The energy crisis in the world economy is a major problem, as published by the International Energy Agency (IEA) in the 17 June 2014 mid-term outlook for the oil market report (Oil Medium-Term Market Report [

1]). The world oil demand is expected to increase by an annual average of 1.3% by 2019. On the other hand, oil is a limited resource. Therefore, efforts to replace fossil fuels due to oil depletion are ongoing and necessary. In particular, Korea is the world’s 10

th highest energy consumer but it imports more than 97% of its energy. The percentage of energy in the total amount of imports is increasing gradually. An energy crisis may endanger the economy. Consequently, national efforts are needed to respond to the future energy crisis. Therefore, the government is fostering a renewable energy industry as a means of handling the energy crisis. The development of renewable energy in a resource poor country is important. Among the renewable energy systems available, geothermal energy has been highlighted as highly efficient and safely operable without being effected by outdoor air. In addition, it is one of the oldest renewable energy resources in the world, and it supplies the most energy.

Studies on the trends of GHP systems and importance of GHP systems are as follows. In the past, many studies have focused on efficiency enhancement and performance evaluations of various GHP systems [

2,

3,

4,

5]. Accordingly, studies of GHP are in progress from many worldwide perspectives. Haehnlein

et al. [

6] published a comprehensive overview of the current international legal status for the use of shallow geothermal energy. In their study, an international survey was performed using a questionnaire sent to more than 60 countries worldwide. Luo

et al. [

7] and Rees and Curtis [

8] examined the importance of the research trends and the design of a GHP system. Study on the performance of the GHP systems is as follows. In addition, Byun

et al. [

9] studied a fuel cell driven ground source heat pump (GSHP) system applied in a community building, and the heat pump system performance was analyzed using computational methods. Considering the long-term stability of the soil temperature and energy conservation of the system, Zhai

et al. [

10] suggested that a higher indoor temperature be set for the indoor environment. Bakirci

et al. [

11] examined the performance of a solar-GSHP system with vertical ground handling equipment (GHE). The results suggested that this solar-GSHP system can be used for heating applications in the cold climate regions of Turkey. Yang [

12] assessed the performance characteristics of a vertical U-bend direct-expansion ground source (geothermal) heat pump system (DX GSHPS) for both heating and cooling. Their study highlighted the energy efficiency of the DX GSHP system. Kim

et al. [

13] reported that the design of a proper indoor temperature for variable outdoor conditions is very important for maintaining high system performance and reliability in a hybrid solar-geothermal CO

2 heat pump system. Ozgener and Hepbaslib [

14] examined the energetic and exergetic modeling of GSHP systems for system analysis and performance assessments. Salvalai [

15] reported a parameter estimation study of a water-to-water heat pump model, implemented in IDA Indoor Climate and Energy (IDA-ICE) simulation environment, is presented and validated using experimental data. Some studies on economic evaluation of GHP systems are the following: Esen

et al. [

16] conducted performance experiments and economic analyses of a horizontal GSHP system. A detailed cost analysis was presented and the payback periods when substituting for different local fuel/power sources were determined. Studies on the energy efficiency of GHP systems include the following: Ally

et al. [

17,

18] provided excellent data on the energy savings and the fraction of energy that could be extracted from the ground for both space heating and water heating. They described the advanced building envelope characteristics, instrumentation, data acquisition, tabulated data collected, analysis, measures of performance, and conclusions for ground-coupled heat pumps for reducing the energy footprint in buildings. Chen

et al. [

19] discussed an underground water-source water-loop heat-pump (UWSWLHP) air-conditioning system for tall apartment buildings in Beijing. Sivasakthivel

et al. [

20] provided extensive data from India highlighting the energy and CO

2 saving potential of GSHP system. In the case of GSHP, the CO

2 emissions are between 4022 million kg and 12,071 million kg, resulting in a reduction of about 24.54% in a year. They estimated that India can save a minimum of 1639 GW to 18,760 GW of electricity and 1248 million tons to 14,280 million tons of CO

2 emission annually by employing GSHP technology. Studies on the composite heat source utilizing GHP system are as follows: recognition of the economic and convenient effects of geothermal heating and cooling systems in Korea is increasing because renewable energy systems supply business and installation obligations in public buildings. Geothermal energy, however, is only in charge of a part of the building load due to the high initial installation cost. Moreover, its efficiency is reduced due to the use of independent existing heat sources. Accordingly, research into GHP systems is on-going, focusing on increasing the efficiency of underground heat exchangers and evaluating the performance.

Complex operations combining solar heat and GHP have been studied in Korea and abroad. When a complex heat source was used, Kong

et al. [

21] examined the operation priority based on the energy consumption. Hwang

et al. [

22], Ozgener and Hepbasli [

23,

24], Nam [

25], and Shu

et al. [

26] examined solar heat and GHP systems and suggested an efficient way of operation through performance analysis. Ozgener and Hepbasli [

23,

24] assessed the complex operations of existing heat sources systems and GHP systems and reported the optimal capacity selection in terms of energy consumption in the case of design. Jeon

et al. [

27] reported that the use of a GHP system energy-efficient should be a priority but this study of the method of complex operation was inadequate. Yu

et al. [

28] evaluated the practical suggestions of complex operations regarding existing heat sources systems and GHP systems. The present study was conducted based on their results. Opening and closing of the air handling unit (AHU) added to the control point and sequencing control of the time delay was proposed.

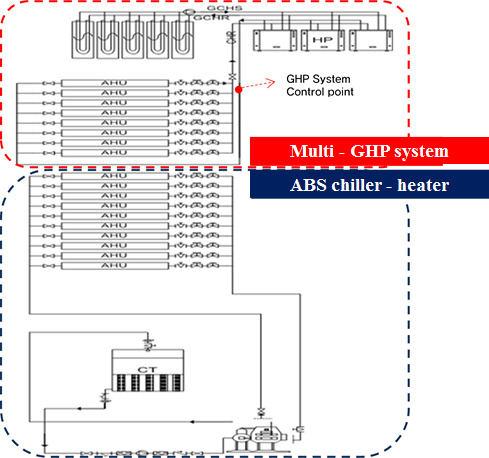

On the other hand, operation was not considered when examining the performance of the GHP unit or to reflect the indoor thermal environment. In addition, the focus was adjusted to compare the energy. The debate on the performance improvement of the heat of room environment or equipment is insufficient. Kalz

et al. [

29] emphasized the substantial impact of auxiliary energy use on the efficiency of heating and cooling performance. Kalz

et al. [

30] also presented a comprehensive analysis of the heating and cooling concepts of 11 low-energy buildings in terms of energy use, efficiency and occupant thermal comfort. Therefore, with reference to the following study was carried out in this study. In addition, the research into complex operations regarding multi-geothermal heat pump (Multi-GHP) systems and absorption (ABS) chiller-heaters is insufficient. Therefore, a hybrid operation method was proposed for a Multi-GHP system and ABS chiller-heater. In this study, after selecting a building containing an actual installed GHP, the use of GHP systems was maximized in terms of the energy efficiency. This paper proposes and evaluates the methods of hybrid operation regarding ABS chiller-heater and GHP systems through simulations.