Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wastewater Preparation and Bioreactor Acclimatization

2.2. Bioreactor Set-Up

2.3. Bioreactor Operation

2.4. Analytical Methods

2.5. Scanning Electron Microscope

2.6. Energy Estimation

3. Results and Discussion

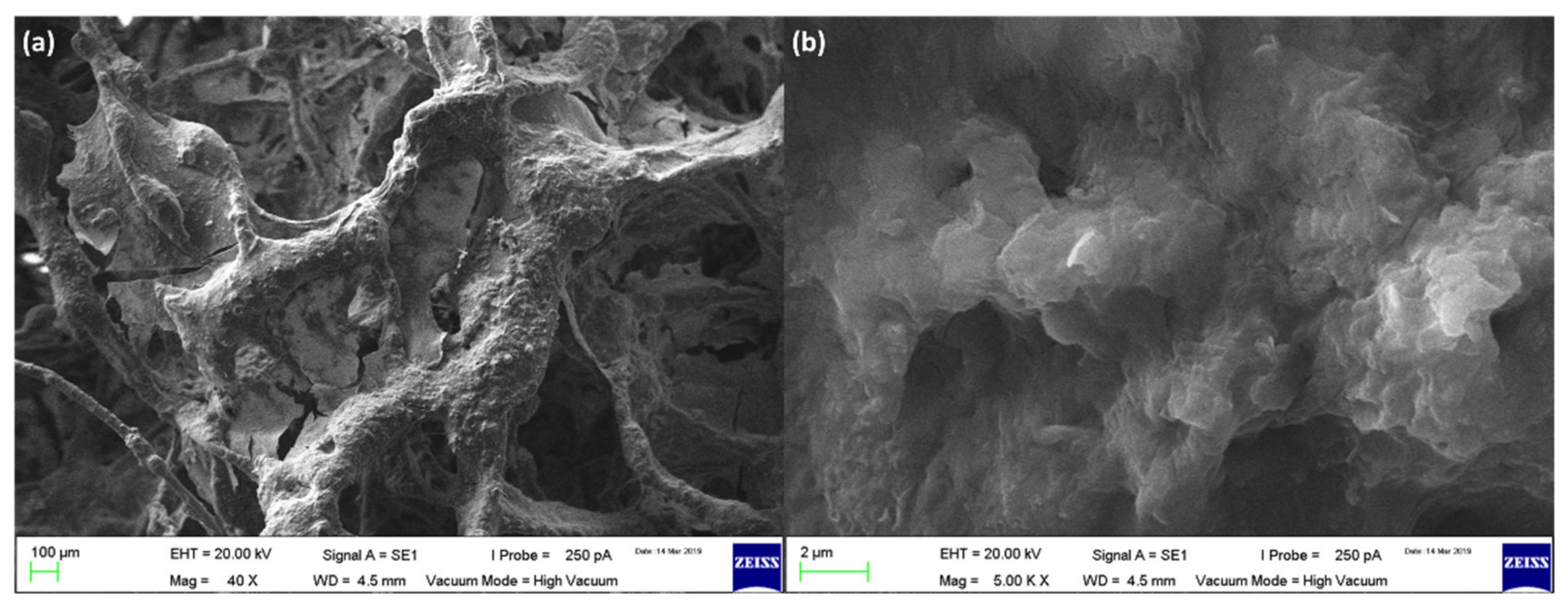

3.1. Biofilm Analysis

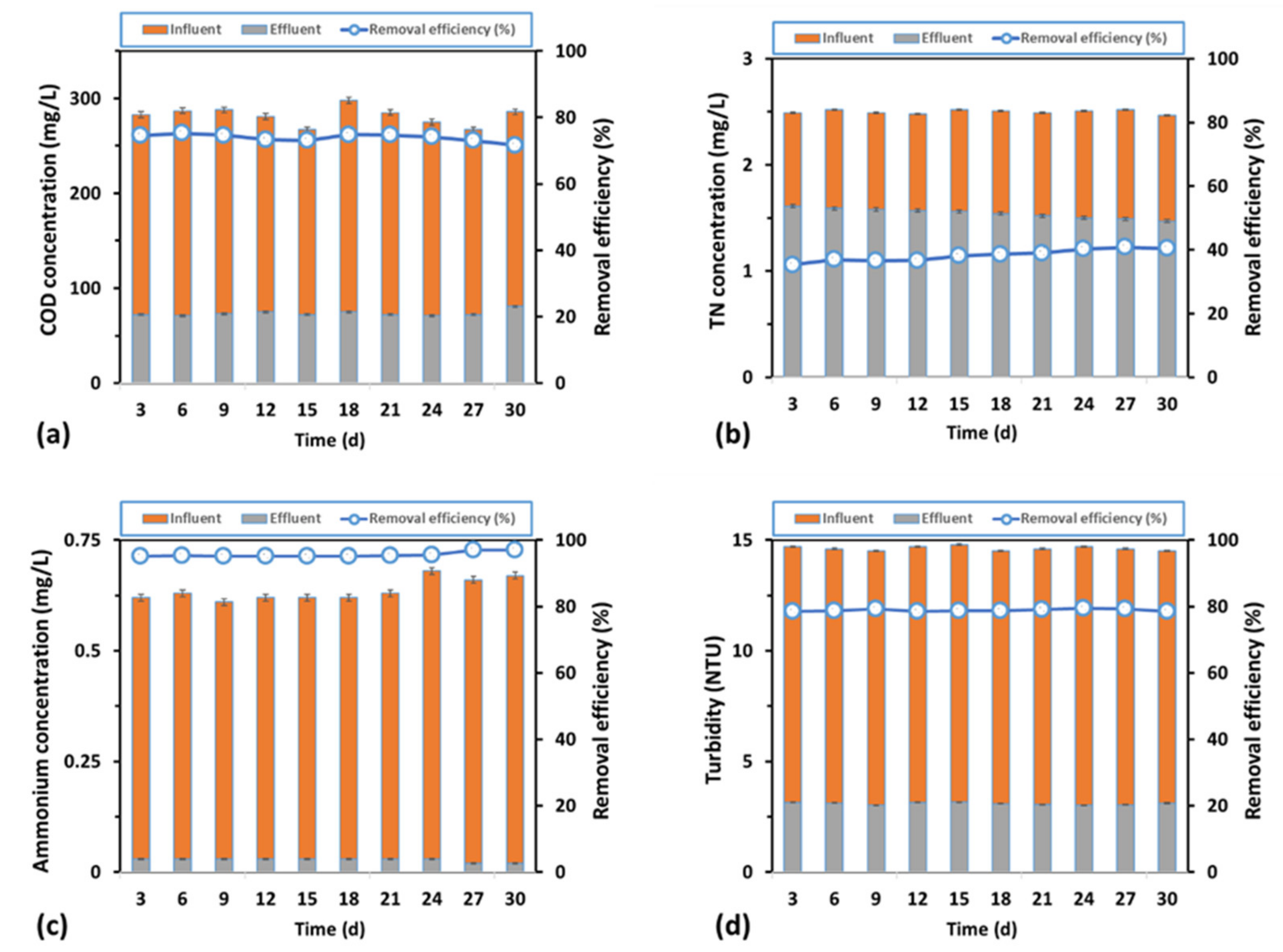

3.2. Biological Performance

3.3. Effect of Disk Rotational Speed

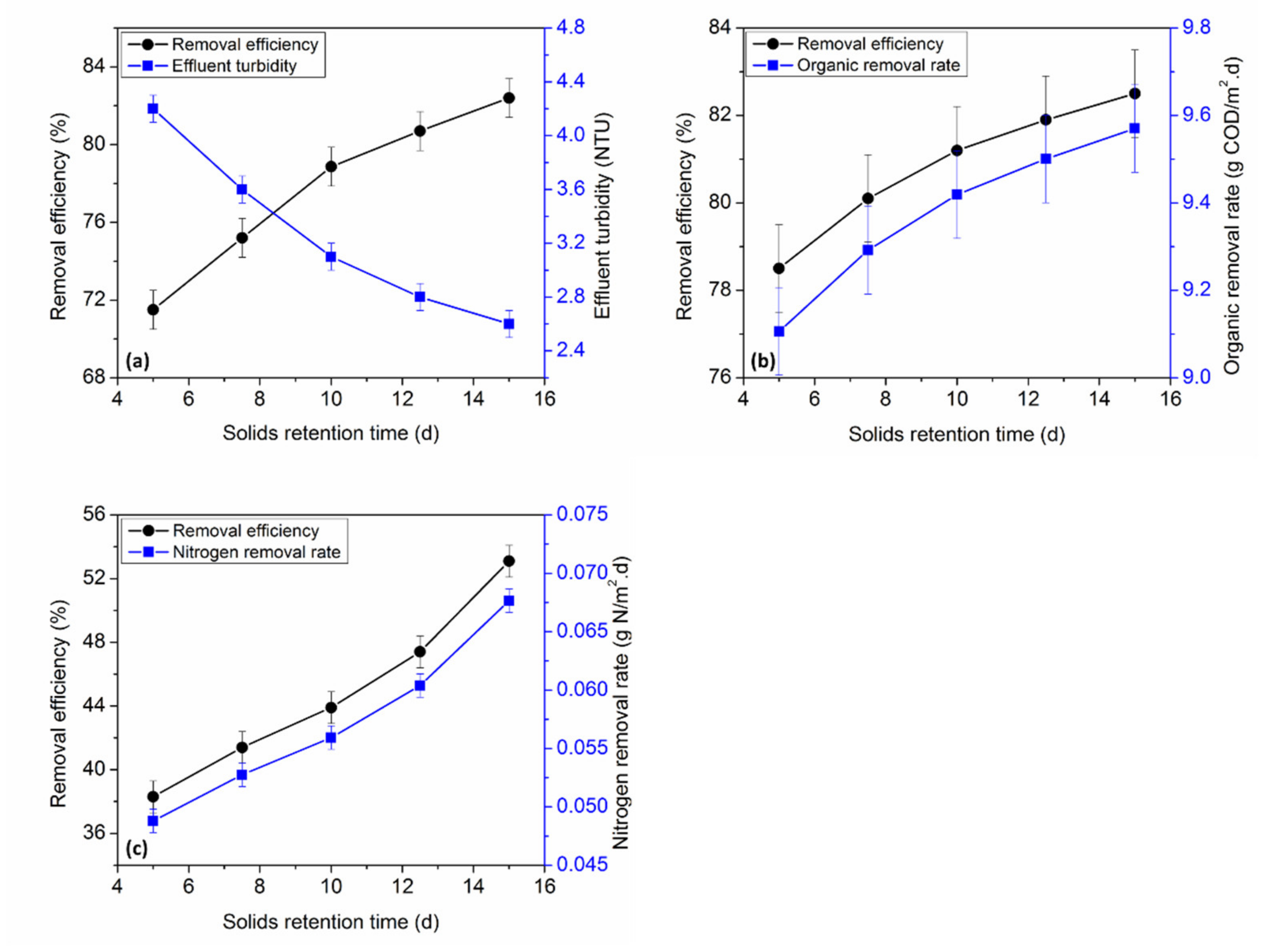

3.4. Effect of Sludge Retention Time

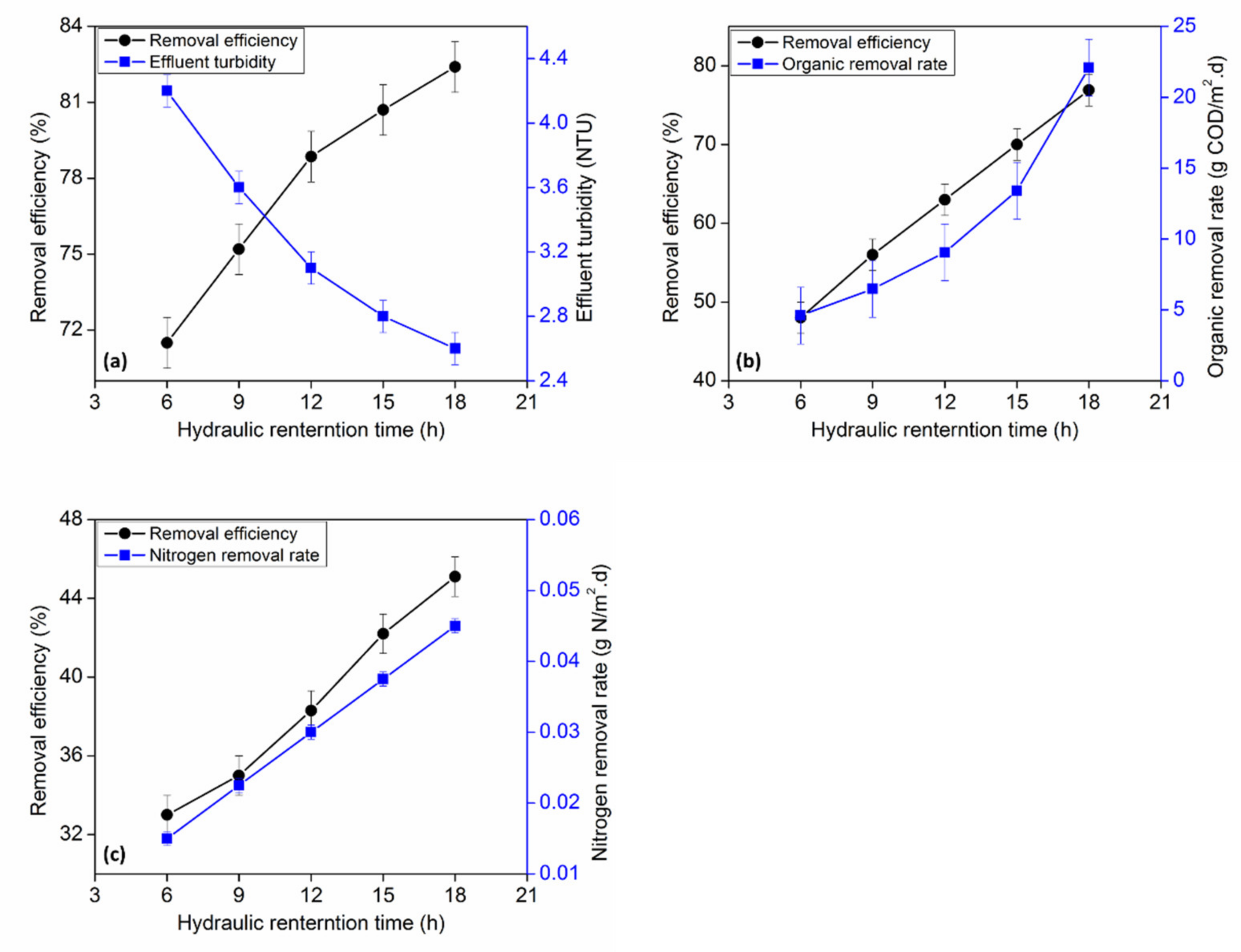

3.5. Effect of Hydraulic Rentention Time

3.6. Biomass Characterization

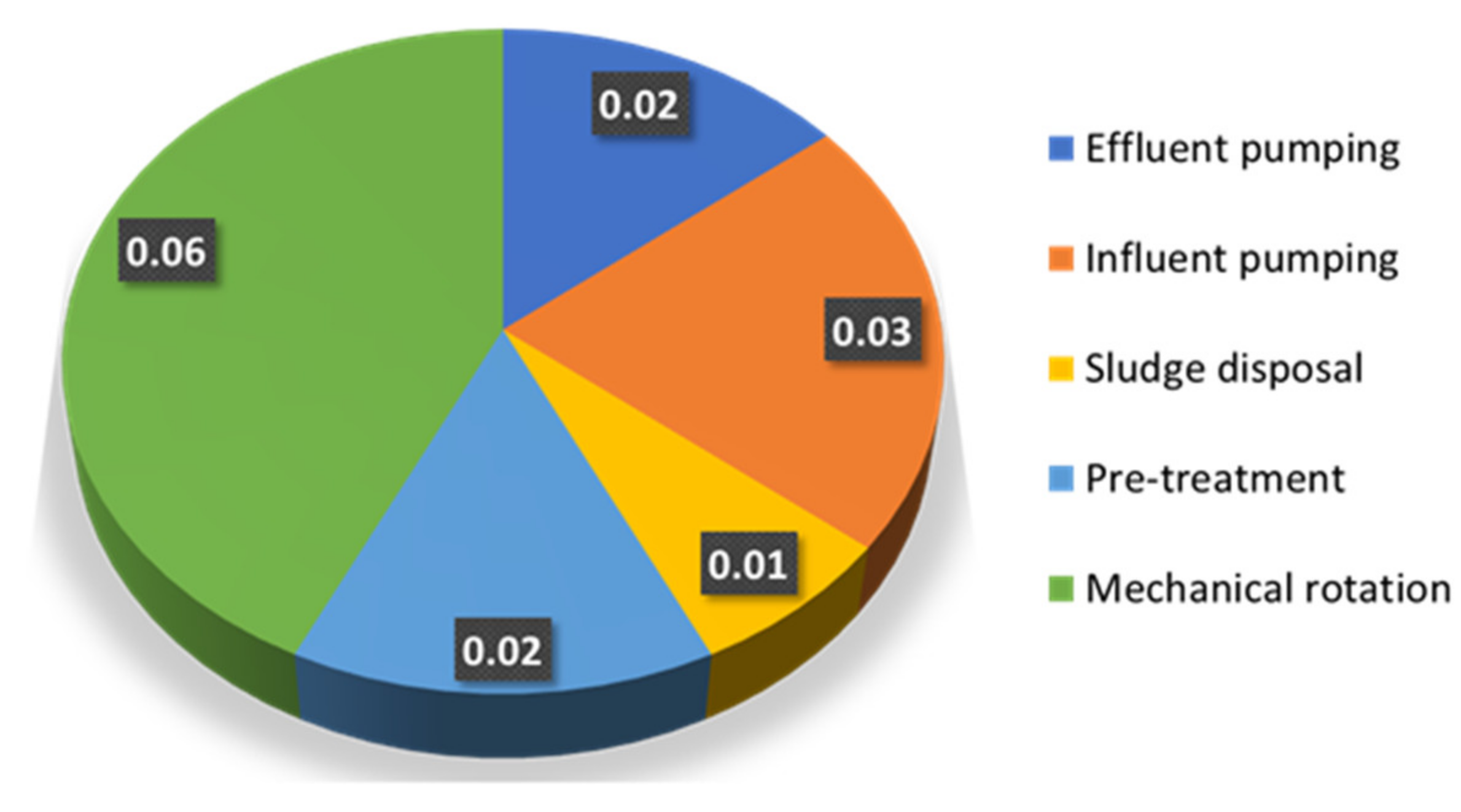

3.7. Energy Audit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meena, M.; Yadav, G.; Sonigra, P.; Shah, M.P. A comprehensive review on application of bioreactor for industrial wastewater treatment. Lett. Appl. Microbiol. 2022, 74, 131–158. [Google Scholar] [CrossRef] [PubMed]

- Edokpayi, J.N.; Odiyo, J.O.; Durowoju, O.S. Impact of wastewater on surface water quality in developing countries: A case study of South Africa. Water Qual. 2017, 10, 66561. [Google Scholar]

- Leonard, P.; Clifford, E.; Finnegan, W.; Siggins, A.; Zhan, X. Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater. Energies 2021, 14, 7365. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R. A review on rotating biological contactors. Indones. J. Sci. Technol. 2019, 4, 241–256. [Google Scholar] [CrossRef]

- Enayathali, S.S. Mathematical Modelling For Rotating Biological Contactor for Treatment of Grey wastewater. SSRG Int. J. Civ. Eng. 2019, 6, 6–10. [Google Scholar] [CrossRef]

- Hendrasarie, N.; Trilta, M. Removal of nitrogen-phosphorus in food wastewater treatment by the Anaerobic Baffled Reactor (ABR) and Rotating Biological Contactor (RBC). In Proceedings of the IOP Conference Series: Earth and Environmental Science, Moscow, Russia, 27 May–6 June 2019; p. 012017. [Google Scholar]

- Vairavel, P.; Murty, V.R. Decolorization of Congo red dye in a continuously operated rotating biological contactor reactor. Desalination Water Treat. 2020, 196, 299–314. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef]

- Vergara-Araya, M.; Hilgenfeldt, V.; Steinmetz, H.; Wiese, J. Combining Shift to Biogas Production in a Large WWTP in China with Optimisation of Nitrogen Removal. Energies 2022, 15, 2710. [Google Scholar] [CrossRef]

- Ghalehkhondabi, V.; Fazlali, A.; Fallah, B. Performance analysis of four-stage rotating biological contactor in nitrification and COD removal from petroleum refinery wastewater. Chem. Eng. Processing-Process Intensif. 2021, 159, 108214. [Google Scholar] [CrossRef]

- Ito, T.; Aoi, T.; Miyazato, N.; Hatamoto, M.; Fuchigami, S.; Yamaguchi, T.; Watanabe, Y. Diversity and abundance of denitrifying bacteria in a simultaneously nitrifying and denitrifying rotating biological contactor treating real wastewater at low temperatures. H2Open J. 2019, 2, 58–70. [Google Scholar] [CrossRef] [Green Version]

- Waqas, S.; Bilad, M.R.; Aqsha, A.; Harun, N.Y.; Ayoub, M.; Wirzal, M.D.H.; Jaafar, J.; Mulyati, S.; Elma, M. Effect of membrane properties in a membrane rotating biological contactor for wastewater treatment. J. Environ. Chem. Eng. 2021, 9, 104869. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Huda, N.; Harun, N.Y.; Md Nordin, N.A.H.; Shamsuddin, N.; Wibisono, Y.; Khan, A.L.; Roslan, J. Membrane Filtration as Post-Treatment of Rotating Biological Contactor for Wastewater Treatment. Sustainability 2021, 13, 7287. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Bilad, M.R.; Samsuri, T.; Nordin, N.A.H.M.; Shamsuddin, N.; Nandiyanto, A.B.D.; Huda, N.; Roslan, J. Response Surface Methodology for Optimization of Rotating Biological Contactor Combined with External Membrane Filtration for Wastewater Treatment. Membranes 2022, 12, 271. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.; Mohammadi, P.; Karami, N.; Barzegar, A.; Annuar, M.S.M. Efficient hydrogen gas production from molasses in hybrid anaerobic-activated sludge-rotating biological contactor. Int. J. Hydrog. Energy 2019, 44, 2592–2602. [Google Scholar] [CrossRef]

- Hamedi, S.; Babaeipour, V.; Rouhi, M. Design, construction and optimization a flexible bench-scale rotating biological contactor (RBC) for enhanced production of bacterial cellulose by Acetobacter Xylinium. Bioprocess Biosyst. Eng. 2021, 44, 1071–1080. [Google Scholar]

- Li, N.; Zeng, W.; Yang, Y.; Wang, B.; Li, Z.; Peng, Y. Oxygen mass transfer and post-denitrification in a modified rotating drum biological contactor. Biochem. Eng. J. 2019, 144, 48–56. [Google Scholar] [CrossRef]

- Subhadarsini, L.; Dash, R.R. Treatment of Industrial Waste Water using Single-Stage Rotating Biological Contactor. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Moscow, Russia, 27 May–6 June 2019; p. 012025. [Google Scholar]

- Delgado, N.; Navarro, A.; Marino, D.; Peñuela, G.; Ronco, A. Removal of pharmaceuticals and personal care products from domestic wastewater using rotating biological contactors. Int. J. Environ. Sci. Technol. 2019, 16, 1–10. [Google Scholar] [CrossRef]

- Spasov, E.; Tsuji, J.M.; Hug, L.A.; Doxey, A.C.; Sauder, L.A.; Parker, W.J.; Neufeld, J.D. High functional diversity among Nitrospira populations that dominate rotating biological contactor microbial communities in a municipal wastewater treatment plant. ISME J. 2020, 14, 1857–1872. [Google Scholar] [CrossRef] [Green Version]

- Tauber, J.; Ramsbacher, A.; Svardal, K.; Krampe, J. Energetic Potential for Biological Methanation in Anaerobic Sewage Sludge Digesters in Austria. Energies 2021, 14, 6618. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L.; Aslam, M. Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. J. Environ. Manag. 2020, 268, 110718. [Google Scholar] [CrossRef]

- Ziembińska-Buczyńska, A.; Ciesielski, S.; Żabczyński, S.; Cema, G. Bacterial community structure in rotating biological contactor treating coke wastewater in relation to medium composition. Environ. Sci. Pollut. Res. 2019, 26, 19171–19179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Suleman, H.; Nordin, N.A.H.; Jaafar, J.; Othman, M.H.D.; Elma, M. An energy-efficient membrane rotating biological contactor for wastewater treatment. J. Clean. Prod. 2021, 282, 124544. [Google Scholar] [CrossRef]

- APHA; WPCF. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Bilad, M.R.; Declerck, P.; Piasecka, A.; Vanysacker, L.; Yan, X.; Vankelecom, I.F. Treatment of molasses wastewater in a membrane bioreactor: Influence of membrane pore size. Sep. Purif. Technol. 2011, 78, 105–112. [Google Scholar] [CrossRef]

- Fenu, A.; Roels, J.; Wambecq, T.; De Gussem, K.; Thoeye, C.; De Gueldre, G.; Van De Steene, B. Energy audit of a full scale MBR system. Desalination 2010, 262, 121–128. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Klaysom, C.; Jaafar, J.; Khan, A.L. An integrated rotating biological contactor and membrane separation process for domestic wastewater treatment. Alex. Eng. J. 2020, 59, 4257–4265. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Performance and Energy Consumption Evaluation of Rotating Biological Contactor for Domestic Wastewater Treatment. Indones. J. Sci. Technol. 2021, 6, 101–112. [Google Scholar] [CrossRef]

- Vázquez-Padín, J.R.; Mosquera-Corral, A.; Campos, J.L.; Méndez, R.; Carrera, J.; Pérez, J. Modelling aerobic granular SBR at variable COD/N ratios including accurate description of total solids concentration. Biochem. Eng. J. 2010, 49, 173–184. [Google Scholar] [CrossRef]

- Brazil, B.L. Performance and operation of a rotating biological contactor in a tilapia recirculating aquaculture system. Aquac. Eng. 2006, 34, 261–274. [Google Scholar] [CrossRef]

- Annavajhala, M.K.; Kapoor, V.; Santo-Domingo, J.; Chandran, K. Comammox functionality identified in diverse engineered biological wastewater treatment systems. Environ. Sci. Technol. Lett. 2018, 5, 110–116. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Effect of organic and nitrogen loading rate in a rotating biological contactor for wastewater treatment. In Proceedings of the Journal of Physics: Conference Series, Nanchang, China, 26–28 October 2021; p. 012063. [Google Scholar]

- Ebrahimi, M.; Kazemi, H.; Mirbagheri, S.; Rockaway, T.D. Integrated approach to treatment of high-strength organic wastewater by using anaerobic rotating biological contactor. J. Environ. Eng. 2018, 144, 04017102. [Google Scholar] [CrossRef]

- Choi, W.-H.; Shin, C.-H.; Son, S.-M.; Ghorpade, P.A.; Kim, J.-J.; Park, J.-Y. Anaerobic treatment of palm oil mill effluent using combined high-rate anaerobic reactors. Bioresour. Technol. 2013, 141, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Kim, E.-S.; Ahn, Y. Microbial community analysis of bulk sludge/cake layers and biofouling-causing microbial consortia in a full-scale aerobic membrane bioreactor. Bioresour. Technol. 2017, 227, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Prinčič, A.; Mahne, I.; Paul, E.A.; Tiedje, J.M. Effects of pH and oxygen and ammonium concentrations on the community structure of nitrifying bacteria from wastewater. Appl. Environ. Microbiol. 1998, 64, 3584–3590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kogler, A.; Farmer, M.; Simon, J.A.; Tilmans, S.; Wells, G.F.; Tarpeh, W.A. Systematic Evaluation of Emerging Wastewater Nutrient Removal and Recovery Technologies to Inform Practice and Advance Resource Efficiency. ACS EST Eng. 2021, 1, 662–684. [Google Scholar] [CrossRef]

- Gil, J.; Túa, L.; Rueda, A.; Montaño, B.; Rodríguez, M.; Prats, D. Monitoring and analysis of the energy cost of an MBR. Desalination 2010, 250, 997–1001. [Google Scholar] [CrossRef]

- Van Dijk, L.; Roncken, G. Membrane bioreactors for wastewater treatment: The state of the art and new developments. Water Sci. Technol. 1997, 35, 35–41. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammadi, P. Developing single-substrate steady-state model for biohydrogen production in continuous anaerobic activated sludge-rotating biological contactor system: Novel insights on the process. Int. J. Energy Res. 2022, 46, 2041–2050. [Google Scholar] [CrossRef]

| Sr # | Contaminant | Unit | Concentration |

|---|---|---|---|

| 1 | COD | mg/L | 281 ± 8.5 |

| 2 | Ammonium | mg/L | 0.66 ± 0.03 |

| 3 | TN | mg/L | 2.5 ± 0.19 |

| 4 | TKN | mg/L | 0.91± 0.09 |

| 5 | Nitrate | mg/L | 0.49 ± 0.04 |

| 6 | Turbidity | NTU | 14.6 ± 0.55 |

| 7 | pH | -- | 6.28 ± 0.21 |

| Sr # | Contaminant | Unit | Concentration |

|---|---|---|---|

| 1 | COD | mg/L | 73.4 ± 3.0 |

| 2 | Ammonium | mg/L | 0.03 ± 0.0 |

| 3 | TN | mg/L | 1.54 ± 0.05 |

| 4 | TKN | Mg/L | 0.05± 0.01 |

| 5 | Nitrate | mg/L | 1.36 ± 0.07 |

| 6 | Turbidity | NTU | 3.09 ± 0.06 |

| 7 | pH | -- | 7.35 ± 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, M.; Waqas, S.; Khan, J.A.; Rahman, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Legutko, S.; Ochowiak, M.; Włodarczak, S.; Czernek, K. Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment. Energies 2022, 15, 3523. https://doi.org/10.3390/en15103523

Irfan M, Waqas S, Khan JA, Rahman S, Kruszelnicka I, Ginter-Kramarczyk D, Legutko S, Ochowiak M, Włodarczak S, Czernek K. Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment. Energies. 2022; 15(10):3523. https://doi.org/10.3390/en15103523

Chicago/Turabian StyleIrfan, Muhammad, Sharjeel Waqas, Javed Akbar Khan, Saifur Rahman, Izabela Kruszelnicka, Dobrochna Ginter-Kramarczyk, Stanislaw Legutko, Marek Ochowiak, Sylwia Włodarczak, and Krystian Czernek. 2022. "Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment" Energies 15, no. 10: 3523. https://doi.org/10.3390/en15103523