Thermal Interface Materials with Hexagonal Boron Nitride and Graphene Fillers in PDMS Matrix: Thermal and Mechanical Properties

Abstract

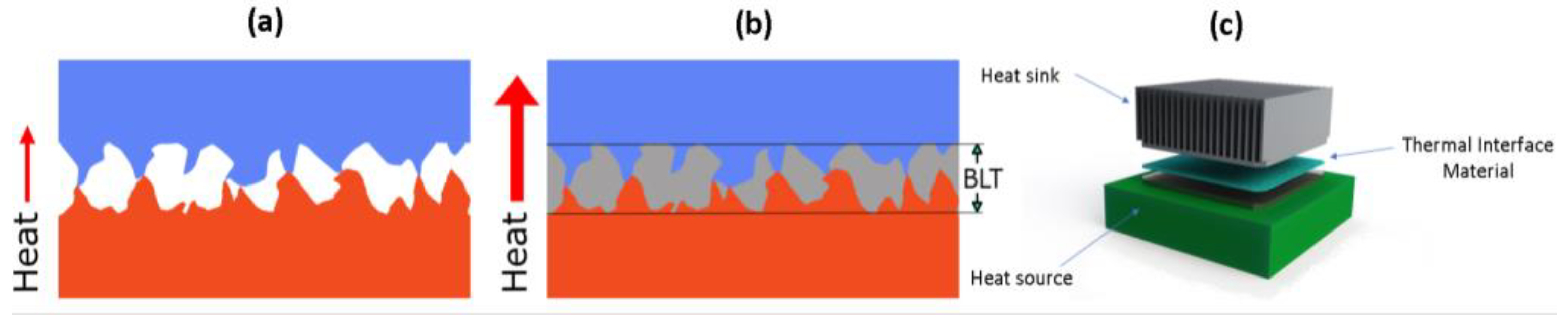

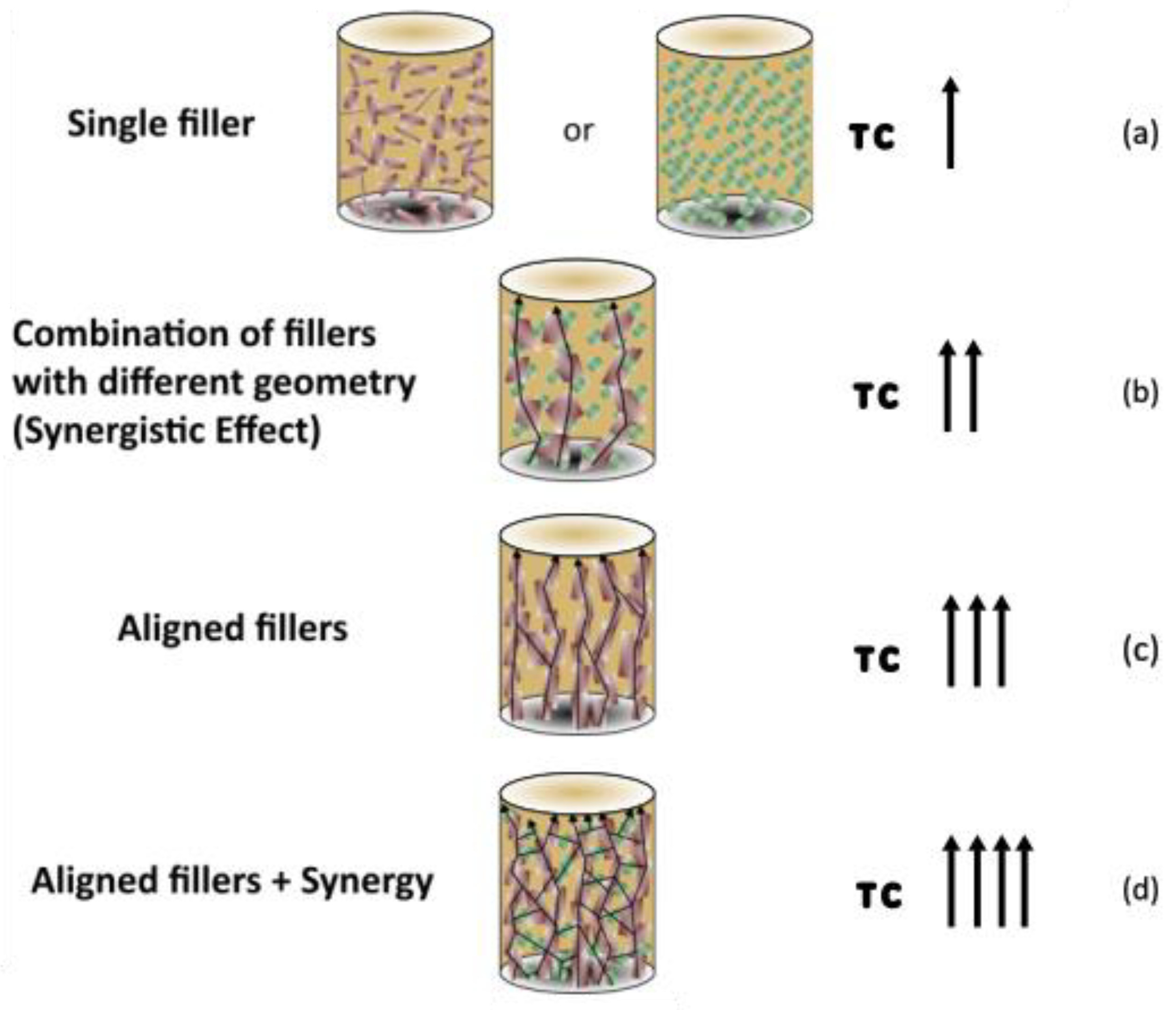

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of hBN/PDMS Composites, GNP/PDMS Nanocomposites and hBN/GNP/PDMS Nanocomposites

2.3. Thermal Characterisation of hBN/GNP Nanocomposites

2.3.1. Thermal Conductivity Measurements

2.3.2. Curing Study by Differential Scanning Calorimetry (DSC)

2.3.3. Thermal Stability Study by Thermogravimetry (TGA)

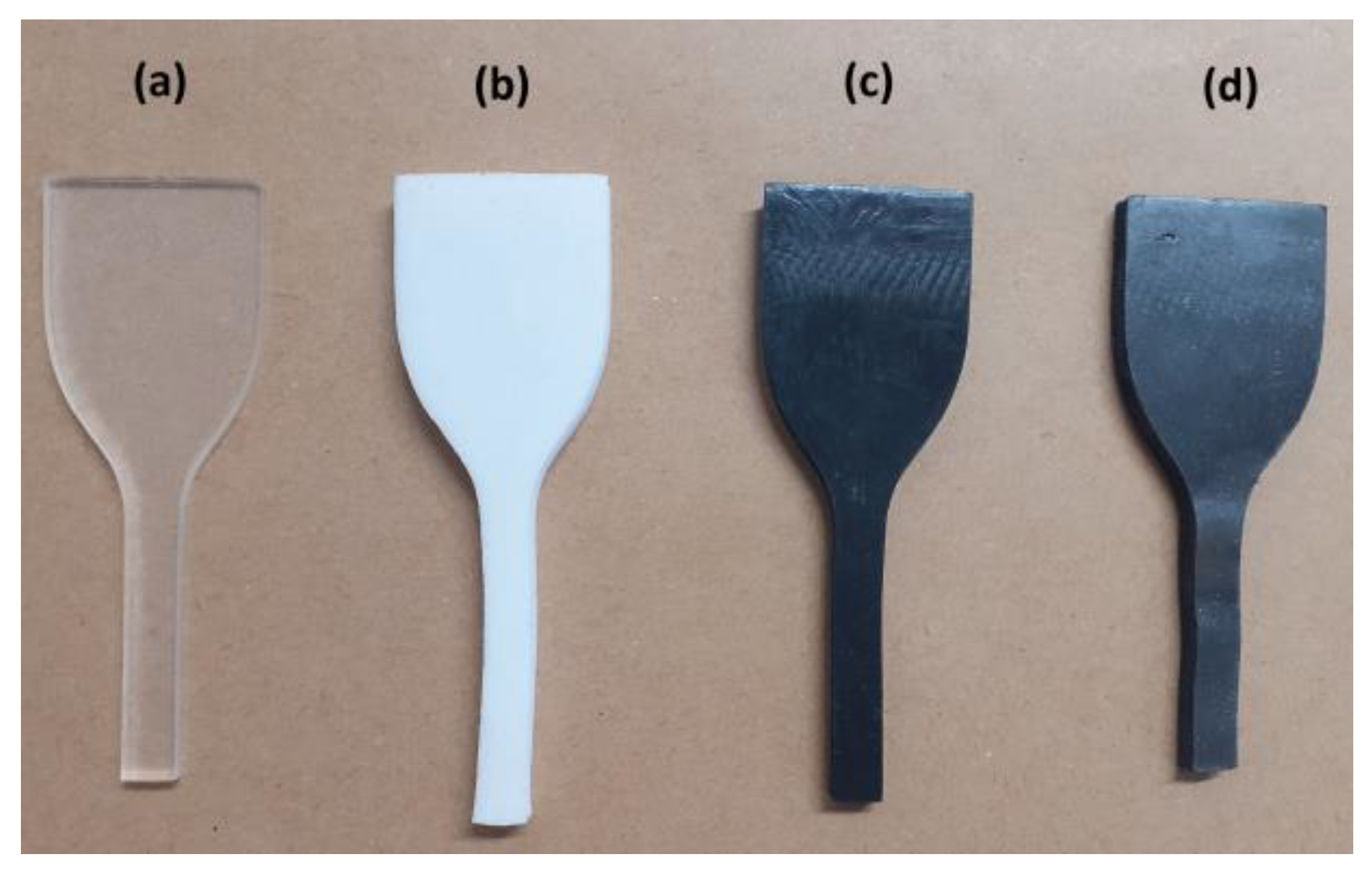

2.4. Mechanical Characterisation of Neat PDMS, hBN/PDMS, GNP/PDMS and hBN/GNP/PDMS Nanocomposites

2.4.1. Tensile Testing

2.4.2. Shore Hardness

2.4.3. Rheology

2.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

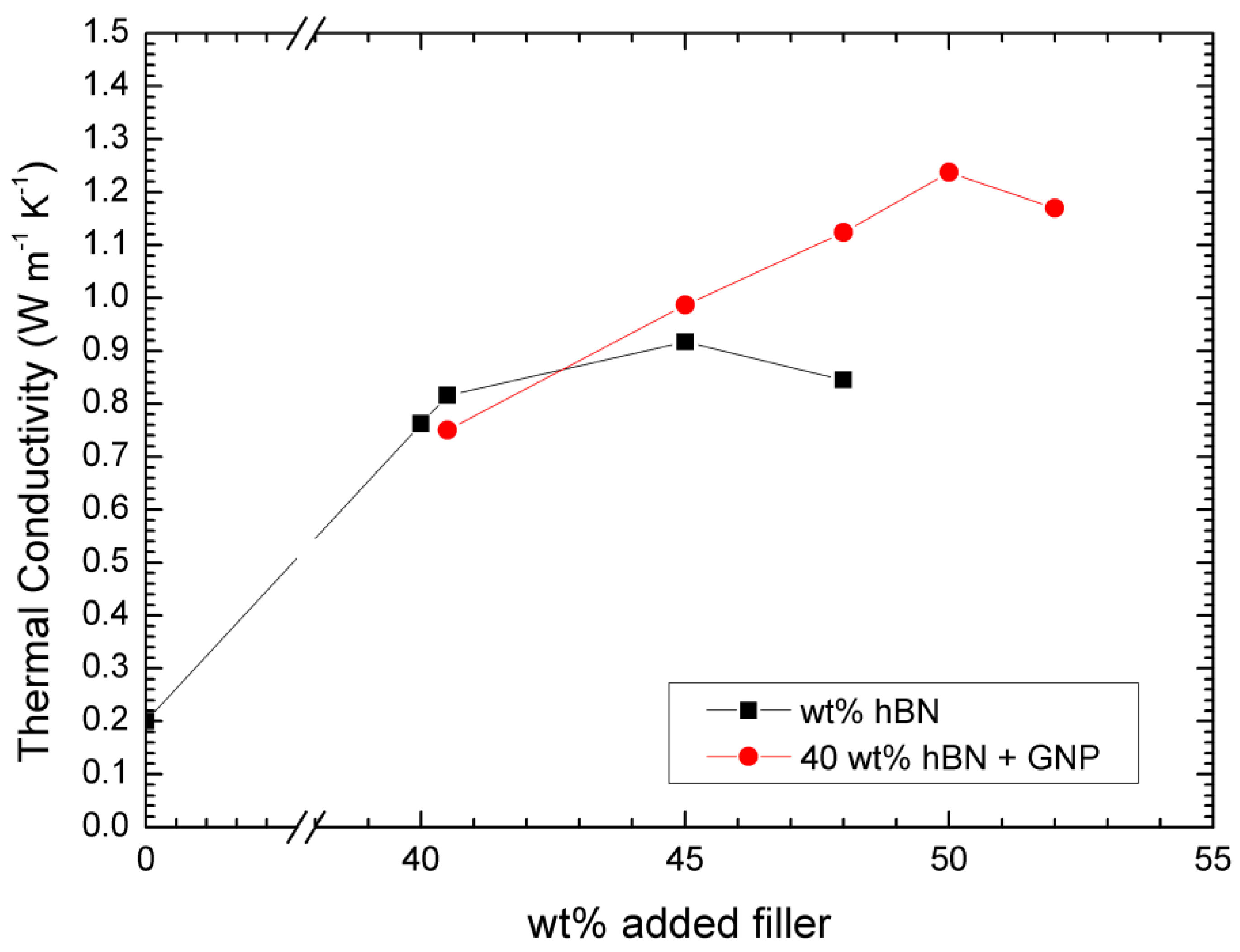

3.1. Thermal Measurements

3.1.1. Thermal Conductivity Tests

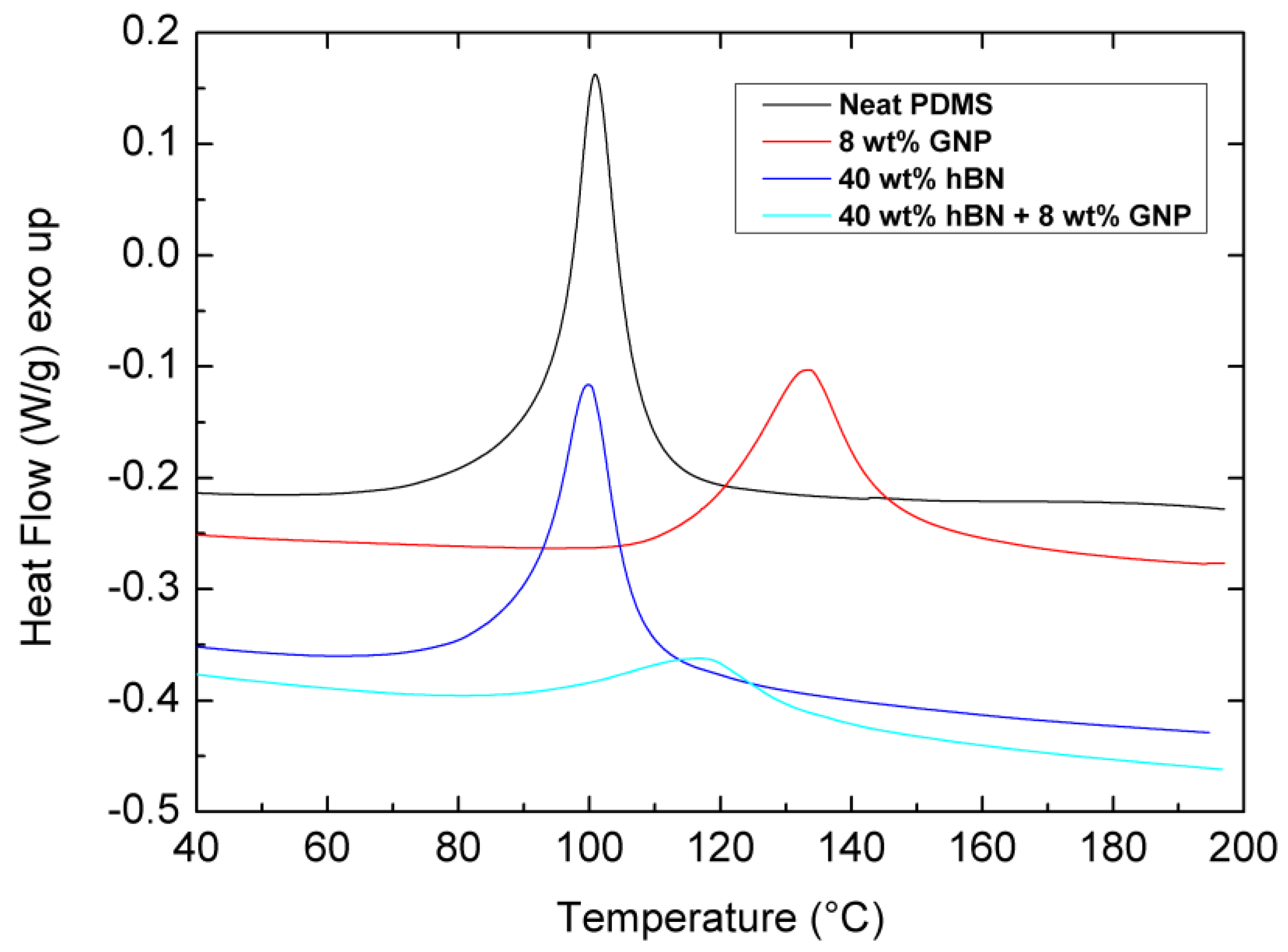

3.1.2. DSC Tests

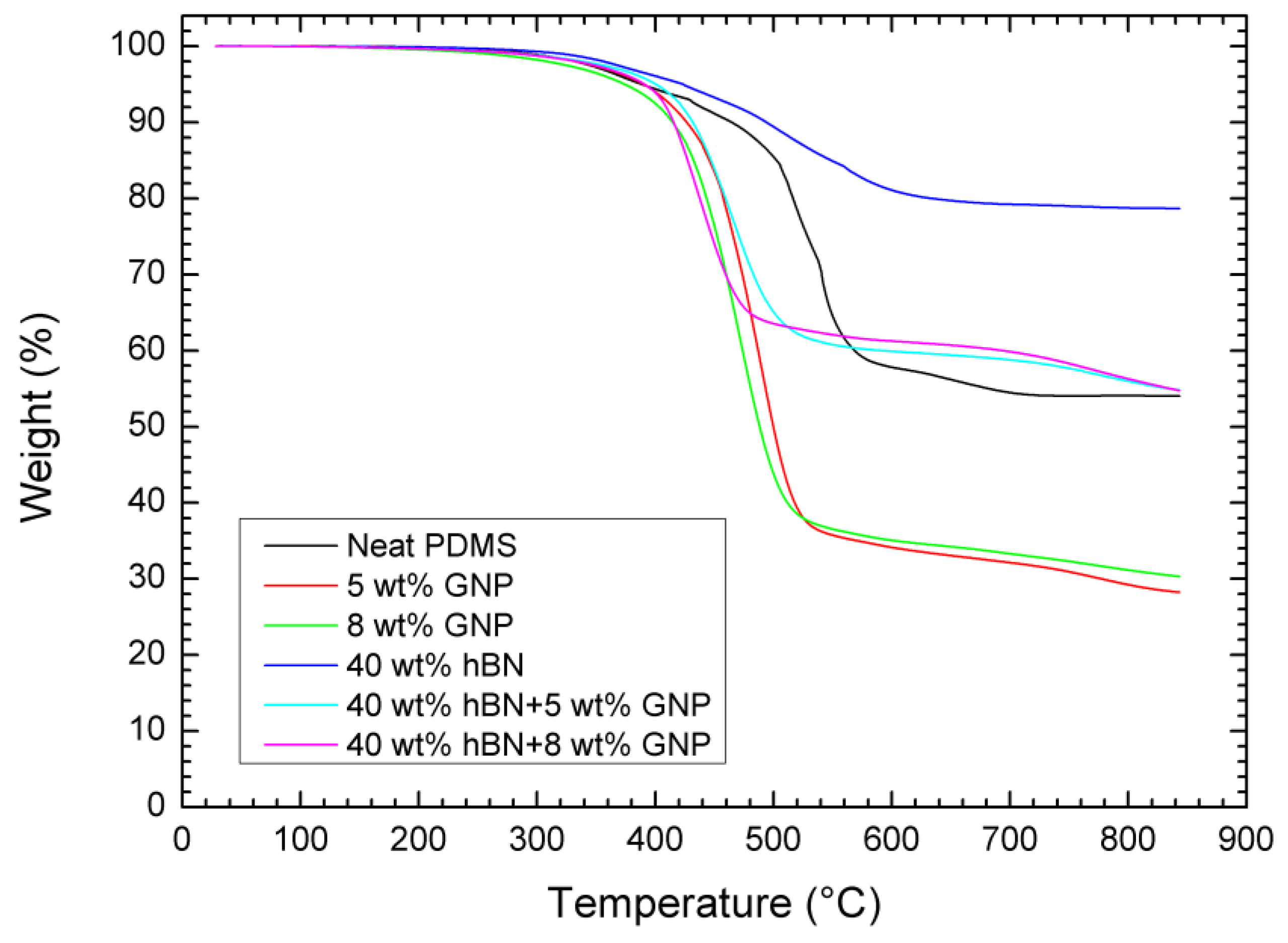

3.1.3. TGA Tests

3.2. Mechanical Measurements

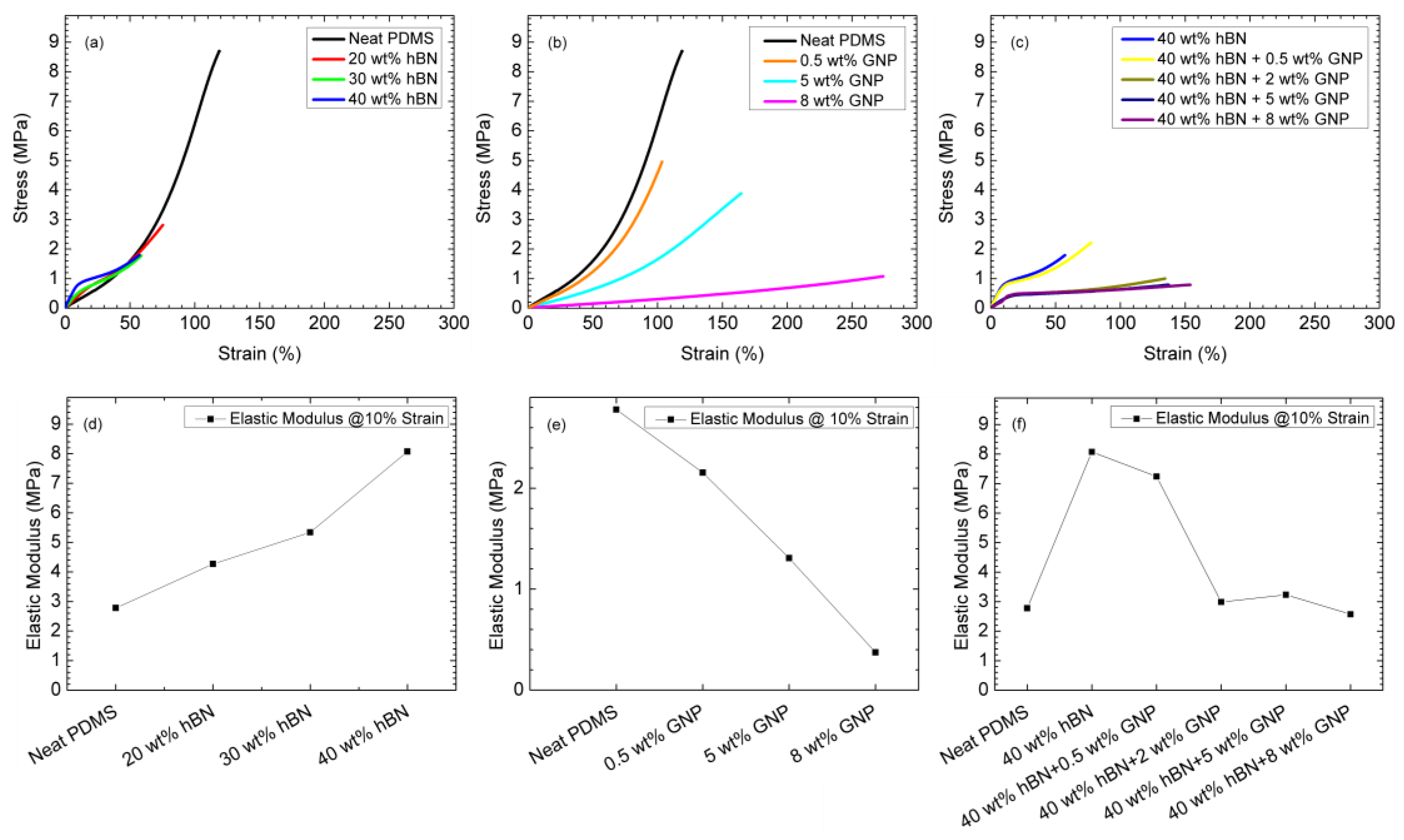

3.2.1. Tensile Tests

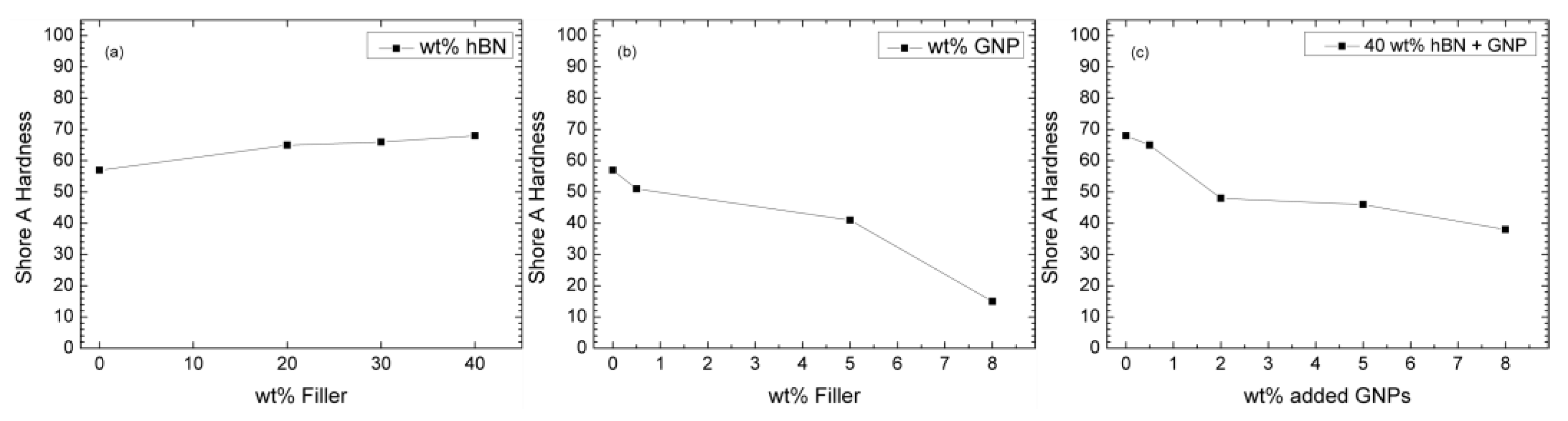

3.2.2. Shore Hardness

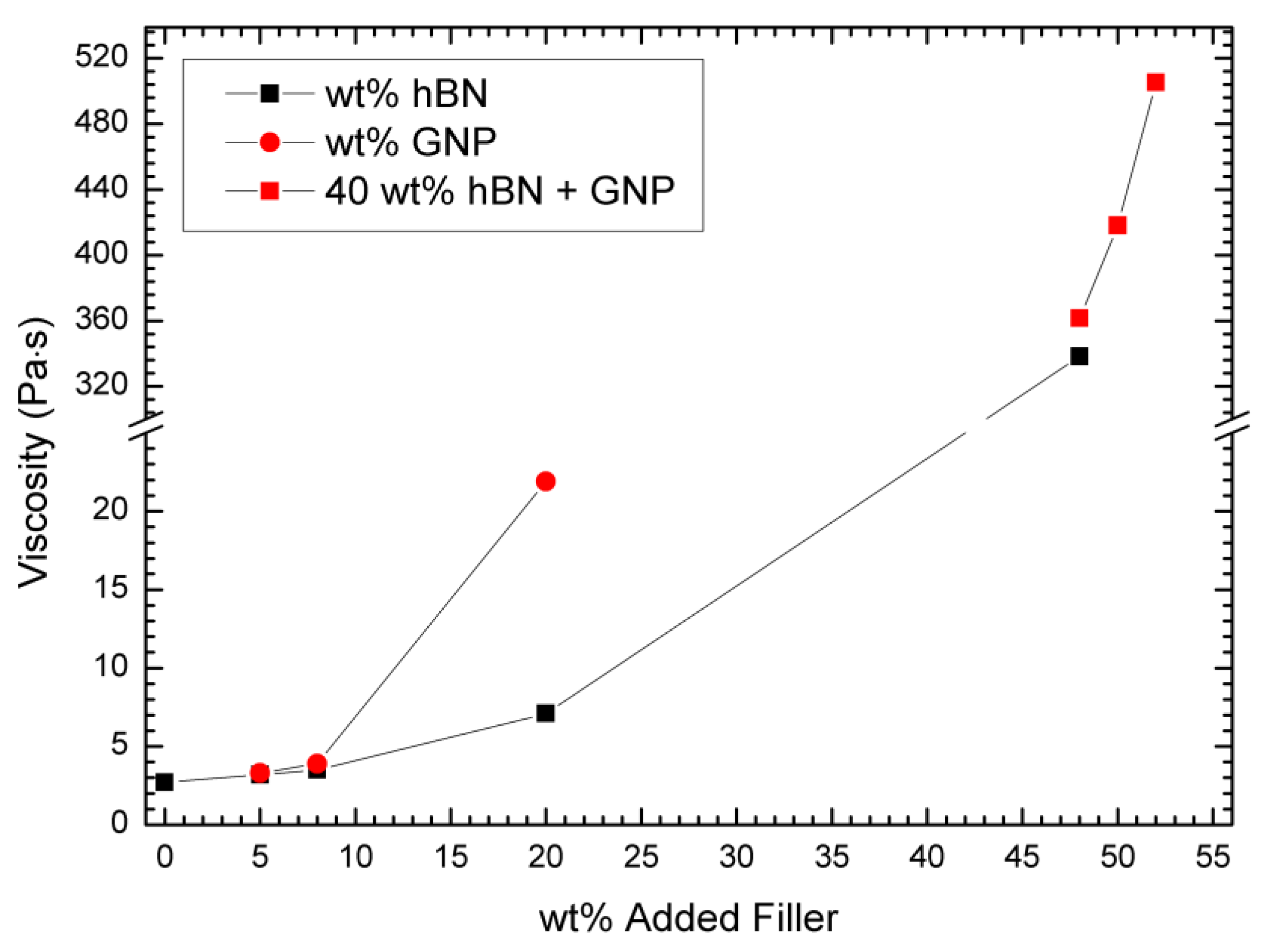

3.2.3. Rheology of Uncured PDMS/hBN, PDMS/GNP and PDMS/hBN/GNP Samples

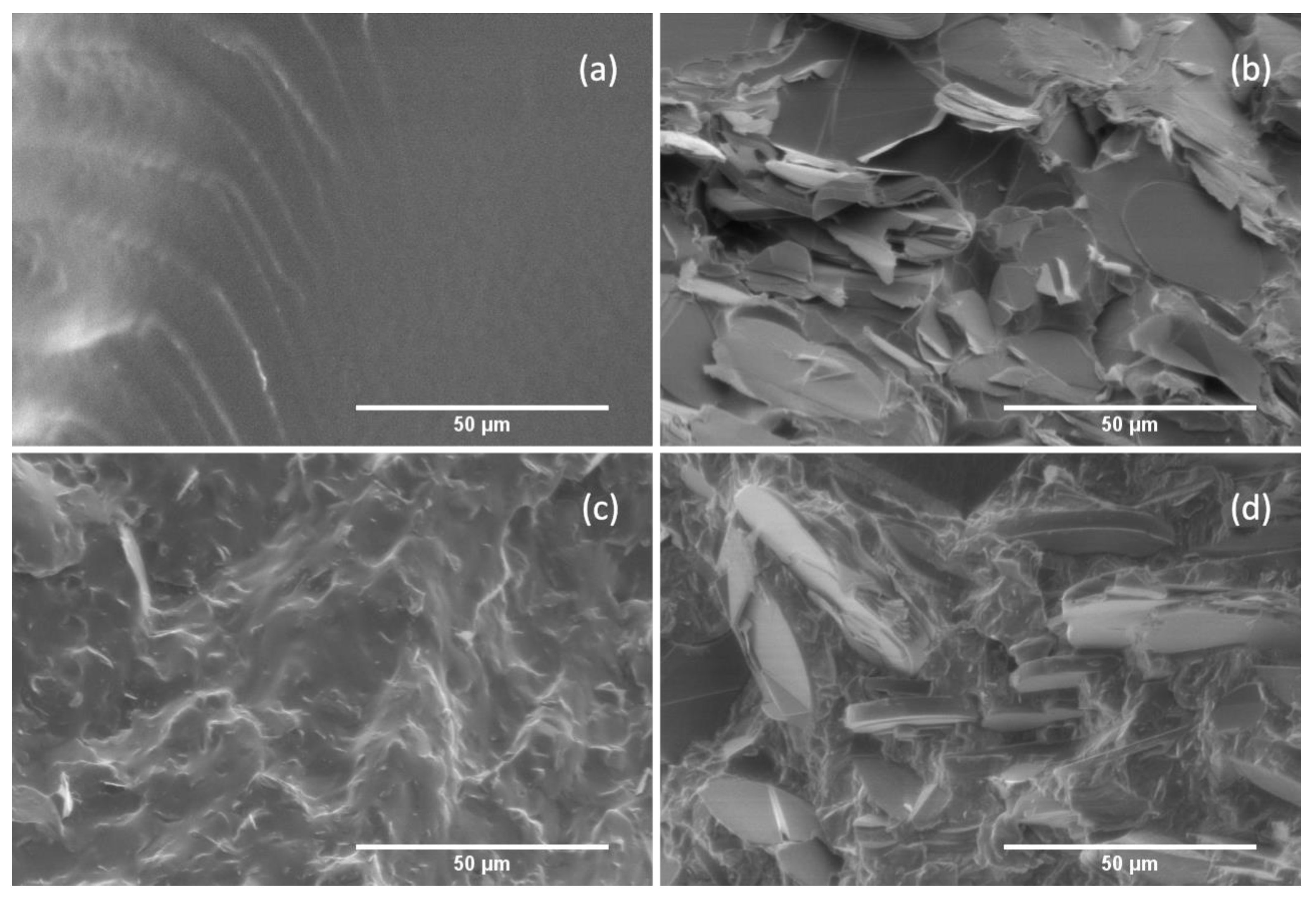

3.3. SEM

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prasher, R.; Chiu, C.-P. Thermal Interface Materials. In Materials for Advanced Packaging; Lu, D., Wong, C.P., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 511–535. [Google Scholar] [CrossRef]

- Xiong, J.; Chen, S.; Choi, Y.; Matsugi, K. Development of polyvinyl alcohol-based carbon nano fiber sheet for thermal interface material. Sci. Rep. 2021, 11, 17183. [Google Scholar] [CrossRef] [PubMed]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Chandran, M. Chapter Six-Synthesis, Characterization, and Applications of Diamond Films. In Carbon-Based Nanofillers and Their Rubber Nanocomposites; Yaragalla, S., Mishra, R., Thomas, S., Kalarikkal, N., Maria, H.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 183–224. [Google Scholar] [CrossRef]

- Manno, M.; Yang, B.; Khanna, S.; McCluskey, P.; Bar-Cohen, A. Microcontact-Enhanced Thermoelectric Cooling of Ultrahigh Heat Flux Hotspots. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1775–1783. [Google Scholar] [CrossRef]

- Yuan, G.; Li, H.; Shan, B.; Liu, J. Thermal Interface Materials Based on Vertically Aligned Carbon Nanotube Arrays: A Review. Micro Nanosyst. 2019, 11, 3–10. [Google Scholar] [CrossRef]

- Si, Y.; Wang, X.; Dou, L.; Yu, J.; Ding, B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci. Adv. 2018, 4, 8925. [Google Scholar] [CrossRef] [Green Version]

- An, D.; Cheng, S.; Zhang, Z.; Jiang, C.; Fang, H.; Li, J.; Liu, Y.; Wong, C.-P. A polymer-based thermal management material with enhanced thermal conductivity by introducing three-dimensional networks and covalent bond connections. Carbon 2019, 155, 258–267. [Google Scholar] [CrossRef]

- Si, W.; Sun, J.; He, X.; Huang, Y.; Zhuang, J.; Zhang, J.; Murugadoss, V.; Fan, J.; Wu, D.; Guo, Z. Enhancing thermal conductivity via conductive network conversion from high to low thermal dissipation in polydimethylsiloxane composites. J. Mater. Chem. C 2020, 8, 3463–3475. [Google Scholar] [CrossRef]

- Ouyang, Y.; Ding, F.; Bai, L.; Li, X.; Hou, G.; Fan, J.; Yuan, F. Design of network Al2O3 spheres for significantly enhanced thermal conductivity of polymer composites. Compos. Part A Appl. Sci Manuf. 2020, 128, 105673. [Google Scholar] [CrossRef]

- Yue, C.; Guan, L.; Zhang, X.; Wang, Y.; Weng, L. Thermally conductive epoxy/boron nitride composites with high glass transition temperatures for thermal interface materials. Mater. Des. 2021, 212, 110190. [Google Scholar] [CrossRef]

- Shimamura, A.; Hotta, Y.; Hyuga, H.; Hotta, M.; Hirao, K. Improving the thermal conductivity of epoxy composites using a combustion-synthesized aggregated β-Si3N4 filler with randomly oriented grains. Sci. Rep. 2020, 10, 14926. [Google Scholar] [CrossRef]

- Barani, Z.; Mohammadzadeh, A.; Geremew, A.; Huang, C.Y.T.; Coleman, D.; Mangolini, L.; Kargar, F.; Balandin, A. Thermal Properties of the Binary-Filler Hybrid Composites with Graphene and Copper Nanoparticles. Adv. Funct. Mater. 2019, 30, 1904008. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P.; He, H.; Zhai, S.; Xian, Y.; Ma, W.; Wang, L. Enhanced Thermal Transport Properties of Epoxy Resin Thermal Interface Materials. ES Energy Environ. 2019, 4, 41–47. [Google Scholar] [CrossRef]

- Shang, Y.; Yang, G.; Su, F.; Feng, Y.; Ji, Y.; Liu, D.; Yin, R.; Liu, C.; Shen, C. Multilayer polyethylene/ hexagonal boron nitride composites showing high neutron shielding efficiency and thermal conductivity. Compos. Commun. 2020, 19, 147–153. [Google Scholar] [CrossRef]

- Guo, Y.; Cao, C.; Cheng, H.; Chen, Q.; Huang, B.; Luo, F.; Qian, Q. Thermal Performances of UHMWPE/BN Composites Obtained from Different Blending Methods. Adv. Polym. Technol. 2019, 2019, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Jing, J.; Chen, Y.; Shi, S.; Yang, L.; Lambin, P. Facile and scalable fabrication of highly thermal conductive polyethylene/graphene nanocomposites by combining solid-state shear milling and FDM 3D-printing aligning methods. Chem. Eng. J. 2020, 402, 126218. [Google Scholar] [CrossRef]

- Morishita, T.; Okamoto, H. Facile Exfoliation and Noncovalent Superacid Functionalization of Boron Nitride Nanosheets and Their Use for Highly Thermally Conductive and Electrically Insulating Polymer Nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 27064–27073. [Google Scholar] [CrossRef]

- Vallés, C.; Papageorgiou, D.; Lin, F.; Li, Z.; Spencer, B.F.; Young, R.J.; Kinloch, I.A. PMMA-grafted graphene nanoplatelets to reinforce the mechanical and thermal properties of PMMA composites. Carbon 2020, 157, 750–760. [Google Scholar] [CrossRef] [Green Version]

- Semerci, E.; Bedri, T.E.; Kizilcan, N. Preparation of thermal conductive Poly(methyl methacrylate)/Silicon nitride nanocomposites via click chemistry. Polymer 2021, 212, 123285. [Google Scholar] [CrossRef]

- Oh, H.; Kim, J. Fabrication of polymethyl methacrylate composites with silanized boron nitride by in-situ polymerization for high thermal conductivity. Compos. Sci. Technol. 2019, 172, 153–162. [Google Scholar] [CrossRef]

- Ouyang, Y.; Li, X.; Tian, H.; Bai, L.; Yuan, F. A Novel Branched Al2O3/Silicon Rubber Composite with Improved Thermal Conductivity and Excellent Electrical Insulation Performance. Nanomaterials 2021, 11, 2654. [Google Scholar] [CrossRef]

- Ren, L.; Zeng, X.; Sun, R.; Xu, J.-B.; Wong, C.P. Spray-assisted assembled spherical boron nitride as fillers for polymers with enhanced thermally conductivity. Chem. Eng. J. 2019, 370, 166–175. [Google Scholar] [CrossRef]

- Shen, C.; Wang, H.; Zhang, T.; Zeng, Y. Silica coating onto graphene for improving thermal conductivity and electrical insulation of graphene/polydimethylsiloxane nanocomposites. J. Mater. Sci. Technol. 2019, 35, 36–43. [Google Scholar] [CrossRef]

- Wei, J.; Liao, M.; Ma, A.; Chen, Y.; Duan, Z.; Hou, X.; Li, M.; Jiang, N.; Yu, J. Enhanced thermal conductivity of polydimethylsiloxane composites with carbon fiber. Compos. Commun. 2020, 17, 141–146. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, X.; Jiang, P. Enhanced Thermal Conductivity of Dielectric Polydimethylsiloxane Composites by Size-Controllable Boron Nitride Nanosheets. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020. [Google Scholar] [CrossRef]

- Balandin, A. In-plane and cross-plane thermal conductivity of graphene: Applications in thermal interface materials. In Proceedings of the SPIE vol. 8101, Carbon Nanotubes, Graphene, and Associated Devices IV, 810107, San Diego, California, CA, USA, 19 September 2011. [Google Scholar] [CrossRef]

- Witpathomwong, S.; Okhawilai, M.; Jubsilp, C.; Karagiannidis, P.; Rimdusit, S. Highly filled graphite/graphene/carbon nanotube in polybenzoxazine composites for bipolar plate in PEMFC. Int. J. Hyd. Energy 2020, 45, 30898–30910. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; Sun, B.; Jiang, P. Highly Thermally Conductive Yet Electrically Insulating Polymer/Boron Nitride Nanosheets Nanocomposite Films for Improved Thermal Management Capability. ACS Nano 2019, 13, 337–345. [Google Scholar] [CrossRef] [PubMed]

- Simpson, A.; Stuckes, A.D. The thermal conductivity of highly oriented pyrolytic boron nitride. J. Phys. C Solid State Phys. 1971, 4, 1710–1718. [Google Scholar] [CrossRef]

- Sichel, E.K.; Miller, R.E.; Abrahams, M.S.; Buiocchi, C.J. Heat capacity and thermal conductivity of hexagonal pyrolytic boron nitride. Phys. Rev. B 1976, 13, 4607–4611. [Google Scholar] [CrossRef]

- Jiang, P.; Qian, X.; Yang, R.; Lindsay, L. Anisotropic thermal transport in bulk hexagonal boron nitride. Phys. Rev. Mater. 2018, 2, 064005. [Google Scholar] [CrossRef]

- Kim, K.K.; Hsu, A.; Jia, X.; Kim, S.M.; Shi, Y.; Dresselhaus, M.; Palacios, T.; Kong, J. Synthesis and Characterization of Hexagonal Boron Nitride Film as a Dielectric Layer for Graphene Devices. ACS Nano 2012, 6, 8583–8590. [Google Scholar] [CrossRef]

- Shen, H.; Cai, C.; Guo, J.; Qian, Z.; Zhao, N.; Xu, J. Fabrication of oriented hBN scaffolds for thermal interface materials. RSC Adv. 2016, 6, 16489–16494. [Google Scholar] [CrossRef]

- Bashir, A.; Maqbool, M.; Lv, R.; Usman, A.; Guo, H.; Aftab, W.; Niu, H.; Liu, M.; Bai, S.-L. Surface modified boron nitride towards enhanced thermal and mechanical performance of thermoplastic polyurethane composite. Compos. B. Eng. 2021, 218, 108871. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Hou, X.; Zhan, Z.; Wang, H.; Fu, H.; Lin, C.-T.; Fu, L.; Jiang, N.; Yu, J. Highly thermal conductive and electrical insulating polymer composites with boron nitride. Compos. B. Eng. 2020, 184, 107746. [Google Scholar] [CrossRef]

- Shang, Z.; Ding, D.; Wang, X.; Liu, B.; Chen, Y.; Gong, L.; Liu, Z.; Zhang, Q. High thermal conductivity of self-healing polydimethylsiloxane elastomer composites by the orientation of boron nitride nano sheets. Polym. Adv. Technol. 2021, 32, 4745–4754. [Google Scholar] [CrossRef]

- Zhao, L.; Yan, L.; Wei, C.; Li, Q.; Huang, X.; Wang, Z.; Fu, M.; Ren, J. Synergistic Enhanced Thermal Conductivity of Epoxy Composites with Boron Nitride Nanosheets and Microspheres. J. Phys. Chem. C 2020, 124, 12723–12733. [Google Scholar] [CrossRef]

- Mai, V.-D.; Lee, D.-I.; Park, J.-H.; Lee, D.-S. Rheological Properties and Thermal Conductivity of Epoxy Resins Filled with a Mixture of Alumina and Boron Nitride. Polymers 2019, 11, 597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shao, L.; Shi, L.; Li, X.; Song, N.; Ding, P. Synergistic effect of BN and graphene nanosheets in 3D framework on the enhancement of thermal conductive properties of polymeric composites. Compos. Sci. Technol. 2016, 135, 83–91. [Google Scholar] [CrossRef]

- Guo, F.; Shen, X.; Zhou, J.; Liu, D.; Zheng, Q.; Yang, J.; Jia, B.; Lau, A.K.T.; Kim, J.-K. Highly Thermally Conductive Dielectric Nanocomposites with Synergistic Alignments of Graphene and Boron Nitride Nanosheets. Adv. Funct. Mater. 2020, 30, 1910826. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, J.; Dong, S.; Wu, G.; Jiang, P.; Huang, X. Wet-resilient graphene aerogel for thermal conductivity enhancement in polymer nanocomposites. J. Mater. Sci. Technol. 2021, 83, 219–227. [Google Scholar] [CrossRef]

- Song, P.; Liu, B.; Liang, C.; Ruan, K.; Qiu, H.; Ma, Z.; Guo, Y.; Gu, J. Flexible Cellulose-Derived Carbon Aerogel@Reduced Graphene Oxide/PDMS Composites with Outstanding EMI Shielding Performances and Excellent Thermal Conductivities. Nano-Micro Lett. 2021, 13, 91. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, R.; Wang, P.; Wang, Y.; Zhou, Z.; Zhang, H.; Wu, Z.; Li, L. Highly Compressible, Thermally Conductive, yet Electrically Insulating Fluorinated Graphene Aerogel. ACS Appl. Mater. Interfaces 2020, 12, 58170–58178. [Google Scholar] [CrossRef]

- Zhang, W.; Kong, Q.-Q.; Tao, Z.; Wei, J.; Xie, L.; Cui, X.; Chen, C.-M. 3D Thermally Cross-Linked Graphene Aerogel–Enhanced Silicone Rubber Elastomer as Thermal Interface Material. Adv. Mater. Interfaces 2019, 6, 1900147. [Google Scholar] [CrossRef]

- Hou, X.; Chen, Y.; Lv, L.; Dai, W.; Zhao, S.; Wang, Z.; Fu, L.; Lin, C.-T.; Jiang, N.; Yu, J. High-Thermal-Transport-Channel Construction within Flexible Composites via the Welding of Boron Nitride Nanosheets. ACS Appl. Nano Mater. 2019, 2, 360–368. [Google Scholar] [CrossRef]

- Han, J.; Du, G.; Gao, W.; Bai, H. An Anisotropically High Thermal Conductive Boron Nitride/Epoxy Composite Based on Nacre-Mimetic 3D Network. Adv. Funct. Mater. 2019, 29, 1900412. [Google Scholar] [CrossRef]

- Cho, H.-B.; Nakayama, T.; Suematsu, H.; Suzuki, T.; Jiang, W.; Niihara, K.; Song, E.; Eom, N.S.A.; Kim, S.; Choa, Y.-H. Insulating polymer nanocomposites with high-thermal-conduction routes via linear densely packed boron nitride nanosheets. Compos. Sci. Technol. 2016, 129, 205–213. [Google Scholar] [CrossRef]

- Goto, T.; Ito, T.; Mayumi, K.; Maeda, R.; Shimizu, Y.; Hatakeyama, K.; Ito, K.; Hakuta, Y.; Terashima, K. Movable cross-linked elastomer with aligned carbon nanotube/nanofiber as high thermally conductive tough flexible composite. Compos. Sci. Technol. 2020, 190, 108009. [Google Scholar] [CrossRef]

- Kim, K.; Ju, H.; Kim, J. Filler orientation of boron nitride composite via external electric field for thermal conductivity enhancement. Ceram. Int. 2016, 42, 8657–8663. [Google Scholar] [CrossRef]

- Kim, K.; Ju, H.; Kim, J. Vertical particle alignment of boron nitride and silicon carbide binary filler system for thermal conductivity enhancement. Compos. Sci. Technol. 2016, 123, 99–105. [Google Scholar] [CrossRef]

- Gurijala, A.; Zando, R.B.; Faust, J.L.; Barber, J.R.; Zhang, L.; Erb, R.M. Castable and Printable Dielectric Composites Exhibiting High Thermal Conductivity via Percolation-Enabled Phonon Transport. Matter 2020, 2, 1015–1024. [Google Scholar] [CrossRef]

- Yuan, C.; Duan, B.; Li, L.; Xie, B.; Huang, M.; Luo, X. Thermal Conductivity of Polymer-Based Composites with Magnetic Aligned Hexagonal Boron Nitride Platelets. ACS Appl. Mater. Interfaces 2015, 7, 13000–13006. [Google Scholar] [CrossRef]

- Hu, Q.; Bai, X.; Zhang, C.; Zeng, X.; Huang, Z.; Li, J.; Zhang, Y. Oriented BN/Silicone rubber composite thermal interface materials with high out-of-plane thermal conductivity and flexibility. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106681. [Google Scholar] [CrossRef]

- Liu, M.; Chiang, S.-W.; Chu, X.; Li, J.; Gan, L.; He, Y.; Li, B.; Kang, F.; Du, H. Polymer composites with enhanced thermal conductivity via oriented boron nitride and alumina hybrid fillers assisted by 3-D printing. Ceram. Int. 2020, 46, 20810–20818. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Xia, L.; Li, C.; Wang, J.; Xu, F.; Zhang, X.; Wu, H.; Guo, S. Simple and Consecutive Melt Extrusion Method to Fabricate Thermally Conductive Composites with Highly Oriented Boron Nitrides. ACS Appl. Mater. Interfaces 2017, 9, 22977–22984. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, J.; Zhang, X.; Li, C.; Wang, J.; Li, H.; Xia, L.; Wu, H.; Guo, S. Toward high efficiency thermally conductive and electrically insulating pathways through uniformly dispersed and highly oriented graphites close-packed with SiC. Compos. Sci. Technol. 2017, 150, 217–226. [Google Scholar] [CrossRef]

- He, X.; Huang, Y.; Wan, C.; Zheng, X.; Kormakov, S.; Gao, X.; Sun, J.; Zheng, X.; Wu, D. Enhancing thermal conductivity of polydimethylsiloxane composites through spatially confined network of hybrid fillers. Compos. Sci. Technol. 2019, 172, 163–171. [Google Scholar] [CrossRef]

- He, X.; Huang, Y.; Liu, Y.; Zheng, X.; Kormakov, S.; Sun, J.; Zhuang, J.; Gao, X.; Wu, D. Improved thermal conductivity of polydimethylsiloxane/short carbon fiber composites prepared by spatial confining forced network assembly. J Mater Sci 2018, 53, 14299–14310. [Google Scholar] [CrossRef]

- Wu, D.; Gao, X.; Sun, J.; Wu, D.; Liu, Y.; Kormakov, S.; Zheng, X.; Wu, L.; Huang, Y.; Guo, Z. Spatial Confining Forced Network Assembly for preparation of high-performance conductive polymeric composites. Compos. Part A Appl. Sci. Manuf. 2017, 102, 88–95. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Balinskiy, M.G.; Magana, A.S.; Lewis, J.S.; Balandin, A.A. Graphene Composites with Dual Functionality: Electromagnetic Shielding and Thermal Management, Aug. 2018. Available online: https://www.researchgate.net/publication/326988625_Graphene_Composites_with_Dual_Functionality_Electromagnetic_Shielding_and_Thermal_Management (accessed on 8 January 2022).

- Barani, Z.; Kargar, F.; Mohammadzadeh, A.; Naghibi, S.; Lo, C.; Rivera, B.; Balandin, A.A. Multifunctional Graphene Composites for Electromagnetic Shielding and Thermal Management at Elevated Temperatures. Adv. Electron. Mater. 2020, 6, 2000520. [Google Scholar] [CrossRef]

- Poot, M.; van der Zant, H.S.J. Nanomechanical properties of few-layer graphene membranes. Appl. Phys. Lett. 2008, 92, 063111. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Huang, N.-J.; Zang, J.; Zhang, G.-D.; Guan, L.-Z.; Li, S.-N.; Zhao, L.; Tang, L.-C. Efficient interfacial interaction for improving mechanical properties of polydimethylsiloxane nanocomposites filled with low content of graphene oxide nanoribbons. RSC Adv. 2017, 7, 22045–22053. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Yu, J.; Yu, L.; Alam, F.E.; Dai, W.; Li, C.; Jiang, N. Enhancing the thermal, electrical, and mechanical properties of silicone rubber by addition of graphene nanoplatelets. Mater. Des. 2015, 88, 950–957. [Google Scholar] [CrossRef]

- Zhang, Y.; Mark, J.E.; Zhu, Y.; Ruoff, R.S.; Schaefer, D.W. Mechanical properties of polybutadiene reinforced with octadecylamine modified graphene oxide. Polymer 2014, 55, 5389–5395. [Google Scholar] [CrossRef]

- Sheshkar, N.; Verma, G.; Pandey, C.; Sharma, A.K.; Gupta, A. Enhanced thermal and mechanical properties of hydrophobic graphite-embedded polydimethylsiloxane composite. J. Polym Res. 2021, 28, 403. [Google Scholar] [CrossRef]

- Ketikis, P.; Damopoulos, E.; Pilatos, G.; Klonos, P.; Kyritsis, A.; Tarantili, P.A. Preparation by solution mixing and characterization of condensation type poly(dimethyl siloxane)/graphene nanoplatelets composites. J. Compos. Mater. 2022, 56, 251–266. [Google Scholar] [CrossRef]

- Battegazzore, D.; Fadda, E.; Fina, A. Flexible and high thermal conductivity composites based on graphite nanoplates paper impregnated with polydimethylsiloxane. J. Compos. Sci. 2021, 5, 309. [Google Scholar] [CrossRef]

- Kuang, H.; Li, Y.; Huang, S.; Shi, L.; Zhou, Z.; Gao, C.; Zeng, X.; Pandey, R.; Wang, X.; Dong, S.; et al. Piezoelectric boron nitride nanosheets for high performance energy harvesting devices. Nano Energy 2021, 80, 105561. [Google Scholar] [CrossRef]

- Karlsson, J.M.; Haraldsson, T.; Carlborg, C.F.; Hansson, J.; Russom, A.; van der Wijngaart, W. Fabrication and transfer of fragile 3D PDMS microstructures. J. Micromech. Microeng. 2012, 22, 085009. [Google Scholar] [CrossRef]

- Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. Available online: https://www.astm.org/c0518-04.html (accessed on 9 January 2022).

- Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. Available online: https://www.astm.org/d0412-16r21.html (accessed on 2 December 2021).

- Yousuff, C.M.; Danish, M.; Ho, E.T.W.; Basha, I.H.K.; Hamid, N.H.B. Study on the Optimum Cutting Parameters of an Aluminum Mold for Effective Bonding Strength of a PDMS Microfluidic Device. Micromachines 2017, 8, 8. [Google Scholar] [CrossRef] [Green Version]

- Standard Test Method for Rubber Property—Durometer Hardness. Available online: https://www.astm.org/d2240-00.html (accessed on 4 January 2022).

- Bardelli, T.; Marano, C.; Vangosta, F.B. Polydimethylsiloxane crosslinking kinetics: A systematic study on Sylgard184 comparing rheological and thermal approaches. J. Appl. Polym. Sci. 2021, 138, 51013. [Google Scholar] [CrossRef]

- Esteves, A.C.C.; Brokken-Zijp, J.; Laven, J.; Huinink, H.P.; Reuvers, N.J.W.; Van, M.P.; de With, G. Influence of cross-linker concentration on the cross-linking of PDMS and the network structures formed. Polymer 2009, 50, 3955–3966. [Google Scholar] [CrossRef]

- Sheats, J.E.; Carraher, C.E.; Pittman, C.U.; Zeldin, M.; Culbertson, B.M. Inorganic and Organometallic Polymers—An Overview. In Metal-Containing Polymeric Materials; Pittman, C.U., Carraher, C.E., Zeldin, M., Sheats, J.E., Culbertson, B.M., Eds.; Springer: Boston, MA, USA, 1990; pp. 3–37. [Google Scholar] [CrossRef]

- Zhou, W.-Y.; Qi, S.-H.; Zhao, H.-Z.; Liu, N.-L. Thermally conductive silicone rubber reinforced with boron nitride particle. Polym. Compos. 2007, 28, 23–28. [Google Scholar] [CrossRef]

- Khuu, V.; Osterman, M.; Bar-Cohen, A.; Pecht, M. Effects of Temperature Cycling and Elevated Temperature/Humidity on the Thermal Performance of Thermal Interface Materials. IEE Trans. Device Mater. Reliab. 2009, 9, 379–391. [Google Scholar] [CrossRef]

- Lewis, J.S.; Perrier, T.; Mohammadzadeh, A.; Kargar, F.; Balandin, A.A. Power Cycling and Reliability Testing of Epoxy-Based Graphene Thermal Interface Materials. C 2020, 6, 2. [Google Scholar] [CrossRef]

| Material | Flake Lateral Size (μm) | Thickness (nm)/ Number of Layers | SSA (m2/g) | Density (Untapped) (g/cm3) | Thermal Conductivity (W m−1 K−1) |

|---|---|---|---|---|---|

| hBN | 45 μm, D10/D90 = 20/80 | NA | 0.6 | 0.7 | ~300 |

| GNPs (Nanene-002) | D10(x) ~0.97 D50(x) ~2.16 D90(x) ~4.01 / D10(y) ~0.89 D50(y) ~1.78 D90(y) ~3.06 | D10 ~1.3 D50 ~4.9 D90 ~20 / D10 ~4 D50 ~14.5 D90 ~60 | 25 | <0.25 | ~2000 |

| Setpoint | Top Plate Temperature (°C) | Bottom Plate Temperature (°C) | Mean Temperature (°C) |

|---|---|---|---|

| 1 | 60 | 50 | 55 |

| 2 | 70 | 60 | 65 |

| 3 | 80 | 70 | 75 |

| Filler Type and Content (wt%) | Ti (°C) | Tp (°C) | Tf (°C) | ΔHult (J/g) * |

|---|---|---|---|---|

| Neat PDMS | 58 | 100 | 135 | 28.29 |

| GNP (8) | 94 | 133 | 193 | 22.37 |

| hBN (40) | 68 | 101 | 130 | 25.55 |

| hBN (40) + GNP (8) | 82 | 117 | 140 | 9.94 |

| Filler Type and Content (wt%) | 5 wt% Loss (°C) | 50 wt% Loss (°C) | End of Degradation (°C) | Max. Rate of Decomposition (°C) | Residue at 800 °C (wt%) |

|---|---|---|---|---|---|

| Neat PDMS | 388.3 | NA | 586 | 543 | 54 |

| GNP (5) | 388.7 | 498 | 537 | 489 | 29.2 |

| GNP (8) | 368.8 | 483 | 541 | 467 | 31 |

| hBN (40) | 414.1 | NA | 648 | 495 | 78.7 |

| hBN (40) + GNP (5) | 395.1 | NA | 530 | 460 | 55.8 |

| hBN (40) + GNP (8) | 387.9 | NA | 489 | 435 | 56.2 |

| Filler Type and Content (wt%) | Viscosity (Pa·s) |

|---|---|

| Neat PDMS | 2.7 |

| hBN (5) | 3.2 |

| hBN (8) | 3.5 |

| hBN 20 | 7.1 |

| GNP (5) | 3.3 |

| GNP (8) | 3.9 |

| GNP (20) | 21.9 |

| hBN (48) | 338.2 |

| hBN (40) + GNP (8) | 361.6 |

| hBN (40) + GNP (10) | 418.1 |

| hBN (40) + GNP (12) | 505.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fakiridis, S.; Hodge, S.A.; Karagiannidis, P.G. Thermal Interface Materials with Hexagonal Boron Nitride and Graphene Fillers in PDMS Matrix: Thermal and Mechanical Properties. Energies 2023, 16, 2522. https://doi.org/10.3390/en16062522

Fakiridis S, Hodge SA, Karagiannidis PG. Thermal Interface Materials with Hexagonal Boron Nitride and Graphene Fillers in PDMS Matrix: Thermal and Mechanical Properties. Energies. 2023; 16(6):2522. https://doi.org/10.3390/en16062522

Chicago/Turabian StyleFakiridis, Spyridon, Stephen A. Hodge, and Panagiotis G. Karagiannidis. 2023. "Thermal Interface Materials with Hexagonal Boron Nitride and Graphene Fillers in PDMS Matrix: Thermal and Mechanical Properties" Energies 16, no. 6: 2522. https://doi.org/10.3390/en16062522