Neutronic Analysis of Start-Up Tests at China Experimental Fast Reactor

Abstract

:1. Introduction

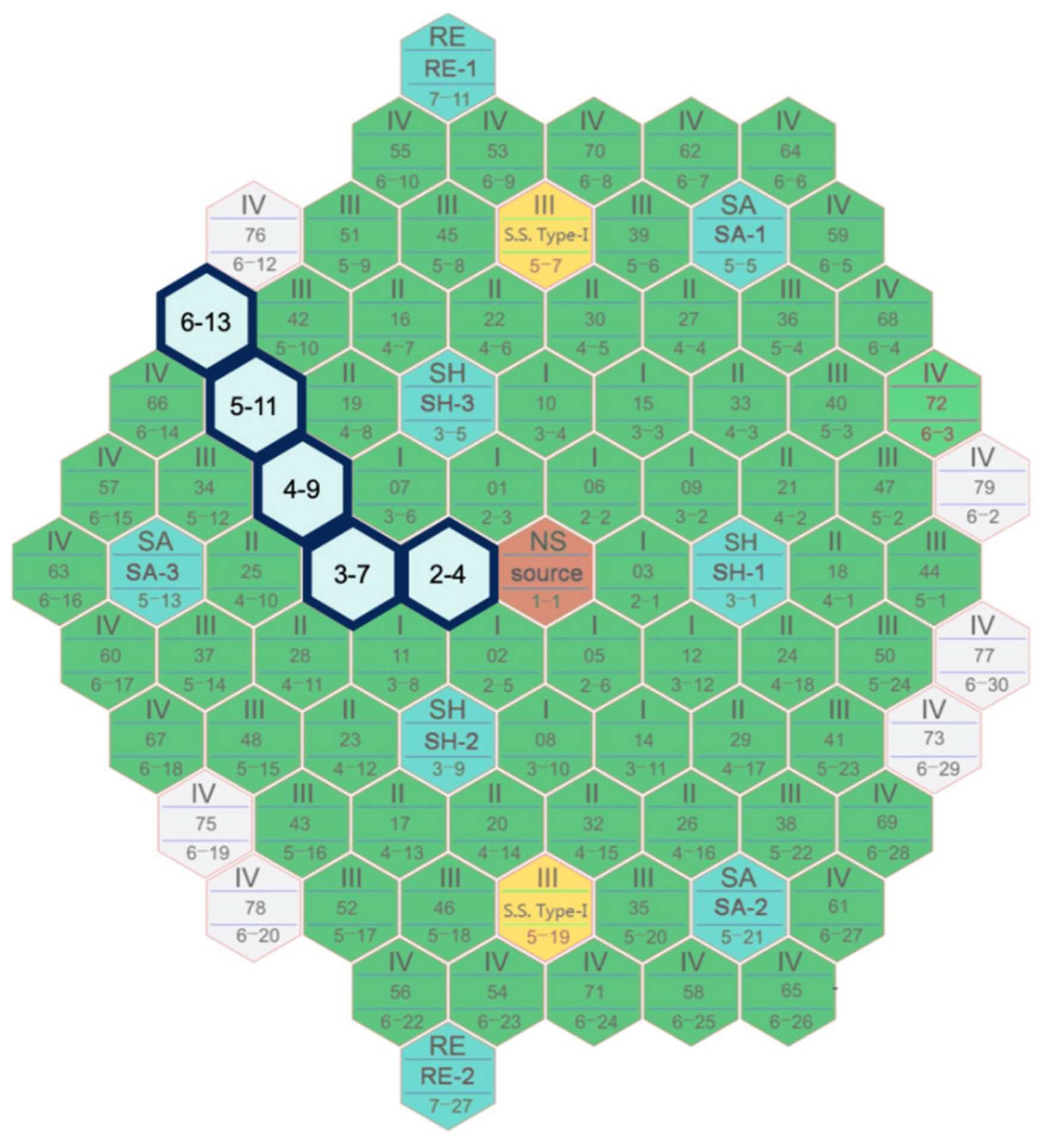

2. CEFR Benchmark Description

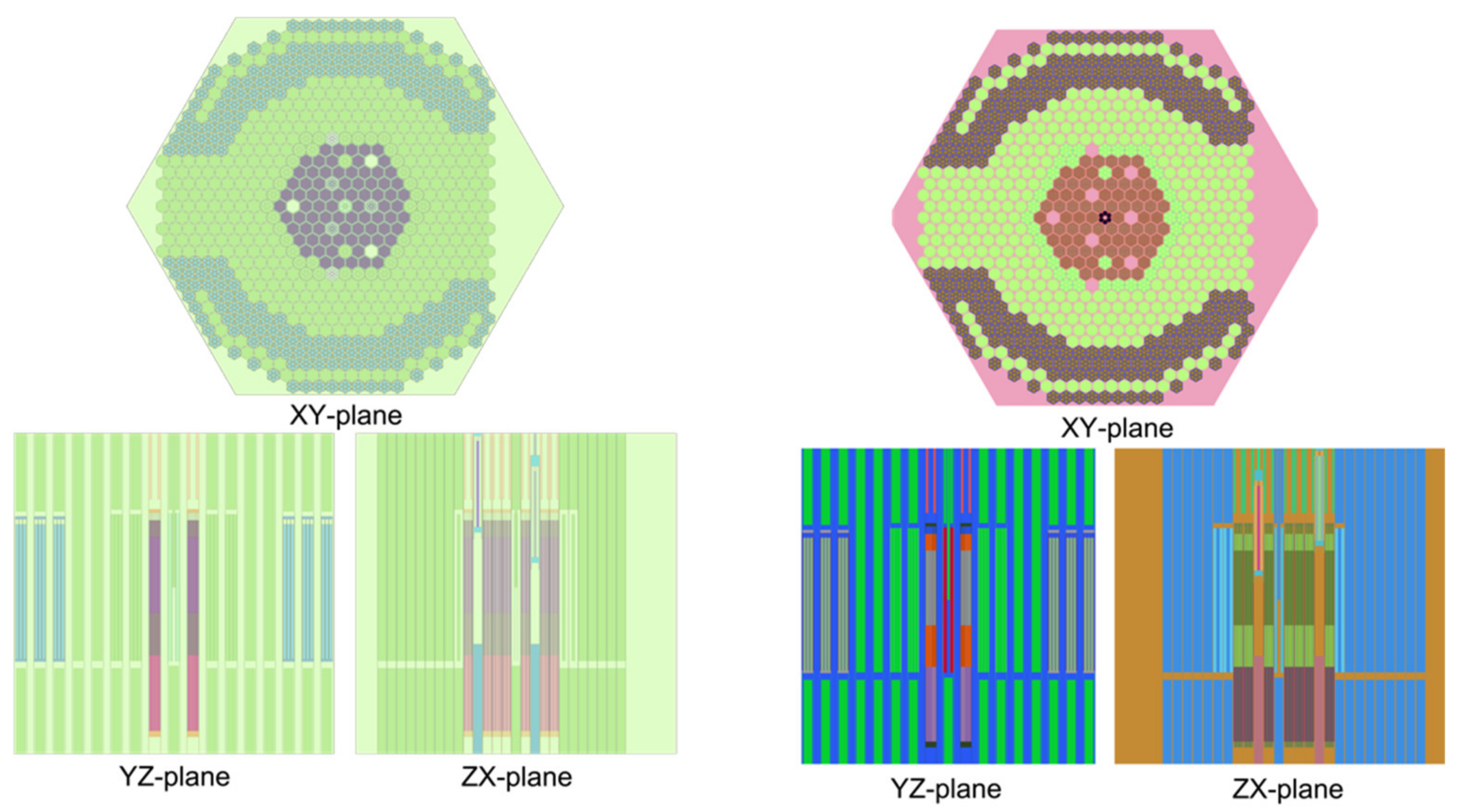

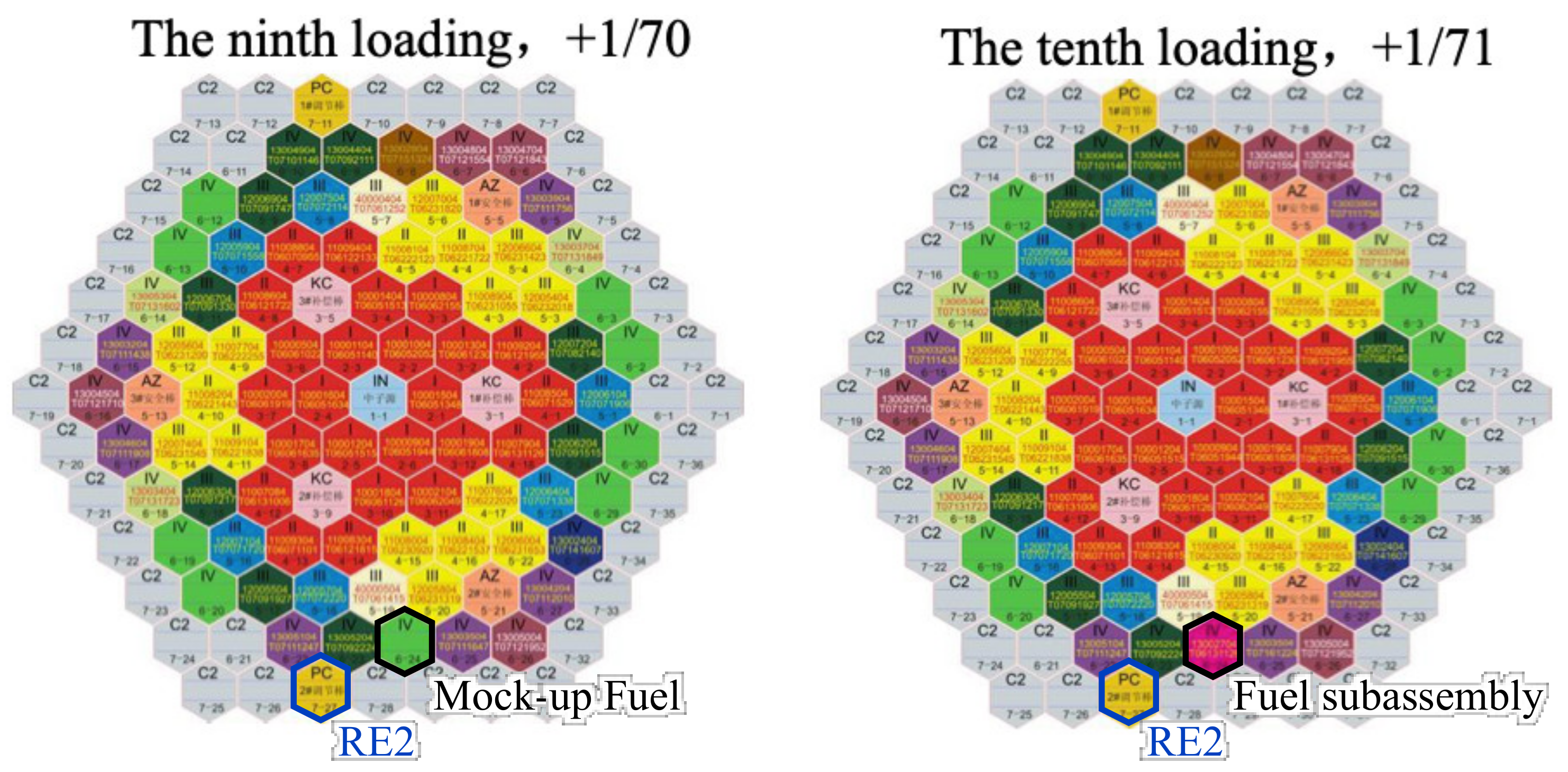

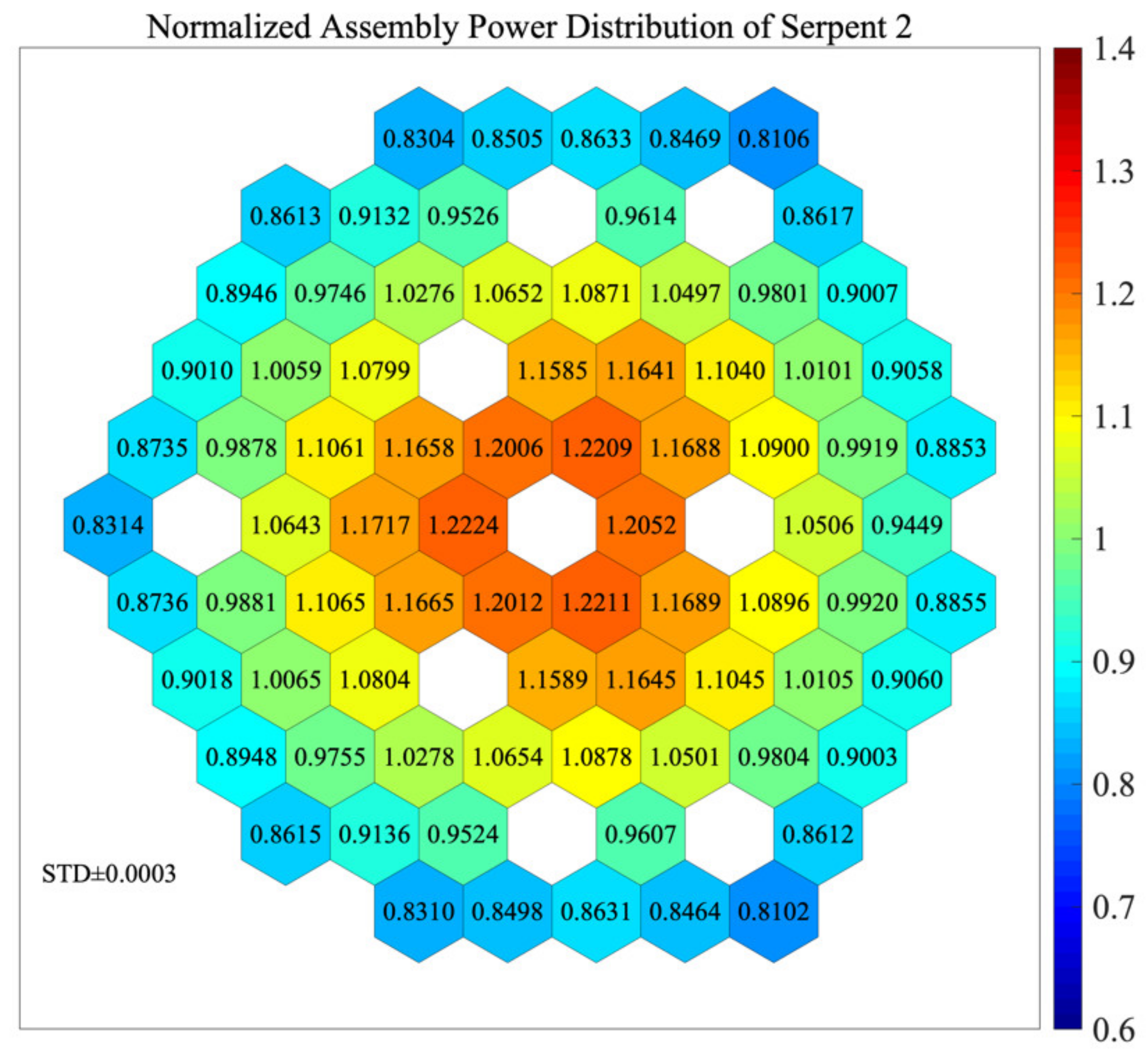

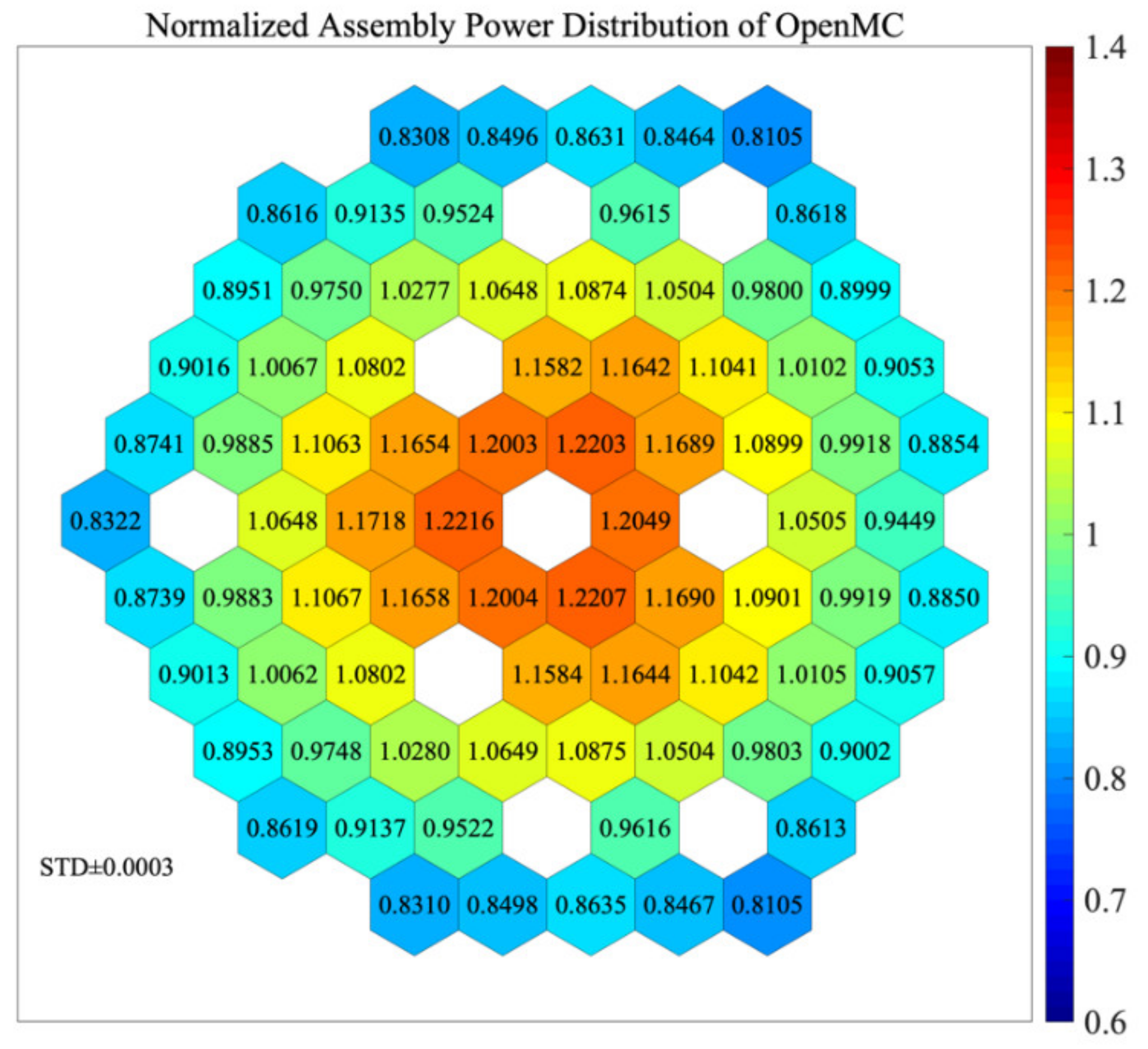

2.1. Core Description and Modeling

2.2. Start-Up Tests Used in the Benchmark

2.3. Coefficient-Measurement Methods in the Experiments

3. Simulation Codes and Computation Options

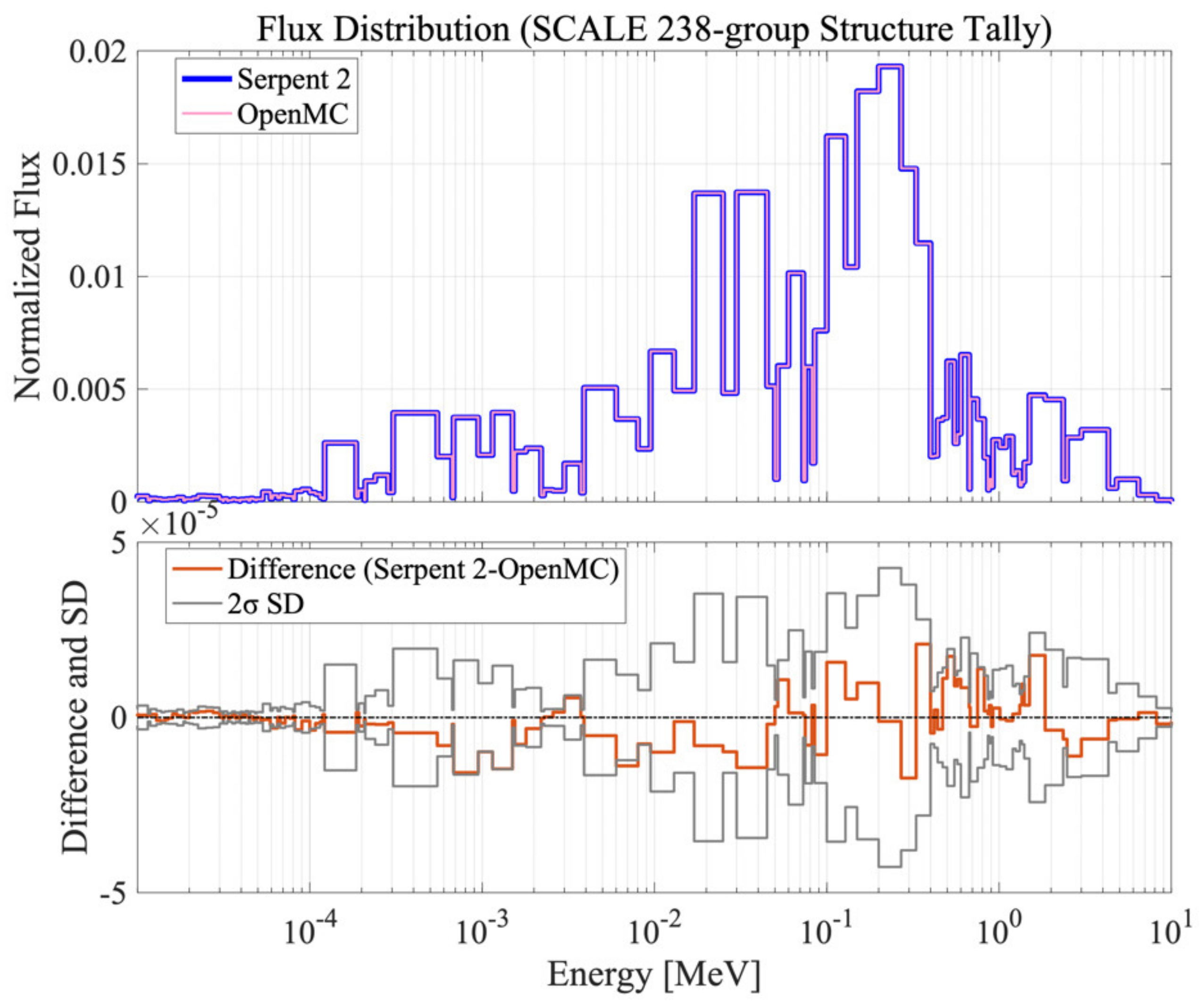

4. Calculation Results

4.1. Criticality

4.2. Control-Rod Worth

4.2.1. Integral Control-Rod Worth

4.2.2. S-Curve

4.3. Sodium-Void Reactivities

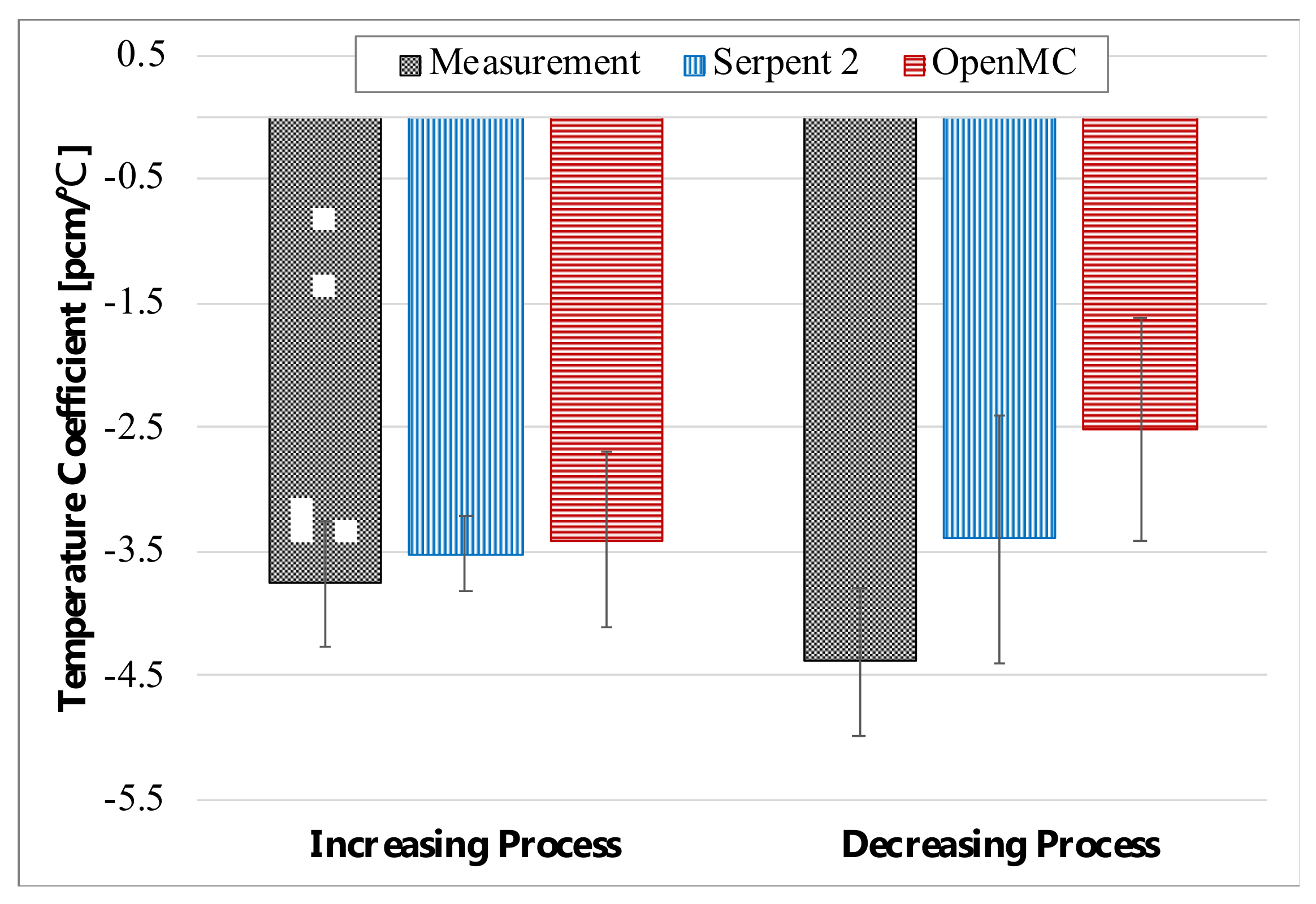

4.4. Temperature Coefficients

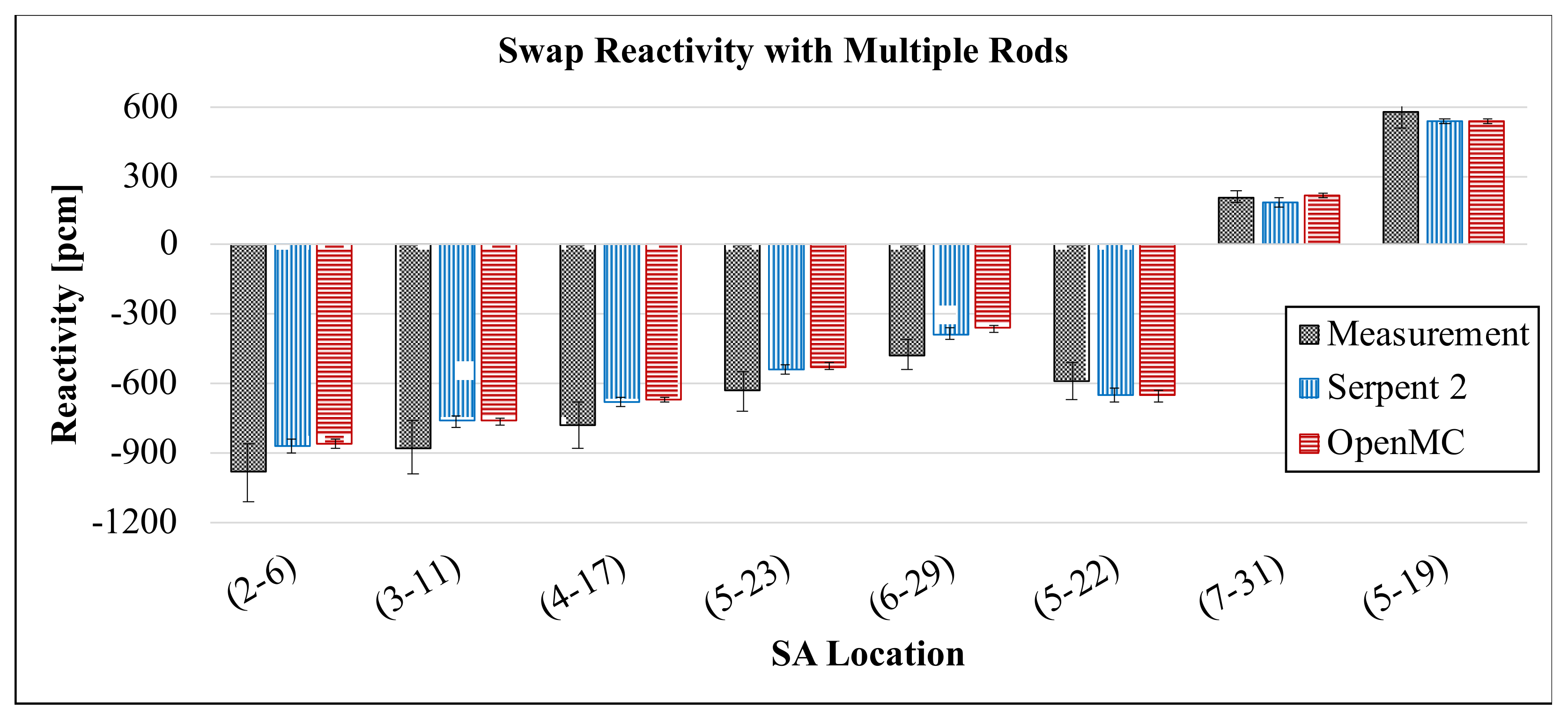

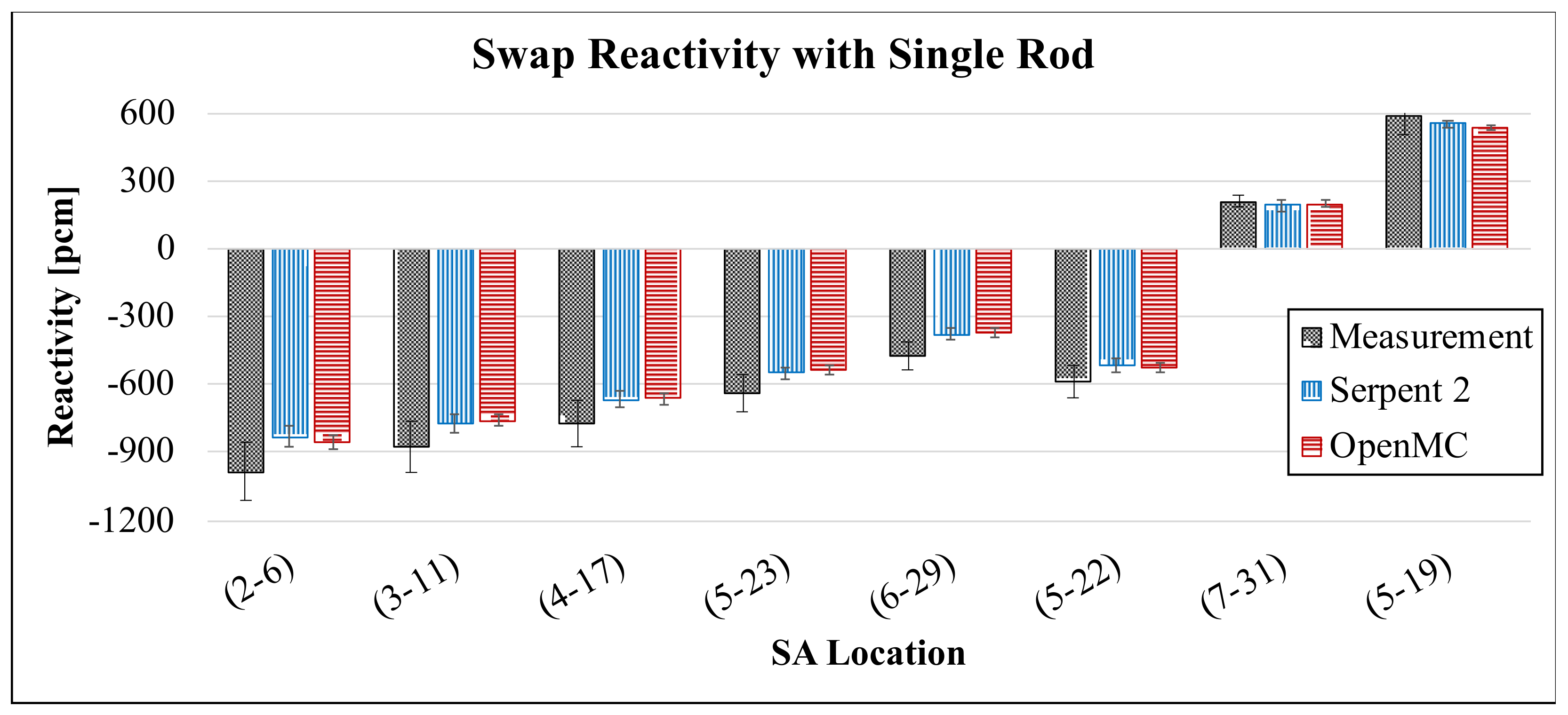

4.5. Swap Reactivity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IAEA. Status of Fast Reactor Research and Technology Development; IAEA-TECDOC-1691; IAEA: Vienna, Austria, 2013. [Google Scholar]

- Bernnat, W.; Blanchet, D.; Brun, E.; Buiron, L.; Fridman, E.; Guilliard, N.; Keresztúri, A.; Kim, T.K.; Kozlowski, T.; Kudo, T.; et al. Benchmark for Neutronic Analysis of Sodium-Cooled Fast Reactor Cores with Various Fuel Types and Core Sizes; NEA-NSC-R--2015-9; Nuclear Energy Agency of the OECD (NEA): Paris, France, 2016. [Google Scholar]

- IAEA. E. IAEA CRP: Neutronics Benchmark of CEFR Start-Up Tests (I31032). Available online: https://iaea.org/projects/crp/i31032 (accessed on 15 November 2021).

- IAEA. Power Reactor Information System: CEFR. Available online: https://pris.iaea.org/PRIS/CountryStatistics/ReactorDetails.aspx?current=1047 (accessed on 15 November 2021).

- Leppänen, J.; Pusa, M.; Viitanen, T.; Valtavirta, V.; Kaltiaisenaho, T. The Serpent Monte Carlo code: Status, development and applications in 2013. Ann. Nucl. Energy 2015, 82, 142–150. [Google Scholar] [CrossRef]

- Romano, P.K.; Horelik, N.E.; Herman, B.R.; Nelson, A.G.; Forget, B.; Smith, K. OpenMC: A state-of-the-art Monte Carlo code for research and development. Ann. Nucl. Energy 2015, 82, 90–97. [Google Scholar] [CrossRef] [Green Version]

- Chadwick, M.B.; Herman, M.; Obložinský, P.; Dunn, M.; Danon, Y.; Kahler, A.; Smith, D.; Pritychenko, B.; Arbanas, G.; Arcilla, R.; et al. ENDF/B-VII.1 Nuclear Data for Science and Technology: Cross Sections, Covariances, Fission Product Yields and Decay Data. Nucl. Data Sheets 2011, 112, 2887–2996. [Google Scholar] [CrossRef]

- Tran, T.Q.; Choe, J.; Du, X.; Lee, H.; Lee, D. Neutronic simulation of China experimental fast reactor start-up tests–part II: MCS code Monte Carlo calculation, Ann. Nucl. Energy 2020, 148, 107710. [Google Scholar] [CrossRef]

- Huo, X.; Hu, Y.; Chen, X.; Xu, L.; Duan, T. Technical Specifications for Neutronics Benchmark of CEFR Start-Up Tests (CRP-I31032) V5.0; NCBI: Beijing, China, 2018. [Google Scholar]

- Forget, B.; Xu, S.; Smith, K. Direct Doppler broadening in Monte Carlo simulations using the multipole representation. Ann. Nucl. Energy 2014, 64, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Viitanen, T. Implementing a Doppler-Preprocessor of Cross Section Libraries in Reactor Physics Code Serpent. Master’s Thesis, Helsinki University of Technology, Espoo, Finland, 2009. [Google Scholar]

- Josey, C.; Forget, B.; Smith, K. Windowed multipole sensitivity to target accuracy of the optimization procedure. J. Nucl. Sci. Technol. 2015, 52, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Viitanen, T.; Leppänen, J. Target motion sampling temperature treatment technique with elevated basis cross-section temperatures. Nucl. Sci. Eng. 2014, 177, 77–89. [Google Scholar] [CrossRef]

- Yang, W.S. Fast Reactor Physics and Computational Methods. Nucl. Eng. Technol. 2012, 44, 177–198. [Google Scholar] [CrossRef] [Green Version]

- Stock, R. Encyclopedia of Nuclear Physics and Its Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 978-3-527-40742-2. [Google Scholar]

| Material | Linear Expansion Coefficient [1/°C] |

|---|---|

| Fuel | 1.10 × 10−5 |

| Blanket fuel | 1.00 × 10−5 |

| B4C | 4.20 × 10−6 |

| Stainless steel | 1.80 × 10−5 |

| Category | Experiment | Data Provided | Result Generated |

|---|---|---|---|

| Criticality | Fuel loading and first criticality | Y | Y |

| Criticality at cold state in operation loading | N | N | |

| Criticality at hot state in operation loading | N | N | |

| Measurement of starting point of nuclear heating | N | N | |

| Control-rod worth | Calibration at first criticality | N | N |

| Calibration at cold state in operation loading | Y | Y | |

| Calibration at hot state in operation loading | N | N | |

| Reactivity coefficients | Pressure coefficient | N | N |

| Flow-rate coefficient | N | N | |

| Sodium-void reactivity | Y | Y | |

| Rod-swap reactivity | Y | Y | |

| Temperature coefficient | Y | N | |

| Foil activation | Distribution of reaction rate | Y | N |

| Cross-section ratios | N | N | |

| Neutron spectrum | N | N | |

| Nuclear-power calibration | N | N |

| No. of Fuel Subassemblies | RE2 [mm] | Core State | ρ(Δk/k) [pcm] | ||

|---|---|---|---|---|---|

| Measured | Serpent 2 | OpenMC | |||

| 71 | OOC 1 | Subcritical | N/A | −350 ± 6 | −367 ± 4 |

| 72 | 190 | Supercritical | 40 | −2 ± 6 | −11 ± 4 |

| 72 | 170 | Supercritical | 34 | −11 ± 6 | −21 ± 4 |

| 72 | 151 | Supercritical | 25 | −19 ± 6 | −25 ± 4 |

| 72 | 70 | Predicted critical | 0 | −39 ± 6 | −56 ± 4 |

| Rod or Rod Group | Rod Worth (dk/kk’) [pcm] | ||

|---|---|---|---|

| Measurement | Serpent 2 | OpenMC | |

| RE1 | 150 ± 9 | 150 ± 8 | 132 ± 4 |

| RE2 | 149 ± 9 | 146 ± 8 | 150 ± 4 |

| SH1 | 2019 ± 250 | 1906 ± 8 | 1914 ± 5 |

| SH2 | 1839 ± 225 | 1854 ± 8 | 1861 ± 5 |

| SH3 | 1839 ± 226 | 1854 ± 8 | 1842 ± 5 |

| SA1 | 945 ± 100 | 897 ± 8 | 903 ± 6 |

| SA2 | 911 ± 100 | 879 ± 8 | 892 ± 4 |

| SA3 | 946 ± 98 | 961 ± 8 | 960 ± 4 |

| 3 × SH + 2 × RE | 2877 ± 335 | 3055 ± 8 | 3049 ± 4 |

| SH2 + SH3 + 2 × RE | 881 ± 76 | 989 ± 8 | 1002 ± 4 |

| 3 × SA | 2981 ± 395 | 2803 ± 8 | 2809 ± 6 |

| SA1 + SA2 | 1950 ± 226 | 1798 ± 8 | 1795 ± 5 |

| 2 × RE + 3 × SH + 3 × SA | 6079 ± 989 | 6042 ± 8 | 6055 ± 5 |

| 2 × RE + SH2 + SH3 + 3 × SA | 3899 ± 551 | 3914 ± 8 | 3927 ± 5 |

| Control Rod | Rod Position [mm] | |

|---|---|---|

| Shim rods | SH1 | 239.3 |

| SH2 | 239.2 | |

| SH3 | 239.8 | |

| Safety rods | SA1 | 498.3 |

| SA2 | 499.8 | |

| SA3 | 499.1 | |

| Measurement Position in Core | Rod Positions | Temp. *** [°C] | Sodium-Void Worth [pcm] | ||||

|---|---|---|---|---|---|---|---|

| RE1 | RE2 | Measurement | Serpent 2 | OpenMC | |||

| (2–4) | O * | 277.6 | 277.3 | 248 | −39 ± 6 | −32 ± 22 | −41 ± 15 |

| V ** | 336.8 | 336.8 | 247 | ||||

| (3–7) | O | 278.0 | 277.4 | 248 | −43 ± 6 | −29 ± 22 | −52 ± 16 |

| V | 337.9 | 337.9 | N/A | ||||

| (4–9) | O | 277.7 | 277.6 | 248 | −41 ± 6 | −37 ± 22 | −36 ± 15 |

| V | 338.0 | 337.6 | N/A | ||||

| (5–11) | O | 278.4 | 276.2 | 248 | −40 ± 6 | −36 ± 22 | −46 ± 15 |

| V | 338.0 | 337.5 | N/A | ||||

| (6–13) | O | 302.9 | 303.3 | 248 | −33 ± 6 | −25 ± 16 | −41 ± 11 |

| V | 338.1 | 337.8 | N/A | ||||

| Process | Rod Position [mm] | Temp. [°C] | Measurement | Serpent 2 | OpenMC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RE1 | RE2 | SH1 | SH2 | SH3 | Δρ [pcm] | Coef. [pcm/°C] | Δρ [pcm] | Coef. [pcm/°C] | Δρ [pcm] | Coef. [pcm/°C] | ||

| Increasing | 207 | 208 | 248 | 248 | 248 | 250 | 0 * | −3.8 ± 0.5 | 0 * | −3.5 ± 0.3 | 0 * | −3.4 ± 0.7 |

| 212 | 213 | 254 | 253 | 254 | 274 | −91 ± 13 | −75 ± 17 | −81 ± 12 | ||||

| 240 | 239 | 253 | 253 | 254 | 283 | −116 ± 16 | −135 ± 23 | −140 ± 17 | ||||

| 283 | 283 | 253 | 253 | 254 | 293 | −152 ± 20 | −131 ± 31 | −137 ± 22 | ||||

| 308 | 307 | 255 | 255 | 256 | 302 | −202 ± 27 | −189 ± 23 | −178 ± 15 | ||||

| Decreasing | 408 | 409 | 502 | 162 | 162 | 300 | 0 * | −4.4 ± 0.6 | 0* | −3.4 ± 1.0 | 0 * | −2.5 ± 0.9 |

| 283 | 284 | 254 | 254 | 254 | 290 | 45 ± 7 | 121 ± 161 | 85 ± 112 | ||||

| 285 | 285 | 502 | 162 | 162 | 280 | 81 ± 12 | 75 ± 107 | 34 ± 74 | ||||

| 232 | 232 | 502 | 162 | 162 | 270 | 129 ± 17 | 141 ± 34 | 86 ± 24 | ||||

| 119 | 119 | 502 | 162 | 163 | 250 | 220 ± 29 | 196 ± 61 | 146 ± 43 | ||||

| Position | Type of Subassembly Loaded after Swap | |||||||

|---|---|---|---|---|---|---|---|---|

| (2–06) | (3–11) | (4–17) | (5–23) | (6–29) | (5–22) | (7–31) | (5–19) | |

| (2–06) | SS | Fuel | Fuel | Fuel | Fuel | Fuel | SS | SS |

| (3–11) | Fuel | SS | Fuel | Fuel | Fuel | Fuel | SS | SS |

| (4–17) | Fuel | Fuel | SS | Fuel | Fuel | Fuel | SS | SS |

| (5–23) | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS | SS |

| (6–29) | Fuel | Fuel | Fuel | Fuel | SS | Fuel | SS | SS |

| (5–22) | Fuel | Fuel | Fuel | Fuel | Fuel | SS | SS | SS |

| (7–31) | Fuel | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS |

| (5–19) | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS | Fuel |

| Subassembly Position | Temp. [°C] | Swap Reactivity [pcm] | ||

|---|---|---|---|---|

| Measurement | Serpent 2 | OpenMC | ||

| (2–06) | 246 | −986 ± 128 | −871 ± 30 | −859 ± 20 |

| (3–11) | 246 | −880 ± 114 | −763 ± 23 | −765 ± 15 |

| (4–17) | 246 | −777 ± 101 | −678 ± 21 | −670 ± 15 |

| (5–23) | 246 | −634 ± 82 | −536 ± 20 | −525 ± 14 |

| (6–29) | 246 | −474 ± 62 | −384 ± 25 | −363 ± 17 |

| (5–22) | 246 | −590 ± 77 | −650 ± 32 | −654 ± 22 |

| (7–31) | 246 | 210 ± 27 | 188 ± 19 | 216 ± 13 |

| (5–19) | 246 | 582 ± 76 | 536 ± 12 | 538 ± 9 |

| Subassembly Position | Temp. [°C] | Swap Reactivity [pcm] | ||

|---|---|---|---|---|

| Measurement | Serpent 2 | OpenMC | ||

| (2–06) | 246 | −984 ± 128 | −832 ± 44 | −856 ± 31 |

| (3–11) | 246 | −880 ± 114 | −763 ± 23 | −765 ± 15 |

| (4–17) | 246 | −875 ± 114 | −771 ± 38 | −757 ± 26 |

| (5–23) | 246 | −634 ± 82 | −536 ± 20 | −525 ± 14 |

| (6–29) | 246 | −772 ± 100 | −664 ± 34 | −662 ± 23 |

| (5–22) | 246 | −590 ± 77 | −650 ± 32 | −654 ± 22 |

| (7–31) | 246 | −639 ± 83 | −548 ± 27 | −537 ± 19 |

| (5–19) | 246 | 582 ± 76 | 536 ± 12 | 538 ± 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choe, J.; Batra, C.; Kriventsev, V.; Lee, D. Neutronic Analysis of Start-Up Tests at China Experimental Fast Reactor. Energies 2022, 15, 1249. https://doi.org/10.3390/en15031249

Choe J, Batra C, Kriventsev V, Lee D. Neutronic Analysis of Start-Up Tests at China Experimental Fast Reactor. Energies. 2022; 15(3):1249. https://doi.org/10.3390/en15031249

Chicago/Turabian StyleChoe, Jiwon, Chirayu Batra, Vladimir Kriventsev, and Deokjung Lee. 2022. "Neutronic Analysis of Start-Up Tests at China Experimental Fast Reactor" Energies 15, no. 3: 1249. https://doi.org/10.3390/en15031249