Simulation Research on an Electric Vehicle Chassis System Based on a Collaborative Control System

Abstract

:1. Introduction

2. Modeling the Chassis System

2.1. Vehicle Dynamics Model

2.2. Active Suspension Model

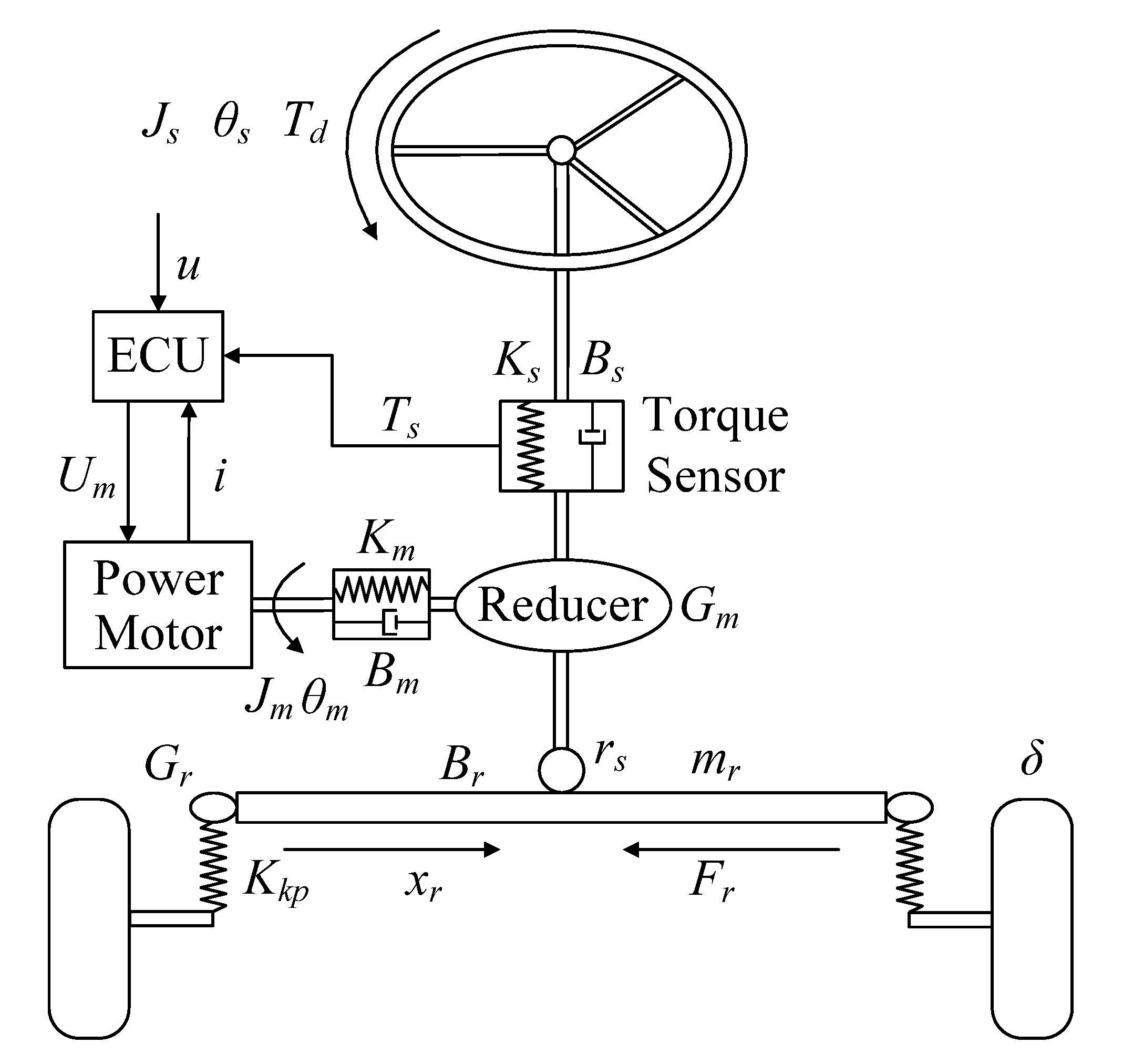

2.3. Electric Power Steering Model

2.4. Anti-Lock Braking System Model

2.5. Wheel Motor Model

2.6. Tyre Model

2.7. Road Input Model

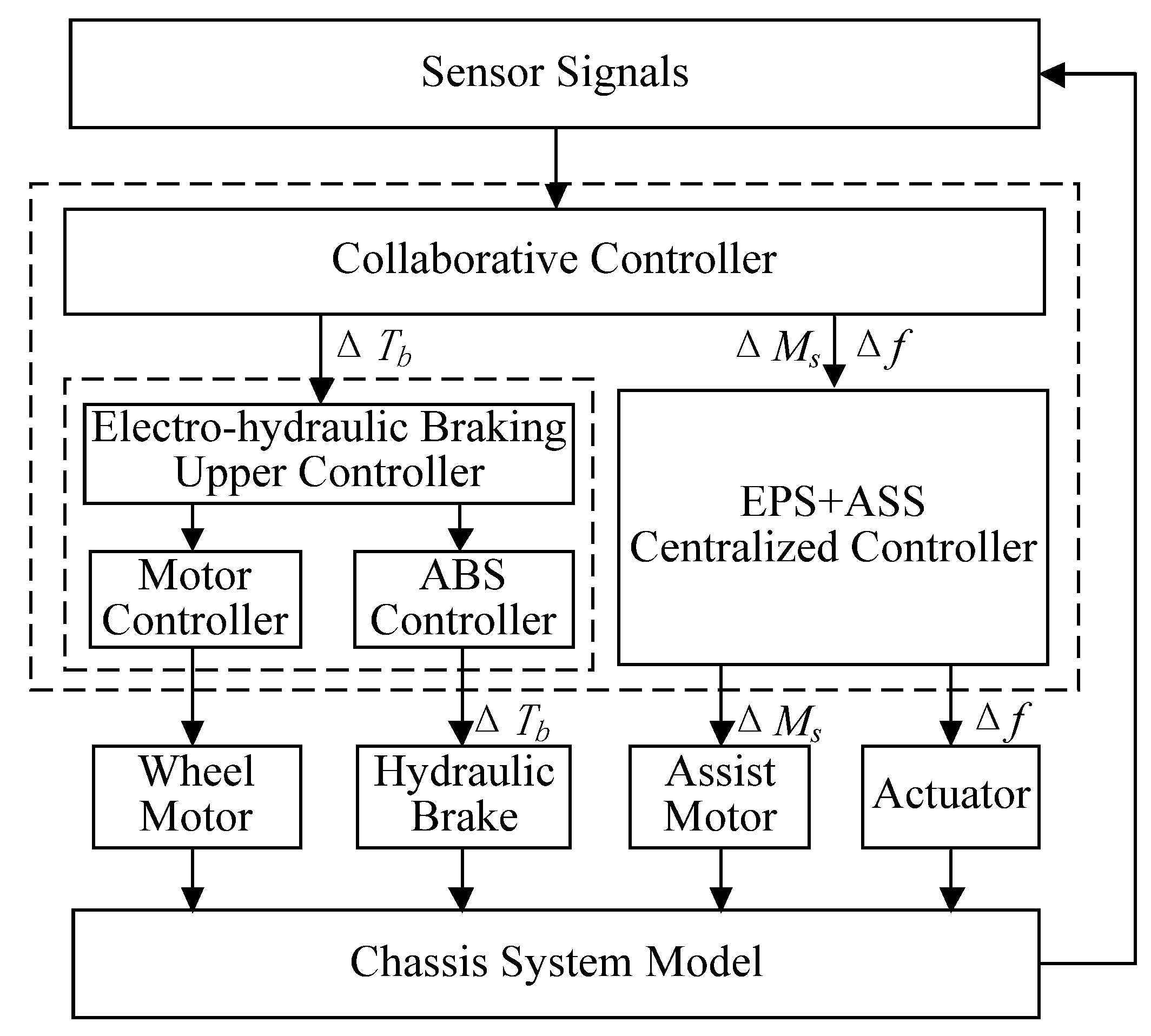

3. Chassis Collaborative Control System

3.1. Collaborative Control Definition

3.2. Electric Vehicle Chassis System Collaborative Control Strategy

3.3. ASS+EPS Controller Design

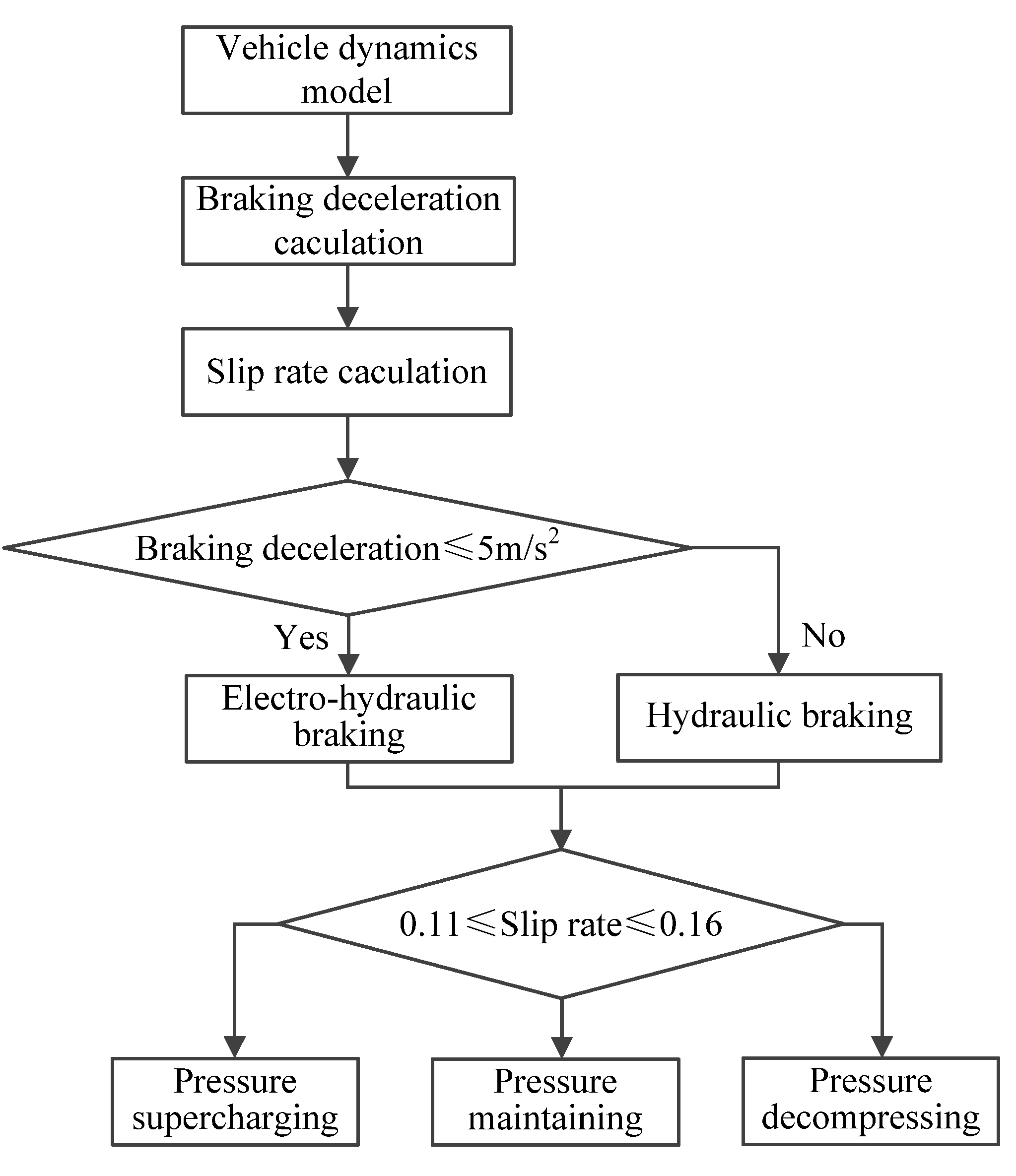

3.4. Electro-Hydraulic Braking System Controller Design

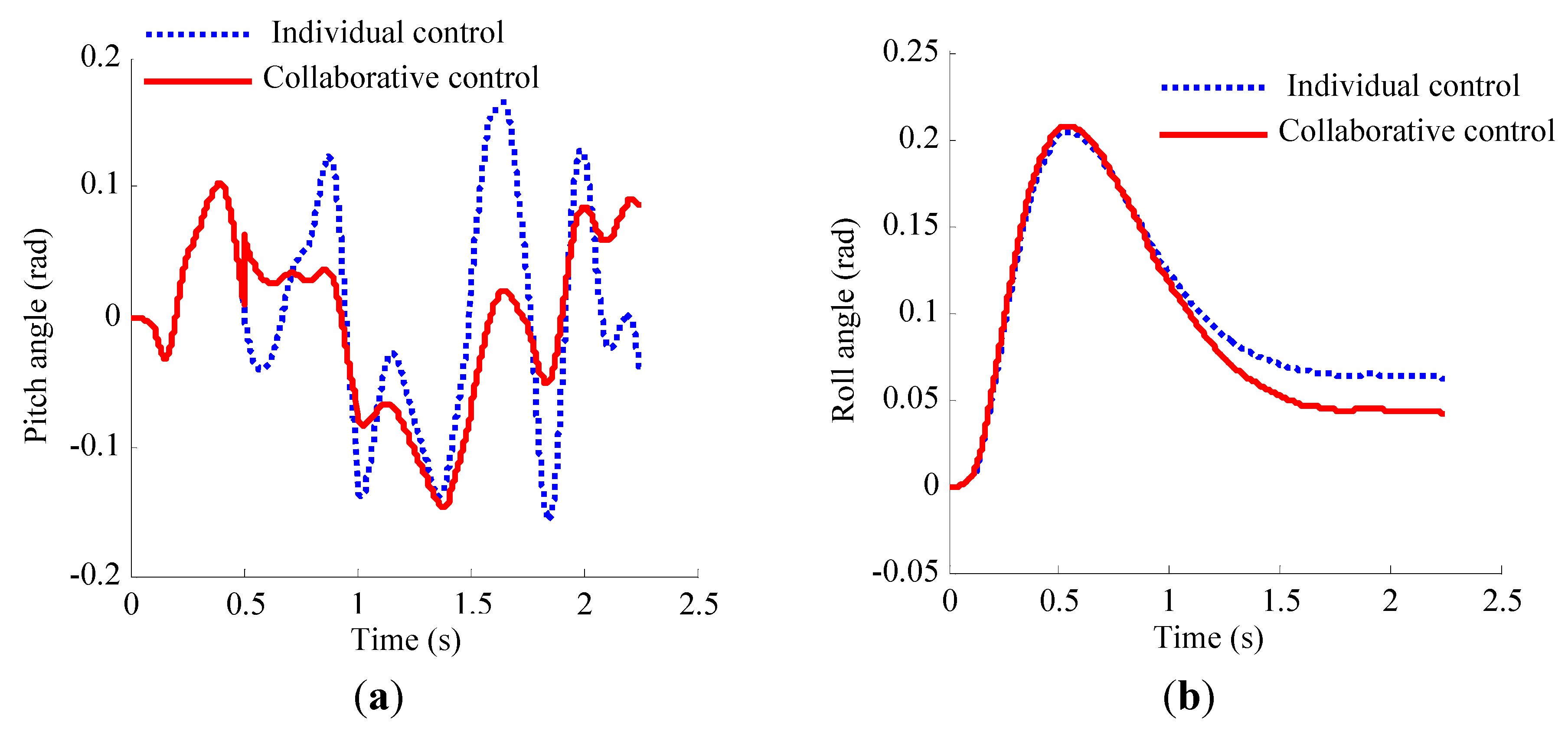

4. Simulation Results and Analysis

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Bm | 0.0035 N·m·s/rad | Ka | 0.5 N·m/A |

| Bs | 0.0275N·m·s/rad | Kkp | 10 N·m/rad |

| Br | 0.0275 N·m·s/rad | Km | 626 N·m /rad |

| cs | 0.1 m | Ks | 183 N·m/rad |

| cf | 1.100 m | Kv | 0.0367 V·s/rad |

| cr | 1.585 m | Kx | 10,000 N·m/rad |

| df | 1.58 m | Kf | 0.95 N·m /Pa |

| dr | 1.60 m | lf | 1.185 m |

| f0 | 0.01 Hz | lr | 1.500 m |

| f | 0.015 | L | 0.0000009 H |

| G0 | 0.000005 m3/cycle | Lm | 0.008 H |

| Gm | 7.5 | Ls | 0.00005 H |

| Gr | 10 | mr | 33 kg |

| hf | 0.35 m | ms | 1080 kg |

| hr | 0.32 m | m | 1350 kg |

| is | 15 | np | 2 |

| Iw | 15 kg·m2 | R | 0.035 Ω |

| Izu | 1598kg·m2 | Rs | 0.975 Ω |

| Iys | 2444 kg·m2 | rs | 0.007 m |

| Js | 0.042 kg.m2 | rw | 0.303 m |

| Jm | 0.00047 kg.m2 | Tpwm | 0.0002 s |

| Cbi | 1500 N·s/m(1,2), 1300 N·s/m(3,4) | Kui | 200,000 N/m(1,2), 180,000 N/m(3,4) |

| Ksi | 17,000 N/m(1,2), 22,000 N/m(3,4) | mui | 40.5 kg(1,2), 45.4 kg (3,4) |

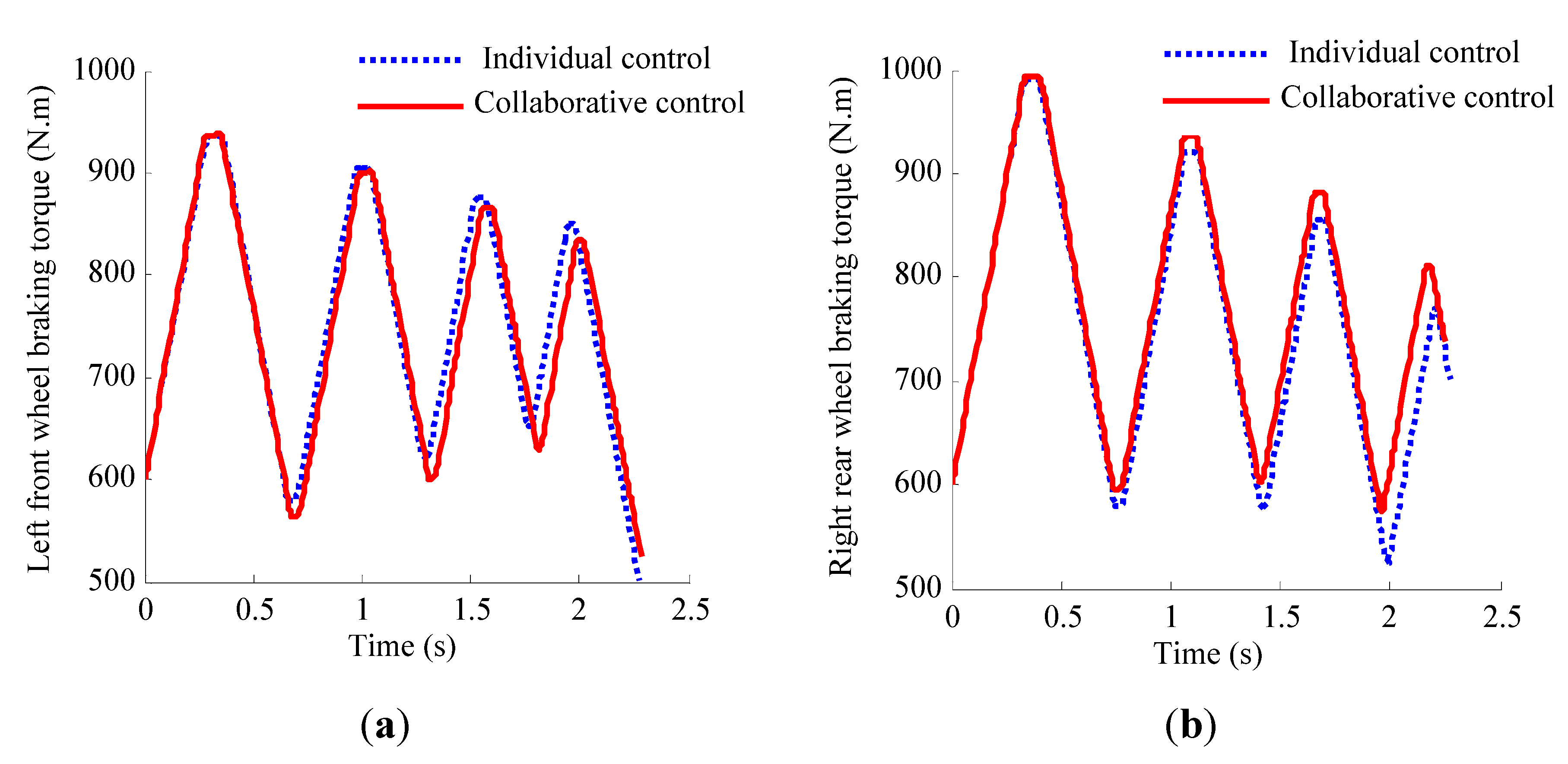

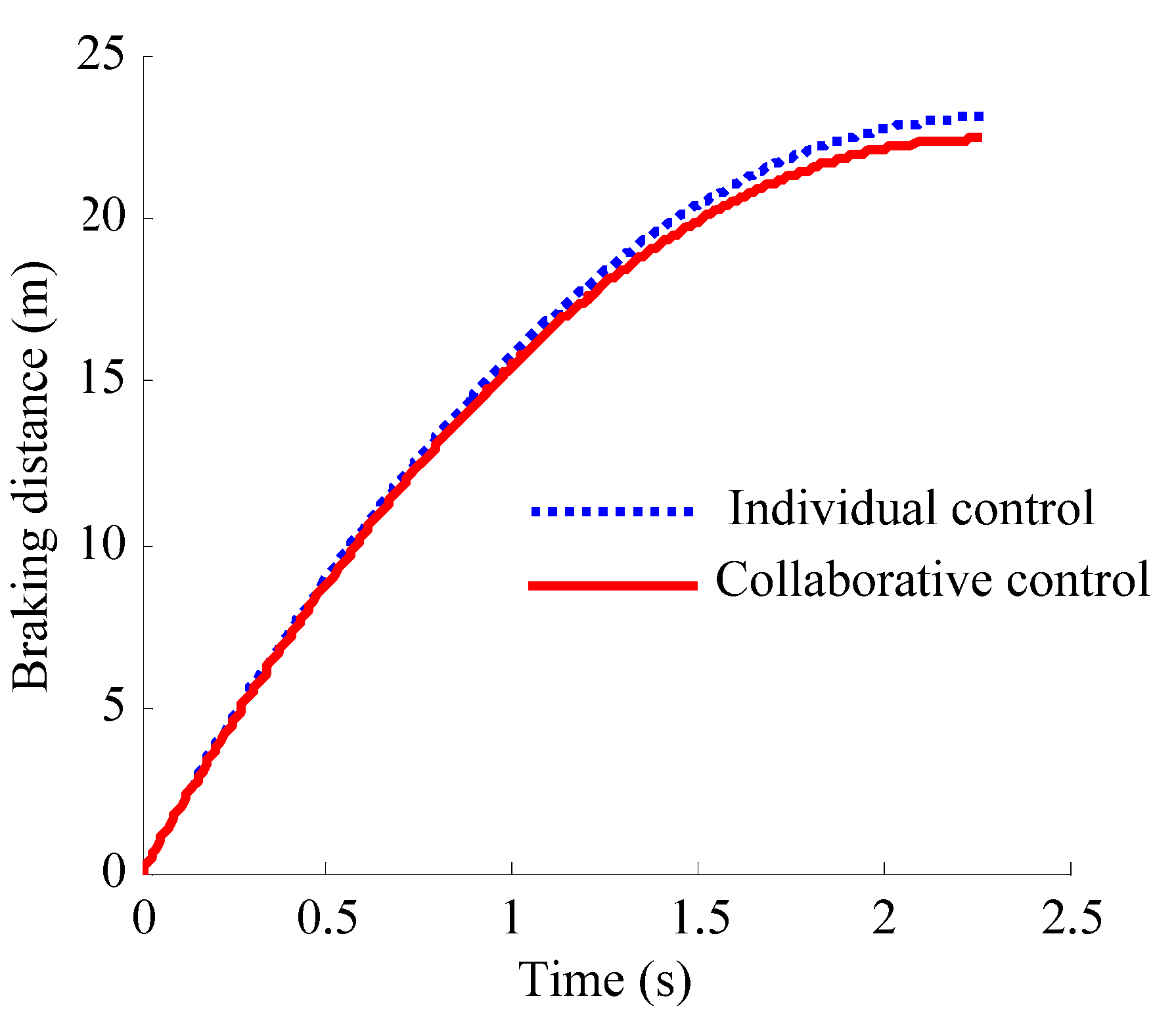

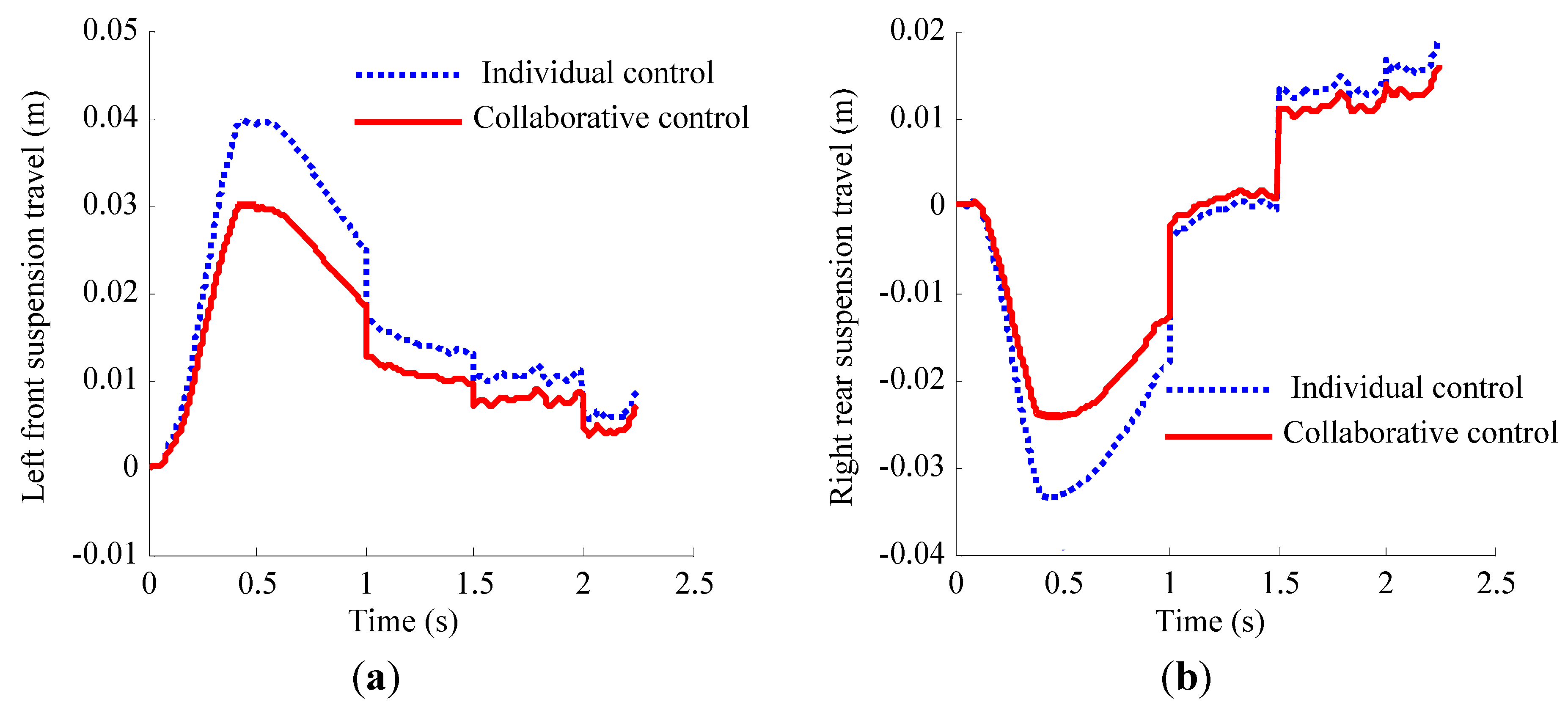

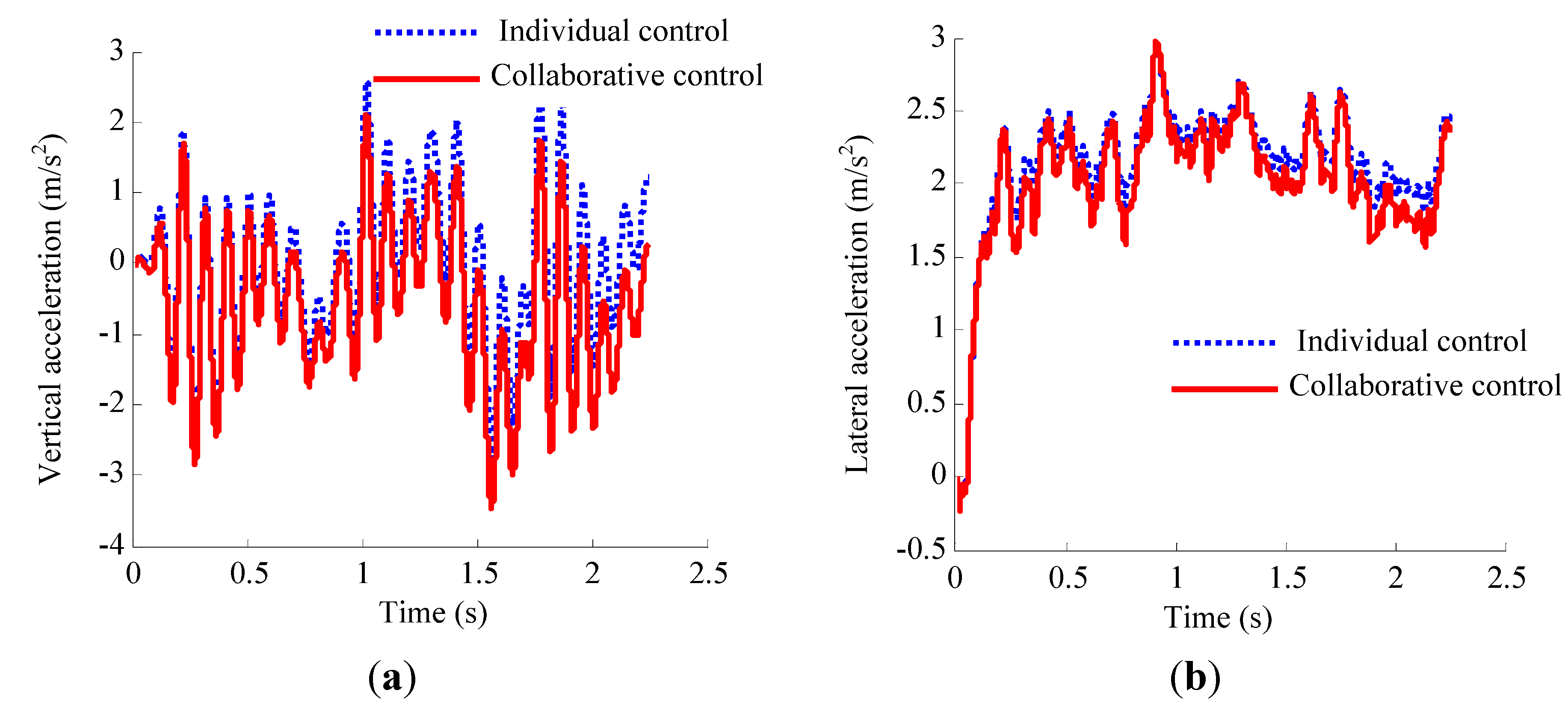

| RMS value | Individual control | Collaborative control |

|---|---|---|

| (rad) | 0.0632 | 0.0478 |

| (rad) | 0.0845 | 0.0653 |

| (rad) | 12.3832 | 10.1294 |

| (rad/s) | 0.6192 | 0.4055 |

| (N·m) | 768.83 | 765.26 |

| (N·m) | 787.87 | 805.50 |

| (m) | 0.0197 | 0.0145 |

| (m) | 0.0093 | 0.0056 |

| (rad/s2) | 0.9732 | 0.9657 |

| (m/s2) | 2.3186 | 2.2312 |

5. Conclusions

Acknowledgements

References

- Choi, S.B.; Sung, K.G.; Cho, M.S.; Lee, Y.S. The braking performance of a vehicle anti-lock brake system featuring an electro-rheological valve pressure modulator. Smart Mater. Struct. 2007, 16, 1285–1297. [Google Scholar] [CrossRef]

- Dannöhl, C.; Müller, S.; Ulbrich, H. H∞-control of a rack-assisted electric power steering system. Veh. Syst. Dyn. 2012, 50, 527–544. [Google Scholar] [CrossRef]

- Hyniova, K.; Antonin, S.; Jaroslav, H.; Kruczek, A. Active suspension system with linear electric motor. WSEAS Trans. Syst. 2009, 8, 278–287. [Google Scholar]

- Lu, S.B.; Li, Y.N.; Choi, S.B.; Zheng, L.; Seong, M.S. Integrated control on MR vehicle suspension system associated with braking and steering control. Veh. Syst. Dyn. 2011, 49, 361–380. [Google Scholar] [CrossRef]

- Hac, A.; Bodie, M. Improvements in vehicle handling through integrated control of chassis systems. Int. J. Veh. Auton. Syst. 2002, 1, 83–110. [Google Scholar] [CrossRef]

- Gordon, T.; Howell, M.; Brandao, F. Integrated control methodologies for road vehicles. Veh. Syst. Dyn. 2003, 40, 157–190. [Google Scholar] [CrossRef]

- Gao, X.J.; Yu, Z.P.; Zhang, L.J. A study on the control architecture of an integrated chassis control system. Automot. Eng. 2007, 29, 21–26. [Google Scholar]

- Chen, W.W.; Xiao, H.S.; Liu, L.Q. Integrated control of automotive electrical power steering and active suspension systems based on random sub-optimal control. Int. J. Veh. Des. 2006, 42, 370–391. [Google Scholar] [CrossRef]

- Peng, J.K.; Zhang, X.L.; Feng, N.L. Integrated modeling and simulation of electric power steering system. J. Hubei Autom. Ind. Inst. 2011, 25, 19–23. [Google Scholar]

- Peng, D. Study on Combined Control of Regenerative Braking and Anti-Lock Braking System for Hybrid Electric Vehicle. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2007. [Google Scholar]

- Yang, G.; Luo, Y.L. Electrical Machinery and Motion Control Systems, 1st ed.; Tsinghua University Press: Beijing, China, 2006; pp. 338–356. [Google Scholar]

- Wang, H.G.; Xu, W.L.; Yang, G.; Li, J. Variable-structure torque control of induction motors using space vector modulation. Electr. Eng. 2005, 87, 93–102. [Google Scholar] [CrossRef]

- Pacejka, H.B.; Bakker, E. The magic formula tyre model. Veh. Syst. Dyn. 1992, 21, 1–18. [Google Scholar] [CrossRef]

- Yu, F.; Crolla, D.A. An optimal self-tuning controller for an active suspension. Veh. Syst. Dyn. 1998, 29, 51–65. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Peng, J.; He, H.; Feng, N. Simulation Research on an Electric Vehicle Chassis System Based on a Collaborative Control System. Energies 2013, 6, 312-328. https://doi.org/10.3390/en6010312

Peng J, He H, Feng N. Simulation Research on an Electric Vehicle Chassis System Based on a Collaborative Control System. Energies. 2013; 6(1):312-328. https://doi.org/10.3390/en6010312

Chicago/Turabian StylePeng, Jiankun, Hongwen He, and Nenglian Feng. 2013. "Simulation Research on an Electric Vehicle Chassis System Based on a Collaborative Control System" Energies 6, no. 1: 312-328. https://doi.org/10.3390/en6010312

APA StylePeng, J., He, H., & Feng, N. (2013). Simulation Research on an Electric Vehicle Chassis System Based on a Collaborative Control System. Energies, 6(1), 312-328. https://doi.org/10.3390/en6010312