Optimal Scheduling of Energy Storage System for Self-Sustainable Base Station Operation Considering Battery Wear-Out Cost

Abstract

:1. Introduction

2. System Model

2.1. Sustainable Base Station Model in Smart Grid Environment

2.2. Power Consumption Model for Macro Base Station

2.3. Battery Wear-Out Model

2.4. Photovoltaic Generator Model

2.5. Converter System Model

3. Multi-Functional Energy Storage System Optimization

- (1)

- Operational input layer: This layer consists of multi-functional objective and load calculation parts. The multi-functional objective part consists of peak shift, DR and TOU for maximizing economic profit. In load calculation, renewable output power is calculated by applying PV output power modeling and convert system based on the average temperature and irradiance level data. Then, through a power consumption model for macro BS, total required BS load is finally calculated. Operational conditions and load prediction data base are delivered from this layer to the scheduling layer.

- (2)

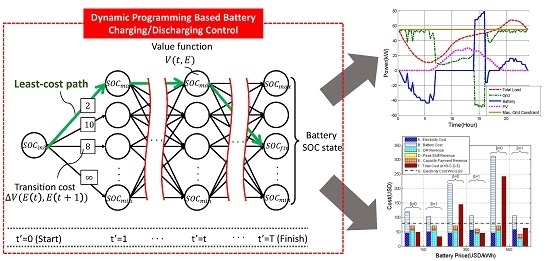

- Scheduling layer: Using DP, optimization is performed to obtain the ESS scheduling by combining the operating conditions and load prediction data with the measured battery characteristics, scheduling constraints and SOC/SOH estimation. The scheduling layer transfers the optimized scheduling output to the physical layer for operating ESS by charging and discharging.

- (3)

- Physical layer: Based on the scheduling result from the scheduling layer, the power conversion system (PCS) performs practical ESS charging and discharging.

3.1. Multi-Functional Framework Using Dynamic Programming

3.2. Peak Shift

| Algorithm Peak Shift |

| Input: and |

| Output: |

|

4. Experimental Results from Operational Scenarios

4.1. Experimental Set-Up

4.2. Case Study

4.2.1. Case 1: Basic Dynamic Programming with Time of Use Only

4.2.2. Case 2: Multi-Functional Dynamic Programming without Considering Battery Wear-Out

4.2.3. Case 3: Multi-Functional Dynamic Programming with Battery Wear-Out Model

4.3. Performance Evaluations

4.3.1. Trade-Off between the Operating Cost and the Battery Cost

4.3.2. Cost Analysis with Battery Usage and Prices

4.3.3. Maximum Grid Constraint and Total Revenue

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Piro, G.; Miozzo, M.; Forte, G.; Baldo, N.; Grieco, L.A.; Boggia, G.; Dini, P. Hetnets powered by renewable energy sources: Sustainable next-generation cellular networks. IEEE Internet Comput. 2013, 17, 32–39. [Google Scholar] [CrossRef]

- Issaadi, W.; Khireddine, A.; Issaadi, S. Management of a base station of a mobile network using a photovoltaic system. Renew. Sustain. Energy Rev. 2016, 59, 1570–1590. [Google Scholar] [CrossRef]

- Zordan, D.; Miozzo, M.; Dini, P.; Rossi, M. When telecommunications networks meet energy grids: Cellular networks with energy harvesting and trading capabilities. IEEE Commun. Mag. 2015, 53, 117–123. [Google Scholar] [CrossRef]

- Aris, A.M.; Shabani, B. Sustainable Power Supply Solutions for Off-Grid Base Stations. Energies 2015, 8, 10904–10941. [Google Scholar] [CrossRef]

- Sui, X.; Tang, Y.; He, H.; Wen, J. Energy-storage-based low-frequency oscillation damping control using particle swarm optimization and heuristic dynamic programming. IEEE Trans. Power Syst. 2014, 29, 2539–2548. [Google Scholar] [CrossRef]

- Ye, Y.; Jimenez Arribas, F.; Elmirghani, J.; Idzikowski, F.; Lopez Vizcaino, J.; Monti, P.; Musumeci, F.; Pattavina, A.; Van Heddeghem, W. Energy-efficient resilient optical networks: Challenges and trade-offs. IEEE Commun. Mag. 2015, 53, 144–150. [Google Scholar] [CrossRef]

- Wang, C.X.; Haider, F.; Gao, X.; You, X.H.; Yang, Y.; Yuan, D.; Aggoune, H.; Haas, H.; Fletcher, S.; Hepsaydir, E. Cellular architecture and key technologies for 5G wireless communication networks. IEEE Commun. Mag. 2014, 52, 122–130. [Google Scholar] [CrossRef]

- Public Utilities Code Section 2835–2839; State of California: USA, 2010. Available online: http://www.leginfo.ca.gov/cgi-bin/displaycode?section=puc (accessed on 1 January 2011).

- Soroudi, A.; Siano, P.; Keane, A. Optimal DR and ESS Scheduling for Distribution Losses Payments Minimization Under Electricity Price Uncertainty. IEEE Trans. Smart Grid 2016, 7, 261–272. [Google Scholar] [CrossRef]

- Tan, Z.; Li, H.; Ju, L.; Song, Y. An Optimization Model for Large-Scale Wind Power Grid Connection Considering Demand Response and Energy Storage Systems. Energies 2014, 7, 7282–7304. [Google Scholar] [CrossRef]

- Grillo, S.; Marinelli, M.; Massucco, S.; Silvestro, F. Optimal management strategy of a battery-based storage system to improve renewable energy integration in distribution networks. IEEE Trans. Smart Grid 2012, 3, 950–958. [Google Scholar] [CrossRef]

- Shi, W.; Xie, X.; Chu, C.C.; Gadh, R. Distributed optimal energy management in microgrids. IEEE Trans. Smart Grid 2015, 6, 1137–1146. [Google Scholar] [CrossRef]

- Pudjianto, D.; Aunedi, M.; Djapic, P.; Strbac, G. Whole-systems assessment of the value of energy storage in low-carbon electricity systems. IEEE Trans. Smart Grid 2014, 5, 1098–1109. [Google Scholar] [CrossRef]

- Yang, H.; Chung, C.; Zhao, J. Application of plug-in electric vehicles to frequency regulation based on distributed signal acquisition via limited communication. IEEE Trans. Power Syst. 2013, 28, 1017–1026. [Google Scholar] [CrossRef]

- Levron, Y.; Guerrero, J.M.; Beck, Y. Optimal power flow in microgrids with energy storage. IEEE Trans. Power Syst. 2013, 28, 3226–3234. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Qian, K.; Allan, M.; Zhou, W. Modeling of the cost of EV battery wear due to V2G application in power systems. IEEE Trans. Energy Convers. 2011, 26, 1041–1050. [Google Scholar] [CrossRef]

- Tang, L.; Rizzoni, G.; Onori, S. Energy Management Strategy for HEVs Including Battery Life Optimization. IEEE Trans. Transp. Electr. 2015, 1, 211–222. [Google Scholar] [CrossRef]

- Shen, J.; Dusmez, S.; Khaligh, A. Optimization of sizing and battery cycle life in battery/ultracapacitor hybrid energy storage systems for electric vehicle applications. IEEE Trans. Ind. Inf. 2014, 10, 2112–2121. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Chen, J.; Wang, C.; Guo, L. Operation optimization of standalone microgrids considering lifetime characteristics of battery energy storage system. IEEE Trans. Sustain. Energy 2013, 4, 934–943. [Google Scholar] [CrossRef]

- Gee, A.M.; Robinson, F.V.; Dunn, R.W. Analysis of battery lifetime extension in a small-scale wind-energy system using supercapacitors. IEEE Trans. Power Syst. 2013, 28, 24–33. [Google Scholar] [CrossRef]

- Tran, D.; Khambadkone, A.M. Energy management for lifetime extension of energy storage system in micro-grid applications. IEEE Trans. Smart Grid 2013, 4, 1289–1296. [Google Scholar] [CrossRef]

- Jiang, Q.; Gong, Y.; Wang, H. A battery energy storage system dual-layer control strategy for mitigating wind farm fluctuations. IEEE Trans. Power Syst. 2013, 28, 3263–3273. [Google Scholar] [CrossRef]

- Han, S.; Han, S.; Aki, H. A practical battery wear model for electric vehicle charging applications. Appl. Energy 2014, 113, 1100–1108. [Google Scholar] [CrossRef]

- Divya, K.; stergaard, J. Battery energy storage technology for power systems—An overview. Electr. Power Syst. Res. 2009, 79, 511–520. [Google Scholar] [CrossRef]

- Asghari, B.; Patil, R.; Shi, D.; Sharma, R. A Mixed-Mode Management System for Grid Scale Energy Storage Units. In Proceedings of the 2015 IEEE International Conference on Smart Grid Communications, Miami, FL, USA, 2–5 November 2015.

- Auer, G.; Giannini, V.; Desset, C.; Godor, I.; Skillermark, P.; Olsson, M.; Imran, M.A.; Sabella, D.; Gonzalez, M.J.; Blume, O.; et al. How much energy is needed to run a wireless network? IEEE Wirel. Commun. 2011, 18, 40–49. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Riffonneau, Y.; Bacha, S.; Barruel, F.; Ploix, S. Optimal power flow management for grid connected PV systems with batteries. IEEE Trans. Sustain. Energy 2011, 2, 309–320. [Google Scholar] [CrossRef]

- Kihara, H.; Yokoyama, A.; Liyanage, K.M.; Sakuma, H. Optimal placement and control of BESS for a distribution system integrated with PV systems. J. Int. Counc. Electr. Eng. 2011, 1, 298–303. [Google Scholar] [CrossRef]

| Parameters (unit) | (W) | (W) | (W) | (W) | (%) | (dB) | (%) | (%) | (%) | (#) |

|---|---|---|---|---|---|---|---|---|---|---|

| Values | 20.0 | 128.2 | 12.9 | 29.6 | 31.1 | -3 | 7.5 | 9.0 | 10.0 | 6 |

| Parameters | a | b | Range of b |

|---|---|---|---|

| Battery A | 695.4 | 0.7916 | |

| Battery B | 700 | 1 | |

| Battery C | 534.4 | 1.118 |

| Parameters | Symbols | Values (unit) |

|---|---|---|

| Rated battery capacity | 300 (kWh) | |

| Time interval | Δt | 15 (min) |

| Time step | t | 1 to 96 (based on 24 h) |

| Battery price | 150, 350, 550 (USD/kWh) | |

| Battery type | Battery A, | |

| Battery efficiency | 85% | |

| Weighting factor | 0.5 | |

| Initial SOC | 0.1 | |

| Maximum/Minimum SOC | 0.9/0.1 | |

| Maximum battery power rate | 150 (kW) | |

| Maximum grid constraint | 55 (kW) | |

| DR incentive | 0.55 (USD/kWh) 1 | |

| DR capacity payment | 40.8 (USD/kW/year) 1 | |

| Base electricity price | 8.3 (USD/kW) 1 |

| Case | Electricity Cost | Battery Cost | DR Revenue | Capacity Revenue | Peak Shift Revenue | Total Cost | Battery Usage |

|---|---|---|---|---|---|---|---|

| () | () | () | () | () | () | () | |

| Case 1 | $43.8 | $268.0 | 0 | 0 | -$40.6 | $352.4 | 1.79 |

| Case 2 | $47.0 | $169.0 | $53.8 | $13.4 | $3.6 | $145.2 | 1.07 |

| Case 3 | $51.0 | $123.4 | $53.8 | $13.4 | $3.6 | $103.6 | 0.83 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.; Kim, H. Optimal Scheduling of Energy Storage System for Self-Sustainable Base Station Operation Considering Battery Wear-Out Cost. Energies 2016, 9, 462. https://doi.org/10.3390/en9060462

Choi Y, Kim H. Optimal Scheduling of Energy Storage System for Self-Sustainable Base Station Operation Considering Battery Wear-Out Cost. Energies. 2016; 9(6):462. https://doi.org/10.3390/en9060462

Chicago/Turabian StyleChoi, Yohwan, and Hongseok Kim. 2016. "Optimal Scheduling of Energy Storage System for Self-Sustainable Base Station Operation Considering Battery Wear-Out Cost" Energies 9, no. 6: 462. https://doi.org/10.3390/en9060462

APA StyleChoi, Y., & Kim, H. (2016). Optimal Scheduling of Energy Storage System for Self-Sustainable Base Station Operation Considering Battery Wear-Out Cost. Energies, 9(6), 462. https://doi.org/10.3390/en9060462