Market Suitability and Performance Tradeoffs Offered by Commercial Wind Turbines across Differing Wind Regimes †

Abstract

:1. Introduction

1.1. A Temporally- and Spatially-Varying Energy Resource

1.2. Role of Turbine Selection in Wind Farm Design

- The installed capacity of the wind farm,

- The land configuration and the placement of turbines in the wind farm (i.e., macro- and micro-siting), and

- The types of wind turbines to be installed.

- Actual energy production capacity of a turbine (when operating as a group) based on the local wind resource, and

- Leveled cost of the wind farm attributable to the turbines.

1.3. Geographical Variation of Wind Patterns

1.4. Exploring “Turbine-Wind Regime” Compatibilities

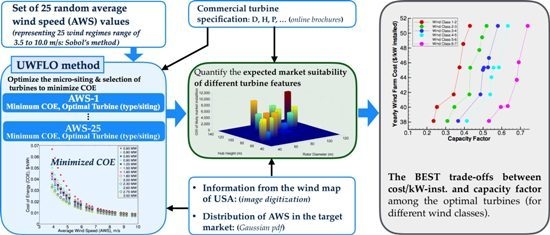

- Step 1 The geographical variation/distribution of wind regimes (in terms of AWS) in the target market is characterized; the U.S. onshore market is used as the case study.

- Step 2 The types of commercial turbines that provide the minimum COE values are determined for different wind regimes, where the minimum COE value is given by optimized arrangement of a group of such turbines.

- Step 3 The likely demand/market-suitability of the currently available (commercial) turbine feature combinations (namely, rated power, rotor diameter and hub height) is determined for the entire target market, based on the expected installation rate, geographical distribution of wind regimes (Step 1) and estimated economic potential of the best-suited turbines for different wind regimes (Step 2).

- Step 4 The tradeoffs between the cost and capacity factor offered by the best performing turbines (for different wind regimes) are also determined to explore how these tradeoffs are related to the turbine-feature combinations.

2. Determining Optimal Wind Turbines (under Group Operation) for Different Wind Regimes

2.1. Characterizing Wind Regimes

2.1.1. Extracting Wind Map Information

2.1.2. Distribution of Wind Regimes in the Target Market

2.2. Approach to Determine Optimal Turbine Choices

2.3. Turbine Characterization Model

2.4. Wind Turbine Cost Model

2.5. Optimization of Farm Layout and Turbine Type Selection

3. Pool of Optimal Turbine Choices for Differing Wind Regimes

4. Market Suitability of Turbines

4.1. Development of a Market Suitability Metric for Wind Turbines

- How often different feature combinations were selected during the wind farm optimizations, across the different wind regimes (from Section 3);

- What level of performance (in terms of COE) was offered by the best performing turbines (from each rated-power class); and

- The probability of occurrence of each of the n sample average wind speeds (for which wind farm optimization was performed) over the U.S. onshore market; determined in Section 2.1.

4.2. Suitability of Wind Turbine Features for the U.S. Onshore Market

5. Performance Tradeoffs Offered by Current Commercial Turbines

5.1. Turbine Best Tradeoffs for Different Wind Classes

- , or

- .

5.2. Comparing the Features of the Best Tradeoff Turbines to those of all Turbines Considered

6. Conclusion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, J.; Chowdhury, S.; Messac, A.; Castillo, L. A multivariate and multimodal wind distribution model. Renew. Energy 2013, 51, 436–447. [Google Scholar] [CrossRef]

- Erdem, E.; Shi, J. Comparison of bivariate distribution construction approaches for analysing wind speed and direction data. Wind Energy 2011, 14, 27–41. [Google Scholar] [CrossRef]

- Probst, O.; Cardenas, D. State of the art and trends in wind resource assessment. Energies 2010, 3, 1087–1141. [Google Scholar] [CrossRef]

- Diaz-Gonzalez, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafafila-Robles, R. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 61400-1, Wind Turbines Part 1: Design Requirements, 3rd ed.; International Electrotechnical Commission: Geneva, Switzerland, 2005. [Google Scholar]

- Chowdhury, S.; Zhang, J.; Catalano, M.; Mehmani, A.; Notaro, S.; Messac, A.; Castillo, L. Exploring the Best Performing Commercial Wind Turbines for Different Wind Regimes in a Target Market. In Proccedings of 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hawaii, 23–26 April 2012.

- Chowdhury, S.; Zhang, J.; Mehmani, A.; Messac, A.; Castillo, L. Tradeoffs Offered by the Best Performing Commercial Turbines. In Proccedings of 14th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Indianapolis, Indiana, 17–19 September 2012.

- Chowdhury, S.; Zhang, J.; Messac, A.; Castillo, L. Optimizing the arrangement and the selection of turbines for a wind farm subject to varying wind conditions. Renew. Energy 2013, 52, 273–282. [Google Scholar] [CrossRef]

- Chowdhury, S.; Zhang, J.; Messac, A.; Castillo, L. Unrestricted Wind Farm Layout Optimization (UWFLO): Investigating key factors influencing the maximum power generation. Renew. Energy 2012, 38, 16–30. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.; Jin, K.; Song, Q. Wind farm layout optimization using genetic algorithm with different hub height wind turbines. Energy Conv. Manag. 2013, 70, 56–65. [Google Scholar] [CrossRef]

- Sorensen, P.; Nielsen, T. Recalibrating Wind Turbine Wake Model Parameters—Validating the Wake Model Performance for Large Offshore Wind Farms. In Proceedings of the European Wind Energy Conference and Exhibition, Athens, Greece, 27 February 2006.

- Mikkelsen, R.; Sorensen, J.N.; Oye, S.; Troldborg, N. Analysis of power enhancement for a row of wind turbines using the actuator line technique. J. Phys. Conf. Series 2007, 75, 012044. [Google Scholar] [CrossRef]

- Grady, S.A.; Hussaini, M.Y.; Abdullah, M.M. Placement of wind turbines using genetic algorithms. Renew. Energy 2005, 30, 259–270. [Google Scholar] [CrossRef]

- Sisbot, S.; Turgut, O.; Tunc, M.; Camdali, U. Optimal positioning of wind turbines on gokceada using multi-objective genetic algorithm. Lecture Notes Comput. Sci. Adv. Swarm Intell. 2009, 13, 297–306. [Google Scholar] [CrossRef]

- Gonzalez, J.S.; Rodriguezb, A.G.G.; Morac, J.C.; Santos, J.R.; Payan, M.B. Optimization of wind farm turbines layout using an evolutive algorithm. Renew. Energy 2010, 35, 1671–1681. [Google Scholar] [CrossRef]

- Kusiak, A.; Song, Z. Design of wind farm layout for maximum wind energy capture. Renew. Energy 2010, 35, 685–694. [Google Scholar] [CrossRef]

- Kwong, W.Y.; Zhang, P.Y.; Romero, D.; Moran, J.; Morgenroth, M.; Amon, C. Multi-objective wind farm layout optimization considering energy generation and noise propagation with NSGA-II. J. Mech. Des. 2014, 136, 091010. [Google Scholar] [CrossRef]

- Chen, L.; MacDonald, E. A system-level cost-of-energy wind farm layout optimization with landowner modeling. Energy Conv. Manag. 2014, 77, 484–494. [Google Scholar] [CrossRef]

- Fleming, P.A.; Ning, A.; Gebraad, P.M.; Dykes, K. Wind plant system engineering through optimization of layout and yaw control. Wind Energy 2015, 19, 329–344. [Google Scholar] [CrossRef]

- NREL-RReDC. Classes of Wind Power Density at 10 m and 50 m. Available online: http://rredc.nrel.gov/ wind/pubs/atlas/tables/1-1T.html (accessed on 1 March 2012).

- Truepower, A. NREL: Dynamic Maps, Geographic Information System (GIS) Data and Analysis Tools: Wind Maps. Available online: http://www.nrel.gov/gis/wind.html (accessed on 1 June 2011).

- Pishgar-Komleh, S.; Keyhani, A.; Sefeedpari, P. Wind speed and power density analysis based on Weibull and Rayleigh distributions (a case study: Firouzkooh county of Iran). Renew. Sustain. Energy Rev. 2015, 42, 313–322. [Google Scholar] [CrossRef]

- Rosen, K.; Van Buskirk, R.; Garbesi, K. Wind energy potential of coastal Eritrea: An analysis of sparse wind data. Solar Energy 1999, 66, 201–203. [Google Scholar]

- Rehman, S.; Halawani, T.; Husain, T. Weibull parameters for wind speed distribution in Saudi Arabia. Solar Energy 1994, 53, 473–479. [Google Scholar] [CrossRef]

- Celik, A.N. Energy output estimation for small-scale wind power generators using Weibull-representative wind data. J. Wind Eng. Ind. Aerodyn. 2003, 91, 693–707. [Google Scholar] [CrossRef]

- Crasto, G. Numerical Simulations of the Atmospheric Boundary Layer; Universita degli Studi di Cagliari: Cagliari, Italy, 2007. [Google Scholar]

- Frandsen, S.; Barthelmie, R.; Pryor, S.; Rathmann, O.; Larsen, S.; Hojstrup, J.; Thogersen, M. Analytical Modeling of Wind Speed Deficit in Large Offshore Wind Farms. Wind Energy 2006, 9, 39–53. [Google Scholar] [CrossRef]

- Katic, I.; Hojstrup, J.; Jensen, N.O. A Simple Model for Cluster Efficiency. In Proceedings of the European Wind Energy Conference and Exhibition, Rome, Italy, 7–9 October 1986.

- Elkinton, C.; Manwell, J.; McGowan, J. Offshore Wind Farm Layout Optimization (OWFLO) Project: Priliminary Results. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006.

- Crespo, A.J.; Hernandez, S.; Frandsen, S. Survey of modeling methods for wind turbine wakes and wind farms. Wind Energy 1999, 2, 1–24. [Google Scholar] [CrossRef]

- Herbert-Acero, J.F.; Probst, O.; Rethore, P.; Larsen, G.C.; Castillo-Villar, K.K. A review of methodological approaches for the design and optimization of wind farms. Energies 2014, 7, 6930–7016. [Google Scholar] [CrossRef]

- Cal, R.B.; Lebron, J.; Kang, H.S.; Meneveau, C.; Castillo, L. Experimental Study of the Horizontally Averaged Flow Structure in a Model Wind-Turbine Array Boundary Layer. J. Renew. Sustain. Energy 2010, 2, 013106. [Google Scholar] [CrossRef]

- Fingersh, L.; Hand, M.; Laxson, A. Wind Turbine Design Cost and Scaling Mode; National Renewable Energy Laboratory: Golden, CO, USA, 2006. [Google Scholar]

- Chowdhury, S.; Tong, W.; Messac, A.; Zhang, J. A mixed-discrete Particle Swarm Optimization algorithm with explicit diversity-preservation. Struct. Multidiscip. Optim. 2013, 47, 367–388. [Google Scholar] [CrossRef]

- Sobol, M. Uniformly Distributed Sequences with an Additional Uniform Property. USSR Comput. Math. Math. Phys. 1976, 16, 236–242. [Google Scholar] [CrossRef]

- Sobol, I.M. A Primer for the Monte Carlo Method; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Tong, W.; Chowdhury, S.; Mehmani, A.; Messac, A.; Zhang, J. Sensitivity of wind farm output to wind conditions, land configuration, and installed capacity, under different wake models. J. Mech. Des. 2015, 137, 061403. [Google Scholar] [CrossRef]

- Chowdhury, S.; Zhang, J.; Messac, A.; Castillo, L. Characterizing the Influence of Land Area and Nameplate Capacity on the Optimal Wind Farm Performance. In Proceedings of the ASME 2012 6th International Conference on Energy Sustainability, San Diego, CA, USA, 23–16 July 2012.

- Denholm, P.; Hand, M.; Jackson, M.; Ong, S. Land-Use Requirements of Modern Wind Power Plants in the United States; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- GE-Energy. 1.5 MW Wind Turbine. Available online: http://www.ge-energy.com/products and services/products/wind turbines/index.jsp (accessed on 1 December 2009).

- Crespo, A.; Hernández, J.; Frandsen, S. Survey of modelling methods for wind turbine wakes and wind farms. Wind Energy 1999, 2, 1–24. [Google Scholar] [CrossRef]

- Malcolm, D.J.; Hansen, A.C. WindPACT Turbine Rotor Design Study: June 2000–June 2002 (Revised); National Renewable Energy Laboratory: Golden, CO, USA, 2006. [Google Scholar]

- Shafer, D.A.; Strawmyer, K.R.; Conley, R.M.; Guidinger, J.H.; Wilkie, D.C.; Zellman, T.F.; Bernadett, D.W. WindPACT Turbine Design Scaling Studies: Technical Area 4 — Balance-of-Station Cost; National Renewable Energy Laboratory: Golden, CO, USA, 2001. [Google Scholar]

- Chowdhury, S.; Zhang, J.; Messac, A.; Castillo, L. Developing a Flexible Platform for Optimal Engineering Design of Commercial Wind Farms. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011.

- Fairley, P. Wind Turbines Shed Their Gears: Both Siemens and GE Bet on Direct-Drive Generators. Available online: http://www.technologyreview.com/energy/25188 (accessed on 1 February 2012).

- Trabish, H.K. Wind Turbines, the Next Generation: Forget Gears. The Future Could Lie with Direct Drive. Available online: http://www.greentechmedia.com/articles/read/wind-tubines-the-next-generation (accessed on 1 February 2012).

- Tan, A. A Direct Drive to Sustainable Wind Energy. Available online: http://www.technologyreview.com/energy/25188 (accessed on 1 February 2012).

- Bartos, F.J. Direct-drive Wind Turbines Flex Muscles. Available online: http://www.controleng.com/single-article/direct-drive-wind-turbines-flex-muscles/4be132ffb0.html (accessed on 1 February 2012).

- NREL. Estimate of Windy Land Area and Wind Energy Potential, by States, for Areas ≥ 30 percent Capacity Factor at 80 m. Available online: www.windpoweringamerica.gov/docs/ (accessed on 1 December 2011).

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef] [PubMed]

| Property | Value |

|---|---|

| Nameplate capacity | 25.0 MW |

| Radius of the circular farm | 964.0 m |

| Average terrain roughness | 0.1 m (grassland) |

| Density of air | 1.2 kg/m |

| Rated-Power Class (MW) | Number of Available Choices | Number Installed in the Farm |

|---|---|---|

| 0.60 | 3 | 42 |

| 0.80 | 7 | 31 |

| 0.85 | 13 | 29 |

| 0.90 | 3 | 28 |

| 1.25 | 6 | 20 |

| 1.50 | 16 | 17 |

| 1.60 | 5 | 16 |

| 1.80 | 10 | 14 |

| 2.00 | 36 | 13 |

| 2.30 | 14 | 11 |

| 2.60 | 3 | 10 |

| 2.75 | 4 | 9 |

| 3.00 | 11 | 8 |

| Rated-Power Class (MW) | R value | RMS Error | ||

|---|---|---|---|---|

| 0.60 | 1.190 | −2.222 | 0.9720 | 0.0027 |

| 0.80 | 0.363 | −1.746 | 0.9691 | 0.0015 |

| 0.85 | 0.447 | −1.845 | 0.9741 | 0.0015 |

| 0.90 | 0.725 | −2.028 | 0.9895 | 0.0012 |

| 1.25 | 0.526 | −1.897 | 0.9797 | 0.0015 |

| 1.50 | 0.299 | −1.684 | 0.9791 | 0.0011 |

| 1.60 | 0.414 | −1.789 | 0.9722 | 0.0016 |

| 1.80 | 0.474 | −1.796 | 0.9837 | 0.0013 |

| 2.00 | 0.239 | −1.563 | 0.9792 | 0.0010 |

| 2.30 | 0.293 | −1.676 | 0.9850 | 0.0009 |

| 2.60 | 0.369 | −1.716 | 0.9753 | 0.0014 |

| 2.75 | 0.430 | −1.769 | 0.9783 | 0.0015 |

| 3.00 | 0.184 | −1.433 | 0.9784 | 0.0009 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, S.; Mehmani, A.; Zhang, J.; Messac, A. Market Suitability and Performance Tradeoffs Offered by Commercial Wind Turbines across Differing Wind Regimes. Energies 2016, 9, 352. https://doi.org/10.3390/en9050352

Chowdhury S, Mehmani A, Zhang J, Messac A. Market Suitability and Performance Tradeoffs Offered by Commercial Wind Turbines across Differing Wind Regimes. Energies. 2016; 9(5):352. https://doi.org/10.3390/en9050352

Chicago/Turabian StyleChowdhury, Souma, Ali Mehmani, Jie Zhang, and Achille Messac. 2016. "Market Suitability and Performance Tradeoffs Offered by Commercial Wind Turbines across Differing Wind Regimes" Energies 9, no. 5: 352. https://doi.org/10.3390/en9050352