Experimental Study on Flame Response Characteristics of a Non-Premixed Swirl Model Combustor

Abstract

:1. Introduction

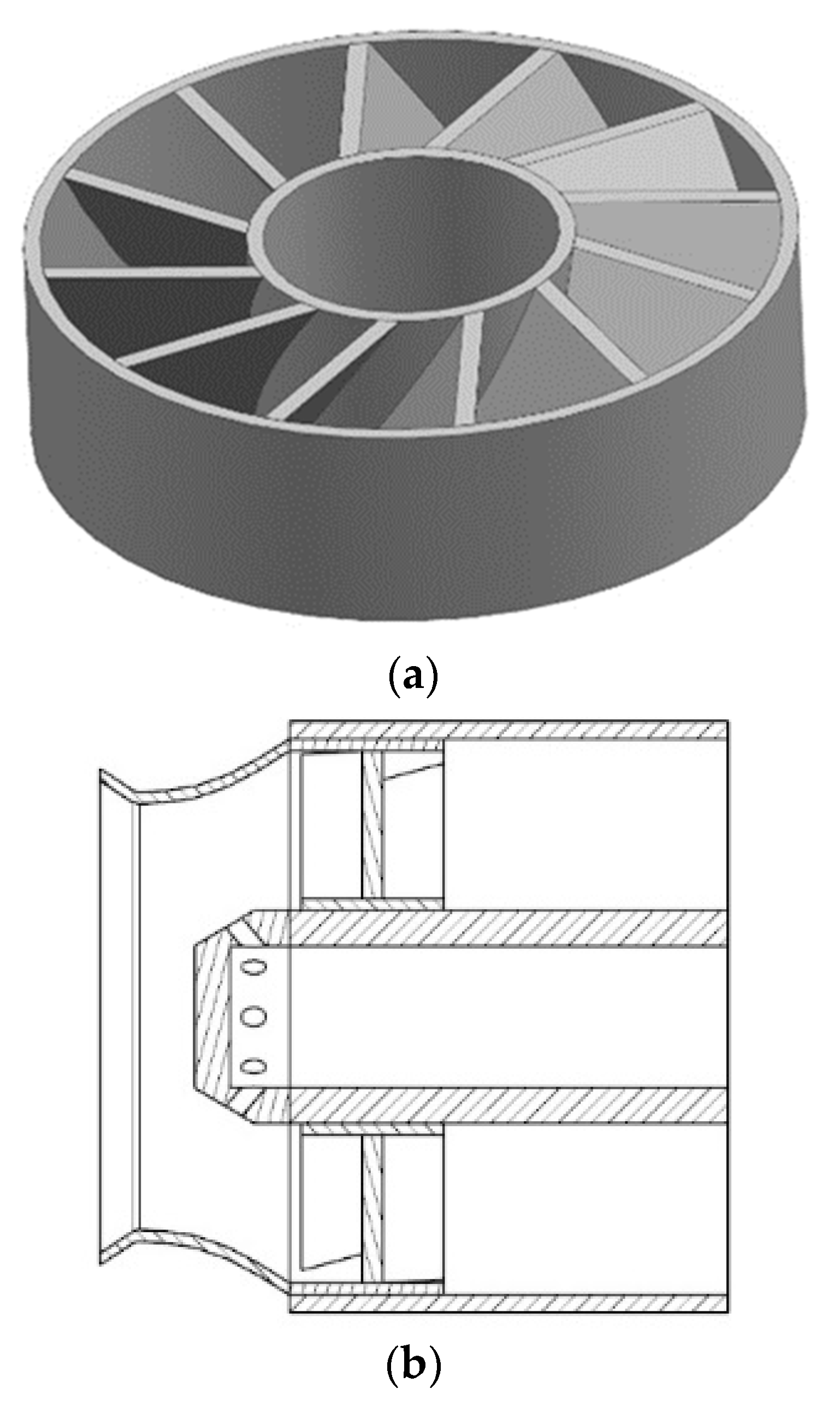

2. Experimental Setup and Measurement Layout

2.1. Experimental Setup

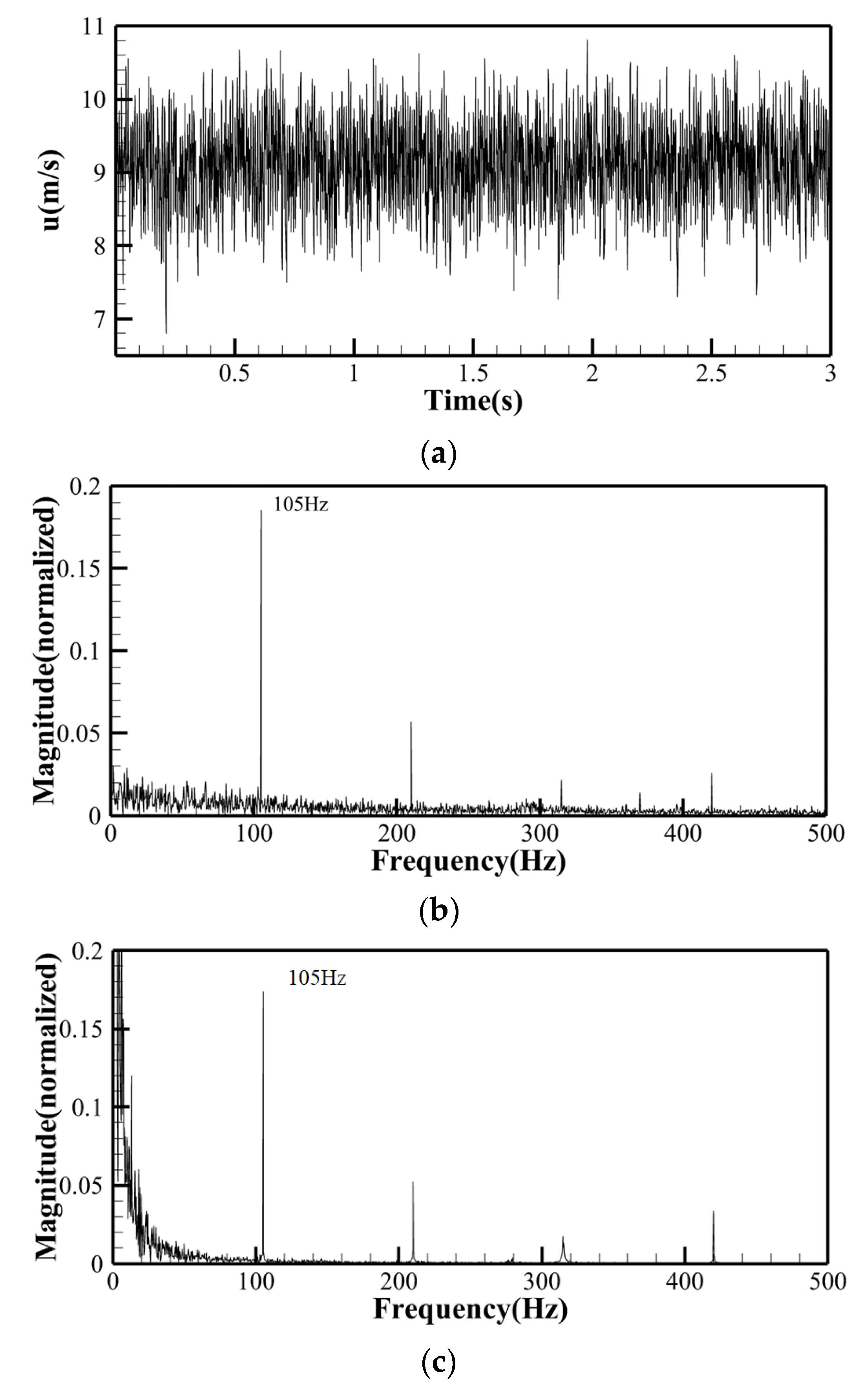

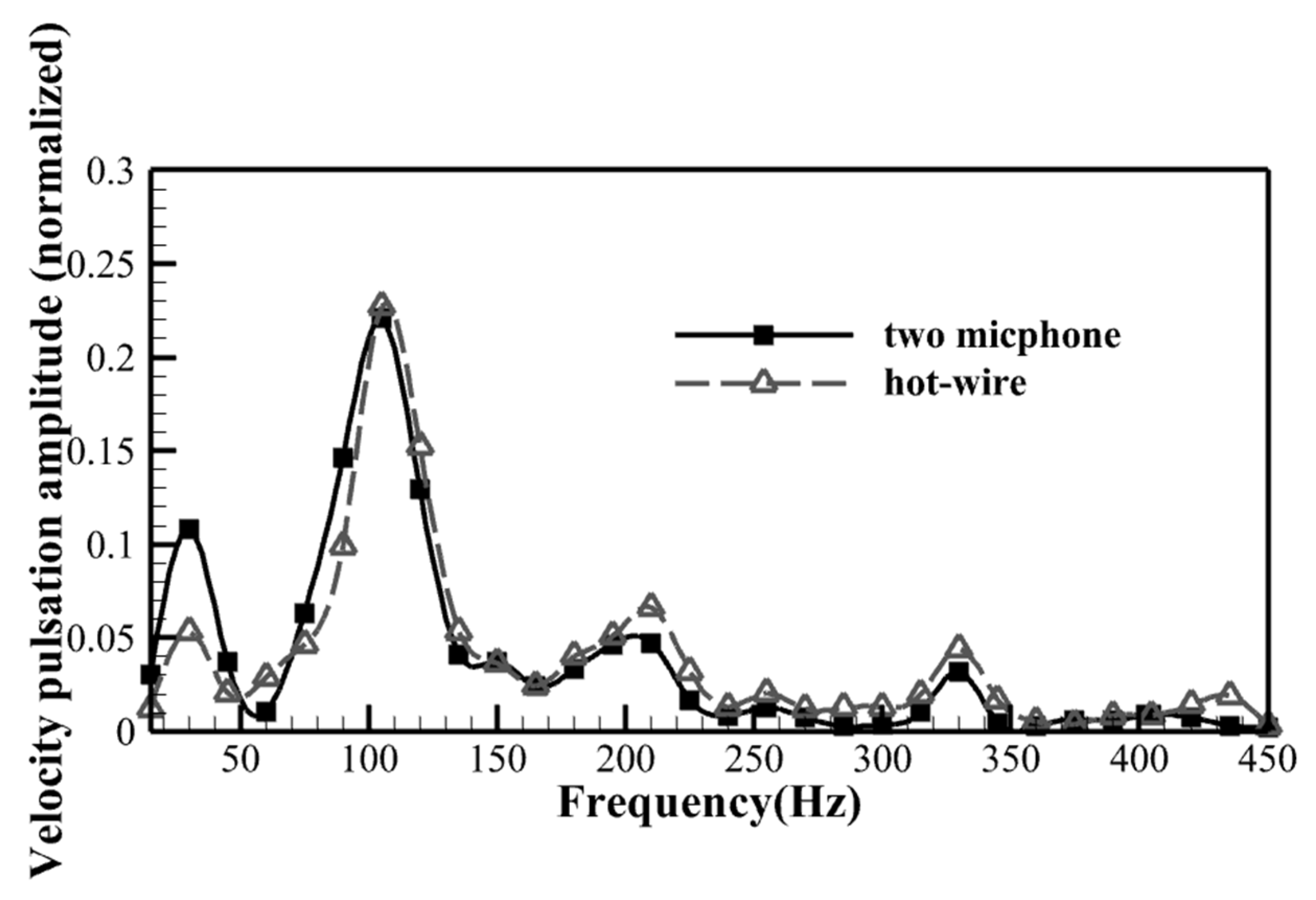

2.2. Measurement System

3. Results

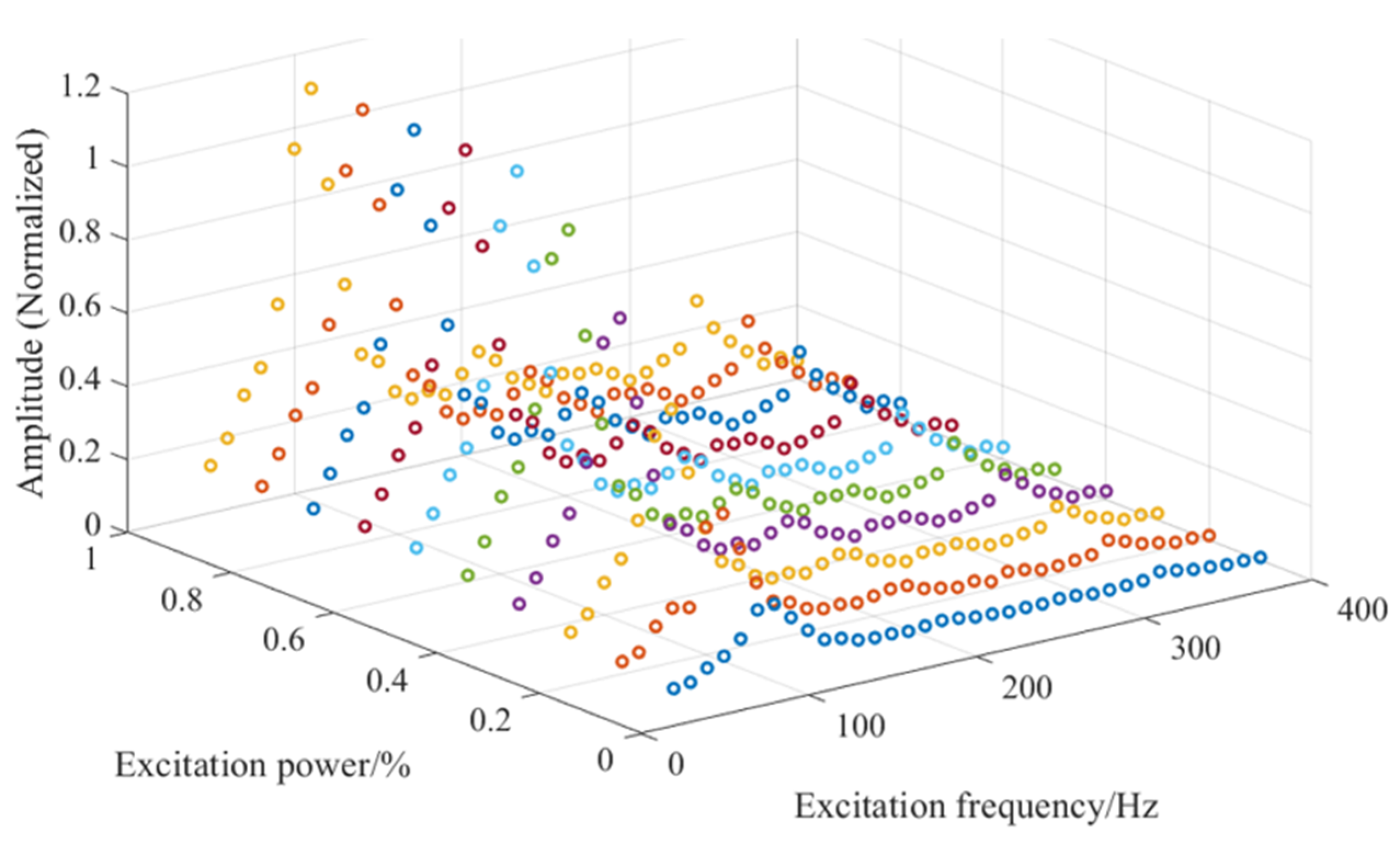

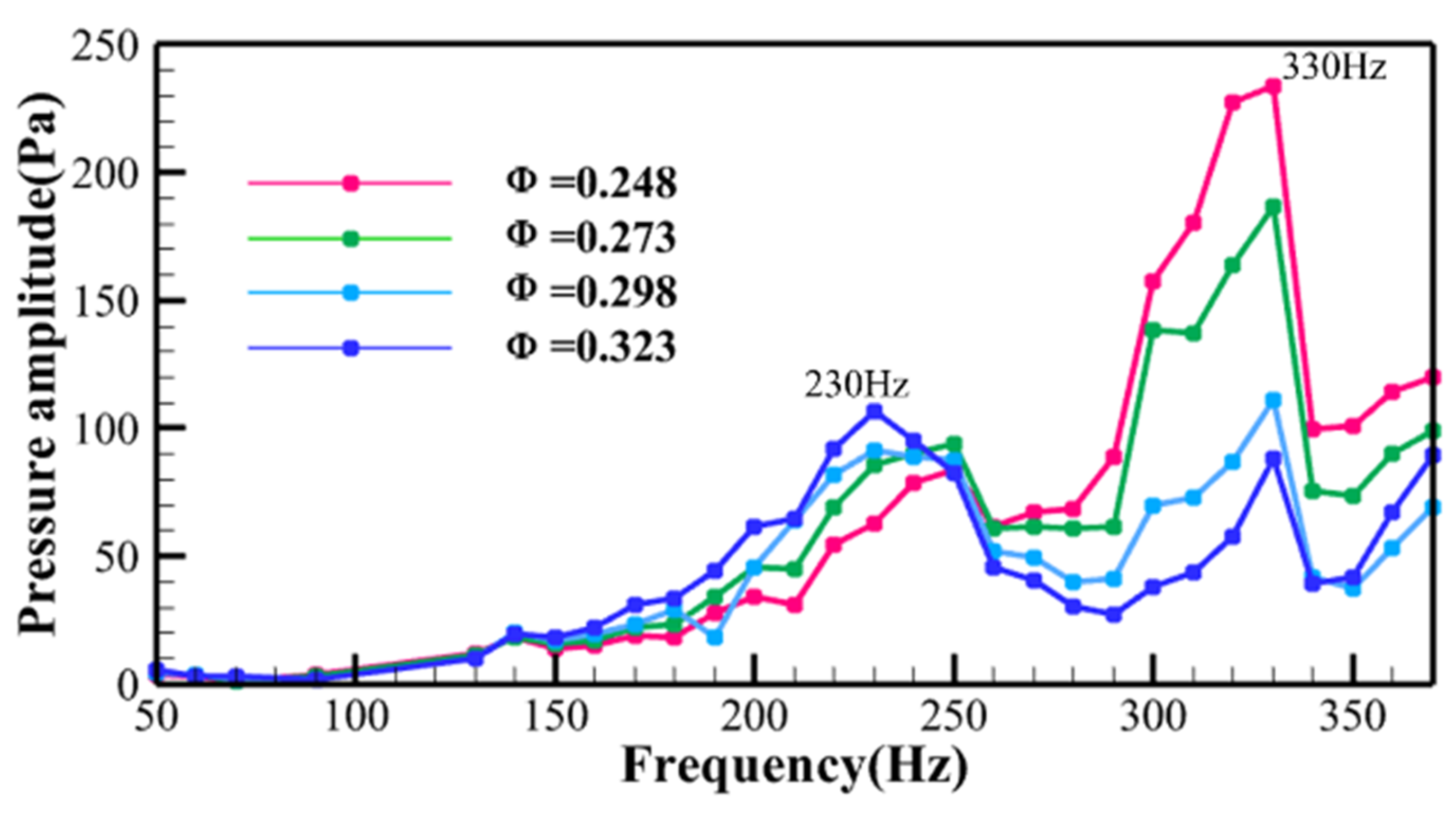

3.1. FTF Results

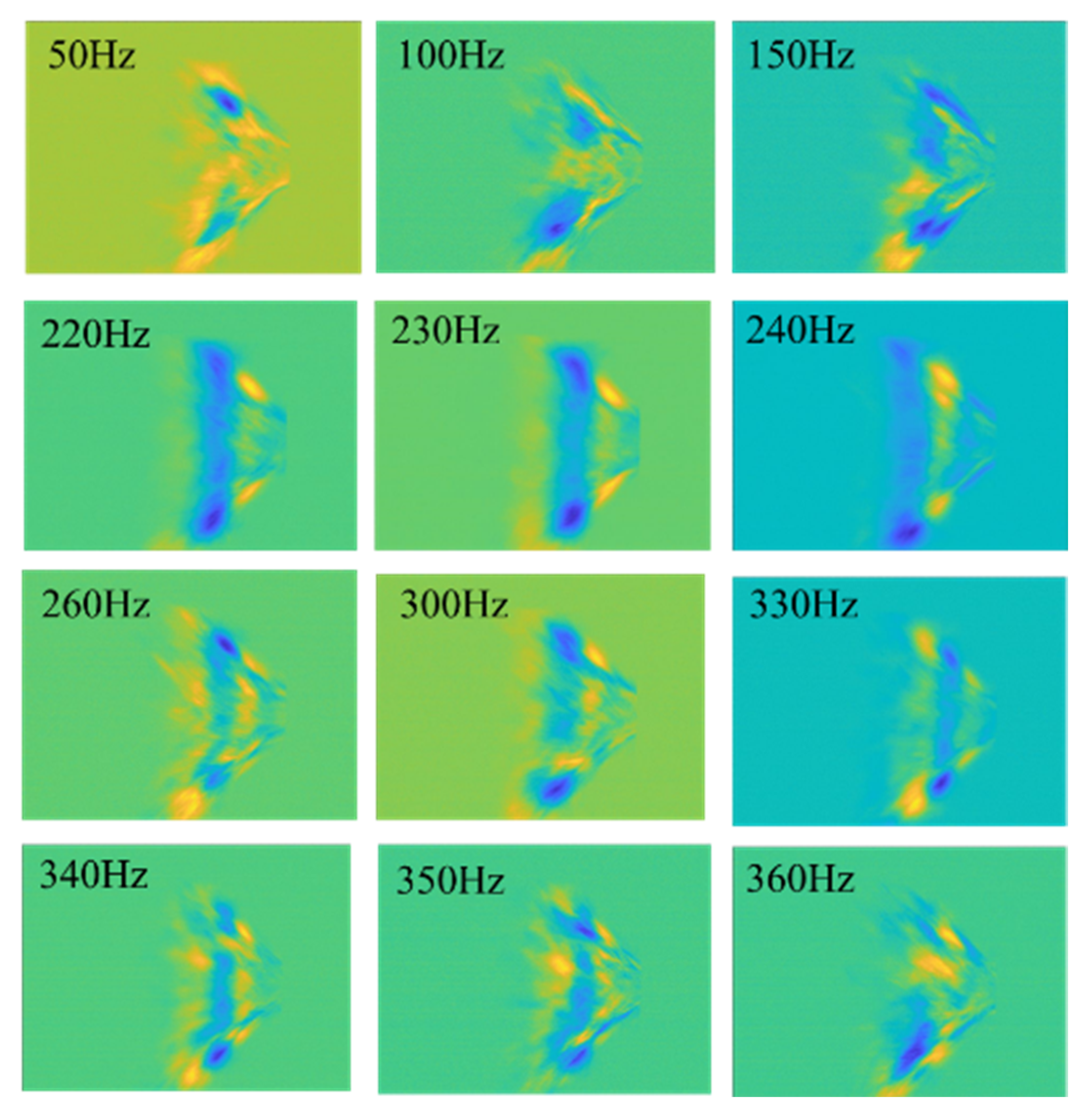

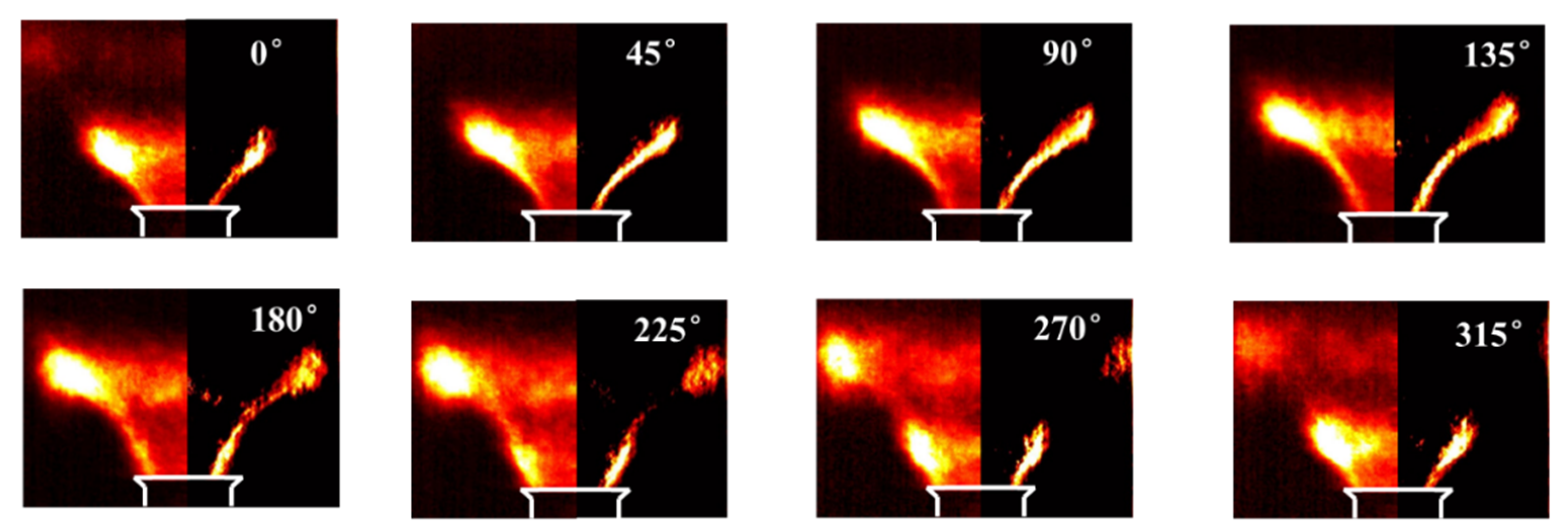

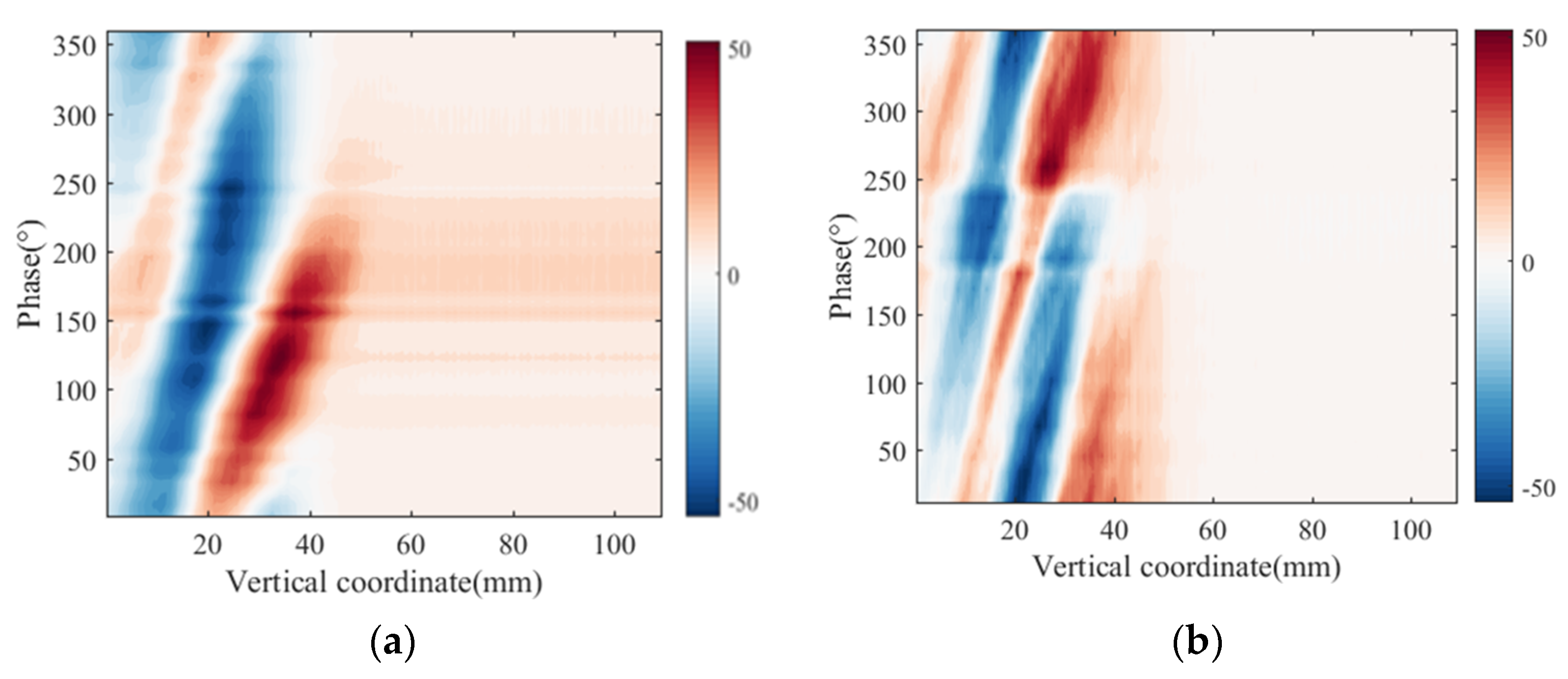

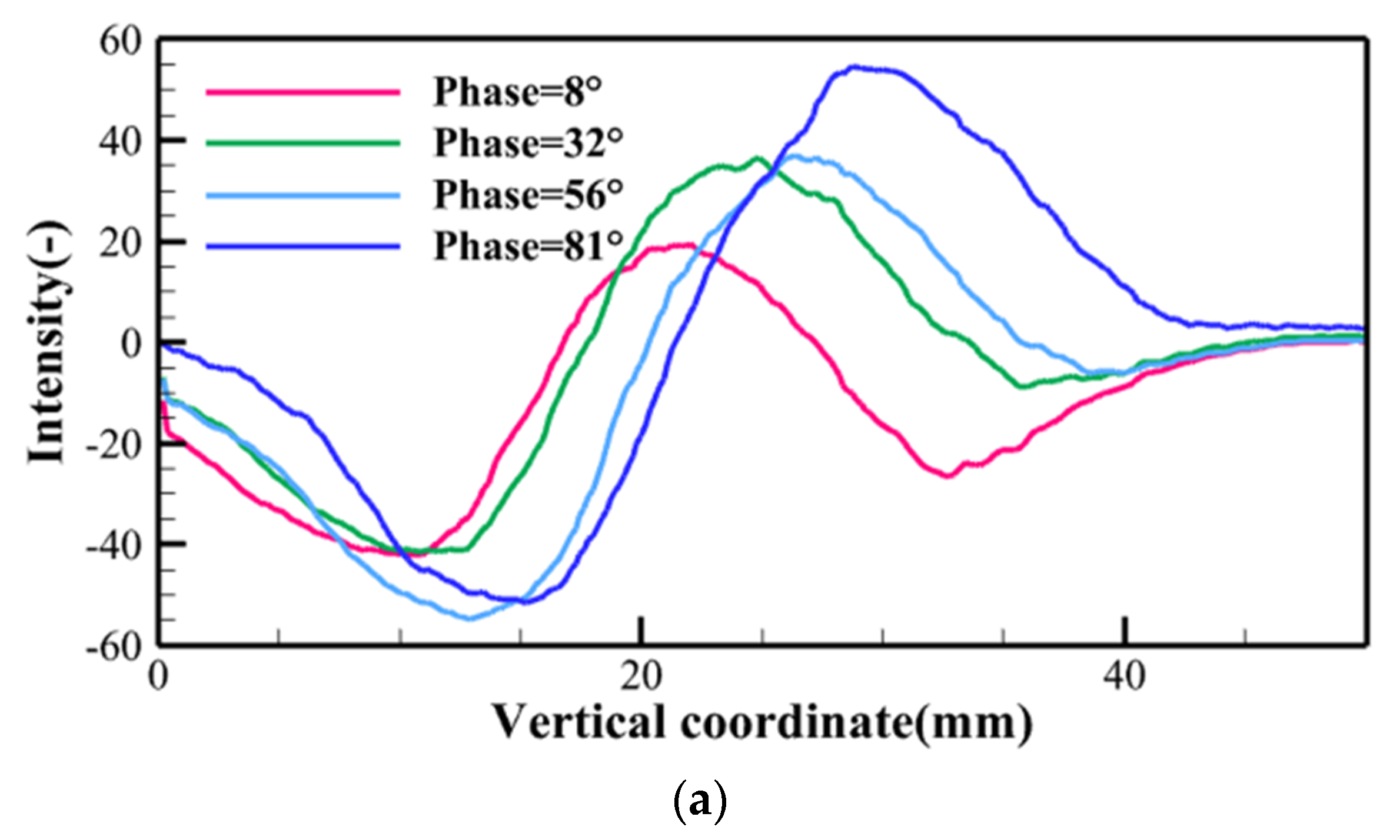

3.2. Flame Response Analysis

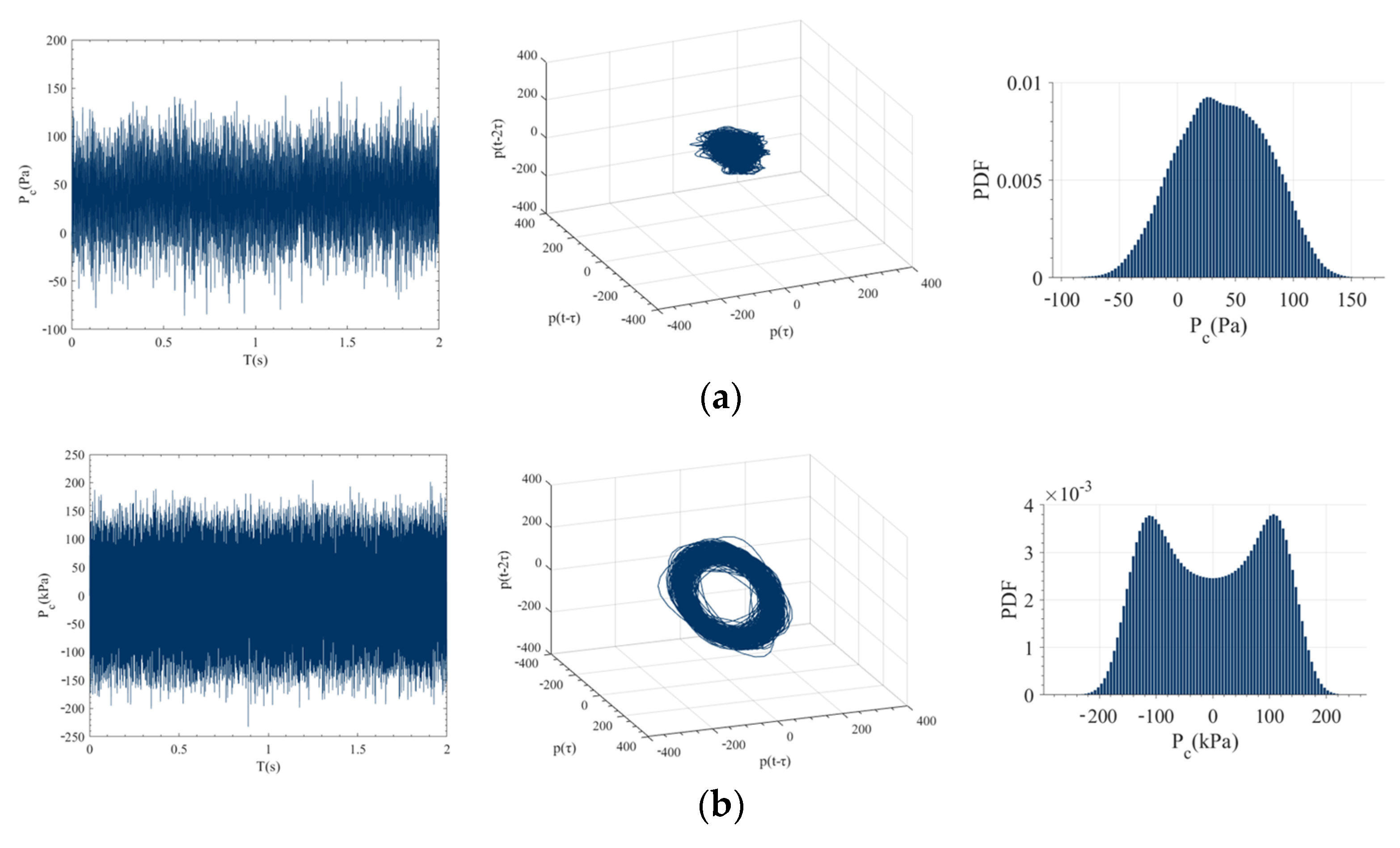

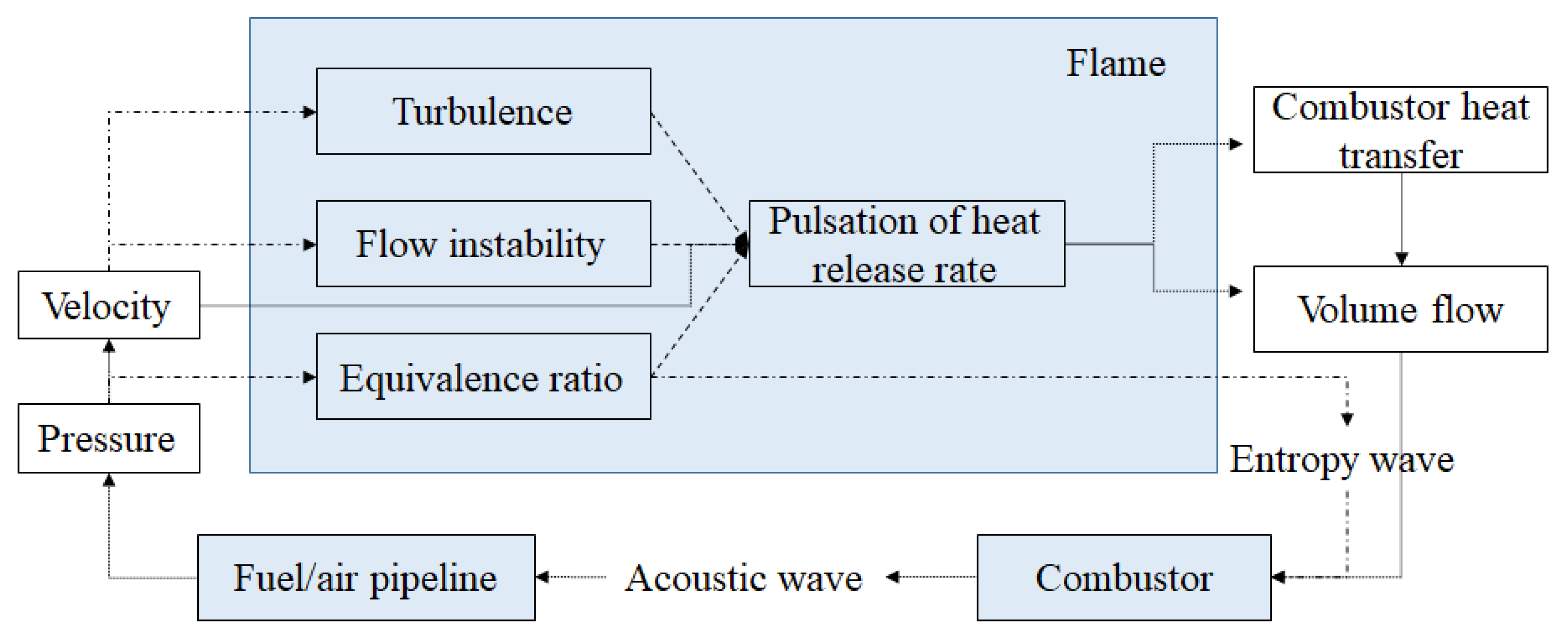

3.3. Coupling Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, X.; Zhang, G.; Wang, X.; Li, L.; Deng, X.; Cheng, R. Research Progress on Prediction and Control of Combustion Instability in Aeroengines. Acta Aeronaut. Astronaut. Sin. 2023, 44, 1–20. (In Chinese) [Google Scholar]

- O’Connor, J. Understanding the Role of Flow Dynamics in Thermoacoustic Combustion Instability. Proc. Combust. Inst. 2023, 39, 4583–4610. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, Y.; Li, J. Sinusoidal Approximation Active Control for Combustion Oscillation. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Nanjing, China, 20–23 May 2019. [Google Scholar]

- Litvinov, I.; Yoon, J.; Noren, C.; Stöhr, M.; Boxx, I.; Geigle, K.P. Time-resolved study of mixing and reaction in an aero-engine model combustor at increased pressure. Combust. Flame 2021, 231, 111474. [Google Scholar] [CrossRef]

- Tyagi, A.; Boxx, I.; Peluso, S.; O’Connor, J. The Role of Flow Interaction in Flame-Flame Interaction Events in a Dual Burner Experiment. Proc. Combust. Inst. 2019, 37, 2485–2491. [Google Scholar] [CrossRef]

- Ghani, A.; Steinbacher, T.; Albayrak, A.; Polifke, W. Intrinsic Thermo-Acoustic Feedback Loop in Turbulent Spray Flames. Combust. Flame 2019, 205, 22–32. [Google Scholar] [CrossRef]

- Sakaki, K.; Funahashi, T.; Nakaya, S.; Tsue, M.; Kanai, R.; Suzuki, K.; Inagawa, T.; Hiraiwa, T. Longitudinal Combustion Instability of a Pintle Injector for a Liquid Rocket Engine Combustor. Combust. Flame 2018, 194, 115–127. [Google Scholar] [CrossRef]

- Tan, W. Study on Thermoacoustic Coupling Characteristics of Model Afterburner. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Tachibana, S.; Saito, K.; Yamamoto, T.; Makida, M.; Kitano, T.; Kurose, R. Experimental and Numerical Investigation of Thermo-Acoustic Instability in a Liquid-Fuel Aero-Engine Combustor at Elevated Pressure: Validity of Large-Eddy Simulation of Spray Combustion. Combust. Flame 2015, 162, 2621–2637. [Google Scholar] [CrossRef]

- Erickson, R.R.; Soteriou, M.C. The Influence of Reactant Temperature on the Dynamics of Bluff Body Stabilized Premixed Flames. Combust. Flame 2011, 158, 2441–2457. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Sun, M.; Qin, N. Large-Eddy/Reynolds-Averaged Navier–Stokes Simulation of Combustion Oscillations in a Cavity-Based Supersonic Combustor. Int. J. Hydrogen Energy 2013, 38, 5918–5927. [Google Scholar] [CrossRef]

- Palies, P.; Durox, D.; Schuller, T.; Candel, S. Experimental Study on the Effect of Swirler Geometry and Swirl Number on Flame Describing Functions. Int. J. Hydrogen Energy 2011, 183, 704–717. [Google Scholar] [CrossRef]

- Han, X.; Morgans, A.S. Simulation of the Flame Describing Function of a Turbulent Premixed Flame Using an Open-Source LES Solver. Combust. Flame 2015, 162, 1778–1792. [Google Scholar] [CrossRef]

- Kim, T.; Ahn, M.; Lim, D.; Yoon, Y. Flame Describing Function and Combustion Instability Analysis of Non-Premixed Coaxial Jet Flames. Exp. Therm. Fluid Sci. 2022, 136, 110642. [Google Scholar] [CrossRef]

- Haeringer, M.; Merk, M.; Polifke, W. Inclusion of Higher Harmonics in the Flame Describing Function for Predicting Limit Cycles of Self-Excited Combustion Instabilities. Proc. Combust. Inst. 2019, 37, 5255–5262. [Google Scholar] [CrossRef]

- Silva, C.F.; Nicoud, F.; Schuller, T.; Durox, D.; Candel, S. Combining a Helmholtz Solver with the Flame Describing Function to Assess Combustion Instability in a Premixed Swirled Combustor. Combust. Flame 2013, 160, 1743–1754. [Google Scholar] [CrossRef]

- Ni, F.; Nicoud, F.; Méry, Y.; Staffelbach, G. Including Flow–Acoustic Interactions in the Helmholtz Computations of Industrial Combustors. AIAA J 2018, 56, 4815–4829. [Google Scholar] [CrossRef]

- Æsøy, E.; Nygård, H.T.; Worth, N.A.; Dawson, J.R. Tailoring the Gain and Phase of the Flame Transfer Function through Targeted Convective-Acoustic Interference. Combust. Flame 2022, 236, 111813. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, L.; Xue, R.; Yang, Q.; Wang, H. Experimental Investigation on Nonlinear Response of a Low-Swirl Flame to Acoustic Excitation with Large Amplitude. J. Eng. Gas Turbines Power 2021, 143, 121201. [Google Scholar] [CrossRef]

- Wang, G.; Zheng, J.; Li, L.; Liu, X.; Qi, F. Relationship of Gain and Phase in the Transfer Function of Swirling Flames. Proc. Combust. Inst. 2021, 38, 6173–6182. [Google Scholar] [CrossRef]

- Yoon, J.; Joo, S.; Kim, J.; Lee, M.C.; Lee, J.G.; Yoon, Y. Effects of Convection Time on the High Harmonic Combustion Instability in a Partially Premixed Combustor. Proc. Combust. Inst. 2017, 36, 3753–3761. [Google Scholar] [CrossRef]

- Hermeth, S.; Staffelbach, G.; Gicquel, L.Y.M.; Anisimov, V.; Cirigliano, C.; Poinsot, T. Bistable Swirled Flames and Influence on Flame Transfer Functions. Combust. Flame 2014, 161, 184–196. [Google Scholar] [CrossRef]

- Mejia, D.; Miguel-Brebion, M.; Ghani, A.; Kaiser, T.; Duchaine, F.; Selle, L.; Poinsot, T. Influence of Flame-Holder Temperature on the Acoustic Flame Transfer Functions of a Laminar Flame. Combust. Flame 2018, 188, 5–12. [Google Scholar] [CrossRef]

- Kaiser, T.L.; Öztarlik, G.; Selle, L.; Poinsot, T. Impact of Symmetry Breaking on the Flame Transfer Function of a Laminar Premixed. Proc. Combust. Inst. 2019, 37, 1953–1960. [Google Scholar] [CrossRef]

- Huber, A.; Polifke, W. Dynamics of Practical Premixed Flames, Part II: Identification and Interpretation of CFD Data. Int. J. Spray Combust. Dyn. 2009, 1, 229–249. [Google Scholar] [CrossRef]

- Lee, M.; Kim, K.T.; Gupta, V.; Li, L.K. System Identification and Early Warning Detection of Thermoacoustic Oscillations in a Turbulent Combustor Using Its Noise-Induced Dynamics. Proc. Combust. Inst. 2021, 38, 6025–6033. [Google Scholar] [CrossRef]

- Zhu, R.; Pan, D.; Ji, C.; Zhu, T.; Lu, P.; Gao, H. Combustion Instability Analysis on a Partially Premixed Swirl Combustor by Thermoacoustic Experiments and Modeling. Energy 2020, 211, 118884. [Google Scholar] [CrossRef]

- Æsøy, E.; Aguilar, J.G.; Wiseman, S.; Bothien, M.R.; Worth, N.A.; Dawson, J.R. Scaling and Prediction of Transfer Functions in Lean Premixed H2/CH4-Flames. Combust. Flame 2020, 215, 269–282. [Google Scholar] [CrossRef]

- Polifke, W.; Kopitz, J.; Serbanoviv, A. Impact of the Fuel Time Lag Distribution in Elliptical Premix Nozzles on Combustion Stability. In Proceedings of the 7th AIAA/CEAS Aeroacoustics Conference and Exhibit, Garching, Germany, 28–30 May 2001. [Google Scholar]

- Dupuy, F.; Gatti, M.; Mirat, C.; Gicquel, L.; Nicoud, F.; Schuller, T. Combining Analytical Models and LES Data to Determine the Transfer Function from Swirled Premixed Flames. Combust. Flame 2020, 217, 222–236. [Google Scholar] [CrossRef]

- You, D.; Huang, Y.; Yang, V. A Generalized Model of Acoustic Response of Turbulent Premixed Flame and Its Application to Gas-Turbine Combustion Instability Analysis. Combust. Sci. Technol. 2005, 177, 1109–1150. [Google Scholar] [CrossRef]

- Orchini, A.; Juniper, M.P. Linear Stability and Adjoint Sensitivity Analysis of Thermoacoustic Networks with Premixed Flames. Combust. Flame 2016, 165, 97–108. [Google Scholar] [CrossRef]

- Xu, Z. Basic Research on the Effects of Active Disturbance on Non-Premixed Combustion. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2022. (In Chinese). [Google Scholar]

- Huang, Y. Mechanism and Control of Thermoacoustic Instability in Non-Premixed Swirling Combustion. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2016. (In Chinese). [Google Scholar]

- Wiseman, S.; Gruber, A.; Dawson, J.R. Flame Transfer Functions for Turbulent, Premixed, Ammonia-Hydrogen-Nitrogen-Air Flames. J. Eng. Gas Turbines Power 2023, 145, 031015. [Google Scholar] [CrossRef]

- Vance, F.H.; Alanyalıoğlu, Ç.; Hasse, C. Analysis of Lewis number effects on dynamic response of laminar premixed flames. Combust. Flame 2023, 248, 112508. [Google Scholar] [CrossRef]

- Flores, E.; Muntean, V.; Pozo-Estivariz, D.; Martínez-Ruiz, D. Thermoacoustic coupling regions of premixed-flames in non-adiabatic tubes. Combust. Flame 2023, 247, 112478. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, V. Dynamics and Stability of Lean-Premixed Swirl-Stabilized Combustion. Prog. Energy Combust. Sci. 2009, 35, 293–364. [Google Scholar] [CrossRef]

- Åbom, M.; Bodén, H. Error Analysis of Two-Microphone Measurements in Ducts with Flow. J. Acoust. Soc. Am. 1988, 83, 2429–2438. [Google Scholar] [CrossRef]

- Nori, V.N.; Seitzman, J.M. CH* Chemiluminescence Modeling for Combustion Diagnostics. Proc. Combust. Inst. 2009, 32, 895–903. [Google Scholar] [CrossRef]

- Ahn, M.; Kim, T.; Yoon, Y. Comparison of Flame Response Characteristics between Non-Premixed and Premixed Flames under Acoustic Excitation. Exp. Therm. Fluid Sci. 2022, 139, 110707. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Han, Q.; Yan, Y. Study of Combustion Oscillation Mechanism and Flame Image Processing. AIAA J. 2019, 57, 824–835. [Google Scholar] [CrossRef]

- Keefer, D.R.; Smith, L.M.; Sudharsanan, S.I. Abel Inversion Using Transform Techniques. J. Quant. Spectrosc. Radiat. Transf. 1988, 39, 367–373. [Google Scholar]

- Liu, X.; Wang, G. Experimental Study of Periodic Flow Structure of Swirling Flames under Strong Acoustic Excitation. Exp. Fluid Mech. 2020, 34, 53–60. (In Chinese) [Google Scholar]

- Ge, Y.; Li, S.; Wei, X. Analysis of Laminar Diffusion Flame Combustion Instability Phenomena Using Phase Space Reconstruction Method. J. Eng. Thermophys. 2020, 41, 1550–1555. (In Chinese) [Google Scholar]

- Jiang, A.; Zhou, P.; Zhang, Y.; Hua, H. Improvement of Delay Time Mutual Information Algorithm for Phase Space Reconstruction. J. Vib. Shock 2015, 34, 79–84. (In Chinese) [Google Scholar]

- Han, M. Chaos Time Series Prediction Theory and Methods; China Water & Power Press: BeiJing, China, 2007. (In Chinese) [Google Scholar]

- Palies, P.; Durox, D.; Schuller, T.; Candel, S. The Combined Dynamics of Swirler and Turbulent Premixed Swirling Flames. Combust. Flame 2010, 157, 1698–1717. [Google Scholar] [CrossRef]

- Culick, F.E.C. Nonlinear Behavior of Acoustic Waves in Combustors—II. Acta Astronaut. 1976, 3, 735–757. [Google Scholar] [CrossRef]

- Gao, L. Study on Self-Excited Oscillations of Methane Premixed Flames under Open Space Conditions. Ph.D. Thesis, Chongqing University, Chongqing, China, 2021. (In Chinese). [Google Scholar]

- Wang, Y.; Zhu, M. Flame Dynamics and Its Influence on Thermoacoustic Stability. J. Tsinghua Univ. (Sci. Technol.) 2022, 62, 785–793. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Liu, Y.; Zhang, X.; Li, H.; Ge, X.; Jin, F.; Liu, C. Experimental Study on Flame Response Characteristics of a Non-Premixed Swirl Model Combustor. Energies 2023, 16, 6834. https://doi.org/10.3390/en16196834

Yang C, Liu Y, Zhang X, Li H, Ge X, Jin F, Liu C. Experimental Study on Flame Response Characteristics of a Non-Premixed Swirl Model Combustor. Energies. 2023; 16(19):6834. https://doi.org/10.3390/en16196834

Chicago/Turabian StyleYang, Chen, Yong Liu, Xiang Zhang, Hao Li, Xinkun Ge, Feng Jin, and Chongyang Liu. 2023. "Experimental Study on Flame Response Characteristics of a Non-Premixed Swirl Model Combustor" Energies 16, no. 19: 6834. https://doi.org/10.3390/en16196834