Approaching the Theoretical Maximum Performance of Highly Transparent Thermochromic Windows

Abstract

:1. Introduction

2. Methods

2.1. Theoretical Investigation

2.2. Coating Preparation

3. Results and Discussion

3.1. Investigation of Theoretical Maximum Performance

3.2. Current Record Performance

3.3. Optimization Strategies to Approach Theoretical Maximum

3.3.1. Purity of Active Material

3.3.2. Size and Distribution of Active Domains within the Matrix (Including Layer Thickness)

3.3.3. Integration into Antireflective Coating Stack

3.3.4. Other Strategies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Beute, F.; de Kort, Y.A.W. Salutogenic Effects of the Environment: Review of Health Protective Effects of Nature and Daylight. Appl. Psychol. Health Well-Being 2014, 6, 67–95. [Google Scholar] [CrossRef]

- Mann, D.; Yeung, C.; Habets, R.; Vroon, Z.; Buskens, P. Comparative Building Energy Simulation Study of Static and Thermochromically Adaptive Energy-Efficient Glazing in Various Climate Regions. Energies 2020, 13, 2842. [Google Scholar] [CrossRef]

- Tsikaloudaki, K.; Theodosiou, T.; Laskos, K.; Bikas, D. Assessing cooling energy performance of windows for residential buildings in the Mediterranean zone. Energy Convers. Manag. 2012, 64, 335–343. [Google Scholar] [CrossRef]

- Jaber, S.; Ajib, S. Thermal and economic windows design for different climate zones. Energy Build. 2011, 43, 3208–3215. [Google Scholar] [CrossRef]

- Solar Control. Available online: https://www.pilkington.com/en-gb/uk/products/product-categories/solar-control (accessed on 30 November 2022).

- Kirimtat, A.; Koyunbaba, B.K.; Chatzikonstantinou, I.; Sariyildiz, S. Review of simulation modeling for shading devices in buildings. Renew. Sustain. Energy Rev. 2016, 53, 23–49. [Google Scholar] [CrossRef]

- Ke, Y.; Chen, J.; Lin, G.; Wang, S.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066. [Google Scholar] [CrossRef]

- SageGlass. Available online: https://www.sageglass.com/ (accessed on 30 November 2022).

- HALIO. Available online: https://halioinc.com/ (accessed on 30 November 2022).

- Granqvist, C.G.; Arvizu, M.A.; Bayrak Pehlivan, I.; Qu, H.-Y.; Wen, R.-T.; Niklasson, G.A. Electrochromic materials and devices for energy efficiency and human comfort in buildings: A critical review. Electrochim. Acta 2018, 259, 1170–1182. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Ke, Y.; Liu, C.; Chen, Z.; Wang, N.; Zhang, L.; Zhou, Y.; Wang, S.; Gao, Y.; Long, Y. Thermochromic VO2 for energy-efficient smart windows. Joule 2018, 2, 1707–1746. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhang, L.; Zhou, Y.; Cui, Y.; Chen, Z.; Liu, Y.; Li, J.; Long, Y.; Gao, Y. Thermochromic Energy Efficient Windows: Fundamentals, Recent Advances, and Perspectives. Chem. Rev. 2023, 123, 7025–7080. [Google Scholar] [CrossRef]

- Chang, T.-C.; Cao, X.; Bao, S.-H.; Ji, S.-D.; Luo, H.-J.; Jin, P. Review on thermochromic vanadium dioxide based smart coatings: From lab to commercial application. Adv. Manuf. 2018, 6, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Yeung, C.P.K.; Habets, R.; Leufkens, L.; Colberts, F.; Vroon, Z.; Mann, D.; Buskens, P. Phase separation of VO2 and SiO2 on SiO2-Coated float glass yields robust thermochromic coating with unrivalled optical properties. Sol. Energy Mater. Sol. Cells 2021, 230, 111256. [Google Scholar] [CrossRef]

- Mann, D.; Yeung, C.P.K.; Habets, R.; Van Zandvoort, R.; Leufkens, L.; Hupperetz, J.; Out, D.; Valckenborg, R.; Vroon, Z.; Buskens, P. SunSmart—The First Affordable, Energy Optimized Smart Window. IOP Conf. Ser. Earth Environ. Sci. 2022, 1085, 012060. [Google Scholar] [CrossRef]

- Chang, Q.; Wang, D.; Zhao, Z.; Ling, C.; Wang, C.; Jin, H.; Li, J. Size-Controllable M-Phase VO2 Nanocrystals for Flexible Thermochromic Energy-Saving Windows. ACS Appl. Nano Mater. 2021, 4, 6778–6785. [Google Scholar] [CrossRef]

- Okada, M.; Kuno, M.; Yamada, Y. Fast synthesis of monoclinic VO2 nanoparticles by microwave-assisted hydrothermal method and application to high-performance thermochromic film. Sol. Energy Mater. Sol. Cells 2023, 255, 112311. [Google Scholar] [CrossRef]

- Calvi, L.; Leufkens, L.; Yeung, C.P.K.; Habets, R.; Mann, D.; Elen, K.; Hardy, A.; Van Bael, M.K.; Buskens, P. A Comparative Study on the Switching Kinetics of W/VO2 Powders and VO2 Coatings and Their Implications for Thermochromic Glazing. Sol. Energy Mater. Sol. Cells 2021, 224, 110977. [Google Scholar] [CrossRef]

- Calvi, L.; van Zandvoort, R.; Leufkens, L.; Hupperetz, J.F.B.; Habets, R.; Mann, D.; Meulendijks, N.; Elen, K.; Verheijen, M.A.; Hardy, A.; et al. Thermochromic glass laminates comprising W/VO2 nanoparticles obtained by wet bead milling: An in-depth study of the switching performance. Sol. Energy Mater. Sol. Cells 2023, 257, 112350. [Google Scholar] [CrossRef]

- Kim, Y.; Yu, S.; Park, J.; Yoon, D.; Dayaghi, A.M.; Kim, K.J.; Ahn, J.S.; Son, J. High-throughput roll-to-roll fabrication of flexible thermochromic coatings for smart windows with VO2 nanoparticles. J. Mater. Chem. C 2018, 6, 3451–3458. [Google Scholar] [CrossRef]

- Mann, D.; Yeung, C.P.K.; Habets, R.; Vroon, Z.; Buskens, P. Building energy simulations for different building types equipped with a high performance thermochromic smart window. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012001. [Google Scholar] [CrossRef]

- Warwick, M.E.A.; Ridley, I.; Binions, R. The effect of variation in the transition hysteresis width and gradient in thermochromic glazing systems. Sol. Energy Mater. Sol. Cells 2015, 140, 253–265. [Google Scholar] [CrossRef]

- Hutchins, M.G.; Platzer, W.J. The thermal performance of advanced glazing materials. Renew. Energy 1996, 8, 540–545. [Google Scholar] [CrossRef]

- Cao, X.; Chang, T.; Shao, Z.; Xu, F.; Luo, H.; Jin, P. Challenges and Opportunities toward Real Application of VO2-Based Smart Glazing. Matter 2020, 2, 862–881. [Google Scholar] [CrossRef]

- EN 410; Glass in Building-Determination of Luminous and Solar Characteristics of Glazing. Comite Europeen de Normalisation: Brussels, Belgium, 2011.

- International Glazing Database (IGDB). WINDOW Software and Optics Software, Lawrence Berkley National Laboratory, University of California. Available online: https://windows.lbl.gov/software (accessed on 30 November 2022).

- Sol, C.; Portnoi, M.; Li, T.; Gurunatha, K.L.; Schläfer, J.; Guldin, S.; Parkin, I.P.; Papakonstantinou, I. High-Performance Planar Thin Film Thermochromic Window via Dynamic Optical Impedance Matching. ACS Appl. Mater. Interfaces 2020, 12, 8140–8145. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, A.; Li, Y.; Ji, S.; Gao, Y.; Jin, P. Surface plasmon resonance induced excellent solar control for VO2@SiO2 nanorods-based thermochromic foils. Nanoscale 2013, 5, 9208–9213. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, Y.; Wang, B.; Zheng, J.; Ji, S.; Yao, H.; Luo, H.; Jin, P. Vanadium Dioxide Nanoparticle-based Thermochromic Smart Coating: High Luminous Transmittance, Excellent Solar Regulation Efficiency and Near Room Temperature Phase Transition. ACS Appl. Mater. Interfaces 2015, 7, 27796–27803. [Google Scholar] [CrossRef]

- Srivastava, A.; Rotella, H.; Saha, S.; Pal, B.; Kalon, G.; Mathew, S.; Motapothula, M.; Dykas, M.; Yang, P.; Okunishi, E.; et al. Selective growth of single phase VO2 (A, B, and M) polymorph thin films. APL Mater. 2015, 3, 026101. [Google Scholar] [CrossRef]

- Kniec, K.; Marciniak, L. Different Strategies of Stabilization of Vanadium Oxidation States in Lagao3 Nanocrystals. Front. Chem. 2019, 7, 520. [Google Scholar] [CrossRef]

- Calvi, L.; van Geijn, R.; Leufkens, L.; Habets, R.; Gurunatha, K.L.; Stout, K.; Mann, D.; Papakonstantinou, I.; Parkin, I.P.; Elen, K.; et al. The Impact of Bead Milling on the Thermodynamics and Kinetics of the Structural Phase Transition of VO2 Particulate Materials and Their Potential for Use in Thermochromic Glazing. Sol. Energy Mater. Sol. Cells 2022, 242, 111783. [Google Scholar] [CrossRef]

- Lockwood, D.J. Rayleigh and Mie Scattering. In Encyclopedia of Color Science and Technology; Luo, M.R., Ed.; Springer: New York, NY, USA, 2016. [Google Scholar]

- Wang, D.; Guo, D.; Zhao, Z.; Ling, C.; Li, J.; Hong, S.; Zhao, Y.; Jin, H. Surface modification-assisted solvent annealing to prepare high quality M-phase VO2 nanocrystals for flexible thermochromic films. Sol. Energy Mater. Sol. Cells 2019, 200, 110031. [Google Scholar] [CrossRef]

- Schläfer, J.; Sol, C.; Li, T.; Malarde, D.; Portnoi, M.; Macdonald, T.J.; Laney, S.K.; Powell, M.J.; Top, I.; Parkin, I.P.; et al. Thermochromic VO2–SiO2 nanocomposite smart window coatings with narrow phase transition hysteresis and transition gradient width. Sol. Energy Mater. Sol. Cells 2019, 200, 109944. [Google Scholar] [CrossRef]

- Currie, M.; Mastro, M.A.; Wheeler, V.D. Characterizing the tunable refractive index of vanadium dioxide. Opt. Mater. Express 2017, 7, 1697–1707. [Google Scholar] [CrossRef]

- Mlyuka, N.R.; Niklasson, G.A.; Granqvist, C.G. Mg doping of thermochromic VO2 films enhances the optical transmittance and decreases the metal-insulator transition temperature. Appl. Phys. Lett. 2009, 95, 171909. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Huang, A.; Ma, H.; Tong, K.; Ji, S.; Bao, S.; Cao, X.; Jin, P. Composite Film of Vanadium Dioxide Nanoparticles and Ionic Liquid-nickel-chlorine Complexes with Excellent Visible Thermochromic Performance. ACS Appl. Mater. Interfaces 2016, 8, 29742–29748. [Google Scholar] [CrossRef]

- Zhou, C.; Li, D.; Tan, Y.; Ke, Y.; Wang, S.; Zhou, Y.; Liu, G.; Wu, S.; Peng, J.; Li, A.; et al. 3D Printed Smart Windows for Adaptive Solar Modulations. Adv. Opt. Mater. 2020, 8, 2000013. [Google Scholar] [CrossRef]

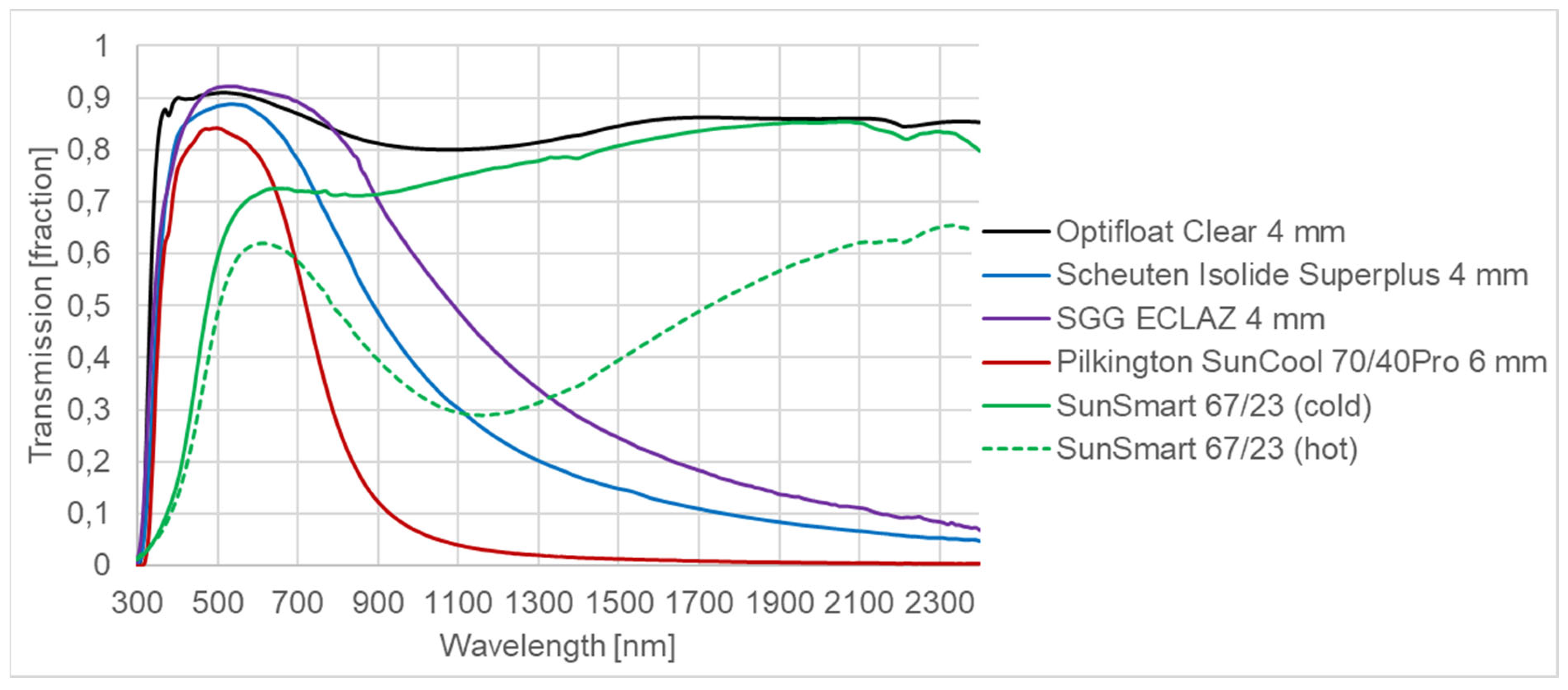

| Glass | Glazing System (Outer Glass Pane × Inner Glass Pane) | |||

|---|---|---|---|---|

| Product Name | Manufacturer | Type of Glass | Thickness | |

| Optifloat Clear | Pilkington, Lathom, UK | Monolithic | 4 mm | |

| ECLAZ | Saint-Gobain, Courbevoie, France | Coated | 4 mm | Optifloat × ECLAZ |

| Isolide Superplus | Scheuten Glas, Venlo, The Netherlands | Coated | 4 mm | Optifloat × Isolide |

| SunCool 70/40Pro | Pilkington, Lathom, UK | Coated | 6 mm * | Optifloat × SunCool |

| SunSmart 67/23 | TNO, Geleen, The Netherlands | Coated/thermochromic | 4 mm | SunSmart × ECLAZ |

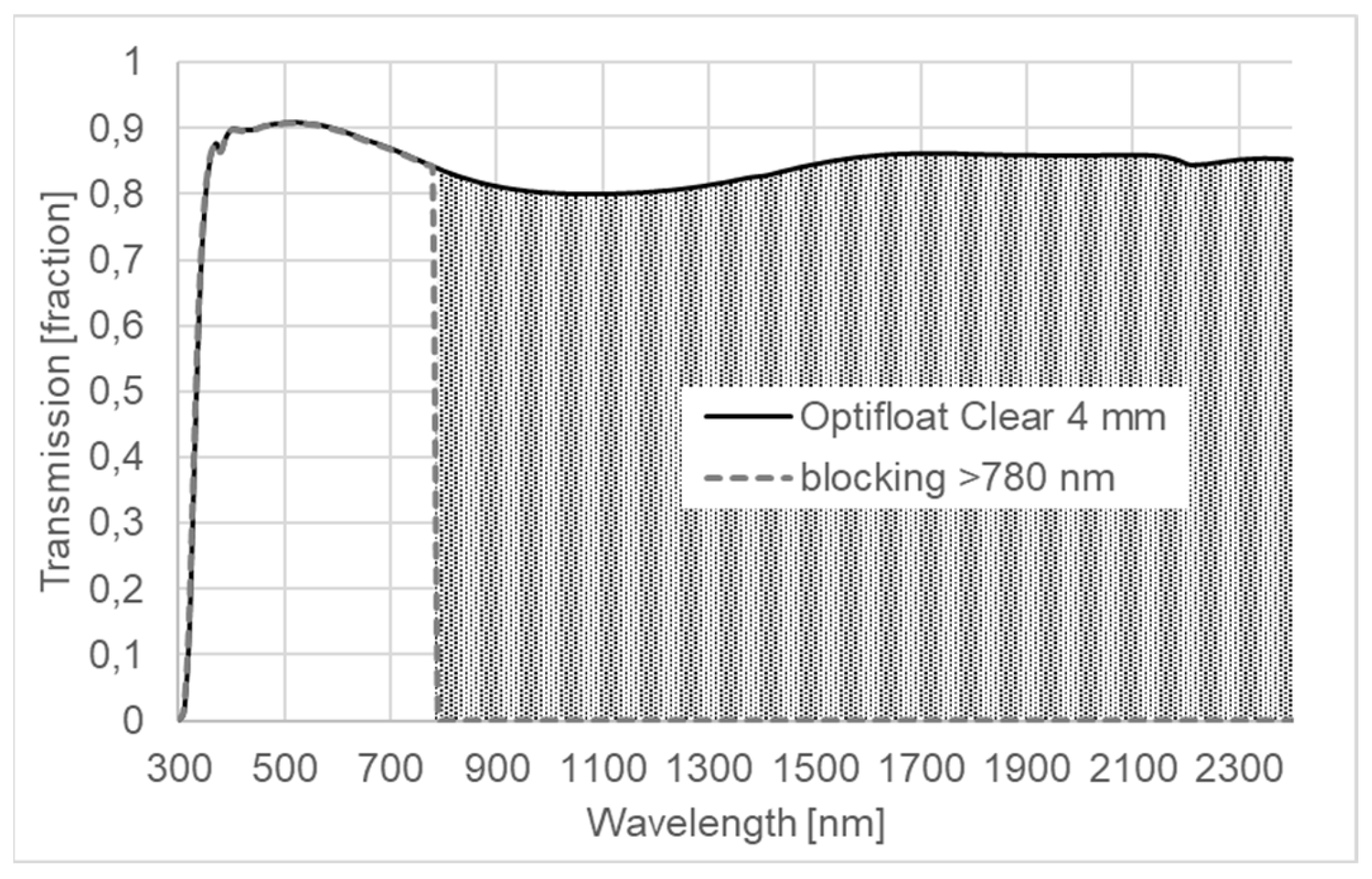

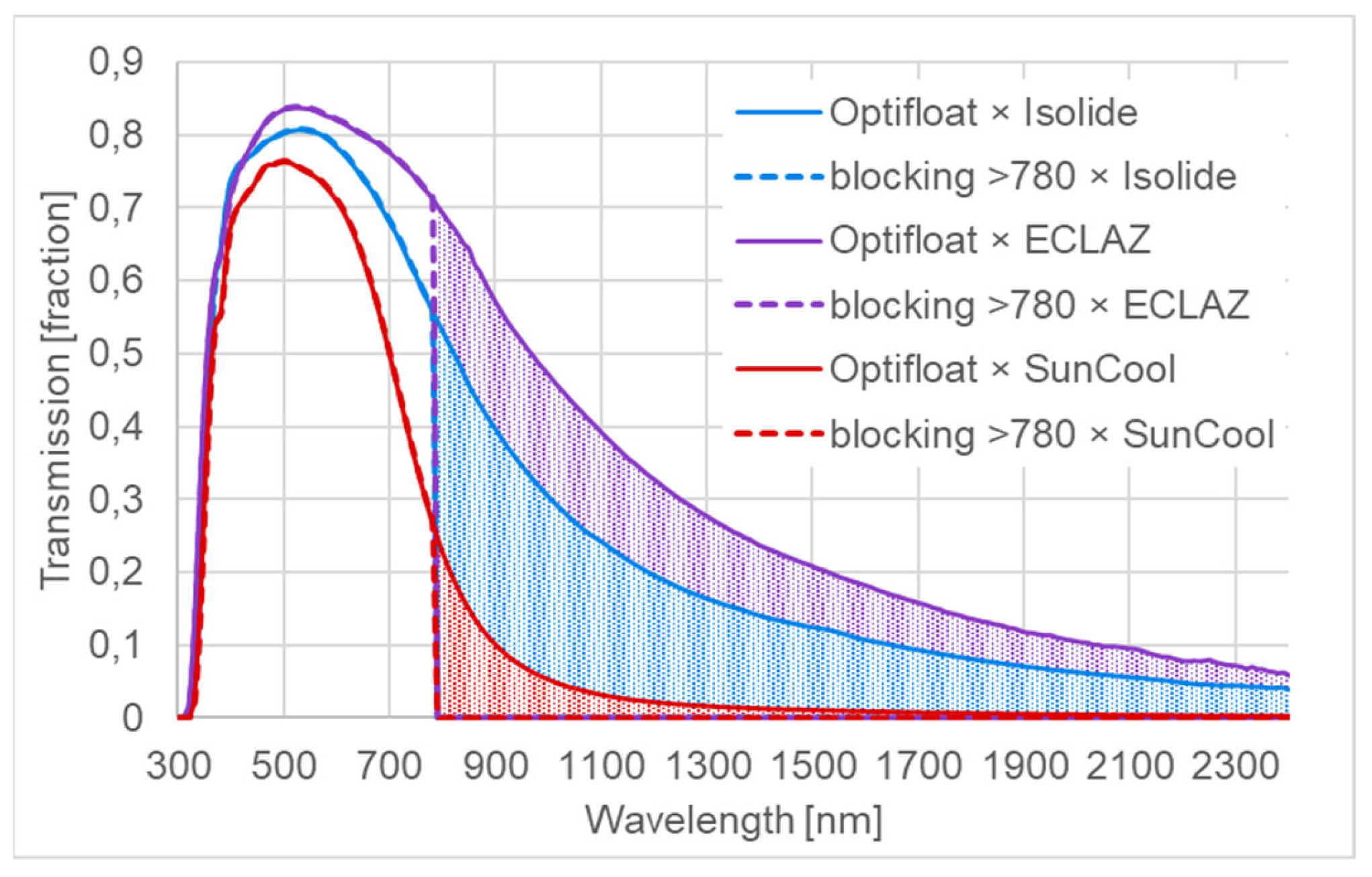

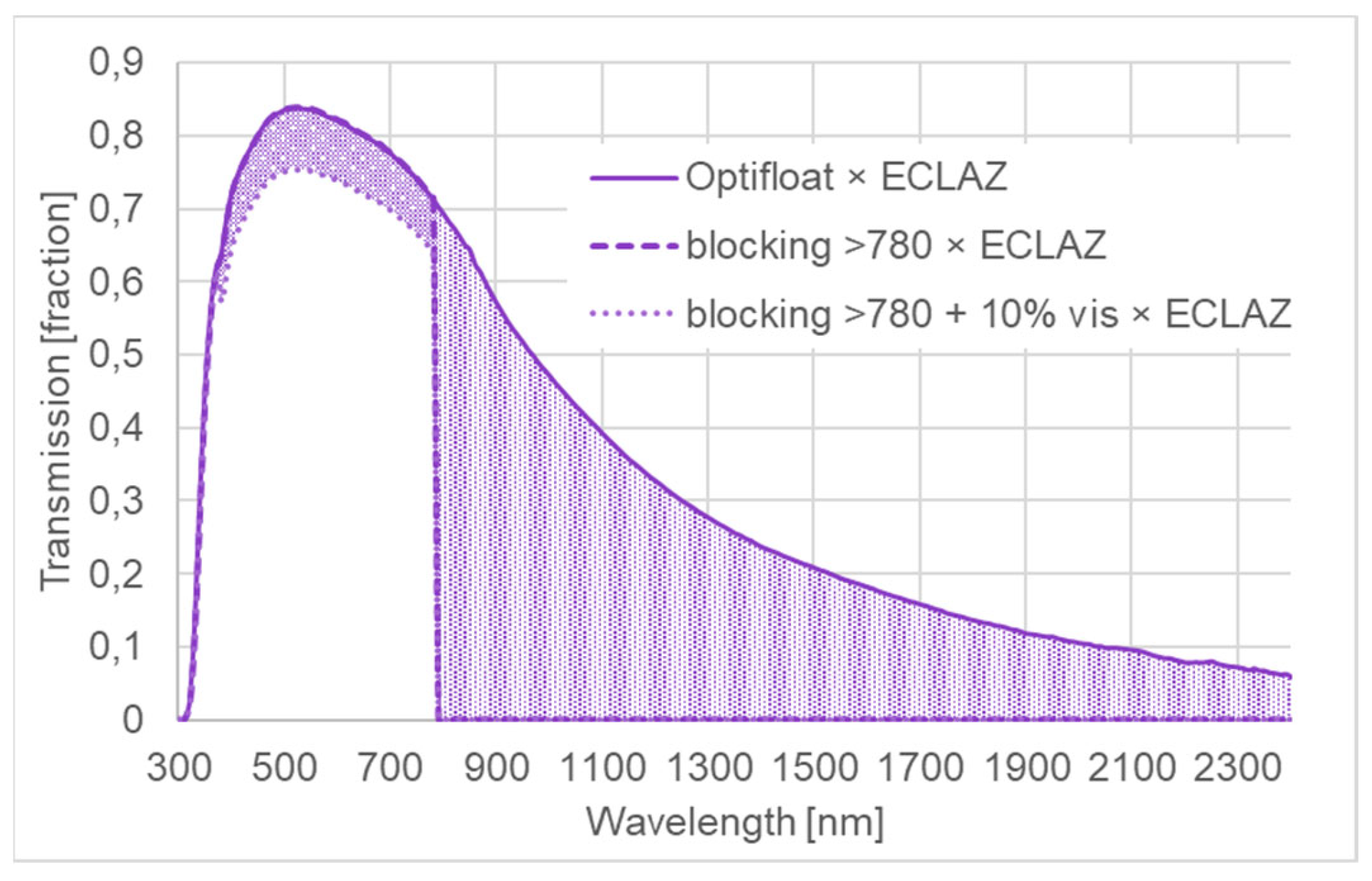

| Glass/Glazing System | Scenario | Tvis [%] | Tsol [%] | ΔTsol [%] |

|---|---|---|---|---|

| Optifloat Clear | Full transmission | 90.3 | 85.4 | 39.1 |

| blocking > 780 nm | 90.3 | 46.3 | ||

| Optifloat × ECLAZ | Full transmission | 83.2 | 60.3 | 19.0 |

| blocking > 780 nm | 83.2 | 41.3 | ||

| blocking > 780 + 10% vis | 74.9 | 37.2 | 23.1 | |

| Optifloat × Isolide | Full transmission | 79.8 | 51.3 | 12.9 |

| blocking > 780 nm | 79.8 | 38.4 | ||

| Optifloat × SunCool | Full transmission | 73.7 | 35.8 | 3.1 |

| blocking > 780 nm | 73.7 | 32.7 | ||

| SunSmart | Cold state | 67.1 | 67.7 | 22.9 |

| Hot state | 57.4 | 44.8 | ||

| SunSmart × ECLAZ | Cold state | 61.7 | 45.7 | 13.4 |

| Hot state | 52.8 | 32.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mann, D.; Calvi, L.; Yeung, C.P.K.; Habets, R.; Elen, K.; Hardy, A.; Van Bael, M.K.; Buskens, P. Approaching the Theoretical Maximum Performance of Highly Transparent Thermochromic Windows. Energies 2023, 16, 4984. https://doi.org/10.3390/en16134984

Mann D, Calvi L, Yeung CPK, Habets R, Elen K, Hardy A, Van Bael MK, Buskens P. Approaching the Theoretical Maximum Performance of Highly Transparent Thermochromic Windows. Energies. 2023; 16(13):4984. https://doi.org/10.3390/en16134984

Chicago/Turabian StyleMann, Daniel, Lavinia Calvi, Cindy P. K. Yeung, Roberto Habets, Ken Elen, An Hardy, Marlies K. Van Bael, and Pascal Buskens. 2023. "Approaching the Theoretical Maximum Performance of Highly Transparent Thermochromic Windows" Energies 16, no. 13: 4984. https://doi.org/10.3390/en16134984