Experimental Study of Oil Non-Condensable Gas Pyrolysis in a Stirred-Tank Reactor for Catalysis of Hydrogen and Hydrogen-Containing Mixtures Production

Abstract

:1. Introduction

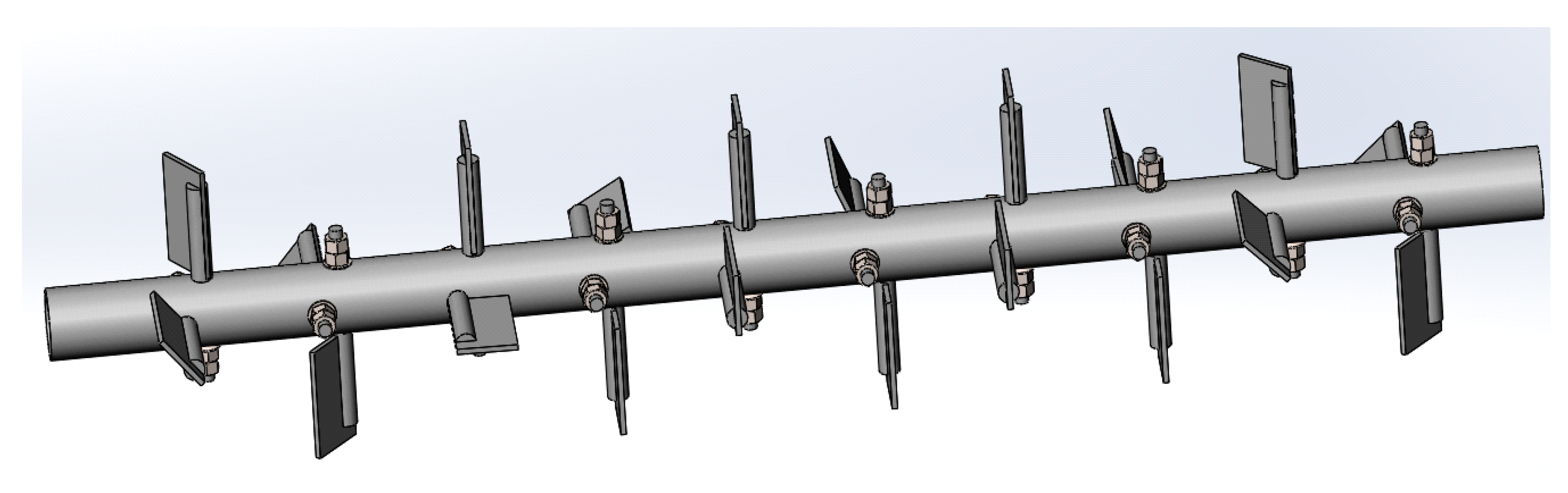

2. Materials and Methods

3. Results and Discussion

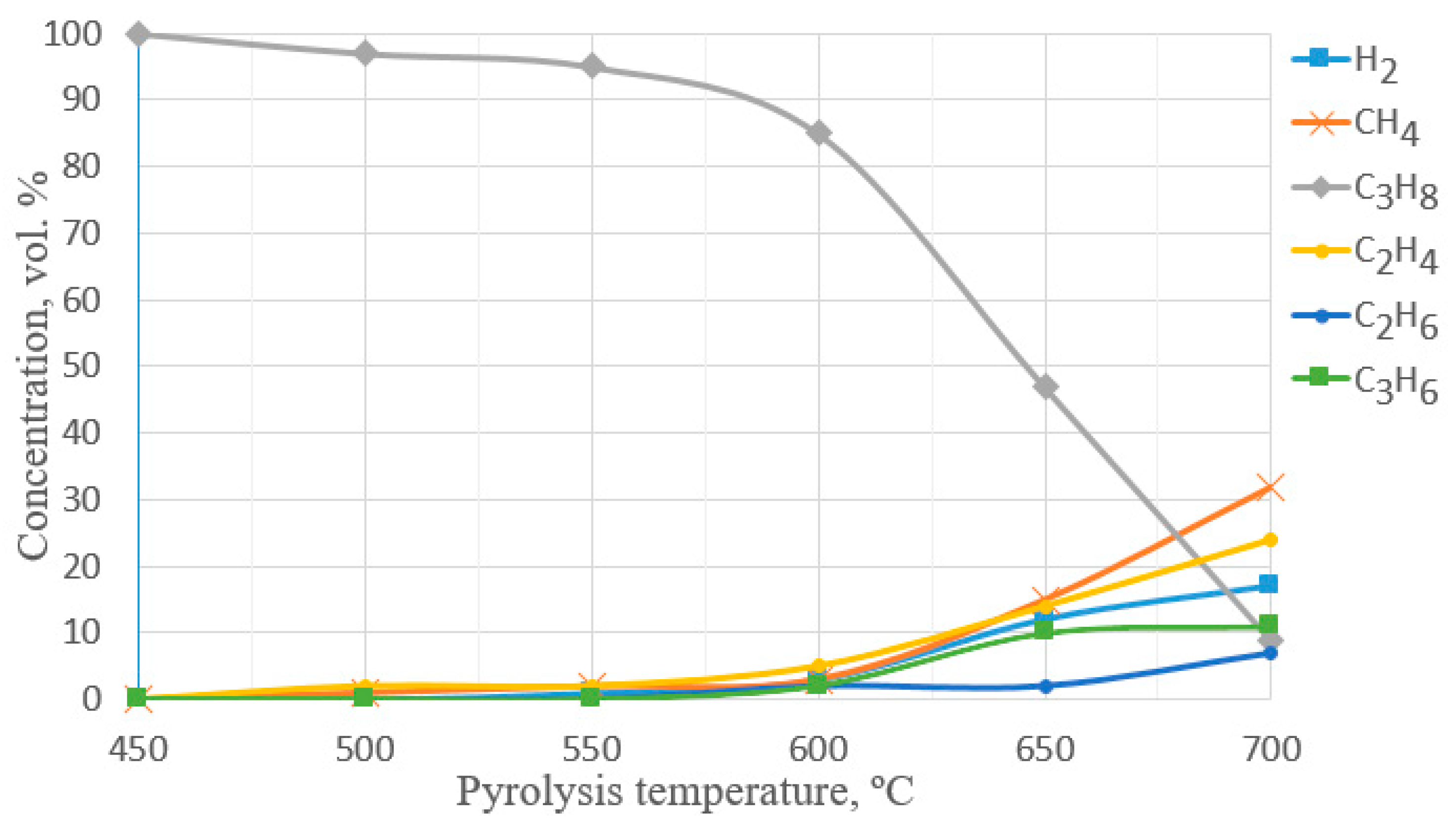

3.1. Non-Catalytic Pyrolysis

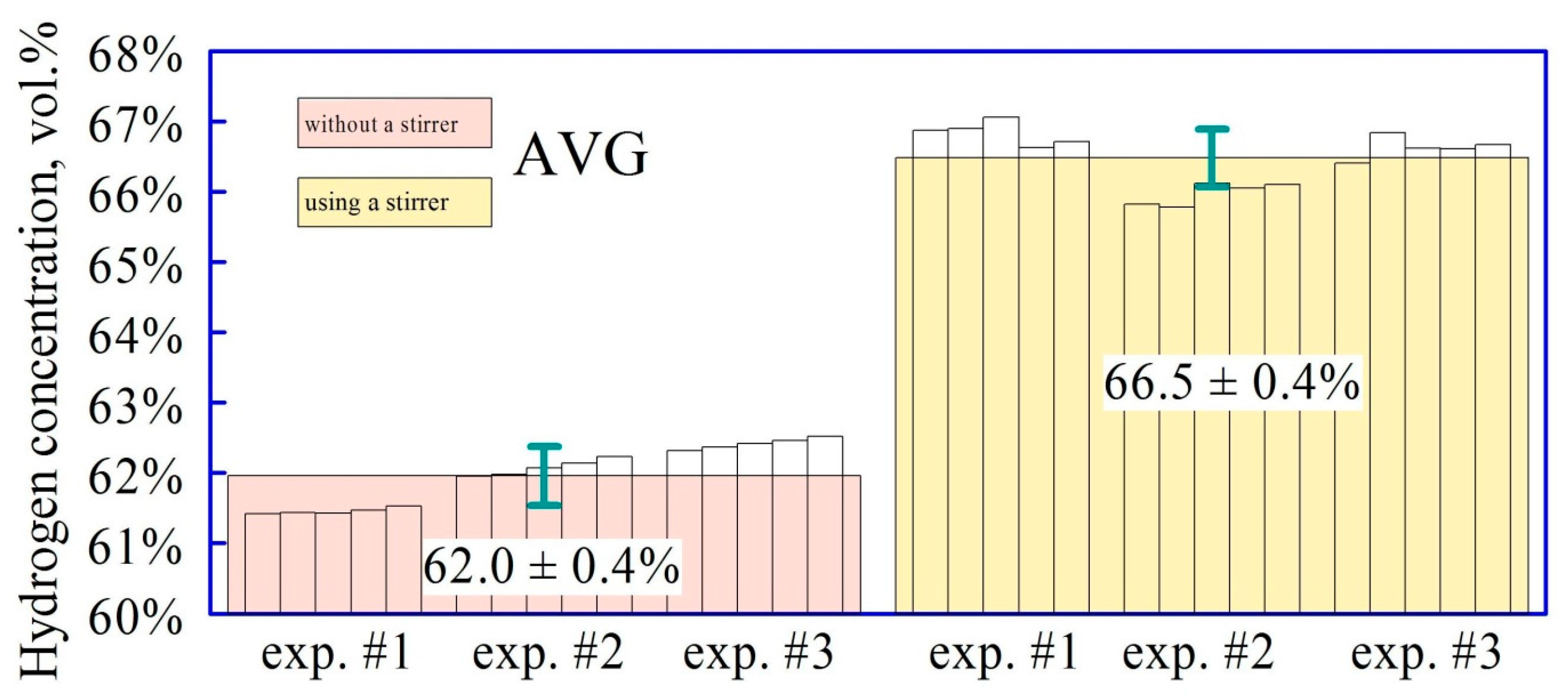

3.2. Catalytic Pyrolysis

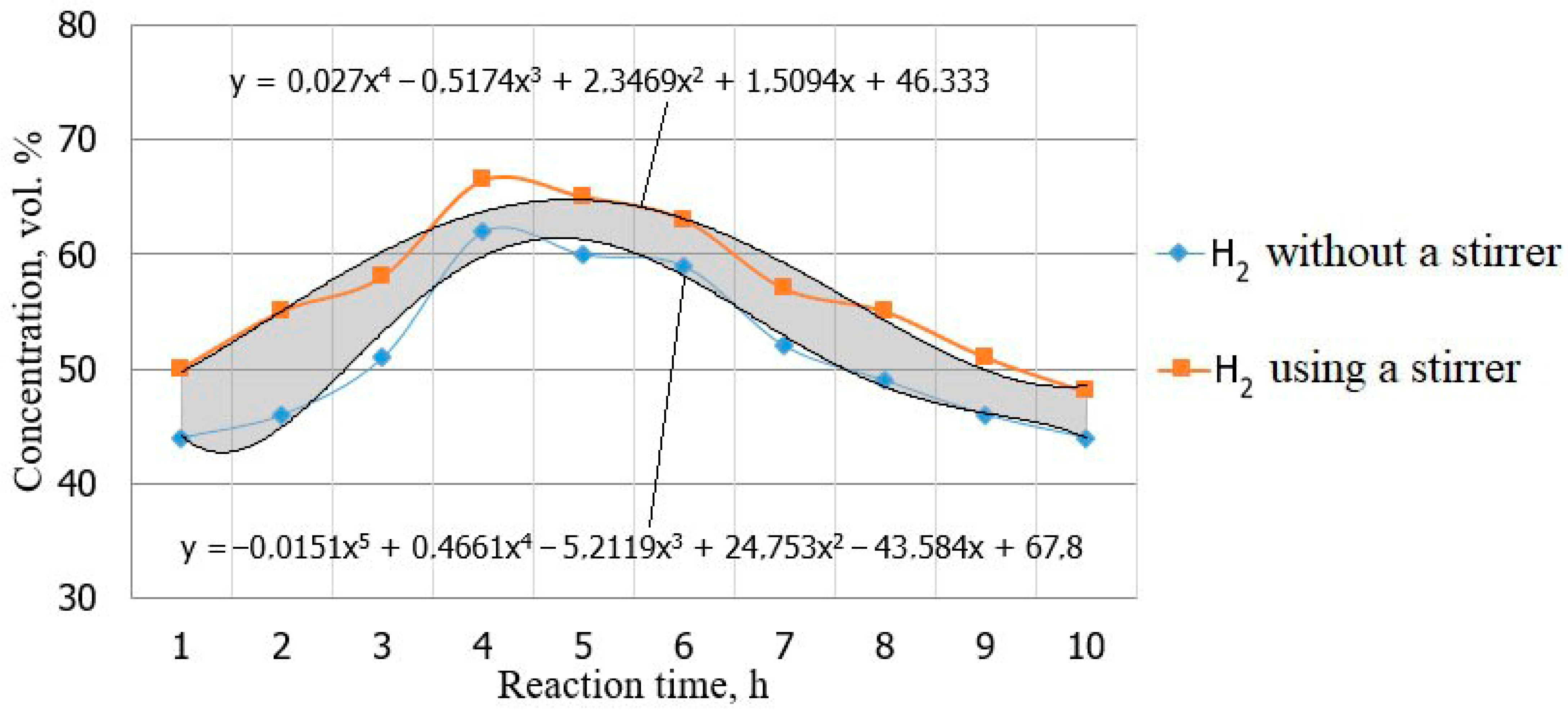

3.3. Heat and Mass Transfer Processes When Using a Stirrer in Pyrolysis of Non-Condensable Gases

3.4. Comparing Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OPEC Monthly Oil Market Report. Available online: https://www.opec.org/opec_web/en/publications/338.htm (accessed on 9 September 2022).

- Hu, G.; Li, J.; Zeng, G. Recent Development in the Treatment of Oily Sludge from Petroleum Industry: A Review. J. Hazard. Mater. 2013, 261, 470–490. [Google Scholar] [CrossRef] [PubMed]

- Al-Mebayedh, H.; Niu, A.; Lin, C. Petroleum Hydrocarbon Composition of Oily Sludge and Contaminated Soils in a Decommissioned Oilfield Waste Pit under Desert Conditions. Appl. Sci. 2022, 12, 1355. [Google Scholar] [CrossRef]

- De Medeiros, A.D.M.; da Silva Junior, C.J.G.; de Amorim, J.D.P.; Durval, I.J.B.; de Santana Costa, A.F.; Sarubbo, L.A. Oily Wastewater Treatment: Methods, Challenges, and Trends. Processes 2022, 10, 743. [Google Scholar] [CrossRef]

- Sun, X.; Yu, T.; Huang, Y.; Xue, M.; Qu, C.; Yang, P.; Zhang, X.; Yang, B.; Li, J. Effects of Different Heat Treatment Methods on Organic Pollutants and Heavy Metal Content in Oil Sludge Waste and Ecotoxicological Evaluation. Appl. Sci. 2022, 12, 3609. [Google Scholar] [CrossRef]

- Suleimanov, R.R.; Gabbasova, I.M.; Sitdikov, R.N. Changes in the Properties of Oily Gray Forest Soil during Biological Reclamation. Biol. Bull. 2005, 32, 93–99. [Google Scholar] [CrossRef]

- Wang, H.; Kuang, S.; Lang, Q.; Yu, W. Effects of Aged Oil Sludge on Soil Physicochemical Properties and Fungal Diversity Revealed by High-Throughput Sequencing Analysis. Archaea 2021, 2018, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Trofimov, S.Y.; Rozanova, M.S. Transformation of Soil Properties under the Impact of Oil Pollution. Eurasian Soil Sci. 2003, 36, 82–87. [Google Scholar]

- Robertson, S.J.; McGill, W.B.; Massicotte, H.B.; Rutherford, P.M. Petroleum Hydrocarbon Contamination in Boreal Forest Soils: A Mycorrhizal Ecosystems Perspective. Biol. Rev. 2007, 82, 213–240. [Google Scholar] [CrossRef]

- Martínez González, A.; Silva Lora, E.E.; Escobar Palacio, J.C.; Almazán del Olmo, O.A. Hydrogen Production from Oil Sludge Gasification/Biomass Mixtures and Potential Use in Hydrotreatment Processes. Int. J. Hydrogen Energy 2018, 43, 7808–7822. [Google Scholar] [CrossRef]

- Maximov, A.; Tsivadze, A.; Fridman, A.; Kuchinskaya, T.; Novikov, A.; Shabanov, M.; Naranov, E. The Prospects for Processing Reservoir Oil Sludge into Hydrocarbons by Low-Temperature Hydrogenation in Sorbing Electrochemical Matrices in Comparison with Conventional High-Temperature Hydrocracking. Energies 2020, 13, 5362. [Google Scholar] [CrossRef]

- Larionov, K.; Kaltaev, A.; Slyusarsky, K.; Gvozdyakov, D.; Zenkov, A.; Kirgina, M.; Bogdanov, I.; Gubin, V. Steam Pyrolysis of Oil Sludge for Energy-Valuable Products. Appl. Sci. 2022, 12, 1012. [Google Scholar] [CrossRef]

- Hu, J.; Gan, J.; Li, J.; Luo, Y.; Wang, G.; Wu, L.; Gong, Y. Extraction of Crude Oil from Petrochemical Sludge: Characterization of Products Using Thermogravimetric Analysis. Fuel 2017, 188, 166–172. [Google Scholar] [CrossRef]

- Fonts, I.; Gea, G.; Azuara, M.; Ábrego, J.; Arauzo, J. Sewage Sludge Pyrolysis for Liquid Production: A Review. Renew. Sustain. Energy Rev. 2012, 16, 2781–2805. [Google Scholar] [CrossRef]

- Petrovsky, E.A.; Kolenchukov, O.A.; Smirnov, N.A. Process Reactor Line for Increasing the Efficiency of Oil-Containing Waste Pyrolysis. Equip. Technol. Oil Gas Complex 2021, 4, 16–20. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, J.; Qiu, K.; Pan, Z.; Wang, S.; Chi, Y.; Yan, J. Catalytic Pyrolysis of Petroleum Sludge for Production of Hydrogen-Enriched Syngas. Int. J. Hydrogen Energy 2015, 40, 16077–16085. [Google Scholar] [CrossRef]

- Qazi, U.Y. Future of Hydrogen as an Alternative Fuel for Next-Generation Industrial Applications; Challenges and Expected Opportunities. Energies 2022, 15, 4741. [Google Scholar] [CrossRef]

- Arutyunov, V.; Savchenko, V.; Sedov, I.; Arutyunov, A.; Nikitin, A. The Fuel of Our Future: Hydrogen or Methane? Methane 2022, 1, 96–106. [Google Scholar] [CrossRef]

- Ktalkherman, M.G.; Namyatov, I.G.; Emel’Kin, V.A.; Pozdnyakov, B.A. Investigation of High-Temperature Pyrolysis of Propane in a Fast-Mixing Reactor. High Temp. 2009, 47, 707–717. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A Techno-Economic-Environmental Study Evaluating the Potential of Oxygen-Steam Biomass Gasification for the Generation of Value-Added Products. Energy Convers. Manag. 2019, 196, 664–676. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, Y.; Gao, N.; Takahashi, F.; Li, A.; Yoshikawa, K. Pyrolysis of Oil Sludge with Oil Sludge Ash Additive Employing a Stirred Tank Reactor. J. Anal. Appl. Pyrolysis 2016, 120, 511–520. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Haghighi, M.N.; Yeganeh, H. Evaluation of Pyrolysis Product of Virgin High Density Polyethylene Degradation Using Different Process Parameters in a Stirred Reactor. Fuel Process. Technol. 2013, 109, 90–95. [Google Scholar] [CrossRef]

- Bashmur, K.A.; Kolenchukov, O.A.; Bukhtoyarov, V.V.; Tynchenko, V.S.; Kurashkin, S.O.; Tsygankova, E.V.; Kukartsev, V.V.; Sergienko, R.B. Biofuel Technologies and Petroleum Industry: Synergy of Sustainable Development for the Eastern Siberian Arctic. Sustainability 2022, 14, 13083. [Google Scholar] [CrossRef]

- Kolenchukov, O.A.; Petrovsky, E.A.; Mikhaylov, A.Y.; Bashmur, K.A. Investigation of nanofiber material production by catalytic pyrolysis. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2021; Volume 1031, pp. 37–42. [Google Scholar] [CrossRef]

- Mirholov, V.A. Catalytic Synthesis of Carbon Materials and Their Use in Catalysis. Forty Sch. J. 1997, 3, 35–42. [Google Scholar]

- Kuvshinov, D.G.; Kurmashov, P.B.; Bannov, A.G.; Popov, M.V.; Kuvshinov, G.G. Synthesis of Ni-based Catalysts by Hexa-methylenetetramine-Nitrates Solution Combustion Method for Co-Production of Hydrogen and Nanofibrous Carbon from Methane. Int. J. Hydrogen Energy 2019, 44, 16271–16286. [Google Scholar] [CrossRef]

- Ermakova, M.A.; Ermakov, D.Y.; Kuvshinov, G.G.; Plyasova, L.M. New Nickel Catalysts for the Formation of Filamentous Carbon in the Reaction of Methane Decomposition. J. Catal. 1999, 187, 77–84. [Google Scholar] [CrossRef]

- Popov, M.V.; Bannov, A.G. Production of carbon nanostructures by propane decomposition over ni-containing catalysts. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2022; Volume 2390, p. 020060. [Google Scholar] [CrossRef]

- Kurmashov, P.B.; Bannov, A.G.; Popov, M.V.; Brester, A.E.; Ukhina, A.V.; Ishchenko, A.V.; Maksimovskii, E.A.; Tolstobrova, L.I.; Chulkov, A.O.; Kuvshinov, G.G. COx-Free Catalytic Decomposition of Methane over Solution Combustion Synthesis Derived Catalyst: Synthesis of Hydrogen and Carbon Nanofibers. Int. J. Energy Res. 2022, 46, 11957–11971. [Google Scholar] [CrossRef]

- Ouyang, M.; Boldrin, P.; Maher, R.C.; Chen, X.; Liu, X.; Cohen, L.F.; Brandon, N.P. A Mechanistic Study of the Interactions between Methane and Nickel Supported on Doped Ceria. Appl. Catal. B Environ. 2019, 248, 332–340. [Google Scholar] [CrossRef]

- Msheik, M.; Rodat, S.; Abanades, S. Methane Cracking for Hydrogen Production: A Review of Catalytic and Molten Media Pyrolysis. Energies 2021, 14, 3107. [Google Scholar] [CrossRef]

- Klinger, J.L.; Westover, T.L.; Emerson, R.M.; Williams, C.L.; Hernandez, S.; Monson, G.D.; Ryan, J.C. Effect of Biomass Type, Heating Rate, and Sample Size on Microwave-Enhanced Fast Pyrolysis Product Yields and Qualities. Appl. Energy 2018, 228, 535–545. [Google Scholar] [CrossRef]

- Vambol, S.; Vambol, V.; Sobyna, V.; Koloskov, V.; Poberezhna, L. Investigation of the Energy Efficiency of Waste Utilization Technology, with Considering the Use of Low-Temperature Separation of the Resulting Gas Mixtures. Energetika 2018, 64, 186–195. [Google Scholar] [CrossRef]

- Mishakov, I.V.; Buyanov, R.A.; Zaikovskii, V.I.; Strel’tsov, I.A.; Vedyagin, A.A. Catalytic Synthesis of Nanosized Feathery Carbon Structures via the Carbide Cycle Mechanism. Kinet. Catal. 2008, 49, 868–872. [Google Scholar] [CrossRef]

- Zimbardi, F.; Li, Z.; Yuan, Q.; Tang, J.; Zhang, X.; Huang, S.; Gong, J. Study on High Temperature Pyrolysis Light Cycle Oil to Acetylene and Carbon Black. Processes 2022, 10, 1732. [Google Scholar] [CrossRef]

- Solov’ev, E.A.; Kuvshinov, D.G.; Chukanov, L.S.; Ermakov, D.Y.; Kuvshinov, G.G. Hydrogen Production Based on the Selective Catalytic Pyrolysis of Propane. Theor. Found. Chem. Eng. 2008, 42, 611–621. [Google Scholar] [CrossRef]

- Corbo, P.; Migliardini, F. Hydrogen Production by Catalytic Partial Oxidation of Methane and Propane on Ni and Pt Catalysts. Int. J. Hydrogen Energy 2007, 32, 55–56. [Google Scholar] [CrossRef]

| Option/ Parameter | Approximation Function y(x) | Mean of a Function yavg (Formula (2)), vol. % | “Work” on the Hydrogen Yield (Area under the Function), vol. %·h | ||||

|---|---|---|---|---|---|---|---|

| for All the Reaction Time | in 4 h of Reaction | 4 to 10 h | for All the Reaction Time | in 4 h of Reaction | 4 to 10 h | ||

| Without a stirrer | yp(x) = −0.0151x5 + 0.4661x4 − 5.211x3 + 24.753x2 − 43.584x + 67.8 | 52.48 | 49.71 | 53.87 | 472.33 | 149.13 | 323.20 |

| Using a stirrer | yst(x) = 0.027x4 − 0.5174x3 + 2.3469x2 + 1.5094x + 46.333 | 57.76 | 57.38 | 57.95 | 519.85 | 172.14 | 347.71 |

| Proportional ratio of values, % | 9.14 | 13.37 | 7.05 | —//— | |||

| Value difference (formula (4)), % | 5.28 | 7.67 | 4.08 | 47.52 * | 23.01 | 24.51 | |

| Feature of the Process | Catalyst (Reaction Time) | Reaction Temperature (°C) | Molar Concentration of Hydrogen in the Pyrolysis Gas (Peak), vol. % |

|---|---|---|---|

| Current study results | |||

| Pressure near atmospheric pressure | Not present, ~1 s. | 600 700 | ~12 ~17 |

| Pressure near atmospheric pressure, with a stirrer | Not present, ~1 s. | 600 700 | ~15 ~19 |

| Pressure near atmospheric pressure | Ni–Cu, 1 to 10 h | 590 ± 10 | ~62.0 (4 h) |

| Pressure near atmospheric pressure, with a stirrer | Ni–Cu, 1 to 10 h | 590 ± 10 | ~66.5 (4 h) |

| Results of other studies | |||

| Pressure near atmospheric pressure [36] | 70Ni–20Cu; 63Ni–23Cu; 50Ni–40Cu, 1 to 40 h | 500 | ~30 (1.5 h, 70Ni–20Cu); ~35 (less than 1 h, 63Ni–23Cu); ~17 (0.5 h, 50Ni–40Cu) |

| 600 | ~62.5 (4 h, 70Ni–20Cu); ~43 (less than 1 h, 63Ni–23Cu); ~59 (1–2 h, 50Ni–40Cu) | ||

| 700 | ~68 (1 h, 70Ni–20Cu); ~80 (1.5 h, 63Ni–23Cu); ~75 (1 h, 50Ni–40 Cu) | ||

| Pressure change 0.1 to 0.5 MPa [28] | Ni–Cu; Ni–Fe | 600 | ~53 (5 h, 0.1 MPa, 50Ni–40Cu); ~52 (12.5 h, 0.3 MPa, 50Ni–40Cu); ~50 (14 h, 0.5 MPa, 50Ni–40Cu) ~53 (4 h, 0.1 MPa, 50Ni–40Fe); ~57 (6 h, 0.3 MPa, 50Ni–40Fe); ~50 (9.5 h, 0.5 MPa, 50Ni–40Fe) |

| Pressure near atmospheric pressure, adding oxidizer [37] | Pt; Ni–Al2O3, 1 to 60 min. | 600 700 800 900 | ~27 ~36 ~39 ~40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolenchukov, O.A.; Bashmur, K.A.; Bukhtoyarov, V.V.; Kurashkin, S.O.; Tynchenko, V.S.; Tsygankova, E.V.; Sergienko, R.B.; Kukartsev, V.V. Experimental Study of Oil Non-Condensable Gas Pyrolysis in a Stirred-Tank Reactor for Catalysis of Hydrogen and Hydrogen-Containing Mixtures Production. Energies 2022, 15, 8346. https://doi.org/10.3390/en15228346

Kolenchukov OA, Bashmur KA, Bukhtoyarov VV, Kurashkin SO, Tynchenko VS, Tsygankova EV, Sergienko RB, Kukartsev VV. Experimental Study of Oil Non-Condensable Gas Pyrolysis in a Stirred-Tank Reactor for Catalysis of Hydrogen and Hydrogen-Containing Mixtures Production. Energies. 2022; 15(22):8346. https://doi.org/10.3390/en15228346

Chicago/Turabian StyleKolenchukov, Oleg A., Kirill A. Bashmur, Vladimir V. Bukhtoyarov, Sergei O. Kurashkin, Vadim S. Tynchenko, Elena V. Tsygankova, Roman B. Sergienko, and Vladislav V. Kukartsev. 2022. "Experimental Study of Oil Non-Condensable Gas Pyrolysis in a Stirred-Tank Reactor for Catalysis of Hydrogen and Hydrogen-Containing Mixtures Production" Energies 15, no. 22: 8346. https://doi.org/10.3390/en15228346