1. Introduction

The latest trends in environmental legislation associated with carbon dioxide (CO

2) emission reductions are a great challenge for the industrial sector. It can be assumed that a competitive position for businesses utilizing fossil fuels will be strongly conditioned on the ability to meet strict environmental regulations. Therefore, the necessity of reducing CO

2 emissions has led to the development of various technological solutions, called carbon capture and storage technologies. One of these technologies is associated with hydrogen or hydrogen-enriched fuel combustion. The pre-combustion CO

2 capture technology can be applied to power plants, but also to industrial processes as in refineries [

1,

2,

3]. In this case, the fossil fuel is processed by gasification or reforming and water-gas shift reaction to generate a fuel composed mainly of hydrogen and CO

2. CO

2 is then captured leaving a hydrogen-rich fuel, what allows for CO

2 emission reduction. However, the use of such fuels in engineering applications is associated with corresponding changes in nitrogen oxides (NO

x) emissions, which in turn are affected by many factors.

In both science and engineering, determining which factors of a complex system are significant and how they affect the response of the system is often difficult. In such cases, usually full factorial design of the experiment is used to test all possible combinations of various factors. Full factorial design is often the only choice when one is interested in accurate measurement results under various operating conditions or when the response is expected to change in unforeseen ways. Note that this approach often requires a large number of experimental trials, because the number of trials increases geometrically with the number of factors to be tested. Furthermore, the interpretation of a large set of measurement data is difficult and may be unnecessary, because especially in engineering and practical applications, focus on only trends in how factors affect system response can be sufficient. Therefore, response surface methodology combined with central composite design (CCD) [

4] is an efficient technique for experimentally exploring relationships between investigated factors and system response.

Most practical industrial burner designs are much more sophisticated combustion systems than those used in the scientific investigations of combustion processes. Many factors may affect pollutant emissions from these burners, while in cases of high-burner thermal power, conducting measurements in such industrial facilities is often difficult and expensive [

5]. Statistically cognizant design of experiment facilitates an understanding of the influence of the factors tested and the interactions between these factors on system response by using a minimum number of experimental trials. Such an approach applied to testing of burners might be also helpful in reducing the costs of large industrial scale experiments.

The purpose of this paper is to present the use of the high performance and predictive strength of CCD to study NOx emissions from a Partially Premixed Bluff Body (PPBB) burner. The PPBB burner was chosen because it allows testing several factors including fuel composition, excess air, fuel distribution method and the factor that determines burner geometry. Understanding the influence of these factors on NOx emissions is considerably important for burner development.

3. Central Composite Design of the Experiment

CCD enables estimation of the regression parameters to fit a second-degree polynomial regression model to a given response. A polynomial, as given by Equation (1), quantifies relationships among the measured response y and a number of experimental variables

X1…Xk, where k is the number of factors considered, β are regressors and ε is an error associated with the model:

The regressors (β1, β2, β3…) in the various terms of Equation (1) provide a quantitative measure of the significance of linear effects, curvilinear effects of factors and interactions between factors. It is worth noting that the model presented by Equation (1) is not a model in purely physical sense, but rather it should be understood as a statistical model, i.e., a correlation developed based on regression analysis. However, this nomenclature is widely used in the field of design of experiments and statistics, and therefore it is used hereafter.

CCD requires three types of trials,

i.e., 2

k factorial trials, 2

k axial trials and

nc center point trials, where

k is number of factors studied in the experiment [

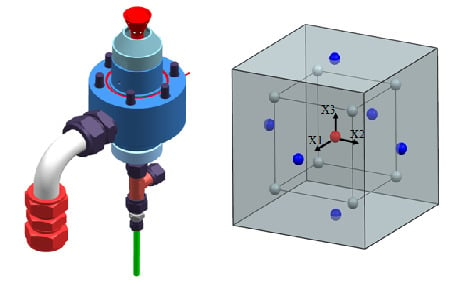

15]. As an example, this is illustrated in

Figure 3, where each point defines a unique set of values of experimental trials for the three factors (

k = 3) tested in an experiment.

Figure 3.

Visualization of original type rotatable CCD for three factors: X1, X2 and X3.

Figure 3.

Visualization of original type rotatable CCD for three factors: X1, X2 and X3.

Values at the center point (red point with coordinates 0, 0, 0) that is located in the center of the cube are used to detect curvature in the response,

i.e., they contribute to the estimation of the coefficients of quadratic terms. Axial points (six blue points located at a distance α from the center point) are also used to estimate the coefficients of quadratic terms, while factorial points (eight grey points located at corners of the cube with a side length equal to 2) are used mainly to estimate the coefficients of linear terms and two-way interactions. For testing four or more factors in an experiment,

Figure 3 should be extended to the fourth or more dimensions.

In CCD, factors are tested at a minimum of three levels: minimum, middle and maximum, equivalent to levels −1, 0 and 1, which are called

coded units. If

Xmin and

Xmax are respectively minimum and maximum absolute,

i.e.,

uncoded, values of a factor, the absolute values

X corresponding the respective coded values can be obtained by a simple linear transformation of the original measurement scale, namely:

where:

To obtain the

rotatability of a design, each experimental factor must be represented at the five levels of coded units: −α, −1, 0, 1, α. This property ensures constant variance at points that are equidistant from the center point, and therefore provides equal precision of response estimation in any direction of the design. For a full factorial CCD, it can be shown [

16] that a design is rotatable if:

A geometric region restricted by levels −1 and 1 on factor setting is defined as a region of interest to the experimenter. Therefore, based on the positions of factorial and axial points in the design one can distinguish the following main varieties of CCD: circumscribed CCD, face-centered CCD and inscribed CCD. Circumscribed CCD, shown in

Figure 3, is the original type of CCD, where axial points are located at distance α, defined by Equation (4), from the center point. In face-centered CCD that is presented in

Figure 4, axial points are located at a distance 1 from the center point,

i.e., at the face of the design cube, if the design involves three experimental factors. In turn, inscribed CCD is characterized by that axial points are located at factor levels −1 and 1, while factorial points are brought into the interior of the design space and located at distance 1/α from the center point, as illustrated in

Figure 4. Geometrically, inscribed CCD reminds of circumscribed CCD. This is because factorial points are set at a distance from the center point so that these distances between the factorial points, the axial points and the center point are in the same proportion as in circumscribed CCD.

Figure 4.

Visualization of face-centered CCD (a) and inscribed CCD (b) for three factors: X1, X2 and X3.

Figure 4.

Visualization of face-centered CCD (a) and inscribed CCD (b) for three factors: X1, X2 and X3.

All the varieties of CCD enable the experimenter to study the same region of interest, but they differ in respect of combinations of factor level settings to be tested. However, this affects properties of the prediction variance of a design. Design performance can be evaluated using variance dispersion graph (VDG) [

17].

VDG displays the maximum, the minimum and the averaged scaled prediction variance (SPV) against the radius of the spherical space with the center at the center point of the design. SPV can be estimated with the Equation (5):

where

N is the number of points in the experimental design;

Var[

y(x)] is the variance of a predicted value at a point

x;

is the variance of the experimental error;

X is the design matrix; and

x is a vector valued function of the coordinates whose elements correspond to the columns of the design matrix

X. According to Equation (5), SPV is independent of the response data and quality of a design can be assessed

a priori.

The main varieties of CCD were compared using VDGs, assuming that three factors are tested in the experiment and second-order polynomial model will be developed based on the design. VDGs for the CCDs are shown in

Figure 5. SPV for the circumscribed CCD is relatively constant over the distance 1 from the center point of the design. The minimum, the maximum and the averaged SPV are equal at the same distance from the origin and it is evidence that the design is rotatable.

Figure 5.

VDGs for: (a) circumscribed CCD; (b) face-centered CCD; (c) inscribed CCD. SPVs plotted in the graphs have been calculated assuming that full quadratic model for 3 factors is tested when running the experiment and each of the designs consists of 20 experimental trials, including 6 center point trials.

Figure 5.

VDGs for: (a) circumscribed CCD; (b) face-centered CCD; (c) inscribed CCD. SPVs plotted in the graphs have been calculated assuming that full quadratic model for 3 factors is tested when running the experiment and each of the designs consists of 20 experimental trials, including 6 center point trials.

The face-centered CCD ensures lower SPV near the center point compared to the circumscribed CCD, however, at a certain point of the design SPV increases to a level higher than for circumscribed CCD. Furthermore, the maximum and the minimum SPV at the same distance from the origin are not equal to each other, hence the design is not rotatable. VDG for the inscribed CCD shows the same trend as for the circumscribed CCD, but SPV value is higher. This design is also rotatable, similarly to the circumscribed CCD. Despite the fact inscribed CCD does not require testing factors at as extreme levels as the remaining types of CCD, the penalty for this is seen in the variance, because the further is the distance from the center point, the higher is the variance. It is worth noting that each type of CCD strictly defines design points. Therefore, selection of type of CCD should be made taking into account region of experiment operability. If a design point cannot be tested due to various experiment constraints, the experimenter should reduce factor ranges, what affects the region of interest, or generate face-centered CCD or inscribed CCD.

In practice, no model can be fit perfectly to measured values because of measurement errors or relationships between factors and response that cannot be described by a second-order polynomial. This results in residual values at the design points, i.e., deviations from the measured values. The quality of the model is assessed by the coefficients of determination: R2, adjusted R2 and predicted R2.

R2 represents a pure correlation between measured and predicted values and is indicative of the response variation explained by a model [

18]. However, every term added to the model equation will improve the model fit to the measured data. Therefore, adjusted

R2 is used to compare the explanatory power of models, and its value increases only when an added term improves the model more than by chance [

18]. Both these coefficients are calculated using data that were themselves used for model development. A model’s predictive capability for new observations is assessed using predicted

R2. This coefficient is calculated by systematically removing each observation from the data set, estimating the regression equation and determining the model’s capability in predicting the removed observations [

19]. Predicted residual sums of squares statistic [

20] is used to calculate the value of predicted

R2.

The statistical significance of the terms of the model defined by Equation (1) can be evaluated using the analysis of variance (ANOVA) [

21]. ANOVA is based on partitioning the variation in the data into components. For all the terms of the model equation, values characteristic of a so-called ANOVA table are calculated individually. These values will be important in subsequent discussions and are thus defined here.

The adjusted sum of squares (Adj SS) for a specific term calculates reduction in the residual sum of squares resulting from the inclusion of this term to the model. Adjusted mean squares (Adj MS) are calculated by dividing Adj SS by the number of degrees of freedom (DF) for the respective term.

Variation in the data unexplained by the model is represented by the Residual Error (RE), for which Adj SS is calculated as the residual sum of squares and Adj MS value of the RE is calculated as explained above.

Ratios of the Adj MS for all terms of the model equation and Adj MS of the RE are calculated. Because the ratios of variances follow an F-distribution [

16], a statistical F-test [

18] is employed to identify statistically significant terms of the model. One can obtain

p-values from this test for each term of the model, which are a measure of the probability of obtaining data at least as extreme as the data from the model, assuming that the

null hypothesis is true,

i.e., in this case, a particular term does not provide an effect on the results from the model [

22]. Therefore, the lower the

p-values for the analyzed terms, the greater effect these terms have on the response predicted by the model.

Pure error lack-of-fit test [

18] is used to assess whether the model is adequate to describe the functional relationships between the experimental factors and the response. The test is based on partitioning the RE sum of squares into two components: lack-of-fit sum of squares, which is associated with variation due to factors other than measurement error, and pure error sum of squares, resulting from random variation caused by measurement error. The ratio of mean squares for lack-of-fit and pure error follows F-statistic, and similar to the aforementioned description, low

p-value for lack-of-fit in ANOVA table means that the analyzed model does not fit to the experimental data.

4. Experimental Apparatus and Approach

The experimental campaign involved NO

x emission measurements from the PPBB burner, shown in

Figure 1, fuelled by pure methane and hydrogen-enriched methane mixtures. All the measurements were conducted at a constant thermal load equal to 25 kW (calculated based on lower heating value, LHV). The fuel mixture was supplied to the burner using two separate fuel supply lines for primary and secondary fuel ports. Mass flow controllers were used to obtain accurate mass flow rates of methane, hydrogen and air to the burner. Maximum measurement error of the mass flow controllers for the investigated burner settings was ±1 nL/min for each fuel supply line and ±10 nL/min for air.

The combustion process took place in a stainless steel combustion chamber at atmospheric pressure. The height of the combustion chamber was 1000 mm with an outer diameter of 360 mm; while the wall thickness was 5 mm. The chamber was cooled only by natural convection and radiation to ambient conditions. The wall temperature was measured on the side of the chamber at a height 300 mm from the bottom to be 390 °C–400 °C. The exhaust gas composition was determined by probing a sample of exhaust gases at the combustion chamber outlet section. The sample was transported through a heated hose to the cooler to avoid uncontrolled water condensation in the gas sampling line and dissolving of nitrogen dioxide (NO

2) in water droplets formed in the hose. NO

x; CO; CO

2 and O

2 were measured with a pre-calibrated Horiba PG-250 gas analyzer. The NO

x concentration in the dry exhaust gas (cooled to 5 °C) was measured by chemiluminescence at a precision of 1 ppmv (part per million by volume); and concentrations of CO

2 and CO were measured using non-dispersive infrared technique. In addition; a Fourier transform infrared gas analyzer was used to measure methane and water concentration in the wet exhaust gas to ensure that all fuel provided to the chamber was burned. The influence of the following four factors on NO

x emissions from the PPBB burner was experimentally investigated:

Levels for the investigated factors were specified as follows: hydrogen content in the fuel was measured by hydrogen mass fraction (X1), excess air was measured using the global air/fuel equivalence ratio (X2), lance position was defined as the distance between the top of the lance and the burner throat (X3) and the amount of secondary fuel was determined as the ratio of the secondary fuel flow rate to the total fuel flow rate (X4).

All the tested factors affect the flow field in the burner and may change the mixing process, flow pattern or flame stability because of complex fluid dynamics. Furthermore, hydrogen addition to methane influences chemical processes occurring in the reaction zone. Interactions between the tested parameters obscure the impact of individual parameters on NOx emissions from the burner, and the influence of these factors on the emissions cannot be easily described or predicted based on theoretical analyses alone.

Thus, response surface methodology and CCD were employed to identify the significance of each of these factors and develop a second-degree polynomial correlation for NOx emission prediction. A rotatable CCD was used as the experimental design. Because four factors were studied in the experiment, the number of factorial runs was equal to 24 = 16, and to maintain rotatability in accordance with Equation (4), α was set to 2.

The operating ranges for all the factors were chosen by a series of preliminary measurements to ensure complete fuel combustion and to avoid flame instability, extinction phenomena and combustion chamber acoustic issues at the measurement points. The experimental variables and the levels at which they were tested are shown in

Table 1.

Table 1.

Tested levels of experimental factors X1, X2, X3 and X4.

Table 1.

Tested levels of experimental factors X1, X2, X3 and X4.

| Factor | Short Name | Unit | Coded Levels and Corresponding Absolute Levels |

|---|

| −1 | −1/α | 0 | 1/α | 1 |

|---|

| X1 | Hydrogen fraction | % | 0 | 3.75 | 7.5 | 11.25 | 15 |

| X2 | Air/fuel equivalence ratio | - | 1.05 | 1.1125 | 1.175 | 1.2375 | 1.3 |

| X3 | Lance position | mm | 20 | 21.25 | 22.5 | 23.75 | 25 |

| X4 | Secondary fuel fraction | % | 0 | 1.5 | 3 | 4.5 | 6 |

Emission measurement at the center point, i.e., at level zero in coded units for each factor, was replicated four times at various stages of the experiment to obtain an estimate of experimental error. Therefore, the total number of experimental trials, based on the number of design factors k = 4, was equal to N = 2k + 2k + nc = 28. Full factorial design represents a possible alternative approach, but it would require a minimum of 34 = 81 experimental trials, while measurement error could not be evaluated and the model would be unnecessarily made far more complicated.

The entire experiment was conducted in random order without replication. The approach enabled the identification of important parameters for NOx emission reduction and trends in NOx emissions from the PPBB burner.

5. Results and Discussion

Statistical analysis of the experimental results was performed using the Minitab

® 16 software (Minitab, Inc., State College, PA, USA) [

19]. A least squares method was used to derive a mathematical correlation by fitting a response surface to the measured values of NO

x emissions at specific points of the experimental design matrix presented in

Table 2. NO

x emissions from the burner have been analyzed for all fuel mixtures investigated, various air/fuel equivalence ratios and burner design parameters.

Table 2.

Experimental matrix.

Table 2.

Experimental matrix.

| Factor | X1 | X2 | X3 | X4 | NOx | CO | NOx | Predicted NOx | Residual |

|---|

| % | – | mm | % | ppmvd | ppmvd | mg/kWh | mg/kWh | mg/kWh |

|---|

| 1 | 3.75 | 1.1125 | 21.25 | 1.5 | 17.9 | 0 | 35.2 | 35.2 | −0.04 |

| 2 | 3.75 | 1.2375 | 21.25 | 1.5 | 15.5 | 5.5 | 34.3 | 34.1 | 0.18 |

| 3 | 11.25 | 1.1125 | 21.25 | 1.5 | 20.1 | 0 | 37.9 | 37.6 | 0.35 |

| 4 | 11.25 | 1.2375 | 21.25 | 1.5 | 17.7 | 0 | 37.7 | 37.7 | 0.00 |

| 5 | 3.75 | 1.1125 | 21.25 | 4.5 | 17.9 | 0 | 35.3 | 35.2 | 0.03 |

| 6 | 3.75 | 1.2375 | 21.25 | 4.5 | 15.5 | 7.9 | 34.2 | 34.1 | 0.15 |

| 7 | 11.25 | 1.1125 | 21.25 | 4.5 | 20.0 | 0 | 37.7 | 37.6 | 0.13 |

| 8 | 11.25 | 1.2375 | 21.25 | 4.5 | 18.0 | 0 | 38.2 | 37.7 | 0.54 |

| 9 | 3.75 | 1.1125 | 23.75 | 1.5 | 18.5 | 0 | 36.3 | 35.7 | 0.59 |

| 10 | 3.75 | 1.2375 | 23.75 | 1.5 | 15.6 | 4.5 | 34.6 | 34.6 | 0.00 |

| 11 | 11.25 | 1.1125 | 23.75 | 1.5 | 20.2 | 0 | 38.2 | 38.1 | 0.13 |

| 12 | 11.25 | 1.2375 | 23.75 | 1.5 | 17.8 | 0.1 | 37.8 | 38.2 | −0.37 |

| 13 | 3.75 | 1.1125 | 23.75 | 4.5 | 18.0 | 0 | 35.4 | 35.7 | −0.29 |

| 14 | 3.75 | 1.2375 | 23.75 | 4.5 | 15.5 | 4.7 | 34.2 | 34.6 | −0.32 |

| 15 | 11.25 | 1.1125 | 23.75 | 4.5 | 19.9 | 0 | 37.5 | 38.1 | −0.53 |

| 16 | 11.25 | 1.2375 | 23.75 | 4.5 | 17.8 | 0.1 | 37.8 | 38.2 | −0.37 |

| 17 | 7.5 | 1.05 | 22.5 | 3 | 20.2 | 0 | 36.4 | 36.6 | −0.17 |

| 18 | 7.5 | 1.3 | 22.5 | 3 | 15.6 | 10.0 | 35.7 | 35.6 | 0.12 |

| 19 | 0 | 1.175 | 22.5 | 3 | 15.4 | 3.3 | 32.8 | 32.9 | −0.13 |

| 20 | 15 | 1.175 | 22.5 | 3 | 19.7 | 0 | 38.9 | 38.8 | 0.09 |

| 21 | 7.5 | 1.175 | 22.5 | 0 | 17.8 | 0 | 36.4 | 36.8 | −0.44 |

| 22 | 7.5 | 1.175 | 22.5 | 6 | 17.8 | 0 | 36.3 | 36.8 | −0.48 |

| 23 | 7.5 | 1.175 | 20 | 3 | 17.6 | 0 | 36.0 | 36.3 | −0.29 |

| 24 | 7.5 | 1.175 | 25 | 3 | 18.7 | 0 | 38.3 | 37.3 | 0.96 |

| 25 | 7.5 | 1.175 | 22.5 | 3 | 18.0 | 0 | 36.8 | 36.8 | −0.02 |

| 26 | 7.5 | 1.175 | 22.5 | 3 | 18.1 | 0 | 37.1 | 36.8 | 0.28 |

| 27 | 7.5 | 1.175 | 22.5 | 3 | 17.7 | 2.3 | 36.2 | 36.8 | −0.61 |

| 28 | 7.5 | 1.175 | 22.5 | 3 | 18.2 | 0 | 37.3 | 36.8 | 0.51 |

5.1. Statistical Analysis of the Model

Due to the fact that mixtures of methane and hydrogen were tested during the experiment, it was found that it is useful to express NO

x emissions measured in parts per million by volume on dry basis (ppmvd) as mass of emitted NO

x per unit of heat released during the combustion process. Such definition is independent of O

2 concentration in flue gas, amount of water present in flue gas that is different for methane and hydrogen combustion, and also takes into account various lower heating values of fuels used in the experimental campaign. Therefore, the formula defined by Equation (6) was used to recalculate NO

x emissions to mg/kWh:

In Equation (6) rNOx is measured NOx emissions expressed in ppmvd; Vdry gas is volume of dry flue gas at standard conditions produced from combustion of 1 kg of fuel in Nm3/kg, assuming that the flue gas consists of CO2, N2 and O2; is density of NO2 at standard conditions equal to 2.05 kg/m3 and LHVfuel is the lower heating value of fuel mixture used during the burner test in J/kg.

Based on the experimental results of NO

x emissions expressed in mg/kWh and regression analysis for CCD, the full quadratic model is given by Equation (7):

This model takes into account linear effects, quadratic effects and two-way interactions between the studied factors. The empirical correlation represented in Equation (7) must use factors expressed in uncoded units, i.e., actual values of these factors. NOx emissions obtained using this correlation are given in mg/kWh.

The coefficient of determination

R2, presented in

Table 3, indicates that the model approximates the data at the design points. The predictive power of the developed model for new observations may be 85%, based on the predicted

R2 value. The calculated

p-value for lack-of-fit is greater than 0.05; therefore, there is no statistically significant evidence that the model does not represent the data at a 95% confidence level.

Table 3.

Model fitting test results.

Table 3.

Model fitting test results.

| Model Parameter | Full Quadratic Model | Enhanced Model |

|---|

| R2 | 96.63% | 94.06% |

| Adjusted R2 | 93.01% | 92.36% |

| Predicted R2 | 84.99% | 90.19% |

| p-value for lack-of-fit | 0.75 | 0.195 |

Based on the results of ANOVA, shown in

Table 4, the model was improved by removing terms (one-by-one) with

p-values greater than 0.05, considered as statistically insignificant at a 95% confidence level. The removed terms were not taken into account in the regression analysis.

Table 4.

ANOVA table for the full quadratic model.

Table 4.

ANOVA table for the full quadratic model.

| Source of Variation | DF | Adj SS | Adj MS | F-Ratio | p-Value |

|---|

| X1 | 1 | 53.2362 | 53.2362 | 322.24 | <0.001 |

| X2 | 1 | 1.5645 | 1.5645 | 9.47 | 0.009 |

| X3 | 1 | 1.4741 | 1.4741 | 8.92 | 0.010 |

| X4 | 1 | 0.1050 | 0.1050 | 0.64 | 0.440 |

| X1·X1 | 1 | 1.4259 | 1.4259 | 8.63 | 0.012 |

| X2·X2 | 1 | 0.8937 | 0.8937 | 5.41 | 0.037 |

| X3·X3 | 1 | 0.1648 | 0.1648 | 1.00 | 0.336 |

| X4·X4 | 1 | 0.3233 | 0.3233 | 1.96 | 0.185 |

| X1·X2 | 1 | 1.6182 | 1.6182 | 9.80 | 0.008 |

| X1·X3 | 1 | 0.2071 | 0.2071 | 1.25 | 0.283 |

| X1·X4 | 1 | 0.0410 | 0.0410 | 0.25 | 0.627 |

| X2·X3 | 1 | 0.1176 | 0.1176 | 0.71 | 0.414 |

| X2·X4 | 1 | 0.2187 | 0.2187 | 1.32 | 0.271 |

| X3·X4 | 1 | 0.3088 | 0.3088 | 1.87 | 0.195 |

| Residual Error | 13 | 2.1477 | 0.1652 | | |

| Lack-of-fit | 10 | 1.4444 | 1.4444 | 0.62 | 0.754 |

| Pure error | 3 | 0.7033 | 0.2344 | | |

| Total | 27 | | | | |

The enhanced model is defined by Equation (8):

This model predicts NOx emissions in mg/kWh based on three linear effects, two quadratic effects and one two-way interaction. Secondary fuel fraction (X4) has been found to be negligible. Again, the empirical correlation given in Equation (8) must be used with the actual, uncoded factor values.

Although

R2 and adjusted

R2, shown in

Table 3, decreased compared with those of the full quadratic model given by Equation (7), the enhanced model offers a higher prediction capability of 90.19% for new observations. Simultaneously, with a

p-value for lack-of-fit greater than 0.05, it can be assumed that the model adequately represents the experimental results.

A summary of ANOVA applied to the enhanced model is presented in

Table 5. The estimated standard deviation of the error in the model is 0.42 mg/kWh. Since all the terms are statistically significant and the model gives reasonable response estimation, it was used to analyze the NO

x emissions from the PPBB burner.

Table 5.

ANOVA table for the enhanced model.

Table 5.

ANOVA table for the enhanced model.

| Source of Variation | DF | Adj SS | Adj MS | F-Ratio | p-Value |

|---|

| X1 | 1 | 53.2362 | 53.2362 | 295.01 | <0.001 |

| X2 | 1 | 1.5645 | 1.5645 | 8.67 | 0.008 |

| X3 | 1 | 1.4741 | 1.4741 | 8.17 | 0.009 |

| X1·X1 | 1 | 1.4992 | 1.4992 | 8.31 | 0.009 |

| X2·X2 | 1 | 0.9259 | 0.9259 | 5.13 | 0.034 |

| X1·X2 | 1 | 1.6182 | 1.6182 | 8.97 | 0.007 |

| Residual Error | 21 | 3.7895 | 0.1805 | | |

| Lack-of-fit | 8 | 1.9270 | 0.2409 | 1.68 | 0.195 |

| Pure error | 13 | 1.8625 | 0.1433 | | |

| Total | 27 | | | | |

5.2. Effects of the Factors

Figure 6 shows the sorted absolute values of the coefficients for each term of the second-degree polynomial based on factors expressed in coded units. Coding of factors removes any pseudo effects due to the use of different measurement scales. Therefore, coefficients in the model equation developed on the basis of coded units are a measure of the magnitude of the response resulting from one unit change in a factor in one specific term, with all other terms held constant. It should be stressed that this interpretation applies over the entire investigated range of factors to linear effects only. Because the model includes an interaction involving two factors (X1 and X2), the effect of a change in one factor associated with the interaction term varies depending on the value chosen for the other factor. In the case of quadratic terms, the response to a change in the value of a factor depends on the value of the factor itself.

Figure 6.

Comparison of the absolute values of the coefficients for each term of the enhanced model, which is expressed in coded units.

Figure 6.

Comparison of the absolute values of the coefficients for each term of the enhanced model, which is expressed in coded units.

The most significant factor for NO

x emissions is clearly hydrogen fraction in the fuel (X1). The coefficient of the linear term determining fuel composition causes this term to dominate the other terms. Adiabatic flame temperatures, assuming chemical equilibrium of products, for various stoichiometric mixtures of methane and hydrogen and air as oxidizer are presented in

Figure 7. Significance of the factor X1for the NO

x emission prediction can as expected be attributed to the increased flame temperature that results from the added hydrogen and thus enhanced thermal NO

x formation.

However, it is worth noting that the above brief explanation does not show the overall picture of the problem and the complexity of NOx chemistry. When firing hydrocarbon fuels, NOx are largely formed via thermal or prompt mechanism and, for simplicity, it can be assumed that total NOx emissions are a combination of these two mechanisms.

Figure 7.

Adiabatic flame temperature for various mixtures of methane and hydrogen and air as oxidizer at stoichiometric conditions at pressure equal to 1 atm and temperature of reactants equal to 293 K, calculated assuming chemical equilibrium of products.

Figure 7.

Adiabatic flame temperature for various mixtures of methane and hydrogen and air as oxidizer at stoichiometric conditions at pressure equal to 1 atm and temperature of reactants equal to 293 K, calculated assuming chemical equilibrium of products.

The NNH mechanism [

23] plays a role in NO

x formation in hydrogen-enriched flames, but it is not discussed here. As it is well-known that hydrogen addition to methane increases flame temperature, it is also known that prompt NO

x formation mechanism requires carbon-containing radicals in the reaction zone. Concentration of these radicals decreases when hydrogen is added to methane and then prompt NO

x formation is inhibited. In the light of the above and despite the fact that NO

x increase is explained here by the higher adiabatic flame temperature of hydrogen-enriched flames, if a low NO

x burner that effectively reduces peak flame temperature is used, the situation when total NO

x emissions from hydrogen combustion are lower than NO

x emissions from pure methane combustion cannot be ruled out [

24].

Linear terms related to excess air (X2) and the lance position (X3) are considerably less significant than the hydrogen fraction in the fuel. The effect of the interaction between fuel composition and excess air (X1X2) varies depending on the values of these factors, but for all values of excess air, the interaction affects the response less than hydrogen enrichment of methane. Comparable values for the coefficients of quadratic terms of hydrogen fraction and excess air are evidence that there is a curvature in the response surface describing NOx emissions. These terms may significantly change the response of the model over the investigated range of factors, depending on the values of the respective factors, but never more than the linear term determining fuel composition. Because the fuel composition is the most important factor, the value of X1 was always taken into account while evaluating the influence of the other experimental variables on NOx emissions.

5.3. Excess Air Effect

Significant change in NO

x emissions was observed with increasing air flow to the burner in comparison with stoichiometric air consumption in the combustion process. However, this relationship is visible only for pure methane and fuel mixtures containing hydrogen of a few percent mass fraction. As illustrated in

Figure 8, with increasing hydrogen content, NO

x emissions approach a state independent of excess air, or even slightly increase with increasing excess air for hydrogen content approaching 15% mass fraction. The lowest NO

x emissions are approximately 30 and 38 mg/kWh for pure methane and hydrogen-rich fuel, respectively. Calculated 95% confidence intervals for these values are between 29.0 and 31.7 mg/kWh, and 37.5 and 40.2 mg/kWh.

Figure 8.

NOx emissions in mg/kWh versus X1 and X2 for the fuel lance positioned at 22.5 mm.

Figure 8.

NOx emissions in mg/kWh versus X1 and X2 for the fuel lance positioned at 22.5 mm.

The relationship shown in

Figure 8 can be explained by that additional air plays the role of an inert gas and suppresses NO

x formation via the thermal mechanism. However, for methane enriched with 15% mass fraction hydrogen, this suppressing effect is diminished. Despite the fact that the fuel mixture is partially mixed with air before combustion and the flame is stabilized behind the lance, NO

x emissions are not reduced. It can be assumed that the higher adiabatic flame temperature of hydrogen-enriched methane entails increased thermal NO

x formation, and this mechanism cannot be inhibited by partially premixed air, even at global excess air values approaching 30%. Simultaneously, this effect can be caused by the fact that hydrogen-rich methane-hydrogen-air flame is short and it is stabilized just behind the trailing edge of the lance, while in case of hydrogen-lean methane-hydrogen-air flame or pure methane-air flame, the reaction zone extends over a certain distance further downstream the lance to a better mixed region, for example, due to turbulence. Therefore, in the latter case, higher amount of excess air enables effective reduction of peak flame temperature, what in turn results in lower NO

x emissions.

Note that because the density of hydrogen is approximately eightfold lower than that of methane, hydrogen addition results in increased fuel mixture velocity at the fuel ports. Consequently, air and fuel mixing occurs differently for different fuel mixtures due to different both physical properties such as diffusivity and flow pattern. The amount of excess air provided to the combustion zone behind the lance is probably not linearly dependent on the global excess air value. Therefore, it should be kept in mind when comparing the results that the measured emissions are affected by the different flow fields created by both different fuel composition and excess air. Thus, the extent of NOx formation may result from either a modified chemical kinetic mechanism, when hydrogen is added, or altered fluid dynamics.

5.4. PPBB Burner Design Parameters Effect

Modifications of the distance between the lance and the burner exit section create variations in air velocity in the air/fuel mixing region. The location of the fuel distribution ports is different for various lance positions. According to

Figure 9, for all the investigated fuel compositions, NO

x emissions are reduced with the lance shifted upstream relative to air flow. Minimum NO

x emissions estimated based on 95% confidence interval are between 28.5 mg/kWh and 31.2 mg/kWh, and are observed at a lance position of 20 mm when the burner is fuelled by pure methane. This trend is confirmed for hydrogen-enriched methane as well. However, measurements were conducted with lance positions from 20 to 25 mm because the further shifting of the lance upstream results in incomplete combustion of pure methane. For the investigated settings, primary fuel ports are always located above the top edge of the air outlet, and the lance shape does not substantially affect air velocity at the burner throat,

i.e., air outlet section. Therefore, the effect of lance position on NO

x emissions is not strong.

All the terms associated with secondary fuel provided to the burner (X4) were determined to be statistically insignificant over the range of burner settings investigated and have therefore not been included in the enhanced model. The influence of this factor was investigated over rather low mass flow rates ranging from 0% to 6% of total fuel stream. The reason for this was flame extinction, which occurs when a higher amount of secondary fuel is provided to the burner and the burner is fuelled by pure methane. The low settings resulted in the unstable operation of mass flow controllers, and as a result, the influence of this factor may have been underestimated. ANOVA results of the full quadratic model indicated that these terms contributed to the response of the model, with a magnitude lower than the inaccuracy of the model. Quantitatively, the full quadratic model would give approximately the same value for NOx emissions as the enhanced model. However, the quality of the enhanced model has been improved in that the model facilitates an understanding of the impact of the tested factors on NOx emissions and has a better predictive capability.

Figure 9.

NOx emissions in mg/kWh versus X1 and X3 for (a) X2 = 1.05; (b) X2 = 1.3.

Figure 9.

NOx emissions in mg/kWh versus X1 and X3 for (a) X2 = 1.05; (b) X2 = 1.3.

5.5. Limitations of the CCD Approach

CCD is perhaps the most popular class of experimental designs, which allow for efficient estimation of second-order response surfaces. Nevertheless, some important limitations have been identified when it comes to application of CCD in the field of combustion.

Second-order polynomial model is unable to describe real behavior of the explanatory variable as a function of the investigated factors, if significant non-linearities or multimodal distribution are present within the tested range of factors. Expert knowledge or additional measurements are necessary in order to ensure that the explanatory variable can be estimated with second-order response surface and higher-order effects do not occur. In contrast to NO

x emissions that can be described by the model developed based on CCD, it was found during preliminary measurements that CCD approach could not be used for CO emission prediction. CO emission trends often exhibit exponential dependence on various factors, e.g., due to so-called CO breakthrough at low amounts of excess air, and thus the predicted values of CO emission do not fit to the experimental data. One possible solution to this problem is to conduct burner tests at a firebox temperature high enough to completely oxidize CO formed in the reaction zone, and focus only on NO

x emissions, as it was done in the experiment described above. Reasonableness of this approach is, however, conditioned by the target application of the tested burner,

i.e., whether it will be used in high-temperature furnaces or low-temperature furnaces [

25]. It is worth noting that NO

x emissions are dependent on a firebox temperature [

26], but as soon as combustion process is complete, means all CO is reburned to CO

2, optimal burner design parameters determined at a certain firebox temperature are still optimal in terms of emissions at a higher firebox temperature.

Another important limitation of the CCD is the fact that this approach requires symmetrical design space. In other words minimum and maximum values of tested factors must be equidistant from the respective values of these factors at a center point. It may be a significant disadvantage when CCD is used for burner development, because conducting measurements at certain points of the design may not be possible due to operational reasons. At certain combinations of factors tested within the design, burner operation may not be stable or even possible due to difficulties such as: unacceptably high CO emission, flame instability or extinction, chamber acoustic issues, and flame stabilization at surfaces, which are not designed for this purpose. These issues naturally affect region of experiment operability and they may cause that it can be highly asymmetrical. An easy way to deal with these difficulties is to resign from testing the most limiting factor or narrow ranges of the factors tested in an experiment. However, one may be also interested in NO

x emissions beyond the symmetrical design space of the reduced CCD, which is fitted into a wider region of operability. If it is the case, an alternative approach to experimental design is D-optimal or I-optimal design. The former aims to minimize the variance of the factor-effect estimates, while the latter minimizes the average variance of prediction over the region of experimentation and it makes I-optimal design more appropriate for prediction than D-optimal design [

27]. These methods offer a great deal of flexibility to reach a viable compromise between number of experimental trials, design choices, constraints, and usable results. On the other hand, the disadvantage of the optimal designs is that they are model-dependent. It means that they require knowledge about form of a model,

i.e., knowledge of terms of the second-order polynomial which should be used for a proper description of the relationship between the response and the factors. This information is necessary to generate optimal design and the form of the model must be specified by the experimenter

a priori. Testing of all the unique combinations of factors overcomes all the aforementioned difficulties, but reasonableness of this approach is, of course, dependent on its intended purpose and available resources.