On the Feasibility of Using Poles Computed from Frequency Domain Spectroscopy to Assess Oil Impregnated Paper Insulation Conditions

Abstract

:1. Introduction

2. Background on Frequency Domain Spectroscopy

3. Experimental Procedures

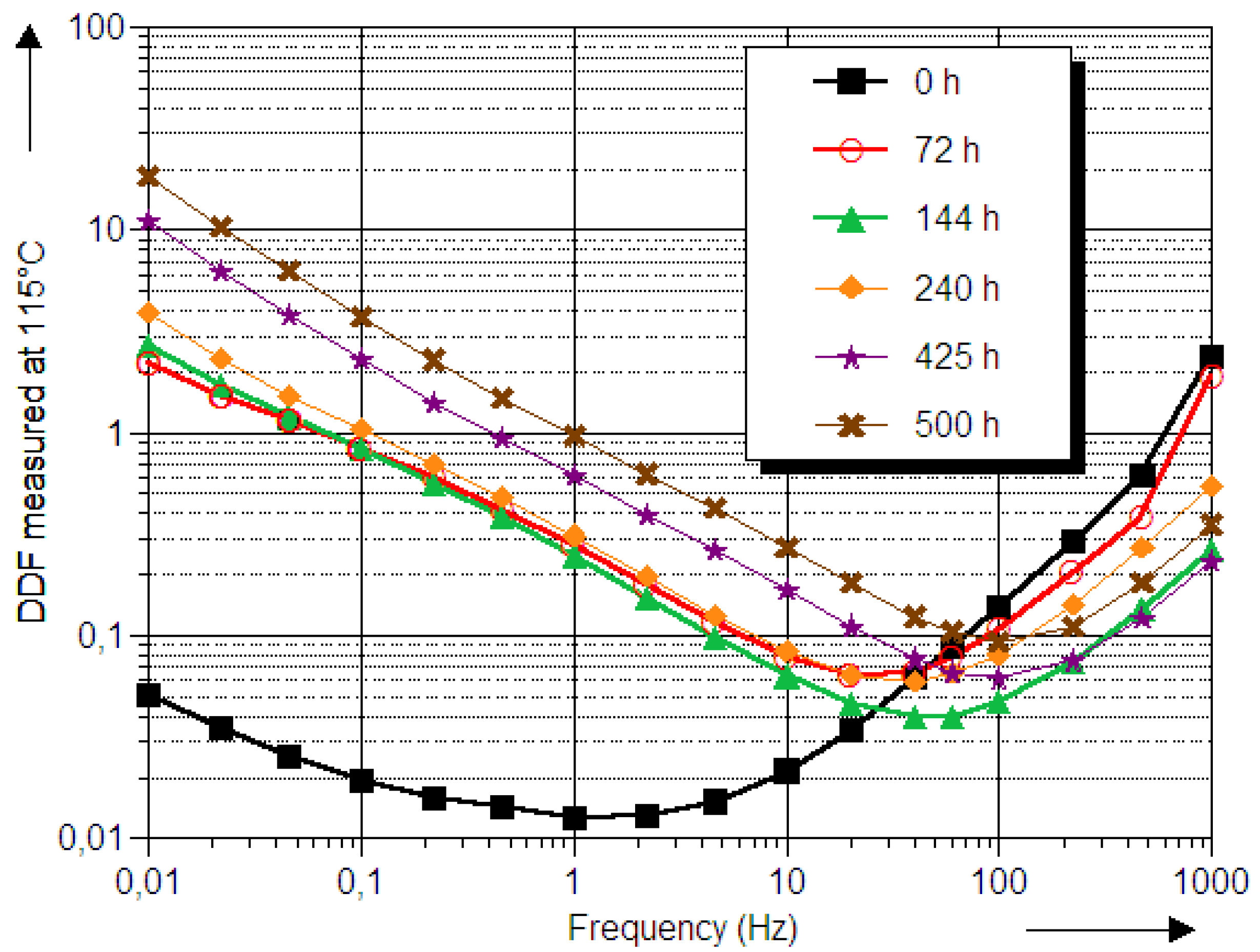

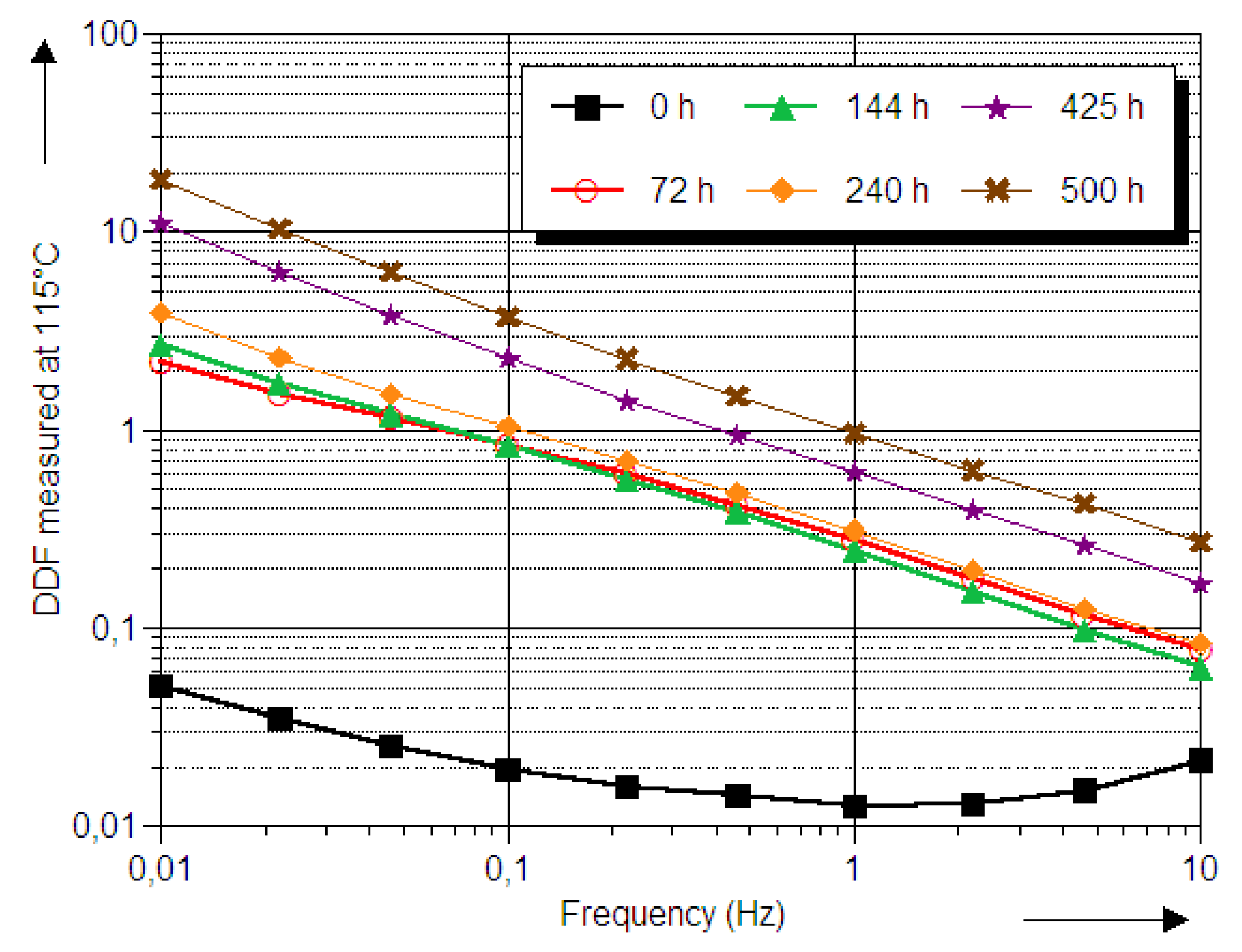

4. Results of the Investigations

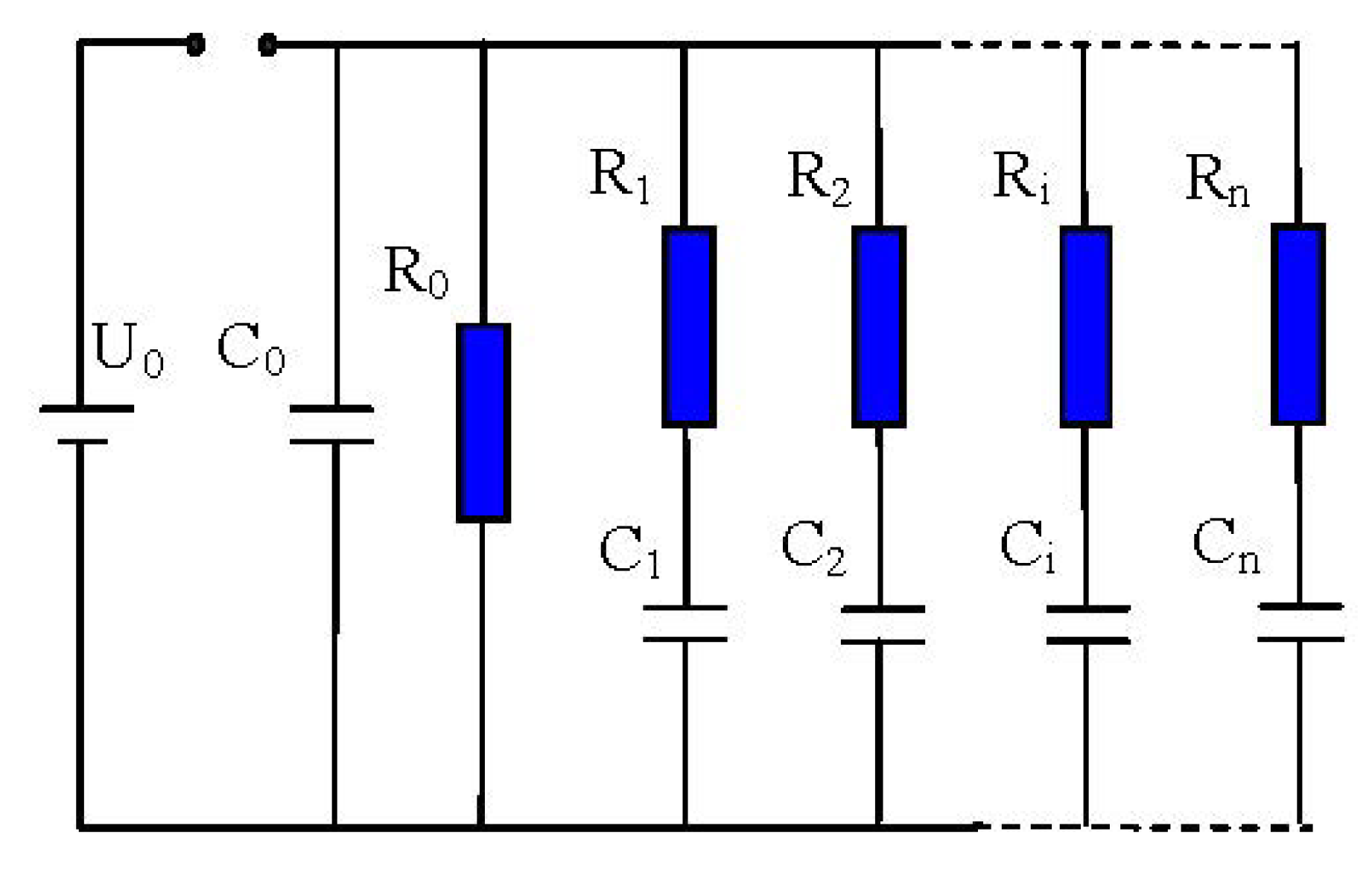

4.1. Insulation Model for Dielectric Response

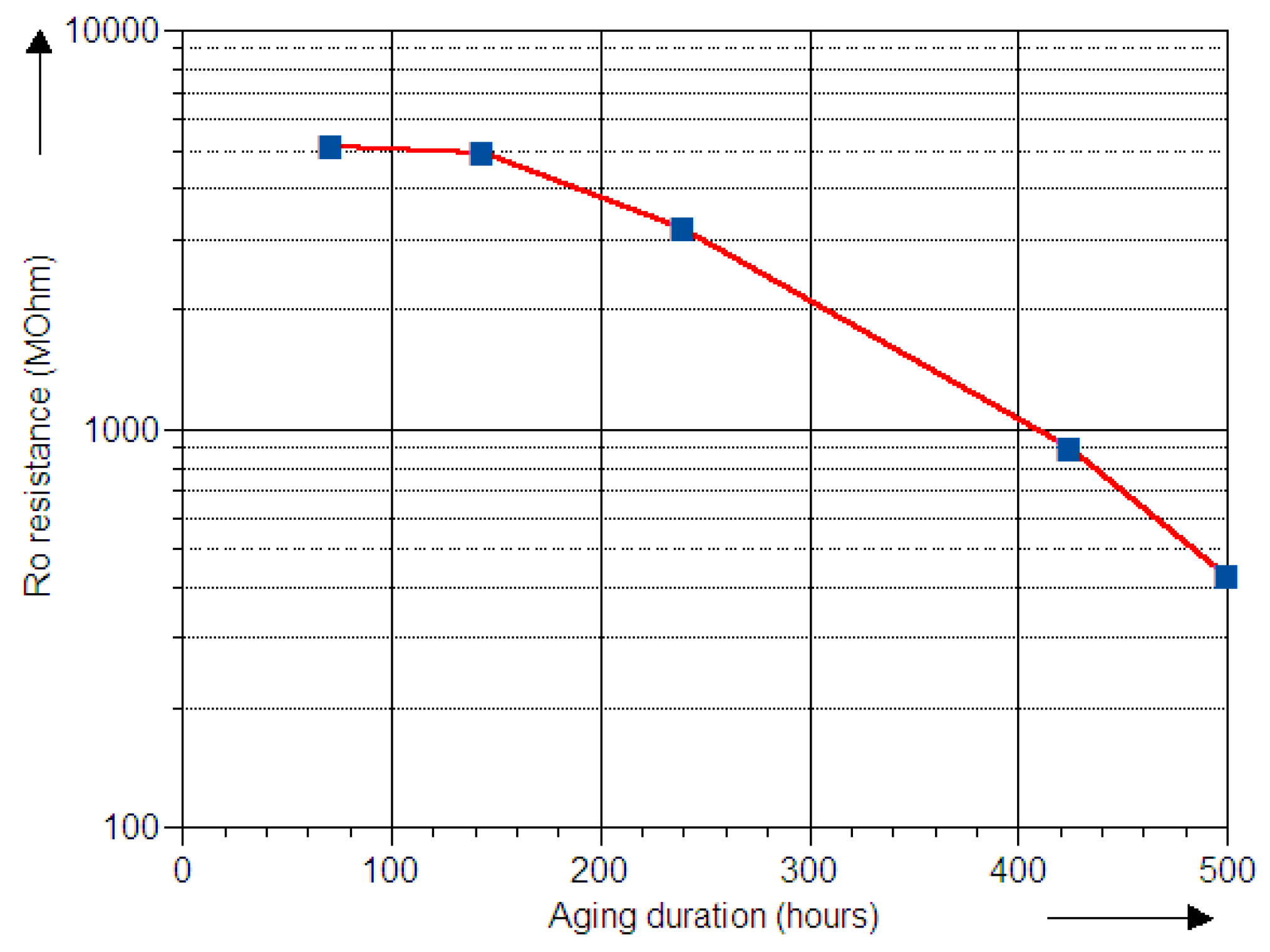

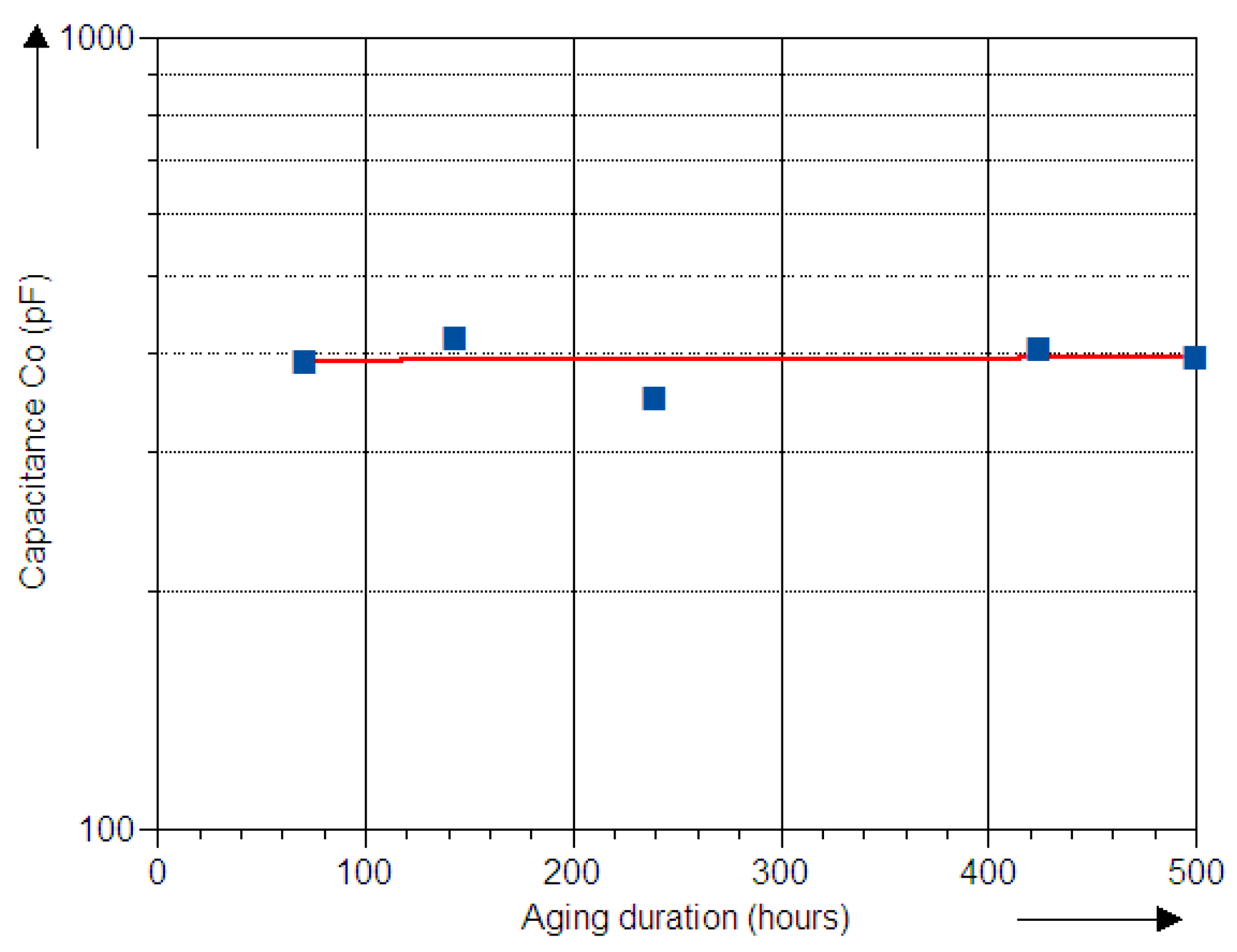

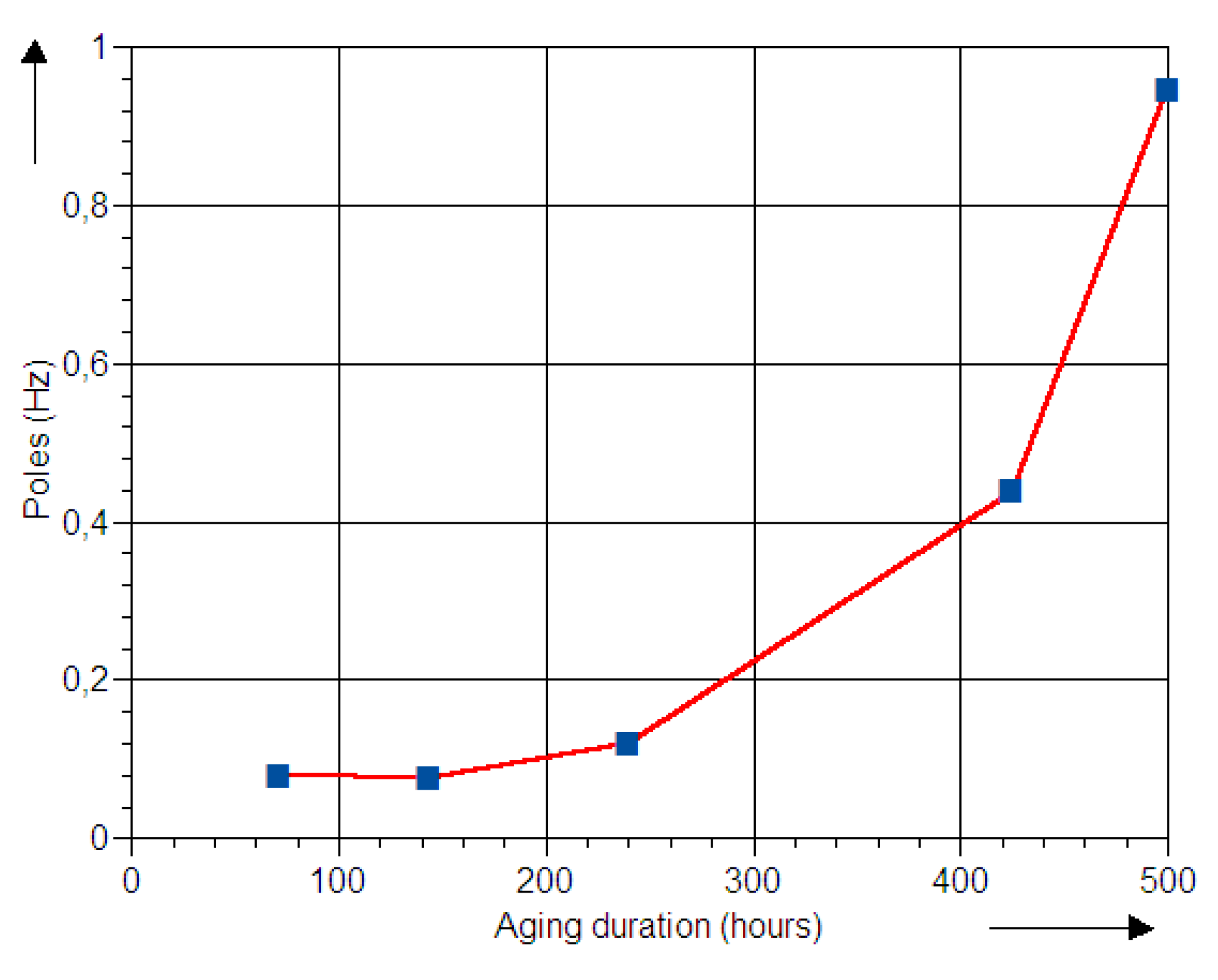

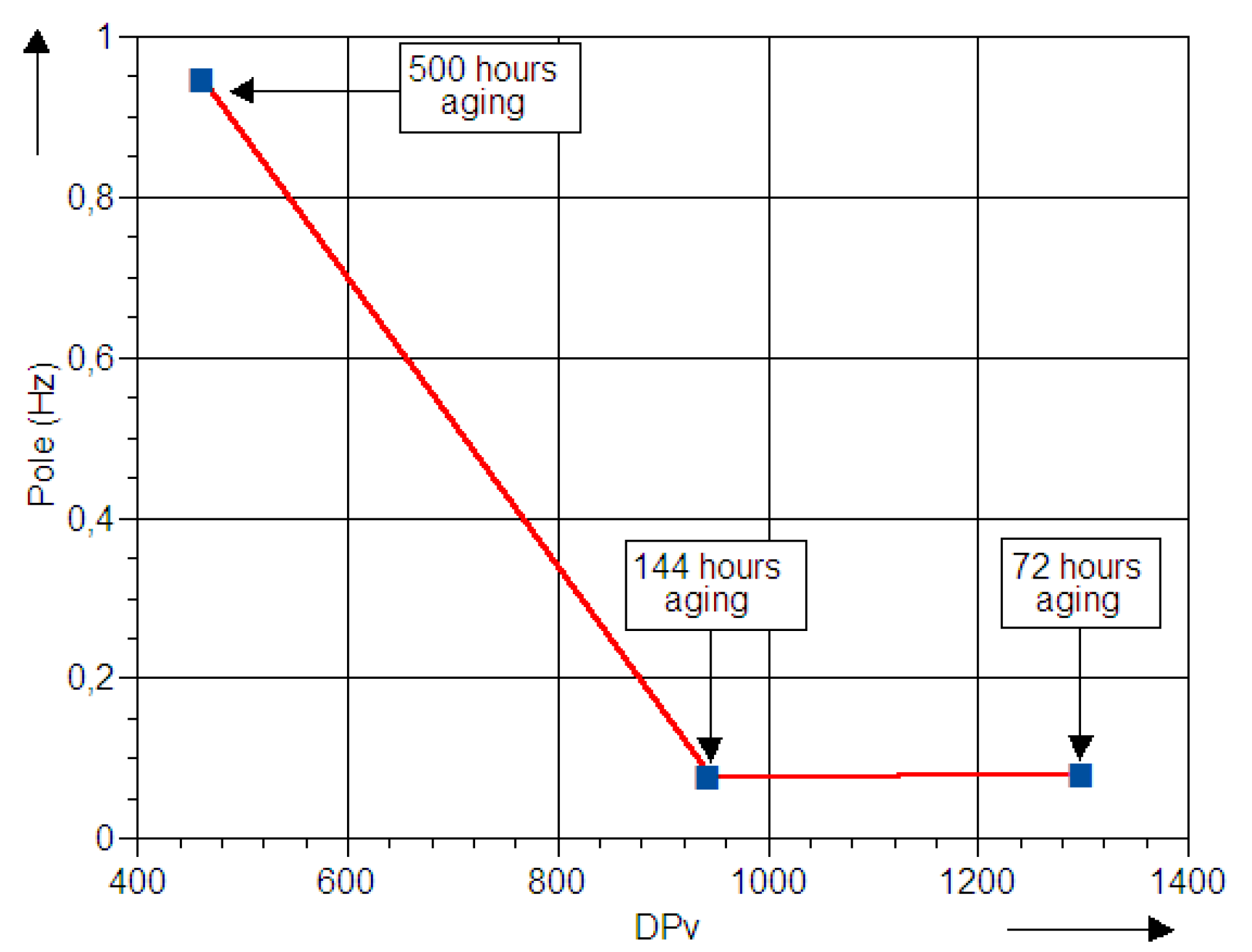

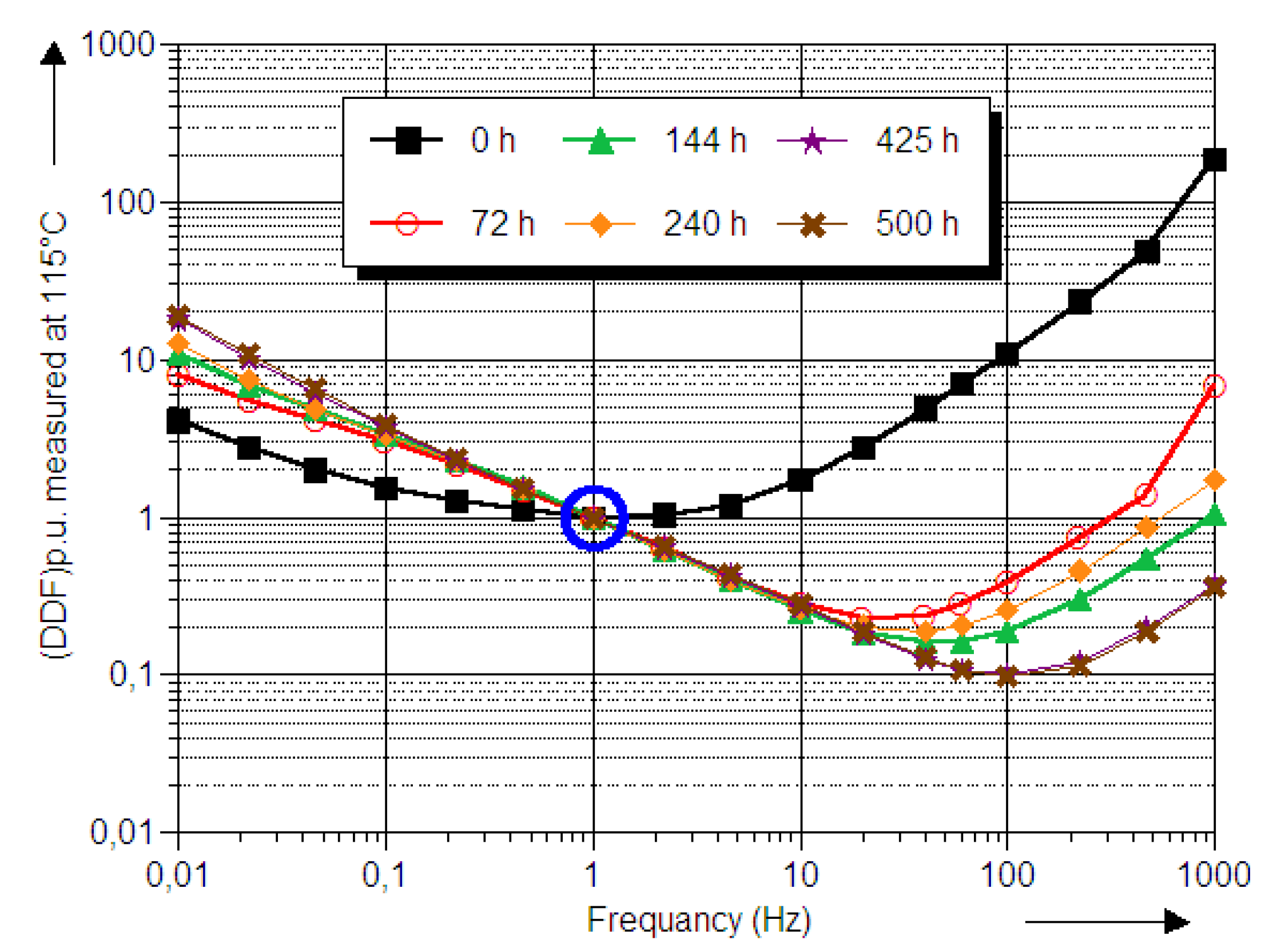

4.2. Using Poles as Aging Indicator

4.3. Moisture Content in Oil-Paper Insulation Estimation

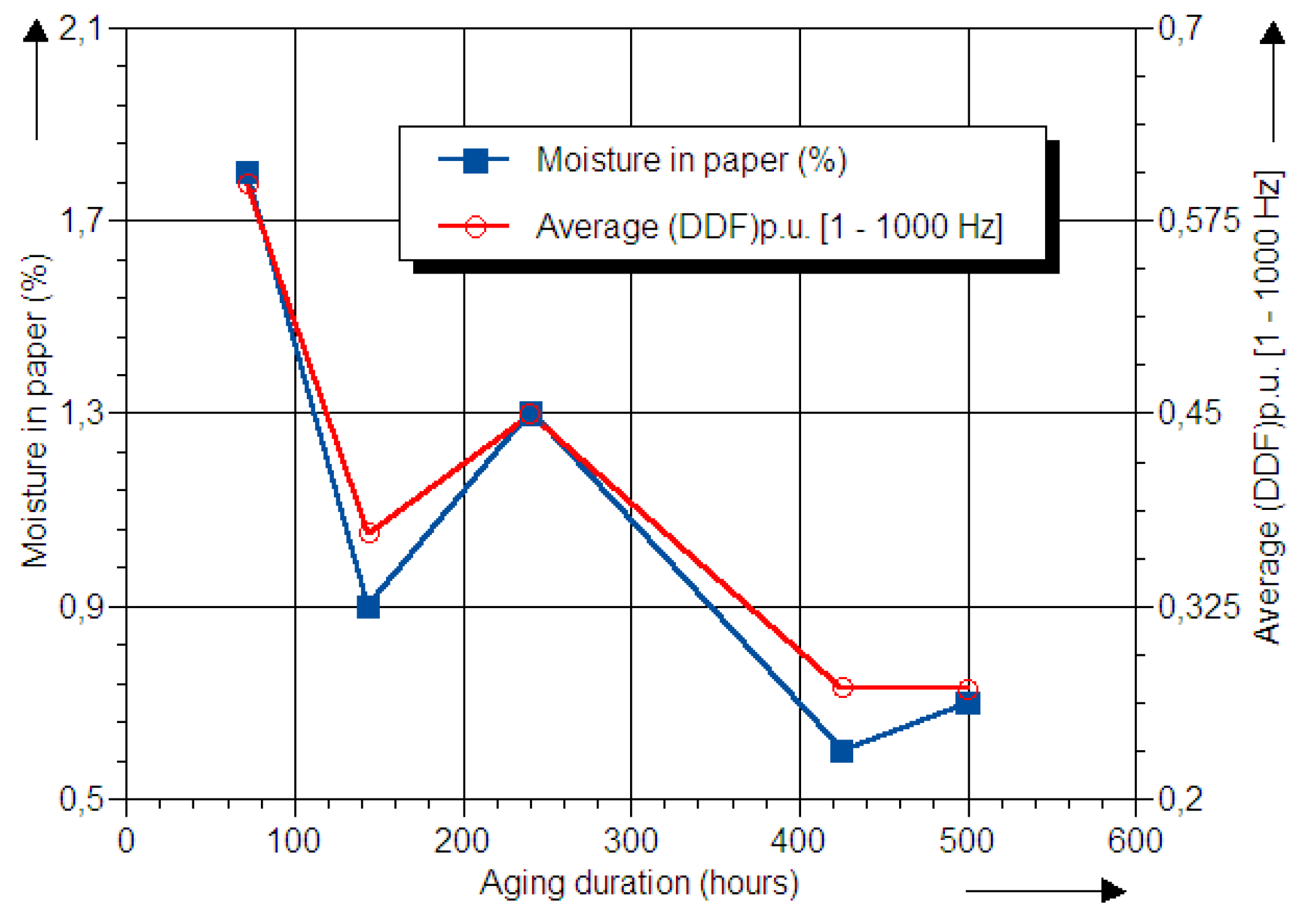

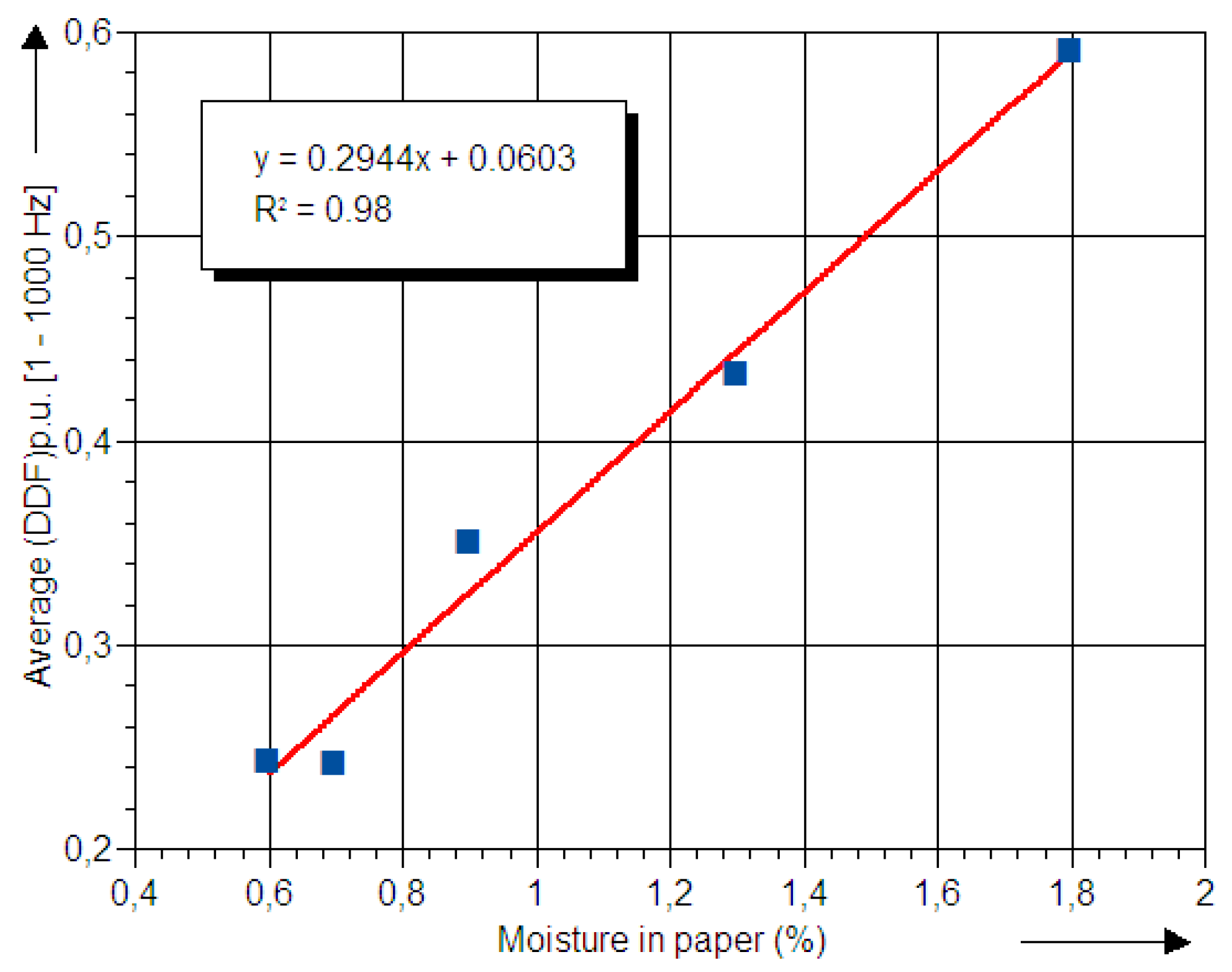

| Aging duration (hours) | Water content in the paper (%) | Average [DDF]p.u. [1–1000] Hz |

|---|---|---|

| 0 | 2 | 6.14 |

| 72 | 1.8 | 0.59 |

| 144 | 0.9 | 0.35 |

| 240 | 1.3 | 0.43 |

| 425 | 0.6 | 0.24 |

| 500 | 0.7 | 0.24 |

5. Conclusions

Acknowledgments

References

- Wilson, A.C.M. Insulating Liquids: Their Use, Manufacture and Properties; Peter Peregrinus Ltd. (on behalf of the Institution of Electrical Engineers): London, UK, 1980. [Google Scholar]

- Zaengl, W.S. Dielectric spectroscopy in time and frequency domain for HV power equipment, Part I: Theoretical considerations. IEEE Electr. Insul. Mag. 2003, 19, 5–19. [Google Scholar] [CrossRef]

- Seytashmehr, A.; Fofana, I.; Eichler, C.; Akbari, A.; Borsi, H.; Gockenbach, E. Dielectric spectroscopic measurements on transformer oil-paper insulation under controlled laboratory conditions. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1100–1111. [Google Scholar] [CrossRef]

- Gubanski, S.M.; Boss, P.; Gspes, G.; Houanessian, V.D.; Filippini, J.; Guuinic, P.; Gäfvert, U.; Karius, V.; Lapworth, J.; Urbani, G.; Werelius, P.; Zaengl, W. Dielectric Response Methods for Diagnostics of Power Transformers; Technical Brochures Published in Electra; International Council on Large Electric Systems (CIGRE): Paris, France, 2002; Volume 202, pp. 25–36. [Google Scholar]

- Saha, T.K.; Purkait, P. Investigations of temperature effects on the dielectric response measurements of transformer oil-paper insulation system. IEEE Trans. Power Deliv. 2008, 23, 252–260. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockenbach, E. On the frequency domain dielectric response of oil-paper insulation at low temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 805–813. [Google Scholar] [CrossRef]

- Bouaïcha, A.; Fofana, I.; Farzaneh, M.; Seytashmehr, A.; Borsi, H.; Gockenbach, E.; Béroual, A.; Aka, N.T. On the usability of dielectric spectroscopy techniques as quality control tool. IEEE Electr. Insul. Mag. 2009, 25, 6–14. [Google Scholar] [CrossRef]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.; Bi, J.; Gong, Y.; Deng, Y. Effect factors analysis of frequency domain spectroscopy test. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference (APPEEC), Shanghai, China, 27–29 March 2012; pp. 1–5.

- Saha, T.K.; Purkait, P. Understanding the impacts of moisture and thermal aging on transformer’s insulation by dielectric response and molecular weight measurements. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 568–582. [Google Scholar] [CrossRef]

- Breitenbauch, B.; Küchler, A.; Leibfried, T.; Zaengl, W.S. Insulation diagnosis by polarisation and depolarisation current measurements. In Proceedings of the 13th International Symposium on High Voltage Engineering (ISH), Delft, The Netherlands, 25–29 August 2003.

- Pradhan, M.K.; Yew, J.H.; Saha, T.K. Influence of the geometrical parameters of power transformer insulation on the frequency domain spectroscopy measurement. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–8.

- Küchler, A.; Bedel, T. Dielectric diagnosis of water content in transformer insulation systems. Eur. Trans. Electr. Power 2001, 11, 65–68. [Google Scholar] [CrossRef]

- Gubanski, S.M.; Boss, P.; Gspes, G.; Houanessian, V.D.; Filippini, J.; Guuinic, P.; Gäfvert, U.; Karius, V.; Lapworth, J.; Urbani, G.; Werelius, P.; Zaengl, W. Dielectric response methods for diagnostics of power transformers. IEEE Electr. Insul. Mag. 2003, 19, 12–18. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F. Effect of thermal transient on the polarization and depolarization current measurements of oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 513–520. [Google Scholar] [CrossRef]

- De Nigris, M.; Passaglia, R.; Berti, R.; Bergonzi, L.; Maggi, R. Application of Modern Techniques for the Condition Assessment of Power Transformers; International Council on Large Electric Systems: Paris, France, 2004. [Google Scholar]

- Goetz, M.P. Permittivity Measurements of Frequency Dependent Electronic Materials; Hewlett-Packard: Palo Alto, CA, USA, 1995; pp. 5964–1506. [Google Scholar]

- Pradhan, M.K.; Yew, K.J.H. Experimental investigation of insulation parameters affecting power transformer condition assessment using frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1851–1859. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P.; Müller, F. Deriving an equivalent circuit of transformers insulation for understanding the dielectric response measurements. IEEE Trans. Power Deliv. 2006, 20, 149–157. [Google Scholar] [CrossRef]

- Liao, R.; Hao, J.; Chen, G.; Yang, L. Quantitative analysis of ageing condition of oil-paper insulation by frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 821–830. [Google Scholar] [CrossRef]

- Tang, M.; Lei, M.; Xu, H.; Lu, Y.; Wei, X.; Wu, P.; Zhang, G. Frequency domain characteristics and insulation condition evaluation of power transformer oil-paper insulation. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application (ICHVE), Shanghai, China, 17–20 September 2012; pp. 443–446.

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, R57–R70. [Google Scholar] [CrossRef]

- Jonscher, A.K. Universal Relaxation Law; Chelsea Dielectrics Press: London, UK, 1996. [Google Scholar]

- Fofana, I.; Bouaicha, A.; Farzaneh, M. Aging characterization of transformer oil-pressboard insulation using modern diagnostic techniques. Eur. Trans. Electr. Power Eng. 2011, 21, 1110–1127. [Google Scholar] [CrossRef]

- Yao, Z.T.; Saha, T.K. Separation of Aging and Moisture Impacts on Transformer Insulation Degradation by Polarization Measurement; International Council on Large Electric Systems: Paris, France, 2002; pp. 15–304. [Google Scholar]

- Betie, A.; Meghnefi, F.; Fofana, I.; Yéo, Z. On the Impacts of Ageing and Moisture on Dielectric Response of Oil Impregnated Paper Insulation Systems. In Proceedings of the IEEE Annual Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Montreal, Canada, 14–17 October 2012; pp. 219–222.

- Shayegani, A.A.; Gockenbach, E.; Borsi, H.; Mohseni, H. Investigation on the transformation of time domain spectroscopy data to frequency domain data for impregnated pressboard to reduce measurement time. Electr. Eng. 2006, 89, 11–20. [Google Scholar] [CrossRef]

- Setayeshmehr, A.; Eichler, C.; Akbari, A.; Borsi, H.; Gockenbach, E. Condition Evaluation of Oil-Pressboard Insulation by Fourier Transform of Time Domain Dielectric Response. In Proceedings of the Nordic Insulation Symposium (Nord-IS 07), Lyngby, Denmark, 11–13 June 2007; pp. 169–172.

- Jaya, M.; Geißler, D.; Leibfried, T. Accelerating dielectric response measurements on power transformers—Part I: A frequency domain approach. IEEE Trans. Power Deliv. 2013, in press. [Google Scholar]

- ASTM D1934—Standard Test Method for Oxidative Aging of Electrical Insulating Petroleum Oils by Open-Beaker Method; ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Insulation Diagnostics Spectrometer IDA 200: User’s Manual; Programma Electric AB: Täby, Sweden, 2000.

- Du, Y.; Zahn, M.; Lesieutre, B.C.; Mamishev, A.V.; Lindgren, S.R. Moisture equilibrium in transformer paper-oil systems. IEEE Electr. Insul. Mag. 1999, 15, 11–20. [Google Scholar] [CrossRef]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence properties of the nelder-mead simplex method in low dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

- ASTM D4243—Standard Test Method for Measurement of Average Viscometric Degree of Polymerization of New and Aged Electrical Papers and Boards; ASTM International: West Conshohocken, PA, USA, 2009. [CrossRef]

- Bouaïcha, A.; Fofana, I.; Farzaneh, M. A three dimensional electrical network for oil-paper insulation modeling. In Proceedings of the 16th International Symposium on High Voltage Engineering, Cape Town, South Africa, 24–28 August 2009; pp. 436–441.

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Hadjadj, Y.; Meghnefi, F.; Fofana, I.; Ezzaidi, H. On the Feasibility of Using Poles Computed from Frequency Domain Spectroscopy to Assess Oil Impregnated Paper Insulation Conditions. Energies 2013, 6, 2204-2220. https://doi.org/10.3390/en6042204

Hadjadj Y, Meghnefi F, Fofana I, Ezzaidi H. On the Feasibility of Using Poles Computed from Frequency Domain Spectroscopy to Assess Oil Impregnated Paper Insulation Conditions. Energies. 2013; 6(4):2204-2220. https://doi.org/10.3390/en6042204

Chicago/Turabian StyleHadjadj, Yazid, Fethi Meghnefi, Issouf Fofana, and Hassan Ezzaidi. 2013. "On the Feasibility of Using Poles Computed from Frequency Domain Spectroscopy to Assess Oil Impregnated Paper Insulation Conditions" Energies 6, no. 4: 2204-2220. https://doi.org/10.3390/en6042204