1. Introduction

Hybrid propulsion systems for tracked vehicles are being actively pursued, owing to their improved fuel economy, significant on-board electricity supply and stealth operation ability. Some hybrid powertrains have been applied to tracked vehicles, and the engineering and prototype implementation was reported [

1,

2,

3,

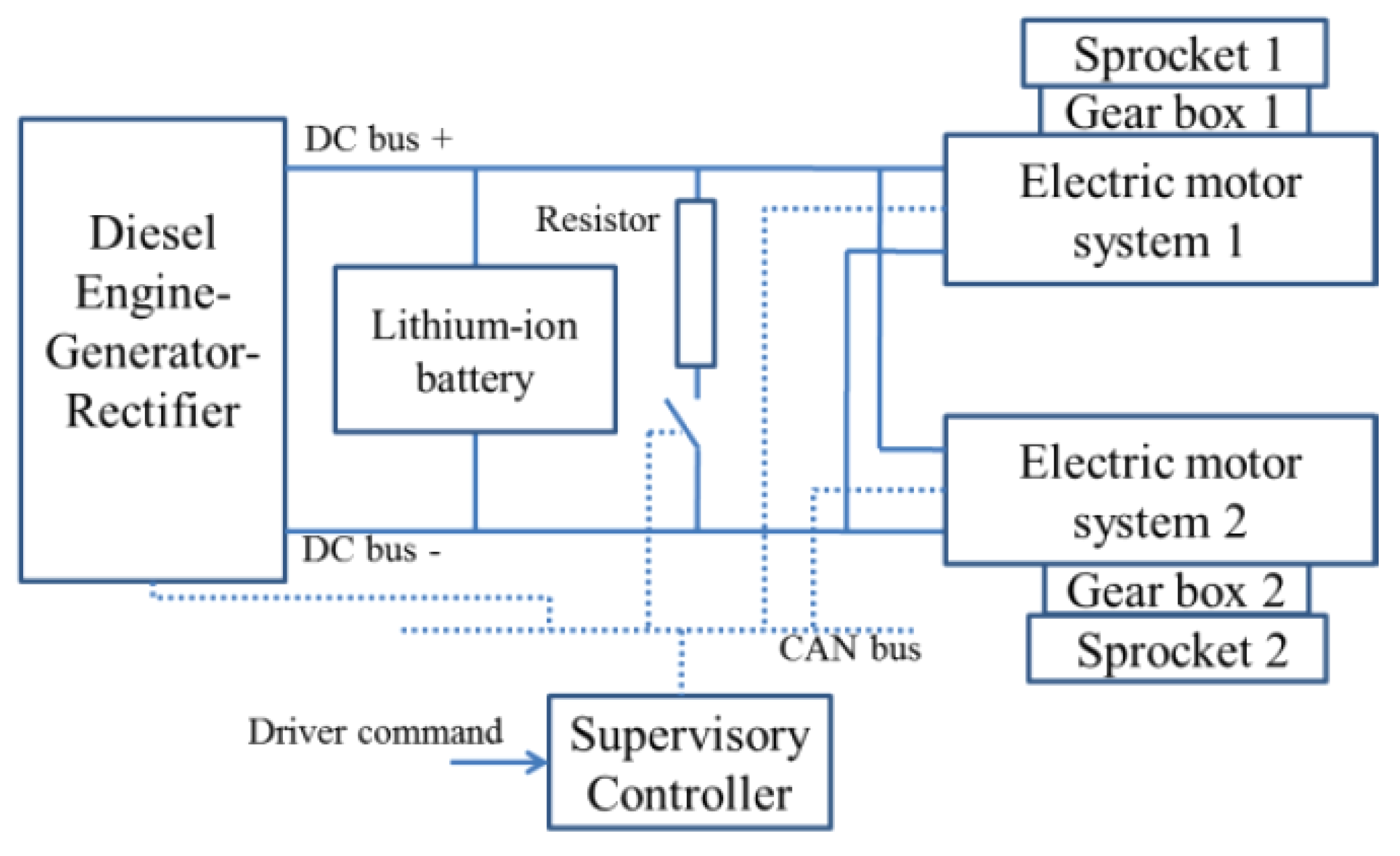

4]. Compared to hybrid wheeled vehicles, research on hybrid tracked vehicles in an optimization setting is still scanty. Constrained by the component power density and packaging space, a dual-motor drive structure is adopted for a heavy-duty hybrid tracked vehicle, as shown in

Figure 1. The two sprockets are separately powered by two electric motors. A diesel engine-generator set and a traction battery pack provide the two motors with electric energy. The vehicle’s drivability like heading or turning is maintained by controlling the speeds/torques of the two motors, while the diesel engine-generator set is controlled to regulate the power distribution between the generator and the battery. This vehicle mostly operates as a serial hybrid, except during the turning, when the outside motor propels and inside one performs braking. The supervisory controller assesses the driver intention and coordinates the work of engine-generator set, battery pack and the two electric motors in an optimal way.

Figure 1 also shows a safety design, where a resistor bank is installed and can be switches in case the DC bus voltage exceeds a threshold value.

Figure 1.

Dual-motor drive structure of the hybrid tracked vehicle.

Figure 1.

Dual-motor drive structure of the hybrid tracked vehicle.

Several studies have focused on the sizing and configuration design to maintain the drivability, and the design of the control strategy for optimal fuel economy [

5,

6,

7,

8]. Relatively little work has investigated the parameter sizing and control strategy simultaneously. A general iterative design methodology was used for the optimal design of the plant and controller [

9] and it has been applied successfully to the combined automotive suspension and fuel cell optimization [

9,

10]. In terms of optimal control design, the dynamic programming techniques have been widely applied to wheeled hybrid vehicles and recognized by the academic community for its generic applicability for discrete or continuous state problems with constraints [

11,

12,

13,

14]. In this paper, an iterative combined plant-controller optimization methodology is applied to optimize the key parameters of the powertrain and the control strategy simultaneously for a tracked hybrid vehicle. An automatic process iteratively evaluates the fuel consumption as the sizing parameters vary until the combined optimal sizing and control result is obtained.

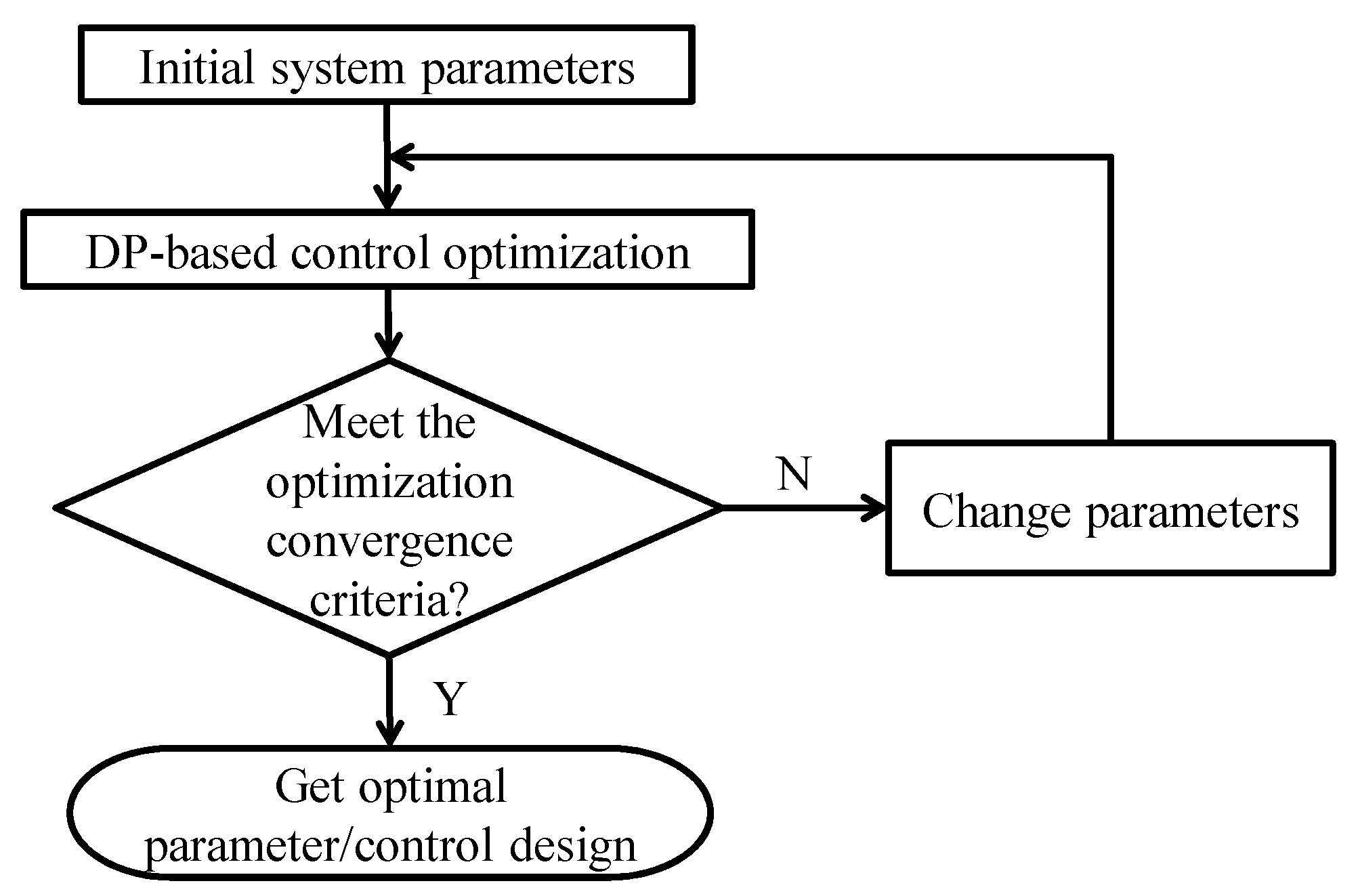

3. DP-Based Strategy and Optimization

Equations (1)–(15) are discretized to formulate into a DP problem. The time step

Ts is set to 0.1 s considering the balance between computation cost and accuracy. The optimal control

Acceng(

k) (

k = 0, 1, …,

N − 1) is pursued to minimize the total fuel consumption during the given driving schedule as follows:

subject to the following constraints:

In Equations (16)–(22), F is the fuel consumption rate determined by neng(k) and Teng(k), normally obtained through a fuel consumption table derived through bench tests. x(k) = [SOC(k), neng(k)], and f represents the discrete dynamics from Equations (1)–(15). The increment of neng is also constrained to emulate the dynamics of the engine. Typically, the HEV control strategy requests the energy balance for the battery pack at the end of the driving schedule, and SOC(N) is hence enforced to equal the initial value.

The DP technique is applied to solve the above problem based on the principle of optimality, which is expressed as:

where

J(

x(

k)) is the optimal cost function at state (

x(

k) starting from step

k. When (

x(

k) and

Acceng(

k) are discretized into the finite states and Equation (23) is solved backwards, the optimal control and corresponding cost are stored and then the optimal solution with the specific initial states is retrieved forwardly by applying the optimal controls through the horizon.

The control rule can be extracted from the DP results, as a casual control strategy. However, since some important parameters couple closely with the control, and the DP-based control strategy is just optimal given the particular system parameters, the following combined optimization of the system parameters and control strategy in the synergic way is significant.

5. Results and Discussion

The combined optimization is computationally expensive due to the dual-loop iterative process. In order to improve the computational efficiency, once the constraint in the inner loop is violated the current exploitation stops and the cost is set to a large infeasible value. A strong nonlinearity is observed and the data shown in the map is a bit noisy. The DOE (Design of Experiments) technique is first applied to explore the response map in all the feasible design spaces based on Latin Hypercube sampling and then the Non-linear Programming by Quadratic Lagrangian (NLPQL) algorithm is applied to obtain the global optimal value [

18].

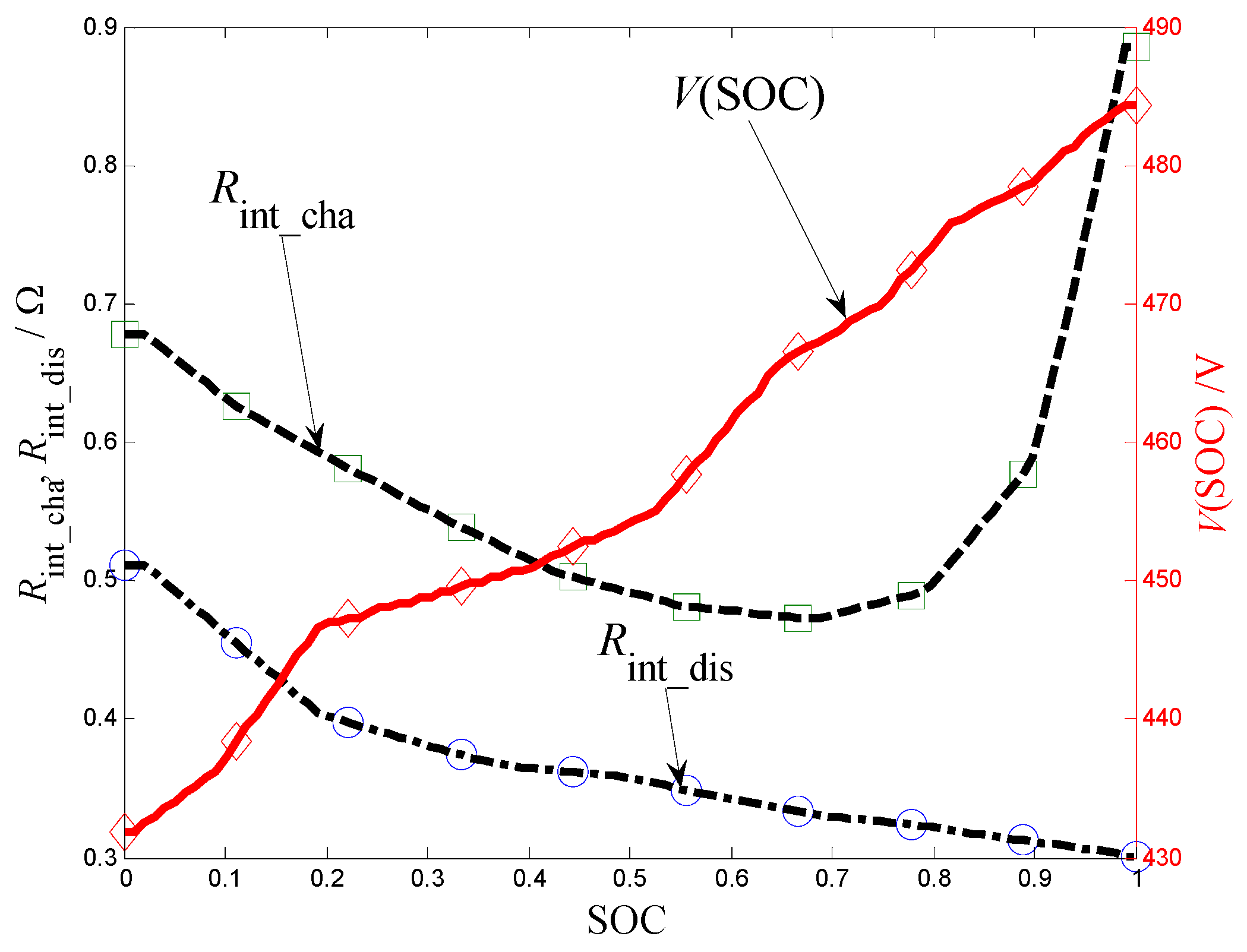

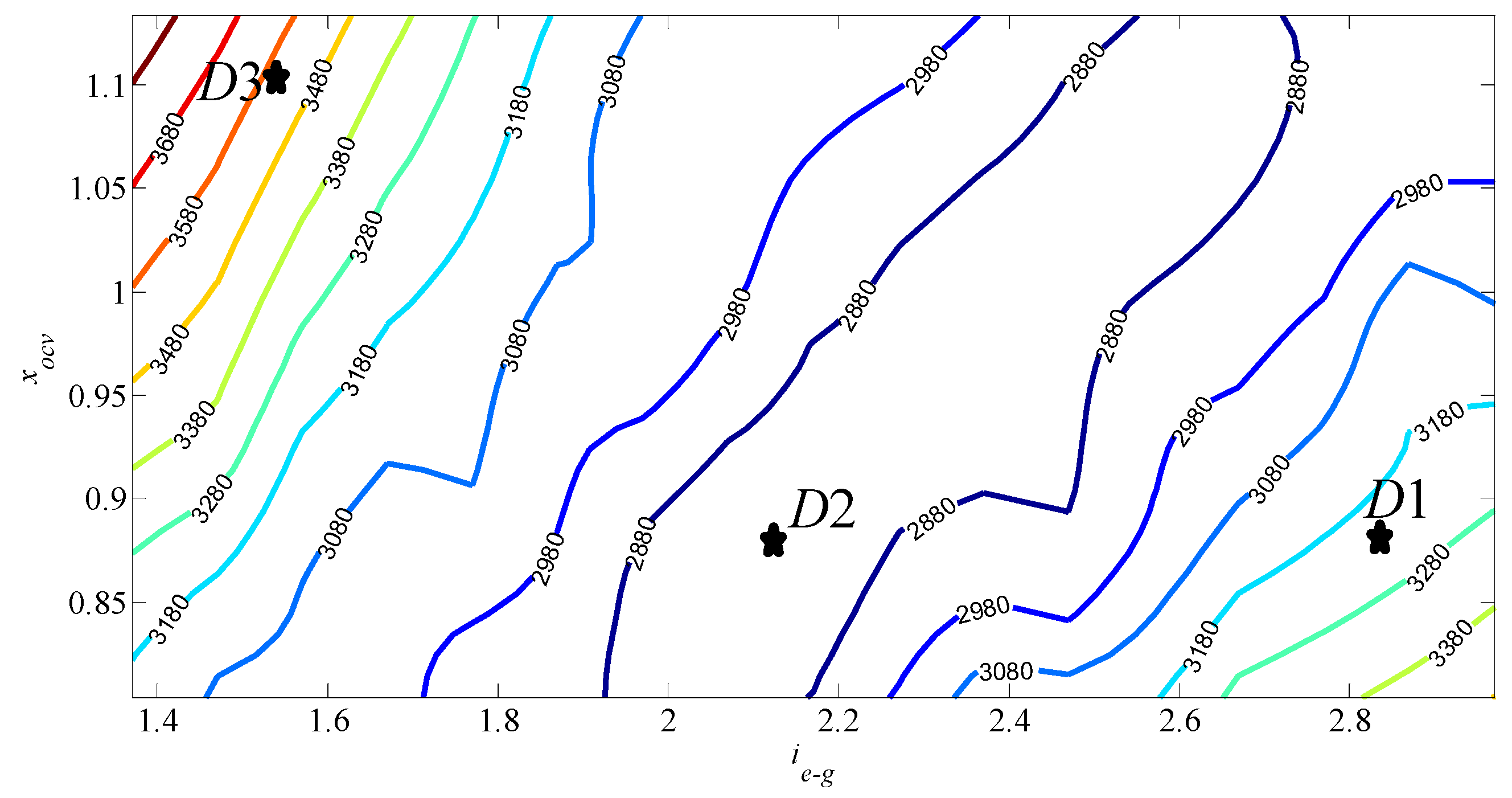

The relationship of the fuel consumption,

ie-g and

xocv is shown in

Figure 7, in which the optimal correspondence between

ie-g and

xocv is observed explicitly. This means that

ie-g increases or decreases with

xocv to maintain an optimal fuel economy. Further investigation shows that the voltage range of the battery pack and the engine-generator match well to make the optimal power distribution between them possible. It may thus be concluded that the energy distribution control has a limited influence on the fuel economy without the proper match between

ie-g and the voltage range of the battery pack. The proper match is necessary to keep a good fuel economy. It should be noted that the optimal power distribution control plays a valuable role if

ie-g and the voltage range of the battery is constrained to the optimal area shown in

Figure 7, which allows the component sizing or parameter to be freely selected.

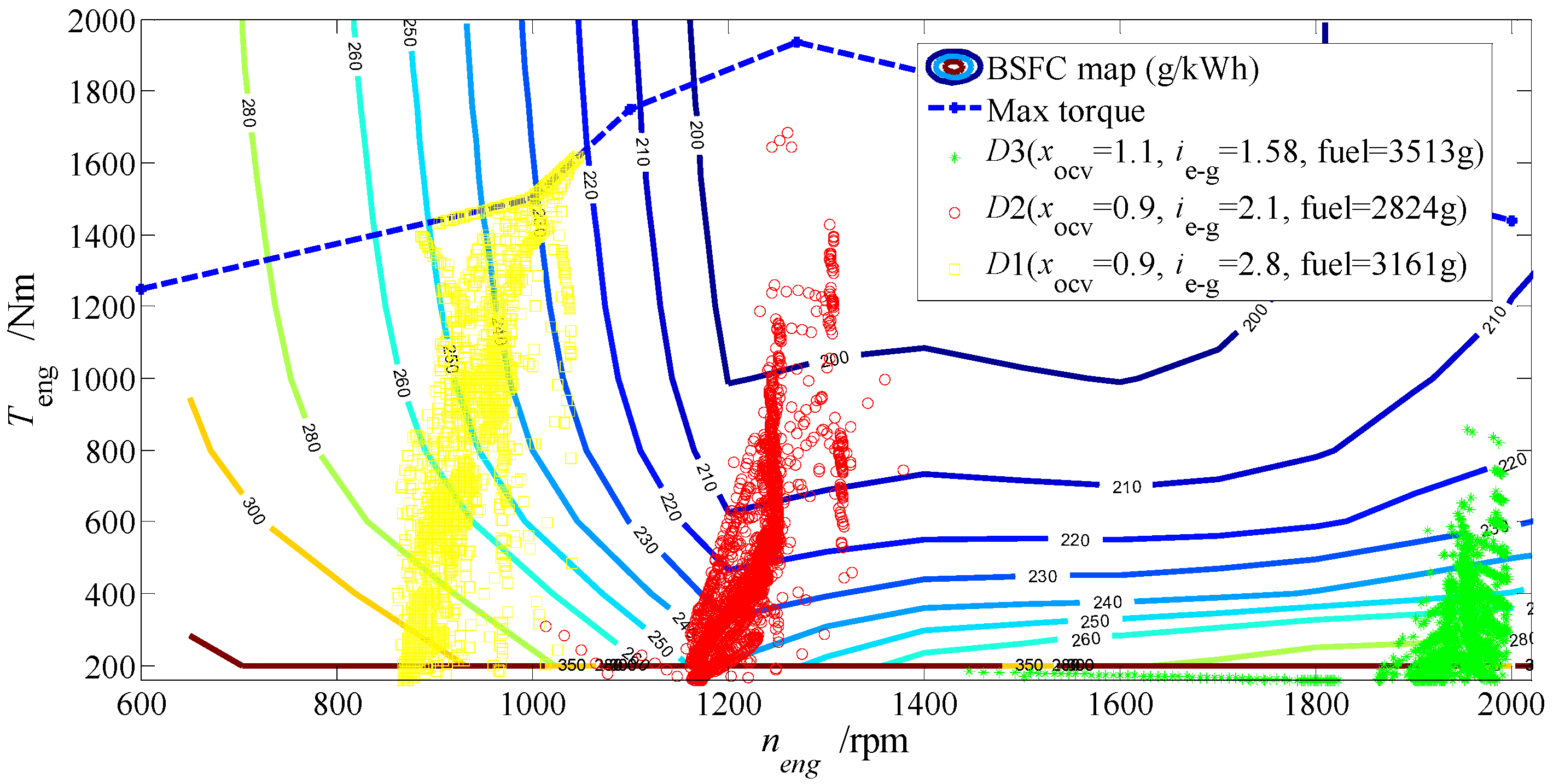

Figure 8 shows the engine working points under the optimal control when

ie-g and

xocv are selected differently. It can be seen that the engine works near the high efficiency area if

ie-g and

xocv match well, just as the parameter selection

D2 in

Figure 8, with a lower fuel consumption of 2824 grams. Otherwise the engine works far from the high efficiency area, just like the parameter selections

D1 or

D3 with 3163 and 3513 grams, 12.0% and 24.4% higher than that of

D1, respectively.

Figure 7.

The fuel consumption contour (grams) vs. ie-g and xocv.

Figure 7.

The fuel consumption contour (grams) vs. ie-g and xocv.

Figure 8.

Engine operating points in three different parameter selection (xcap = 2, xh < 0.4).

Figure 8.

Engine operating points in three different parameter selection (xcap = 2, xh < 0.4).

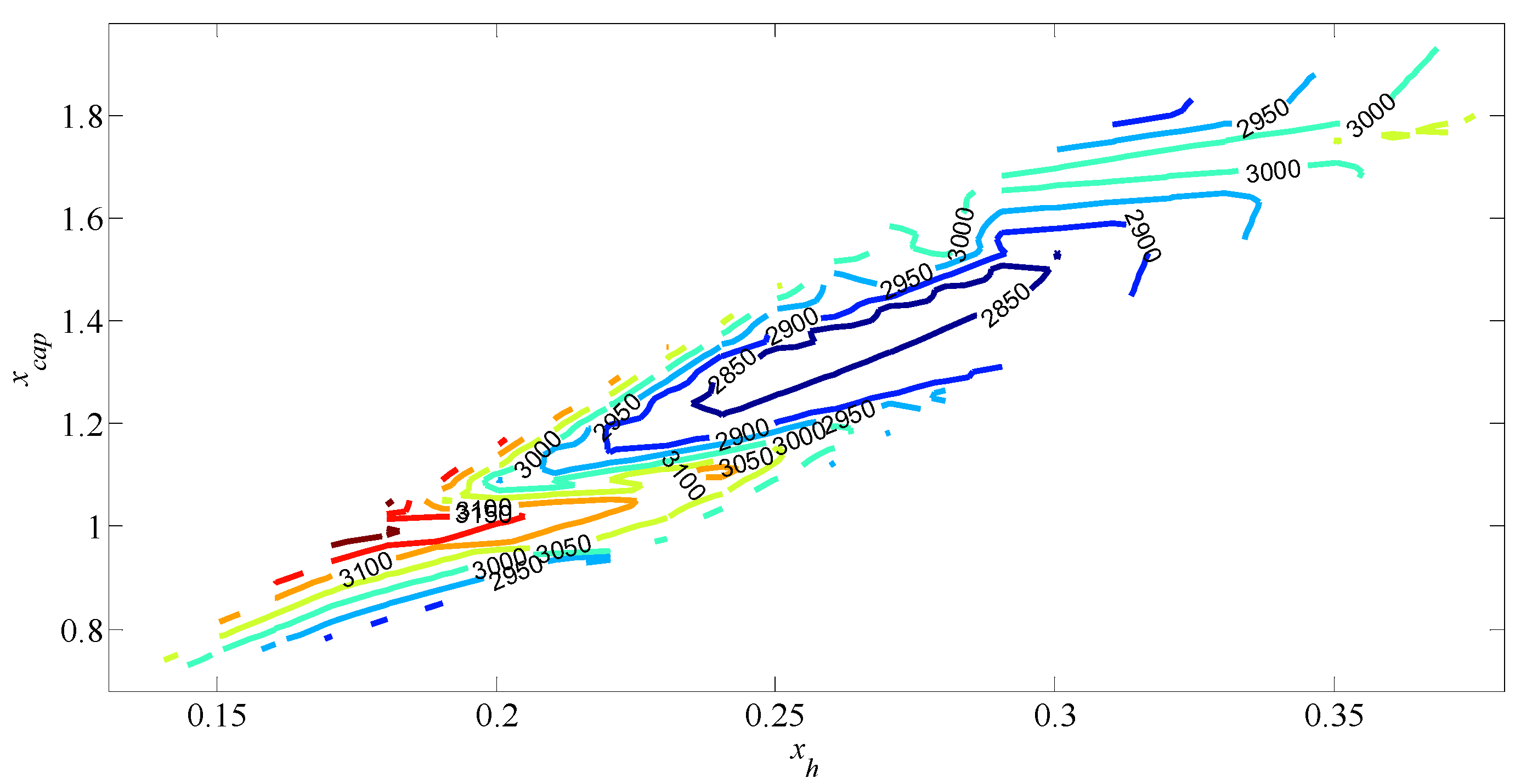

The relationship of the fuel consumption,

xcap and

xh is shown in

Figure 9. The values of

xh and

xcap must remain in a specific range to obtain the optimal fuel economy. Although this map is a bit noisy, there is an optimal range [0.25, 0.32] for

xh. This fact allows us to conclude that in such a kind of hybrid vehicle,

xh should be selected with great caution because the fuel economy does not always increase as

xh increases. There is a more sophisticated interaction between the fuel consumption,

xh and

xcap.

Figure 9.

Fuel consumption vs. xcap and xh.

Figure 9.

Fuel consumption vs. xcap and xh.

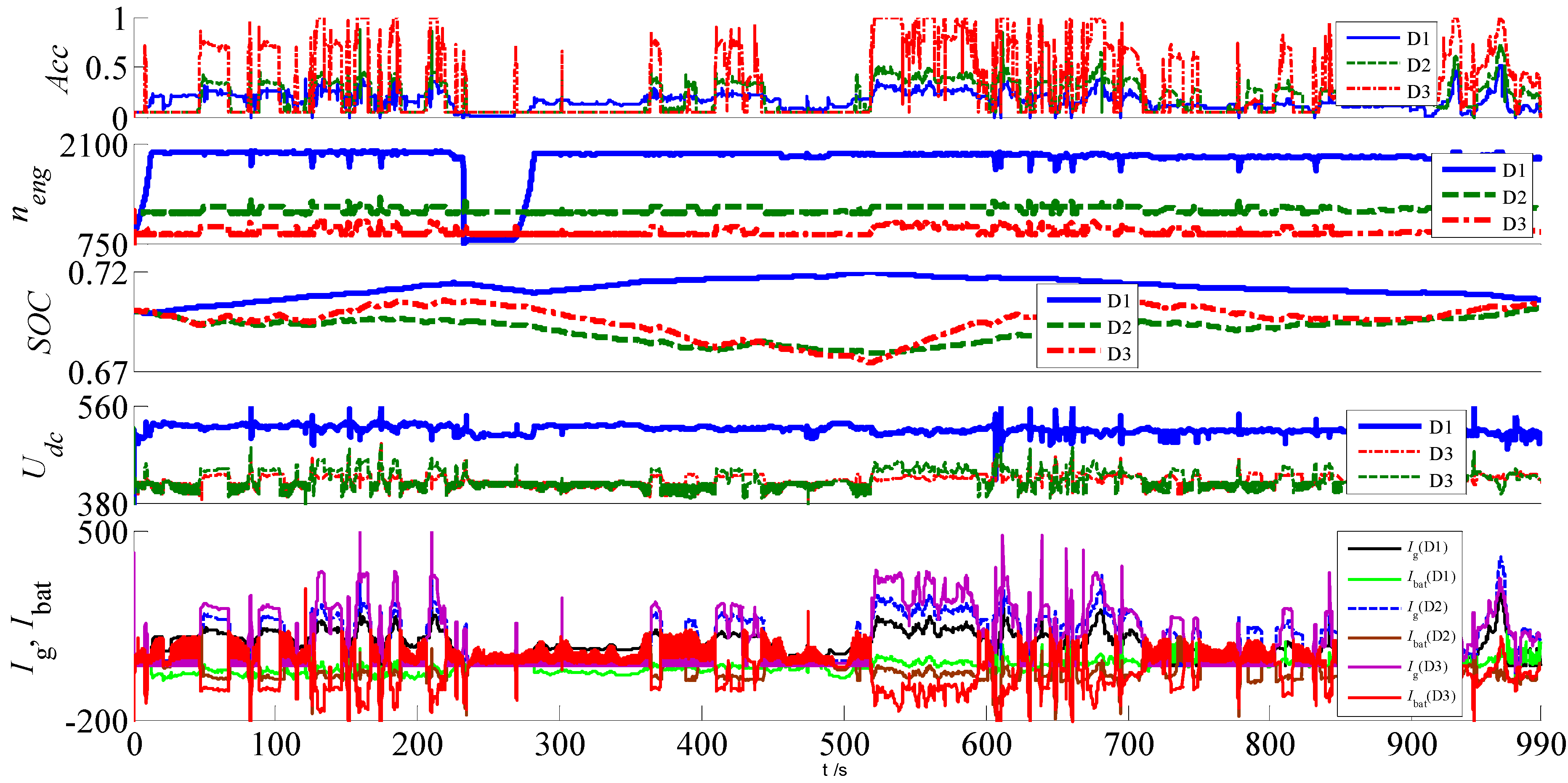

The dynamic evolutions of the system with the parameter selection

D1,

D2,

D3 are shown in

Figure 10.

D1 and

D3 represent two type mismatches of the engine-generator and the battery. The value of

ie-g is too higher than the voltage range of the battery in

D1, and vice versa in

D3.

Figure 10.

Dynamic history of typical variables in D1, D2, D3.

Figure 10.

Dynamic history of typical variables in D1, D2, D3.

The engine speed is constrained to the undesirable range in D1 and D3. Clearly, DP finds the different controls for the different parameter selections. For D1, the engine always operates in the high speed range to generate electricity, while the engine is idled when the power request is low during around 230–260 s. For D1 and D2, the engine works around 900 rpm and 1200 rpm, respectively. The engine frequently generates maximum torque to increase its power output in D1 due to its low speed range. D2 has the relative proper torque and speed output and achieves the lowest fuel consumption. It is clear that the battery tends to be charged or discharged at higher current in D3 than in D2, and it is used less frequently in D1 than in D2. This observation is also useful for the proper battery parameter design. This may lead to the conclusion that the voltage match between the generator at the desired speed range and the battery at admission SOC range is very important. A good match will guarantee the battery can supply the electric power properly, avoiding overuse and insufficient participation.

The optimized and initial parameters are shown in

Table 2, where

ie-g, the battery capacity and the voltage range are solved simultaneously to obtain the results shown in

Figure 8 and

Figure 9. It should be noted the battery capacity increases by 28.0%, and the voltage decreases to 89.9% of the original level. This helps improve the ability to supply the bigger transient electric current without any significant loss of the battery reliability. A considerable reduction of fuel consumption is achieved, namely 16.2% lower than the fuel consumption under the initial parameters.

Table 2.

The combined optimal design vs. the initial design.

Table 2.

The combined optimal design vs. the initial design.

| Optimal design results | Initial design values | Fuel economy Improvement |

|---|

| x*ocv | x*cap | x*h | i*e-g | c* [Ah] | V*(1) [V] | Fuel consumption* [grams] | C [Ah] | V(1) [V] | ie-g | Fuel consumption [grams] |

|---|

| 0.90 | 1.68 | 0.25 | 2.15 | 64 | 436 | 2820 | 50 | 485 | 1.60 | 3365 | 16.2% |

Clearly in this hybrid tracked vehicle the parameter selection plays a significant role in the optimal system design and the proper parameter match is a necessary prerequisite for a good fuel economy, especially for some predominant parameters, such as the battery voltage and the generator speed which are influenced heavily by the gear-ratio between the engine and generator. The mismatch results in the limited improvement in fuel economy even through the control optimization. It should also be noted that the fuel economy obtained in the paper is the theoretically best with respect to the current parameter selection and the optimal control. The casual control algorithm approximating DP behavior should be pursued in the following practical controller design, which is not covered in the paper.