A Review of Environmental and Economic Implications of Closing the Nuclear Fuel Cycle—Part One: Wastes and Environmental Impacts

Abstract

:1. Introduction

2. Background and Context

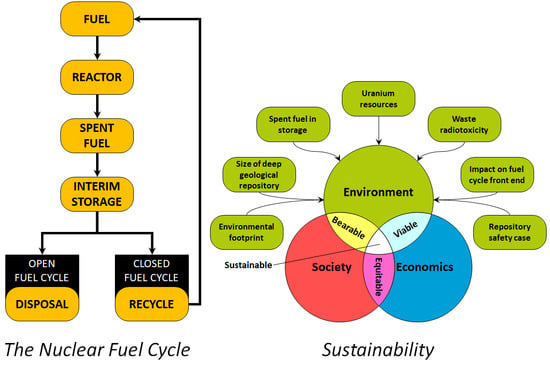

2.1. Nuclear Fuel Cycles

- The open or once-through cycle (OTC), where spent uranium oxide (UOX) fuels are stored before direct disposal in a deep geological repository (DGR), also known as a geological disposal facility (GDF) in the UK.

- The partially closed, thermal recycle or twice-through cycle (TTC), based on reprocessing SNF to recover fissile material (i.e., uranium and plutonium), which is then recycled as mixed oxide (MOX) fuel, sometimes referred to as plutonium mono-recycling.

- The fully closed cycle (FCC), in which SNF is reprocessed and fissile materials are usually recycled in a fast reactor multiple times to maximise the energy value of the fuel components, also referred to as plutonium multi-recycling. There are a number of variations in this concept, such as transition scenarios where light water reactors (LWRs) and FRs operate together, or a fleet comprised only of FRs. FRs can be configured to either burn or breed plutonium depending on the nuclear fuel cycle strategy to be followed.

- The partitioning and transmutation (P&T) scenario, where MAs are also recycled for burning (usually) in fast reactors or accelerator-driven systems (ADS). As will be seen later, after the separation of plutonium the MA account for the majority of the heat generation and radiotoxicity in the medium to longer term. The P&T scenario is thus aimed at minimising the MA waste burden to the DGR, rather than for its energy value.

2.2. Benefits of New Systems

- Sustainability, including more efficient use of natural resources.

- Reduction in volume and/or heat load of waste.

- Reduction in the radiotoxicity of waste.

- Economic benefits.

- Enhanced proliferation resistance and/or inherent physical protection.

- Plutonium management.

- Improved public acceptability.

2.3. Sustainability

- Economic drivers concern achieving affordable energy prices based on long-term predictable production costs that are resilient to international influences [23].

- Societal drivers largely concern public acceptability, including reducing risks to health as well as the promotion of intra- and intergenerational equity. Specifically, for nuclear energy, concerns over nuclear safety, security and proliferation risks are also relevant.

- Environmental ambitions can be broken down into three broad drivers:

- ○

- Reducing greenhouse gas emissions (i.e., the carbon footprint).

- ○

- Reducing waste generation to a level where nature can absorb it, and consumption of resources to a point where they can be regenerated (i.e., the environmental footprint).

- ○

- Preserving finite natural resources.

- Sustainable use and protection of water and marine resources.

- Transition to a circular economy.

- Pollution prevention control.

- Protection and restoration of biodiversity and ecosystems.

2.4. Spent Nuclear Fuel Arisings

2.5. Fuel Cycle Modelling

3. Environmental Assessments of Fuel Cycles

3.1. Natural Resources (Uranium Utilisation)

- Improving the probability of 238U fission.

- The use of depleted uranium stocks.

- Recycling and reusing fissile material.

- One CANDU reactor was needed for every two PWRs (to sustain the DUPIC cycle).

- One MOX-burning PWR for every seven UO2-fuelled PWRs (in the TTC).

- One SFR for every PWR (in the Pyro-SFR cycle).

- IPCC-1: Central and Eastern Europe (including states of the former Soviet Union).

- IPCC-2: North America, Western Europe and Pacific OECD nations (such as Australia and Japan).

- IPCC-3: centrally planned Asia (including India and China).

- IPCC-4: Latin America, Caribbean, Middle East and Africa.

- “…potential future scarcity of uranium resources is not unreasonable, but is a very serious prospect for regions of the world where the energy demand growth is and will very probably continue to be high and where nuclear energy will be employed to at least partially meet that demand.”

- “…rapid development of fast reactors, especially in areas with rapidly expanding economies and strong energy demand growth, is essential for nuclear energy sustainability, for the global saving of natural uranium resources and for the reduction of high-level waste generation requiring disposal.”

- “In the case of an open cycle, increased pressure on the uranium market is to be expected towards the end of the current century.”

3.2. Environmental Assessment and Life Cycle Analysis (LCA)

3.2.1. Background—LCA of Nuclear Energy

3.2.2. Nuclear Fuel Cycle LCA

- “Base line”—the nominal UK fuel cycle whereby SNF was reprocessed and products stored pending decisions on disposition [61].

- Scenario one—the products from the baseline are disposed of in a repository.

- Scenario two—SNF is reprocessed and RepU is recycled whilst Pu is disposed of in a repository.

- Scenario three—SNF is reprocessed and RepU and Pu are recycled as MOX fuel.

- Scenario four—SNF is reprocessed and RepU is recycled whilst Pu is mixed with depleted uranium and recycled as MOX fuel.

- Direct disposal—the OTC.

- Of the natural uranium requirement, 95% is from outside Europe, with the remainder primarily from Ukraine. Nearly half of the uranium is processed outside Europe, causing wastes and emissions outside their system boundaries. This leads to 1.1 × 107 t/y of waste rock and 2 × 106 t/y mill tailings outside Europe.

- In Europe 6.4 × 105 t waste rock, 1.3 × 105 t mill tailings, 6.4 × 103 t depleted uranium and 2.5 × 103 t SNF accumulate per year, and nearly 80% of the energy requirement for the European nuclear fuel cycle is due to front-end activities (e.g., enrichment, conversion and disposal of depleted uranium).

- Scenario R1 allows a reduction in natural uranium usage of 15%, and R5 reduces fresh uranium and waste production by over 99%; the environmental improvements require trade-offs with economic and proliferation risks.

3.3. Fuel Cycle Impacts on the Waste Repository

3.3.1. General Considerations

- Reduction in radionuclide inventory (and/or radiotoxicity) of HLW.

- Changes in volumes of radioactive wastes for disposal (ILW and HLW).

- Reduction in heat generation (thermal power) of HLW.

- Increase in waste form durability.

3.3.2. Specific Fuel Cycle Studies

- SC1—OTC based on PWRs.

- SC2—OTC based on high-temperature reactors.

- SC3—TTC based on PWRs.

- SC4—as SC3 but spent MOX fuel is recycled in SFRs for burning TRU (Pu, Np and Am).

- SC5—closed cycle based on SFRs (iso-breeders, conversion ratio of 1).

- Reduce the wastes for disposal by a factor of 10 or more.

- Reduce long-term radioactivity by a factor of 10 or more.

- Reduce residual uranium wastes by a factor of 100 or more.

- Reduce use of uranium resources by a factor of 100 or more.

- Reduce carbon dioxide emissions by a factor of two.

- The OTC.

- TTC and plutonium recycle in fast reactors.

- The P&T scenarios:

- ○

- Pu and MA recycle.

- ○

- A simplified double-strata concept with LWRs and accelerator-driven systems (ADS).

- ○

- A double-strata concept with LWR, FR and ADS.

- Conventional reprocessing, producing separate U and Pu products that are recycled as MOX by blending with natural uranium.

- Advanced reprocessing, in which a U and Pu product is obtained from reprocessing that can be directly converted into MOX without blending.

- Disposal area increases with burnup except for vitrified HLW, which is insensitive to burnup and has the smallest disposal area per ton at 50 GWd/t.

- MOX fuels require substantially larger disposal areas due to their heat loading, which limits only one assembly (instead of four) that can be placed in a disposal canister. This impacts the overall disposal area per ton of fresh uranium fuel that is calculated for the TTC.

- TTCs produce less HLW (~30%) and generate ~20% more electricity per ton of fresh U fuel, although it is calculated to require ~7% more disposal area (due to the low-density disposal of MOX fuel).

- The disposal area advantage factor is defined as the total electricity generated per m2 of disposal area normalised to a reference cycle (OTC with 33 GWd/t fuel). This factor goes down with increasing burnup, implying that disposal of once-through low-burnup UOX fuel is the most efficient use of disposal capacity. However, the TTC are close to the OTC at all burnups; the difference is due to the recycling of RepU, which has a disposal area of ~22 m2/tU.

- The times for the radioactive wastes to decay to levels of toxicity comparable to the natural fuel are lower in the TTC but still around 10,000 years. This is because vitrified HLW has the lowest decay period of < 1500 years, but some MOX fuel also must be disposed of (decay period of 60,000–80,000 years depending on burnup).

- Multi-recycling (in FRs) and the impacts of recycling MAs were not assessed.

3.4. Recycle and Reuse of Wastes

4. Discussion

- Recognize the long-term benefits of developing Generation IV (Gen IV) systems in terms of resource utilisation and waste management.

- Support R&D in advanced recycling technologies to reduce the volume and toxicity of high-level waste.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Energy White Paper: Powering our Net Zero Future; BEIS (Department for Business Energy and Industrial Strategy): London, UK, 2020. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/945899/201216_BEIS_EWP_Command_Paper_Accessible.pdf (accessed on 7 December 2021).

- Management of Spent Nuclear Fuel and Its Waste; EASAC (European Academies Science Advisory Council): Publications Office of the European Union: Luxembourg, 2014. [CrossRef]

- Netter, P. Reprocessing of spent oxide fuel from nuclear power reactors. In Nuclear Fuel Cycle Science and Engineering; Woodhead Publishing: Sawston, UK, 2012; pp. 459–500. [Google Scholar] [CrossRef]

- Behar, C. Energy for the future: Generation IV fast reactors and the closed fuel cycle. Nucl. Future 2014, 10, 23–25. [Google Scholar]

- Poinssot, C.; Rostaing, C.; Greandjean, S.; Boullis, B. Recycling the Actinides, The Cornerstone of Any Sustainable Nuclear Fuel Cycles. Procedia Chem. 2012, 7, 349–357. [Google Scholar] [CrossRef] [Green Version]

- Baron, P.; Cornet, S.M.; Collins, E.D.; DeAngelis, G.; Del Cul, G.; Fedorov, Y.; Glatz, J.P.; Ignatiev, V.; Inoue, T.; Khaperskaya, A.; et al. A review of separation processes proposed for advanced fuel cycles based on technology readiness level assessments. Prog. Nucl. Energy 2019, 117, 24. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.J.; Ko, W.I. Dynamic analysis of once-through and closed fuel cycle economics using Monte Carlo simulation. Nucl. Eng. Des. 2014, 277, 234–247. [Google Scholar] [CrossRef]

- Allibert, M.; Ault, T.; Baron, P.; Bergeron, A.; Bromley, B.; Butler, G.; Chauvin, N.; Collins, E.; Cornet, S.; Croff, A.; et al. Introduction of Thorium in the Nuclear Fuel Cycle: Short- to Long-Term Considerations; NEA (Nuclear Energy Agency OECD): Paris, France, 2015; Available online: https://www.oecd-nea.org/science/pubs/2015/7224-thorium.pdf (accessed on 7 December 2021).

- Sokolov, F.; Fukuda, K.; Nawada, H.P. Thorium Fuel Cycle-Potential Benefits and Challenges; IAEA (International Atomic Energy Agency): Vienna, Austria, 2005; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TE_1450_web.pdf (accessed on 7 December 2021).

- Ekberg, C. Developments in reprocessing of spent nuclear fuels for the thorium fuel cycle. In Reprocessing and Recycling of Spent Nuclear Fuel; Taylor, R., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 603–640. [Google Scholar] [CrossRef]

- Vijayan, P.; Shivakumar, V.; Basu, S.; Sinha, R. Role of thorium in the Indian nuclear power programme. Prog. Nucl. Energy 2017, 101, 43–52. [Google Scholar] [CrossRef]

- Wilson, P. (Ed.) The Nuclear Fuel Cycle: From Ore to Waste; Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- Hyatt, N. Plutonium management policy in the United Kingdom: The need for a dual track strategy. Energy Policy 2017, 101, 303–309. [Google Scholar] [CrossRef] [Green Version]

- Gregg, R.; Hesketh, K. The benefits of a fast reactor closed fuel cycle in the UK. In Proceedings of the GLOBAL 2013: International Nuclear Fuel Cycle Conference-Nuclear Energy at a Crossroads, Salt Lake City, UT, USA, 29 September–3 October 2013; pp. 1235–1244. [Google Scholar]

- Dungan, K.; Gregg, R.; Morris, K.; Livens, F.; Butler, G. Assessment of the disposability of radioactive waste inventories for a IAEA range of nuclear fuel cycles: Inventory and evolution over time. Energy 2021, 221, 119826. [Google Scholar] [CrossRef]

- NNL (National Nuclear Laboratory); Burstall, R. FISPIN. 1979. Available online: https://www.answerssoftwareservice.com/fispin/ (accessed on 7 December 2021).

- Bunn, M.; Fetter, S.; Holdren, J.; van der Zwann, B. The Economics of Reprocessing vs. Direct Disposal of Spent Nuclear Fuel; Belfer Center for Science and International Affairs: Cambridge, MA, USA, 2003; Available online: https://www.belfercenter.org/sites/default/files/files/publication/repro-report.pdf (accessed on 7 December 2021).

- Butler, G. A Catalyst for Change? Nuclear Engineering International: London, UK, 2012; pp. 1–5. Available online: https://www.nsenergybusiness.com/features/featurea-catalyst-for-change/ (accessed on 7 December 2021).

- Waddington, I.; Thomas, P.; Taylor, R.; Vaughan, G. J-value assessment of relocation measures following the nuclear power plant accidents at Chernobyl and Fukushima Daiichi. Process Saf. Environ. Prot. 2017, 112, 16–49. [Google Scholar] [CrossRef]

- Butler, G.; Matthews, J.; Bodel, W. Nuclear Energy for Net Zero: A Strategy for Action; Dalton Nuclear Institute: Manchester, UK, 2021; Available online: https://documents.manchester.ac.uk/display.aspx?DocID=55791 (accessed on 7 December 2021).

- Resolution 42/187: Report of the World Commission on Environment and Development; UN (United Nations): New York, NY, USA, 1987; Available online: http://www.un-documents.net/a42r187.htm (accessed on 7 December 2021).

- Poinssot, C.; Boullis, B.; Bourg, S. Role of recycling in advanced nuclear fuel cycles. In Reprocessing and Recycling of Spent Nuclear Fuel; Taylor, R., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 27–48. [Google Scholar] [CrossRef]

- Poinssot, C.; Bourg, S.; Boullis, B. Improving the nuclear energy sustainability by decreasing its environmental footprint. Guidelines from life cycle assessment simulations. Prog. Nucl. Energy 2016, 92, 234–241. [Google Scholar] [CrossRef]

- Use of Nuclear Fuel Resources for Sustainable Development—Entry Pathways. UNECE (United Nations Economic Commission for Europe): Geneva, Switzerland, 2021; Available online: https://unece.org/sites/default/files/2021-03/UNFC%26amp%3B UNRMS NuclearEntryPathwaysRevised.pdf (accessed on 7 December 2021).

- Stamford, L.; Azapagic, A. Sustainability indicators for the assessment of nuclear power. Energy 2011, 36, 6037–6057. [Google Scholar] [CrossRef]

- Stamford, L.; Azapagic, A. Life cycle sustainability assessment of UK electricity scenarios to 2070. Energy Sustain. Dev. 2014, 23, 194–211. [Google Scholar] [CrossRef]

- Benoît Norris, C.; Traverso, M.; Neugebauer, S.; Ekener, E.; Schaubroeck, T.; Garrido, S.R.; Valdivia, S.; Lehmann, A.; Finkbeiner, M.; Arcese, G. Guidelines for Social Life Cycle Assessment of Products and Organizations 2020; UNEP (United Nations Environment Programme): Nairobi, Kenya, 2020; Available online: https://www.lifecycleinitiative.org/wp-content/uploads/2021/01/Guidelines-for-Social-Life-Cycle-Assessment-of-Products-and-Organizations-2020-22.1.21sml.pdf (accessed on 7 December 2021).

- Technical Assessment of Nuclear Energy with Respect to the 'Do No Significant Harm’ Criteria of Regulation (EU) 2020/852 (‘Taxonomy Regulation’); JRC (Joint Research Centre): Ispra, Italy, 2021; Available online: https://ec.europa.eu/info/sites/default/files/business_economy_euro/banking_and_finance/documents/210329-jrc-report-nuclear-energy-assessment_en.pdf (accessed on 7 December 2021).

- Nuclear Technology Review 2019; IAEA (International Atomic Energy Agency): Vienna, Austria, 2019; Available online: https://www.iaea.org/sites/default/files/gc/gc63-inf2.pdf (accessed on 7 December 2021).

- Spent Fuel Reprocessing Options; IAEA (International Atomic Energy Agency): Vienna, Austria, 2008; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TE_1587_web.pdf (accessed on 7 December 2021).

- Processing of Used Nuclear Fuel; WNA (World Nuclear Association): London, UK, 2018; Available online: https://world-nuclear.org/information-library/nuclear-fuel-cycle/fuel-recycling/processing-of-used-nuclear-fuel.aspx (accessed on 7 December 2021).

- Nuclear Technology Review; IAEA (International Atomic Energy Agency): Vienna, Austria, 2016; Available online: https://www.iaea.org/sites/default/files/16/08/ntr2016.pdf (accessed on 7 December 2021).

- Le, T. Spent Nuclear Fuel and Disposal: An Examination of Spent Nuclear Fuel Storage and Disposal Around the World; Stimson Centre, 2020; Available online: https://www.stimson.org/2020/spent-nuclear-fuel-storage-and-disposal/ (accessed on 7 December 2021).

- Transition towards a Sustainable Nuclear Fuel Cycle; NEA (Nuclear Energy Agency OECD): Paris, France, 2019; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2019-12/7133-transition-sustainable-fuel-cycle.pdf (accessed on 7 December 2021).

- Procedures for Expansion of Spent Nuclear Fuel Final Disposal Facility are Progressing; Posiva, 2008; Available online: https://www.posiva.fi/en/index/news/pressreleasesstockexchangereleases/2008/procedures_for_expansion_of_spent_nuclear_fuel_final_disposal_facility_are_progressing.181.html (accessed on 7 December 2021).

- A Repository for Nuclear Fuel that is Placed in 1.9 Billion Years Old Rock; SKB (Svensk Kärnbränslehantering), 2021; Available online: http://www.skb.com/future-projects/the-spent-fuel-repository/ (accessed on 7 December 2021).

- Lyons, P. Lessons Learned from the U.S. National Strategy-A Personal Perspective. Available online: http://www-pub.iaea.org/MTCD/Publications/PDF/SupplementaryMaterials/P1905_Proceedings_Series.zip (accessed on 7 December 2021).

- Bonano, E.J.; Kalinina, E.A.; Swift, P.N. The Need for Integrating the Back End of the Nuclear Fuel Cycle in the United States of America. MRS Adv. 2018, 3, 991–1003. [Google Scholar] [CrossRef] [Green Version]

- Technology Roadmap: Nuclear Energy; IEA (International Energy Agency) and NEA (Nuclear Energy Agency): Paris, France, 2015. Available online: https://www.oecd-nea.org/pub/techroadmap/techroadmap-2015.pdf (accessed on 7 December 2021).

- Climate Change and Nuclear Power 2020; IAEA (International Atomic Energy Agency): Vienna, Austria, 2020; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/PUB1911_web.pdf (accessed on 7 December 2021).

- González-Romero, E. Impact of Partitioning and Transmutation on the High Level Waste Management. Nucl. Eng. Des. 2011, 241, 3436–3444. [Google Scholar] [CrossRef]

- Cairns, M. Supporting NDA strategy development on spent oxide fuel management. Nucl. Future 2018, 14, 43–47. [Google Scholar]

- UK Radioactive Material Inventory; NDA (Nuclear Decommissioning Authority): Moor Row, UK, 2019. Available online: https://ukinventory.nda.gov.uk/wp-content/uploads/2020/01/2019-Materials-Report-Final.pdf (accessed on 7 December 2021).

- Hinkley Point C Pre-Application Consultation-Stage 2; Environmental Appraisal Volume 2; EDF Energy; Available online: https://www.edfenergy.com/sites/default/files/V2 C06 Spent Fuel and Radioactive Waste Management.pdf (accessed on 7 December 2021).

- Benedicic, J. Life without reprocessing—The end of an era. Nucl. Future 2017, 13, 34–39. [Google Scholar]

- Benchmark Study on Nuclear Fuel Cycle Transition Scenarios Analysis Codes; NEA (Nuclear Energy Agency OECD): Paris, France, 2012.

- Guérin, L.; Feng, B.; Hejzlar, P.; Forget, B.; Kazimi, M.S.; Van Den Durpel, L.; Yacout, A.; Taiwo, T.; Dixon, B.W.; Matthern, G.; et al. A Benchmark Study of Computer Codes for System Analysis of the Nuclear Fuel Cycle; MIT (Massachusetts Institute of Technology): Cambridge, MA, USA, 2009; Available online: https://dspace.mit.edu/handle/1721.1/75245 (accessed on 7 December 2021).

- The Effects of the Uncertainty of Input Parameters on Nuclear Fuel Cycle Scenario Studies; NEA (Nuclear Energy Agency OECD): Paris, France, 2017; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2020-01/dir1/nsc-r2016-4.pdf (accessed on 7 December 2021).

- Serp, J.; Poinssot, C.; Bourg, S. Assessment of the Anticipated Environmental Footprint of Future Nuclear Energy Systems. Evidence of the Beneficial Effect of Extensive Recycling. Energies 2017, 10, 1445. [Google Scholar] [CrossRef] [Green Version]

- Poinssot, C.; Bourg, S.; Ouvrier, N.; Combernoux, N.; Rostaing, C.; Vargas-Gonzalez, M.; Bruno, J. Assessment of the environmental footprint of nuclear energy systems. Comparison between closed and open fuel cycles. Energy 2014, 69, 199–211. [Google Scholar] [CrossRef] [Green Version]

- Nuclear Energy: Combating Climate Change; NEA (Nuclear Energy Agency OECD): Paris, France, 2015; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2019-12/7208-climate-change-2015.pdf (accessed on 7 December 2021).

- Gao, F.; Ko, W.I. Modeling and system analysis of fuel cycles for nuclear power sustainability (I): Uranium consumption and waste generation. Ann. Nucl. Energy 2014, 65, 10–23. [Google Scholar] [CrossRef]

- Park, B.H.; Gao, F.; Kwon, E.-H.; Ko, W.I. Comparative study of different nuclear fuel cycle options: Quantitative analysis on material flow. Energy Policy 2011, 39, 6916–6924. [Google Scholar] [CrossRef]

- Kazimi, M.; Moniz, E.J.; Forsberg, C.W. The Future of the Nuclear Fuel Cycle; MIT (Massachusetts Institute of Technology): Cambridge, MA, USA, 2011; Available online: https://energy.mit.edu/wp-content/uploads/2011/04/MITEI-The-Future-of-the-Nuclear-Fuel-Cycle.pdf (accessed on 7 December 2021).

- Strategies and Considerations for the Back End of the Fuel Cycle; NEA (Nuclear Energy Agency OECD): Paris, France, 2021; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2021-02/7469_best_report_2021-02-19_17-42-24_447.pdf (accessed on 7 December 2021).

- Warner, E.S.; Heath, G.A. Life Cycle Greenhouse Gas Emissions of Nuclear Electricity Generation: Systematic Review and Harmonization. J. Ind. Ecol. 2012, 16, S73–S92. [Google Scholar] [CrossRef]

- Lenzen, M. Life cycle energy and greenhouse gas emissions of nuclear energy: A review. Energy Convers. Manag. 2008, 49, 2178–2199. [Google Scholar] [CrossRef]

- Sovacool, B.K. Valuing the greenhouse gas emissions from nuclear power: A critical survey. Energy Policy 2008, 36, 2950–2963. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Cooper, J.; Stamford, L.; Azapagic, A. Environmental Impacts of Shale Gas in the UK: Current Situation and Future Scenarios. Energy Technol. 2014, 2, 1012–1026. [Google Scholar] [CrossRef]

- Paulillo, A.; Dodds, J.M.; Milliken, A.; Palethorpe, S.J.; Lettieri, P. The environmental impacts of reprocessing used nuclear fuels: A UK case study. Sustain. Mater. Technol. 2020, 25, e00186. [Google Scholar] [CrossRef]

- Paulillo, A.; Dodds, J.M.; Palethorpe, S.J.; Lettieri, P. Reprocessing vs direct disposal of used nuclear fuels: The environmental impacts of future scenarios for the UK. Sustain. Mater. Technol. 2021, 28, e00278. [Google Scholar] [CrossRef]

- Tendall, D.M.; Binder, C.R. Nuclear Energy in Europe: Uranium Flow Modeling and Fuel Cycle Scenario Trade-Offs from a Sustainability Perspective. Environ. Sci. Technol. 2011, 45, 2442–2449. [Google Scholar] [CrossRef]

- Swift, P.N.; Sassani, D.C. Impacts of Nuclear Fuel Cycle Choices on Permanent Disposal of High-Activity Radioactive Wastes. 2019. Available online: https://www.osti.gov/servlets/purl/1640197 (accessed on 7 December 2021).

- Greneche, D.; Boucher, L.; Gonzalez, E.; Cufiado, M.A.; Serrano, G.; Kuckshinrichs, W.; Wallenius, J.; Zimmerman, C.; Marivoet, J. Impact of Partitioning, Transmutation and Waste Reduction Technologies on the Final Nuclear Waste Disposal; Jülich Forschungszentrum: Jülich, Germany, 2008; Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/39/117/39117966.pdf?r=1 (accessed on 7 December 2021).

- Peters, R.; Seshadri, P.; Aubert, G.; Barracco, T.; Billès-Garabédian, L. Economic Assessment of Used Nuclear Fuel Management in the United States; Boston Consulting Group: Boston, MA, USA, 2006; Available online: https://image-src.bcg.com/Images/BCG_Economic_Assessment_of_Used_Nuclear_Fuel_Management_in_the_US_Jul_06_tcm9-132990.pdf (accessed on 7 December 2021).

- Wigeland, R.; Taiwo, T.; Ludewig, H.; Todosow, M.; Halsey, W.; Gehin, J.; Jubin, R.; Buelt, J.; Stockinger, S.; Jenni, K.; et al. Nuclear Fuel Cycle Evaluation and Screening—Final Report; INL (Idaho National Laboratory): Idaho Falls, Idaho, 2014. Available online: https://fuelcycleevaluation.inl.gov/Shared Documents/ES Main Report.pdf (accessed on 7 December 2021).

- Salvatores, M.; Palmiotti, G. Radioactive waste partitioning and transmutation within advanced fuel cycles: Achievements and challenges. Prog. Part. Nucl. Phys. 2011, 66, 144–166. [Google Scholar] [CrossRef]

- Topin, S.; Aupiais, J. The pentavalent actinide solution chemistry in the environment. J. Environ. Radioact. 2016, 153, 237–244. [Google Scholar] [CrossRef]

- Acar, B.B.; Zabunoğlu, O.H. Impact assessment of alternative back-end fuel cycles on geological disposal of resultant spent fuels and high level wastes. Ann. Nucl. Energy 2019, 130, 452–472. [Google Scholar] [CrossRef]

- Ko, W.I.; Gao, F. Economic Analysis of Different Nuclear Fuel Cycle Options. Sci. Technol. Nucl. Install. 2012, 2012, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Nishihara, K.; Nakayama, S.; Morita, Y.; Oigawa, H.; Iwasaki, T. Impact of Partitioning and Transmutation on LWR High-Level Waste Disposal. J. Nucl. Sci. Technol. 2008, 45, 84–97. [Google Scholar] [CrossRef]

- Nishihara, K.; Oigawa, H.; Nakayama, S.; Ono, K.; Shiotani, H. Impact of Partitioning and Transmutation on High-Level Waste Disposal for the Fast Breeder Reactor Fuel Cycle. J. Nucl. Sci. Technol. 2010, 47, 1101–1117. [Google Scholar] [CrossRef]

- Lindley, B.A.; Fiorina, C.; Gregg, R.; Franceschini, F.; Parks, G.T. The effectiveness of full actinide recycle as a nuclear waste management strategy when implemented over a limited timeframe—Part I: Uranium fuel cycle. Prog. Nucl. Energy 2015, 85, 498–510. [Google Scholar] [CrossRef] [Green Version]

- Hesketh, K.; Gregg, R.; Butler, G.; Worrall, A. Key conclusions from UK strategic assessment studies of fast reactor fuel cycles. Ann. Nucl. Energy 2017, 110, 330–337. [Google Scholar] [CrossRef]

- Poinssot, C.; Rostaing, C.; Baron, P.; Warin, D.; Boullis, B. Main Results of the French Program on Partitioning of Minor Actinides, a Significant Improvement Towards Nuclear Waste Reduction. Procedia Chem. 2012, 7, 358–366. [Google Scholar] [CrossRef]

- Boullis, B.; Chabert, C. Routes for Pu multi-recycling. Routes for Pu Multi-recycling. In Encyclopedia of Nuclear Energy; Greenspan, E., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2021; Volume 2, pp. 510–522. [Google Scholar] [CrossRef]

- Modolo, G.; Geist, A.; Miguirditchian, M. Minor actinide separations in the reprocessing of spent nuclear fuels: Recent advances in Europe. In Reprocessing and Recycling of Spent Nuclear Fuel; Taylor, R., Ed.; Woodhead Publishing: Oxford, UK, 2015; pp. 245–287. [Google Scholar] [CrossRef]

- Bush, R.P. Recovery of Platinum Group Metals from High Level Radioactive Waste: Possibilities of Separation and Use Re-Evaluated. Platin. Met. Rev. 1991, 34, 202–208. Available online: https://www.technology.matthey.com/pdf/pmr-v35-i4-202-208.pdf (accessed on 7 December 2021).

- Bourg, S.; Poinssot, C. Could spent nuclear fuel be considered as a non-conventional mine of critical raw materials? Prog. Nucl. Energy 2017, 94, 222–228. [Google Scholar] [CrossRef] [Green Version]

- Brown, J.; Campbell, C.; Carrigan, C.; Carrott, M.; Greenough, K.; Maher, C.; McLuckie, B.; Mason, C.; Gregson, C.; Griffiths, T.; et al. Americium and Plutonium Purification by Extraction (the AMPPEX process): Development of a new method to separate 241Am from aged plutonium dioxide for use in space power systems. Prog. Nucl. Energy 2018, 106, 396–416. [Google Scholar] [CrossRef]

- Witze, A. Nuclear power: Desperately seeking plutonium. Nature 2014, 515, 484–486. [Google Scholar] [CrossRef] [Green Version]

- Kaushik, C.P.; Kumar, A.; Wadhwa, N.S.T.S.; Mehta, D.; Mishra, R.K.; Diwan, J.; Suresh Babu, S.K.; Marathe, A.P.; Jain, S.; Anand, G.; et al. Recovery of Cesium from High Level Liquid Radioactive Waste for Societal Application: An Important Milestone; BARC Newsletter: Mumbai, India, 2017; pp. 3–4. Available online: http://barc.gov.in/barc_nl/2017/20170304.pdf (accessed on 7 December 2021).

- Sasaki, Y.; Morita, K.; Suzuki, S.; Shiwaku, H.; Ito, K.; Takahashi, Y.; Kaneko, M. Extraction and Separation of Se, Zr, Pd, and Cs Including Long-Lived Radionuclides. Solvent Extr. Res. Dev. Jpn. 2017, 24, 113–122. [Google Scholar] [CrossRef] [Green Version]

- Collins, E.; Delcul, G.; Spencer, B.; Brunson, R.; Johnson, J.; Terekhov, D.; Emmanuel, N. Process Development Studies for Zirconium Recovery/Recycle from used Nuclear Fuel Cladding. Procedia Chem. 2012, 7, 72–76. [Google Scholar] [CrossRef] [Green Version]

- Regalbuto, M. INL HALEU Program: Advancing Tomorrow’s Nuclear Supply Chain; INL (Idaho National Lab): Idaho Falls, Idaho, 2019. Available online: https://gain.inl.gov/SiteAssets/Micro-ReactorWorkshopPresentations/Presentations/08-Regalbuto-INLHALEUProgramOverview_June2019.pdf (accessed on 7 December 2021).

- Bodel, W.; Hesketh, K.; McGlynn, G.; Matthews, J.; Butler, G. Generic Feasibility Assessment: Helping to Choose the Nuclear Piece of the Net Zero Jigsaw. Energies 2021, 14, 1229. [Google Scholar] [CrossRef]

| Technoeconomic | Environmental | Social |

|---|---|---|

| Operability | Material recyclability | Provision of employment |

| Technological lock-in | Water ecotoxicity | Human health impacts |

| Immediacy | Global warming potential | Large accident risk |

| LCOE | Ozone layer depletion potential | Local community impacts |

| Cost variability | Acidification potential | Human rights and corruption |

| Financial incentives | Eutrophication potential | Energy security |

| Photochemical smog creation potential | Nuclear proliferation | |

| Land use and quality | Intergenerational equity |

| Country | Site | Plant | Fuels | Operations | Capacity (t/a SNF) | ||

|---|---|---|---|---|---|---|---|

| Start | Shutdown | Present | Future | ||||

| Belgium | MOL | Eurochemic | LWR | 1966 | 1975 | ||

| China | Jiuquan | RPP | LWR | * | 25 | ||

| Lanzhou | LWR | 800 | |||||

| France | Marcoule | APM | FBR | 1988 | 1996 | ||

| Marcoule | UP1 | GCR | 1958 | 1997 | |||

| La Hague | UP2 | LWR | 1967 | 1000 | 1000 | ||

| La Hague | UP3 | LWR | 1990 | 1000 | 1000 | ||

| Germany | Karlsruhe | WAK | LWR | 1971 | 1990 | ||

| India | Trombay | PP | Research | 1964 | 60 | 60 | |

| Tarapur | PREFRE 1 | PHWR | 1974 | 100 | 100 | ||

| Kalpakkam | PREFRE 2 | PHWR | 1998 | 100 | 100 | ||

| Kalpakkam | PREFRE 3A | PHWR | 2010 | 150 | |||

| Tarapur | PREFRE 3B | PHWR | 2012 | 150 | |||

| Japan | Tokai-mura | JAEA TRP | LWR | 1977 | 90 | 90 | |

| Rokkasho-mura | JNFL RRP | LWR | 2007 | 800 | |||

| Russia | Chelyabinsk | RT1 | WWER and BN | 1977 | 400 | 400 | |

| Krasnoyarsk | RT2 | WWER | 1500 | ||||

| Krasnoyarsk | Demonstration | VVER, RBMK | 2013 | 150 | |||

| UK | Sellafield | Magnox | GCR | 1967 | 2021 | ||

| Sellafield | THORP | LWR AGR | 1994 | 2018 | |||

| Dounreay | UKAEA RP | FBR | 1980 | 2001 | |||

| USA | West Valley | NFS | LWR | 1966 | 1972 | ||

| Hanford | Rockwell | U metal | 1956 | 1989 | |||

| Savannah River | SR | U metal | 1954 | 1989 | |||

| Sum total | 2750 | 6325 | |||||

| Corrected for maximum throughput at La Hague of 1700 t/a | −300 | −300 | |||||

| Total | 2440 | 6025 | |||||

| Cycle | Electricity (TWe) | Inputs | |||

| Fresh (Natural) U (t/y) | MOX * (t/y) | RepU Reused (t/y) | DepU Reused (t/y) | ||

| OTC (a) [50] | 408 | 9145 | 0 | 0 | 0 |

| OTC (b) [23] # | 430 | 9500 | 0 | 0 | 0 |

| TTC [50] | 408 | 7647 | 120 | 600 | 110 |

| EPR and TTC [49] | 453 | 6590 | 83 | 587 | 74 |

| SFR [49] | 453 | 0 | 448 | 356 | 49 |

| Cycle | Electricity (TWe) | Outputs | |||

| Tails U (t/y) | Total SNF (t/y) | SNF to Reprocessing (t/y) | SNF to Storage (t/y) | ||

| OTC (a) [50] | 408 | 7972 | 1173 | 0 | 1173 |

| OTC (b) [23] # | 430 | 8300 | 1200 | 0 | 1200 |

| TTC [50] | 408 | 7085 | 1173 | 1050 | 123 |

| EPR and TTC [49] | 453 | 6316 | 944 | 775 | 169 |

| SFR [49] | 453 | 0 | 448 | 448 | 0 |

| System | Reactor One | Fuel Cycle One | Reactor Two | Fuel Cycle Two | Reactor Three | Fuel Cycle Three |

|---|---|---|---|---|---|---|

| OTC | PWR | Disposal | ||||

| DUPIC | PWR | OREOX | CANDU | Disposal | ||

| TTC | PWR | PUREX | PWR (MOX) | Disposal | ||

| Pyro-SFR | PWR | Pyro | SFR | Pyro | ||

| MA P&T | PWR | PUREX | PWR (MOX) | Pyro | SFR (TRU) | Pyro |

| Pu multi-recycle | PWR | PUREX | PWR (MOX) | Pyro | SFR (MOX) | Repro II |

| Breeder | PWR | LMBR * | Pyro |

| System | CR | U Consumption | LILW-SL | LILW-LL | HLW | SF | Pu | EV | Factor |

|---|---|---|---|---|---|---|---|---|---|

| OTC | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 1.0 | |

| DUPIC | 92 | 155 | 155 | 120 | 117 | 73 | 54 | 1.9 | |

| TTC | 87 | 125 | 178 | 21 | 13 | 62 | 90 | 1.1 | |

| Pyro-SFR | 0.36 | 82 | 101 | 91 | 1.9 | 0 | 0.1 | 14 | 7.1 |

| 0.71 | 60 | 87 | 72 | 1.7 | 0 | 0.3 | 31 | 3.2 | |

| 1.00 | 9 | 54 | 26 | 1.2 | 0 | 0.5 | 72 | 1.4 | |

| MA P&T | 0.35 | 72 | 111 | 173 | 7.6 | 0 | 0.2 | 58 | 1.7 |

| 0.70 | 70 | 106 | 165 | 7.4 | 0 | 0.3 | 54 | 1.9 | |

| 1.00 | 55 | 87 | 126 | 5.8 | 0 | 0.3 | 52 | 1.9 | |

| Pu multi-recycle | 0.35 | 78 | 106 | 161 | 7.0 | 0 | 0.3 | 50 | 2.0 |

| 0.70 | 72 | 104 | 159 | 7.0 | 0 | 0.3 | 49 | 2.0 | |

| 1.00 | 49 | 92 | 134 | 6.0 | 0 | 0.4 | 42 | 2.4 | |

| Breeder | 1.2 | 1 | 70 | 116 | 2.3 | 0 | 0.8 | 28 | 3.6 |

| Indicator | Fr | UK | Fuel Cycle | Fr | UK |

|---|---|---|---|---|---|

| Greenhouse gas emissions | ✔ | ✔ | Once-through | [50] | [62] |

| Atmospheric pollution (SOx, NOx) | ✔ | ✔ * | Twice-through | [50] | [61,62] |

| Water pollution | ✔ | Plutonium multi-recycling | [49] | ||

| Land use | ✔ | MA P&T | [49] | ||

| Water consumption and withdrawal | ✔ | ✔ | |||

| Technological waste | ✔ | ||||

| Radioactive gaseous emissions | ✔ | ✔ ‡ | |||

| Radioactive liquid emissions | ✔ | ✔ ‡ | |||

| Solid radioactive waste | ✔ | ✔ ‡ | |||

| Repository footprint | ✔ | ||||

| Acidification | ✔ | ✔ | |||

| Eutrophication | ✔ | ✔ † | |||

| Photochemical ozone creation potential | ✔ | ✔ | |||

| Ecotoxicity | ✔ | ✔ | |||

| Human toxicity | ✔ | ✔ | |||

| Ozone depletion | ✔ | ||||

| Resource depletion, mineral, fossils and renewables | ✔ |

| Area of Impact | Units | Scenario Number | Direct Disposal | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| Acidification | (mol H+ eq.) | 2680 | −2470 | −3940 | −3970 | 2480 |

| Climate change | (kg CO2 eq.) | 3.01 × 105 | −1.88 × 105 | −3.18 × 105 | −3.18 × 105 | 1.39 × 105 |

| Ecotoxicity freshwater | (CTUe) | 1.42 × 107 | 5.46 × 106 | 6.40 × 105 | 5.49 × 105 | 1.75 × 107 |

| Eutrophication freshwater | (kg P eq.) | 358 | −38.6 | −190 | −194 | 434 |

| Eutrophication marine | (kg N eq.) | 963 | −17,700 | −20,900 | −21,100 | 319 |

| Eutrophication terrestrial | (mol N eq.) | 4490 | −15,000 | −19,100 | −19,300 | 2900 |

| Human toxicity, cancer effects | (CTUh) | 5.01 × 10−2 | 1.4 × 10−2 | −2.8 × 10−3 | −3.2 × 10−3 | 6.08 × 10−2 |

| Human toxicity, noncancer effects | (CTUh) | 0.656 | −0.212 | −0.511 | −0.520 | 0.812 |

| Ionising radiations | (Bq 235U air eq.) | 1.88 × 109 | 1.83 × 109 | 1.82 × 109 | 1.82 × 109 | 3.35 × 106 |

| Ionising radiations, GDF | (Bq 238U ILLW eq.) | 7.1 × 1010 | 4.1 × 1010 | 3.5 × 1010 | 3.4 × 1010 | 7.9 × 1010 |

| Ozone depletion | (kg CFC-11 eq.) | 3.88 × 10−2 | −3.7 × 10−2 | −5.4 × 10−2 | −5.4 × 10−2 | 1.21 × 10−2 |

| Particulate matter/respiratory inorganics, human health | (kg PM2.5 eq.) | 250 | −437 | −607 | −612 | 231 |

| Photochemical ozone formation, human health | (kg NMVOC) | 1290 | −3970 | −5090 | −5130 | 874 |

| Resource depletion, mineral, fossils and renewables | (kg Sb eq.) | 56.9 | −794 | −944 | −953 | 36.1 |

| Resource depletion water | (m3 eq.) | 2110 | −6260 | −8180 | −8180 | 1130 |

| Scenario | Decay Heat | ||||

|---|---|---|---|---|---|

| t/TWh | /TWh | W/TWh | |||

| SNF | HLW | Canisters | 50 y | 200 y | |

| SC1 | 2.24 | 0 | 1.06 | 1689 | 552 |

| SC2 | 0.91 | 0 | 8.85 | 1576 | 579 |

| SC3 | 0.41 | 0.10 | 0.93 | 1756 | 591 |

| SC4 | 0 | 0.12 | 0.48 | 1296 | 107 |

| SC5 | 0 | 0.10 | 0.45 | 935 | 28 |

| Parameter | PWR | FR | ADS | |||

|---|---|---|---|---|---|---|

| (U,Pu) MOX | Full TRU Recycle | Pu Only | Full TRU * | MA Target † | MA Dominated | |

| Decay heat | 1 | 3 | 0.5 | 2.5 | 20–80 | 90 |

| Neutrons | 1 | 8000 | ~1 | 150 | 1000–4000 | 20,000 |

| Scenario | Acar Term | Disposal Area Advantage Factor | Waste Per Ton of Fresh U Fuel (t) | Disposal Area Per Ton of Fresh U Fuel (m2/t) | Electricity Per Ton of Fresh U Fuel (GWhe/t) | Decay Time (y) † |

| OTC | OT | 0.5909 | 1 | 207 | 0.390 | 30,200 |

| TTC (conventional) | SRNU | 0.6343 | 0.690 | 223.1 | 0.476 | 10,800 |

| TTC (advanced) | PC | 0.6240 | 0.683 | 225.5 | 0.473 | 12,500 |

| Waste | Acar Term | Disposal Area (m2/t) | Waste Per Ton of Fresh U Fuel (t) | Disposal Area Per Ton of Fresh U Fuel (m2/t) | Electricity Per Ton of Fresh U Fuel (GWhe/t) | Decay Time (y) |

| Spent UOX | SUOX | 207 | 1 | 207 | 0.390 | 30,200 |

| Spent RepU | SRcU | 207 | 0.107/0.103 | 22.3/21.3 | 0.042/0.04 | 30,200 |

| Vitrified HLW | VHLW | 195 | 0.47 | 79.4 | n/a | 1360 |

| Spent MOX (1) # | SMOXSRNU | 1076 | 0.113 | 121.6 | 0.044 | 76,000 |

| Spent MOX (2) # | SMOXPC | 1134 | 0.110 | 124.8 | 0.043 | 83,300 |

| Waste | OTC | DUPIC | TTC | Pyro-SFR | |

|---|---|---|---|---|---|

| SNF | (t/TWh) | 2.088 | 2.469 | 0.259 | 0.000 |

| LILW-SL | (m3/TWh) | 13.409 | 19.644 | 15.549 | 10.784 |

| LILW-LL | (m3/TWh) | 1.629 | 2.883 | 2.930 | 1.192 |

| HLW | (m3/TWh) | 3.130 | 4.031 | 0.637 | 0.055 |

| Pu for disposal | (kg/TWh) | 24.990 | 20.250 | 13.997 | 0.028 |

| Excavation volume | (m3/TWh) | 40.500 | 22.010 | 19.800 | 0.093 |

| Costs | (Mills/kWh) * | 7.35 | 9.06 | 8.94 | 7.70 |

| Relative costs | (%) | 100 | 123 | 122 | 105 |

| U breakeven price | ($/kgU) | 800 | 215 | ||

| Configuration | V−1 | V0 | V1 | V2 | C |

|---|---|---|---|---|---|

| Area (m2/waste form) | 88.8 | 44.4 | 22.2 | 11.1 | 0.95 |

| Volume (m3/waste form) | 214 | 115 | 64 | 38 | 1.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taylor, R.; Bodel, W.; Stamford, L.; Butler, G. A Review of Environmental and Economic Implications of Closing the Nuclear Fuel Cycle—Part One: Wastes and Environmental Impacts. Energies 2022, 15, 1433. https://doi.org/10.3390/en15041433

Taylor R, Bodel W, Stamford L, Butler G. A Review of Environmental and Economic Implications of Closing the Nuclear Fuel Cycle—Part One: Wastes and Environmental Impacts. Energies. 2022; 15(4):1433. https://doi.org/10.3390/en15041433

Chicago/Turabian StyleTaylor, Robin, William Bodel, Laurence Stamford, and Gregg Butler. 2022. "A Review of Environmental and Economic Implications of Closing the Nuclear Fuel Cycle—Part One: Wastes and Environmental Impacts" Energies 15, no. 4: 1433. https://doi.org/10.3390/en15041433