Building Agro-Energy Supply Chains in the Basilicata Region: Technical and Economic Evaluation of Interchangeability between Fossil and Renewable Energy Sources

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Context

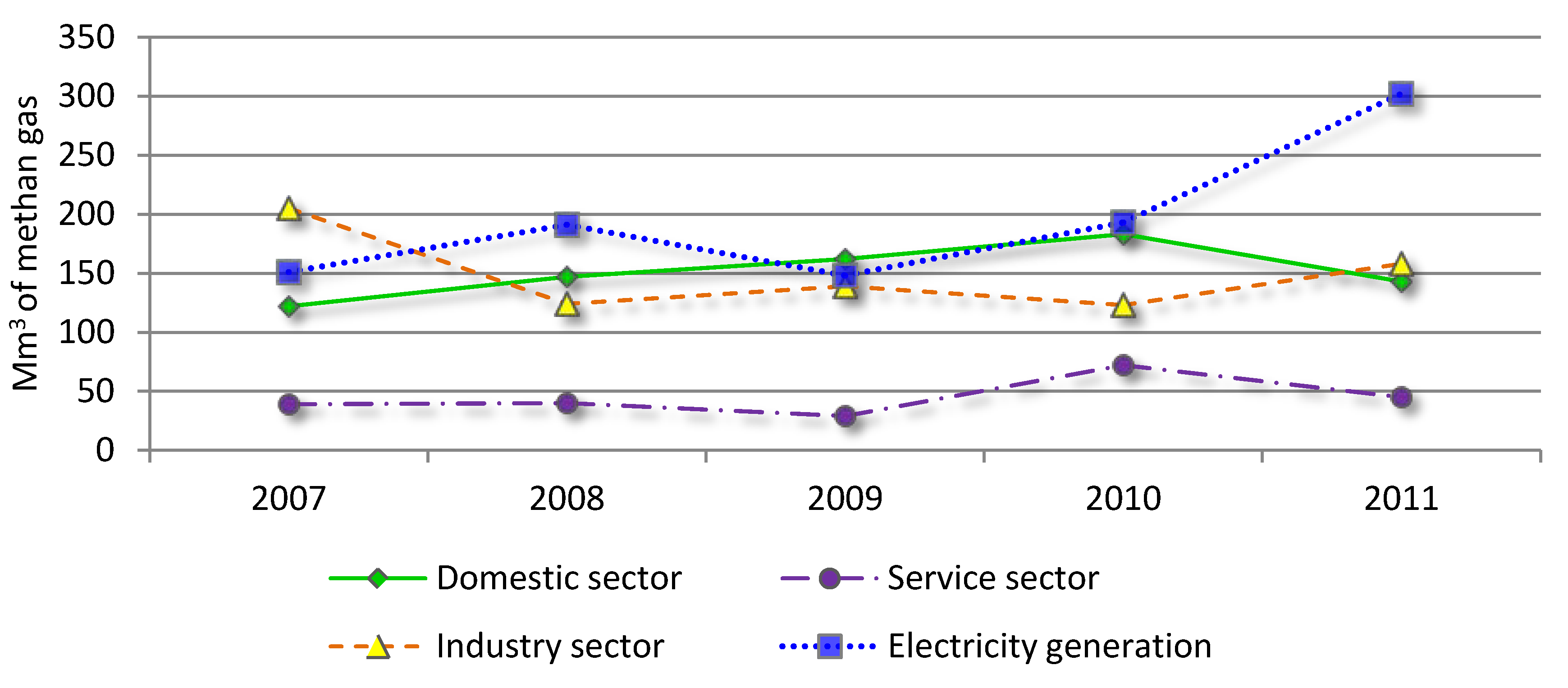

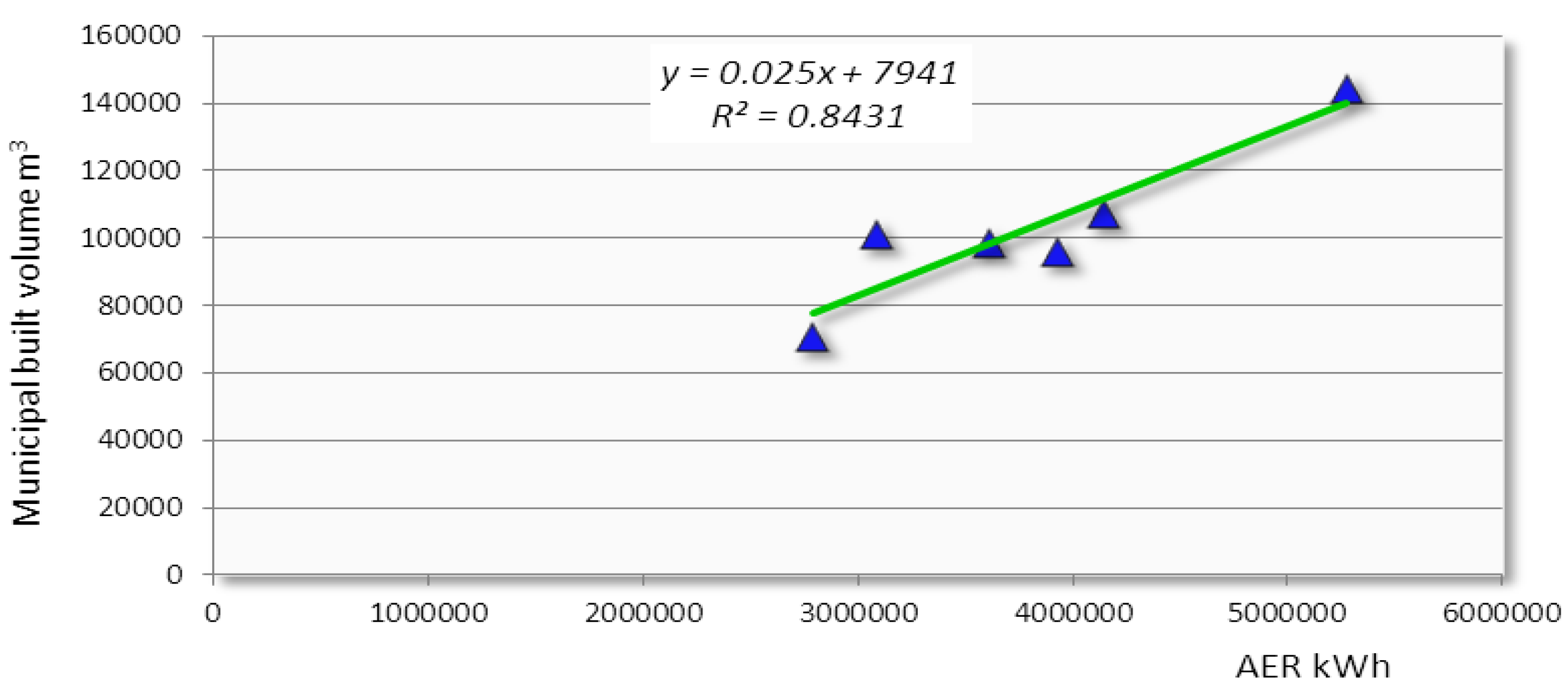

2.2. Estimate of Methane Gas Consumption

- the residential surface of the built-up area (ba) of the Municipality;

- the residential surface of the housing clusters (hc);

- the residential surface of scattered houses (sh);

- the resident population, divided into ba, hc and sh.

| Climate zone | A | B | C | D | E | F | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| HDD | ≤600 | 601 | 900 | 901 | 1400 | 1401 | 2100 | 2101 | 3000 | ≥3000 |

| S/V≤ 0.2 | 0.49 | 0.49 | 0.46 | 0.46 | 0.42 | 0.42 | 0.34 | 0.30 | 0.30 | 0.30 |

| S/V≥ 0.9 | 1.16 | 1.16 | 1.08 | 1.08 | 0.95 | 0.95 | 0.78 | 0.78 | 0.73 | 0.73 |

| Altitude range | Heating days | Daily heating coefficient | Plant type | Variation coefficient compared to 20 °C |

|---|---|---|---|---|

| m a.s.l. | Hd | λ | - | Δc |

| 0–150 | 100 | 0.66 | Centralized | 0 |

| Independent | −1 | |||

| Individual | −1 | |||

| Undefined | 0 | |||

| 151–300 | 120 | 0.71 | Centralized | 0.25 |

| Independent | −0.75 | |||

| Individual | −0.75 | |||

| Undefined | 0 | |||

| 301–500 | 150 | 0.76 | Centralized | 0.5 |

| Independent | −0.5 | |||

| Individual | −0.5 | |||

| Undefined | 0 | |||

| 501–1000 | 180 | 0.84 | Centralized | 0.75 |

| Independent | −0.25 | |||

| Individual | −0.25 | |||

| Undefined | 0 | |||

| >1000 | 200 | 0.93 | Centralized | 1 |

| Independent | 0 | |||

| Individual | 0 | |||

| Undefined | 0 |

2.3. Sizing of Processing Plants

2.4. Municipal Forests

| Species | Tall Trees | Coppice | |

|---|---|---|---|

| % Residues | |||

| Beech | 8% | 25% | |

| Oak | 15% | 20% | |

| Chestnut | 15% | 16% | |

| Hornbeam | 15% | 20% | |

| Hygrophilous formations | 100% | 100% | |

| Holm oak | 25% | 32% | |

| Mountain pine forests | 100% | - | |

| Mediterranean pine forests | 100% | - | |

| Plantations and reforestation | 15% | - | |

| Species | Fresh wood | Commercial Moisture Content (12%–15%) | Commercial/Fresh | |||

|---|---|---|---|---|---|---|

| Kg × 102/m3 | m3/Kg × 102 | Kg × 102/m3 | m3/Kg × 102 | |||

| (1) | Beech | 10.5 | 0.095 | 7.5 | 0.133 | 0.7 |

| (2) | Oak | 11.0 | 0.091 | 9.0 | 0.111 | 0.8 |

| (1) | Chestnut | 10.0 | 0.100 | 5.8 | 0.172 | 0.6 |

| (3) | Hornbeam | 10.0 | 0.100 | 8.0 | 0.125 | 0.8 |

| (4) | Hygrophilous formations | 8.6 | 0.116 | 5.6 | 0.179 | 0.7 |

| (1) | Holm oak | 11.0 | 0.091 | 9.6 | 0.104 | 0.9 |

| (5) | Mountain pine for. | 9.0 | 0.111 | 5.6 | 0.179 | 0.6 |

| (6) | Mediterranean pine for. | 9.5 | 0.105 | 6.4 | 0.156 | 0.7 |

| Municipality | Allowable cut | Forest residues | Total | |||

|---|---|---|---|---|---|---|

| Total 50% WCs (t) | Annual 50% WCs (t) * | Total 50% WCs (t) | Annual 50% WCs (t) | 50% WCs (t) | 25% WCs (t) | |

| Acerenza (PZ) | 7,339.51 | 366.98 | 1,100.93 | 110.09 | 477.07 | 357.80 |

| Albano di L. (PZ) | 12,840.94 | 642.05 | 1,926.14 | 192.61 | 834.66 | 626.00 |

| Aliano (MT) | 1,924.30 | 96.22 | 288.65 | 28.86 | 125.08 | 93.81 |

| Cancellara (PZ) | 6,401.97 | 320.10 | 960.29 | 96.03 | 416.13 | 312.10 |

| Castelmezzano (PZ) | 7,001.77 | 350.09 | 1,050.27 | 105.03 | 455.11 | 341.33 |

| Castronuovo di S. (PZ) | 14,185.44 | 709.27 | 2,127.82 | 212.78 | 922.05 | 691.54 |

| Cersosimo (PZ) | 7,808.20 | 390.41 | 1,171.23 | 117.12 | 507.53 | 380.65 |

| Fardella (PZ) | 13,539.43 | 676.97 | 1,143.36 | 114.34 | 791.31 | 593.48 |

| Forenza (PZ) | 31,635.87 | 1,581.79 | 4,745.38 | 474.54 | 2,056.33 | 1,542.25 |

| Francavilla sul S. (PZ) | 14,565.54 | 728.28 | 1,472.70 | 147.27 | 875.55 | 656.66 |

| Ginestra (PZ) | 15,232.72 | 761.64 | 2,284.91 | 228.49 | 990.13 | 742.60 |

| Gorgoglione (MT) | 4,447.33 | 222.37 | 2,197.05 | 219.70 | 442.07 | 331.55 |

| Lagonegro (PZ) | 18,787.27 | 939.36 | 1,502.98 | 150.30 | 1,089.66 | 817.25 |

| Latronico (PZ) | 23,834.57 | 1,191.73 | 3,029.03 | 302.90 | 1,494.63 | 1,120.97 |

| Noepoli (PZ) | 20,899.96 | 1,045.00 | 2,471.66 | 247.17 | 1,292.16 | 969.12 |

| Palazzo S. G. (PZ) | 599.84 | 29.99 | 89.98 | 9.00 | 38.99 | 29.24 |

| Pietragalla (PZ) | 10,228.61 | 511.43 | 3,409.36 | 340.94 | 852.37 | 639.28 |

| Pietrapertosa (PZ) | 20,111.29 | 1,005.56 | 3,016.69 | 301.67 | 1,307.23 | 980.42 |

| Pignola (PZ) | 29,564.05 | 1,478.20 | 3,273.40 | 327.34 | 1,805.54 | 1,354.16 |

| Rotonda (PZ) | 27,874.60 | 1,393.73 | 2,229.97 | 223.00 | 1,616.73 | 1,212.55 |

| San Chirico R. (PZ) | 3,845.48 | 192.27 | 576.82 | 57.68 | 249.96 | 187.47 |

| S. Costantino A. (PZ) | 15,151.58 | 757.58 | 2,017.26 | 201.73 | 959.30 | 719.48 |

| San Mauro F. (MT) | 2,859.39 | 142.97 | 428.91 | 42.89 | 185.86 | 139.40 |

| San Severino L. (PZ) | 20,720.92 | 1,036.05 | 1,657.67 | 165.77 | 1,201.81 | 901.36 |

| Sasso di Castalda (PZ) | 15,570.90 | 778.54 | 1,284.65 | 128.47 | 907.01 | 680.26 |

| Spinoso (PZ) | 7,268.64 | 363.43 | 604.85 | 60.49 | 423.92 | 317.94 |

| Stigliano (MT) | 2,395.37 | 119.77 | 359.31 | 35.93 | 155.70 | 116.78 |

| Tito (PZ) | 7,705.13 | 385.26 | 843.60 | 84.36 | 469.62 | 352.22 |

| Tricarico (MT) | 13,272.44 | 663.62 | 1,990.87 | 199.09 | 862.71 | 647.03 |

| Venosa (PZ) | 5,861.47 | 293.07 | 879.22 | 87.92 | 381.00 | 285.75 |

2.5. The Incentive Scheme: White Certificates and Energy Saving Companies

- standardized assessment methods, whose savings associated with the procedure are determined on the basis of the number of physical reference units (PRUs) involved in the proposed intervention;

- analytical evaluation methods that quantify the energy savings on the basis of a specific algorithm for each type of intervention;

- ex-post evaluation methods applied to the proposals that include heterogeneous interventions in relation to the evaluation method and to which the above methods are not applicable.

| Project type | Minimum project size | |

|---|---|---|

| Obliged subjects—Energy manager | Voluntary subjects | |

| Standardized | 25 toe/year | |

| Analytical | 100 toe/year | 50 toe/year |

| Ex-post | 200 toe/year | 100 toe/year |

- type I: certifying the achievement of primary energy savings through a reduction of power consumption;

- type II: certifying the achievement of primary energy savings through a reduction of natural gas consumption;

- type III: certifying the achievement of savings of primary energy forms other than electricity and natural gas not intended for use in motor vehicles;

- type IV: certifying the achievement of savings of primary energy forms other than electricity and natural gas intended for use in motor vehicles.

- more employment, associated with energy production-related activities (cut, harvest, logging, transportation, operation of the system, etc.);

- reduction of energy costs, with regards to energy supply for housing.

3. Results

3.1. Technical Evaluation

| MunicipalityMunicipality | A | B | C | D | E | F | G | H | I | L | M | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Methane gas consumption (m3 × 1000) | AER (GJ) | Energy produced from methane gas (MW h) | 25% energy from methane gas D = C × 25% (MW h) | Climate zone | Estimated built volume (m3 × 1000) | 25% built volume potentially supplied by district heating G = F × 25% (m3 × 1000) | Plant power 0.03 KW/m3 × G (MW) | ARF (annual requirements of fuel) (t_WC = 25%) | Annual available biomass (t_WC = 25%) | Deficit/surplus of available biomass of ARF M = L – I (t_WC = 25%) | Feasibility | |

| Acerenza (PZ) | 917.00 | - | 9,704.64 | 2,426.16 | E | 250.56 | 62.64 | 1.88 | 819.65 | 357.80 | −461.85 | Insufficient biomass |

| Albano di Lucania (PZ) | 453.00 | - | 4,794.12 | 1,198.53 | E | 127.79 | 31.95 | 0.96 | 404.91 | 626.00 | 221.09 | Positive |

| Aliano (MT) | - | 11,128.55 | 3,091.18 | 772.79 | D | 85.22 | 21.31 | 0.64 | 261.08 | 93.81 | −167.27 | Insufficient biomass |

| Cancellara (PZ) | 312.00 | - | 3,301.91 | 825.48 | E | 90.49 | 22.62 | 0.68 | 278.88 | 312.10 | 33.22 | Positive |

| Castelmezzano (PZ) | - | 10,051.31 | 2,791.95 | 697.99 | E | 77.74 | 19.43 | 0.58 | 235.81 | 341.33 | 105.53 | Positive |

| Castronuovo di S. A. (PZ) | - | 12,998.64 | 3,610.63 | 902.66 | D | 98.21 | 24.55 | 0.74 | 304.95 | 691.54 | 386.59 | Positive |

| Cersosimo (PZ) | 110.00 | - | 1,164.13 | 291.03 | D | 37.04 | 9.26 | 0.28 | 98.32 | 380.65 | 282.33 | Positive |

| Fardella (PZ) | 130.00 | - | 1,375.79 | 343.95 | E | 42.34 | 10.58 | 0.32 | 116.20 | 593.48 | 477.28 | Positive |

| Forenza (PZ) | 848.00 | - | 8,974.42 | 2,243.60 | E | 232.30 | 58.08 | 1.74 | 757.97 | 1,542.25 | 784.27 | Positive |

| Francavilla sul Sinni (PZ) | 594.00 | - | 6,286.32 | 1,571.58 | D | 165.10 | 41.27 | 1.24 | 530.94 | 656.66 | 125.72 | Positive |

| Ginestra (PZ) | 188.00 | - | 1,989.61 | 497.40 | D | 57.68 | 14.42 | 0.43 | 168.04 | 742.60 | 574.56 | Positive |

| Gorgoglione (MT) | - | 14,152.15 | 3,931.04 | 982.76 | E | 106.22 | 26.55 | 0.80 | 332.01 | 331.55 | −0.46 | Insufficient biomass |

| Lagonegro (PZ) | 1,436.00 | - | 15,197.24 | 3,799.31 | E | 387.87 | 96.97 | 2.91 | 1,283.55 | 817.25 | −466.31 | Insufficient biomass |

| Latronico (PZ) | 693.00 | - | 7,334.04 | 1,833.51 | E | 191.29 | 47.82 | 1.43 | 619.43 | 1,120.97 | 501.54 | Positive |

| Noepoli (PZ) | 245.00 | - | 2,592.84 | 648.21 | E | 72.76 | 18.19 | 0.55 | 218.99 | 969.12 | 750.13 | Positive |

| Palazzo S. Gervasio (PZ) | 1,743.00 | - | 18,446.23 | 4,611.56 | D | 469.10 | 117.27 | 3.52 | 1,557.96 | 29.24 | −1,528.72 | Insufficient biomass |

| Pietragalla-Filiano (PZ) | 912.00 | - | 9,651.73 | 2,412.93 | E | 249.23 | 62.31 | 1.87 | 815.18 | 639.28 | −175.90 | Insufficient biomass |

| Pietrapertosa (PZ) | - | 18,328.19 | 5,091.02 | 1,272.76 | E | 135.22 | 33.80 | 1.01 | 429.98 | 980.42 | 550.44 | Positive |

| Pignola (PZ) | 1,708.00 | - | 18,075.83 | 4,518.96 | E | 459.84 | 114.96 | 3.45 | 1,526.67 | 1,354.16 | −172.52 | Insufficient biomass |

| Rotonda (PZ) | 718.00 | - | 7,598.62 | 1,899.66 | E | 197.91 | 49.48 | 1.48 | 641.78 | 1,212.55 | 570.77 | Positive |

| San Chirico Raparo (PZ) | - | 14,906.28 | 4,140.52 | 1,035.13 | E | 111.45 | 27.86 | 0.84 | 349.71 | 187.47 | −162.24 | Insufficient biomass |

| San Costantino A. (PZ) | 100.00 | - | 1,058.30 | 264.58 | D | 34.40 | 8.60 | 0.26 | 89.38 | 719.48 | 630.09 | Positive |

| San Mauro Forte (MT) | 336.00 | - | 3,555.90 | 888.98 | D | 96.84 | 24.21 | 0.73 | 300.33 | 139.40 | −160.93 | Insufficient biomass |

| San Severino L. (PZ) | 257.00 | - | 2,719.84 | 679.96 | E | 75.94 | 18.98 | 0.57 | 229.72 | 901.36 | 671.64 | Positive |

| Sasso di Castalda (PZ) | 214.00 | - | 2,264.77 | 566.19 | E | 64.56 | 16.14 | 0.48 | 191.28 | 680.26 | 488.98 | Positive |

| Spinoso (PZ) | - | 18,991.51 | 5,275.27 | 1,318.82 | D | 139.82 | 34.96 | 1.05 | 445.55 | 317.94 | −127.61 | Insufficient biomass |

| Stigliano (MT) | 2,188.00 | - | 23,155.68 | 5,788.92 | E | 586.83 | 146.71 | 4.40 | 1,955.72 | 116.78 | −1,838.94 | Insufficient biomass |

| Tito (PZ) | 2,405.00 | - | 25,452.20 | 6,363.05 | D | 644.25 | 161.06 | 4.83 | 2,149.68 | 352.22 | −1,797.46 | Insufficient biomass |

| Tricarico (MT) | 2,132.00 | - | 22,563.03 | 5,640.76 | D | 572.02 | 143.00 | 4.29 | 1,905.66 | 647.03 | −1,258.63 | Insufficient biomass |

| Venosa (PZ) | 5,065.00 | - | 53,603.08 | 1,3400.77 | D | 1,348.02 | 337.00 | 10.11 | 4,527.29 | 285.75 | −4,241.54 | Insufficient biomass |

3.2. Economic Evaluation

| Thermal plant biomass | District heating network | Machinery room | Annual running costs as a percentage (%) | Chip fuel cost (€/t) WCs = 25% | |||

|---|---|---|---|---|---|---|---|

| Power (kWt) | Cost (€/kWt) | Power (kWt) | Network length (m) | Cost (€/m) | Cost (€) | ||

| ≤100 | 400.00 | ≤100 | 500 | 190.00 | 30,000 | 3 | 30.00 |

| 100 < P ≤ 300 | 300.00 | 100 < P ≤ 250 | 800 | 190.00 | 30,000 | 3 | 30.00 |

| 300 < P ≤ 450 | 260.00 | 250 < P ≤ 500 | 1200 | 190.00 | 30,000 | 3 | 30.00 |

| 450 < P ≤ 700 | 170.00 | P > 500 | 1500 | 190.00 | 40,000 * | 3 | 30.00 |

| P > 700 | 120.00 | 190.00 | 40,000 | 3 | 30.00 | ||

| Year | % energy supplied from biomass | Served users |

|---|---|---|

| Year 1 | 30% | Public users |

| Year 2 | 55% | Public and private users |

| Year 3 | 80% | Public and private users |

| Year 4–20 | 100% | Public and private users |

| Country | A | B | C | D | E | F | G | H | I | L | M | N | O | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | 25% energy from methane gas (kW h) | TOE saved per year | TOE Subsidised by national legislation | Total cost (€) | Annual payment (4.2%) (€) | Annual running cost (€) | Cost of wood chips (€30/t) | Break Even Point (€/KW h) | Selling price of energy (€/kW h) | Revenues from energy sales (€) | Revenues from White Certificates (€) | NPV (€) | IRR (%) | Payback Period (years) |

| Albano di Lucania | 1,198,528.94 | 90.60 | 304.42 | 440,014.50 | 73,853.42 | 12,000.44 | 12,147.25 | 0.042 | 0.095 | 113,860.25 | 132,390.52 | 742,435.96 | >50% | 4.6 |

| Cancellara | 825,476.89 | 62.40 | 209.66 | 440,373.90 | 73,913.74 | 12,011.22 | 8,366.32 | 0.056 | 0.095 | 78,420.30 | 87,535.56 | 311,462.96 | 19.3% | 7.0 |

| Castelmezzano | 697,988.09 | 52.76 | 177.28 | 424,118.26 | 71,185.34 | 11,523.55 | 7,074.20 | 0.062 | 0.095 | 66,308.87 | 74,016.34 | 183,656.67 | 13.6% | 8.2 |

| Castronuovo di S. A. | 902,658.06 | - | - | 413,386.13 | 69,384.03 | 11,201.58 | 9,148.56 | 0.049 | 0.095 | 85,752.52 | - | 353,481.06 | 19.8% | 6.3 |

| Cersosimo | 291,033.52 | 22.00 | 73.92 | 341,349.79 | 57,293.22 | 9,340.49 | 2,949.66 | 0.111 | 0.095 | 27,648.18 | 22,503.47 | NEGATIVE | - | - |

| Fardella | 343.948.70 | 26.00 | 87.36 | 340,554.95 | 57,159.78 | 9,316.65 | 3,485.97 | 0.095 | 0.095 | 32,675.13 | 26,595.00 | NEGATIVE | - | - |

| Forenza | 2,243,603.84 | 169.60 | 569.86 | 534,071.25 | 89,640.20 | 14,822.14 | 22,739.23 | 0.031 | 0.095 | 213,142.37 | 247,830.37 | 1,802,114.08 | >50% | 2.8 |

| Francavilla sul Sinni | 171,580.99 | 118.80 | 399.17 | 473,589.19 | 79,488.70 | 13,007.68 | 15,928.19 | 0.036 | 0.095 | 149,300.19 | 173,598.16 | 1,120,700.82 | >50% | 3.7 |

| Ginestra | 497,402.74 | 37.60 | 126.34 | 370,478.48 | 62,182.27 | 10,214.35 | 5,041.24 | 0.074 | 0.095 | 47,253.26 | 49,449.17 | 31,947.79 | 6.6% | 10.7 |

| Latronico | 1,833,511.16 | 138.60 | 465.70 | 497,162.90 | 83,445.39 | 13,714.89 | 18,582.88 | 0.034 | 0.095 | 174,183.56 | 202,531.19 | 1,386,291.01 | >50% | 3.3 |

| Noepoli | 648,211.02 | 49.00 | 164.64 | 417,771.68 | 70,120.11 | 11,333.15 | 6,569.71 | 0.065 | 0.095 | 61,580.05 | 64,441.74 | 137,801.69 | 11.1% | 8.9 |

| Pietrapertosa | 1,272,755.33 | 96.21 | 323.27 | 446,694.88 | 74,974.67 | 12,200.85 | 12,899.55 | 0.040 | 0.095 | 120,911.76 | 140,589.63 | 817,699.58 | >50% | 4.3 |

| Rotonda | 1,899,655.14 | 143.60 | 482.50 | 503,116.00 | 84,444.57 | 13,893.48 | 19,253.26 | 0.033 | 0.095 | 180,467.24 | 209,837.51 | 1,453,359.08 | >50% | 3.2 |

| San Costantino A. | 264,575.93 | 20.00 | 67.20 | 335,396.83 | 56,294.06 | 9,161.90 | 2,681.51 | 0.119 | 0.095 | 25,134.71 | 16,366.16 | NEGATIVE | - | - |

| San Severino L. | 679,960.13 | 51.40 | 172.70 | 421,819.69 | 70,799.54 | 11,454.59 | 6,891.49 | 0.063 | 0.095 | 64,596.21 | 72,104.61 | 172,432.09 | 12.8% | 8.5 |

| Sasso di Castalda | 566,192.48 | 42.80 | 143.81 | 340,314.32 | 57,119.43 | 9,309.43 | 5,738.44 | 0.062 | 0.095 | 53,788.29 | 56,287.29 | 154,568.96 | 13.6% | 8.2 |

4. Conclusions

Conflicts of Interest

List of Acronyms:

| AEEG | Authority for Electricity and Gas |

| AER | Annual Energy Requirement |

| ARF | Annual Requirement of Fuel |

| DCF | Discounted Cash Flow |

| EECs | Energy Efficiency Credits |

| ESCO | Energy Service Companies |

| FMPs | Forest Management Plans |

| GDP | Gross Domestic Product |

| GHGs | Greenhouse Gases |

| GME | Energy Market Managing Board |

| Hvfw | Heating value of fresh wood |

| INEA | National Institute of Energy and Environment |

| IRR | Internal Rate of Return |

| MSE | Ministry of Economic Development |

| NPV | Net Present Value |

| PRU | Physical Reference Units |

| RES | Renewable Energy Sources |

| RU | Research Unit |

| TOE | Tons of Oil Equivalent |

| WCs | Water Contents |

| Wc | White certificates |

References

- OECD. OECD Environmental Outlook to 2050: The Consequences of Inaction; OECD Publishing: Paris, France, 2012. [Google Scholar]

- The World Bank. Turn down the Heat: Why a 4 °C Warmer World Must be Avoided; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Kerckow, B. Competition between agricultural and renewable energy production. J. Int. Agric. 2007, 46, 333–347. [Google Scholar]

- Rathmann, R.; Szklo, A.; Schaeffer, R. Land use competition for production of food and liquid biofuels: An analysis of the arguments in the current debate. Renew. Energy 2010, 35, 14–22. [Google Scholar] [CrossRef]

- Upreti, B.R.; van der Horst, D. National renewable energy policy and local opposition in the UK: The failed development of a biomass electricity plant. Biomass Bioenergy 2004, 26, 61–69. [Google Scholar] [CrossRef]

- Van der Horst, D.; Evans, J. Carbon claims and energy landscape: Exploring the political ecology of biomass. Landsc. Res. 2010, 35, 173–193. [Google Scholar]

- Van der Horst, D. UK biomass energy since 1990: The mismatch between project types and policy objectives. Energy Policy 2005, 33, 705–716. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass: Overview of biomass. Bioresour. Technol. 2002, 83, 37–63. [Google Scholar] [CrossRef] [PubMed]

- Klass, D.L. Biomass for Renewable Energy, Fuels, and Chemicals; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Fischer, G.; Schrattenholzer, L. Global bioenergy potentials through 2050. Biomass Bioenergy 2001, 20, 151–159. [Google Scholar] [CrossRef]

- Johansson, T.B.; Kelly, H.; Reddy, A.K.N.; Williams, R.H. Renewable Fuels and Electricity for a Growing World Economy: Defining and Achieving the Potential. In Renewable Energy-Sources for Fuels and Electricity; Island Press: Washington, DC, USA, 1993; pp. 1–72. [Google Scholar]

- Forest Products Laboratory. Wood Biomass for Energy; U.S. Department of Agriculture: Madison, WI, USA, 2004.

- Combs, J. Biomass energy—An industry waiting for growth. The technology to use almost any organic matter as an energy source is now available, yet the sector is growing only slowly. Renew. Energy World 2002, 5, 132–145. [Google Scholar]

- Rosch, C.; Kaltschmitt, M. Energy from biomass—Do non-technical barriers prevent an increased use? Biomass Bioenergy 1999, 16, 347–356. [Google Scholar] [CrossRef]

- Cozzi, M. Agro-energie in Basilicata: Un approccio analitico per la valutazione dei costi di trasporto. Aestimum 2008, 53, 51–74. (in Italian). [Google Scholar]

- Fiorese, G.; Guariso, G. A Gis-based approach to evaluate biomass potential from energy crops at regional scale. Environ. Model. Softw. 2009, 25, 702–711. [Google Scholar] [CrossRef]

- Kinoshita, T.; Inoue, K.; Iwao, K.; Kagemoto, H. A spatial evaluation of forest biomass usage using GIS. Appl. Energy 2009, 86, 1–8. [Google Scholar] [CrossRef]

- Perpina, C.; Alfonso, D.; Perez-Navaro, A.; Penalvo, E.; Vargas, C.; Cardenas, R. Methodology based on Geographic Information System for biomass logistic and transport optimization. Renew. Energy 2009, 34, 555–565. [Google Scholar] [CrossRef]

- Romano, S.; Cozzi, M.; Luongo, V.; Pesce, F. La Valutazione dei Costi di Trasporto Delle Biomasse Agroforestali: Funzioni e Mappatura dei Costi su Base Geografica (in Italian); Atti del III Congresso Nazionale di Selvicoltura: Taormina, Italy, 2009; pp. 902–908. [Google Scholar]

- Abdallah, R.; Auchet, S.; Meausoone, P.J. Experiment study about the effects of disc chipper settings on the distribution of wood chip size. Biomass Bioenergy 2011, 35, 843–852. [Google Scholar] [CrossRef]

- Manzone, M.; Airoldi, G.; Balsari, P. Energetic and economic evaluation of a poplar cultivation for the biomass production in Italy. Biomass Bioenergy 2009, 33, 125–126. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C.; Cantini, C.; Sani, G.; Picchi, G.; Biocca, M. Integrating olive grove maintenance and energy biomass recovery with a single-pass pruning and harvesting machine. Biomass Bioenergy 2011, 35, 808–813. [Google Scholar] [CrossRef]

- Wiskerke, W.T.; Dornburg, V.; Rubanza, C.D.K.; Malimbwi, R.E.; Faaij, A.P.C. Cost/benefit analysis of biomass energy supply options for rural smallholders in the semi-arid eastern part of Shinyanga Region in Tanzania. Renew. Sustain. Energy Rev. 2010, 14, 148–165. [Google Scholar] [CrossRef]

- Caserini, S.; Livio, S.; Giugliano, M.; Grosso, M.; Rigamonti, L. LCA of domestic and centralized biomass combustion: The case of Lombardy (Italy). Biomass Bioenergy 2010, 34, 474–485. [Google Scholar] [CrossRef]

- Gasol, C.M.; Gabarell, X.; Rigola, M.; Gonzales-Garcia, S. Environmental assessment: LCA and spatial modeling GIS of Energy crop implementation on local scale. Biomass Bioenergy 2011, 35, 2975–2985. [Google Scholar] [CrossRef]

- Valente, C.; Spinelli, R.; Hillring, B.G. LCA of environmental and socio-economic impacts related to wood Energy production in alpine conditions: Valle di Fiemme (Italy). J. Clean. Prod. 2011, 19, 1931–1938. [Google Scholar] [CrossRef]

- Azar, C.; Lindgren, K.; Andersson, B. Global energy scenarios meeting stringent CO2 constraints—Cost effective fuel choices in the transportation sector. Energy Policy 2003, 31, 961–976. [Google Scholar] [CrossRef]

- Wahlund, B.; Yan, J.Y.; Westermark, M. Increasing biomass utilization in energy systems: A comparative study of CO2 reduction and cost for different bioenergy processing options. Biomass Bioenergy 2004, 26, 531–544. [Google Scholar] [CrossRef]

- ISTAT, Statistiche flash, Occupati e disoccupati. October 2012. Available online: http://www.istat.it/it/files/2012/11/Occupati-e-disoccupati_30_nov_2012.pdf (accessed on 9 September 2013).

- SVIMEZ (Associazione per lo Sviluppo dell’industria nel mezzogiorno), Rapporto SVIMEZ Sull’Economia del Mezzogiorno 2011, Schede Regionali. Available online: http://lnx.svimez.info/images/RAPPORTO/materiali2012/rapporto_2012_schede_regionali.pdf (accessed on 9 September 2013).

- ISTAT, 14° Censimento Generale Della Popolazione e Delle Abitazioni. Available online: http://dawinci.istat.it/MD/dawinciMD.jsp (accessed on 18 March 2013).

- Bernetti, I.; Ciampi, C.; Sacchelli, S.; Marinelli, A. La pianificazione dei distretti agro-energetici. Un modello di analisi per la regione Toscana. L’Ital. For. Mont. 2011, 66, 305–320. (in Italian). [Google Scholar]

- Regulation Laying Down Rules for the Design, Installation, Operation and Maintenance of Heating System in Buildings in order to Reduce Energy Consumption; Presidential Decree No. 412 of 26/08/93; Italian Official Gazette: Rome, Italy, 1993.

- Regulation Laying Down Modifications to the Presidential Decree No. 412 of 26/08/93 on the Design, Installation, Operation and Maintenance of Heating System in Buildings in order to Reduce Energy Consumption; Presidential Decree No. 551 of 21/12/99; Italian Official Gazette: Rome, Italy, 1999.

- Marinelli, A.; Fagarazzi, C.; Tirinnanzi, A. La biomassa ad uso energetico: Valutazione della sostenibilità economica di alcune filiere foresta-legno-energia in Toscana. Econ. Dirit. Agroaliment. 2012, 17, 291–315. (in Italian). [Google Scholar]

- Bernetti, I.; Fagarazzi, C. Valutazione Della Domanda di Biocombustibili Solidi (Legno Cippato) Nell’Area Dell’Appennino Pistoiese (in Italian); Centro Editoriale Toscano: Firenze, Italy, 2008. [Google Scholar]

- Pettenella, D.; Favero, M. Disponibilità di Sottoprodotti Legnosi Impiegabili a Fini Energetici. In I Sottoprodotti di Interesse del DM 6.7.2012—Inquadramento, Potenzialità e Valutazioni; Comitato Termotecnico Italiano (CTI): Milano, Italy, 2013; Volume 1, pp. 21–33. [Google Scholar]

- Castellani, C. Tavole Stereometriche ed Alsometriche Costruite per Boschi Italiani (in Italian); Istituto Sperimentale per l’Assestamento Forestale e l’Alpicoltura (ISAFA): Trento, Italy, 1980. [Google Scholar]

- Giordano, E. Tecnologia del Legno; UTET: Torino, Italy, 1971. [Google Scholar]

- Okay, N.; Akman, U. Analysis of ESCO activities using country indicators. Renew. Sustain. Energy Rev. 2010, 14, 2760–2771. [Google Scholar] [CrossRef]

- Energy & Strategy Group-2012. Biomass Energy Executive Report; Le bioenergie in Italia alla prova del Decreto Rinnovabili: Milano, Italy, 2012. [Google Scholar]

© 2013 by the authors licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Romano, S.; Cozzi, M.; Di Napoli, F.; Viccaro, M. Building Agro-Energy Supply Chains in the Basilicata Region: Technical and Economic Evaluation of Interchangeability between Fossil and Renewable Energy Sources. Energies 2013, 6, 5259-5282. https://doi.org/10.3390/en6105259

Romano S, Cozzi M, Di Napoli F, Viccaro M. Building Agro-Energy Supply Chains in the Basilicata Region: Technical and Economic Evaluation of Interchangeability between Fossil and Renewable Energy Sources. Energies. 2013; 6(10):5259-5282. https://doi.org/10.3390/en6105259

Chicago/Turabian StyleRomano, Severino, Mario Cozzi, Francesco Di Napoli, and Mauro Viccaro. 2013. "Building Agro-Energy Supply Chains in the Basilicata Region: Technical and Economic Evaluation of Interchangeability between Fossil and Renewable Energy Sources" Energies 6, no. 10: 5259-5282. https://doi.org/10.3390/en6105259

APA StyleRomano, S., Cozzi, M., Di Napoli, F., & Viccaro, M. (2013). Building Agro-Energy Supply Chains in the Basilicata Region: Technical and Economic Evaluation of Interchangeability between Fossil and Renewable Energy Sources. Energies, 6(10), 5259-5282. https://doi.org/10.3390/en6105259