Towards a Bioeconomy: Supplying Forest Residues for the Australian Market

Abstract

:1. Introduction

2. Materials and Methods

- Designing and developing an expert panel and questionnaire to collect and aggregate individual judgements. An online platform, Alchemer [84], was used.

- Ranking of costs of processes in the biomass-for-energy supply chain to identify the overall cost drivers. A Likert scale of 1 to 5 (most to least important) was employed to rank costs.

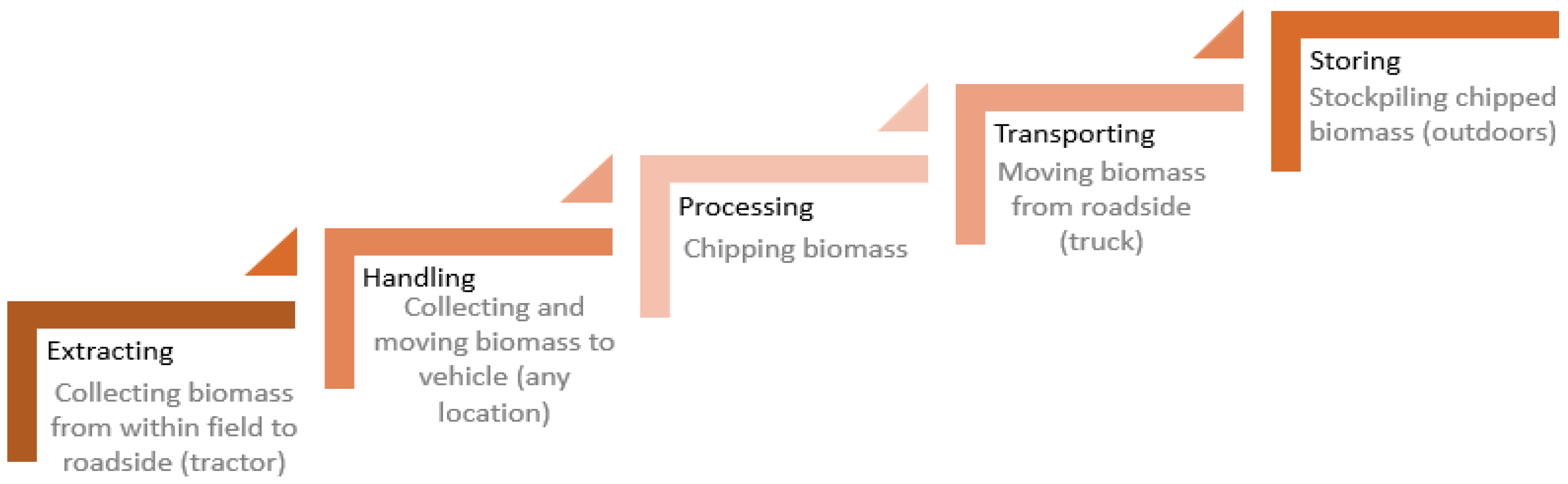

- Undertaking an AHP layer to identify the most efficient biomass supply pathway. Pairwise comparisons were employed to assign weights to factors and then rank these according to importance, measuring the distances between ranks. Factors to be ranked were chosen based on the authors’ perceptions of key factors (see Figure 1).

2.1. Data Collection

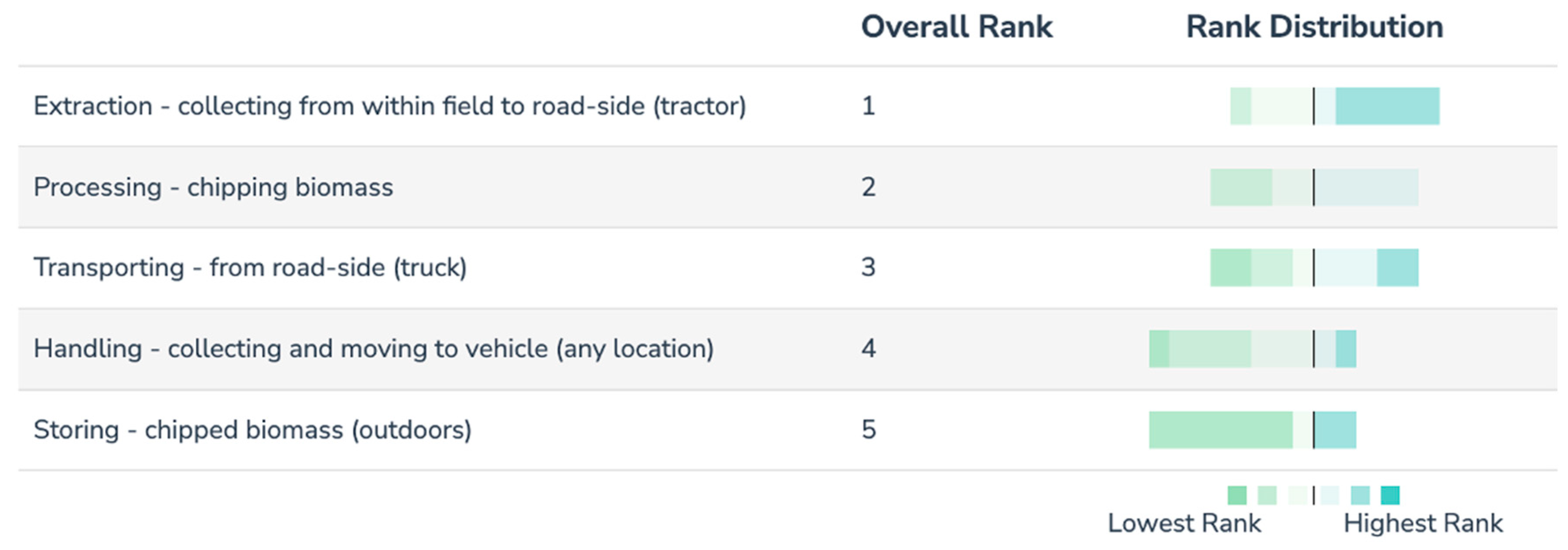

2.2. Ranking Cost Drivers

2.3. Weighted Pairwise Comparisons

- For each of the A’s columns, divide each entry in column i of A by the sum of the entries in column i. This yields a new matrix, called Anorm (for normalized), in which the sum of the entries in each column is 1.

- Estimate Wi as the average of the entries in row i of Anorm.

3. Results

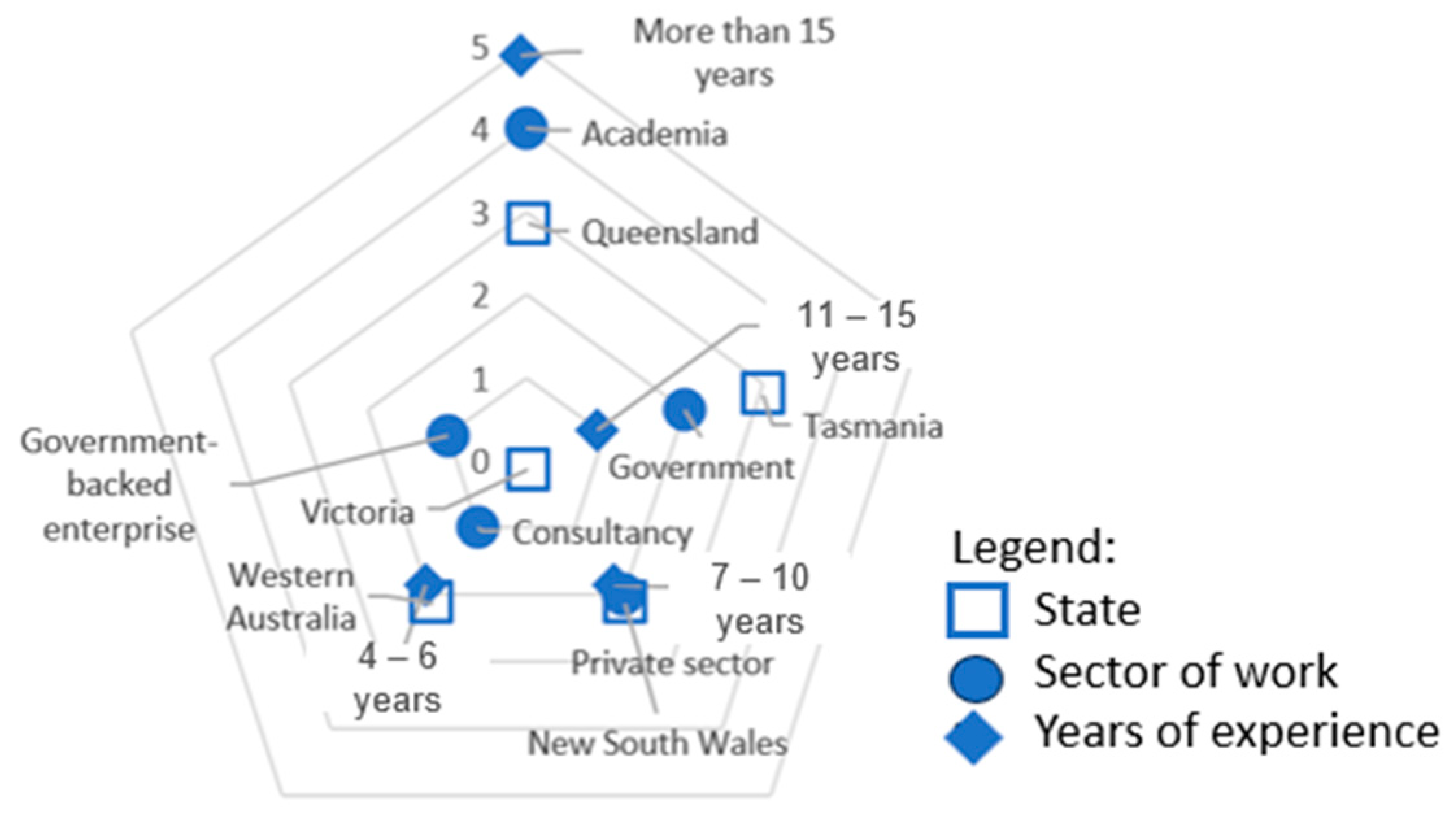

3.1. Expert Profile

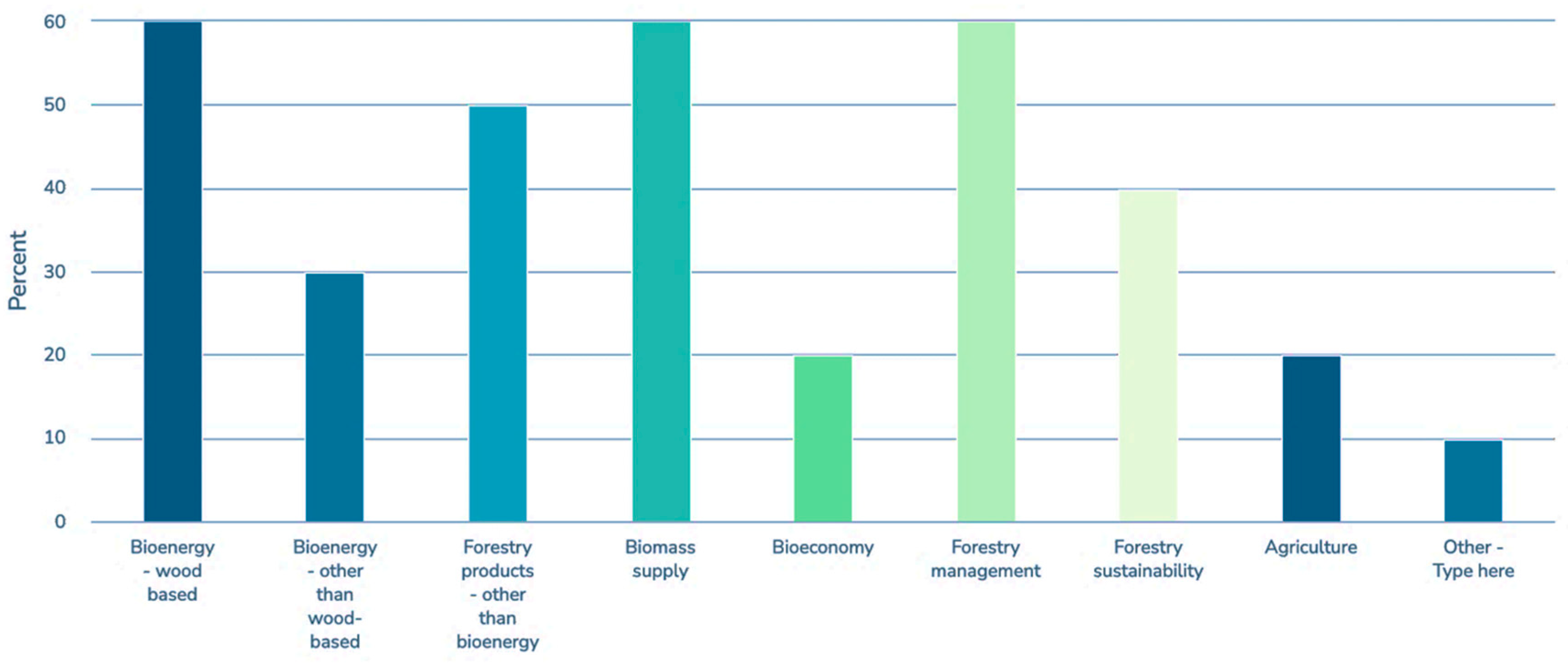

3.2. Results of the Process Cost Rankings

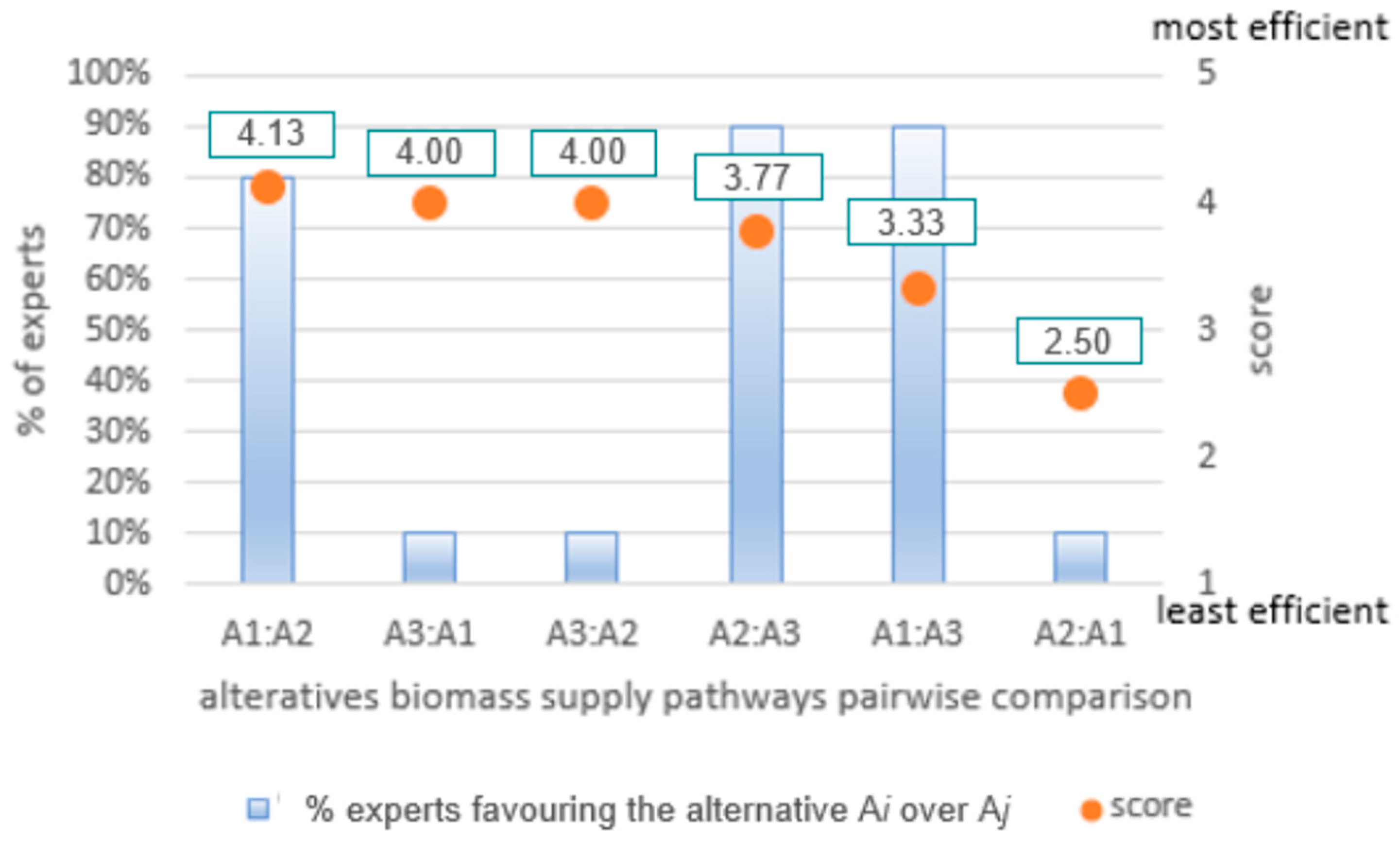

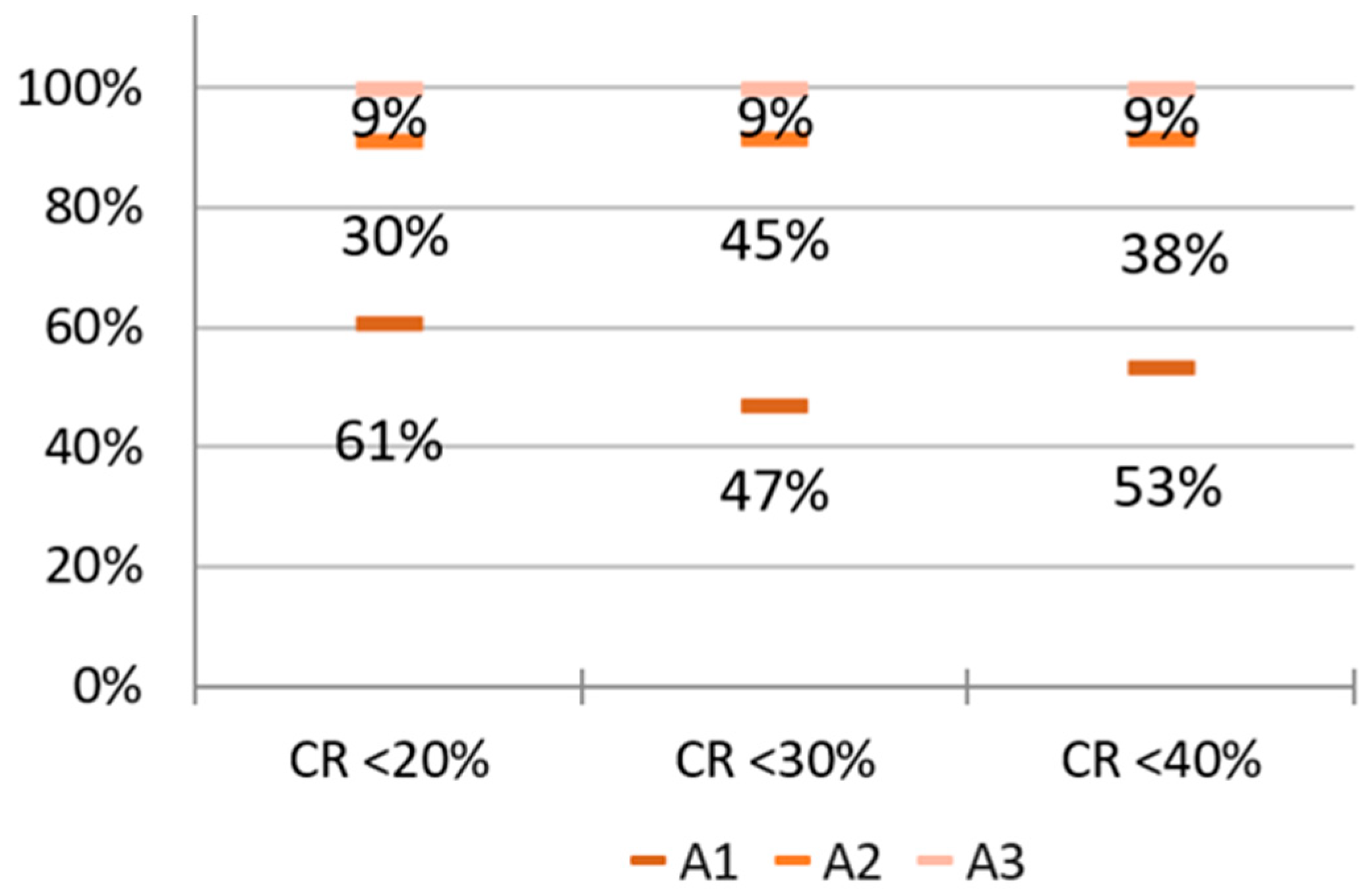

3.3. Results of the Weighted Pairwise Comparisons

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Department of Climate Change, Energy, the Environment and Water. Australian Energy Update 2022; Australian Government: Canberra, Australia, 2022. Available online: https://www.energy.gov.au/publications/australian-energy-update-2022 (accessed on 27 February 2023).

- Burke, P.J. On the way out: Government revenues from fossil fuels in Australia. Aust J. Agric. Res. Econ. 2023, 67, 1–17. [Google Scholar] [CrossRef]

- Department of Industry, Science and Resources. Resources and Energy Quarterly June 2022; Australian Government Office of the Chief Economist: Canberra, Australia, 2022. Available online: https://www.industry.gov.au/sites/default/files/minisite/static/b3caf4fd-b837-4cc5-b443-38782298963a/resources-and-energy-quarterly-june-2022/index.html#top (accessed on 17 May 2023).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Prime Minister of Australia. Media Release 08 Sep 2022: Prime Minister, Minister for Climate Change and Energy. 2022. Available online: https://www.pm.gov.au/media/australia-legislates-emissions-reduction-targets#:~:text=The%20Albanese%20Government%27s%20landmark%20Climate,will%20be%20enshrined%20in%20legislation (accessed on 28 December 2022).

- Nelson, T.; Nolan, T.; Gilmore, J. What’s next for the Renewable Energy Target–resolving Australia’s integration of energy and climate change policy? Aust. J. Agric. Resour. Econ. 2022, 66, 136–163. [Google Scholar] [CrossRef]

- Brolan, C.E. Looking Back—Australia’s Sustainable Development and Climate Change Policy Agendas. Sustainability 2023, 15, 5688. [Google Scholar] [CrossRef]

- Climate Change Act 2022 No.37 (Cth). Available online: https://www.legislation.gov.au/Details/C2022A00037 (accessed on 21 May 2023).

- Department of Energy and Public Works. Queensland’s Renewable Energy Target; Queensland Government: Brisbane City, Australia, 2022. Available online: https://www.epw.qld.gov.au/about/initiatives/renewable-energy-targets (accessed on 29 December 2022).

- Renewable Energy (Jobs and Investment) Act 2017 (Vic). Available online: https://www.legislation.vic.gov.au/in-force/acts/renewable-energy-jobs-and-investment-act-2017/002 (accessed on 21 May 2023).

- Department of State Growth. Tasmanian Renewable Energy Action Plan. Tasmanian Government. 2020. Available online: https://www.stategrowth.tas.gov.au/__data/assets/pdf_file/0012/313041/Tasmanian_Renewable_Energy_Action_Plan_December_2020.pdf (accessed on 18 May 2023).

- He, M.; Sun, Y.; Han, B. Green carbon science: Scientific basis for integrating carbon resource processing, utilization, and recycling. Angew. Chem. Int. Ed. 2013, 52, 9620–9633. [Google Scholar] [CrossRef] [PubMed]

- Queneau, Y.; Han, B. Biomass: Renewable carbon resource for chemical and energy industry. Innovation 2022, 3, 100184. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Jonsson, R.; Korhonen, J.; Jänis, J.; Mäkinen, M.; Leskinen, P.; Hetemäki, L. Diversification of the forest industries: Role of new wood-based products. Can. J. For. Res. 2018, 48, 1417–1432. [Google Scholar] [CrossRef]

- Schmid, B.; Mosley, F.; Hassegawa, M.; Leskinen, P.; Verkerk, P.J. Forest-Based Bioeconomy and Climate Change Mitigation; European Forest Institute: Joensuu, Finland, 2021; Available online: https://efi.int/sites/default/files/files/publication-bank/projects/Bio-economy%202.0_final_report.pdf (accessed on 17 May 2023).

- Daioglou, V.; Muratori, M.; Lamers, P.; Fujimori, S.; Kitous, A.; Köberle, A.C.; Bauer, N.; Junginger, M.; Kato, E.; Leblance, F.; et al. Implications of climate change mitigation strategies on international bioenergy trade. Clim. Chang. 2020, 163, 1639–1658. [Google Scholar] [CrossRef]

- Mandley, S.; Wicke, B.; Junginger, H.; van Vuuren, D.; Daioglou, V. Integrated assessment of the role of bioenergy within the EU energy transition targets to 2050. GCB Bioenergy 2022, 14, 157–172. [Google Scholar] [CrossRef]

- Zabaniotou, A. Redesigning a bioenergy sector in EU in the transition to circular waste-based Bioeconomy-A multidisciplinary review. J. Clean. Prod. 2018, 177, 197–206. [Google Scholar] [CrossRef]

- Venkatesh, G. Circular bio-economy-Paradigm for the future: Systematic review of scientific journal publications from 2015 to 2021. Circ. Econ. Sust. 2022, 2, 231–279. [Google Scholar] [CrossRef]

- Cutz, L.; Masera, O.; Santana, D.; Faaij, A.P.C. Switching to efficient technologies in traditional biomass intensive countries: The resultant change in emissions. Energy 2017, 126, 513–526. [Google Scholar] [CrossRef]

- Panepinto, D.; Viggiano, F.; Genon, G. Analysis of the environmental impact of a biomass plant for the production of bioenergy. Renew. Sustain. Energy Rev. 2015, 51, 634–647, 4586. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2022; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 16 June 2023).

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., Eds.; Global warming of 1.5°C. An IPCC special report on the impacts of global warming of 1.5 °C above pre- industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty. Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018; pp. 93–174. [Google Scholar]

- Junginger, H.M.; Mai-Moulin, T.; Daioglou, V.; Fritsche, U.; Guisson, R.; Hennig, C.; Thrän, D.; Heinimö, J.; Hess, J.R.; Lamers, P.; et al. The future of biomass and bioenergy deployment and trade: A synthesis of 15 years IEA Bioenergy Task 40 on sustainable bioenergy trade. Biofuel Bioprod. Biorefin. 2019, 13, 247–266. [Google Scholar] [CrossRef]

- Enea and Deloitte. Australia’s Bioenergy Roadmap; ARENA: Canberra, Australia, 2021. Available online: https://arena.gov.au/assets/2021/11/australia-bioenergy-roadmap-report.pdf (accessed on 9 January 2023).

- International Energy Agency (IEA). Technology Roadmap: Delivering Sustainable Bioenergy; IEA: Paris, France, 2017; Available online: https://www.ieabioenergy.com/blog/publications/technology-roadmap-delivering-sustainable-bioenergy/ (accessed on 24 November 2019).

- IEA Bioenergy. Country Reports: Implementation of Bioenergy in Canada–2021 Update; Pelkmans, L., Ed.; IEA: Paris, France, 2021; Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/11/CountryReport2021_Canada_final.pdf (accessed on 7 February 2023).

- Eurostat. Energy Balances. European Union. 2021. Available online: https://ec.europa.eu/eurostat/databrowser/view/enps_nrg_bal_c/default/table?lang=en (accessed on 28 January 2023).

- European Commission. Research and Innovation Bioeconomy. 2022. Available online: https://research-and-innovation.ec.europa.eu/research-area/environment/bioeconomy_en (accessed on 30 December 2022).

- Mateos, E.; Ormaetxea, L. Sustainable renewable energy by means of using residual forest biomass. Energies 2019, 12, 13. [Google Scholar] [CrossRef]

- Falcone, P.M.; Tani, A.; Tartiu, V.E.; Imbriani, C. Towards a sustainable forest-based bioeconomy in Italy: Findings from a SWOT analysis. For. Policy Econ. 2020, 110, 101910. [Google Scholar] [CrossRef]

- Spinelli, R.; Visser, R.; Björheden, R.; Roser, D. Recovery energy biomass in conventional forest operations: A review of integrated harvesting systems. Curr. For. Rep. 2019, 5, 90–100. [Google Scholar] [CrossRef]

- Strandgard, M.; Béland, M. Economics of forest biomass for bioenergy: Potential site preparation savings from coarse woody harvesting residue removal in a short-rotation Eucalyptus globulus (Labill.) plantation. Silva Balc. 2021, 22, 45–55. [Google Scholar] [CrossRef]

- Ximenes, F. Forestry, bioenergy and climate–a way forward in Australia. Aust. For. 2021, 84, 1–3. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Incorporating social benefits in multi-objective optimization of forest-based bioenergy and biofuel supply chains. Appl. Energy 2016, 178, 721–735. [Google Scholar] [CrossRef]

- Kline, K.L.; Dale, V.H.; Rose, E.; Tonn, B. Effects of Production of Woody Pellets in the Southeastern United States on the Sustainable Development Goals. Sustainability 2021, 13, 821. [Google Scholar] [CrossRef]

- Berndes, G.; Abt, B.; Asikainen, A.; Cowie, A.; Dale, V.; Egnell, V.; Lindner, G.; Marelli, M.; Paré, D.; Pingoud, K.; et al. Forest Biomass, Carbon Neutrality and Climate Change Mitigation; European Forest Institute: Joensuu, Finland, 2016. [Google Scholar] [CrossRef]

- Jones, H.S.; Beets, P.N.; Kimberley, M.O.; Garrett, L.G. Harvest residue management and fertilisation effects on soil carbon and nitrogen in a 15-year-old Pinus radiata plantation forest. For. Ecol. Manag. 2011, 262, 339–347. [Google Scholar] [CrossRef]

- Achat, D.L.; Deleuze, C.; Landmann, G.; Pousse, N.; Ranger, J.; Augusto, L. Quantifying consequences of removing harvesting residues on forest soils and tree growth–A meta-analysis. For. Ecol. Manag. 2015, 348, 124–141. [Google Scholar] [CrossRef]

- Vance, E.D.; Prisley, S.P.; Schilling, E.B.; Tatum, V.L.; Bently Wigley, T.; Lucier, A.A.; Van Deusen, P.C. Environmental implications of harvesting lower-value biomass in forests. For. Ecol. Manag. 2018, 407, 47–56. [Google Scholar] [CrossRef]

- Tutua, S.; Zhang, Y.; Xu, Z.; Blumfield, T. Residue retention mitigated short-term adverse effect of clear-cutting on soil carbon and nitrogen dynamics in subtropical Australia. J. Soils Sediments 2019, 19, 3786–3796. [Google Scholar] [CrossRef]

- Pergola, M.; Angelo, R.; Tortora, A.; Castellaneta, M.; Borghetti, M.; De Franchi, A.S.; Lapolla, A.; Moretti, N.; Pecora, G.; Pierangeli, D.; et al. Identification of suitable areas for biomass power plant construction through environmental impact assessment of forest harvesting residues transportation. Energies 2020, 13, 2699. [Google Scholar] [CrossRef]

- Montreal Process Implementation Group for Australia and National Forest Inventory Steering Committee. Australia’s State of the Forests Report 2018; ABARES: Canberra, Australia, 2018. Available online: https://www.agriculture.gov.au/abares/forestsaustralia/sofr/sofr-2018 (accessed on 8 July 2022).

- Legg, P.; Frakes, I.; Gavran, M. Australian Plantation Statistics and Log Availability Report 2021; Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2021. [Google Scholar] [CrossRef]

- Lock, P.; Whittle, L. Future Opportunities for Using Forest and Sawmill Residues in Australia; Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES): Canberra, Australia, 2018. Available online: https://www.agriculture.gov.au/abares/research-topics/forests/forest-economics/forest-economic-research/forest-sawmill-residues-report (accessed on 19 July 2022).

- Garvie, L.C.; Roxburgh, S.; Ximenes, F. Greenhouse gas emission offsets of forest residues for bioenergy in Queensland, Australia. Forests 2021, 12, 1570. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives–A review of literature. Renew. Sust. Energ. Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- European Forest Institute, n.d. ToSIA–Leading the Way to Sustainability. Available online: http://tosia.efi.int/ (accessed on 6 January 2023).

- Santos, A.; Carvalho, A.; Barbosa-Póvoa, A.P.; Marques, A.; Amorim, P. Assessment and optimization of sustainable forest wood supply chains–A systematic literature review. For. Policy Econ. 2019, 105, 112–135. [Google Scholar] [CrossRef]

- Panepinto, D.; Viggiano, F.; Genon, G. The potential of biomass supply for energetic utilization in a small Italian region: Basilicata. Clean Techn. Environ. Policy 2014, 16, 833–845. [Google Scholar] [CrossRef]

- Acuna, M.; Sessions, J.; Zamora, R.; Boston, K.; Brown, M.; Ghaffariyan, M.R. Methods to manage and optimize forest biomass supply chains: A review. Curr. For. Rep. 2019, 5, 124–141. [Google Scholar] [CrossRef]

- Australian Competition & Consumer Commission (ACCC). War in Ukraine and OPEC Production Limits Pushed February Petrol Prices to Eight-Year High. 2022. Available online: https://www.accc.gov.au/media-release/war-in-ukraine-and-opec-production-limits-pushed-february-petrol-prices-to-eight-year-high (accessed on 6 January 2023).

- Crawford, D.F.; O’Connor, M.H.; Jovanovic, T.; Herr, A.; Raison, R.J.; O’Connell, D.A.; Baynes, T. A spatial assessment of potential biomass for bioenergy in Australia in 2010, and possible expansion by 2030 and 2050. GCB Bioenergy 2016, 8, 707–772. [Google Scholar] [CrossRef]

- Ngugi, M.R.; Neldner, V.J.; Ryan, S.; Lewis, T.; Li, J.; Norman, P.; Mogilski, M. Estimating potential harvestable biomass for bioenergy from sustainably managed private native forests in Southeast Queensland, Australia. For. Ecosys. 2018, 5, 62–76. [Google Scholar] [CrossRef]

- Li, W.; Bi, H.; Watt, D.; Li, Y.; Ghaffariyan, M.R.; Ximenes, F. Estimation and spatial mapping of residue biomass following CTL harvesting in Pinus radiata plantations: An application of harvester data analytics. Forests 2022, 13, 428. [Google Scholar] [CrossRef]

- Van Holsbeeck, S.; Ezzati, S.; Röser, D.; Brown, M. A two-stage DSS to evaluate optimal locations for bioenergy facilities. Forests 2020, 11, 968. [Google Scholar] [CrossRef]

- Van Holsbeeck, S.; Srivastava, S.K. Feasibility of locating biomass-to-bioenergy conversion facilities using spatial information technologies: A case study on forest biomass in Queensland, Australia. Biomass Bioenergy 2020, 139, 105620. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I.; Hobson, P. A Geographical Information System based framework to identify optimal location and size of biomass energy plants using single or multiple biomass types. Appl. Energy 2020, 275, 116398. [Google Scholar] [CrossRef]

- Middelhoff, E.; Madden, B.; Li, M.; Ximenes, F.; Lenzen, M.; Florin, N. Bioenergy siting for low-carbon electricity supply in Australia. Biomass Bioenergy 2022, 163, 106496. [Google Scholar] [CrossRef]

- Luo, L.; O’Hehir, J.; Regan, C.M.; Meng, L.; Connor, J.D.; Chow, C.W.K. An integrated strategic and tactical optimization model for forest supply chain planning. For. Policy Econ. 2021, 131, 102571. [Google Scholar] [CrossRef]

- Acuna, M. Timber and biomass transport optimization: A review of planning issues, solution techniques and decision support tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Strandgard, M.; Mitchell, R. Comparison of the productivity, cost and stem breakage of two- and three- machine harvest systems clearfelling a mature Pinus radiata stand. Aust. For. 2020, 83, 91–98. [Google Scholar] [CrossRef]

- Rodriguez, L.C.; May, B.; Herr, A.; O’Connell, D. Biomass assessment and small scale biomass fired electricity generation in the Green Triangle, Australia. Biomass Bioenergy 2011, 35, 2589–2599. [Google Scholar] [CrossRef]

- Ossadnik, W.; Schinke, S.; Kaspar, R.H. Group Aggregation Techniques for Analytic Hierarchy Process and Analytic Network Process: A Comparative Analysis. Group Decis. Negot. 2016, 25, 421–457. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; Kulwer Academic Publishers: Boston, MA, USA; London, UK, 2001. [Google Scholar]

- Tavana, M.; Soltanifar, M.; Santos-Arteaga, F.J. Analytic hierarchy process: Revolution and evolution. Ann. Oper. Res. 2021, 326, 879–907. [Google Scholar] [CrossRef]

- Schmidt, K.; Aumann, I.; Hollander, I.; Damm, K.; von der Schulenburg, J.-M.G. Applying the Analytic Hierarchy Process in healthcare research: A systematic literature review and evaluation of reporting. BMC Med. Inf. Decis. Mak. 2015, 15, 112. [Google Scholar] [CrossRef] [PubMed]

- Pohekar, S.D.; Ramachandran, M. Application of multi-criteria decision making to sustainable energy planning—A review. Renew. Sust. Energ. Rev. 2004, 8, 365–381. [Google Scholar] [CrossRef]

- Wolfslehner, B.; Vacik, H.; Lexer, M.J. Application of the analytic network process in multi-criteria analysis of sustainable forest management. For. Ecol. Manag. 2005, 207, 157–170. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sust. Energ. Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Chan, H.K.; Sun, X.; Chung, S.-H. When should fuzzy analytic hierarchy process be used instead of analytic hierarchy process? Decis. Support Syst. 2019, 125, 113114. [Google Scholar] [CrossRef]

- García-Alcaraz, J.L.; García-Alcaraz, P.; Aryanfar, Y.; Realyyásquez-Vargas, A.; Mohtaram, S.; Haj-Assad, M.E. Multicriteria decision making methods–A review and case study. In Handbook on Decision Making; Zapata-Cortes, J.A., Sánchez-Ramírez, C., Alor-Hernández, G., García-Alcaraz, J.L., Eds.; Intelligent Systems Reference Library, 226; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Buchholz, T.; Rametsteiner, E.; Volk, T.A.; Luzadis, V.A. Multi Criteria Analysis for bioenergy systems assessments. Energy Policy 2009, 37, 484–495. [Google Scholar] [CrossRef]

- Mardani, A.; Kazimieras Zavadskas, E.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A review of multi-criteria decision-making applications to solve energy management problems: Two decades from 1995 to 2015. Renew. Sust. Energ. Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Brunnhofer, M.; Gabriella, N.; Schöggl, J.-P.; Stern, T.; Posch, A. The biorefinery transition in the European pulp and paper industry–A three-phase Delphi study including a SWOT-AHP analysis. For. Policy Econ. 2020, 110, 101882. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Solangi, Y.A.; Ikram, M. Analysis of barriers to the adoption of cleaner energy technologies in Pakistan using modified Delphi and fuzzy analytical hierarchy process. J. Clean. Prod. 2019, 235, 1037–1050. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, M.C.; Kim, Y.J. Barriers and strategies of hydrogen fuel cell power generation based on expert survey in South Korea. Int. J. Hydrog. Energy 2022, 47, 5709–5719. [Google Scholar] [CrossRef]

- Brandao, R.D.; Thiffault, E.; Levasseur, A. Development of a multi-criteria analysis decision-support tool for the sustainability of forest biomass heating projects in Quebec. Sustainability 2022, 14, 13200. [Google Scholar] [CrossRef]

- Taylan, O.; Alamoudi, R.; Kabli, M.; Aljifri, A.; Ramzi, F.; Herrera-Viedma, E. Assessment of energy systems using extended fuzzy AHP, fuzzy VIKOR, and TOPSIS approaches to manage non-cooperative opinions. Sustainability 2020, 12, 2745. [Google Scholar] [CrossRef]

- Kulišić, B.; Dimitrou, I.; Mola-Yudego, B. From preferences to concerted policy on mandated share for renewable energy in transport. Energy Policy 2021, 155, 112355. [Google Scholar] [CrossRef]

- Kulišić, B.; Dimitrou, I.; Mola-Yudego, B. Positioning the biofuel policy in the bioeconomy of the BioEast macro-region. Biofuels 2022, 13, 833–842. [Google Scholar] [CrossRef]

- Blagojevic, B.; Athanassiadis, D.; Spinelli, R.; Raitila, J.; Vos, J. Determining the relative importance of factors affecting the success of innovations in forest technology using AHP. J. Multi-Criteria Decis. Anal. 2020, 27, 129–140. [Google Scholar] [CrossRef]

- Alchemer, n.d. Available online: https://www.alchemer.com/ (accessed on 6 January 2023).

- Arrow, K.J. Social Choice and Individual Values; Yale University Press: New Haven, CT, USA, 1978. [Google Scholar]

- Saaty, T.L. Modeling unstructured decision problems—The theory of analytical hierarchies. Math. Comput. Simul. 1978, 20, 147–158. [Google Scholar] [CrossRef]

- Pecchia, L.; Martin, J.L.; Ragozzino, A.; Vanzanella, C.; Scognamiglio, A.; Mirarchi, L.; Morgan, S.P. User needs elicitation via analytic hierarchy process (AHP): A case study on a Computed Tomography (CT) scanner. BMC Med. Inform. Decis. Mak. 2013, 13, 2. [Google Scholar] [CrossRef]

- Ho, D.C.W.; Leung, H.F.; Wong, S.K.; Cheung, A.K.C.; Lau, S.S.Y.; Wong, W.S.; Lung, D.P.Y.; Chau, K.W. Assessing the health and hygiene performance of apartment buildings. Facilities 2004, 22, 58–69. [Google Scholar] [CrossRef]

- Mahmoud, M.; Hine, J. Using AHP to measure the perception gap between current and potential users of bus services. Transp. Plan. Technol. 2012, 36, 4–23. [Google Scholar] [CrossRef]

- European Biomass Industry Association. Recovery of Forest Residues. 2023. Available online: https://www.eubia.org/cms/wiki-biomass/biomass-resources/challenges-related-to-biomass/recovery-of-forest-residues/ (accessed on 9 January 2023).

- Pokharel, R.; Grala, R.K.; Grebner, D.L. Woody residue utilization for bioenergy by primary forest products manufacturers: An exploratory analysis. For. Policy Econ. 2017, 85, 161–171. [Google Scholar] [CrossRef]

- Tzelepi, V.; Zeneli, M.; Kourkoumpas, D.-S.; Karampinis, E.; Gypakis, A.; Nikolopoulos, N.; Grammelis, P. Biomass availability in Europe as an alternative fuel for full conversion of lignite power plants: A critical review. Energies 2020, 13, 3390. [Google Scholar] [CrossRef]

- Tahvanainen, T.; Anttila, P. Supply chain cost analysis of long-distance transportation of energy wood in Finland. Biomass Bioenergy 2011, 35, 3360–3375. [Google Scholar] [CrossRef]

- Altus Renewables. The Tuan Facility. 2021. Available online: https://www.altusrenewables.com/altus-renewables-projects-collection/the-tuan-facility (accessed on 10 January 2021).

- Hurmekoski, E.; Lovrić, M.; Lovrić, N.; Hetemäki, L.; Winkel, G. Frontiers of the forest-based bioeconomy–A European Delphi study. For. Policy Econ. 2019, 102, 86–99. [Google Scholar] [CrossRef]

- Li, M.; Lenzen, M.; Yousefzadeh, M.; Ximenes, F.A. The roles of biomass and CSP in a 100% renewable electricity supply in Australia. Biomass Bioenergy 2020, 143, 105802. [Google Scholar] [CrossRef]

- Cowie, A.L.; Berndes, G.; Bentsen, N.S.; Brandão, M.; Cherubini, F.; Egnell, G.; George, B.; Gustavsson, L.; Hanewinkel, M.; Harris, Z.M.; et al. Applying a science-based systems perspective to dispel misconceptions about climate effects of forest bioenergy. GCB Bioenergy 2021, 13, 1210–1231. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Bryngemark, E. Second generation biofuels and the competition for forest raw materials: A partial equilibrium analysis of Sweden. For. Policy Econ. 2019, 109, 102022. [Google Scholar] [CrossRef]

- Soam, S.; Börjesson, P. Considerations on potentials, greenhouse gas, and energy performance of biofuels based on forest residues for heavy-duty road transport in Sweden. Energies 2020, 13, 6701. [Google Scholar] [CrossRef]

- Department of Climate Change, Energy, the Environment and Water. National Inventory Report 2021: The Australian Government Submission to the United Nations Framework Convention on Climate Change; Australian Government: Canberra, Australia, 2023. Available online: https://www.dcceew.gov.au/sites/default/files/documents/national-inventory-report-2021-volume-1.pdf (accessed on 19 May 2023).

- Tisserant, A.; Cherubini, F. Potential, limitations, co-benefits, and trade-offs of biochar applications to soils for climate change mitigation. Land 2019, 8, 179. [Google Scholar] [CrossRef]

- Bergman, R.; Sahoo, K.; Englund, K.; Mousavi-Avval, S.H. Lifecycle assessment and techno-economic analysis of biochar pellet production from forest residues and field application. Energies 2022, 15, 1559. [Google Scholar] [CrossRef]

- Windisch, J.; Väätäinen, K.; Anttila, P.; Nivala, M.; Laitila, J.; Asikainen, A.; Sikanen, L. Discrete-event simulation of an information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Appl. Energy 2015, 149, 315–325. [Google Scholar] [CrossRef]

- Sánchez-García, S.; Athanassiadis, D.; Martínez-Alonso, C.; Tolosana, E.; Majada, J.; Canga, E. A GIS methodology for optimal location of a wood-fired power plant: Quantification of available woodfuel, supply chain costs and GHG emissions. J. Clean. Prod. 2017, 157, 201–212. [Google Scholar] [CrossRef]

- Gendek, A.; Nurek, T.; Zychowicz, W.; Moskalik, T. Effects of intentional reduction in moisture content of forest wood chips during transport on truckload price. Bio. Res. 2018, 13, 4310–4322. [Google Scholar] [CrossRef]

- World Bioenergy Association. Biomass Supply Chains: Harvesting & Collection, Pre-Treatment and Upgrading, Storage, Transportation and Handling; WBA: Stockholm, Sweden, 2018; Available online: https://www.worldbioenergy.org/uploads/Factsheet%20-%20Biomass%20Supply%20Chains.pdf (accessed on 4 May 2023).

- Department of Foreign Affairs and Trade. Australia’s Trade in Goods and Services 2020–21; Australian Government: Canberra, Australia, 2022. Available online: https://www.dfat.gov.au/trade/trade-and-investment-data-information-and-publications/trade-statistics/trade-in-goods-and-services/australias-trade-goods-and-services-2020-21 (accessed on 9 January 2023).

- Council Directive 2021/0104 (COD) on Corporate Sustainability Reporting, 2022 (EU). Unpublished. Available online: https://data.consilium.europa.eu/doc/document/PE-35-2022-INIT/en/pdf (accessed on 4 May 2023).

- Marttunen, M.; Lienert, J.; Belton, V. Structuring problems for Multi-Criteria Decision Analysis in practice: A literature review of method combinations. Eur. J. Oper. Res. 2017, 263, 1–17. [Google Scholar] [CrossRef]

- Kajanus, M.; Leskinen, P.; Kurttila, M.; Kangas, J. Making use of MCDS methods in SWOT analysis—Lessons learnt in strategic natural resources management. For. Policy Econ. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Rauch, P.; Wolfsmayr, U.J.; Borz, S.A.; Triplat, M.; Krajnc, N.; Kolck, M.; Oberwimmer, R.; Ketikidis, C.; Vasiljevic, A.; Stauder, M.; et al. SWOT analysis and strategy development for forest fuel supply chains in South East Europe. For. Policy Econ. 2015, 61, 87–94. [Google Scholar] [CrossRef]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy; Publications Office of the European Union: Luxembourg, 2018; Available online: https://op.europa.eu/en/publication-detail/-/publication/edace3e3-e189-11e8-b690-01aa75ed71a1/language-en (accessed on 16 June 2023).

- European Commission. Guidance on Cascading Use of Biomass with Selected Good Practice Examples on Woody Biomass; Publications Office of the European Union: Luxembourg, 2019; Available online: https://data.europa.eu/doi/10.2873/68553 (accessed on 20 April 2023).

- Mair, C.; Stern, T. Cascading Utilization of Wood: A Matter of Circular Economy? Curr. For. Rep. 2017, 3, 281–295. [Google Scholar] [CrossRef]

- Maximo, Y.I.; Hassegawa, M.; Verkerk, P.J.; Missio, A.L. Forest Bioeconomy in Brazil: Potential Innovative Products from the Forest Sector. Land 2022, 11, 1297. [Google Scholar] [CrossRef]

- Martins, A.H.; Rouboa, A.; Monteiro, E. On the green hydrogen production through gasification processes: A techno-economic approach. J. Clean. Prod. 2023, 383, 135476. [Google Scholar] [CrossRef]

- Kraxner, F.; Aoki, K.; Leduc, S.; Kindermann, G.; Fuss, S.; Yang, J.; Yamagata, Y.; Tak, K.-I.; Obersteiner, M. BECCS in South Korea—Analyzing the negative emissions potential of bioenergy as a mitigation tool. Renew. Energy 2014, 61, 102–108. [Google Scholar] [CrossRef]

- Jarre, M.; Petit-Boix, A.; Priefer, C.; Meyer, R.; Leipold, S. Transforming the bio-based sector towards a circular economy—What can we learn from wood cascading? For. Policy Econ. 2020, 110, 101872. [Google Scholar] [CrossRef]

| Alternative | Biomass Supply Pathways |

|---|---|

| A1 | Extracting and chipping in the field |

| A2 | Extracting and transporting to roadside, chipping at roadside |

| A3 | Extracting and transporting to roadside, then transporting to conversion facility gate, chipping at conversion plant. |

| Verbal Expressions | Far more Important | Strongly More Important | Moderately More Important | Somewhat More Important | Equally Important | Somewhat More Important | Moderately More Important | Strongly More Important | Far more Important |

|---|---|---|---|---|---|---|---|---|---|

| Values used in survey | 5 | 3 | 1 | 3 | 5 | ||||

| Saaty’s values used in analysis | 9 | 7 | 5 | 3 | 1 | 1/3 | 1/5 | 1/7 | 1/9 |

| 2,4,6,8 | Intermediate values, for example, a value of 8 means that objective i is midway between strongly and far more important than objective j | ||||||||

| n | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garvie, L.C.; Lee, D.J.; Kulišić, B. Towards a Bioeconomy: Supplying Forest Residues for the Australian Market. Energies 2024, 17, 397. https://doi.org/10.3390/en17020397

Garvie LC, Lee DJ, Kulišić B. Towards a Bioeconomy: Supplying Forest Residues for the Australian Market. Energies. 2024; 17(2):397. https://doi.org/10.3390/en17020397

Chicago/Turabian StyleGarvie, Leanda C., David J. Lee, and Biljana Kulišić. 2024. "Towards a Bioeconomy: Supplying Forest Residues for the Australian Market" Energies 17, no. 2: 397. https://doi.org/10.3390/en17020397