Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model

Abstract

:1. Introduction

2. Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga

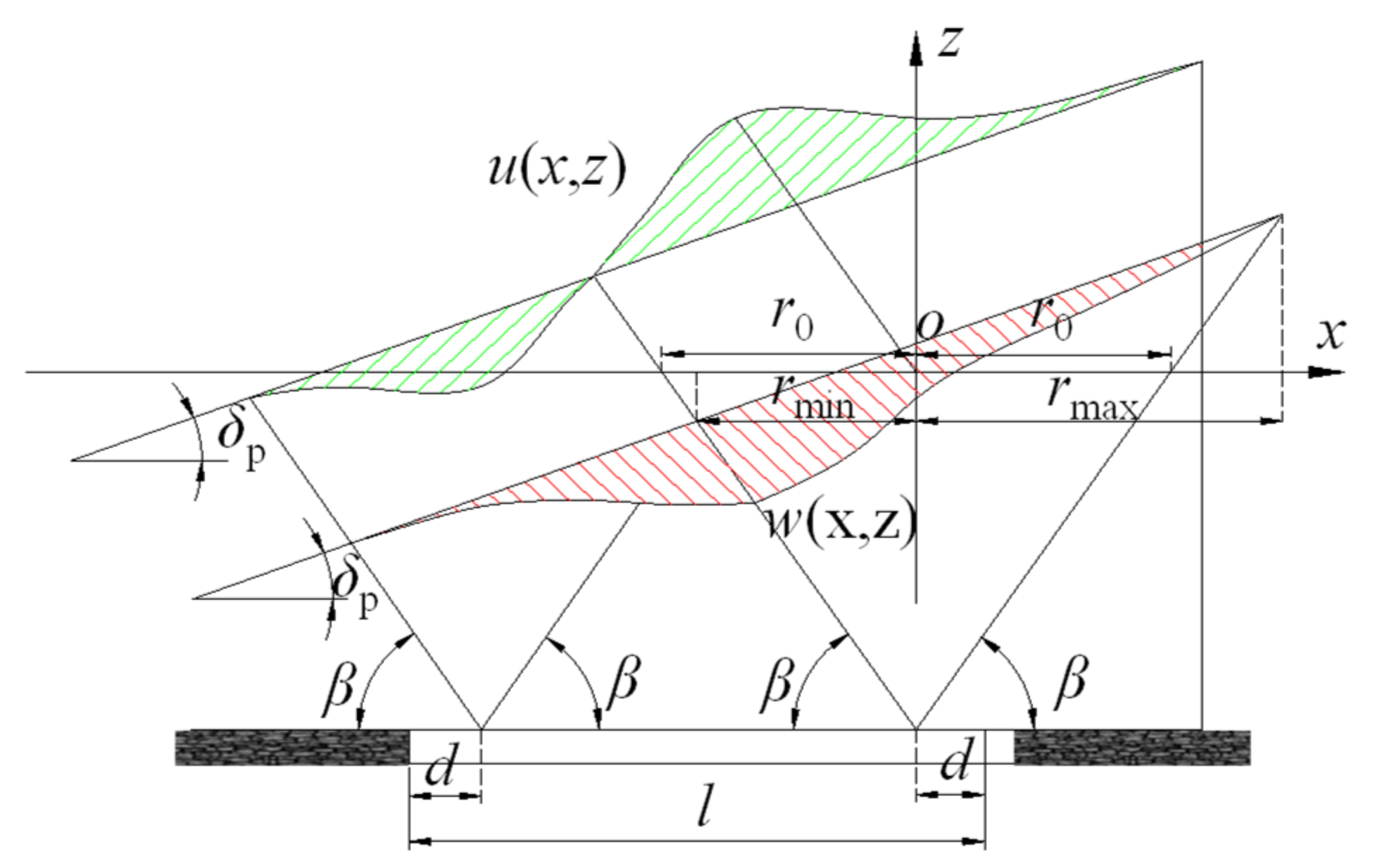

2.1. The Probability Integration Model

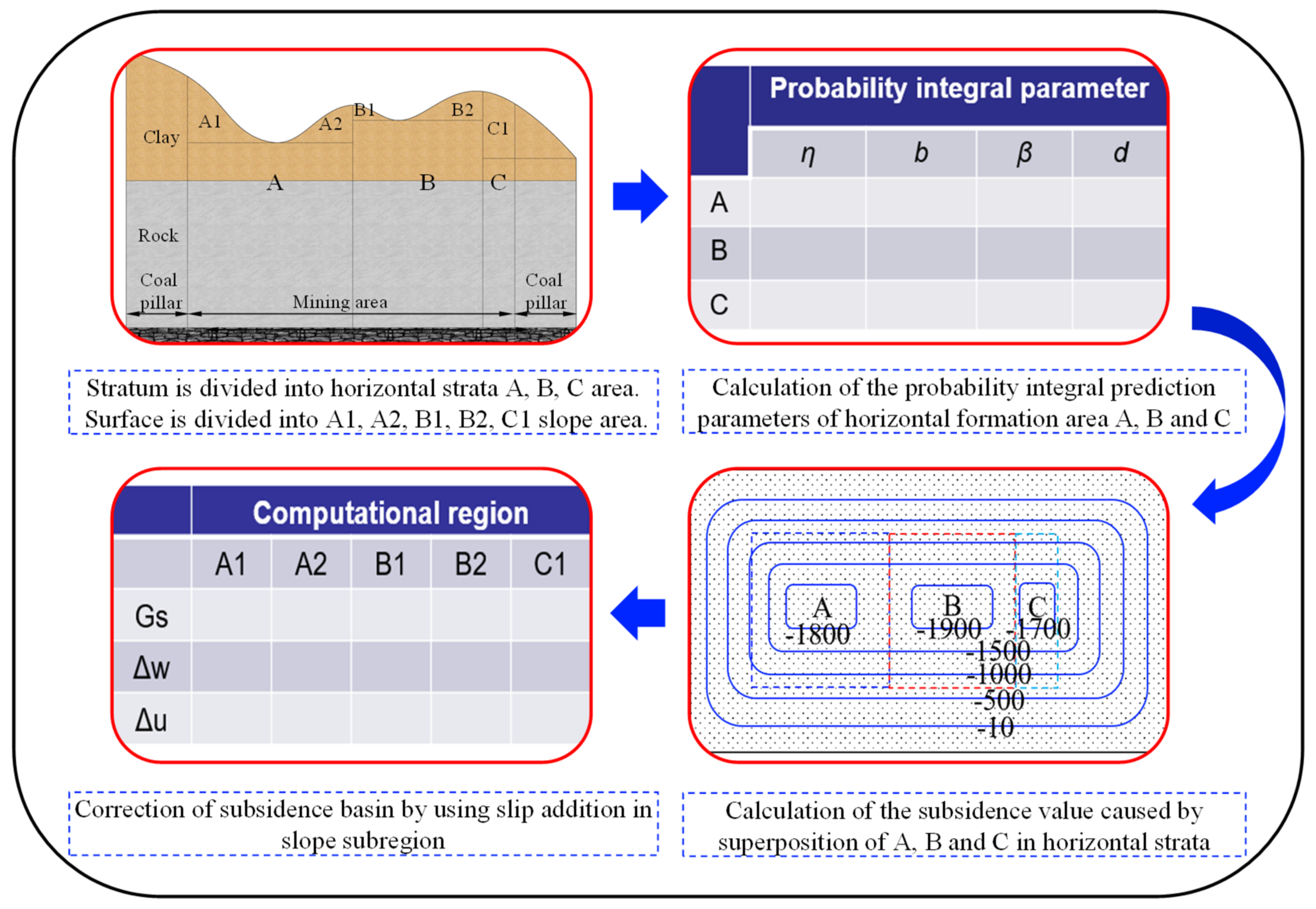

2.2. Prediction Process of Surface Subsidence in Loess Donga

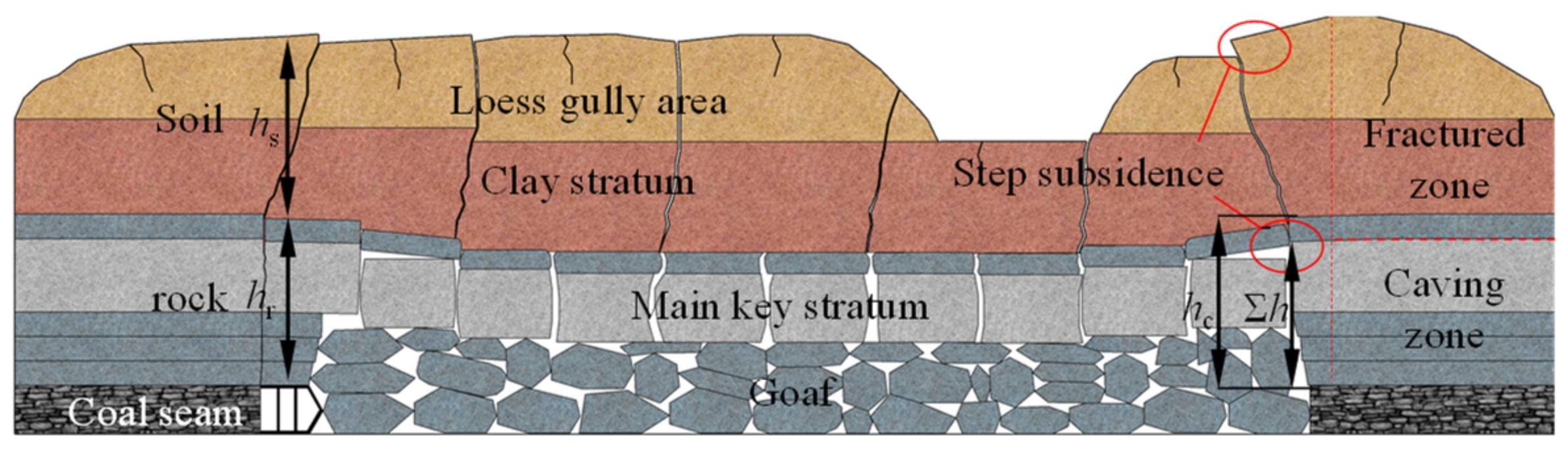

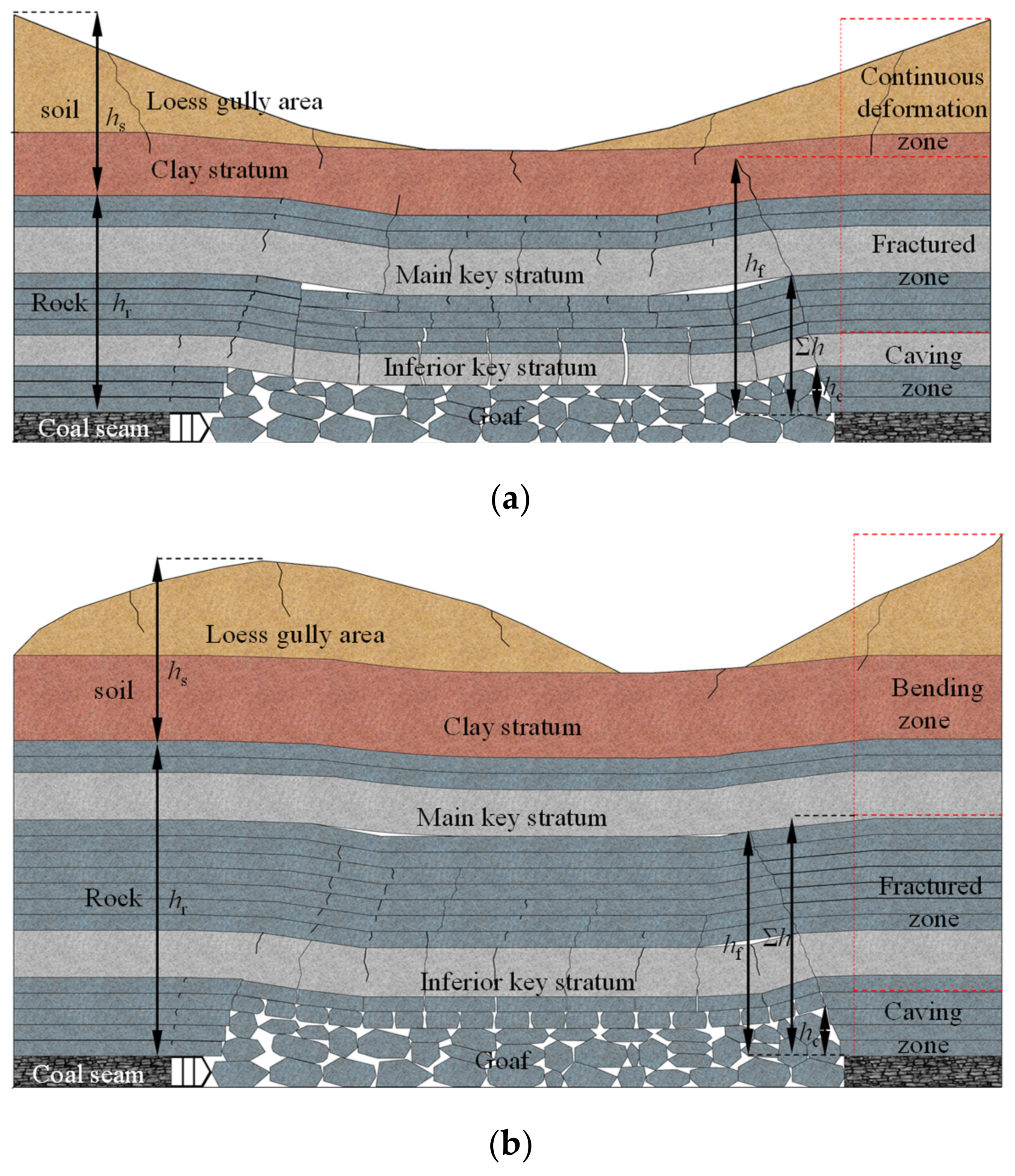

3. Determination of Probability Integration Parameters in LDS

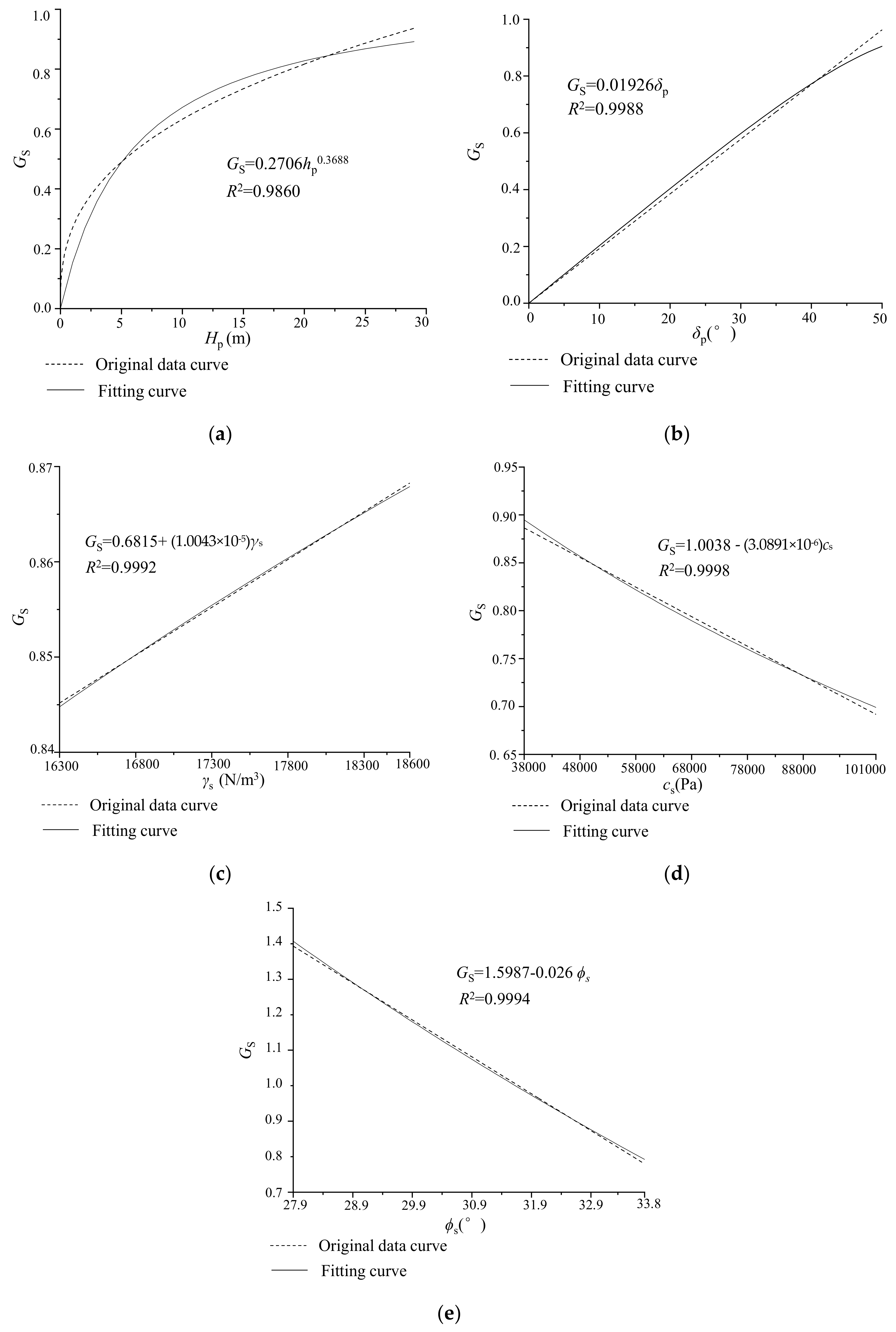

3.1. Calculation of Subsidence Coefficient

3.2. Comprehensive Movement Angle, Horizontal Movement Coefficient, and Deviation of Inflection Point

4. Slope Stability and Slip Principles in Loess Donga

4.1. Analysis of Slope Stability in Loess Donga

4.2. Additional Displacement of Slope Mining Slip

5. Case Study

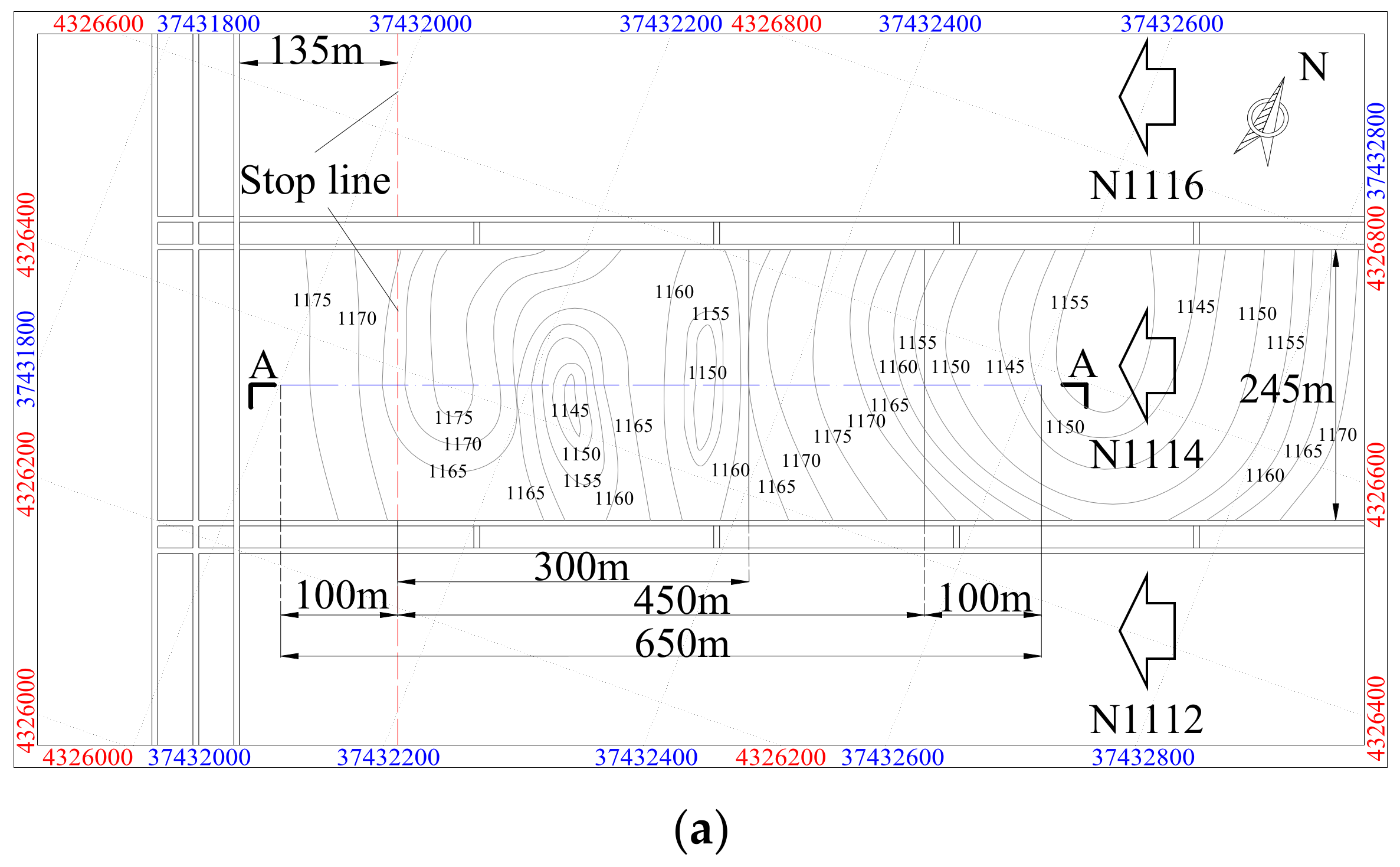

5.1. Engineering Case

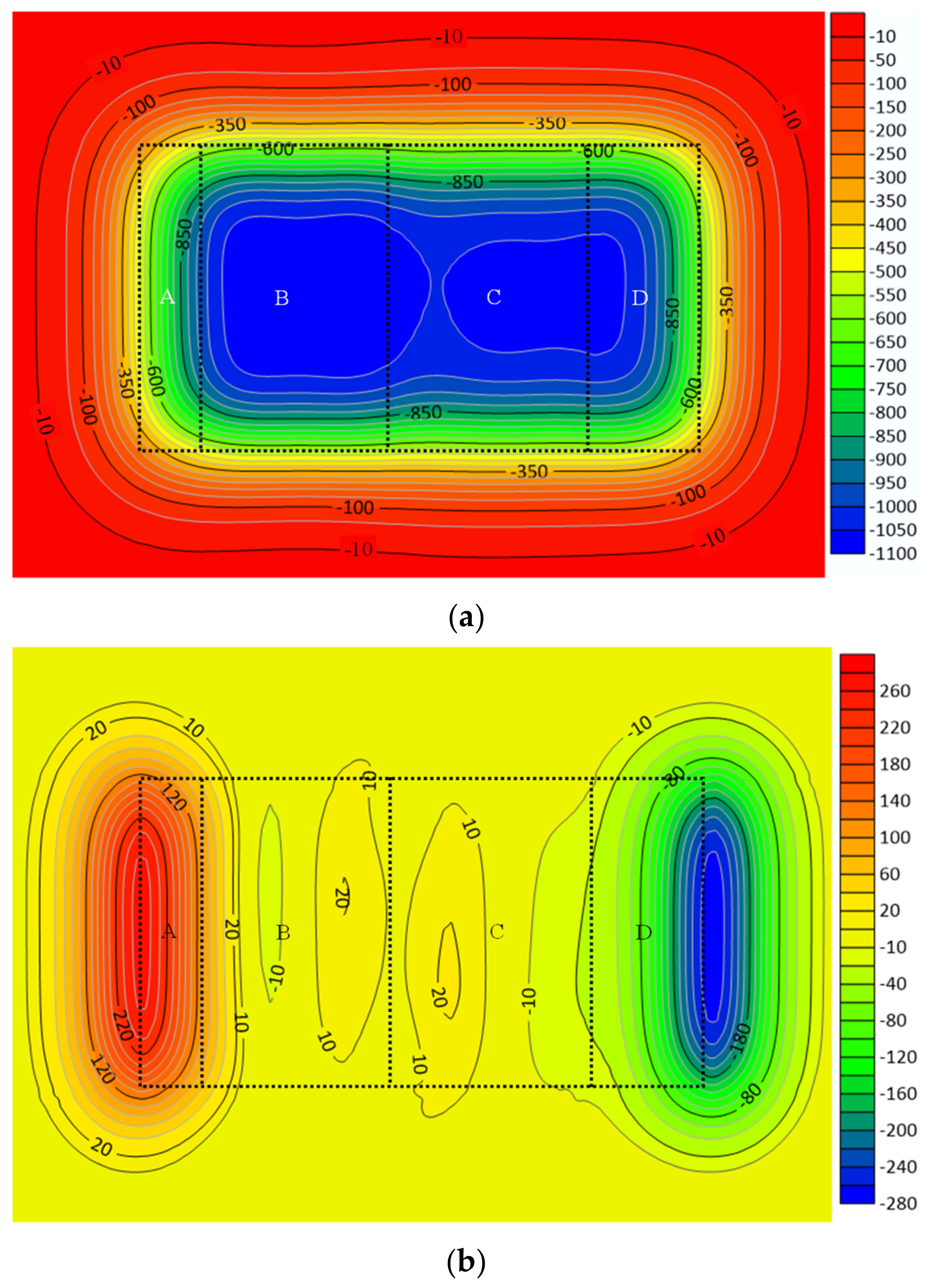

5.2. LDS Prediction

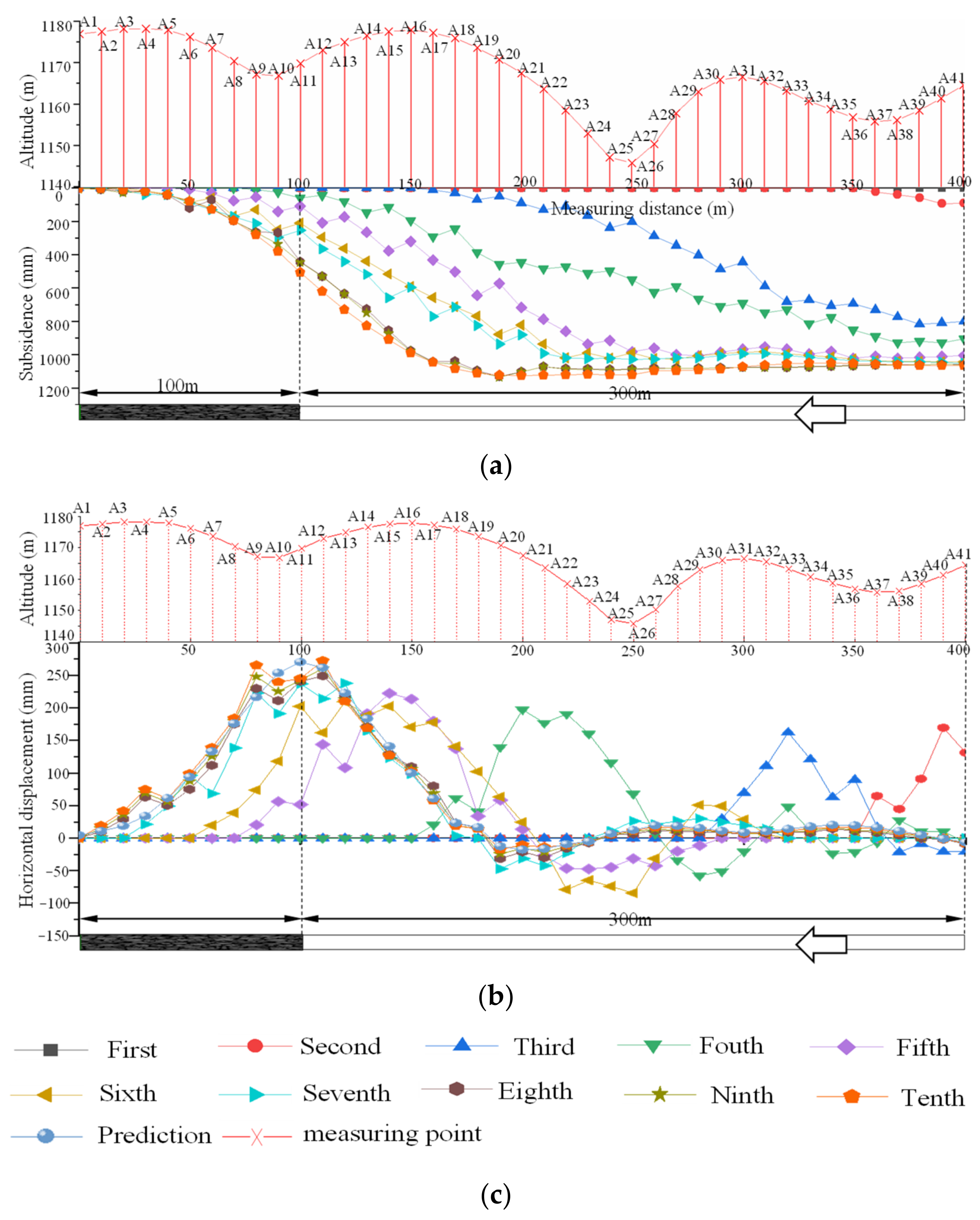

5.3. The Field Test

6. Discussion

7. Conclusions

- (1)

- Slope slip can easily lead to large deviations in the prediction of subsidence in loess donga. In order to solve this long-standing problem, a solution of “regional subsidence prediction in loess donga” is put forward, and the subsidence prediction method for horizontal strata and slope area in loess donga is established.

- (2)

- Determine the probability integration parameters of the horizontal stratigraphic region based on the position of the main key stratum and the stratigraphic distribution. With the help of the probability integration software, the subsidence basin formed by the superposition of multiple horizontal stratigraphic regions can easily be obtained.

- (3)

- When the mining instability coefficient of the slope Gcs > 0.87, the slope produces slip instability. The additional displacement of subsidence generated in the landslide area is calculated by the mining instability coefficient.

- (4)

- Combined with the subsidence prediction results of the two regions in loess donga, the accuracy of the prediction of surface subsidence in the area is improved. Correlation of the calculated data with results of the field test document a 98.4% fit for the LDS subsidence curve and an 88.7% fit for the horizontal movement curve. In case of mining-slip instability of the slope, the estimated error of the subsidence curve is 0.96%, and the estimated error of the horizontal movement curve is 9.8%, thus fulfilling the requirements of engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, S.; Zhao, X.; Xie, J.; Guan, Y. Grey Correlation Analysis and Regression Estimation of Mining Subsidence in Yu-Shen-Fu Mining Area. Procedia Environ. Sci. 2011, 10, 1747–1752. [Google Scholar] [CrossRef] [Green Version]

- Jianjun, S.; Chunjian, H.; Ping, L.; Junwei, Z.; Deyuan, L.; Minde, J.; Lin, Z.; Jingkai, Z.; Jianying, S. Quantitative prediction of mining subsidence and its impact on the environment. Int. J. Min. Sci. Technol. 2012, 22, 69–73. [Google Scholar] [CrossRef]

- Fan, H.; Gu, W.; Qin, Y.; Xue, J.; Chen, B. A model for extracting large deformation mining subsidence using D-InSAR technique and probability integral method. Trans. Nonferrous Met. Soc. China 2014, 24, 1242–1247. [Google Scholar] [CrossRef]

- Tang, F.-Q. Mining subsidence prediction model in western thick loess layer mining areas. Meitan Xuebao J. China Coal Soc. 2011, 36, 74–78. [Google Scholar] [CrossRef]

- Curtaz, M.; Ferrero, A.M.; Roncella, R.; Segalini, A.; Umili, G. Terrestrial Photogrammetry and Numerical Modelling for the Stability Analysis of Rock Slopes in High Mountain Areas: Aiguilles Marbrées case. Rock Mech. Rock Eng. 2014, 47, 605–620. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Tong, C.; Liu, Z.; Liu, L.; Xueyi, Y.U. Characteristics of mining-induced surface damage in western ecological fragile region. J. Cent. South Univ. Technol. 2017, 48, 2990–2997. [Google Scholar]

- Luo, Y. An improved influence function method for predicting subsidence caused by longwall mining operations in inclined coal seams. Int. J. Coal Sci. Technol. 2015, 3, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Zhu, G.; Jiang, X.; Dou, M. Study of Dynamic Coordinates Time Function in Mine Subsidence. Adv. Mater. Res. 2012, 594–597, 56–60. [Google Scholar] [CrossRef]

- Peng, S.S. Topical areas of research needs in ground control—A state of the art review on coal mine ground control. Int. J. Min. Sci. Technol. 2015, 25, 1–6. [Google Scholar] [CrossRef]

- Deguchi, T.; Kato, M.; Akcin, H.; Kutoglu, H.S. Automatic processing of interferometric SAR and accuracy of surface deformation measurement. SPIE Eur. Remote Sens. 2006, 6363, 47–54. [Google Scholar] [CrossRef]

- Saeidi, A.; Deck, O.; Marwan, A.; Verdel, T.; Rouleau, A. Adjusting the Influence Function Method for Subsidence Prediction. Key Eng. Mater. 2013, 553, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Yanli, H.; Jixiong, Z.; Baifu, A.; Qiang, Z. Overlying strata movement law in fully mechanized coal mining and backfilling longwall face by similar physical simulation. J. Min. Sci. 2011, 47, 618–627. [Google Scholar] [CrossRef]

- Zheng, R.; Kan, W.; Ru, L. Study on Overburden’s Destructive Rules Based on Similar Material Simulation. Int. J. Mod. Educ. Comput. Sci. 2011, 3, 54–60. [Google Scholar] [CrossRef]

- Guo, W.; Hou, Q.; Zou, Y. Relationship between surface subsidence factor and mining depth of strip pillar mining. Trans. Nonferrous Met. Soc. China 2011, 21, s594–s598. [Google Scholar] [CrossRef]

- Zhang, B.; Ye, J.; Zhang, Z.; Xu, L.; Xu, N. A Comprehensive Method for Subsidence Prediction on Two-Seam Longwall Mining. Energies 2019, 12, 3139. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yu, H.; Dong, J.; Liu, S.; Huang, Z.; Wang, J.; Wong, H. A physical and numerical model-based research on the subsidence features of overlying strata caused by coal mining in Henan, China. Environ. Earth Sci. 2017, 76, 705.1–705.11. [Google Scholar] [CrossRef]

- Kim, K.D.; Lee, S.; Oh, H.J. Erratum: Prediction of ground subsidence in Samcheok City, Korea using artificial neural networks and GIS. Environ. Geol. 2009, 58, 61–70. [Google Scholar] [CrossRef]

- Tan, Z.; Li, P.; Yan, L.; Deng, K. Study of the method to calculate subsidence coefficient based on SVM. Proced. Earth Planet. Sci. 2009, 1, 970–976. [Google Scholar] [CrossRef] [Green Version]

- Xiaofang, L.; Hui, S. Intelligent Planning of Tourism Scenic Routes Based on Genetic Algorithm in Coal WANBEI Mining Subsidence. TELKOMNIKA Telecommun. Comput. Electron. Control 2016, 14, 69. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.L.; Lian, G.M.; Zhu, W.B.; Qian, M.G. Influence of the key strata in deep mining to mining subsidence. J. China Coal Soc. 2007, 32, 686–690. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, E. Mining Damage Science; China Coal Industry Publishing House: Beijing, China, 2010. [Google Scholar]

- Guo, W.; Yu, X.; Liu, Z. Analysis of Mining Subsidence Disasters in Loess Gully Areas and its Control Countermeasures. Appl. Mech. Mater. 2015, 737, 456–460. [Google Scholar] [CrossRef]

- Stead, D.; Coggan, J.S.; Eberhardt, E. Realistic simulation of rock slope failure mechanisms: The need to incorporate principles of fracture mechanics. Int. J. Rock Mech. Min. Sci. 2004, 41, 563–568. [Google Scholar] [CrossRef]

- Wang, F.; Shi, C.; Chen, K.; Li, D.; Han, K. Numerical Simulation Analysis on the Collapse of Slope in Iron Mine. Adv. Mater. Res. 2014, 926–930, 593–596. [Google Scholar] [CrossRef]

- Luo, Y.; Cheng, J. An influence function method based subsidence prediction program for longwall mining operations in inclined coal seams. Min. Sci. Technol. China 2009, 19, 592–598. [Google Scholar] [CrossRef]

- Zhao, B.C.; Xue-Yi, Y.U.; Zhao, J.Z. Visual study on prediction evaluation system of mining damage. Coal Geol. Explor. 2006, 34, 61–64. [Google Scholar] [CrossRef] [Green Version]

- Changchun, H.; Xu, J. Subsidence Prediction of Overburden Strata and Surface Based on the Voussoir Beam Structure Theory. Adv. Civ. Eng. 2018, 2018, 2606108. [Google Scholar] [CrossRef]

- Zhang, C.; Tu, S.; Zhao, Y. Compaction characteristics of the caving zone in a longwall goaf: A review. Environ. Earth Sci. 2019, 78, 27. [Google Scholar] [CrossRef]

- Huang, Q. Research on roof control of water conservation mining in shallow seam. J. China Coal Soc. 2017, 42, 50–55. [Google Scholar] [CrossRef]

- He, M.; Zhang, Z.; Zhu, J.; Li, N. Correlation Between the Constant mi of Hoek–Brown Criterion and Porosity of Intact Rock. Rock Mech. Rock Eng. 2022, 55, 923–936. [Google Scholar] [CrossRef]

- Xie, X.; Hou, E.; Wang, S.; Sun, X.; Hou, P.; Wang, S.; Xie, Y.; Huang, Y. Formation Mechanism and the Height of the Water-Conducting Fractured Zone Induced by Middle Deep Coal Seam Mining in a Sandy Region: A Case Study from the Xiaobaodang Coal Mine. Adv. Civ. Eng. 2021, 2021, 6684202. [Google Scholar] [CrossRef]

- Li, L.I.; Wang, Y.X.; Wang, W.B. Effects of Mining Subsidence on Physical and Chemical Properties of Soil in Slope Land in Hilly-gully Region of Loess Plateau. Chin. J. Soil Sci. 2010, 41, 1237–1240. [Google Scholar] [CrossRef]

- Li, K. Research on the Roof Structure and Support Resistance of the Working Face under Close Coal Seam Goaf in Shallow Buried; Xi’an University of Science and Technology: Xian, China, 2020. [Google Scholar]

| Analyzing Conditions | Main Key Stratum Location | Subsidence Coefficient Calculation Formula | |

|---|---|---|---|

| hc ≥ Σh | curved subsidence zone | (5) | |

| hc < Σh < hf ≤ h | Fracture zone | ||

| Loose Layer Thickness (m) | Loose Layer Features | ||

|---|---|---|---|

| Dry, Water-Free | Strong Water Content | Quick-Curing Ground Content | |

| <40 | 50° | 45° | 30° |

| 40–60 | 55° | 50° | 35° |

| >60 | 60° | 55° | 40° |

| Average Rock Firmness Coefficient f | |||

|---|---|---|---|

| f < 3 | 3 ≤ f < 6 | 6 ≤ f | |

| Rock displacement angle | 65° | 70° | 75° |

| f | d | |

|---|---|---|

| f > 6 | if l/h > 2.2, l/h = 2.2 | (8) |

| 3 < f < 6 | if l/h > 1.4, l/h = 1.4 | |

| f < 3 | if l/h > 0.9, l/h = 0.9 | |

| Security Level | First-Class Slope | Second-Class Slope | Third-Class Slope |

|---|---|---|---|

| General condition safety factor | 1.35 | 1.30 | 1.25 |

| Temporary condition safety factor | 1.25 | 1.20 | 1.15 |

| Earthquake condition safety factor | 1.15 | 1.10 | 1.05 |

| Strata | Thickness (m) | Physical and Mechanical Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| σc (MPa) | σt (Mpa) | c (Mpa) | E (Mpa) | γ (N/m3) | μ | φ (°) | ||

| Loess | 30.00–60.00 | 0.29 | 0.03 | 0.059 | 33.42 | 18,600 | 0.32 | 28.2 |

| Fine sandstone | 16.10 | 29.6 | 0.50 | 1.50 | 1258 | 22,700 | 0.29 | 42.0 |

| Sandy mudstone | 7.40 | 34.7 | 0.54 | 0.26 | 2400 | 25,600 | 0.24 | 38.5 |

| Fine sandstone | 13.70 | 45.6 | 0.708 | 2.20 | 2113 | 23,000 | 0.27 | 41.5 |

| Sandy mudstone | 4.70 | 35.3 | 0.56 | 0.27 | 2415 | 26,180 | 0.24 | 38.8 |

| Medium mudstone | 3.40 | 40.6 | 0.56 | 1.50 | 1949 | 23,300 | 0.28 | 44.0 |

| Silty sandstone | 2.20 | 36 | 0.234 | 0.90 | 995 | 24,200 | 0.30 | 40.0 |

| Fine sandstone | 8.00 | 29.8 | 0.60 | 1.57 | 2024 | 23,050 | 0.27 | 39.2 |

| Sandy mudstone | 5.20 | 36.2 | 0.56 | 0.30 | 2423 | 25,780 | 0.24 | 38.5 |

| Silty sandstone | 2.00 | 32.9 | 0.27 | 0.94 | 979 | 22,700 | 0.27 | 39.3 |

| 1−2 Coal | 1.85 | 15.7 | 0.29 | 1.10 | 845 | 12,900 | 0.28 | 37.5 |

| Silty sandstone | 4.90 | 36.4 | 0.28 | 1.01 | 977 | 23,030 | 0.27 | 40.2 |

| Fine sandstone | 12.70 | 34.1 | 0.52 | 1.55 | 1320 | 23,160 | 0.27 | 40.4 |

| Calculation Areas | |||||

|---|---|---|---|---|---|

| A | B | C | D | ||

| Parameters | hs (m) | 50.0 | 30.0 | 40.0 | 30.0 |

| hr (m) | 62.7 | 62.7 | 62.7 | 62.7 | |

| βs (°) | 50.0 | 45.0 | 50.0 | 45.0 | |

| βr (°) | 70.0 | 70.0 | 70.0 | 70.0 | |

| Calculated results | η | 0.58 | 0.58 | 0.58 | 0.58 |

| δ (°) | 60.1 | 64.9 | 63.4 | 64.9 | |

| b | 0.256 | 0.273 | 0.265 | 0.273 | |

| d (m) | 15.65 | 15.65 | 15.65 | 15.65 | |

| Calculation Areas | |||||||

|---|---|---|---|---|---|---|---|

| A1 | B1 | B2 | C1 | C2 | D1 | ||

| Parameters | hp (m) | 10.0 | 30.0 | 20.0 | 10.0 | 20.0 | 30.0 |

| δp (°) | 10.1 | 17.6 | 21.8 | 8.5 | 12.9 | 10.3 | |

| mining direction | downward slope | reverse slope | downward slope | reverse slope | downward slope | reverse slope | |

| Calculated results | GCS | 0.31 | 0.97 | 0.83 | 0.35 | 0.49 | 0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Guo, Y.; Mao, X.; Zhai, D.; Zhu, D.; Huo, Y.; Sun, Z.; Wang, J. Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model. Energies 2022, 15, 2282. https://doi.org/10.3390/en15062282

Zhao B, Guo Y, Mao X, Zhai D, Zhu D, Huo Y, Sun Z, Wang J. Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model. Energies. 2022; 15(6):2282. https://doi.org/10.3390/en15062282

Chicago/Turabian StyleZhao, Bingchao, Yaxin Guo, Xuwei Mao, Di Zhai, Defu Zhu, Yuming Huo, Zedong Sun, and Jingbin Wang. 2022. "Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model" Energies 15, no. 6: 2282. https://doi.org/10.3390/en15062282