Second-Life of Lithium-Ion Batteries from Electric Vehicles: Concept, Aging, Testing, and Applications

Abstract

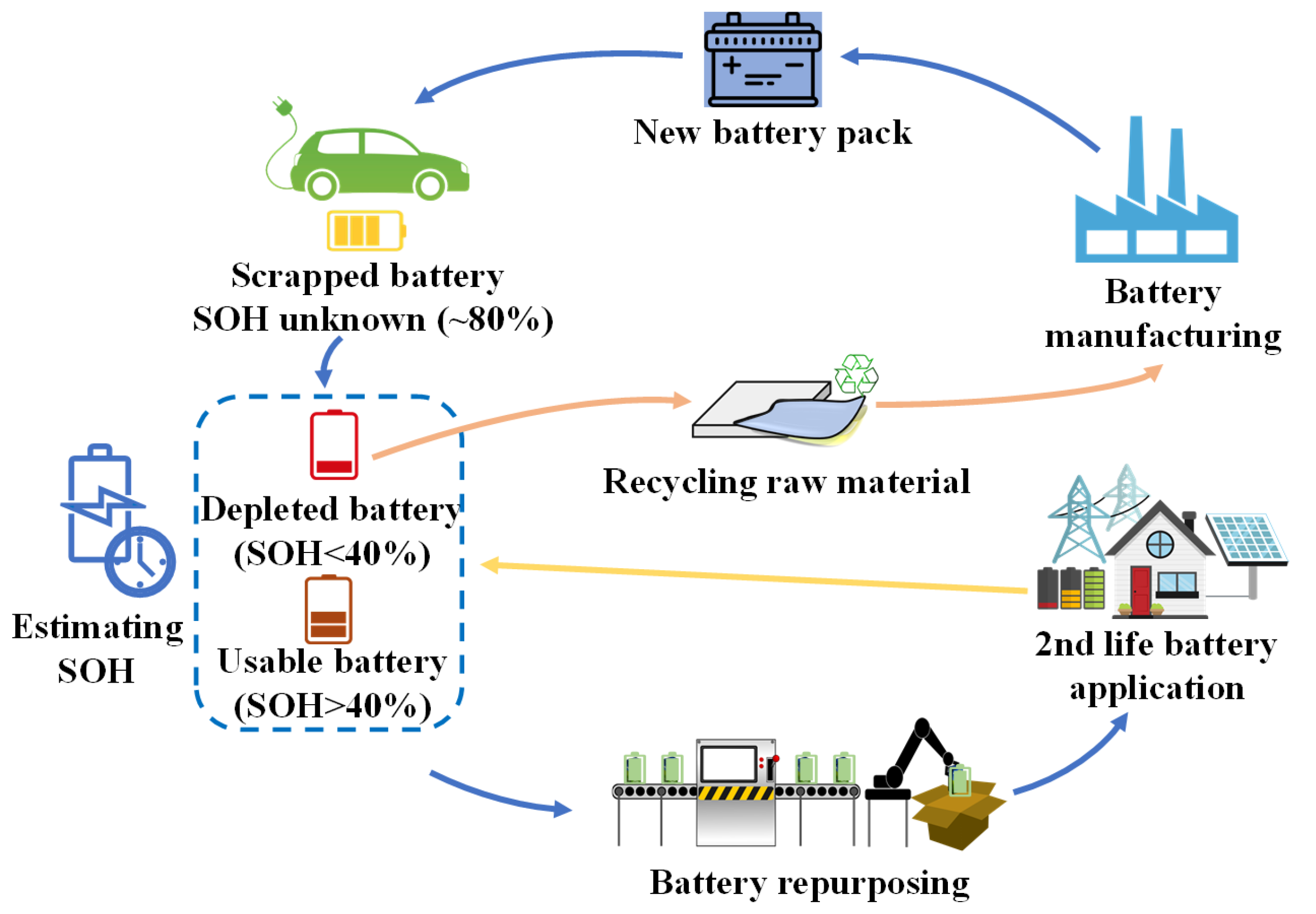

:1. Introduction

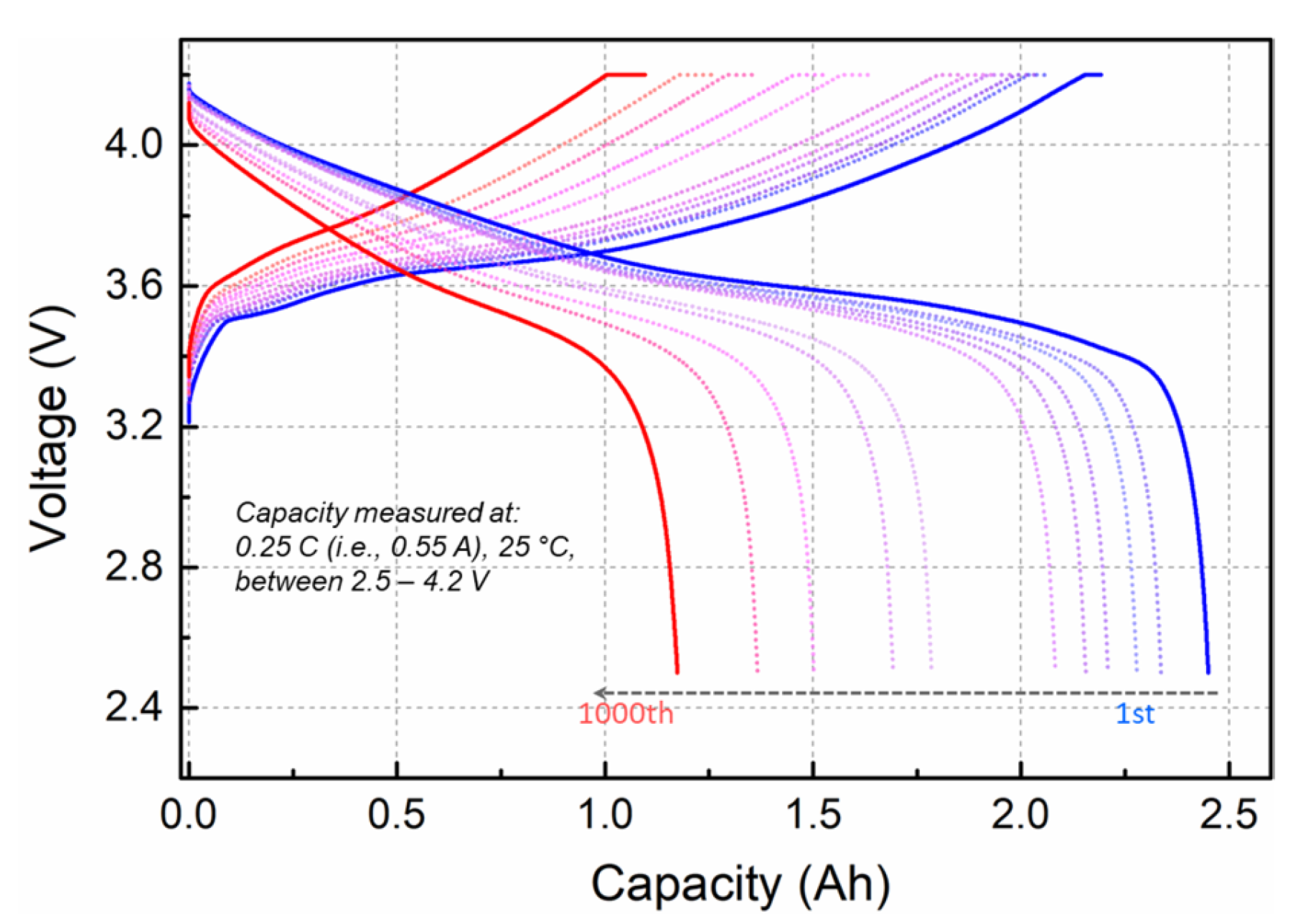

2. Battery Ageing in the Context of Second-Life Batteries

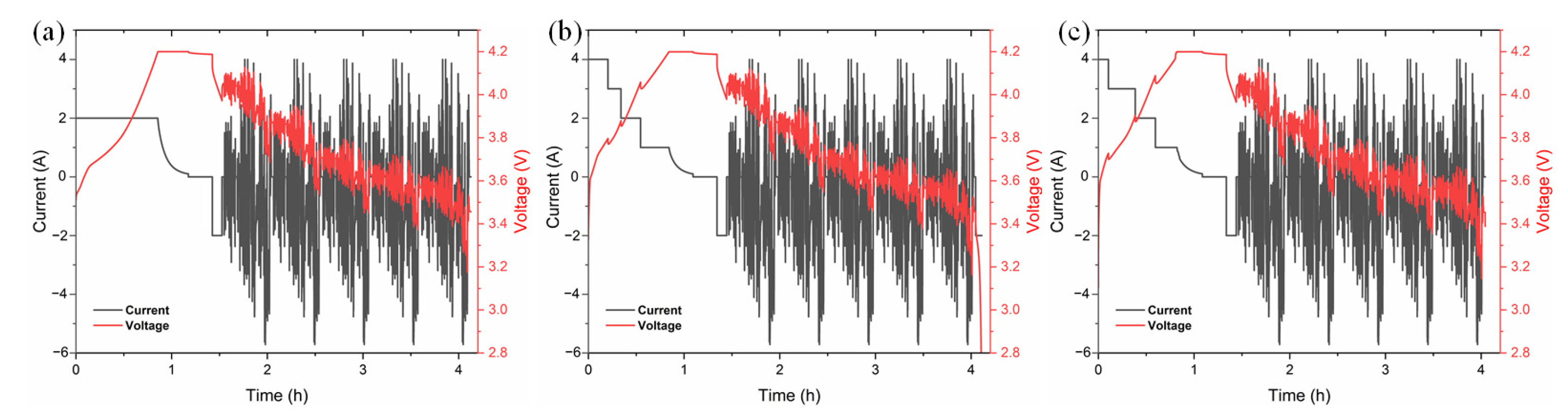

2.1. Aging in Climatic Chamber Based on Driving Profile

2.2. Software Simulations of Second-Life Batteries

3. Battery Testing at the Start of Second Life

3.1. Appropriate Testing Methods

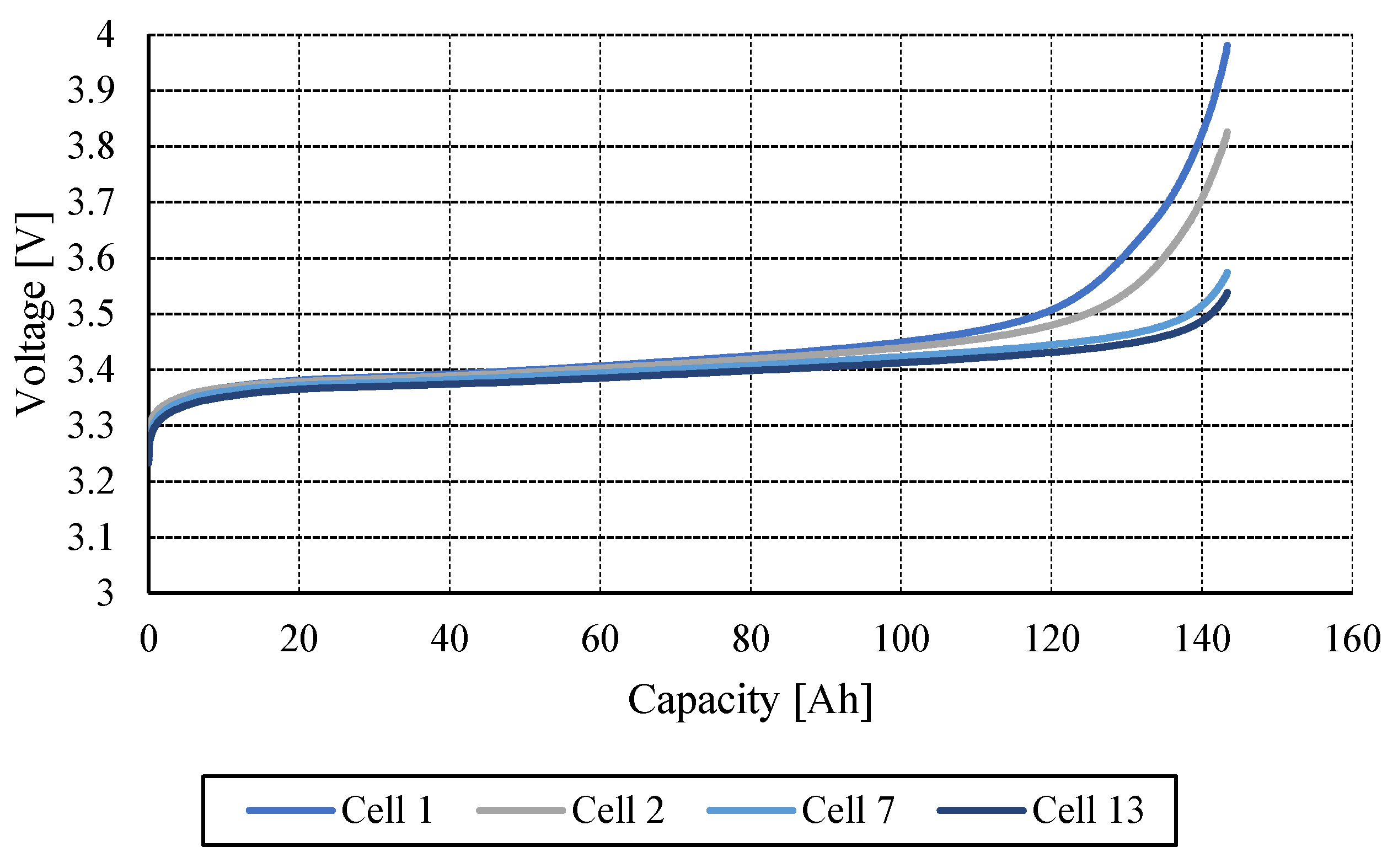

3.1.1. Capacity Test

3.1.2. Internal Resistance

3.1.3. Incremental Capacity Analysis

3.1.4. Electrochemical Impedance Spectroscopy

3.2. Testing Requirements for SLBs

4. Current and Future Applications of Lithium-Ion Second-Life Batteries

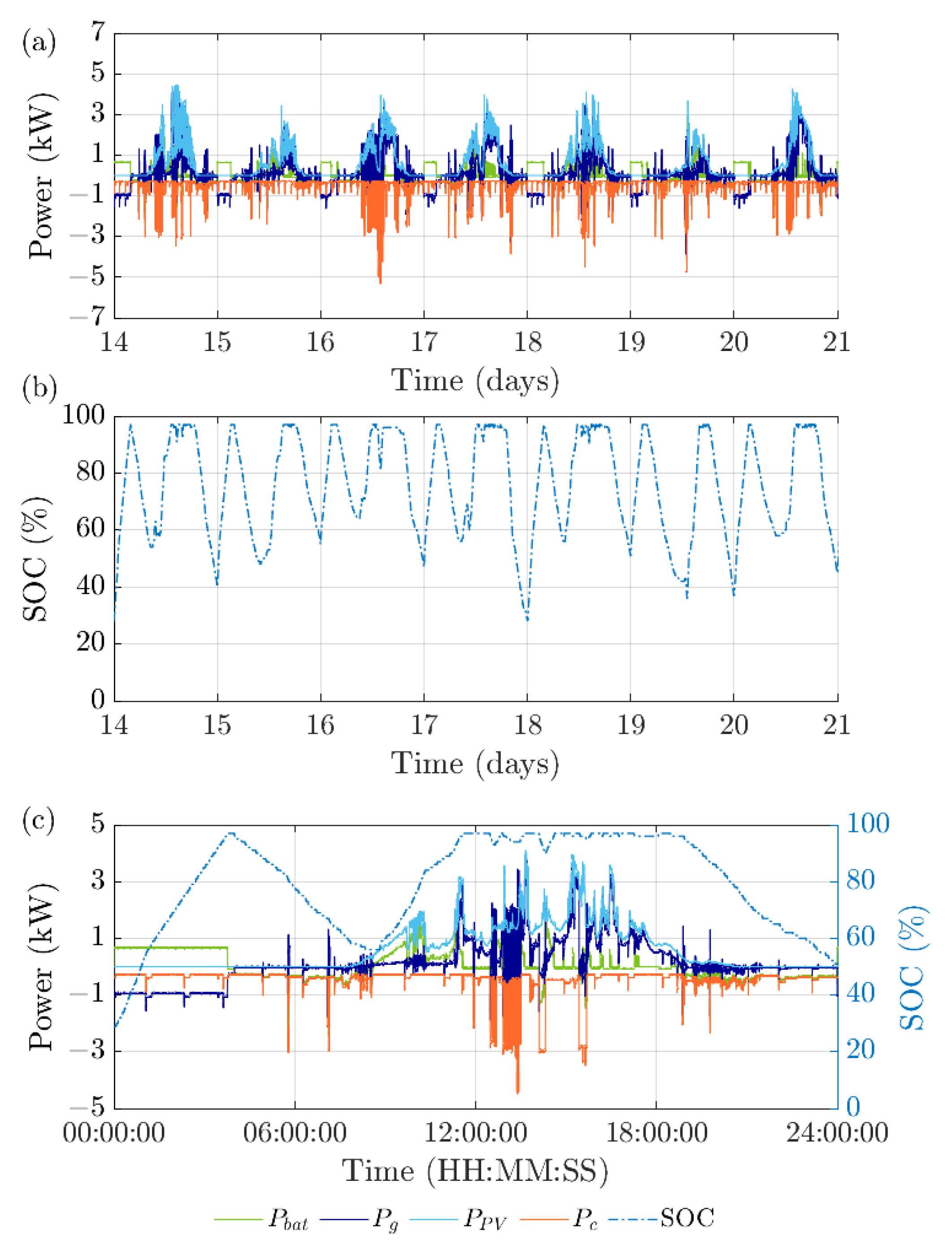

4.1. Residential Microgrids

4.2. EV Fast Charge

4.3. Grid Stability Services

4.4. The Current State and Future of Second-Life Battery Use

5. Economic and Environmental Perspective

5.1. Economic Evaluation

- Cost structures, i.e., SLBs’ purchase and their market price, the balance of system (BOS) and refurbishment costs.

- Revenue streams, i.e., the target market, rate structures, electricity prices, and ancillary service payment structures.

- Technical parameters, i.e., the SLB’s lifetime, power and energy capabilities, efficiency, and heterogeneity.

- Policies and market-specific conditions, i.e., environmental initiatives, subsidies, and legal requirements.

5.2. Environmental Impacts

6. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 21 November 2022).

- Coron, E.; Genies, S.; Cugnet, M.; Thivel, P.X. Impact of Lithium-Ion Cell Condition on Its Second Life Viability. J. Electrochem. Soc. 2020, 167, 110556. [Google Scholar] [CrossRef]

- Electric Vehicles Worldwide. Available online: https://www.statista.com/study/11578/electric-vehicles-statista-dossier/ (accessed on 11 November 2022).

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Tabusse, R.; Bouquain, D.; Jemei, S.; Chrenko, D. Battery Aging Test Design during First and Second Life. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 18 November 2020–16 December 2020; pp. 1–6. [Google Scholar]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A Review on Second-Life of Li-Ion Batteries: Prospects, Challenges, and Issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of Utilising Second Life EV Batteries: Applications, Lifespan, Economics, Environmental Impact, Assessment, and Challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Tan, X. Research on the Classification Method for the Secondary Uses of Retired Lithium-Ion Traction Batteries. Energy Procedia 2017, 105, 2843–2849. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Pedersen, K.; Stroe, D.-I. Lithium-Ion Battery Operation, Degradation, and Aging Mechanism in Electric Vehicles: An Overview. Energies 2021, 14, 5220. [Google Scholar] [CrossRef]

- Albuquerque, L.; Lacressonniere, F.; Roboam, X.; Forgez, C. Incremental Capacity Analysis as a Diagnostic Method Applied to Second Life Li-Ion Batteries. In Proceedings of the ELECTRIMACS 2022, 14th International Conference of the International Association for Mathematics and Computer in Simulation, Nancy, France, 24 May 2022. [Google Scholar]

- Kemény, M.; Ondrejka, P.; Mikolášek, M. Incremental Capacity Analysis for Prediction of Li-Ion Battery Degradation Mechanisms: Simulation Study. In Proceedings of the 2020 13th International Conference on Advanced Semiconductor Devices and Microsystems (ASDAM), Smolenice, Slovakia, 11 October 2020; p. 22. [Google Scholar]

- Braco, E.; San Martin, I.; Ursua, A.; Sanchis, P. Incremental Capacity Analysis of Lithium-Ion Second-Life Batteries from Electric Vehicles under Cycling Ageing. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021; p. 6. [Google Scholar]

- Martín, I.S.; Braco, E.; Martin, Á.; Sanchis, P.; Ursúa, A. Integration of Second-Life Batteries in Residential Microgrids and Fast Charging Stations. In Proceedings of the 2022 IEEE International Conference on Environment and Electrical Engineering and 2022 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Prague, Czech Republic, 28 June–1 July 2022; pp. 1–6. [Google Scholar]

- Canals Casals, L.; García, B.; Canal, C. Second Life Batteries Lifespan: Rest of Useful Life and Environmental Analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Canals Casals, L.; Amante García, B. Second-Life Batteries on a Gas Turbine Power Plant to Provide Area Regulation Services. Batteries 2017, 3, 10. [Google Scholar] [CrossRef] [Green Version]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation Diagnostics for Lithium Ion Cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Ecker, M.; Gerschler, J.B.; Vogel, J.; Käbitz, S.; Hust, F.; Dechent, P.; Sauer, D.U. Development of a Lifetime Prediction Model for Lithium-Ion Batteries Based on Extended Accelerated Aging Test Data. J. Power Sources 2012, 215, 248–257. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Świerczyński, M.; Stan, A.-I.; Teodorescu, R.; Andreasen, S.J. Accelerated Lifetime Testing Methodology for Lifetime Estimation of Lithium-Ion Batteries Used in Augmented Wind Power Plants. IEEE Trans. Ind. Appl. 2014, 50, 4006–4017. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-Life Model for Graphite-LiFePO4 Cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Swierczynski, M.; Kær, S.K.; Laserna, E.M.; Zabala, E.S. Accelerated Aging of Lithium-Ion Batteries Based on Electric Vehicle Mission Profile. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 5631–5637. [Google Scholar]

- Stroe, D.-I.; Schaltz, E. Lithium-Ion Battery State-of-Health Estimation Using the Incremental Capacity Analysis Technique. IEEE Trans. Ind. Appl. 2020, 56, 678–685. [Google Scholar] [CrossRef]

- Micari, S.; Foti, S.; Testa, A.; De Caro, S.; Sergi, F.; Andaloro, L.; Aloisio, D.; Leonardi, S.G.; Napoli, G. Effect of WLTP CLASS 3B Driving Cycle on Lithium-Ion Battery for Electric Vehicles. Energies 2022, 15, 6703. [Google Scholar] [CrossRef]

- Alhadri, M.; Zakri, W.; Farhad, S. Study on Integration of Retired Lithium-Ion Battery With Photovoltaic for Net-Zero Electricity Residential Homes. J. Sol. Energy Eng. 2022, 145, 021011. [Google Scholar] [CrossRef]

- Seger, P.V.H.; Thivel, P.-X.; Riu, D. A Second Life Li-Ion Battery Ageing Model with Uncertainties: From Cell to Pack Analysis. J. Power Sources 2022, 541, 231663. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Villarreal Sarria, I.; Stroe, D.-I.; Swierczynski, M.; Warnecke, A.; Timmermans, J.-M.; Goutam, S.; Omar, N.; Rodriguez, P. Technical Viability of Battery Second Life: A Study from the Ageing Perspective. IEEE Trans. Ind. Appl. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Braco, E.; San Martin, I.; Sanchis, P.; Ursua, A. Characterization and Capacity Dispersion of Lithiumion Second-Life Batteries from Electric Vehicles. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019; p. 6. [Google Scholar]

- ISO 12405-4:2018(En), Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems—Part 4: Performance Testing. Available online: https://www.iso.org/obp/ui/#iso:std:iso:12405:-4:ed-1:v1:en (accessed on 2 January 2023).

- Guo, J.; Jin, S.; Sui, X.; Huang, X.; Xu, Y.; Li, Y.; Kjær Kristensen, P.; Wang, D.; Pedersen, K.; Gurevich, L.; et al. Unravelling and Quantifying the Aging Processes of Commercial Li(Ni0.5Co0.2Mn0.3)O2/Graphite Lithium-Ion Batteries under Constant Current Cycling. J. Mater. Chem. A 2023, 11, 41–52. [Google Scholar] [CrossRef]

- Muhammad, M.; Ahmeid, M.; Attidekou, P.S.; Milojevic, Z.; Lambert, S.; Das, P. Assessment of Spent EV Batteries for Second-Life Application. In Proceedings of the 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, 25–28 November 2019; pp. 1–5. [Google Scholar]

- Kalogiannis, T.; Stroe, D.I.; Nyborg, J.; Nørregaard, K.; Christensen, A.E.; Schaltz, E. Incremental Capacity Analysis of a Lithium-Ion Battery Pack for Different Charging Rates. ECS Trans. 2017, 77, 403. [Google Scholar] [CrossRef]

- Barai, A.; Uddin, K.; Dubarry, M.; Somerville, L.; McGordon, A.; Jennings, P.; Bloom, I. A Comparison of Methodologies for the Non-Invasive Characterisation of Commercial Li-Ion Cells. Prog. Energy Combust. Sci. 2019, 72, 1–31. [Google Scholar] [CrossRef]

- Zhou, Z.; Ran, A.; Chen, S.; Zhang, X.; Wei, G.; Li, B.; Kang, F.; Zhou, X.; Sun, H. A Fast Screening Framework for Second-Life Batteries Based on an Improved Bisecting K-Means Algorithm Combined with Fast Pulse Test. J. Energy Storage 2020, 31, 101739. [Google Scholar] [CrossRef]

- Gismero, A. Electric Vehicle Batteries State Estimation Under a Wide Range of Test and Aging Conditions. Ph.D. Thesis, Aalborg University, Aalborg Øst, Denmark, 2022. [Google Scholar]

- Braco, E.; San Martin, I.; Sanchis, P.; Ursúa, A.; Stroe, D.-I. Health Indicator Selection for State of Health Estimation of Second-Life Lithium-Ion Batteries under Extended Ageing. J. Energy Storage 2022, 55, 105366. [Google Scholar] [CrossRef]

- Middlemiss, L.A.; Rennie, A.J.R.; Sayers, R.; West, A.R. Characterisation of Batteries by Electrochemical Impedance Spectroscopy. Energy Rep. 2020, 6, 232–241. [Google Scholar] [CrossRef]

- Locorotondo, E.; Cultrera, V.; Pugi, L.; Berzi, L.; Pasquali, M.; Andrenacci, N.; Lutzemberger, G.; Pierini, M. Impedance Spectroscopy Characterization of Lithium Batteries with Different Ages in Second Life Application. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Kehl, D.; Jennert, T.; Lienesch, F.; Kurrat, M. Electrical Characterization of Li-Ion Battery Modules for Second-Life Applications. Batteries 2021, 7, 32. [Google Scholar] [CrossRef]

- Schaltz, E.; Stroe, D.-I.; Nørregaard, K.; Ingvardsen, L.S.; Christensen, A. Incremental Capacity Analysis Applied on Electric Vehicles for Battery State-of-Health Estimation. IEEE Trans. Ind. Appl. 2021, 57, 1810–1817. [Google Scholar] [CrossRef]

- Sihvo, J.; Roinila, T.; Stroe, D.-I. Broadband Impedance Measurement of Lithium-Ion Battery in the Presence of Nonlinear Distortions. Energies 2020, 13, 2493. [Google Scholar] [CrossRef]

- Electric Energy Storage Technology Options: A Primer on Applications, Costs & Benefits—An EPRI Executive Summary. Available online: https://www.epri.com/research/products/000000000001022261 (accessed on 6 December 2022).

- Braco, E. On the Second Life of Lithium-Ion Batteries from Electric Vehicles: Characterisation, Aging, and Applications. Ph.D. Dissertation, Pubilc University of Navarra, Pamplona, Spain, 2022. [Google Scholar]

- Pražská Energetika Upravuje Ceny Za Dobíjení Elektromobilů v Síti PREpoint—PRE. Available online: https://www.pre.cz/cs/profil-spolecnosti/media/tiskove-zpravy/prazska-energetika-upravuje-ceny-za-dobijeni-elektromobilu-v-siti-prepoint-132022/ (accessed on 4 December 2022).

- A Second Life for Used Batteries. Available online: https://www.bosch-press.be/pressportal/be/en/press-release-562.html (accessed on 30 January 2023).

- Rybárik, M.; Braciník, P.; Kajanová, M. Overview of the Usability of Second-Life Batteries in Smart Distribution Grids. In Proceedings of the 2022 ELEKTRO (ELEKTRO), Krakow, Poland, 23–26 May 2022; pp. 1–4. [Google Scholar]

- Nové Nabíjecí Centrum v Praze Využívá Recyklované Baterie z Enyaqů—Novinky. Available online: https://www.novinky.cz/clanek/auto-nove-nabijeci-centrum-v-praze-vyuziva-recyklovane-baterie-z-enyaqu-40410686 (accessed on 23 January 2023).

- Second Life Batteries, Expertise and a Can-Do Attitude—Innovation Boosts Hydropower Plant. Available online: https://www.fortum.com/about-us/our-company/strategy/decarbonisation-joint-effort/second-life-batteries-hydropower-plant (accessed on 30 November 2022).

- Martinez-Laserna, E. Methodology for the Techno-Economic Assessment of Second Life Lithium-Ion Batteries. Ph.D. Thesis, Mondragon Unibertsitatea, Mondragón, Spain, 2017. [Google Scholar]

- Reinhardt, R. Sustainable Business Model Perspectives for the Electric Vehicle Industry: The Case of Battery Second Use. Ph.D. Thesis, Universitat Politècnica de Catalunya, Catalonia, Spain, 2019. [Google Scholar]

- Europe’s Largest Energy Storage System Now Live at the Johan Cruijff Arena. Available online: https://global.nissannews.com/en/releases/europes-largest-energy-storage-system-now-live-at-the-johan-cruijff-arena (accessed on 10 January 2023).

- Audi Opens Battery Storage Unit on Berlin EUREF Campus. Available online: https://www.audi-mediacenter.com:443/en/press-releases/audi-opens-battery-storage-unit-on-berlin-euref-campus-11681 (accessed on 10 January 2023).

- Second Life for a Coal Power Plant in Germany—Electrive.Com. Available online: https://www.electrive.com/2020/11/24/second-life-for-a-coal-power-plant-in-germany/ (accessed on 10 January 2023).

- Renault Batteries Find ‘Megawatt-Scale’ 2nd Life Use in Belgium—Energy Storage News. Available online: https://www.energy-storage.news/renault-batteries-find-megawatt-scale-2nd-life-use-in-belgium/ (accessed on 10 January 2023).

- A World-Leading Circular Solution for Charging of Vehicles. Available online: https://batteryloop.com/news-feed/world-leading-circular-solution-for-charging-of-vehicles-inaugurated/ (accessed on 10 January 2023).

- RWE Second Life for EV Batteries: RWE and Audi Create Novel Energy Storage System in Herdecke. Available online: https://www.rwe.com/en/press/rwe-generation/2021-12-28-second-life-for-ev-batteries (accessed on 10 January 2023).

- Marthaler, L.; Grudzien, P.; Buysse, M.; Ierides, M.; Mccready, A. Market-Intelligence-Report-December-2022. Available online: https://projectcobra.eu/wp-content/uploads/2022/12/Market-Intelligence-Report-December-2022.pdf (accessed on 3 January 2022).

- Fortum Installs Innovative Battery Solution at Landafors Hydropower Plant in Sweden. Available online: https://www.fortum.com/media/2021/04/fortum-installs-innovative-battery-solution-landafors-hydropower-plant-sweden (accessed on 10 January 2023).

- Enel Launches Innovative “Second Life” Storage System for Used Electric Car Batteries in Melilla, Spain. Available online: https://www.enel.com/media/explore/search-press-releases/press/2022/03/enel-launches-innovative-second-life-storage-system-for-used-electric-car-batteries-in-melilla-spain- (accessed on 10 January 2023).

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Cogswell, D.; Xing, B.; Sedlatschek, T.; Kantareddy, S.N.R.; Yi, M.; Gao, T.; et al. End-of-Life or Second-Life Options for Retired Electric Vehicle Batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- Kelleher Environmental. Kelleher Environmental Research Study on Reuse and Recycling of Batteries Employed in Electric Vehicles: The Technical, Environmental, Economic, Energy and Cost Implications of Reusing and Recycling EV Batteries; Summary Report; Kelleher Environmental: Toronto, ON, Canada, 2019. [Google Scholar]

- Neubauer, J.; Pesaran, A. The Ability of Battery Second Use Strategies to Impact Plug-in Electric Vehicle Prices and Serve Utility Energy Storage Applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Williams, B.; Lipman, T. Analysis of The Combined Vehicle-and Post-Vehicle-Use Value of Lithium-Ion Plug-In-Vehicle Propulsion Batteries; California Institute for Energy and Environment (CIEE): Berkeley, CA, USA, 2011. [Google Scholar]

- Assunção, A.; Moura, P.S.; de Almeida, A.T. Technical and Economic Assessment of the Secondary Use of Repurposed Electric Vehicle Batteries in the Residential Sector to Support Solar Energy. Appl. Energy 2016, 181, 120–131. [Google Scholar] [CrossRef]

- Ambrose, H.; Gershenson, D.; Gershenson, A.; Kammen, D. Driving Rural Energy Access: A Second-Life Application for Electric-Vehicle Batteries. Environ. Res. Lett. 2014, 9, 094004. [Google Scholar] [CrossRef] [Green Version]

- Neubauer, J.S.; Pesaran, A.; Williams, B.; Ferry, M.; Eyer, J. A Techno-Economic Analysis of PEV Battery Second Use: Repurposed-Battery Selling Price and Commercial and Industrial End-User Value; National Renewable Energy Lab (NREL): Golden, CO, USA, 2012; p. 2012–01–0349.

- Cicconi, P.; Landi, D.; Morbidoni, A.; Germani, M. Feasibility Analysis of Second Life Applications for Li-Ion Cells Used in Electric Powertrain Using Environmental Indicators. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012; pp. 985–990. [Google Scholar]

- Philippot, M.; Costa, D.; Hosen, M.S.; Senécat, A.; Brouwers, E.; Nanini-Maury, E.; Van Mierlo, J.; Messagie, M. Environmental Impact of the Second Life of an Automotive Battery: Reuse and Repurpose Based on Ageing Tests. J. Clean. Prod. 2022, 366, 132872. [Google Scholar] [CrossRef]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part II: Environmental and Economic Perspective. Energies 2022, 15, 7356. [Google Scholar] [CrossRef]

- Braco, E.; San Martín, I.; Berrueta, A.; Sanchis, P.; Ursúa, A. Experimental Assessment of Cycling Ageing of Lithium-Ion Second-Life Batteries from Electric Vehicles. J. Energy Storage 2020, 32, 101695. [Google Scholar] [CrossRef]

| Name | Location | Partners | EV model | Capacity | Application | Date |

|---|---|---|---|---|---|---|

| Johan Cruyff Arena [49] | Amsterdam, Netherlands | Eaton, Nissan, BAM The Mobility House, Johan Cruijff Arena | 148 Nissan Leaf battery pack | 2.8 MWh | PV power supply, emergency supply | 2018 |

| EUREF Campus [50] | Berlin, Germany | Audi | Audi | 1.9 MWh | Multi-use storage unit compensates for fluctuations in the grid and optimizes energy supply | 2019 |

| Former coal-fired power plant in Elverlingsen [51] | Elverlingsen, Germany | Renault | 72 batteries Renault Zoes | 3 MWh | Energy storage for the power grid | 2020 |

| Grid services ENG I E [52] | Olen, Belgium | Renault Connected Energy | Renault Kangoo | 720 kWh | Provides firm frequency response to the grid, acting as a revenue generator | 2020 |

| Battery Loop Energy Storage System [53] | Mölndal, Sweden | Volvo BatteryLoop Essity | Volvo XC40 | NA | PV-powered charging stations for EVs and e-bikes | April 2021 |

| Energy storage system in Herdecke [54] | Herdecke, Germany | Audi RWE | Audi e-tron | 4.5 MWh | Frequency response services | November 2021 |

| TGN Energy battery energy storage [55] | Oslo, Norway | Mercedes-Benz Evergy Evyon, TGN | Mercedes Benz | 216 kWh | Increased self-consumption | November 2021 |

| Landafors hydropower plant [56] | Landafors, Sweden | Fortum Volvo Cars Comsys | Volvo Cars plug-in hybrids | 250 kWh | Offers fast frequency reserve regulation to the power markets | 2021 |

| Enel Group’s Second Life project [57] | Melilla, Spain | Enel group | 78 Nissan Leaf battery pack | 1.7 MWh | Grid stability service—Black start | March 2022 |

| Saxony’s battery storage facility [55] | Freiberg, Germany | Jungheinrich Energy Systems Tricera energy | Jungheinrich forklift batteries | NA | Peak shaving, grid stability services | September 2022 |

| Industrial energy storage system [45] | Prague, Czech Republic | IBG, Škoda, PRE | Škoda Enyaq iV | 300 kWh | EV charging station | October 2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nováková, K.; Pražanová, A.; Stroe, D.-I.; Knap, V. Second-Life of Lithium-Ion Batteries from Electric Vehicles: Concept, Aging, Testing, and Applications. Energies 2023, 16, 2345. https://doi.org/10.3390/en16052345

Nováková K, Pražanová A, Stroe D-I, Knap V. Second-Life of Lithium-Ion Batteries from Electric Vehicles: Concept, Aging, Testing, and Applications. Energies. 2023; 16(5):2345. https://doi.org/10.3390/en16052345

Chicago/Turabian StyleNováková, Kateřina, Anna Pražanová, Daniel-Ioan Stroe, and Vaclav Knap. 2023. "Second-Life of Lithium-Ion Batteries from Electric Vehicles: Concept, Aging, Testing, and Applications" Energies 16, no. 5: 2345. https://doi.org/10.3390/en16052345