Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP

Abstract

1. Introduction

2. Background

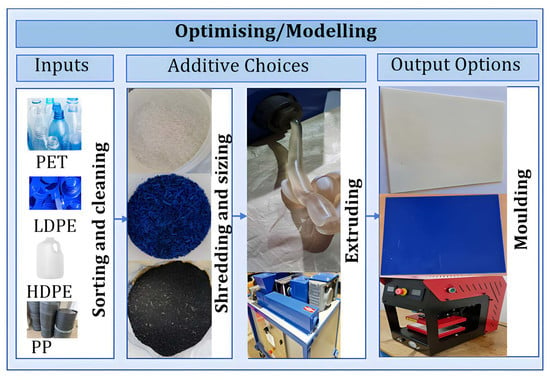

2.1. Scale of the Plastic Waste Problem

2.2. Small-Scale Plastics Recycling

3. Mechanical Recycling Processes

3.1. Separation and Sorting into Polymer Resin Types—Processes

3.1.1. Introduction to Polymer Separation

3.1.2. Automated Sorting

3.1.3. Manual Sorting

3.2. Decontamination/Cleaning

3.3. Shredding and Size Determination

4. Considerations for Effective Operation

4.1. Energy Demands of Machinery

4.2. Comparison of Capacity and Sizes of Extruders

| Single-Screw Option | Merits | Demerits |

|---|---|---|

| Leroy (Maddock) mixer | Mixing flight undercut of greater than 1% of the barrel diameter results in higher chances of resin degradation [143]. | |

| Pin mixing screw |

| A Maddock mixing section may also be required to improve thermal melt homogeneity after shearing [145]. |

| Vented extruder | Vent leakage and contamination are problems associated with the vented extruder [147]. | |

| Barrier screw |

| Conventional barrier screws are prone to shearing type mixing, which results in solid bed plugging; therefore, optimised barrier screw designs are needed to overcome it [148]. |

| Wave screw | Advanced designs of the wave screw, such as the double wave screw, may be needed for improved performance [137,149]. |

4.3. Moulding Machinery Selection

4.4. Modelling and Optimisation

| Reference | Polyolefin and Composites | Output |

|---|---|---|

| Wang et al. [185] |

| Mechanical properties of both materials decreased with increased recycling (reprocessing) of the polymer. The three-dimensional constitutive model used showed results on the propylene-based material’s mechanical performance. |

| Olesik et al. [186] |

| Wear resistance of the polyolefin can be enhanced with the addition of reinforcement. The addition of composites led to a slight increase in crystallinity compared to unreinforced LDPE. |

| Navarro et al. [187] |

| The addition of limited amounts of additives did not alter the stability and thermal properties of the recycled plastic mixture. Results in an economic improvement of the mechanical strength and value of the products. |

| Pulipati and Jack [188] |

| Material performance of the model showed a volume fraction of the glass fibres and the volume ratio of the closed-cell foams. |

| Li et al. [189] |

| The crystallisation temperatures changed when composites were added to PP compared to the pure PP. Moreover, there were fluctuations in the melting temperature using differential scanning calorimetry (DSC). Polarised optical microscopy (POM) analysis also showed a decrease in PP crystal size when EADP composites were added. |

5. Conclusions

5.1. Overview of Conclusions

5.2. Sorting, Cleaning, and Sizing

5.3. Managing Energy Requirements and Operation Cost

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Galovic, N. Life in Plastic, Not Fantastic: Reducing Waste in Our Oceans. In CSIROscope; (Online) CSIRO. 2019; Available online: https://blog.csiro.au/life-in-plastic-not-fantastic-reducing-waste-in-our-oceans (accessed on 15 May 2021).

- Barrett, J.; Chase, Z.; Zhang, J.; Holl, M.M.B.; Willis, K.; Williams, A.; Hardesty, B.D.; Wilcox, C. Microplastic pollution in deep-sea sediments from the Great Australian Bight. Front. Mar. Sci. 2020, 7, 808. [Google Scholar] [CrossRef]

- Belontz, L.S.; Corcoran, P.L.; Davis, H.; Hill, K.A.; Jazvac, K.; Robertson, K. Embracing an interdisciplinary approach to plastics pollution awareness and action. R. Swed. Acad. Sci. 2019, 48, 855–866. [Google Scholar] [CrossRef]

- Parker, L. We Made Plastic. We Depend on It. Now We’re Drowning in It. In National Geographic; (Online) National Geographic Society. 2018. Available online: https://www.nationalgeographic.co.uk/2018/05/we-made-plastic-we-depend-on-it-now-were-drowning-in-it (accessed on 17 May 2021).

- BBC. What Is the Problem with Plastic? Newsround. 2020. Available online: https://www.bbc.co.uk/newsround/42810179 (accessed on 18 October 2020).

- Gu, F.; Guo, J.; Zhang, W.; Summers, P.A.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total Environ. 2017, 601–602, 1192–1207. [Google Scholar] [CrossRef]

- PlasticsEurope. What Are Plastics? 2021. Available online: https://www.plasticseurope.org/en/about-plastics/what-are-plastics (accessed on 1 April 2021).

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of recycling, properties and applications of recycled thermoplastic polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Hale, A. Chapter 9—Thermosets. In Handbook of Thermal Analysis and Calorimetry; Cheng, S.Z.D., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2002; pp. 295–354. [Google Scholar]

- OSBORNE. Primary difference between thermoplastic and thermoset. In RIM; Osborne Industries Inc.: Osborne, KS, USA, 2017; Available online: https://www.osborneindustries.com/news/difference-between-thermoplastic-thermosetting-plastic/ (accessed on 27 November 2020).

- Amin, S.; Amin, M. Thermoplastic elastomeric (TPE) materials and their use in outdoor electrical insulation. Rev. Adv. Mater. Sci. 2011, 29, 15–30. [Google Scholar]

- Kumar, R. Tertiary and quaternary recycling of thermoplastics by additive manufacturing approach for thermal sustainability. Mater. Today Proc. 2020, 37, 2382–2386. [Google Scholar] [CrossRef]

- Zaferani, S.H. 1—Introduction of polymer-based nanocomposites. In Polymer-based Nanocomposites for Energy and Environmental Applications; Jawaid, M., Khan, M.M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 1–25. [Google Scholar]

- Biron, M. Thermoplastics and Thermoplastic Composites; William Andrew: Oxford, UK, 2018; ISBN 9780081025024. [Google Scholar]

- Lee, A.; Liew, M.S. Tertiary recycling of plastics waste: An analysis of feedstock, chemical and biological degradation methods. J. Mater Cycles Waste Manag. 2020, 23, 32–43. [Google Scholar] [CrossRef]

- Posch, W. 3—Polyolefins. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; William Andrew Publishing: Oxford, UK, 2011; pp. 23–48. [Google Scholar]

- Gahleitner, M. Melt rheology of polyolefins. Prog. Polym. Sci. 2001, 26, 895–944. [Google Scholar] [CrossRef]

- Franssen, N.M.G.; Reek, J.N.H.; de Bruin, B. Synthesis of functional ‘polyolefins’: State of the art and remaining challenges. Chem. Soc. Rev. 2013, 42, 5809–5832. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, S.; Matsugi, T.; Saito, J.; Kawahara, N.; Kaneko, H.; Kashiwa, N. 1—Creation of new polyolefin hybrids on the surface of molded polypropylene sheet. In Studies in Surface Science and Catalysis; Shiono, T., Nomura, K., Terano, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–6. [Google Scholar]

- Biron, M. 3—Thermoplastics: Economic overview. In Material Selection for Thermoplastic Parts; Biron, M., Ed.; William Andrew Publishing: Oxford, UK, 2016; pp. 77–111. [Google Scholar]

- ASTM International. ASTM Plastics Committee Releases Major Revisions to Resin Identification Code (RIC) Standard. 2013. Available online: https://newsroom.astm.org/astm-plastics-committee-releases-major-revisions-resin-identification-code-ric-standard (accessed on 27 November 2020).

- ASTM D7611 / D7611M—20; Standard Practice for Coding Plastic Manufactured Articles for Resin Identification. ASTM International: West Conshohocken, PA, USA, 2020.

- SPI. SPI Resin Identification Code—Guide to Correct Use. Available online: https://web.archive.org/web/20160126213345/http://www.plasticsindustry.org/AboutPlastics/content.cfm?ItemNumber=823&navItemNumber=1125 (accessed on 18 October 2020).

- Williams, A.T.; Rangel-Buitrago, N. Marine litter: Solutions for a major environmental problem. J. Coast. Res. 2019, 35, 648–663. [Google Scholar] [CrossRef]

- Jacobsen, R.; Willeghems, G.; Gellynck, X.; Buysse, J. Increasing the quantity of separated post-consumer plastics for reducing combustible household waste: The case of rigid plastics in Flanders. Waste Manag. 2018, 78, 708–716. [Google Scholar] [CrossRef]

- Hannay, F. Rigid Plastics Packaging: Materials, Processes and Applications; Rapra Publishing: Shropshire, UK, 2002; Volume 151. [Google Scholar]

- Hapeman, P.; Fugh, A.; Falk, E.; Case, R.; Yeatter, D.; Balasubramanian, G.; Mehta, K. Community Approaches To Recycling Plastics. Community approaches to recycling plastics. In Proceedings of the 2019 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 17–20 October 2019; pp. 1–7. [Google Scholar]

- Rhodes, C.J. Solving the plastic problem: From cradle to grave, to reincarnation. Sci. Prog. 2019, 102, 218–248. [Google Scholar] [CrossRef]

- Ignatyev, I.A.; Thielemans, W.; Vander Beke, B. Recycling of polymers: A review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef]

- D’Ambrières, W. Plastics recycling worldwide: Current overview and desirable changes. Field Actions Sci. Rep. 2019, 19, 12–21. [Google Scholar]

- Hopewell, J.R.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond. B Bio. Sci. 2009, 364, 2115. [Google Scholar] [CrossRef]

- Bravo, M.; de los Ángeles Gallardo, M.; Luna-Jorquera, G.; Núñez, P.; Vásquez, N.; Thiel, M. Anthropogenic debris on beaches in the SE Pacific (Chile): Results from a national survey supported by volunteers. Mar. Pollut. Bull. 2009, 58, 1718–1726. [Google Scholar] [CrossRef]

- Nkwachukwu, O.; Chima, C.H.; Ikenna, A.O.; Albert, L. Focus on potential environmental issues on plastic world towards a sustainable plastic recycling in developing countries. Inter. J. Ind. Chem. 2013, 4, 34. [Google Scholar] [CrossRef]

- Bender, M. An Earth Law Solution to Ocean Plastic Pollution. Earth Law Center. 2018. Available online: https://www.earthlawcenter.org/blog-entries/2018/3/an-earth-law-solution-to-ocean-plastic-pollution (accessed on 11 December 2020).

- Center for International Environmental Law. Sweeping New Report on Global Environmental Impact of Plastics Severe Damage to Climate. Press Room. 2019. Available online: https://www.ciel.org/news/plasticandclimate/ (accessed on 12 January 2021).

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A. Marine pollution. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Rhodes, C.J. Plastic pollution and potential solutions. Sci. Prog. 2018, 101, 207–260. [Google Scholar] [CrossRef] [PubMed]

- Ghayebzadeh, M.; Aslani, H.; Taghipour, H.; Mousavi, S. Estimation of plastic waste inputs from land into the Caspian Sea: A significant unseen marine pollution. Mar. Poll. Bull. 2020, 151, 110871. [Google Scholar] [CrossRef] [PubMed]

- Borrelle, S.B.; Rochman, C.M.; Liboiron, M.; Bond, A.L.; Lusher, A.; Bradshaw, H.; Provencher, J.F. Opinion: Why we need an international agreement on marine plastic pollution. Proc. Natl. Acad. Sci. USA 2017, 114, 9994. [Google Scholar] [CrossRef] [PubMed]

- Lamb, J.B.; Willis, B.L.; Fiorenza, E.A.; Couch, C.S.; Howard, R.; Rader, D.N.; True, J.D.; Kelly, L.A.; Ahmad, A.; Jompa, J.; et al. Plastic waste associated with disease on coral reefs. Science 2018, 359, 460. [Google Scholar] [CrossRef]

- Brandon, J.A.; Jones, W.; Ohman, M.D. Multidecadal increase in plastic particles in coastal ocean sediments. Sci. Adv. 2019, 5, eaax0587. [Google Scholar] [CrossRef]

- Oberbeckmann, S.; Löder, M.G.; Labrenz, M. Environmental Chemistry; Findings on Environmental Chemistry Discussed by Investigators at University of Bayreuth (Marine Microplastic- Associated Biofilms—A Review); NewsRx: Atlanta, GA, USA, 2015; p. 151. [Google Scholar]

- De Tender, C.A.; Devriese, L.I.; Haegeman, A.; Maes, S.; Ruttink, T.; Dawyndt, P. Bacterial community profiling of plastic litter in the Belgian Part of the North Sea. Environ. Sci. Technol. 2015, 49, 9629–9638. [Google Scholar] [CrossRef]

- Do Sul, J.A.I.; Costa, M.F. The present and future of microplastic pollution in the marine environment. Enviro. Pollut. 2014, 185, 352–364. [Google Scholar] [CrossRef]

- Browne, M.A.; Crump, P.; Niven, S.J.; Teuten, E.; Tonkin, A.; Galloway, T.; Thompson, R. Accumulation of microplastic on shorelines woldwide: Sources and sinks. Environ. Technol. 2011, 45, 9175–9179. [Google Scholar] [CrossRef]

- Moore, C.J. Synthetic polymers in the marine environment: A rapidly increasing, long-term threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef]

- Pegado, T.S.E.S.; Schmid, K.; Winemiller, K.O.; Chelazzi, D.; Cincinelli, A.; Dei, L.; Giarrizzo, T. First evidence of microplastic ingestion by fishes from the Amazon River estuary. Mar. Poll. Bull. 2018, 133, 814–821. [Google Scholar] [CrossRef] [PubMed]

- Cole, M.; Lindeque, P.; Halsband, C.; Galloway, T.S. Microplastics as contaminants in the marine environment: A review. Mar. Poll. Bull. 2011, 62, 2588–2597. [Google Scholar] [CrossRef] [PubMed]

- Lehtiniemi, M.; Hartikainen, S.; Näkki, P.; Engström-Öst, J.; Koistinen, A.; Setälä, O. Size matters more than shape: Ingestion of primary and secondary microplastics by small predators. Food Webs 2018, 17, e00097. [Google Scholar] [CrossRef]

- Silvenius, F.; Grönman, K.; Katajajuuri, J.M.; Soukka, R.; Koivupuro, H.K.; Virtanen, Y. The role of household food waste in comparing environmental impacts of packaging alternatives. Packag. Technol. Sci. 2014, 27, 277–292. [Google Scholar] [CrossRef]

- Iñiguez, M.E.; Conesa, J.A.; Fullana, A. Recyclability of four types of plastics exposed to UV irradiation in a marine environment. Waste Manag. 2018, 79, 339–345. [Google Scholar] [CrossRef]

- Locock, K.E.S.; Deane, J.; Kosior, E.; Prabaharan, H.; Skidmore, M.; Hutt, O.E. The Recycled Plastics Market: Global Analysis and Trend; CSIRO: Canberra, Australia, 2017. [Google Scholar]

- Le, A.T.; Doan, H.D.; Ngo, L.P.; Huynh, L.T.; Huynh, T.N.; Thanh, T.T. A conceptual design and numerical analysis for a small–scale and low–cost plastic recycling Machine. E3S Web Conf. 2019, 93, 02007. [Google Scholar] [CrossRef]

- Beston (Henan) Machinery Co. Small Scale Plastic Recycling Plant. 2021. Available online: https://bestonpyrolysisplant.com/small-scale-plastic-recycling-plant/ (accessed on 12 March 2021).

- Lardinois, I.; van de Klundert, A. Plastic Waste: Options for Small-Scale Resource Recovery; TOOL Publications: Amsterdam, The Netherlands, 1995. [Google Scholar]

- ISO 15270; Plastics—Guidelines for the Recovery and Recycling of Plastics Waste. International Organization for Standardization: Geneva, Switzerland, 2008.

- Solis, M.; Silveira, S. Technologies for chemical recycling of household plastics—A technical review and TRL assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Sadat-Shojai, M.; Bakhshandeh, G.R. Recycling of PVC wastes. Polym. Degrad. Stab. 2011, 96, 404–415. [Google Scholar] [CrossRef]

- Fisher, M. Plastic Recycling. In Plastics and the Environment; Andrady, A.L., Ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2004; ISBN 0471095206. [Google Scholar]

- Hundertmark, T.; Mayer, M.; McNally, C.; Simons, T.J.; Witte, C. How plastics waste recycling could transform the chemical industry, In Chemicals; (Online) McKinsey & Company. 2018, Volume 12, p. 1. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Chemicals/Our%20Insights/How%20plastics%20waste%20recycling%20could%20transform%20the%20chemical%20industry/How-plastics-waste-recycling-could-transform.pdf (accessed on 12 January 2021).

- Chen, S.; Liu, Z.; Jiang, S.; Hou, H. Carbonization: A feasible route for reutilization of plastic wastes. Sci. Total Environ. 2020, 710, 136250. [Google Scholar] [CrossRef]

- Michael, T. 2—Environmental and social impacts of waste to energy (WTE) conversion plants. In Waste to Energy Conversion Technology; Klinghoffer, N.B., Castaldi, M.J., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 15–28. [Google Scholar]

- Patni, N.; Shah, P.; Agarwal, S.; Singhal, P. Alternate strategies for conversion of waste plastic to fuels. ISRN Renew. Energy 2013, 2013, 902053. [Google Scholar] [CrossRef]

- Ragaert, K. Trends in mechanical recycling of thermoplastics. In Kunststoff Kolloquium Leoben; Pinter, G., Pilz, G., Eds.; Leoben, Austria, 2016; pp. 159–165. ISBN 978-3-9503248-5-3. Available online: https://www.researchgate.net/publication/302583613_Trends_in_Mechanical_Recycling_of_Thermoplastics (accessed on 12 January 2021).

- Daniels, S. Small scale recycling and its huge scale impact. In Let’s Talk Trash; Repurpose: New York, NY, USA, 2019; Available online: https://repurpose.global/blog/post/small-scale-recycling-makes-a-huge-difference (accessed on 22 November 2020).

- Hakkens, D. Extrude Beams from Plastic Waste. 2017. Available online: https://www.youtube.com/watch?v=zNGuuSKE1pY&t=160s (accessed on 12 November 2020).

- Plastic Collective. We Help Establish Community Operated Plastic Recycling Micro-Enterprises. 2020. Available online: https://www.plasticcollective.co/resource-recovery/ (accessed on 15 November 2020).

- Yin, S.; Tuladhar, R.; Shi, F.; Shanks, R.A.; Combe, M.; Collister, T. Mechanical reprocessing of polyolefin waste: A review. Polym. Engineer. Sci. 2015, 55, 2899–2909. [Google Scholar] [CrossRef]

- Horvath, B.; Mallinguh, E.; Fogarassy, C. Designing business solutions for plastic waste management to enhance circular transitions in Kenya. Sustainability 2018, 10, 1664. [Google Scholar] [CrossRef]

- Ito, M.; Tsunekawa, M.; Ishida, E.; Kawai, K.; Takahashi, T.; Abe, N.; Hiroyoshi, N. Reverse jig separation of shredded floating plastics—Separation of polypropylene and high density polyethylene. Int. J. Miner. Process. 2010, 97, 96–99. [Google Scholar] [CrossRef]

- Wahab, D.A.; Hussain, A.; Scavino, E.; Mustafa, M.M.; Basri, H. Development of a prototype automated sorting system for plastic recycling. Am. J. Appl. Sci. 2006, 3, 1924–1928. [Google Scholar] [CrossRef]

- Albinsson, M.; Liovin, A. Plastic Sorting—An Evaluation of the Methods Used in Today’s Recycling Business; Engineering Plastic Recycling: Bergamo, Italy, 2005. [Google Scholar]

- Pringle, R.T.; Barker, M.B. Starting a Waste Plastics Recycling Business. In Aberdeen Forward and Aberdeenshire Council; Napier University: Edinburgh, UK, 2004. [Google Scholar]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef]

- Commonwealth of Australia. Analysis of Australia’a Municipal Recycling Infrastructure Capacity; Department of the Environment and Energy: Canberra, Australia, 2018. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/recycling-infrastructure-capacity-report (accessed on 15 March 2021).

- Froelich, D.; Maris, E.; Haoues, N.; Chemineau, L.; Renard, H.; Abraham, F.; Lassartesses, R. State of the art of plastic sorting and recycling: Feedback to vehicle design. Miner. Engineer. 2007, 20, 902–912. [Google Scholar] [CrossRef]

- Martínez, S.S.; Paniza, J.L.; Ramírez, M.C.; Ortega, J.G.; García, J.G. A sensor fusion-based classification system for thermoplastic recycling. In 18th International Conference on Automation and Computing (ICAC); IEEE: Loughborough, UK, 2012. [Google Scholar]

- 4R Sustainability Inc. Demingling the Mix: An Assessment of Commercially Available Automated Sorting Technology; American Chemistry Council: Portland, OR, USA, 2011. [Google Scholar]

- Eriksen, M.K.; Astrup, T.F. Characterisation of source-separated, rigid plastic waste and evaluation of recycling initiatives: Effects of product design and source-separation system. Waste Manag. 2019, 87, 161–172. [Google Scholar] [CrossRef]

- Neidel, T.L.; Jakobsen, J.B. Report on Assessment of Relevant Recycling Technologies; Plastic ZERO—Public Private Cooperations for Avoiding Plastic as a Waste; Lyngby, DK, USA. 2013. Available online: https://docplayer.net/79041951-Report-on-initial-assessment-of-relevant-recycling-technologies.html (accessed on 15 March 2021).

- Andersen, L.; Wejdling, A.; Neidel, T.L. Plastic Sorting at Recycling Centres: Background Report; Nordic Council of Ministers: Copenhagen, Denmark, 2015; p. 62. [Google Scholar]

- Safavi, S.M.; Masoumi, H.; Mirian, S.S.; Tabrizchi, M. Sorting of polypropylene resins by color in MSW using visible reflectance spectroscopy. Waste Manag. 2010, 30, 2216–2222. [Google Scholar] [CrossRef] [PubMed]

- Ruj, B.; Pandey, V.; Jash, P.; Srivastava, V.K. Sorting of plastic waste for effective recycling. Int. J. Appl. Sci. Engineer. Res. 2015, 4, 564–571. [Google Scholar]

- Jimoh, K.; Ajayi, A.; Ayilara, O. Intelligent model for manual sorting of plastic wastes. Inter. J. Comput. Appl. 2014, 101, 20–26. [Google Scholar] [CrossRef]

- CWC. Best Practices in PET Recycling: Manual Sorting Systems; (Online) Clean Washington Center. 1997. Available online: https://p2infohouse.org/ref/14/13522.pdf (accessed on 20 May 2021).

- Braun, D. Simple Methods for Identification of Plastics, 5th ed.; Hanser Publishers: Munich, Germany, 2013; ISBN 978-1-56990-542-5. [Google Scholar]

- TWI Ltd. How, Using Simple Manual Tests, Can I Identify an Unknown Plastic Material? Available online: https://www.twi-global.com/technical-knowledge/faqs/faq-how-using-simple-manual-tests-can-i-identify-an-unknown-plastic-material (accessed on 26 September 2020).

- Wanga, H.; Zhanga, Y.; Wang, C. Surface Modification and Selective Flotation of Waste Plastics for Effective Recycling—A Review. Sep. Purif. Technol. 2019, 226, 75–94. [Google Scholar] [CrossRef]

- Katz, D.A. Identification of Polymers; American Plastics Council and National Middle Level Science Teachers Association: Tucson, AZ, USA, 1998. [Google Scholar]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central sorting and recovery of MSW recyclable materials: A review of technological state-of-the-art, cases, practice and implications for materials recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef] [PubMed]

- Groh, K. Decontamination of Recycled Polyolefins: Scientists Review Decontamination of Recycled Polyolefins, Compare it to PET; Existing Processes Need Re-Examination Using High Molecular Weight Surrogate Contaminants. Migration, Modeling, PET, Polyolefins, Recycling 2016. Available online: https://www.foodpackagingforum.org/news/decontamination-of-recycled-polyolefins (accessed on 3 October 2020).

- Krones (Thailand) Co. Ltd. Washing and recycling of PET and PO plastics. In Sustainability Matters; Westwick-Farrow Media: New South Wales, Australia, 2019; Available online: https://www.sustainabilitymatters.net.au/content/waste/case-study/washing-and-recycling-pet-and-po-plastics-983708727 (accessed on 3 October 2020).

- Krehula, L.K.; Siročić, A.P.; Dukić, M.; Hrnjak-Murgić, Z. Cleaning efficiencyof poly(ethyleneterephthalate) washing procedure in recycling process. J. Elastomers Plast. 2012, 45, 429–444. [Google Scholar] [CrossRef]

- Amos, J.M. Cleaning up the Waste Stream—Recycling Plastics; University of Missouri Extension: Columbia, MO, USA, 1993. [Google Scholar]

- Picuno, C.; Alassali, A.; Sundermann, M.; Godosi, Z.; Picuno, P.; Kuchta, K. Decontamination and recycling of agrochemical plastic packaging waste. J. Hazard. Mater. 2020, 381, 120965. [Google Scholar] [CrossRef]

- Hossain, S.; Mozumder, S.I. Post consumer polyethylene terephthalate (PET) recycling in Bangladesh through optimization of hot washing parameters. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2018, 40, 62–76. [Google Scholar]

- Welle, F. Decontamination efficiency of a new post-consumer poly(ethylene terephthalate) (PET) recycling concept. Food Addit. Contam. 2008, 25, 123–131. [Google Scholar] [CrossRef]

- Santana, R.M.C.; Gondim, G. Influence of cleaning conditions on the degradation of recycled HDPE. J. Appl. Polym. Sci. 2009, 112, 1454–1460. [Google Scholar] [CrossRef]

- Soto, J.M.; Martín-Lara, M.A.; Blázquez, G.; Godoy, V.; Quesada, L.; Calero, M. Novel pre-treatment of dirty post-consumer polyethylene film for its mechanical recycling. Process Saf. Environ. Prot. 2020, 139, 315–324. [Google Scholar] [CrossRef]

- Palkopoulou, S.; Joly, C.; Feigenbaum, A.; Papaspyrides, C.D.; Dole, P. Critical review on challenge tests to demonstrate decontamination of polyolefins intended for food contact applications. Trends Food Sci. Technol. 2016, 49, 110–120. [Google Scholar] [CrossRef]

- Garcia, P.; Cruz, S.; Nerín, C. Comparison of Different Extrusion Processes for Cleaning the Recycled Polypropylene Removing Volatile and Non-volatile Contaminants. Prog. Rubber Plast. Recycl. Technol. 2014, 30, 37–53. [Google Scholar] [CrossRef]

- Shent, H.; Pugh, R.J.; Forssberg, E. A review of plastics waste recycling and the flotation of plastics. Resour. Conserv. Recycl. 1999, 25, 85–109. [Google Scholar] [CrossRef]

- Altieri, V.G.; DeSanctus, M.; Sgherza, D.; Pentassuglia, S.; Barca, E.; Di laconi, C. Treating and reusing wastewater generated by the washing operations in the non-hazardous plastic solid waste recycling process: Advanced method vs. conventional method. J. Environ. Mgmt. 2021, 284, 112011. [Google Scholar] [CrossRef] [PubMed]

- Benabderrahmane, A.; Zeghloul, T.; Aksa, W.; Tilmatine, A.; Medles, K.; Dascalescu, L. Shredding as simultaneous size-reduction and tribo-charging operation for improved performances of an electrostatic separation process for granular plastic waste. Part. Sci. Technol. 2019, 38, 827–834. [Google Scholar] [CrossRef]

- El-Haggar, S.M. Sustainable Industrial Design and Waste Management: Cradle-to-Cradle for Sustainable Development; Elsevier Ltd.: Burlington, MA, USA, 2007; p. 424. [Google Scholar]

- Cruz-Estrada, R.H.; Martínez-Tapia, G.E.; Canché-Escamilla, G.; González-Chí, P.I.; Martín-Barrera, C.; Duarte-Aranda, S.; Guillén-Mallette, J.; Cupul-Manzano, C.V.; Martínez-Domínguez, O.; García-Gómez, C. A preliminary study on the preparation of wood–plastic composites from urban wastes generated in Merida, Mexico with potential applications as building materials. Waste Manag. Res. 2010, 28, 838–847. [Google Scholar] [CrossRef]

- Khait, K. Solid-State Shear Extrusion Pulverization for Recycling Commingled Plastic Waste; Polymer Reclamation Center at BIRL, Northwestern University: Evanston, IL, USA, 2003. [Google Scholar]

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef]

- Pacheco, E.B.; Ronchetti, L.M.; Masanet, E. An overview of plastic recycling in Rio de Janeiro. Resour. Conserv. Recycl. 2012, 60, 140–146. [Google Scholar] [CrossRef]

- Maisel, F.; Chancerel, P.; Dimitrova, G.; Emmerich, J.; Nissen, N.F.; Schneider-Ramelow, M. Preparing WEEE plastics for recycling—How optimal particle sizes in preprocessing can improve the separation efficiency of high quality plastics. Resour. Conserv. Recycl. 2020, 154, 104619. [Google Scholar] [CrossRef]

- De Grano, C.J.A.; Achas, J.C.B.; Caidic, G.P.N.; Mejia, J.M.B.; Saiyari, D.M.; Lictaoa, C.S. Utilization of Recycled Plastic Bottle Caps with Calcium Carbonate Additives as Potential Construction Material. In Proceedings of the 2015 International Conference on Environmental Quality Concern, Control and Conservation, Kaohsiung, Taiwan, 7–8 May 2015. [Google Scholar]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Hanna, E. Recycling of waste mixed plastics blends (PE/PP). J. Eng. Sci. Technol. Rev. 2019, 12, 87–92. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- University of California. Plastic’s Carbon Footprint: Researchers Conduct First Global Assessment of the Life Cycle Greenhouse Gas Emissions from Plastics. ScienceDaily. Available online: https://www.sciencedaily.com/releases/2019/04/190415144004.htm (accessed on 15 April 2021).

- Frankland, J. How Much Horsepower Do You Need? In Plastics Technology; Gardner Business Media: Cincinnati, OH, USA, 2009; Available online: https://www.ptonline.com/articles/how-much-horsepower-do-you-need (accessed on 15 November 2020).

- Plastics Institute of America. Plastics Institute of America Plastics Engineering, Manufacturing & Data Handbook; Rosato, D.V., Schott, N.R., Rosato, M.G., Eds.; Kluwer Academic Publishers: Norwell, MA, USA, 2001; Volume 2, ISBN 0-7923-7316-2. [Google Scholar]

- Deng, J.; Harkin-Jones, E.; Price, M.; Karnachi, N.; Kelly, A.; Vera-Sorroche, J.; Coates, P.; Brown, E.; Fei, M. Energy monitoring and quality control of a single screw extruder. Appl. Ener. 2014, 113, 1775–1785. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P. Feedstock Recycling of Plastic Wastes; Royal Society of Chemistry: Cambridge, UK, 1999; Volume 1, ISBN 0-85404-531-7. [Google Scholar]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Mallouk, R.S.; McKelvey, J.M. Power requirements of melt extruders. Indust. Engineer. Chem. 1953, 45, 987–989. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Vera-Sorroche, J.; Coates, P.D.; Harkin-Jones, E.; Howell, K.B.; Deng, J.; Li, K.; Price, M. Investigation of the process energy demand in polymer extrusion: A brief review and an experimental study. Appl. Energ. 2014, 136, 726–737. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Coates, P.D. The effect of materials, process settings and screw geometry on energy consumption and melt temperature in single screw extrusion. Appl. Energ. 2016, 180, 880–894. [Google Scholar] [CrossRef]

- The ImpEE Project. Recycling of Plastics; University of Cambridge: Cambridge, UK, 2005. [Google Scholar]

- Gibbens, S. What You Need to Know about Plant-Based Plastics. In National Geographic Society; (Online) National Geographic Partners LLC. 2018. Available online: https://www.nationalgeographic.co.uk/environment-and-conservation/2018/11/everything-you-need-to-know-about-plant-based-plastics (accessed on 12 January 2021).

- Zhang, Y.; Pan, P.; Zheng, Y.; Zhao, K.; Zhang, Y.; Ren, X.; Jin, R. Visual search at Alibaba. In Proceedings of the 24th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining; Association for Computing Machinery: New York, NY, USA, 2018; pp. 993–1001. [Google Scholar]

- Alibaba. Single Screw Extruders. Available online: https://www.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&tab=all&SearchText=single+screw+extruders&viewtype= (accessed on 15 January 2021).

- Frankland, J. Get Smarter on Extruder Sizes. In Plastics Technology; Gardner Business Media: Cincinnati, OH, USA, 2012; Available online: https://www.ptonline.com/articles/get-smarter-on-extruder-sizes (accessed on 10 May 2021).

- Vlachopoulos, J.; Strutt, D. Polymer processing. Mater. Sci. Technol. 2003, 19, 1161–1169. [Google Scholar] [CrossRef]

- Drobny, J.G. Processing methods applicable to thermoplastic elastomers. In Handbook of Thermoplastic Elastomers., 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 33–173. [Google Scholar]

- Shrivastava, A. Plastics Processing. In Introduction to Plastics Engineering; Elsevier Inc.: Oxford, UK, 2018; pp. 143–177. [Google Scholar]

- Rosato, D.V.; Rosato, D.V.; Rosato, M.V. Extrusion. In Plastic Product Material and Process Selection Handbook; Elsevier Ltd.: Oxford, UK, 2004; pp. 227–281. [Google Scholar]

- Rosato, D.V. Extruding Plastics: A Practical Processing Handbook; Springer Science & Business Media: Dordrecht, The Netherlands, 1998; ISBN 978-0-412-82810-2. [Google Scholar]

- Andersen, P.; Shih, C.K.; Spalding, M.A.; Wetzel, M.D.; Womer, T.W. Breakthrough inventions in polymer extrusion. SPE ANTEC Tech. Pap. 2009, 55, 668. [Google Scholar]

- Griff, A. Extrusion Basics: Screw Design Essentials You Learned a Long Time Ago, But Maybe Forgot. (Online) Plastics Today. 2016. Available online: https://www.plasticstoday.com/extrusion-pipe-profile/extrusion-basics-screw-design-essentials-you-learned-long-time-ago-maybe (accessed on 12 April 2021).

- Mack, M.H.; Pfeiffer, A. Devolatilization in Single-Screw Extruders. Plast. Eng. 1996, 33, 325–344. [Google Scholar]

- Padsalgikar, A.D. Plastics in Medical Devices for Cardiovascular Applications; Elsevier Inc.: Oxford, UK, 2017; p. 196. [Google Scholar]

- Rauwendaal, C. New developments for extrusion: Compounding with single screw extruders. Plast. Addit. Compd. 2002, 4, 24–27. [Google Scholar] [CrossRef]

- Rauwendaal, C. New developments in mixing and screw design. Plast. Addit. Compound. 2008, 10, 32–36. [Google Scholar] [CrossRef]

- Sun, X.; Spalding, M.A.; Womer, T.W.; Uzelac, N. Design optimization of Maddock mixers for single-screw extrusion using numerical simulation. In Proceedings of the 75th Annual Technical Conference of the Society of Plastic Engineers (ANTEC), Anaheim, CA, USA, 8–10 May 2017; pp. 8–10. [Google Scholar]

- Patel, B.R.; Lageraaen, P.R.; Kalb, P.D. Review of Potential Processing Techniques for the Encapsulation of Wastes in Thermoplastic Polymers; (No. BNL–62200); Environmental & Waste Technology Center, Department of Advanced Technology, Brookhaven National Laboratory: Uptown, NY, USA, 1995.

- Geoff, J.; Whelan, T. The Dynisco Extrusion Processors Handbook, 2nd ed.; DeLaney, D., Ed.; Dynisco: Franklin, MA, USA, 2000; p. 284. [Google Scholar]

- Burlet, R.J.H.; Lemmens, J.M.H. Process for the Processing of a Thermoplastic Polycondensation Polymer. U.S. Patent No. 5,102,594, 4 July 2012. [Google Scholar]

- Frankland, J. Extrusion know-how: The whys & hows (& ifs) of vented extruders. In Plastics Technology; Gardner Business Media: Cincinnati, OH, USA, 2010; Available online: https://www.ptonline.com/articles/extrusion-know-how-the-whys-hows-ifs-of-vented-extruders (accessed on 20 March 2021).

- Rauwendaal, C. Recent advances in barrier screw design. Plast. Addit. Compound. 2005, 7, 36–39. [Google Scholar] [CrossRef]

- Thielke, P.; Räpple, T.; Bonten, C. Investigation of the Melt Quality of a Double Wave Screw in a Grooved Plasticizing Zone. In AIP Conference Proceedings; (Online) AIP Publishing LLC. 2019, Volume 2055. No. 1. Available online: https://aip.scitation.org/doi/abs/10.1063/1.5084857 (accessed on 20 March 2021).

- Wagner, J.R., Jr.; Mount, E.M., Jr.; Giles, H.F., Jr. Extrusion: The Definitive Processing Guide and Handbook, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Cantor, K.M.; Watts, P. Plastics processing. In Applied Plastics Engineering Handbook: Processing and Materials; Kutz, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Thomasnet. Types of Molding Machinery—A ThomasNet Buying Guide. 2020. Available online: https://www.thomasnet.com/articles/machinery-tools-supplies/types-of-molding-machinery/ (accessed on 21 February 2021).

- Fibertech Inc. A Simple Guide to Plastic Molding: Is Rotational Molding Right for You? Available online: https://fibertechplastics.com/custom-rotational-molding/a-simple-guide-to-plastic-molding/ (accessed on 22 March 2021).

- Worth, J. Manufacturing Methods of Plastic Molding. (Online) The Rodon Group. 2018. Available online: https://www.rodongroup.com/blog/manufacturing-methods-of-plastic-molding (accessed on 6 March 2021).

- Biron, M. Thermosets and Composites: Material Selection, Applications, Manufacturing and Cost Analysis, 2nd ed.; Biron, M., Ed.; William Andrew Publishing: Norwich, CT, USA, 2013. [Google Scholar]

- Malkin, A.Y.; Isayev, A. 6—Applications of rheology. In Rheology, 3rd ed.; Malkin, A.Y., Isayev, A., Eds.; ChemTec Publishing: Toronto, ON, Canada, 2017; pp. 377–432. [Google Scholar]

- Cogswell, F.N. Converging flow of polymer melts in extrusion dies. Polym. Engineer. Sci. 1972, 12, 64–73. [Google Scholar] [CrossRef]

- Suchy, I. Handbook of Die Design; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Ranjan, S. Plastic Extrusion Process. (Online) Polymer Academy. 2017. Available online: https://polymeracademy.com/plastic-extrusion-process/ (accessed on 10 November 2021).

- Kostic, M.M.; Reifschneider, L.G. Design of extrusion dies. Encycl. Chem. Process. 2006, 10, 633–649. [Google Scholar]

- Hakkens, D. Dave Hakkens about Precious Plastic—What Design Can Do 2018. Available online: https://www.youtube.com/watch?v=LhI18fGg4eE (accessed on 11 February 2021).

- Catherine, O. Polymer melt rheology and flow simulations applied to cast film extrusion die design: An industrial perspective. AIP Conf. Proc. 2017, 1843, 030009. [Google Scholar]

- Types of Plastic Moulds: The Comprehensive Guide. Stebro Mold Co. Ltd, 2020. Available online: https://www.stebro-mold.com/types-of-plastic-moulds/ (accessed on 14 November 2020).

- Rafizadehl, M.; Patterson, W.; Kamal, M. Physically-based adaptive control of cavity pressure in injection moulding process: Packing phase. Iranian Polym. J. 1999, 8, 99–113. [Google Scholar]

- Vlachopoulos, J.; Society of Plastics (U.S.). The SPE Guide on Extrusion Technology and Troubleshooting; Society of Plastics Engineers: Brookfield, CT, USA, 2001; ISBN 9780972215923. [Google Scholar]

- Doyle, L.; Keyser, C. Manufacturing Processes and Materials for Engineers, 3rd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1985; p. 926. [Google Scholar]

- Lowey, J.R.E. Plastic Extrusion Die; (Online) Google Patents. 1960. Available online: https://patents.google.com/patent/US2938231A/en (accessed on 25 January 2021).

- The Rodon Group. Injection Molding vs. Compression Molding: Which One Works for Your Needs? Available online: https://www.rodongroup.com/blog/injection-molding-vs.-compression-molding-which-one-works-for-your-needs (accessed on 29 March 2021).

- Kutz, M. Applied Plastics Engineering Handbook: Processing and Materials; Elsevier Inc.: Amsterdam, The Netherlands, 2011; ISBN 978-1-4377-3514-7. [Google Scholar]

- Bonten, C.; Haberstroh, E. 10.20—Processing of plastics into structural components. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 355–368. [Google Scholar]

- Mallick, P. Compression moulding. In Composite Materials Technology; Mallick, P.K., Newman, S., Eds.; Hanser Publishers: New York, NY, USA, 1990. [Google Scholar]

- Selke, S.; Culter, J. Plastics Packaging: Properties, Processing, Applications, and Regulations; Carl Hanser Verlag: München, Germany, 2016. [Google Scholar]

- Tatara, R. Compression molding. In Applied Plastics Engineering Handbook: Processing and Materials; Kutz, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Asim, M.; Jawaid, M.; Saba, N.; Nasir, M.; Sultan, M.T.H. 1—Processing of hybrid polymer composites—A review. In Hybrid Polymer Composite Materials; Thakur, V.K., Thakur, M.K., Gupta, R.K., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 1–22. [Google Scholar]

- Lynam, C.; Milani, A.S.; Trudel-Boucher, D.; Borazghi, H. Predicting dimensional distortions in roll forming of comingled polypropylene/glass fiber thermoplastic composites: On the effect of matrix viscoelasticity. J. Compos. Mater. 2014, 48, 3539–3552. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E. Plastic recycling. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Worrell, E., Reuter, M.A., Eds.; Elsevier: Amsterdam, The Nerherlands, 2014; pp. 179–190. [Google Scholar] [CrossRef]

- Morris, J. A review of microstructure in concentrated suspensions and its implications for rheology and bulk flow. Rheologica Acta 2009, 48, 909–923. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The modelling of extrusion processes for polymers—A review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef]

- Taguet, A. Rheological characterization of compatibilized polymer blends. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 453–487. [Google Scholar]

- Rosu, R.F.; Shanks, R.A.; Bhattacharya, S.N. Shear rheology and thermal properties of linear and branched poly(ethylene terephthalate) blends. Polymer 1999, 40, 5891–5898. [Google Scholar] [CrossRef]

- Marek, A.A.; Verney, V. Rheological behavior of polyolefins during UV irradiation at high temperature as a coupled degradative process. Europ. Polym. J. 2015, 72, 1–11. [Google Scholar] [CrossRef]

- Kijo–Kleczkowska, A.; Gnatowski, A. Recycling of Plastic Waste, with Particular Emphasis on Thermal Methods—Review. Energies 2002, 15, 2114. [Google Scholar] [CrossRef]

- Pfaendner, R. How will additives shape the future of plastics? Polym Deg Stab. 2006, 91, 2249–2256. [Google Scholar] [CrossRef]

- Rieckmann, T.; Frei, F.; Völker, S. Modelling of PET quality parameters for a closed-loop recycling system for food contact. Macro. Symp. 2011, 302, 34–45. [Google Scholar] [CrossRef]

- Wang, K.; Matadi Boumbimba, R.; Bahlouli, N.; Pessey, D.; Ahzi, S.; Addiego, F.; Rémond, Y. Constitutive modeling of the tensile behavior of recycled polypropylene-based composites. Materials 2019, 12, 2419. [Google Scholar] [CrossRef]

- Olesik, P.; Godzierz, M.; Kozioł, M. Preliminary characterization of novel LDPE-based wear-resistant composite suitable for FDM 3D printing. Materials 2019, 12, 2520. [Google Scholar] [CrossRef]

- Navarro, R.; Torre, L.; Kenny, J.M.; Jiménez, A. Thermal degradation of recycled polypropylene toughened with elastomers. Polym. Degrad. Stab. 2003, 82, 279–290. [Google Scholar] [CrossRef]

- Pulipati, D.P.; Jack, D.A. Characterization and model validation for large format chopped fiber, foamed, composite structures made from recycled olefin based polymers. Polymers 2020, 12, 1371. [Google Scholar] [CrossRef]

- Li, G.; Cao, S.; Zheng, S.; Wang, W.; Cao, Y.; Wang, J. Crystallization, melting behavior, and crystal structure of reactive, intumescent, flame-retardant polypropylene. J. Appl. Polym. Sci. 2015, 132, 41374. [Google Scholar] [CrossRef]

- Loos, J.; Arndt-Rosenau, M.; Weingarten, U.; Kaminsky, W.; Lemstra, P.J. Melting behavior of nascent polyolefins synthesized at various polymerization conditions. Polym. Bull. 2002, 48, 191–198. [Google Scholar] [CrossRef]

- Contat–Rodrigo, L.; Ribes-Greus, A.; Imrie, C.T. Thermal analysis of high-density polyethylene and low-density polyethylene with enhanced biodegradability. J. Appl. Polym. Sci. 2002, 86, 764–772. [Google Scholar] [CrossRef]

- Liang, J.Z. Effects of extrusion rate, temperature, and die diameter on melt flow properties during capillary flow of low-density-polyethylene. Polym. Plast. Technol. Eng. 2007, 46, 245–249. [Google Scholar] [CrossRef]

- Polymer Database. Polymer Properties Database: Polyolefins (Polyalkenes). Available online: https://polymerdatabase.com/polymer%20classes/Polyolefin%20type.html (accessed on 12 May 2021).

- Chen, Y.; Yang, X.; Li, M.; Mei, M. Influence of working temperatures on mechanical behavior of hybrid joints with carbon fiber reinforced plastic/aluminum lightweight materials for automotive structure. J. Manuf. Process. 2019, 45, 392–407. [Google Scholar] [CrossRef]

- Iqbal, M.H.; Sundararaj, U.; Shah, S. Identification of transient responses of a plasticating twin screw extruder due to excitation in feed rate. Polym. Engineer. Sci. 2011, 51, 482–491. [Google Scholar] [CrossRef]

- Abeykoon, C.; McMillan, A.; Nguyen, B.K. Energy efficiency in extrusion-related polymer processing: A review of state of the art and potential efficiency improvements. Renew. Sustain. Energ. Rev. 2021, 147, 111219. [Google Scholar] [CrossRef]

| Opinions on Energy | Extruders | |

|---|---|---|

| ||

| ||

| ||

| Extruder Classification Based on Design Mechanisms |

|---|

|

|

|

| Moulding Process | Advantages | Disadvantages |

|---|---|---|

| Die Extrusion | Pump may be needed to push extrudate forward [132]. Molecular orientation of extrudate may be imparted by forcing it through the die cast at low temperatures [132]. | |

| Injection Moulding | May not be suitable for reinforced polymers [171]. A high stress level may affect the products [132]. | |

| Compression Moulding | Not economical for making small parts [172]. May require secondary processing—trimming, machining [173]. Limitation on the depth of mould [169] May not be suitable for complex parts [132]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uzosike, C.C.; Yee, L.H.; Padilla, R.V. Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP. Energies 2023, 16, 1406. https://doi.org/10.3390/en16031406

Uzosike CC, Yee LH, Padilla RV. Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP. Energies. 2023; 16(3):1406. https://doi.org/10.3390/en16031406

Chicago/Turabian StyleUzosike, Canice C., Lachlan H. Yee, and Ricardo Vasquez Padilla. 2023. "Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP" Energies 16, no. 3: 1406. https://doi.org/10.3390/en16031406

APA StyleUzosike, C. C., Yee, L. H., & Padilla, R. V. (2023). Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP. Energies, 16(3), 1406. https://doi.org/10.3390/en16031406