Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery

Abstract

:1. Introduction

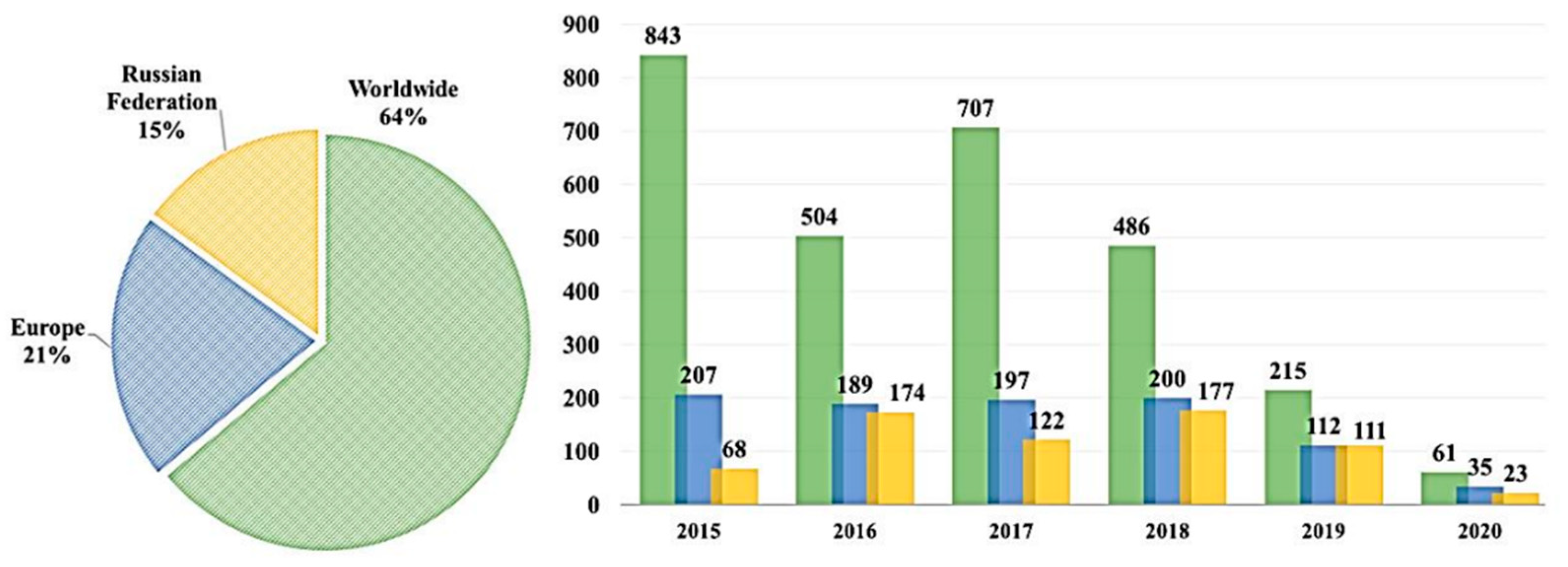

2. Prior History of the In Situ Combustion Method

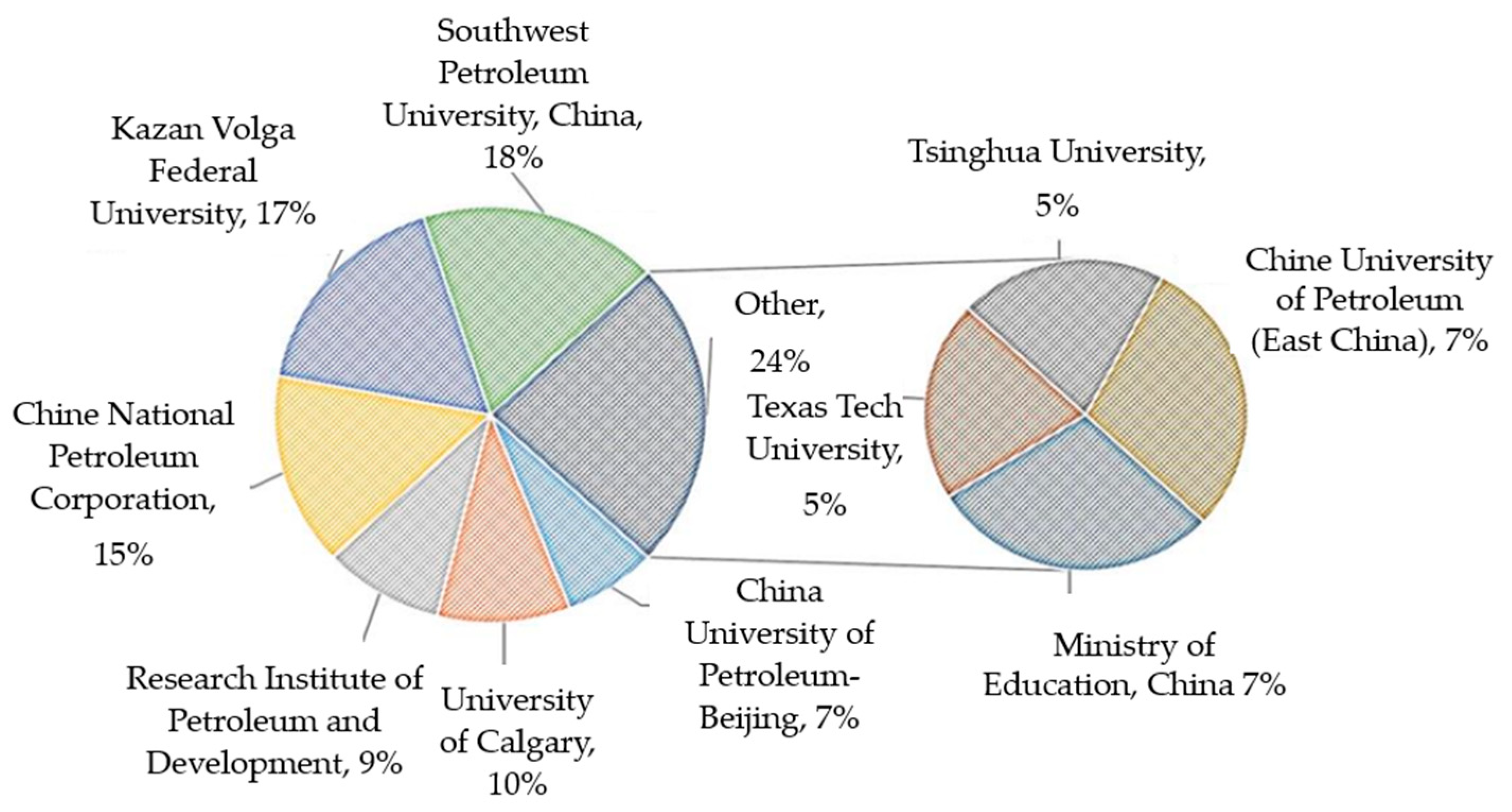

3. Scientometric Analysis of Research Activities

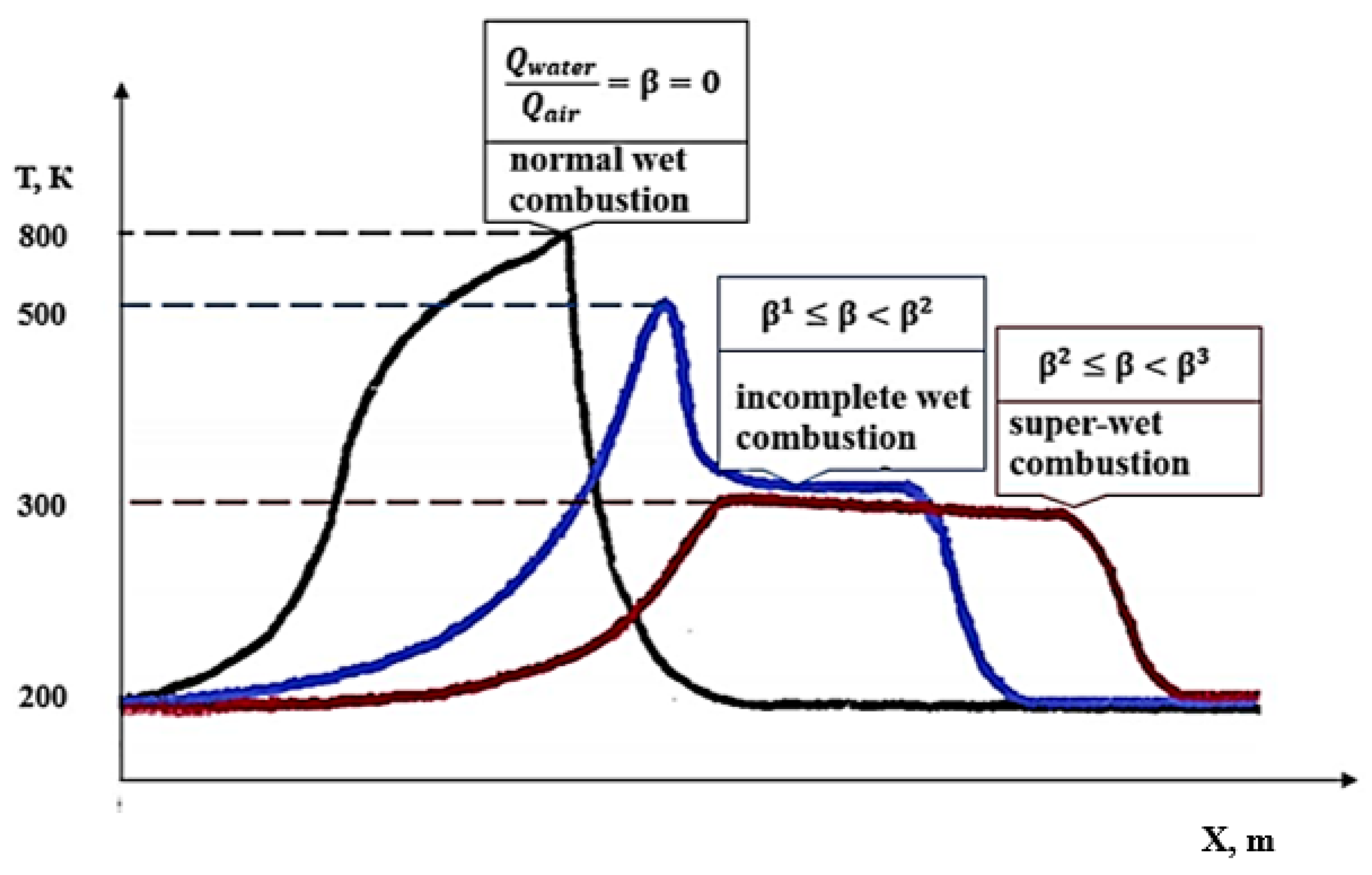

4. The Main Processes of the In Situ Combustion Method

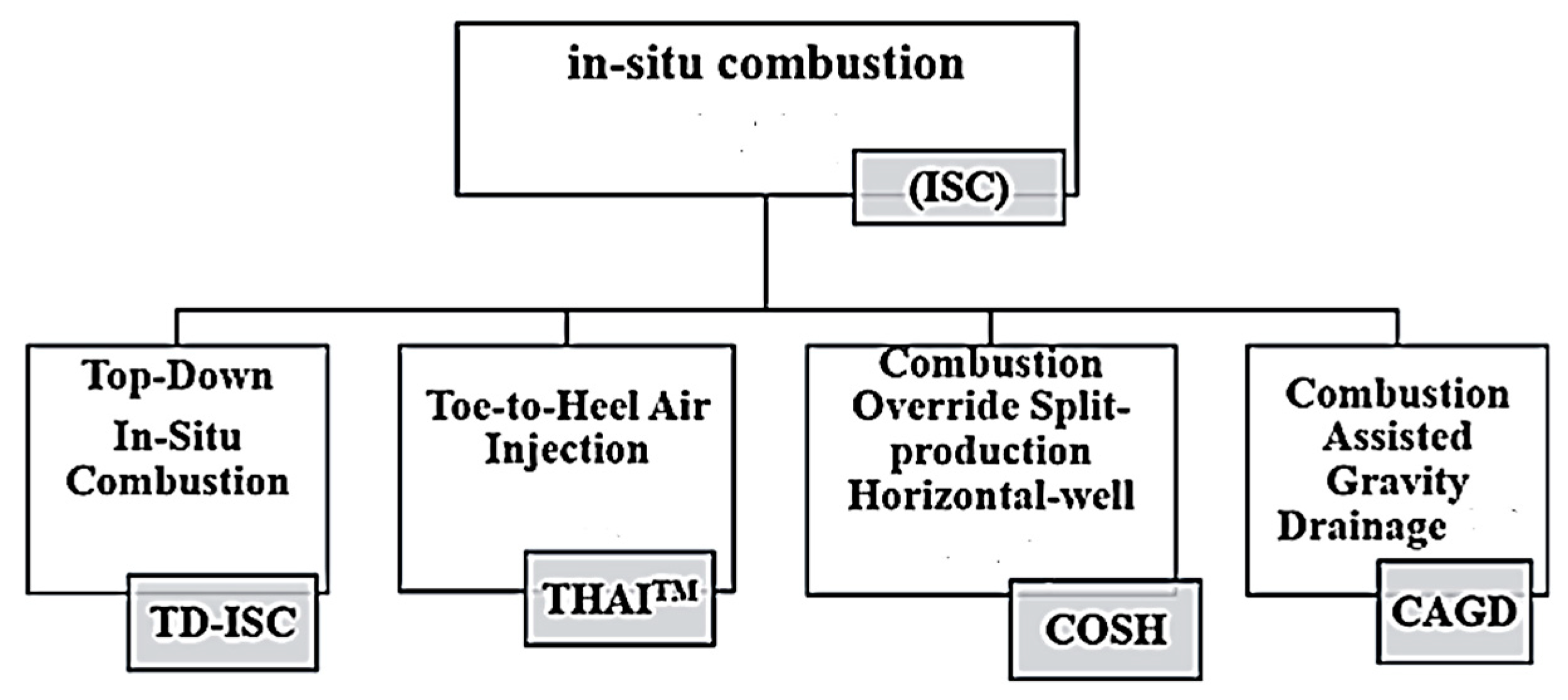

5. Basic In Situ Combustion Technologies

6. Recent Advances in the Study of In Situ Combustion Methods

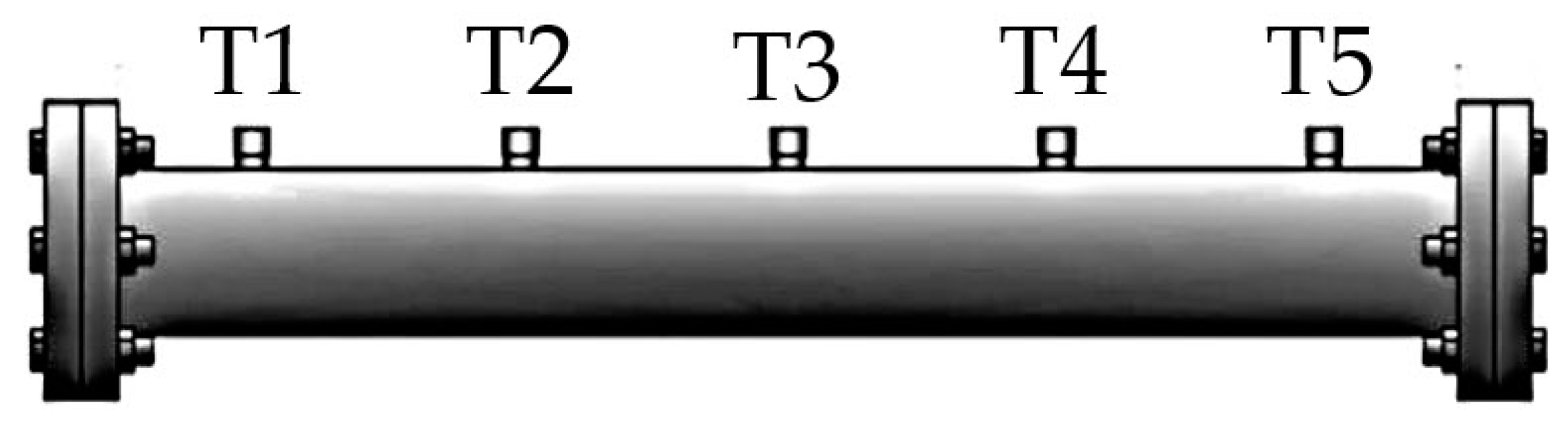

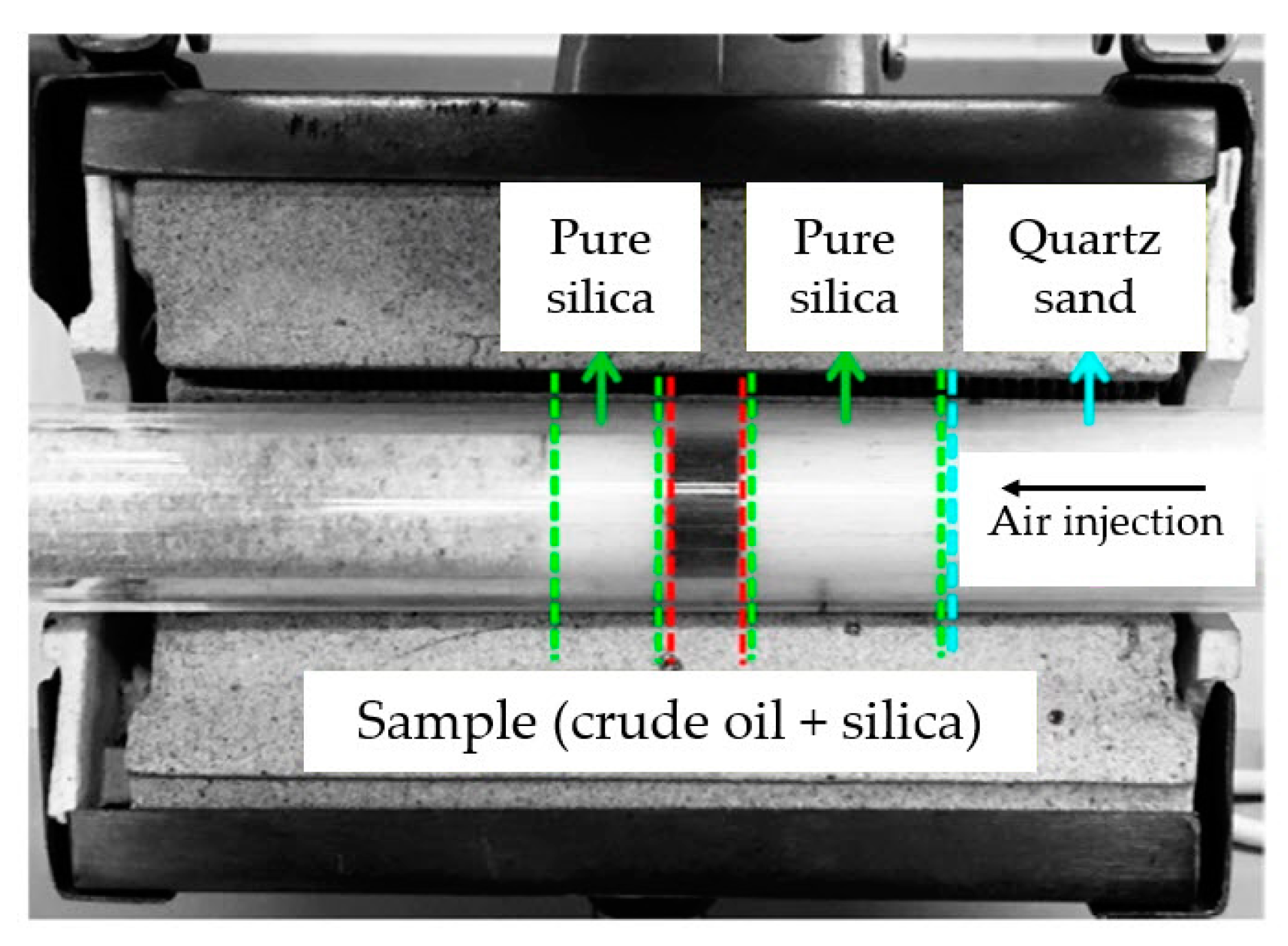

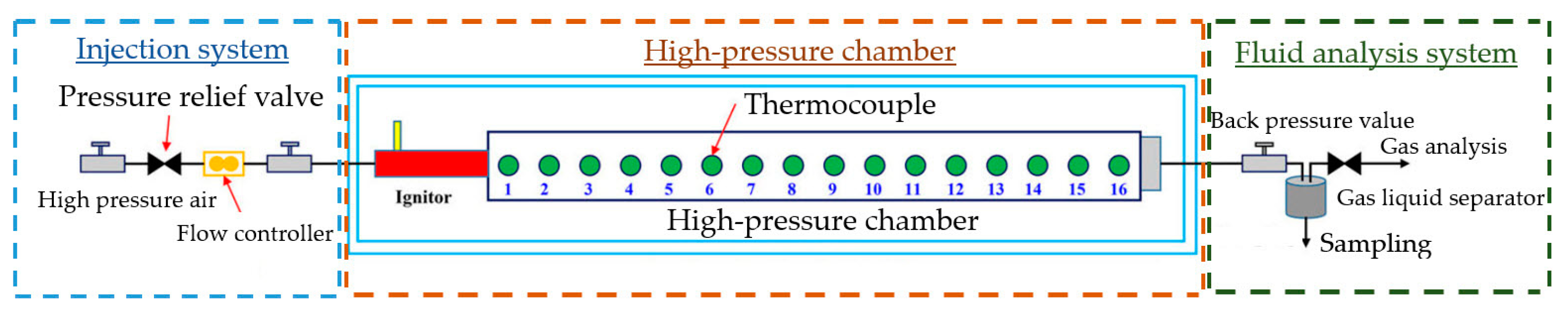

6.1. Review of Experimental Approaches into the Study of the In Situ Combustion Method

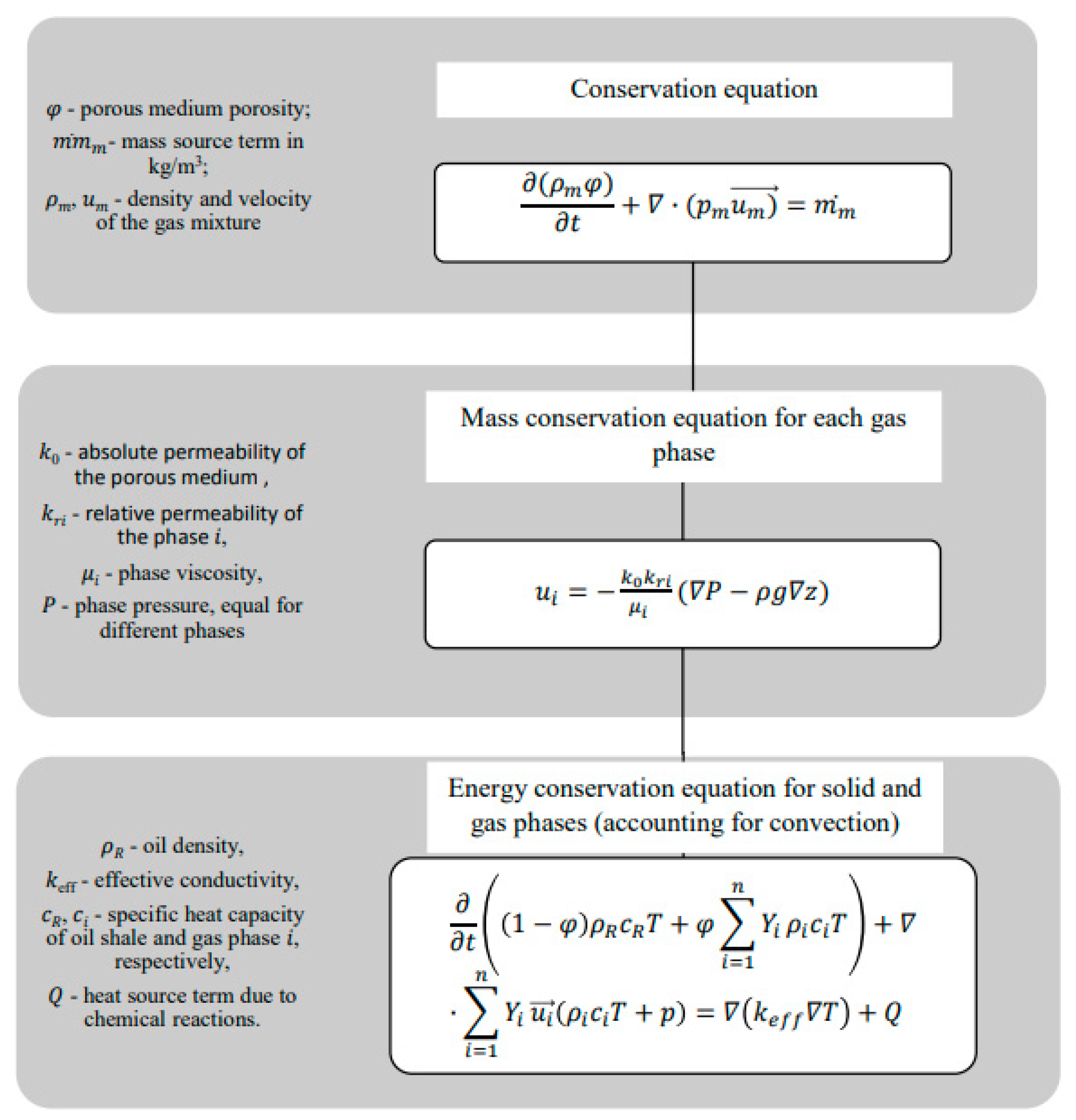

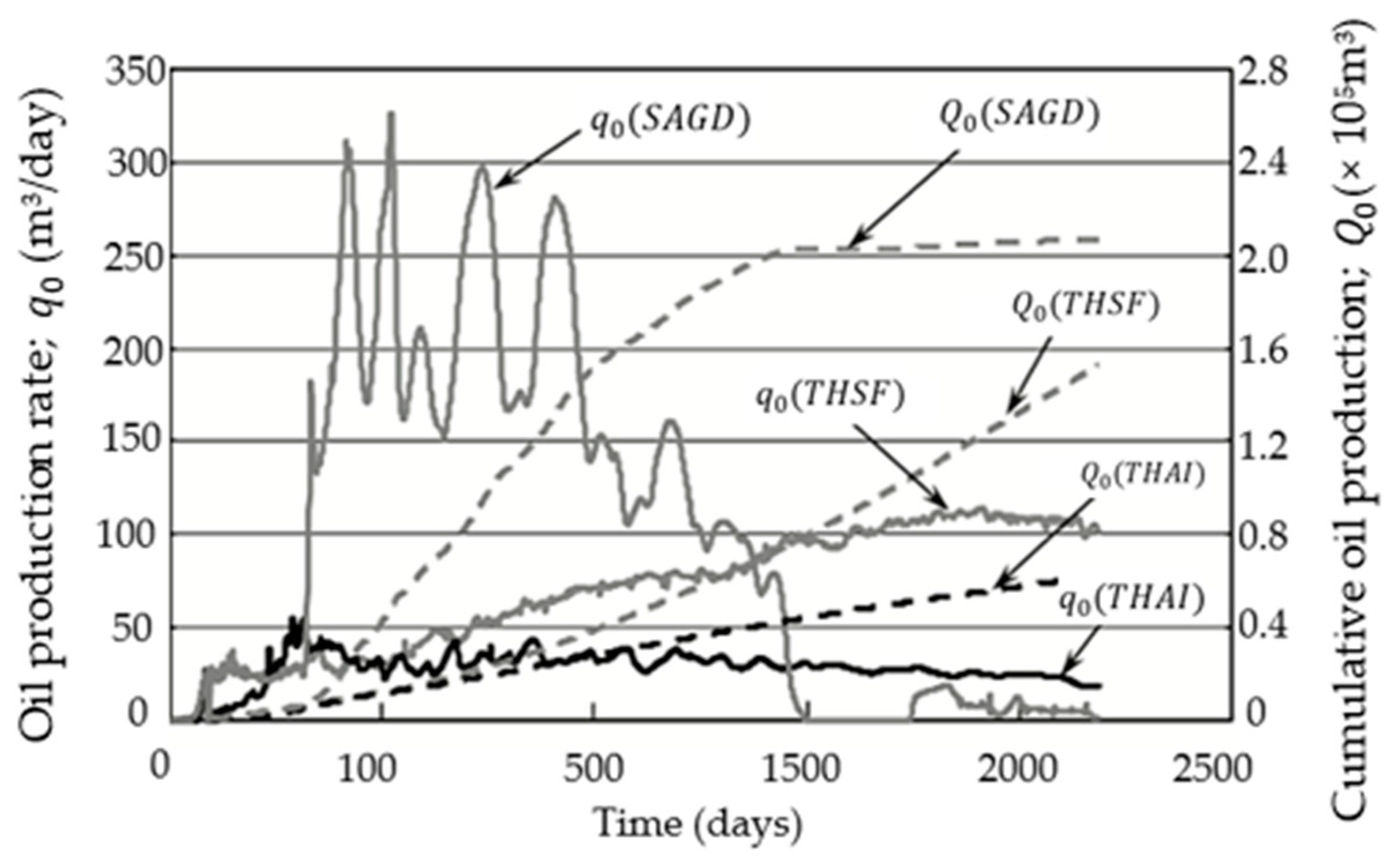

6.2. Review of Numerical Studies of In Situ Fuel Combustion Implementation Technologies

- Coke formation

- Combustion of heavy oil fraction

- Combustion of light oil fraction

- Combustion of cokewhere carbon is considered as coke, which serves as fuel for the combustion process (η is the corresponding stoichiometric coefficient) [50].

7. Conclusions

- The development of the classic in situ combustion method has led to its new modifications that differ from each other both structurally and in their basic approaches to forming the combustion front. Unfortunately, none of four implemented technologies (ND-ISC, THAITM, COSH, and CAGD) has seen widespread use due to the lack of an evidence base for their successful application in the field.

- The main studies of the in situ combustion method are associated with laboratory and experimental works, as well as numerical simulation. The laboratory works mainly determine the effects of the oil-source rock on the combustion processes, because clay components of the rocks can form the basis of new series of catalysts to mitigate the conditions of in situ combustion. It was proven that clays containing quartz and kaolinite, montmorillonite, mica, and clinochlore, as well as the presence of calcite and dolomite, exhibit a good catalytic effect. The development of soluble catalysts is currently under active consideration. For example, copper stearate demonstrates a good catalytic effect, shifting the combustion reaction to a lower temperature range.

- Experimental studies have thus far been aimed at obtaining data on oil reactivity, determining the ignition conditions by revealing the nature of raw hydrocarbons, and most importantly, determining its combustion characteristics. As a rule, these obtained kinetic parameters have been used as basic data for numerical simulation. It is the experimental combustion in a cell that allows us to determine the amount of fuel needed for cracking, as well as estimate the combustion front propagation rate. The main difficulties in conducting experimental studies are associated with the lack of acceptable criteria for planning experiments; therefore, a numerical simulation of the process is used as an alternative method. Different combinations of chemical reactions lead to a variety of numerical models. One of the most common is a scheme of reactions, which includes pyrolysis and combustion; at the same time, the inorganic decomposition process is unpopular since its activation requires high temperatures.

- To implement the method, it is necessary to solve the problems of initiating the exothermic reaction center, as well as for maintaining the optimal temperature, stability, and integrity of temperature and chemical fronts in the reservoir. However, the main problem is the unstable combustion propagation, especially if the reservoir structure is heterogeneous. A difference between the viscosity of the injected air and the reservoir saturating fluids leads to air filtration in the most permeable areas. This results in a decrease in the efficiency of in situ combustion, making its implementation quite dangerous. In addition, during the implementation of in situ combustion in the oil fields containing heavy high-viscosity oil, an excessive amount of coke is often formed, which is necessary to maintain combustion. This increases specific air consumption and decreases the combustion front propagation rate. Another problem is the reduced coke-forming ability of oils in fields containing light low-viscosity oil, which leads to a loss of the combustion front as it moves deeper into the formation. These problems should be solved using detailed numerical simulation with experimental verification of the main elements of the model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CAGD | Combustion assisted gravity drainage |

| COSH | Combustion override split-production horizontal-well |

| Da | Damköhler number |

| ES-SAGD | Expanding Solvent SAGD |

| EHO | Extra heavy oil |

| H/C | Ratio between the carbon and hydrogen atoms |

| HTO | High temperature oxidation |

| HO | Heavy oil |

| ISC | In situ combustion |

| LO | Light oil |

| LTC | Low-temperature combustion |

| LTO | Low temperature oxidation |

| ONGC | Oil and Natural Corporation |

| PMTEC | Porous medium thermo-effect cell |

| PRMS | Petroleum resource management system |

| RLF | Reaction-leading front |

| RTF | Reaction-trailing front |

| SAP | Solvent aided process |

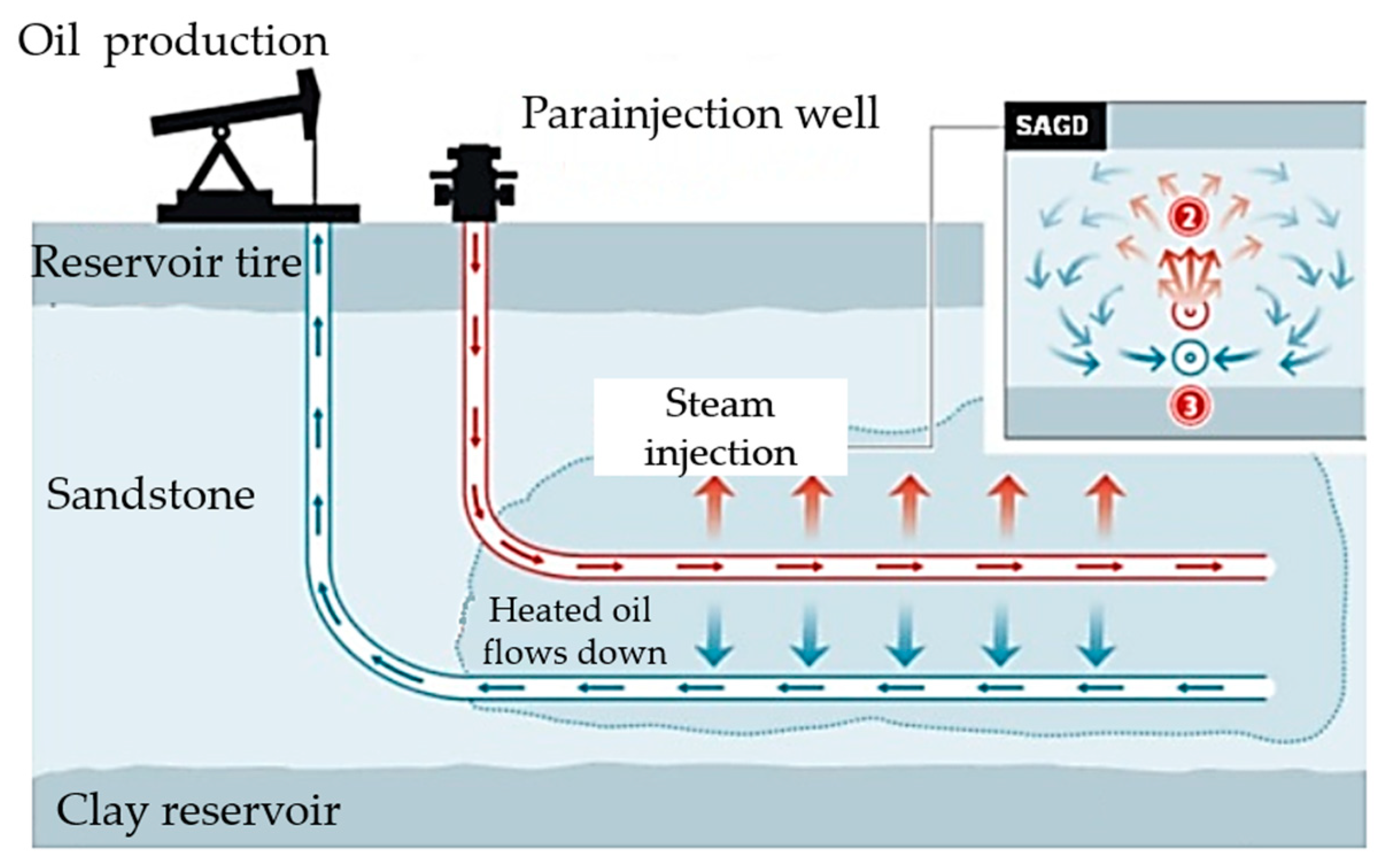

| SAGD | Steam-assisted gravity drainage |

| SAS | Steam alternating solvent |

| TD-ISC | Top-down in situ combustion |

| THAI | Toe-to-heel air injection |

| VAPEX | Vapor extraction |

| VKC | Virtual kinetic cell |

| WOS | Web of Science |

| Water/air consumption, m3/s | |

| Model reaction rate | |

| Prototype speed | |

| φ | Medium porosity |

| Mass source term in, kg/m3 | |

| Density and velocity of the gas mixture | |

| Oil density | |

| Effective heat conductivity | |

| Specific heat capacity of oil shale and i gas phase, respectively | |

| Q | Heat source term in equation due to chemical reactions |

References

- Peacock, D. Unconventional Reserves and Resources in the Petroleum Resource Management System (PRMS): A Square Peg in a Round Hole. APPEA J. 2014, 54, 518. [Google Scholar] [CrossRef]

- Mikhail Men, A.K. Report on the Results of the Expert and Analytical Event. Analysis of the Reproduction of the Mineral Resource Base of the Russian Federation in 2015–2019. 2020. Available online: https://ach.gov.ru/upload/iblock/64f/86t1xajzpwu5blnw66q0rieuy094t8oj.pdf (accessed on 15 May 2023).

- Herald, A. On the Implementation of Measures for the Reproduction of the Mineral Resource Base and Geological Study of the Subsoil of the Russian Federation. 2018. Available online: http://council.gov.ru/activity/documents/98735/ (accessed on 15 May 2023).

- Zhukova, S.V. The World Oil Market in the Process of Change; IMEMO RAN: Moscow, Russia, 2017; 118p. [Google Scholar]

- Meyer, R.F. Prospects for Heavy Crude Oil Development. Energy Explor. Exploit. 1987, 5, 27–55. [Google Scholar] [CrossRef]

- Williams, B. Heavy hydrocarbons playing key role in peak-oil debate, future energy supple. Oil Gas J. 2003, 101, 20. [Google Scholar]

- GOST R 51858-2002 Oil. 2002. Available online: https://docs.cntd.ru/document/1200028839 (accessed on 15 May 2023).

- Meyer, R.F.; Attanasi, E.D.; Freeman, P.A. Heavy Oil and Natural Bitumen Resources in Geological Basins of the World. Available online: https://magazine.neftegaz.ru/articles/aktualno/551452-vysokovyazkie-nefti-i-prirodnye-bitumy-gosudarstvennoe-uchastie-v-povyshenii-effektivnosti-razrabotk/ (accessed on 15 May 2023).

- International Agency for Research on Cancer. Occupational Exposures in Petroleum Refining: Crude Oil and Major Petroleum Fuels; International Agency for Research on Cancer: Lyon, France, 1959.

- Poletaeva, O.Y.; Leontiev, A.Y. Heavy, Super-Viscous, Bituminous, Metalliferous Oils and Oil-Bearing Sandstones. NefteGazoKhimiya 2019, 1, 19–23. [Google Scholar]

- Ivanov, N.A. Shale America: US Energy Policy and Development of Unconventional Oil and Gas Resources. 2014. 304p. Available online: https://fief.ru/files/researches/Shale_America_Ivanov.pdf (accessed on 15 May 2023).

- Santos, R.G.; Loh, W.; Bannwart, A.C.; Trevisan, O.V. An Overview of Heavy Oil Properties and Its Recovery and Transportation Methods. Brazilian J. Chem. Eng. 2014, 31, 571–590. [Google Scholar] [CrossRef]

- Economides, M.J.; Nolte, K.G. Reservoir Stimulation; Prentice Hall: Hoboken, NJ, USA, 1989. [Google Scholar]

- Dubrovay, K.K.; Sheinman, A.B. Underground Gasification of Oil Reservoirs and Thermal Method of Oil Production/NTI NKTP Leningrad-Moscow-Grozny. 1934, p. 96. Available online: https://www.geokniga.org/books/30498 (accessed on 15 May 2023).

- Sheinman, A.B.; Dubrovy, K.K.; Sorokin, N.A. Experiments on Underground Gasification of Oil Reservoirs in Natural Conditions. Oil Ind. 1935, 4, 48–61.33. [Google Scholar]

- Marchant, L.C.; Westhoff, J.D. In-Situ Recovery of Oil from Utah Tar Sand: A Summary of Tar Sand Research at the Laramie Energy Technology Cente; USDOE Morgantown Energy Technology Center: Morgantown, WV, USA, 1985.

- Joseph, N.B. Oil Recovery by Heat from in Situ Combustion. J. Pet. Technol. 1958, 10, 13–17. [Google Scholar]

- Partha, S.S. In-Sity Combustion Handbook—Principles and Practicts; UNT Libraries: Denton, TX, USA, 1999. [Google Scholar]

- Doraiah, A.; Ray, S.; Gupta, P. In-Situ Combustion Technique to Enhance Heavy-Oil Recovery at Mehsana, ONGC—A Success Story. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 11–14 March 2007. [Google Scholar]

- Machedon, V.T.; Popescu, R.P.R. 30 Years of Experience in in Situ Combustion. In Proceedings of the Field Application In Situ Combustion Practices: Past, Present and Future Applications, Tulsa, OK, USA, 21–22 April 1994; National Institute for Petroleum and Energy Research: Bartlesville, OK, USA, 1995. No. NIPER/BDM-0086, CONF. [Google Scholar]

- Anaya, I.; La Cruz, R.E.; Alvarez, A.J.; Gutierrez, D.; Skoreyko, F.A.; Card, C. Simulation study for designing an in-situ combustion pilot in the orinoco belt of venezuela: From laboratory studies to the field scale. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Mehmet OĞÜTÇÜ. Eurasian Energy Prospects and Politics: Need for a Fresh Perspective. J. OpenEdition 1995, 19, 34. [Google Scholar]

- Magomedov, R.N.; Popova, A.Z.; Maryutina, T.A. Current status and prospects of demetallization of heavy petroleum feedstock (Review). Pet. Chem. 2015, 55, 423–443. [Google Scholar] [CrossRef]

- U.S. Department of Energy Washington Proved Reserves of Crude Oil and Natural Gas in the United States, Year-End 2019 Independent. 2019. Available online: https://www.energy.gov/ceser/energy-security (accessed on 15 May 2023).

- Satman, A.; Soliman, M.Y.; Brigham, W.E. A Recovery Correlation for Dry In-Situ Combustion Processes. In Proceedings of the SPE of AIME California Regional Meeting, San Francisco, CA, USA, 12 April 1978; Volume: SPE-7130, p. 12. [Google Scholar]

- Aristizabal, G.; Julián, J. Modelimg segregated in-situ combustion processes throcesses through a vertical displacement model applied to a colomdian field. Tecnol. Future 2005, 3, 111–126. [Google Scholar]

- Penner, S.S.; Benson, S.W.; Camp, F.W.; Clardy, J.; Deutch, J.; Kelley, A.E.; Lewis, A.E.; Mayer, F.X.; Oblad, A.G.; Sieg, R.P.; et al. Assessment of Research Needs for Oil Recovery from Heavy-Oil Sources and Tar Sands. Energy 1982, 7, 567–602. [Google Scholar] [CrossRef]

- Russell, T.J. Oil Recovery. Encycl. Energy 2004, 4, 701–713. [Google Scholar]

- Ringer, M.; Putsche, V.S. Large-Scale Pyrolysis Oil Production: Large-Scale Pyrolysis Oil. NREL/TP-510-37779 Production: A Technology Assessment and Economic Analysis. 2006. Available online: https://www.nrel.gov/docs/fy07osti/37779.pdf (accessed on 15 May 2023).

- Chaudhuri, U.R. Fundamentals of Petroleum and Petrochemical Engineering; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bagci, A.S. Wet forward combustion for heavy oil recovery. Energy Sour. Part Recover. Util. Environ. Eff. 2006, 28, 221–232. [Google Scholar] [CrossRef]

- Akin, S.; Bagci, S.; Kok, M.V. Dry forward combustion with diverse well configurations. In Proceedings of the SPE/AAPG Western Regional Meeting, Long Beach, CA, USA, 19–22 June 2000. [Google Scholar]

- Moore, R.G. New Strategies For in situ combustion. J. Can. Pet. Technol. 1993, 32, 10. [Google Scholar] [CrossRef]

- Cavanzo, E.A.; Muñoz, S.F.; Ordoñez, A.; Bottia, H. Kinetics of wet in-situ combustion: A review of kinetic models. In Proceedings of the SPE Heavy and Extra Heavy Oil Conference—Latin America, Medellín, Colombia, 24–26 September 2014. [Google Scholar]

- Jacques, G.B.; Bernard, C. Sahuquet laboratory research on wet combustion. J. Pet. Technol. 1973, 25, 1137–1146. [Google Scholar]

- Cinar, M.; Castanier, L.M.; Kovscek, A.R. Improved analysis of the kinetics of crude-oil in-situ Combustion. In Proceedings of the SPE Western Regional and Pacific Section AAPG Joint Meeting, Bakersfield, CA, USA, 29 March–2 April 2008. [Google Scholar]

- Glatz, G.; Hascakir, B.; Castanier, L.M.; Clemens, T.; Kovscek, A.R. Kinetic cell and combustion tube results for a central european crude oil. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Cinar, M.; Hasçakir, B.; Castanier, L.M.; Kovscek, A.R. Predictability of crude oil in-situ combustion by the isoconversional kinetic approach. SPE J. 2011, 16, 537–547. [Google Scholar] [CrossRef]

- Shallcross, D.C. Devices and Methods for In-Situ Combustion Ignition. 1989. Available online: https://www.osti.gov/biblio/5568674-devices-methods-situ-combustion-ignition (accessed on 15 May 2023).

- Sadikov, K.; Larionov, V.; Varfolomeev, M. Evaluation method of influence of catalyst precursors on initiation of in-situ combustion and It’s Dynamics. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 16–18 October 2017. [Google Scholar]

- Bandyopadhyay, P. Method for in Situ Combustion. Ignition. Patent US 3672450, 27 June 1972. [Google Scholar]

- Tadema, H.J. Mechanism of oil production by underground combustion. In Proceedings of the 5th World Petroleum Congress, New York, NY, USA, 1–5 June 1959. [Google Scholar]

- Smidovich, E.V. Oil and Gas Processing Technology. Part 2. Cracking of Crude Oil and Processing of Hydrocarbon Gases/Chemistry, Moscow. 1980. 328p. Available online: https://www.geokniga.org/books/11149 (accessed on 15 May 2023).

- Burger, J.G. Chemical aspects of in-situ combustion—Heat of combustion and kinetics. Soc. Pet. Eng. J. 1972, 12, 410–422. [Google Scholar] [CrossRef]

- Cinar, M. Creating enhanced geothermalc systems in deplete oil reservoirs via in situ combustion. In Proceedings of the PROCEEDINGS, Thirty-Eighth Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 11–13 February 2013; SGP-TR-198. pp. 11–13. [Google Scholar]

- Lawal, K.A. Alternating Injection of Steam and CO2 For Thermal Recovery of Heavy Oil. Ph.D. Thesis, Imperial College London, London, UK, 2011. [Google Scholar]

- Archer, J.S.; Wall, C.G. Petroleum Engineering Principles and Practice. 1986. Available online: https://www.scirp.org/(S(351jmbntvnsjt1aadkozje))/reference/referencespapers.aspx?referenceid=2075915 (accessed on 15 May 2023).

- Cui, G.; Liu, T.; Xie, J. A review of SAGD technology development and its possible application potential on thin-layer super-heavy oil reservoirs. Geosci. Front. 2022, 13, 10. [Google Scholar] [CrossRef]

- Tao, L.; Yuan, X.; Cheng, H. Experimental study on well placement optimization for steam-assisted gravity drainage to enhance recovery of thin layer oil sand reservoirs. Geofluids 2021, 2021, 9954127. [Google Scholar] [CrossRef]

- Zheng, H.; Shi, W.; Ding, D.; Zhang, C. Numerical simulation of in situ combustion of oil shale. Geofluids 2017, 2017, 3028974. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Masoumi, M.; Askarinezhad, R. Evolving connectionist model to monitor the efficiency of an in situ combustion process: Application to heavy oil recovery. Energy Technol. 2014, 2, 811–818. [Google Scholar] [CrossRef]

- Jiang, H.; Yuan, S.; Li, L.; Wang, J.; Wang, H.; Li, T. Operation control of in situ combustion based on the material balance equation. Geofluids 2020, 2020, 8898054. [Google Scholar] [CrossRef]

- Ruidas, B.C.; Ganguly, S. In situ combustion of light oil: Stoichiometric kinetic and thermodynamic analyses from the Fflow experiments. Combust. Sci. Technol. 2015, 187, 1542–1561. [Google Scholar] [CrossRef]

- Alamatsaz, A. Experimental Investigation of In Situ Combustion for Heavy Oils at Low Air Flux. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2015. [Google Scholar]

- Dou, L.; Yang, M.; Gao, H.; Jiang, D.; Liu, C. Characterization of the drive mechanism of dynamic imbibition in tight sandstone reservoirs using the NMR method. Geofluids. 2020. 12p. Available online: https://prism.ucalgary.ca/server/api/core/bitstreams/929639a2-d652-4674-9ccd-8c8cf80d279c/content (accessed on 15 May 2023).

- Mahinpey, N.; Ambalae, A.; Asghari, K. In situ combustion in enhanced oil recovery (EOR): A REVIEW. Chem. Eng. Commun. 2007, 194, 995–1021. [Google Scholar] [CrossRef]

- Aguilar-Madera, C.G.; Molina-Espinosa, L.; Velasco-Tapia, F. Numerical simulation of a kinetic cell for in-situ combustion. A Parametric Study and History Matching Aspects. Int. J. Chem. React. Eng. 2017, 1–26. [Google Scholar] [CrossRef]

- Askarova, A.; Popov, E.; Ursenbach, M.; Moore, G.; Mehta, S.; Cheremisin, A. Experimental investigations of forward and reverse combustion for increasing oil recovery of a real oil field. Energies 2020, 13, 4581. [Google Scholar] [CrossRef]

- Ariskina, K.A.; Abaas, M.; Yuan, C.; Emelianov, D.A.; Varfolomeev, M.A. Effect of calcite and dolomite on crude oil combustion characterized by TG-FTIR. J. Pet. Sci. Eng. 2020, 184, 106550. [Google Scholar] [CrossRef]

- Zheng, W.; Tan, X.; Wang, T.; Bai, Y. Experimental and simulation study of the in situ combustion process in offshore heavy oil reservoirs. Pet. Sci. Technol. 2020, 38, 983–991. [Google Scholar] [CrossRef]

- Rahman, A.; Happy, F.A.; Ahmed, S.; Hossain, M.E. Development of Scaling Criteria for Enhanced Oil Recovery: A Review. J. Pet. Sci. Eng. 2017, 158, 66–79. [Google Scholar] [CrossRef]

- Farouq All, S.M.; Redford, D.A.; Islam, M.R. Scaling Laws for Enhance Oil Recovery Experiments. In Proceedings of the China Canada Joint Technical Conference on Heavy Oil Recovery, Zhuo Zhou City, China, 1987. [Google Scholar]

- Islam, M.R.; Erno, B.P.; Davis, D. Hot gas and waterflood equivalence of in-situ combustion. J. Can. Pet Technol. 1992, 21, PETSOC-92-08-04. [Google Scholar] [CrossRef]

- Islam, M.R.; Farouq Ali, S.M. New Scaling Criteria for In-Situ Combustion Experiments. J. Pet. Sci. Eng. 1992, 6, 367–379. [Google Scholar] [CrossRef]

- Garon, A.M.; Geisbrecht, R.A.; Lowry, W.E., Jr. Scaled model experiments of fire-flooding in tar sands. J. Pet. Technol. 1982, 34, 2158–2166. [Google Scholar] [CrossRef]

- Garon, A.M.; Kumar, M.; Cala, G.C. Oxygen fireflooding--the state of the art. In Situ. SPE Res. Eng. 1986, 10, 1–26. [Google Scholar]

- Kumar, M.; Garon, A.M. An experimental investigation of the fireflooding combustion zone. SPE Res Eng. 1988, 6, 55–61. [Google Scholar] [CrossRef]

- Lozada, D.; Farouq Ali, S.M. Experimental design for non-equilibrium immiscible carbon dioxide flood. In Proceedings of the the 4th UNITAR/UNDP International Conference on Heavy Crude and Tar Sands, Edmonton, AB, Canada, 1989; pp. 275–296. [Google Scholar]

- Lin, C.Y.; Chen, W.H.; Lee, S.T.; Culham, W.E. Numerical simulation of combustion tube experiments and the associated kinetics of in-situ combustion processes. Soc. Pet. Eng. J. 1984, 24, 657–666. [Google Scholar] [CrossRef]

- Karpiński, B.S.M. Clay minerals–mineralogy and phenomenon of clay swelling in oil and gas industry. Adv. Mater. Sci. 2015, 15, 37–55. [Google Scholar] [CrossRef]

- Nicola Pernicone, T.F. Catalyst Activation by Reduction. Pure Appl. Chem. 1978, 50, 1169–1191. [Google Scholar] [CrossRef]

- Alves, H.J.; da Rocha, A.M.; Monteiro, M.R.; Moretti, C.; Cabrelon, M.D.; Schwengber, C.A.; Milinsk, M.C. Treatment of clay with KF: New solid catalyst for biodiesel production. Appl. Clay Sci. 2014, 91–92, 98–104. [Google Scholar] [CrossRef]

- Kar, Y. Catalytic cracking of pyrolytic oil by using bentonite clay for green liquid hydrocarbon fuels production. Biomass Bioenergy 2018, 119, 473–479. [Google Scholar] [CrossRef]

- Eman, A.E. Clays as catalysts in petroleum refining industry. ARPN J. Sci. Technol. 2013, 3, 356–375. [Google Scholar]

- Starshinova, V.; Abdelsalam, Y.; Gorelysheva, V.; Oparkin, A.; Gnevashev, S.; Pyataev, A.; Khamidullin, R.; Karalin, E.; Shinkarev, A. Heterogenous catalysts based on fe-pillared clays for catalytic aquathermolysis processes of heavy oil. IOP Conf. Ser. Earth Environ. Sci. 2019, 282, 012036. [Google Scholar] [CrossRef]

- Kozlowski, M.L.; Punase, A.; Nasr-El-Din, H.A.; Hascakir, B. The catalytic effect of clay on in-situ combustion performance. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar]

- Mustafa, A.; Varfolomeev, M.A.; Yuan, C.; Emelyanov, D.A. Influence of dolomite and calcite on crude oil oxidation by thermal analysis methods. Int. Interdiscip. Sci. Geoconference SGEM 2017, 17, 125–130. [Google Scholar]

- Sitnov, S.A.; Vakhin, A.V.; Mukhamatdinov, I.I.; Onishchenko, Y.V.; Feoktistov, D.A. Effects of calcite and dolomite on conversion of heavy oil under subcritical Condition. Pet. Sci. Technol. 2019, 37, 687–693. [Google Scholar] [CrossRef]

- Yuan, C.; Varfolomeev, M.A.; Suwaid, M.A.E. Improving the oxidation behavior of heavy oil using copper stearate as a catalys. Multidiscip. Sci. GeoConference SGEM 2017, 17, 243–248. [Google Scholar]

- Wu, Z.; Liu, H.; Wang, X.; Zhang, Z. Emulsification and improved oil recovery with viscosity reducer during steam injection process for heavy oil. J. Ind. Eng. Chem. 2018, 61, 348–355. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, H.; Pang, Z.; Wu, C.; Gao, M. Pore-scale experiment on blocking characteristics and EOR mechanisms of nitrogen foam for heavy oil: A 2D visualized study. Energy Fuels 2016, 30, 9106–9113. [Google Scholar] [CrossRef]

- Zolotukhin, A.B.; Eremin, N.A. Designing the Development of Oil Fields Using In-Situ Combustion; Gubkin Russian State University of Oil and Gas: Moscow, Russia, 1985. [Google Scholar]

- Hirakawa, S.; Miwa, M. In-situ combustion for enhanced oil recovery. J. Jpn. Assoc. Pet. Technol. 1984, 49, 2, 75–86. [Google Scholar] [CrossRef]

- Rodionov, V.E.; Tsybulin, I.V.; Karpaev, A.A. Numerical simulation of an in-situ combustion wave for two-phase flow through porous media. Proced. MIPT 2016, 8, 180–193. [Google Scholar]

- Koldoba, A.V.; Skalko, Y.I. Numerical simulation of inverse mode propagation in-situ combustion direct-flow waves. Comput. Res. Model. 2020, 12, 993–1006. [Google Scholar] [CrossRef]

- Youtsos, M.S.K.; Mastorakos, E. Numerical simulation of thermal and reaction waves for in situ combustion in hydrocarbon reservoirs. Fuel 2013, 108, 780–792. [Google Scholar] [CrossRef]

- Mailybaev, A.A.; Bruining, J.; Marchesin, D. Analytical formulas for in-situ combustion. SPE J. 2011, 16, 513–523. [Google Scholar] [CrossRef]

- Sinuvasan, R.; Tamizhmani, K.M.; Leach, P.G.L. Symmetries, travelling-wave and self-similar solutions of the burgers hierarchy. Appl. Math. Comput. 2017, 303, 165–170. [Google Scholar] [CrossRef]

- Crookston, R.B.; Culham, W.E.; Chen, W.H. A numerical simulation model for thermal recovery. Process. Soc. Pet. Eng. J. 2013, 19, 37–58. [Google Scholar] [CrossRef]

- Dryer, F.L.; Chaos, M.; Zhao, Z. Spontaneous ignition of pressurized releases of hydrogen and natural gas into air. Combust. Sci. Technol. 2007, 179, 663–694. [Google Scholar] [CrossRef]

- Jafari, A.; Hasani, M.; Hosseini, M. Application of CFD technique to simulate enhanced oil recovery processes: Current status and future opportunities. Pet. Sci. Technol. 2020, 17, 434–456. [Google Scholar] [CrossRef]

- Yang, M. Numerical modelling of hybrid steam and combustion recovery process for oil sands. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, TX, USA, 20–22 February 2017. [Google Scholar]

- He, R.; Yang, B.; Liu, H.; Chen, Z. New in-situ combustion simulator for parallel computers. arXiv 2018, arXiv:1811.11992. [Google Scholar] [CrossRef]

- Nizaev, R.K.; Aleksandrov, G.V. Simulation of interbedding processes with air injection into oil deposits with various geological and physical characteristics. Georesursy 2016, 18, 51–54. [Google Scholar] [CrossRef]

- Yoshioka, Y.; Sasaki, K.; Takatsu, K.; Sugai, Y. Screening of major chemical reactions in in-situ combustion process for bitumen production from oil sands res-ervoirs. Int. J. Pet. Petrochemical Eng. 2017, 3, 82–92. [Google Scholar]

- Sun, Y.-H.; Bai, F.-T.; Lü, X.-S.; Li, Q.; Liu, Y.-M.; Guo, M.-Y.; Guo, W.; Liu, B.-C. A Novel energy-efficient pyrolysis process: Self-pyrolysis of oil shale triggered by topochemical heat in a horizontal fixed bed. Sci. Rep. 2015, 5, 8290. [Google Scholar] [CrossRef]

| Artificial Ignition Method | Advantages | Disadvantages |

|---|---|---|

| Gas burners |

|

|

| Catalytic heaters |

|

|

| Chemical ignition |

|

|

| Steam injection |

|

|

| Name | Approaches | |||||

|---|---|---|---|---|---|---|

| *1 | *2 | *3 | *4 | *5 | *6 | |

| Capillary forces | ✓ | - | - | - | ||

| ✓ | ± | ✓ | ✓ | ✓ | ✓ | |

| Diffusion forces | ✓ | ✓ (one direction only) | ✓ | ✓ | ✓ | ✓ |

| Mass transfer to viscosity ratio | ||||||

| Reaction rate | - | - | ✓ | ✓ | - | ✓ |

| Gravity forces | - | ✓ | ✓ | ✓ | ✓ | ✓ |

| Dispersion forces | - | ✓ | ✓ | ✓ | - | ✓ |

| Gravity forces to viscosity | - | - | - | ✓ | ✓ | ✓ |

| Dispersed effect | three-dimensional | one-dimensional for the combustion pipe | scattering effect | |||

| model reaction rate prototype speed | ||||||

| Composition of the Catalyst | Effect | Results |

|---|---|---|

| 1. Clay mixtures of 3 wt% | Catalytic | Controls the combustion front |

| 2. Quartz and mica containing clay | Catalytic | Mica leads to a decrease in activation energy |

| 3. Clinochlor and talc containing clay | Inhibitory | Leads to a delay in the reaction of isomerization and decomposition, as well as in the reaction of oxidative cracking |

| 4. Kaolinite, montmorillonite, mica, and clinochlor containing clay | Catalytic | Controls the combustion front, but does not lead to a shift at the stage of high-temperature oxidation |

| 5. The level of calcite and dolomite | Catalytic | Provides light ignition and significantly reduces the activation energy |

| 6. Copper stearate | Catalytic | Shifts the combustion reactions to a lower temperature range, especially during high-temperature oxidation. Increases the efficiency of coke combustion. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minakov, A.V.; Meshkova, V.D.; Guzey, D.V.; Pryazhnikov, M.I. Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery. Energies 2023, 16, 4266. https://doi.org/10.3390/en16114266

Minakov AV, Meshkova VD, Guzey DV, Pryazhnikov MI. Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery. Energies. 2023; 16(11):4266. https://doi.org/10.3390/en16114266

Chicago/Turabian StyleMinakov, Andrey V., Victoria D. Meshkova, Dmitry Viktorovich Guzey, and Maksim I. Pryazhnikov. 2023. "Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery" Energies 16, no. 11: 4266. https://doi.org/10.3390/en16114266