Novel Methodology to Assess Advanced Biofuel Production at Regional Level: Case Study for Cereal Straw Supply Chains

Abstract

:1. Introduction

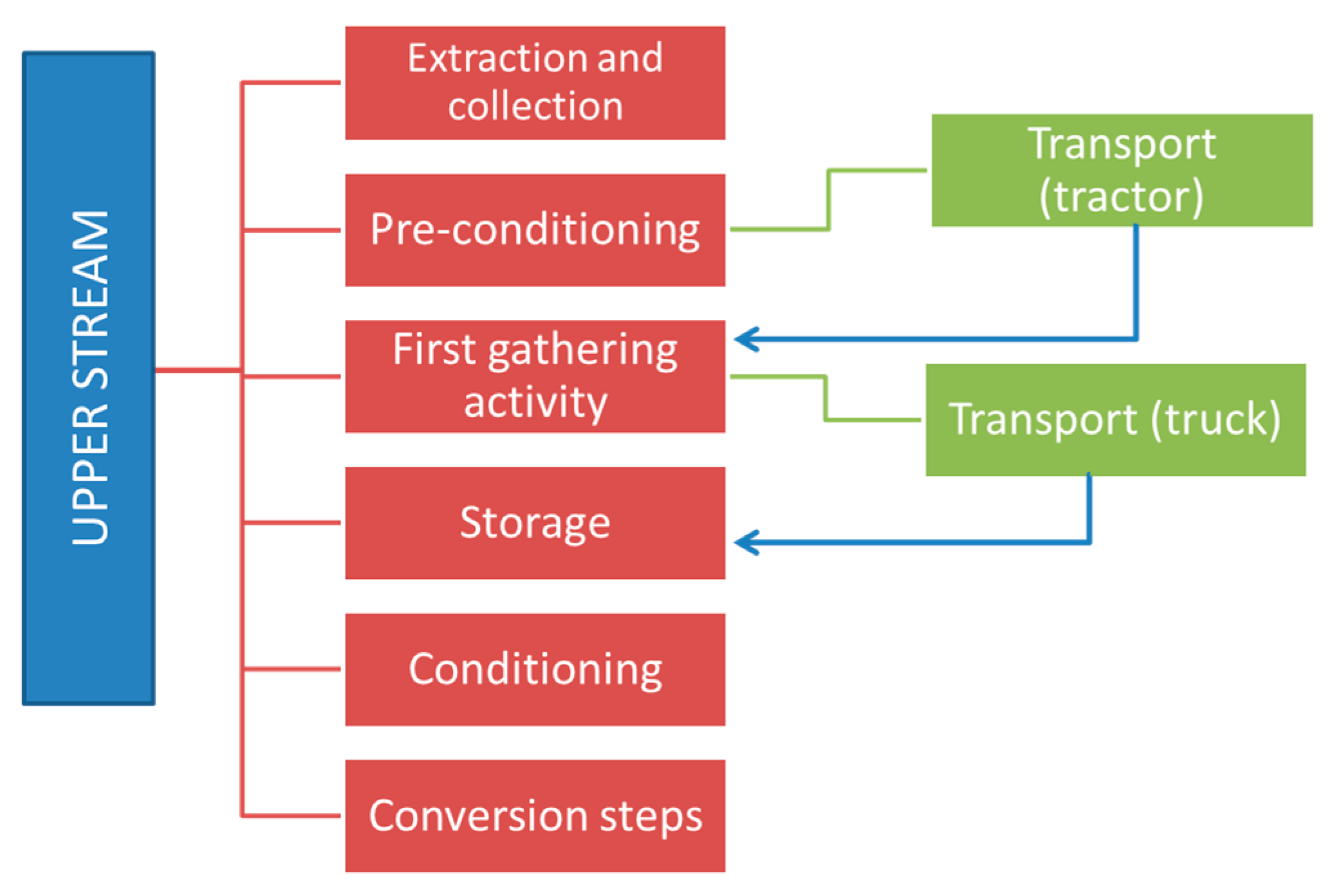

2. Methodology for the Enhanced Biomass Availability Assessment

- first level availability assessment of the bioeconomic potential;

- second level availability assessment for the suitability class allocation;

- spatial distribution at regional level;

- MCA identifying the most promising supply chains and locations for a specific technology.

2.1. First Level Availability Assessment

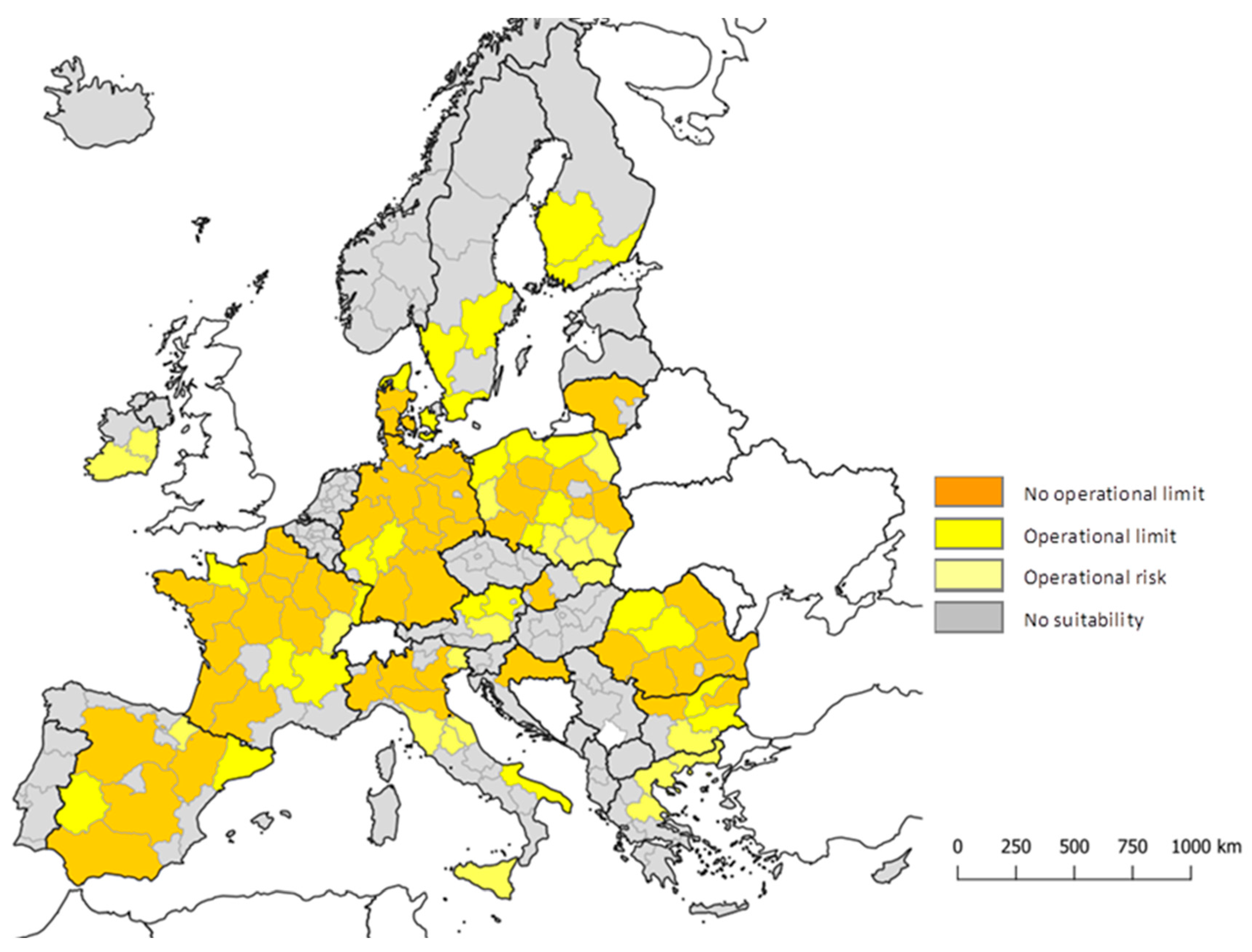

2.2. Second Level Availability Assessment: Suitability Class Allocation

- no operational limit: the bioeconomic potential of a mono-feedstock supply chain is beyond the amount needed to run a selected plant capacity of a certain technology;

- operational limit: the bioeconomic potential of a mono-feedstock supply chain is only enough to cover the amount needed to run one selected plant capacity of a certain technology;

- operational risk: the bioeconomic potential of a mono-feedstock supply chain is not enough to cover the amount needed to run one selected plant capacity of a certain technology, therefore a multi-feedstock supply chain is necessary to operate the plant at full capacity;

- no suitability: the bioeconomic potential of the biomass is not enough to operate the plant capacity of a certain technology.

2.3. Spatialization at Regional Level

2.4. MCA of the Biomass Supply Chains

3. Case Study for Cereal Straw Supply Chains

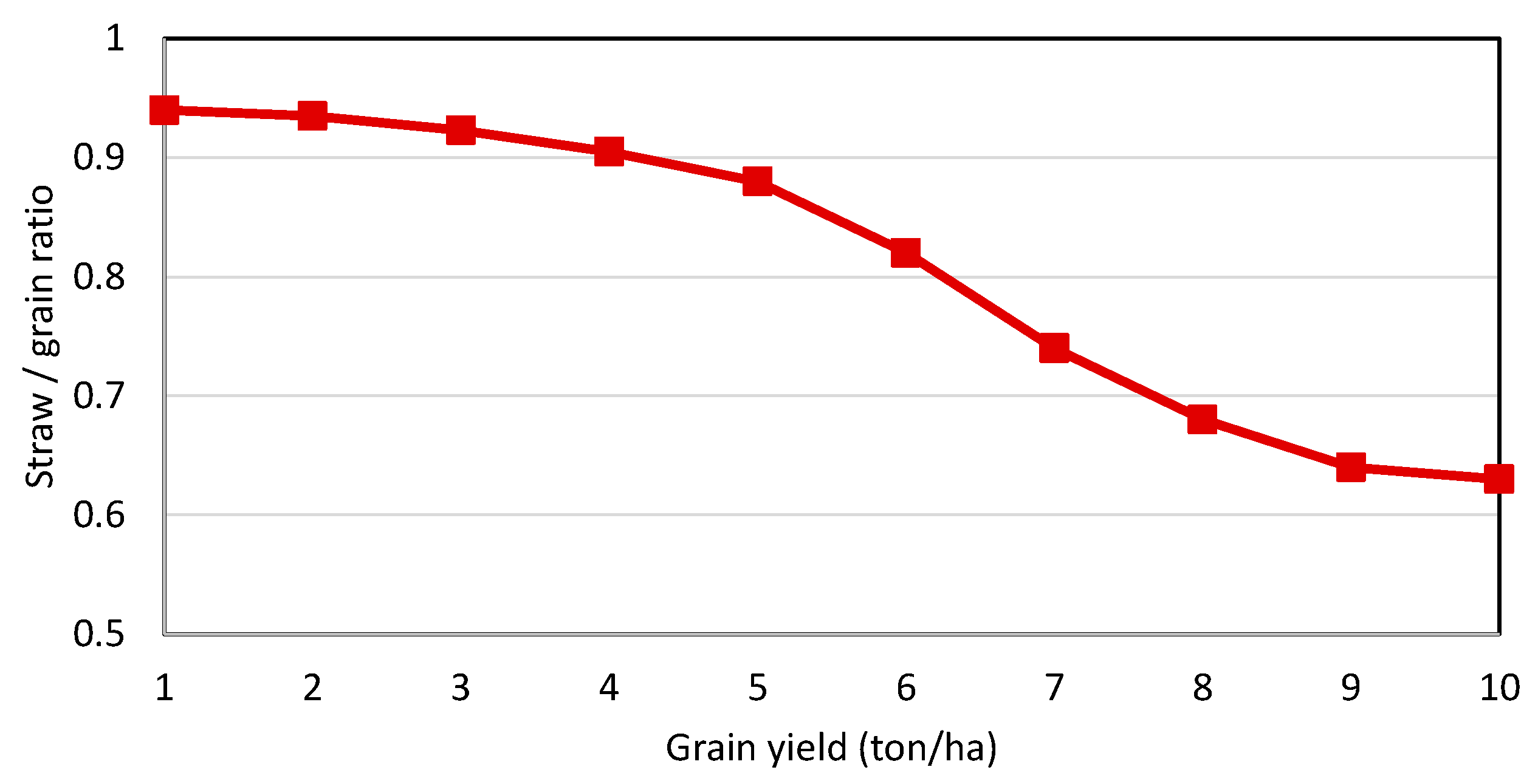

3.1. Biomass Characterization and Logistics

- grain maize harvested by hand, corn-picker, corn-sheller or combine harvester, regardless of the use, including grain for silage, is considered. Grain harvested together with parts of the cob, but with humidity higher than 20% and used for silage (so-called corn-cob-mix, MC 30–35%) is included, too;

- sweet corn cobs for human consumption are included in “Other vegetables cultivated for fruit n.e.c.” (V3900);

- maize harvested green for fodder or renewable energy use (moisture between 65 and 70%) is accounted for within “Green maize” maslin (G3000) and neglected for this calculation. It presents different yield and residue-to-crop ratio in comparison to other crops, and it is a crop with very low sustainability (super intensive, depletion of soil fertility).

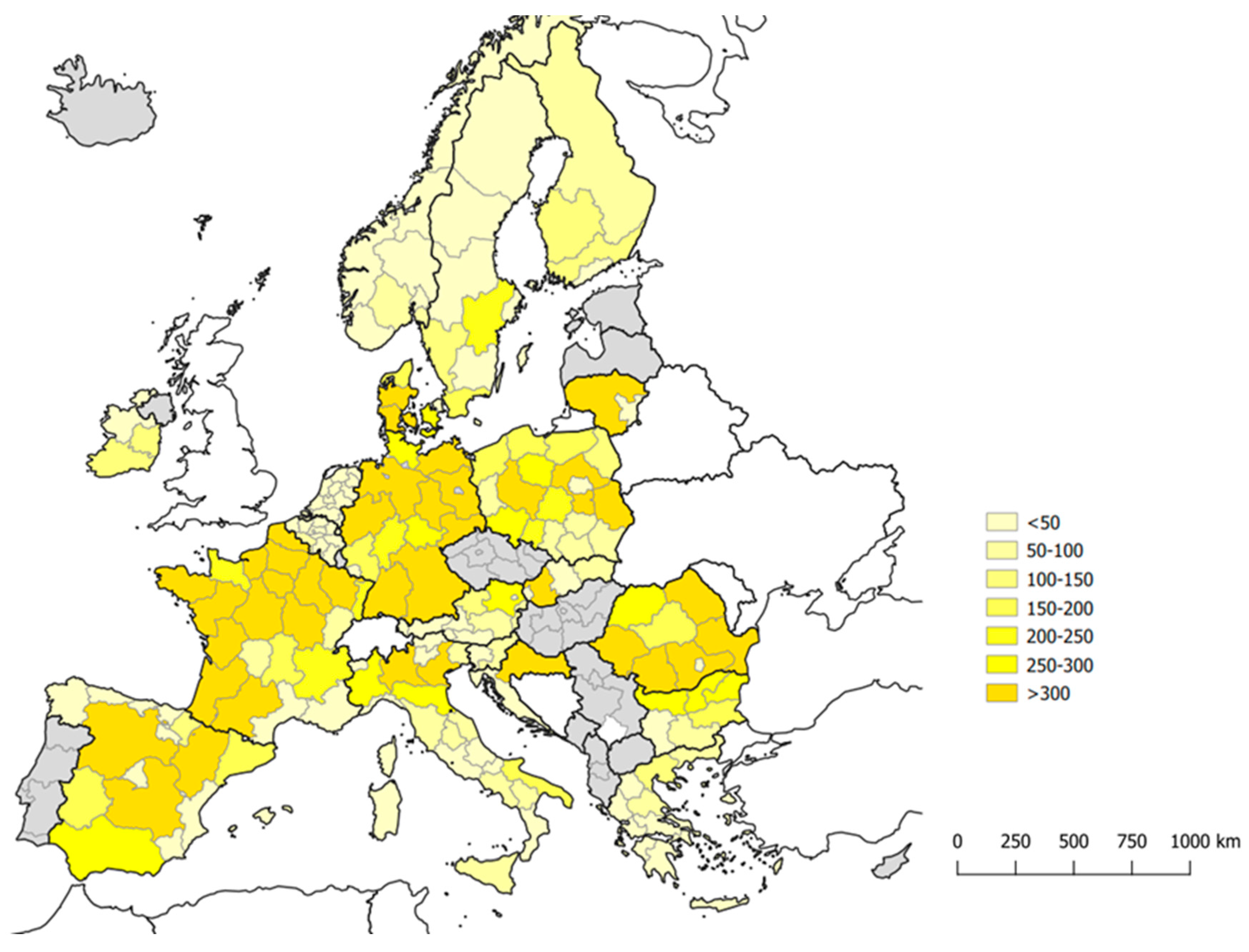

3.2. Bioeconomic Potential Assessment

- conventional uses (livestock littering, industrial, green building, etc.);

- energy production (heat and power).

3.3. Suitability Class Allocation

3.4. Data Spatialization for Cereal Straw

3.5. MCA of the Cereal Straw Supply Chain

4. Conclusions

- (i)

- Central Europe has an overall bioeconomic potential of 16.249 kt (232.359 TJ) distributed over 36 regions and organized in 12 BSRCs. Cereal straw is indeed the most representative biomass supply chain of the district including 36 regions that together provide 96% of the whole bioeconomic potential of the district: 70% is held by France and Germany and the remaining 30% by Romania, Slovakia, Bulgaria and Poland. The biggest cluster is located in France (see Central Europe in Table 6 and Table A3 in Appendix A) and includes the regions of Centre—Val de Loire, Poitou-Charentes, Pays de la Loire, Bretagne, Bourgogne (in total 2.978 kt; 42.590 TJ);

- (ii)

- the Mediterranean district has an overall bioeconomic potential of 3541 kt (50.630 TJ) distributed over nine regions and organized in four BSRCs.

- (i)

- comparative analysis of all the biomass supply chains suitable for the advanced biofuel production;

- (ii)

- combination of the discussed methodology with a supply chain optimization tool for advanced biofuel production;

- (iii)

- multi-feedstock solutions for the Mediterranean and Hanseatic regions;

- (iv)

- integration with a dynamic model for calculating lifecycle GHG emissions of the ligno-cellulosic biomass supply chains for advanced biofuels for road transportation markets, based on the calculation rules of the Revised Renewable Energy Directive (RED-II).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Year | 2015 | 2016 | 2017 | 2018 | Average |

|---|---|---|---|---|---|

| Geographical labels | |||||

| European Union—28 countries | 316,628.57 | 301,748.74 | 309,984.25 | 295,171.77 | 305,883.33 |

| France | 71,788.59 | 53,579.13 | 67,728.63 | 61,840.31 | 63,734.17 |

| Germany | 48,917.70 | 45,401.00 | 45,593.20 | 37,974.80 | 44,471.68 |

| Turkey | 38,637.00 | 35,724.93 | 36,604.93 | 34,705.75 | 36,418.15 |

| Poland | 27,481.72 | 29,293.87 | 31,331.01 | 26,281.55 | 28,597.04 |

| Romania | 19,332.82 | 21,764.82 | 27,138.88 | 31,553.28 | 24,947.45 |

| United Kingdom | 24,591.19 | 21,710.58 | 22,733.55 | 20,839.83 | 22,468.79 |

| Spain | 20,783.82 | 24,955.45 | 17,188.44 | 25,358.14 | 22,071.46 |

| Italy | 16,405.76 | 18,363.10 | 16,554.95 | 16,850.67 | 17,043.62 |

| Hungary | 14,107.34 | 16,594.35 | 13,979.39 | 14,890.26 | 14,892.84 |

| Bulgaria | 8728.97 | 8945.12 | 9737.28 | 10,110.55 | 9380.48 |

| Denmark | 9907.84 | 9024.03 | 9882.96 | 6923.90 | 8934.68 |

| Serbia | 8436.97 | 10868.00 | 6793.30 | n.a. | 8699.42 |

| Czechia | 8183.51 | 8596.41 | 7456.78 | 6970.92 | 7801.91 |

| Sweden | 6168.80 | 5480.50 | 5958.40 | 3260.10 | 5216.95 |

| Lithuania | 6085.05 | 5120.82 | 5074.19 | 3999.50 | 5069.89 |

| Austria | 4826.90 | 5671.46 | 4847.27 | 4785.62 | 5032.81 |

| Slovakia | 3805.71 | 4847.85 | 3484.06 | 4070.76 | 4052.10 |

| Greece | 3588.78 | 3983.13 | 3015.72 | 3043.33 | 3407.74 |

| Finland | 3729.91 | 3609.38 | 3462.12 | 2768.19 | 3392.40 |

| Croatia | 2773.95 | 3472.83 | 2678.79 | 3268.48 | 3048.51 |

| Latvia | 3021.50 | 2703.20 | 2692.50 | 2057.30 | 2618.63 |

| Belgium | 3133.68 | 2228.79 | 2642.25 | 2431.04 | 2608.94 |

| Ireland | 2497.93 | 2184.32 | 2259.53 | 1784.91 | 2181.67 |

| Bosnia and Herzegovina 1 | 1150.87 | 1677.52 | 1176.89 | 1764.10 | 1442.35 |

| Netherlands | 1629.08 | 1344.30 | 1370.62 | 1315.25 | 1414.81 |

| Norway | 1342.11 | 1310.58 | 1205.81 | n.a. | 1286.17 |

| Estonia | 1535.30 | 934.10 | 1311.90 | 919.83 | 1175.28 |

| Portugal | 1252.36 | 1152.27 | 1128.59 | 1115.62 | 1162.21 |

| Switzerland | 901.75 | 752.06 | 986.72 | 876.48 | 879.25 |

| Albania | 695.50 | 698.40 | n.a. | n.a. | 696.95 |

| Slovenia | 624.05 | 638.06 | 546.99 | 596.66 | 601.44 |

| North Macedonia | 483.81 | 640.91 | 447.71 | 598.31 | 542.69 |

| Kosovo 2 | 443.60 | 562.90 | 477.90 | n.a. | 494.80 |

| Luxembourg | 178.57 | 139.43 | 149.81 | 157.65 | 156.37 |

| Cyprus | 88.13 | 10.42 | 36.45 | 24.71 | 39.93 |

| Montenegro | 7.09 | 7.69 | 7.87 | 8.02 | 7.67 |

| Iceland | n.a. | 6.00 | 8.00 | 3.95 | 5.98 |

| Malta | - | - | - | - | - |

| Liechtenstein | n.a. | n.a. | n.a. | n.a. | n.a. |

| Progr. | Country | NUTs2 Region | Precautionary Scenario (kt/y) | Progr. | Country | NUTs2 Region | Precautionary Scenario (kt/y) |

|---|---|---|---|---|---|---|---|

| 1 | DE | Bayern | 940.14 | 25 | PL | Lubelskie | 372.55 |

| 2 | FR | Centre-Val de Loire | 932.09 | 26 | HR | Kontinentalna Hrvatska | 356.17 |

| 3 | ES | Castilla y León | 854.06 | 27 | FR | Nord-Pas-de-Calais | 352.22 |

| 4 | DE | Niedersachsen | 771.92 | 28 | RO | Nord-Est | 351.83 |

| 5 | RO | Sud-Muntenia | 699.29 | 29 | DK | Midtjylland | 330.05 |

| 6 | FR | Picardie | 631.36 | 30 | IT | Lombardia | 318.36 |

| 7 | RO | Sud-Est | 612.53 | 31 | FR | Haute-Normandie | 318.21 |

| 8 | FR | Champagne-Ardenne | 605.39 | 32 | SK | Západné Slovensko | 317.08 |

| 9 | FR | Poitou-Charentes | 576.25 | 33 | DE | Sachsen | 314.68 |

| 10 | DE | Nordrhein-Westfalen | 557.79 | 34 | DE | Brandenburg | 312.22 |

| 11 | LT | Vidurio ir vakaru Lietuvos regionas | 555.77 | 35 | DK | Syddanmark | 308.83 |

| 12 | FR | Pays de la Loire | 551.22 | 36 | FR | Lorraine | 308.37 |

| 13 | FR | Bretagne | 492.67 | 37 | PL | Mazowiecki regionalny | 307.77 |

| 14 | PL | Wielkopolskie | 489.13 | 38 | IT | Veneto | 303.64 |

| 15 | FR | Midi-Pyrénées | 454.16 | 39 | FR | Île de France | 301.28 |

| 16 | DE | Mecklenburg-Vorpommern | 444.73 | 40 | PL | Kujawsko-Pomorskie | 298.08 |

| 17 | ES | Castilla-la Mancha | 441.64 | 41 | DE | Thüringen | 297.22 |

| 18 | DE | Sachsen-Anhalt | 428.22 | 42 | IT | Piemonte | 297.13 |

| 19 | FR | Bourgogne | 426.11 | 43 | BG | Severoiztochen | 295.90 |

| 20 | RO | Sud-Vest Oltenia | 419.55 | 44 | PL | Dolnoslaskie | 288.47 |

| 21 | FR | Aquitaine | 417.81 | 45 | BG | Severozapaden | 287.33 |

| 22 | DE | Baden-Württemberg | 406.34 | 46 | IT | Emilia-Romagna | 286.49 |

| 23 | ES | Aragón | 404.62 | 47 | DE | Schleswig-Holstein | 284.31 |

| 24 | RO | Vest | 384.61 | 48 | ES | Andalucía | 278.44 |

| District | Country | Regions | Cluster Progress ID |

|---|---|---|---|

| Scandinavia | Denmark | Midtjylland Syddanmark | 1 |

| Hanseatic countries | Lithuania | Vidurio ir vakaru Lietuvos regionas | 2 |

| Central EU | France | Centre—Val de Loire Poitou-Charentes Pays de la Loire Bretagne Bourgogne | 3 |

| Picardie Champagne-Ardenne Nord-Pas-de-Calais Haute-Normandie Lorraine Île de France | 4 | ||

| Aquitaine Midi-Pyrénées | 5 | ||

| Germany (NUTS1) | Bayern Baden-Württemberg | 6 | |

| Niedersachsen Nordrhein-Westfalen | 7 | ||

| Mecklenburg-Vorpommern Sachsen-Anhalt Sachsen Brandenburg Schleswig-Holstein Thüringen | 8 | ||

| Poland | Wielkopolskie Dolnoslaskie Kujawsko-Pomorskie Lubelskie Mazowiecki regionalny | 9 | |

| Romania | Sud—Muntenia Sud-Est Sud-Vest Oltenia Nord-Est | 10 | |

| Vest | 11 | ||

| Slovakia | Západné Slovensko | 12 | |

| Bulgaria | Severozapaden | 13 | |

| Severoiztochen | 14 | ||

| Mediterranean EU | Spain | Castilla y León Aragón | 15 |

| Castilla-la Mancha Andalucía | 16 | ||

| Croatia | Kontinentalna Hrvatska | 17 | |

| Italy | Piemonte Lombardia Veneto Emilia-Romagna | 18 |

References

- Chiaramonti, D.; Talluri, G.; Scarlat, N.; Prussi, M. The challenge of forecasting the role of biofuel in EU transport decarbonisation at 2050: A meta-analysis review of published scenarios. Renew. Sustain. Energy Rev. 2021, 139, 110715. [Google Scholar] [CrossRef]

- Guo, X.; Voogt, J.; Annevelink, B.; Snels, J.; Kanellopoulos, A. Optimizing Resource Utilization in Biomass Supply Chains by Creating Integrated Biomass Logistics Centers. Energies 2020, 13, 6153. [Google Scholar] [CrossRef]

- Tallaksen, J. Biomass Gasification: A Comprehensive Demonstration of a Community-Scale Biomass Energy System B; USDA Final Report, Grant Agreement 68-3A75-5-232; West Central Research and Outreach Center: Morris, MN, USA, 2009. [Google Scholar]

- Tallaksen, J. Guidelines for Developing a Sustainable Biomass Supply Chain; Final Report to USDA Rural Development, 2011 Grant 68-3A75-5-232; West Central Research and Outreach Center: Morris, MN, USA, 2011. [Google Scholar]

- Wang, J.; Yang, Y.; Bentley, Y.; Geng, X.; Liu, X. Sustainability Assessment of Bioenergy from a Global Perspective: A Review. Sustainability 2018, 10, 2739. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Maniatis, K. Security of supply, strategic storage and Covid19: Which lessons learnt for renewable and recycled carbon fuels, and their future role in decarbonizing transport? Appl. Energy 2020, 271, 115216. [Google Scholar] [CrossRef] [PubMed]

- Carbon Valorisation in Energy-Efficient Green Fuels, H2020 Project, Grant Agreement No. 818135. Available online: https://www.converge-h2020.eu/ (accessed on 28 August 2022).

- Camia, A.; Robert, N.; Jonsson, R.; Pilli, R.; García-Condado, S.; López-Lozano, R.; van der Velde, M.; Ronzon, T.; Gurría, P.; M’Barek, R.; et al. Biomass Production, Supply, Uses and Flows in the European Union. First Results from an Integrated Assessment; JRC Science for Policy Report; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Edwards, R.A.H.; Súri, M.; Huld, T.A.; Dallemand, J.F. Gis-based assessment of cereal straw energy resource in the european union. In Proceedings of the 14th European Biomass Conference & Exhibition, Biomass for Energy, Industry and Climate Protection, Paris, France, 17–21 October 2005. [Google Scholar]

- Kappler, G.; Leible, L.; Kälber, S.; Niecke, E.; Wintzer, D. D GIS-based analyses and optimization of wood and straw supply for energy purposes at local level. In Proceedings of the Conference Bioenergy in Wood Industry, Jyväskylä, Finland, 12–15 September 2002. [Google Scholar]

- Bharti, A.; Paritosh, K.; Mandla, V.R.; Chawade, A.; Vivekanand, V. GIS Application for the Estimation of Bioenergy Potential from Agriculture Residues: An Overview. Energies 2021, 14, 898. [Google Scholar] [CrossRef]

- Vis, M.W.; van de Berg, D. Harmonization of Biomass Resource Assessment: Best Practices and Methods Handbook; Biomass Energy Europe: Freiburg, Germany, 2010; Volume 1. [Google Scholar]

- Thran, D.; Pfeiffer, D. Method Handbook: Material Flow Oriented Assessment of Greenhouse Gas Effects; German Biomass Research Centre (DBFZ): Leipzig, Germany, 2015. [Google Scholar]

- Garcia-Galindo, D.; Gomez-Palmero, M.; Pueyo, E.; Germer, S.; Pari, L.; Afano, V.; Dyjakon, A.; Sagarna, J.; Rivera, S.; Poutrin, C. Agricultural pruning as biomass resource: Generation, potentials and current fates. An approach to its state in Europe. In Proceedings of the 24th EUBCE, Amsterdam, The Netherlands, 6–9 June 2016. [Google Scholar]

- Verek, P.J.; Fitzgerald, J.B.; Datta, P.; Dees, M.; Hengeveld, G.M.; Linder, M.; Zudin, S. Spatial distribution of the potential forest biomass availability in Europe. For. Ecosyst. 2019, 6, 5. [Google Scholar] [CrossRef]

- Sacchelli, S.; Zambelli, P.; Zatelli, P.; Ciolli, M. Biomasfor: An open-source holistic model for the assessment of sustainable forest bioenergy. iForest 2013, 6, 285–293. [Google Scholar] [CrossRef]

- Moller, B.; Nielsen, P.S. Analyzing Transport Cost of Danish Forest Wood Chip Resources by Means of Continuous Cost Surfaces. Biomass Bioenergy 2007, 31, 291–298. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Optimal Siting and Size of Bioenergy Facilities Using Geographic Information System. Appl. Energy 2012, 94, 192–201. [Google Scholar] [CrossRef]

- Recchia, L.; Boncinelli, P.; Sarri, D.; Cini, E.; Vieri, M.; Garbati Pegna, F. Multicriteria Analysis and LCA Techniques—Approach to Agro-Engineering Problems; Springer: London, UK, 2011; ISBN 9780857297037. [Google Scholar] [CrossRef]

- Helin, T.; Vesterinen, P.; Ahola, H.; Niemelä, K.; Doublet, S.; Couturier, C.; Piotrowski, S.; Carus, M.; Tambuyser, B.; Hasija, R.; et al. Availability of Lignocellulosic Biomass Types of Interest in the Study Regions; Deliverable D1.1, BIOCORE—BIOCOmmodity Refinery, H2020 Projec, Grant Agreement no.: FP7-241566; 2012. Available online: http://www.biocore-europe.org/file/D1_1%20Availability%20of%20lignocellulosic%20biomass%20types%20of%20interest%20in%20the%20study%20regions.pdf (accessed on 15 January 2015).

- Gawor, M.; Majer, S.; Thrän, D. Impact of Promotion Mechanisms for Advanced and Low-iLUC Biofuels on Markets: Straw for Bioenergy; IEA Bioenergy Task 40; 2104. Available online: https://www.ieabioenergy.com/iea-publications/ (accessed on 28 August 2022).

- Tassinari, G. Manuale dell’Agronomo; Reda: Brescia, Italy, 2018. [Google Scholar]

- Trezzini, D. Analisi Tecnico-Economica di un Moderno Impianto di Generazione Elettrica da Energie Rinnovabili (Biomasse). Master’s Thesis, Politecnico di Milano, Milan, Italy, 2013. [Google Scholar]

- ENAMA. Biomasse ed Energia; ENAMA: Roma, Italy, 2010. [Google Scholar]

- Eurostat Handbook for Annual Crop Statistics. 2017. Available online: http://www.eumuda.eu/media/files/table_of_crop_areas/Eurostat_Handbook_apro_acs_esms_an1.pdf (accessed on 28 August 2022).

- Source: U.S. Dairy Forage Research Center in Madison, WI. Available online: https://www.ars.usda.gov/midwest-area/madison-wi/us-dairy-forage-research-center/ (accessed on 28 August 2022).

- Leible, L.; Kälber, S.; Kappler, G.; Lange, S.; Nieke, E.; Fürniss, B. Fischer-Tropsch synfuels from cereal straw via fast pyrolysis and gasification—Costs and benefits. In Proceedings of the 15th European Biomass Conference, Berlin, Germany, 7–11 May 2007. [Google Scholar]

- Helwig, T.; Jannasch, R.; Samson, R.; DeMaio, A.; Caumartin, D. Agricultural Biomass Residue Inventories and Conversion Systems for Energy Production in Eastern Canada; Final Report, Prepared for Natural Resources-Canada Contract #23348-016095/001/SQ; Resource Efficient Agricultural Production (REAP): Quebec, Canada, 2002. [Google Scholar]

- Münch, J. Sustainably Usable Wheat Straw in Germany; Positionspapier of the Institute for Energy and Environmental Research (IFEU): Heidelberg, Germany, 2008. [Google Scholar]

- Thorenz, A.; Wietschel, L.; Stindt, D.; Tuma, A. Assessment of agroforestry residue potentials for the bioeconomy in the European Union. J. Clean. Prod. 2018, 176, 348–359. [Google Scholar] [CrossRef] [PubMed]

- Kretschmer, B.; Allen, B.; Hart, K. Mobilising Cereal Straw in the EU to Feed Advanced Biofuel Production; Report Produced for Novozymes; Institute for European Environmental Policy: London, UK, 2012. [Google Scholar]

- UN Comtrade, 2016 UN Comtrade [WWW Document]. Available online: https://comtrade.un.org/data/ (accessed on 28 August 2022).

| Indicator | Weight | Score | ||

|---|---|---|---|---|

| High (3) | Medium (2) | Low (1) | ||

| Second level availability | 1 | no operational limit | operational limit | operational risk |

| No. of regions | 1 | >8 | 4–8 | <4 |

| Transport complexity | 0.3 | by-product | residue | waste |

| Production seasonality | 0.3 | <8 months | 4–8 months | <4 months |

| Storage complexity | 0.3 | MC < 20% | MC 20–50% | MC > 50% |

| Biomass competition | 0.6 | low market demand | medium market demand | high market demand |

| Supply chain complexity | 0.3 | low no. of processes | medium no. of processes | high no. of processes |

| Standardization of supply chain | 0.3 | low no. of solutions | medium no. of solutions | high no. of solutions |

| Nominal plant capacity | 0.6 | >200 MW | 100–200 MW | <100 MW |

| Transport distance | 0.6 | <50 km | 50–100 km | >100 km |

| Pre-treatment necessity | 0.3 | No | size and M reduction | size or M reduction |

| Traceability complexity | 0.3 | 1 operative subject | 2–3 operative subjects | >3 operative |

| GHG emissions | 1 | transport | collection and transport | collection, transport and pre-treatments |

| LHV | MC | Ash | C | H | O | N | S | Cl |

|---|---|---|---|---|---|---|---|---|

| MJ/kgdm | % | %dm | %wb | %wb | %wb | %wb | %wb | %wb |

| 18.5 | 15 | 11.4 | 43.2 | 5.0 | 39.4 | 0.61 | 0.11 | 0.28 |

| Storage Moisture Content | Dry Matter Loss |

|---|---|

| 11 to 20% | 4.50% |

| 20 to 25% | 7.90% |

| 25 to 34% | 10.90% |

| Transport Distance a) (km) | Means of Transport | Supply Costs (€/Mg DM) | CO2 Emissions (kg CO2,eq/Mg DM) | ||

|---|---|---|---|---|---|

| a Total of | Thereof for Transport | a Total of | Thereof for Transport | ||

| 10 | Tractor | 65 | 12 | 11 | 3 |

| 30 | 71 | 18 | 14 | 6 | |

| 30 | Truck | 75 | 22 | 16 | 8 |

| 100 | 87 | 34 | 29 | 21 | |

| 250 | 110 | 57 | 58 | 50 | |

| 100 | Rail a | 113 | 60 | 21 | 13 |

| 250 | 134 | 81 | 28 | 20 | |

| 100 | Ship a | 97 | 44 | 26 | 18 |

| 250 | 105 | 52 | 33 | 25 | |

| 800 | 134 | 81 | 59 | 51 | |

| Countries | Straw (kt) | Plants |

|---|---|---|

| Denmark | 110 | 55 district heating and CHP plants |

| Sweden | 135 | 8 district heating and CHP plants + 1 large power plant |

| Spain | 160 | 1 large power plant |

| Poland | 5 | 2 boilers |

| Hungary | 270 | 1 large power plant |

| UK | 200 | 1 large power plant |

| France | 6 | 2 boilers |

| Total | 1900 |

| Cereal Straw | Country | Theoretical Potential | Technical Potential | Bioeconomic Potential JRC | Precautionary Scenario (45%) | Precautionary Scenario (10%) |

|---|---|---|---|---|---|---|

| Central Europe | France | 39,833.85 | 26,688.68 | 16,730.22 | 7528.60 | 1673.02 |

| Germany | 27,794.80 | 18,622.51 | 11,673.81 | 5253.22 | 1167.38 | |

| Poland | 17,873.15 | 11,975.01 | 7506.72 | 3378.03 | 750.67 | |

| Romania | 15,592.16 | 10,446.74 | 6548.71 | 2946.92 | 654.87 | |

| Hungary | 9308.02 | 6236.37 | 3909.37 | 1759.22 | 390.94 | |

| Bulgaria | 5862.80 | 3928.08 | 2462.38 | 1108.07 | 246.24 | |

| Serbia | 5437.14 | 3642.88 | 2283.60 | 1027.62 | 228.36 | |

| Czechia | 4876.19 | 3267.05 | 2048.00 | 921.60 | 204.8 | |

| Austria | 3145.51 | 2107.49 | 1321.11 | 594.50 | 132.11 | |

| Slovakia | 2532.56 | 1696.81 | 1063.67 | 478.65 | 106.37 | |

| Bosnia and Herz. | 901.47 | 603.98 | 378.62 | 170.38 | 37.86 | |

| Switzerland | 549.53 | 368.19 | 230.80 | 103.86 | 23.08 | |

| Slovenia | 375.90 | 251.85 | 157.88 | 71.05 | 15.79 | |

| Mediterranean Europe | Spain | 13,794.66 | 9242.42 | 5793.76 | 2607.19 | 579.38 |

| Italy | 10,652.26 | 7137.02 | 4473.95 | 2013.28 | 447.4 | |

| Greece | 2129.84 | 1426.99 | 894.53 | 402.54 | 89.45 | |

| Croatia | 1905.32 | 1276.56 | 800.23 | 360.11 | 80.02 | |

| Portugal | 726.38 | 486.68 | 305.08 | 137.29 | 30.51 | |

| Albania | 435.59 | 291.85 | 182.95 | 82.33 | 18.29 | |

| North Macedonia | 339.18 | 227.25 | 142.45 | 64.1 | 14.25 | |

| Scandinavia | Denmark | 5584.18 | 3741.40 | 2345.35 | 1055.41 | 234.54 |

| Sweden | 3260.59 | 2184.60 | 1369.45 | 616.25 | 136.94 | |

| Finland | 2120.25 | 1420.57 | 890.51 | 400.73 | 89.05 | |

| Norway | 803.85 | 538.58 | 337.62 | 151.93 | 33.76 | |

| North Seas | Lithuania | 3168.68 | 2123.02 | 1330.85 | 598.88 | 133.08 |

| Latvia | 1636.64 | 1096.55 | 687.39 | 309.33 | 68.74 | |

| Belgium | 1630.59 | 1092.49 | 684.85 | 308.18 | 68.48 | |

| Ireland | 1363.55 | 913.58 | 572.69 | 257.71 | 57.27 | |

| Netherlands | 884.26 | 592.45 | 371.39 | 167.12 | 37.14 | |

| Estonia | 734.55 | 492.15 | 308.51 | 138.83 | 30.85 | |

| Luxembourg | 97.73 | 65.48 | 41.05 | 18.47 | 4.10 | |

| TOTAL | 185,351.18 | 124,185.29 | 77,847.49 | 35,031.37 | 7,784.75 |

| Parameter | Unit | System Simulation | Case 1 | Case 2 |

|---|---|---|---|---|

| Plant power | MWth | 10 | 100 | 200 |

| Plant operation | h | 8400 | 8400 | 8400 |

| Energy requirements | TJ/y | 197 | 1969 | 3937 |

| Straw MC | % | 35 | 35 | 35 |

| LHV | MJ/kg | 13.11 | 13.11 | 13.11 |

| Feedstock | kt/y | 15 | 150 | 300 |

| Region Indicator | Scandinavian | Central European | Mediterranean | Hanseatic |

|---|---|---|---|---|

| 2nd level availability | 3 | 3 | 3 | 2 |

| Number of most promising regions | 1 | 3 | 2 | 1 |

| Transport complexity | 2 | 2 | 2 | 2 |

| Production seasonality | 1 | 1 | 1 | 1 |

| Storage complexity | 2 | 3 | 2 | 3 |

| Biomass competition in the geographical region | 2 | 3 | 3 | 1 |

| Supply chain complexity | 2 | 2 | 2 | 2 |

| Standardization of the supply chain | 3 | 3 | 3 | 3 |

| Nominal capacity of the plant | 3 | 3 | 3 | 2 |

| Average total transport distance | 2 | 1 | 2 | 2 |

| Pre-treatment necessity | 2 | 2 | 2 | 2 |

| Traceability complexity and certification costs | 2 | 2 | 2 | 2 |

| GHG emissions due to supply chain complexity | 1 | 1 | 1 | 2 |

| Total score | 26 | 29 | 28 | 25 |

| Weighted total score | 13.4 | 15.7 | 15.0 | 12.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ugolini, M.; Recchia, L.; Guandalini, G.; Manzolini, G. Novel Methodology to Assess Advanced Biofuel Production at Regional Level: Case Study for Cereal Straw Supply Chains. Energies 2022, 15, 7197. https://doi.org/10.3390/en15197197

Ugolini M, Recchia L, Guandalini G, Manzolini G. Novel Methodology to Assess Advanced Biofuel Production at Regional Level: Case Study for Cereal Straw Supply Chains. Energies. 2022; 15(19):7197. https://doi.org/10.3390/en15197197

Chicago/Turabian StyleUgolini, Marco, Lucia Recchia, Giulio Guandalini, and Giampaolo Manzolini. 2022. "Novel Methodology to Assess Advanced Biofuel Production at Regional Level: Case Study for Cereal Straw Supply Chains" Energies 15, no. 19: 7197. https://doi.org/10.3390/en15197197