I.K.; Kargi, F. Bio-hydrogen production from waste materials. Enzym. Microb. Technol. 2006, 38, 569–582. [Google Scholar] [CrossRef]

- Singh, A.; Rathore, D. (Eds.) Biohydrogen Production: Sustainability of Current Technology and Future Perspective, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9788-1322-3577-4. [Google Scholar]

- Ghosh, R.; Grammel, H.; Sauer, A. Neue Strategie zur Wasserstoff-Produktion aus Frucht- und Molkereiabfällen mit Hilfe von Purpurbakterien. Available online: https://www.energetische-biomassenutzung.de/projekte-partner/details/project/show/Project/rhotech-637/ (accessed on 3 April 2021).

- Zeiger, L.; Grammel, H. Model-based high cell density cultivation of Rhodospirillum rubrum under respiratory dark conditions. Biotechnol. Bioeng. 2010, 105, 729–739. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef] [Green Version]

- Full, J.; Miehe, R.; Kiemel, S.; Bauernhansl, T.; Sauer, A. The Biological Transformation of Energy Supply and Storage–Technologies and Scenarios for Biointelligent Value Creation. Procedia Manuf. 2019, 39, 1204–1214. [Google Scholar] [CrossRef]

- Miehe, R.; Bauernhansl, T.; Beckett, M.; Brecher, C.; Demmer, A.; Drossel, W.-G.; Elfert, P.; Full, J.; Hellmich, A.; Hinxlage, J.; et al. The biological transformation of industrial manufacturing–Technologies, status and scenarios for a sustainable future of the German manufacturing industry. J. Manuf. Syst. 2020, 54, 50–61. [Google Scholar] [CrossRef]

- Gaida, B.; Schüttmann, I.; Zorn, H.; Mahro, B. Bestandsaufnahme zum biogenen Reststoffpotential der deutschen Lebensmittel und Biotechnik-Industrie. 2013. Available online: https://www.fnr-server.de/ftp/pdf/berichte/22001910.pdf (accessed on 9 March 2021).

- Kopf, K.A.; Bisig, W.; Jungbluth, N.; Denkel, C. Quantitatives Potenzial zur Verwertung von Molke in Lebensmitteln in der Schweiz. Agrar. Schweiz 2015, 6, 270–277. [Google Scholar] [CrossRef]

- Aschmann, V.; Effenberger, M.; Gronauer, A.; Kaiser, F.; Kissel, R.; Mitterleitner, H.; Neser, S.; Schlattmann, M.; Speckmaier, M.; Ziehfreund, G. Biogashandbuch Bayern-Grundlagen und Technik. 2007. Available online: https://www.lfu.bayern.de/energie/biogashandbuch/index.htm (accessed on 15 March 2021).

- Pospiech, J.; Ullrich, M.; Göttling, S.; Truyen, U.; Speck, S. Hygienisierung von Wirtschaftsdünger und Gärresten. 2014. Available online: https://nbn-resolving.org/urn:nbn:de:bsz:14-qucosa-161847 (accessed on 17 November 2021).

- Vavouraki, A.I.; Angelis, E.M.; Kornaros, M. Optimization of thermo-chemical hydrolysis of kitchen wastes. Waste Manag. 2013, 33, 740–745. [Google Scholar] [CrossRef]

- Patni, N.; Jui, P.Y. Volatile fatty acids in stored dairy-cattle slurry. Agric. Wastes 1985, 13, 159–178. [Google Scholar] [CrossRef]

- Panesar, P.S.; Kennedy, J.F.; Gandhi, D.N.; Bunko, K. Bioutilisation of whey for lactic acid production. Food Chem. 2007, 105, 1–14. [Google Scholar] [CrossRef]

- Fachagentur Nachwachsende Rohstoffe e. V. (n.d.). Faustzahlen. Available online: https://biogas.fnr.de/daten-und-fakten/faustzahlen (accessed on 18 March 2021).

- Bakonyi, P.; Nemestóthy, N.; Bélafi-Bakó, K. Biohydrogen purification by membranes: An overview on the operational conditions affecting the performance of non-porous, polymeric and ionic liquid based gas separation membranes. Int. J. Hydrog. Energy 2013, 68, 9673–9687. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Morales, J.E.; Tapia-Venegas, E.; Toledo-Alarcón, J.; Ruiz-Filippi, G. Simultaneous production and separation of biohydrogen in mixed culture systems by continuous dark fermentation. Water Sci. Technol. 2015, 71, 1271–1285. [Google Scholar] [CrossRef]

- Staffell, I. Zero carbon infinite COP heat from fuel cell CHP. Appl. Energy 2015, 147, 373–385. [Google Scholar] [CrossRef]

- Fajardy, M.; Koeberle, A.; MacDowell, N.; Fantuzzi, A. BECCS deployment: A reality check. Grantham Inst. Brief. Pap. 2019, 28, 1–13. [Google Scholar]

- DEHSt. Leitfaden zur Erstellung von Überwachungsplänen für Stationäre Anlagen-4. Handelsperiode (2021–2030). 2020. Available online: https://bit.ly/31nG9Rz (accessed on 26 March 2021).

- Otto, A.; Robinius, M.; Grube, T.; Schiebahn, S.; Praktiknjo, A.; Stolten, D. Power-to-steel: Reducing CO2 through the integration of renewable energy and hydrogen into the German steel industry. Energies 2017, 10, 451. [Google Scholar] [CrossRef] [Green Version]

- Umweltbundesamt. CO2 Emissions Per Kilowatt Hour of Electricity in Further Decline in 2019. 2020. Available online: https://www.umweltbundesamt.de/presse/pressemitteilungen/bilanz-2019-co2-emissionen-pro-kilowattstunde-strom (accessed on 25 April 2021).

- Pehnt, M. Energieeffizienz; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 9783-6421-4250-5. [Google Scholar]

| Number | Process | Reaction |

|---|---|---|

| (1.1) | Biomass pyrolysis | CnHm → n C + 0.5 m H2 |

| (1.2) | Glucose formation | 6 H2O + 6 CO2 → C6H12O6 + 6 O2 |

| (1.3) | Enzymatic hydrogen generation | C6H12O6 + 6 H2O → 6 CO2 + 12 H2 |

| (1.4) | Microbial electrolysis (acetate) | CH3COO− + 4 H2O → 2 HCO3− + H+ + 4 H2 |

| (1.5) | Photo-fermentation (acetic acid) | CH3COOH + 2 H2O → 4 H2 + 2 CO2 |

| (1.6) | Acidogenesis (butyric acid) | C6H12O6 →CH3CH2CH2COOH + 2 CO2 + 2 H2 |

| Method | Energy Demand | ||

|---|---|---|---|

| Symbol | Name | Wel in MJ/t | Wth in MJ/t |

| (G) | Grinding | 8.9 | 0 * |

| (H) | Hygienization | 9 | 43.2 |

| (TCH) | Thermochemical hydrolysis | 9 | 64.8 |

| (AS) | Anaerobic storage | 0 * | 0 * |

| (HLF) | Homolactic fermentation | 0 * | 0 * |

| Biomass Category | Pretreatment | ||||

|---|---|---|---|---|---|

| (G) | (H) | (TCH) | (AS) | (HLF) | |

| Cattle manure and slurry | x | x | |||

| Pig manure and slurry | x | x | |||

| Cattle dung | x | x | x | ||

| Pig dung | x | x | x | ||

| Organic household waste | x | x | |||

| Kitchen and canteen waste | x | x | |||

| Waste from markets | x | x | |||

| Dairy industry residues | x | x | |||

| Organic fraction of MSW | x | x | |||

| Commercial food waste | x | x | |||

| Energy Carrier | References | ||

|---|---|---|---|

| Natural gas (NG) | 47.4 3 | 56 | [54] (p. 138) |

| Coke (C) | 27.6 | 105 | [54] (p. 138) |

| Hard coal (HC) | 28.3 | 93 | [54] (p. 138) |

| Heavy fuel oil (HFO) | 39.5 | 81 | [54] (p. 138) |

| H2 steam reforming (SR) 1 | 120 | 67 | [36] (p. 239) [55] (Table 1) |

| H2 electrolysis electricity mix (EM) 2 | 120 | 83 | |

| H2 electrolysis renewables (REN) 2 | 120 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Full, J.; Trauner, M.; Miehe, R.; Sauer, A. Carbon-Negative Hydrogen Production (HyBECCS) from Organic Waste Materials in Germany: How to Estimate Bioenergy and Greenhouse Gas Mitigation Potential. Energies 2021, 14, 7741. https://doi.org/10.3390/en14227741

Full J, Trauner M, Miehe R, Sauer A. Carbon-Negative Hydrogen Production (HyBECCS) from Organic Waste Materials in Germany: How to Estimate Bioenergy and Greenhouse Gas Mitigation Potential. Energies. 2021; 14(22):7741. https://doi.org/10.3390/en14227741

Chicago/Turabian StyleFull, Johannes, Mathias Trauner, Robert Miehe, and Alexander Sauer. 2021. "Carbon-Negative Hydrogen Production (HyBECCS) from Organic Waste Materials in Germany: How to Estimate Bioenergy and Greenhouse Gas Mitigation Potential" Energies 14, no. 22: 7741. https://doi.org/10.3390/en14227741