Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs

Abstract

:1. Introduction

2. The Hybrid Electric Vehicle Application

2.1. Structure of the Hybrid Electric Vehicle

2.2. Traction Motor and Compressor Motor

2.3. Integrated Traction and Compressor Drive System

3. Topology and Modulation Strategies of the Dual Output Drive System for Hybrid Electric Vehicle Application

3.1. Indirect Matrix Converter Topology

3.2. Proposed Dual Output Drive System Topology for the Hybrid Electric Vehicle Application

3.3. Modulation Strategy of the Rectifier Stage

3.4. Modulation Strategy of the Four-Leg Inverter Stage

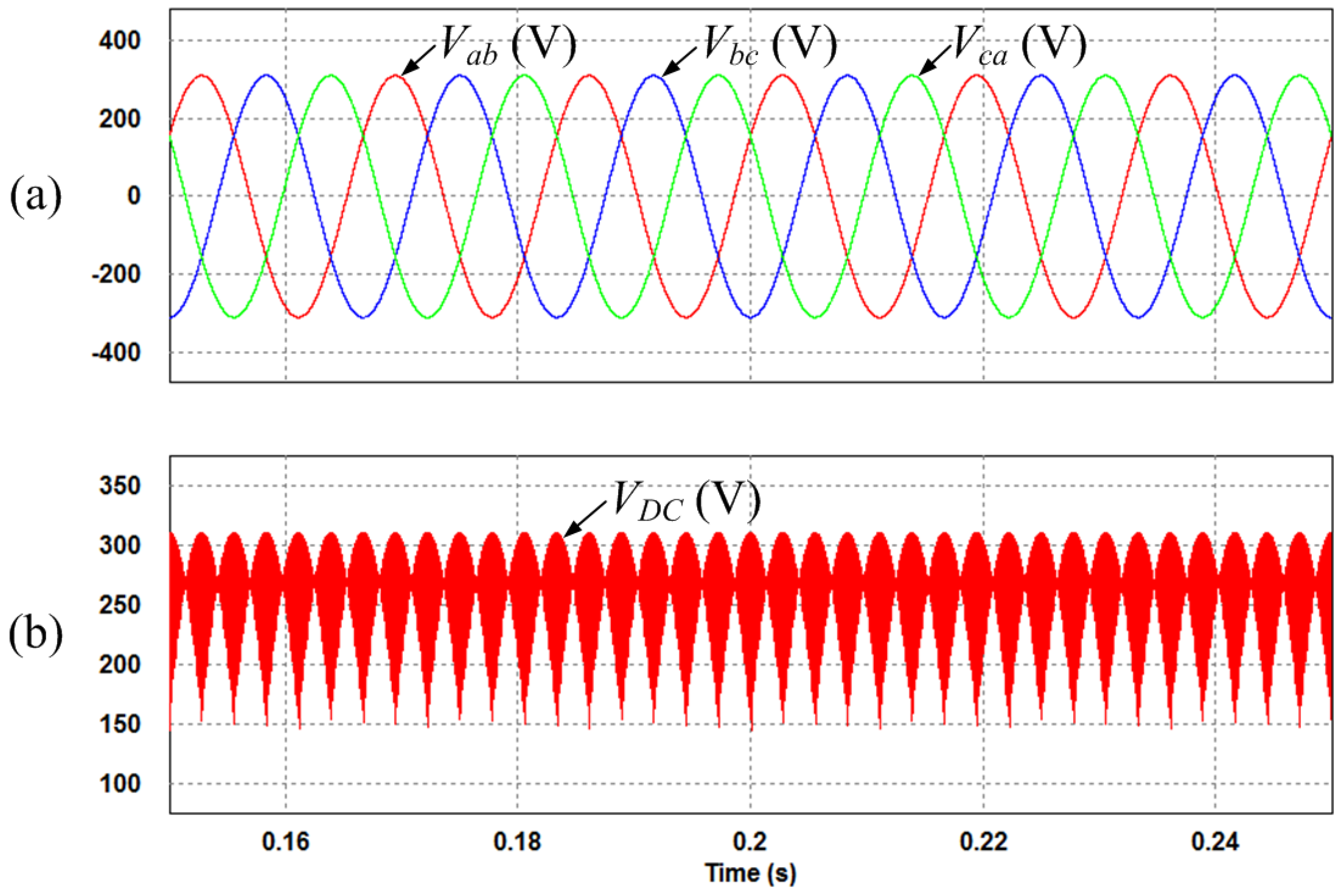

4. Simulation Results

| Classification | Value | |

|---|---|---|

| Input parameters | 3-phase input stage | Vin = 220 Vrms, fin = 60 Hz |

| Input filter | Lf = 2 mH, Cf = 7 μF | |

| Output parameters | 3-phase output stage | Rload1 = 10 Ω, Lload1 = 5 mH |

| 1-phase output stage | Rload2 = 14 Ω, Lload2 = 2 mH |

5. Experimental Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Suh, I.S.; Lee, K.; Lee, M. Dynamic model and control algorithm of HVAC system for dynamic wireless charging EV application. In Proceedings of the IEEE International Electric Machines & Drives Conference (IEMDC), Chicago, IL, USA, 12–15 May 2013; pp. 241–246.

- Rind, S.; Ren, Y.; Jiang, L. Traction motors and speed estimation techniques for sensorless control of electric vehicles: A review. In Proceedings of the 49th International Universities Power Engineering Conference (UPEC), Cluj-Napoca, Romania, 2–5 September 2014; pp. 1–6.

- Heydari, M.; Varjani, A.Y.; Mohamadian, M.; Fatemi, A. A novel dual-output six-switch three-phase inverter. In Proceedings of the 37th Annual Conference on IEEE Industrial Electronics Society Industrial Electronics Conference (IECON), Melbourne, VIC, Australia, 7–10 November 2011; pp. 1109–1114.

- Ledezma, E.; McGrath, B.; Munoz, A.; Lipo, T.A. Dual AC-drive system with a reduced switch count. IEEE Trans. Ind. Appl. 2001, 37, 1325–1333. [Google Scholar] [CrossRef]

- Najmi, E.S.; Rajaei, A.H.; Mohamadian, M.; Dehghan, S.M. A novel dual output six switch inverter for driving two phase induction motor. In Proceedings of the 4th Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Tehran, Iran, 13–14 February 2013; pp. 248–253.

- Dehghan, S.M.; Mohamadian, M.; Yazdian, A.; Ashrafzadeh, F. A dual-input dual-output z-source inverter. IEEE Trans. Power Electron. 2010, 25, 360–368. [Google Scholar] [CrossRef]

- Bak, Y.; Lee, E.; Lee, K.B. An indirect matrix converter for dual output AC-Drive system with reduced number of power transistors. In Proceedings of the IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 13–14 October 2014; pp. 360–364.

- Jeong, H.G.; Ro, H.S.; Lee, K.B. An improved maximum power point tracking method for wind power systems. Energies 2012, 5, 1339–1354. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, K.B.; Blaabjerg, F. Open-switch fault detection method of a back-to-back converter using NPC topology for wind turbine systems. IEEE Trans. Ind. Appl. 2015, 51, 325–335. [Google Scholar] [CrossRef]

- Lee, K.B.; Blaabjerg, F. Simple power control for sensorless induction motor drives fed by a matrix converter. IEEE Trans. Energy Convers. 2008, 23, 781–788. [Google Scholar] [CrossRef]

- Metidji, B.; Taib, N.; Baghli, L.; Rekioua, T.; Bacha, S. Novel single current sensor topology for venturini controlled direct matrix converters. IEEE Trans. Power Electron. 2013, 28, 3509–3516. [Google Scholar] [CrossRef]

- Friedli, T.; Kolar, J.W.; Rodriguez, J.; Wheeler, P.W. Comparative evaluation of three-phase AC-AC matrix converter and voltage DC-link back-to-back converter systems. IEEE Trans. Ind. Electron. 2012, 59, 4487–4510. [Google Scholar] [CrossRef]

- Kolar, J.W.; Schafmeister, F.; Round, S.D.; Ertl, H. Novel three-phase AC-AC sparse matrix converters. IEEE Trans. Power Electron. 2007, 22, 1649–1661. [Google Scholar] [CrossRef]

- Lee, E.; Lee, K.B.; Lim, J.S.; Lee, Y.; Song, J.H. Predictive current control for a sparse matrix converter. In Proceedings of the 7th International Power Electronics and Motion Control Conference (IPEMC), Harbin, China, 2–5 June 2012; pp. 36–40.

- Lee, E.; Lee, K.B.; Lee, Y.; Song, J.H. High performance current controller for sparse matrix converter based on model predictive control. J. Electr. Eng. Technol. 2013, 8, 1138–1145. [Google Scholar] [CrossRef]

- Kumar, D.; Wheeler, P.; Clare, J.; Kim, T.W. Multi-motor drive system based on a two-stage direct power conversion topology for aerospace applications. In Proceedings of the 4th IET Conference on Power Electronics, Machines and Drives (PEMD), York, UK, 2–4 April 2008; pp. 607–610.

- Liu, X.; Wang, P.; Loh, P.C.; Blaabjerg, F. A compact three-phase single-input/dual-output matrix converter. IEEE Trans. Ind. Electron. 2012, 59, 6–16. [Google Scholar] [CrossRef]

- Milan, G.; Dehghan, S.M.; Biabani, M.; Sahraneshin, S.; Mohamadian, M. Single-input-dual-output matrix converters and space vector modulation. In Proceedings of the 20th Iranian Conference on Electrical Engineering (ICEE), Tehran, Iran, 15–17 May 2012; pp. 569–574.

- Nguyen, T.D.; Lee, H.H. Dual three-phase indirect matrix converter with carrier-based PWM method. IEEE Trans. Power Electron. 2014, 29, 569–581. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Lee, H.H. Space vector modulation for single-input dual-output indirect matrix converter. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society Industrial Electronics Conference (IECON), Montreal, QC, Canada, 25–28 October 2012; pp. 6111–6116.

- Kwak, S.; Kim, T.; Park, G. Phase-redundant-based reliable direct AC/AC converter drive for series hybrid off-highway heavy electric vehicles. IEEE Trans. Veh. Technol. 2010, 59, 2674–2688. [Google Scholar] [CrossRef]

- Su, G.J.; Tang, L. Current source inverter based traction drive for EV battery charging applications. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 6–9 September 2011; pp. 1–6.

- Kwak, S.; Kim, T.; Vodyakho, O. Four-leg based matrix converter with fault resilient structures and controls for electric vehicle and propulsion systems. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Arlington, TX, USA, 9–12 September 2007; pp. 519–523.

- Khanchoul, M.; Krebs, G.; Marchand, C. Improvement of a permanent magnet synchronous motor for an electrical compressor. In Proceedings of the 37th Annual Conference on IEEE Industrial Electronics Society Industrial Electronics Conference (IECON), Melbourne, VIC, Australia, 7–10 November 2011; pp. 4583–4588.

- Su, G.J.; Hsu, J.S. An integrated traction and compressor drive system for EV/HEV applications. In Proceedings of the 20th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Austin, TX, USA, 6–10 March 2005; pp. 719–725.

- Su, G.J.; Hsu, J.S. A five-leg inverter for driving a traction motor and a compressor motor. IEEE Trans. Power Electron. 2006, 21, 687–692. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bak, Y.; Lee, E.; Lee, K.-B. Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs. Energies 2015, 8, 3849-3866. https://doi.org/10.3390/en8053849

Bak Y, Lee E, Lee K-B. Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs. Energies. 2015; 8(5):3849-3866. https://doi.org/10.3390/en8053849

Chicago/Turabian StyleBak, Yeongsu, Eunsil Lee, and Kyo-Beum Lee. 2015. "Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs" Energies 8, no. 5: 3849-3866. https://doi.org/10.3390/en8053849

APA StyleBak, Y., Lee, E., & Lee, K. -B. (2015). Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs. Energies, 8(5), 3849-3866. https://doi.org/10.3390/en8053849