A Comparative Thermal and Economic Investigation of Similar Shell & Tube and Plate Heat Exchangers with Low Concentration Ag-H2O Nanofluid

Abstract

:1. Introduction

2. Materials, Experimental Setup, and Procedure

3. Data Analysis

4. Results and Discussion

5. Conclusions

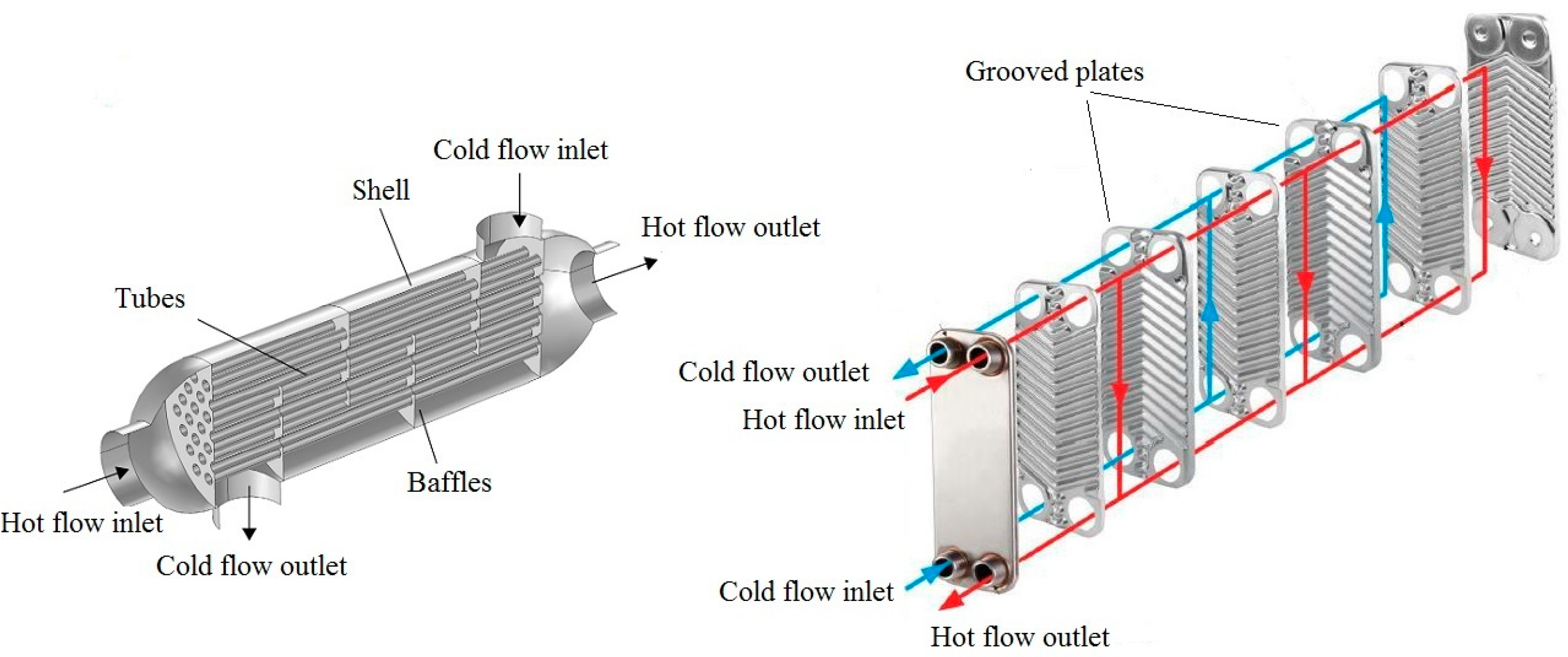

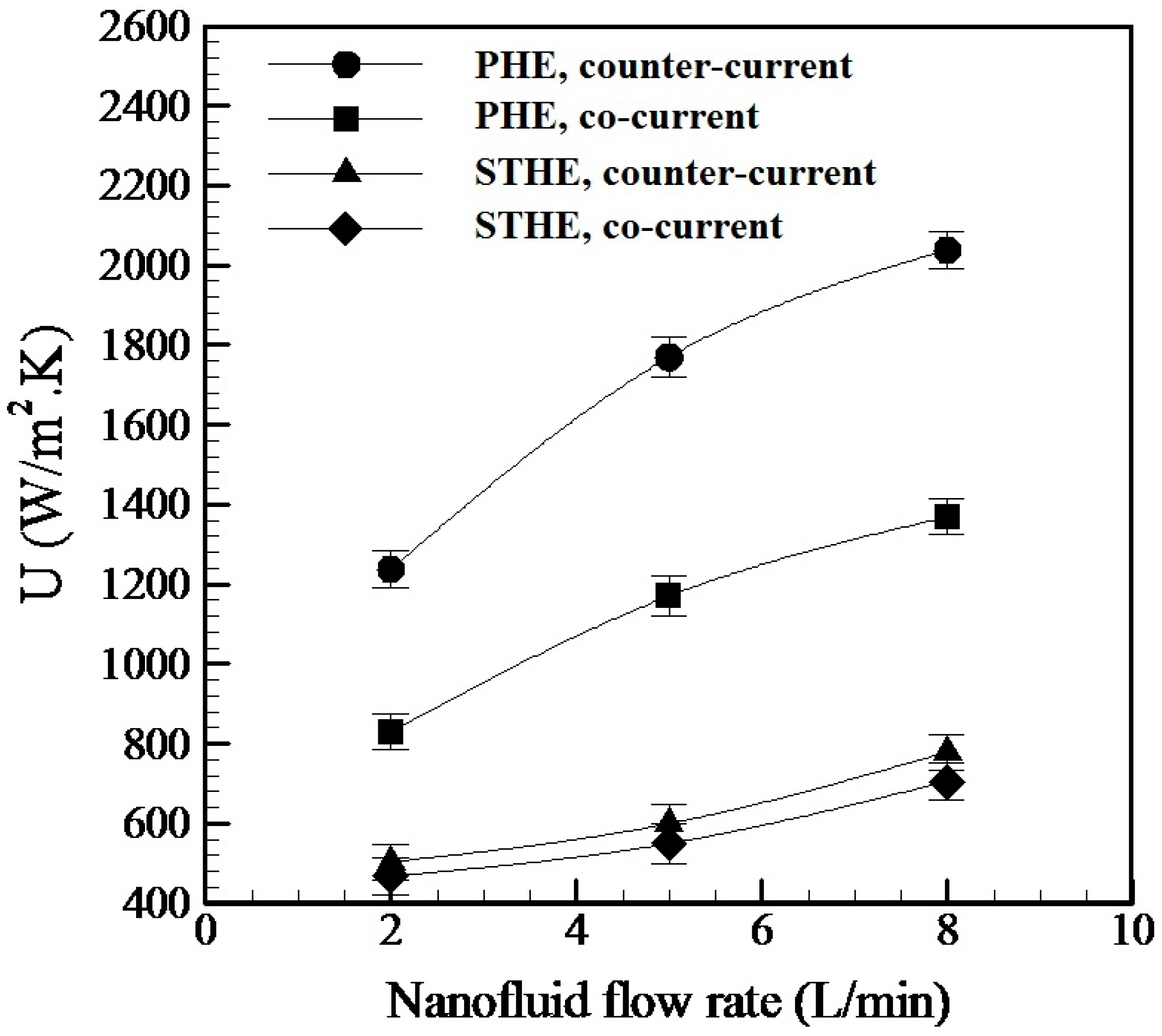

- PHE creates a higher U value than the STHE at various NF concentrations. The main reason is the existence of grooves on the plates of PHE, which raises the probability of turbulent flow compared to laminar flow in the STHE.

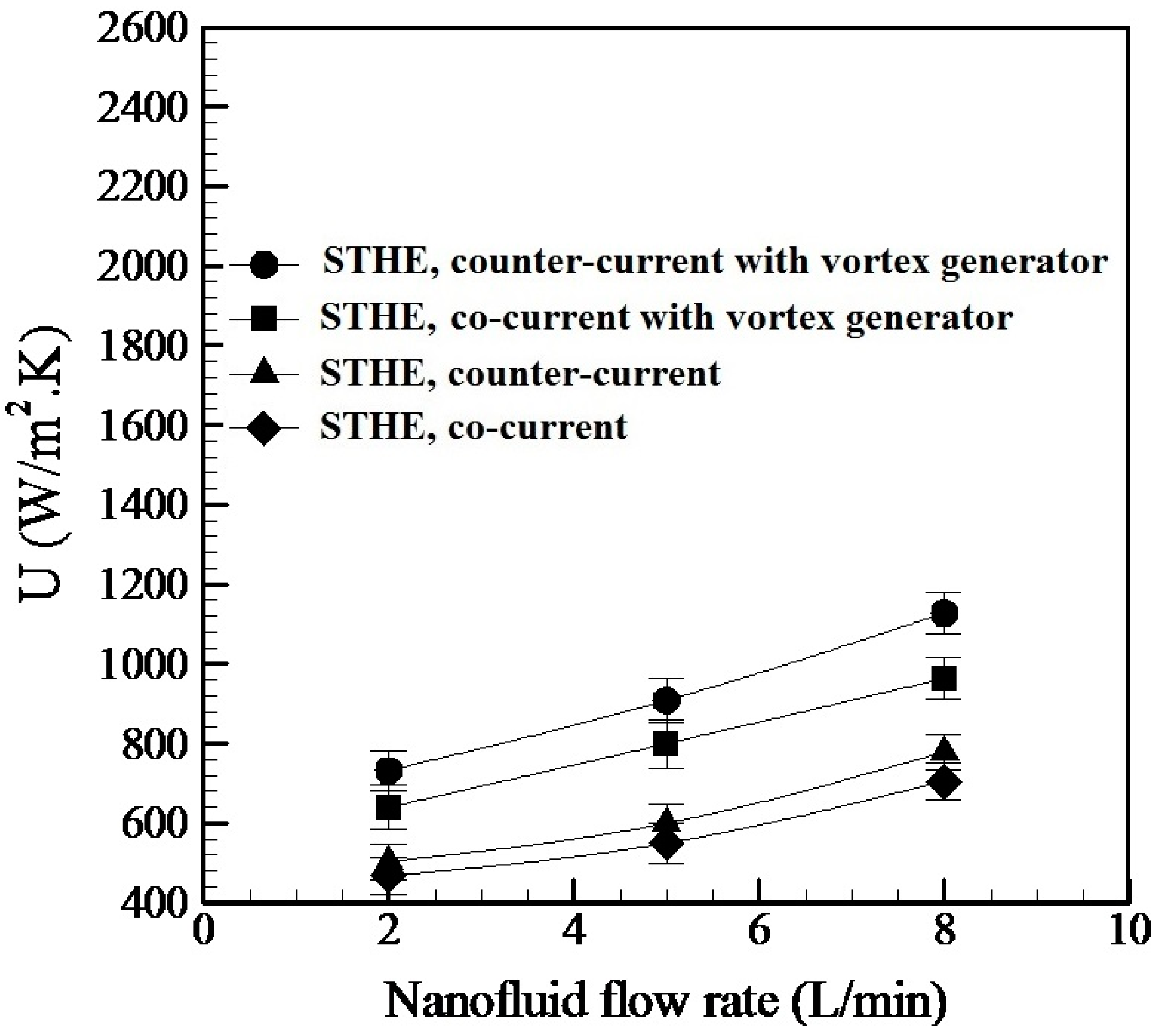

- Low nanofluid concentrations have a negligible impact on the enhancement of the U value of both PHE and STHE, and the nanofluid flow rate has the highest impact on the U value, just like conventional fluid.

- Counter-current flow increases the U value for both PHE and STHE. Nevertheless, it has a higher impact on the U value of PHE than the STHE.

- For both PHE and STHE, increasing the nanofluid flow rate enhances the amount of the U value. Nevertheless, its impact on the PHE U value is more significant than that of STHE.

- In the whole experiment temperature domain, the PHE shows higher performance than STHE, and when the fluid temperature increases from 36 to 56 °C, there is a slight increase in overall heat transfer of both PHE and STHE.

- At the same flow rate, both PHE and STHE have almost the same pump power consumption, and increasing the nanofluid flow rate increases the electrical power consumption of the pump.

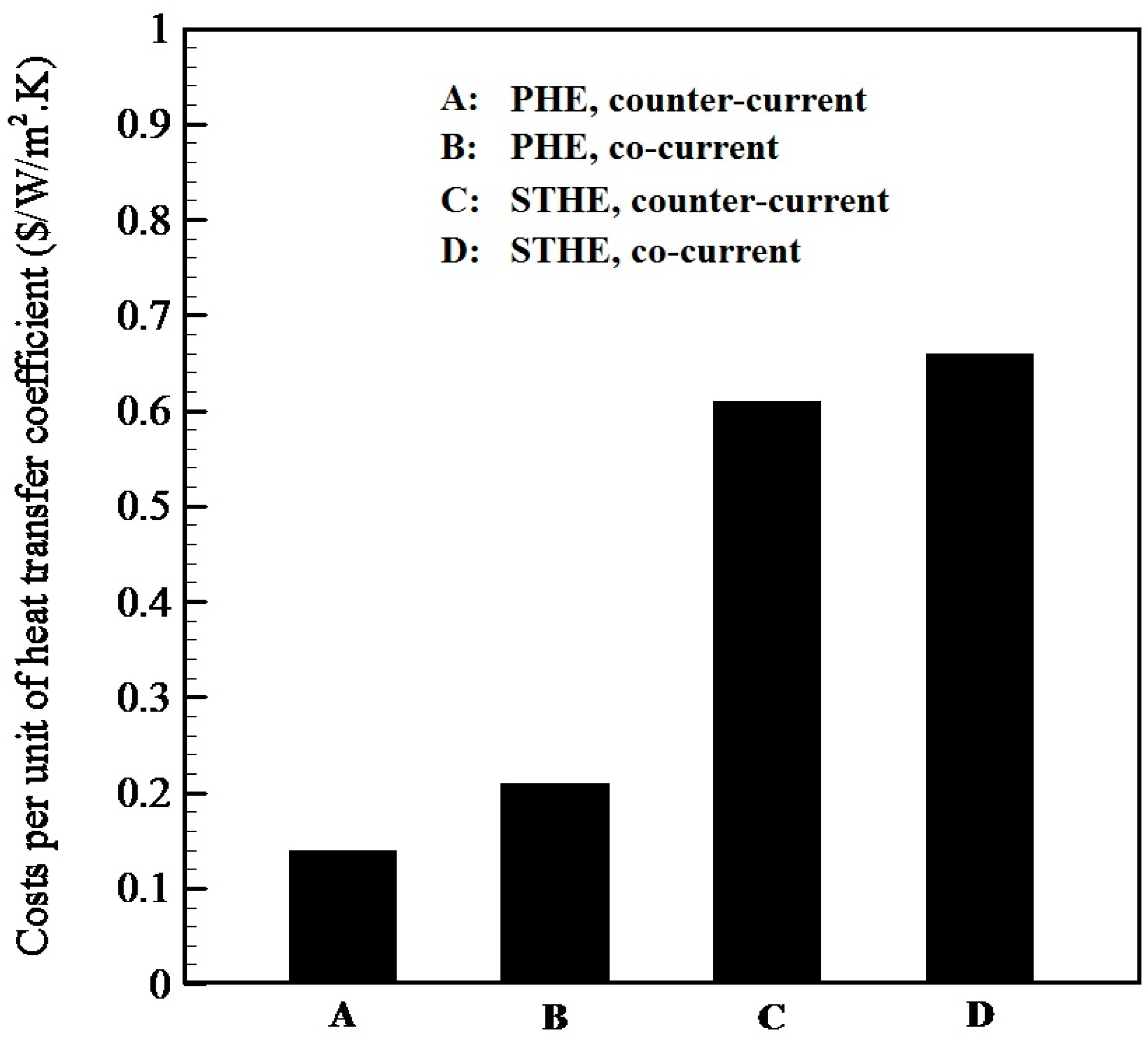

- The costs per unit of heat transfer coefficient for PHE are significantly smaller than that of STHE.

- Using a vortex generator at the inlet of STHE tubes for making turbulent flow dramatically increases the U values of STHE for both co-current and counter-current flows.

- Although turbulent flow increases the U values of STHE, they are lower than the corresponding U values of PHE. Small plates gap in PHE structure which cause higher velocities of fluid flow and create a chain-like structure of NPs between the plates of PHE (especially at higher NF concentrations) are the main reasons for this.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Masoumpour, B.; Ataeizadeh, M.; Hajabdollahi, H.; ShafieyDehaj, M. Performance evaluation of a shell and tube heat exchanger with recovery of mass flow rate. J. Taiwan Inst. Chem. Eng. 2021, 123, 153–165. [Google Scholar] [CrossRef]

- Keramat, F.; Izadpanah, A.B. Thermo-hydraulic performance analysis of converging-diverging heat exchanger with inclined fins using computational fluid dynamics. J. Taiwan Inst. Chem. Eng. 2022, 132, 104119. [Google Scholar] [CrossRef]

- Wang, S.; Wen, J.; Li, Y. An experimental investigation of heat transfer enhancement for a shell-and-tube heat exchanger. Appl. Therm. Eng. 2009, 29, 2433–2438. [Google Scholar] [CrossRef]

- Hosseini, R.; Hosseini-Ghaffar, A.; Soltani, M. Experimental determination of shell side heat transfer coefficient and pressure drop for an oil cooler shell-and-tube heat exchanger with three different tube bundles. Appl. Therm. Eng. 2007, 27, 1001–1008. [Google Scholar] [CrossRef]

- Amini, R.; Amini, M.; Jafarinia, A.; Kashfi, M. Numerical investigation on effects of using segmented and helical tube fins on thermal performance and efficiency of a shell and tube heat exchanger. Appl. Therm. Eng. 2018, 138, 750–760. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, X.; Mondejar, M.E.; Haglind, F. A review of heat transfer enhancement techniques in plate heat exchangers. Renew. Sustain. Energy Rev. 2019, 101, 305–328. [Google Scholar] [CrossRef]

- Gut, J.A.W.; Pinto, J.M. Modeling of plate heat exchangers with generalized configurations. Int. J. Heat Mass Transf. 2003, 46, 2571–2585. [Google Scholar] [CrossRef]

- Luan, Z.J.; Zhang, J.M.; Tian, M.C.; Fan, M.X. Flow resistance and heat transfer characteristics of a new-type plate heat exchanger. J. Hydrodyn. Ser. B 2008, 20, 524–529. [Google Scholar] [CrossRef]

- Mansfield, E.; Tyner, K.M.; Poling, C.M.; Blacklock, J.L. Determination of nanoparticle surface coatings and nanoparticle purity usingmicroscale thermogravimetric analysis. Anal. Chem. 2014, 86, 1478–1484. [Google Scholar] [CrossRef]

- Reznickova, A.; Orendac, M.; Kolska, Z.; Cizmar, E.; Dendisova, M.; Svorcik, V. Copper nanoparticles functionalized PE: Preparation, characterization andmagnetic properties. Appl. Surf. Sci. 2016, 390, 728–734. [Google Scholar] [CrossRef]

- Stueber, D.D.; Villanova, J.; Aponte, I.; Xiao, Z.; Colvin, V.L. Magnetic nanoparticles in biology and medicine: Past, present, and future trends. Pharmaceutics 2021, 13, 943. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, L.; Gomaa, H.G.; Ragab, D.; Zhu, J. Magnetic nanoparticles for environmental and biomedical applications: A review. Particuology 2017, 30, 1–14. [Google Scholar] [CrossRef]

- De Crozals, G.; Bonnet, R.; Farre, C.; Chaix, C. Nanoparticles with multiple properties for biomedical applications: A strategic guide. Nano Today 2016, 11, 435–463. [Google Scholar] [CrossRef]

- Hofmann-Amtenbrink, M.; Grainger, D.W.; Hofmann, H. Nanoparticles in medicine: Current challenges facing inorganic nanoparticle toxicity assessments and standardizations. Nanomed. Nanotechnol. Biol. Med. 2015, 11, 1689–1694. [Google Scholar] [CrossRef]

- Bansal, A.; Zhang, Y. Photocontrolled Nanoparticle Delivery Systems for Biomedical Applications. Acc. Chem. Res. 2014, 47, 3052–3060. [Google Scholar] [CrossRef]

- Kim, J.; Mirando, A.C.; Popel, A.S.; Green, J.J. Gene delivery nanoparticles to modulate angiogenesis. Adv. Drug Deliv. Rev. 2017, 119, 20–43. [Google Scholar] [CrossRef]

- Ahmad, U.; Tubia, A.; Ahmed, A.I.; Rajesh, K.; Al-Assiri, M.S.; Baskoutas, S.; Akhtar, M.S. An efficient chemical sensor based on CeO2 nanoparticles for the detection of acetylacetone chemical. J. Electroanal. Chem. 2020, 864, 114089. [Google Scholar]

- Lan, M.; Zhang, J.; Chui, Y.S.; Wang, P.; Chen, X.; Lee, C.S.; Kwong, H.L.; Zhang, W. Carbon Nanoparticle-based Ratiometric Fluorescent Sensor for Detecting Mercury Ions in Aqueous Media and Living Cells. ACS Appl. Mater. Interfaces 2014, 6, 21270–21278. [Google Scholar] [CrossRef]

- Hamidi-Asl, E.; Raoof, J.; Naghizadeh, N.; Sharifi, S.; Hejazi, M. A bimetallic nanocomposite electrode for direct and rapid biosensing of p53 DNA plasmid. J. Chem. Sci. 2015, 127, 1607–1617. [Google Scholar] [CrossRef]

- Hussain, M.M.; Rahman, M.M.; Asiri, A.M. Ultrasensitive and selective 4-aminophenol chemical sensor development based on nickel oxide nanoparticles decorated carbon nanotube nanocomposites for green environment. J. Environ. Sci. 2017, 53, 27–38. [Google Scholar] [CrossRef]

- Hamidi-Asl, E.; Palchetti, I.; Hasheminejad, E.; Mascini, M. A review on the electrochemical biosensors for determination of microRNAs. Talanta 2013, 115, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Thabet, A.; Mobarak, Y. The effect of cost-fewer nanoparticles on the electrical properties of polyvinyl chloride. Electr. Eng. 2017, 99, 625–631. [Google Scholar] [CrossRef]

- Hu, S.; Zhou, Y.; Yuan, C.; Wang, W.; Hu, J.; Li, Q.; He, J. Surface-modification effect of MgO nanoparticles on the electrical properties of polypropylene nanocomposite. High Volt. 2020, 5, 249–255. [Google Scholar] [CrossRef]

- Gajendiran, M.; Choi, J.; Kim, S.J.; Kim, K.; Shin, H.; Koo, H.J.; Kim, K. Conductive biomaterials for tissue engineering applications. J. Ind. Eng. Chem. 2017, 51, 12–26. [Google Scholar] [CrossRef]

- Sabr, O.H.; Kadhim, H.J.; Salman, M.M. Studying the effect of silica nanoparticles on optical properties of polyvinyl alcohol thin films for semiconductors applications. Test Eng. Manag. 2020, 83, 11014–11019. [Google Scholar]

- Kiarii, E.M.; Govender, K.K.; Ndungu, P.G.; Govender, P.P. The generation of charge carriers in semi-conductors—A theoretical study. Chem. Phys. Lett. 2017, 678, 167–176. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.; Liu, J.; Fang, X.; Zhang, Z. Highly stable graphite nanoparticle-dispersed phase change emulsions with little supercooling and high thermal conductivity for cold energy storage. Appl. Energy 2016, 188, 97–106. [Google Scholar] [CrossRef]

- Fan, F.Y.; Woodford, W.H.; Li, Z.; Baram, N.; Smith, K.C.; Helal, A.; McKinley, G.H.; Carter, W.C.; Chiang, Y.M. Polysulfide Flow Batteries Enabled by Percolating Nanoscale Conductor Networks. Nano Lett. 2014, 14, 2210–2218. [Google Scholar] [CrossRef]

- Park, J.; Kewon, T.; Kim, J.; Jin, H.; Kim, H.Y.; Kim, B.; Joo, S.H.; Lee, K. Hollow nanoparticles as emerging electrocatalysts for renewable energy conversion reactions. Chem. Soc. Rev. 2018, 47, 8173–8202. [Google Scholar] [CrossRef]

- Liu, M.; Wang, X.; Zhu, D.; Li, L.; Duan, H.; Xu, Z.; Wang, Z.; Gan, L. Encapsulation of NiO nanoparticles in mesoporous carbon nanospheres for advanced energy storage. Chem. Eng. J. 2016, 308, 240–247. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S. A general view to converting fossil fuels to cleaner energy source by adding nanoparticles. Int. J. Ambient. Energy 2021, 42, 1569–1574. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Nsofor, E.C. Melting enhancement in triplex-tube latent heat energy storage system using nanoparticles-metal foam combination. Appl. Energy 2016, 191, 22–34. [Google Scholar] [CrossRef]

- Elnaqeeb, T.; Ali Shah, N.; Vieru, D. Heat transfer enhancement in natural convection flow of nanofluid with Cattaneo thermal transport. Phys. Scr. 2020, 95, 115705. [Google Scholar] [CrossRef]

- Hajmohammadi, M.R.; Tork, M.H.M.A. Effects of the magnetic field on the cylindrical Couette flow and heat transfer of a nanofluid. Phys. Scr. 2019, 523, 234–245. [Google Scholar] [CrossRef]

- Pourhoseini, S.H.; Ramezani-Aval, H.; Naghizadeh, N. FHD and MHD effects of Fe3O4-water magnetic nanofluid on the enhancement of overall heat transfer coefficient of a heat exchanger. Phys. Scr. 2020, 95, 045705. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Jafaryar, M.; Shafee, A.; Li, Z. Nanoparticles for water desalination in solar heat exchanger. J. Therm. Anal. Calorim. 2018, 134, 2295–2303. [Google Scholar] [CrossRef]

- Wei, B.; Zou, C.; Li, X. Experimental investigation on stability and thermal conductivity of diathermic oil based TiO2 nanofluids. Int. J. Heat Mass Transf. 2017, 104, 537–543. [Google Scholar] [CrossRef]

- Gkountas, A.A.; Benos, L.T.; Sofiadis, G.N.; Sarris, I.E. A printed-circuit heat exchanger consideration by exploiting an Al2O3-water nanofluid: Effect of the nanoparticles interfacial layer on heat transfer. Therm. Sci. Eng. Prog. 2021, 22, 100818. [Google Scholar] [CrossRef]

- Atashafrooz, M. Effects of Ag-water nanofluid on hydrodynamics and thermal behaviors of three-dimensional separated step flow. Alex. Eng. J. 2018, 57, 4277–4285. [Google Scholar] [CrossRef]

- Harish, R.; Sivakumar, R. Turbulent thermal convection of nanofluids in cubical enclosure using two-phase mixture model. Int. J. Mech. Sci. 2021, 190, 106033. [Google Scholar] [CrossRef]

- Farajollahi, B.; Etemad, S.G.; Hojjat, M. Heat transfer of nanofluids in a shell and tube heat exchanger. Int. J. Heat Mass Transf. 2010, 53, 12–17. [Google Scholar] [CrossRef]

- Elias, M.M.; Shahrul, I.M.; Mahbubul, I.M.; Saidur, R.; Rahim, N.A. Effect of different nanoparticle shapes on shell and tube heat exchangerusing different baffle angles and operated with nanofluid. Int. J. Heat Mass Transf. 2014, 70, 289–297. [Google Scholar] [CrossRef]

- Bahiraei, M.; Naseri, M.; Monavari, A. Thermal-hydraulic performance of a nanofluid in a shell-and-tube heat exchanger equipped with new trapezoidal inclined baffles: Nanoparticle shape effect. Powder Technol. 2022, 395, 348–359. [Google Scholar] [CrossRef]

- Anitha, S.; Thomas, T.; Parthiban, V.; Pichumani, M. What dominates heat transfer performance of hybrid nanofluid in single 5 pass shell and tube heat exchanger? Adv. Powder Technol. 2019, 30, 3107–3117. [Google Scholar] [CrossRef]

- Bahiraei, M.; Monavari, A. Thermohydraulic performance and effectiveness of a mini shell and tube heat exchanger working with a nanofluid regarding effects of fins and nanoparticle shape. Adv. Powder Technol. 2021, 32, 4468–4480. [Google Scholar] [CrossRef]

- Huang, D.; Wu, Z.; Sunden, B. Effects of hybrid nanofluid mixture in plate heat exchangers. Exp. Therm. Fluid Sci. 2016, 72, 190–196. [Google Scholar] [CrossRef]

- Taghizadeh-Tabari, Z.; ZeinaliHeris, S.; Moradi, M.; Kahani, M. The study on application of TiO2/water nanofluid in plate heatexchanger of milk pasteurization industries. Renew. Sustain. Energy Rev. 2016, 58, 1318–1326. [Google Scholar] [CrossRef]

- Barzegarian, B.; Keshavarz Moraveji, M.; Aloueyan, A. Experimental investigation on heat transfer characteristics and pressure drop of BPHE (brazed plate heat exchanger) using TiO2-water nanofluid. Exp. Therm. Fluid Sci. 2016, 74, 11–18. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Heat transfer characteristics of plate heat exchanger using hybrid nanofluids: Effect of nanoparticle mixture ratio. Heat Mass Transf. 2020, 56, 2457–2472. [Google Scholar] [CrossRef]

- Hajabdollahi, H.; Ataeizadeh, M.; Masoumpour, B.; ShafieyDehaj, M. Comparison of the effect of various nanoparticle shapes on optimal design of plate heat exchanger. Heat Transf. Res. 2021, 52, 29–47. [Google Scholar] [CrossRef]

- Gürbüz, E.Y.; Sözen, A.; Variyenli, H.I.; Khanlari, A.; Tuncer, A.D. A comparative study on utilizing hybrid-type nanofluid in plate heat exchangers with different number of plates. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 524. [Google Scholar] [CrossRef]

- Sözen, A.; Khanları, A.; Çiftçi, E.; Sözen, A. Heat transfer enhancement of plate heat exchanger utilizing kaolin-including working fluid. J. Power Energy 2019, 233, 626–634. [Google Scholar] [CrossRef]

- Buszewski, B.; Rafiſska, K.; Pomastowski, P.; Walczak, J.; Rogowska, A. Novel aspects of silver nanoparticles functionalization. Colloids Surf. A Physicochem. Eng. Asp. 2016, 506, 170–178. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, G.; Zeng, G.; Yan, M.; Huang, Z.; Jiang, L.; Peng, C.; Wang, J.; Xiao, Z. Are silver nanoparticles always toxic in the presence of environmental anions? Chemosphere 2016, 171, 318–323. [Google Scholar] [CrossRef] [PubMed]

- Pourhoseini, S.H.; Naghizadeh, N.; Hoseinzadeh, H. Effect of silver-water nanofluid on heat transfer performance of a plate heat exchanger: An experimental and theoretical study. Powder Technol. 2018, 332, 279–286. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Plates area | 0.21 m2 |

| Plates material | Stainless steel 316(L) |

| Plates gap (b) | 2.5 mm |

| Plate height | 193 mm |

| Plate width (W) | 83 mm |

| Plate thickness | 0.5 mm |

| Property | Value |

|---|---|

| Total heat transfer area | 0.21 m2 |

| Tubes material | Stainless steel 316(L) |

| Number of tubes | 30 |

| Tube length | 450 mm |

| Tube ID (Inner Diameter) | 4 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pourhoseini, S.H.; Baghban, M.; Ghodrat, M. A Comparative Thermal and Economic Investigation of Similar Shell & Tube and Plate Heat Exchangers with Low Concentration Ag-H2O Nanofluid. Energies 2023, 16, 1854. https://doi.org/10.3390/en16041854

Pourhoseini SH, Baghban M, Ghodrat M. A Comparative Thermal and Economic Investigation of Similar Shell & Tube and Plate Heat Exchangers with Low Concentration Ag-H2O Nanofluid. Energies. 2023; 16(4):1854. https://doi.org/10.3390/en16041854

Chicago/Turabian StylePourhoseini, Seyed Hadi, Mojtaba Baghban, and Maryam Ghodrat. 2023. "A Comparative Thermal and Economic Investigation of Similar Shell & Tube and Plate Heat Exchangers with Low Concentration Ag-H2O Nanofluid" Energies 16, no. 4: 1854. https://doi.org/10.3390/en16041854