Long-Term High-Temperature Stability of Directionally Grown [Bi2Ba2O4]p[CoO2] Rods

Abstract

:1. Introduction

2. Materials and Methods

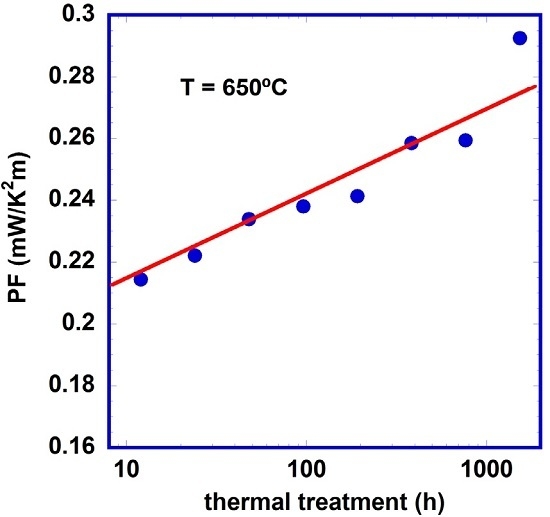

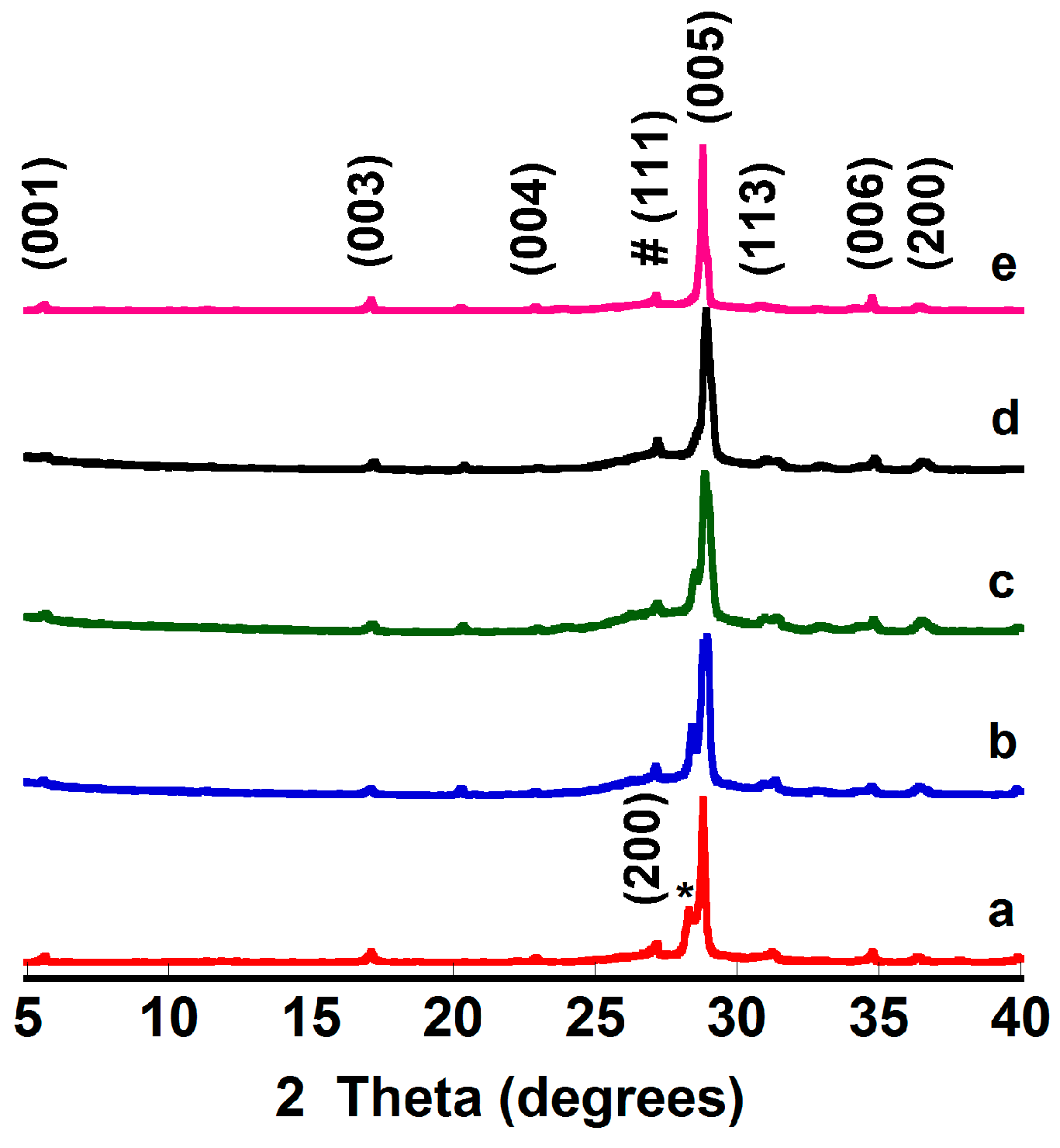

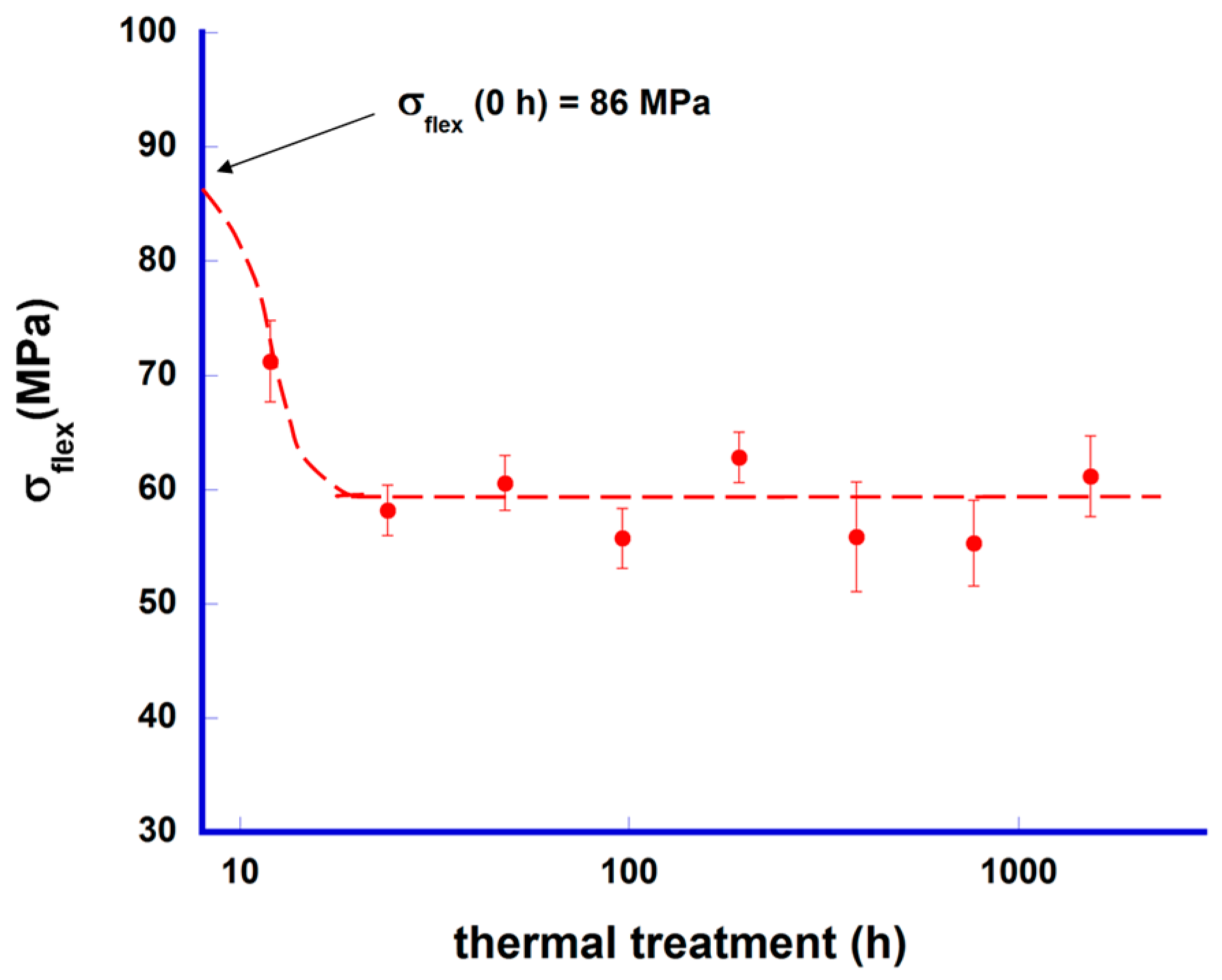

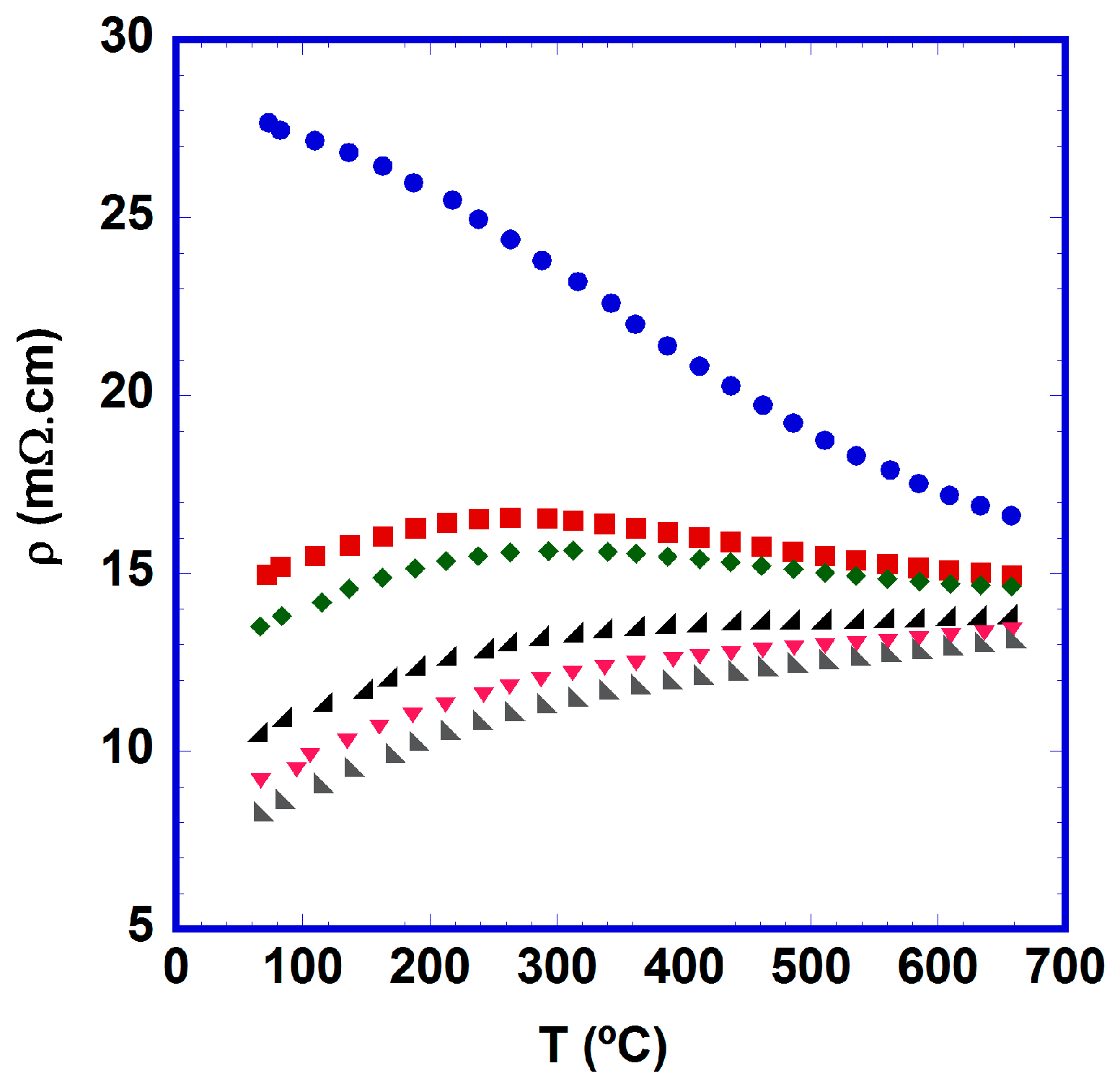

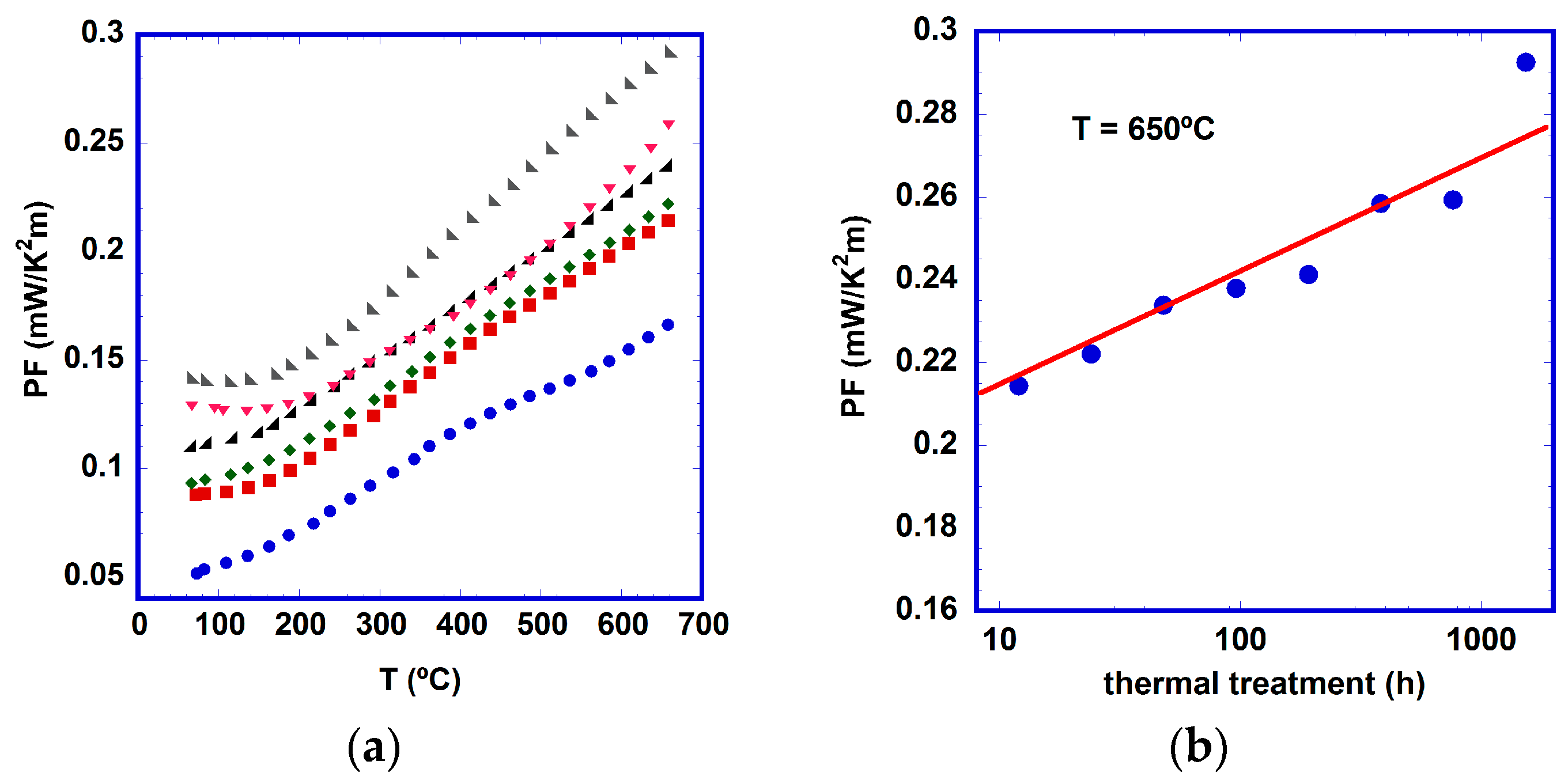

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Perspectives on thermoelectrics: From fundamental to device applications. Energy Environ. Sci. 2012, 5, 5147–5162. [Google Scholar] [CrossRef]

- Liu, W.; Yan, X.; Chen, G.; Ren, Z. Recent advances in thermoelectric nanocomposites. Nano Energy 2012, 1, 42–56. [Google Scholar] [CrossRef]

- Rowe, D.M. General Principles and basic Considerations. In Thermolectrics Handbook: Macro to Nano, 1st ed.; Rowe, D.M., Ed.; CRC Press: Boca Raton, FL, USA; pp. 1-3–1-7.

- Liu, W.; Jie, Q.; Kim, H.S.; Ren, Z. Current progress and future challenges in thermoelectric power generation: From materials to devices. Acta Mater. 2015, 87, 357–376. [Google Scholar] [CrossRef]

- Sharma, S.; Dwivedi, V.K.; Pandit, S.N. A review of thermoelectric devices for cooling applications. Int. J. Green Energy 2014, 11, 899–909. [Google Scholar] [CrossRef]

- Elsheikh, M.H.; Shnawah, D.A.; Sabri, M.F.M.; Said, S.B.M.; Hassan, M.H.; Bashir, M.B.A.; Mohamad, M. A review on thermoelectric renewable energy: Principle parameters that affect their performance. Renew. Sustain Energy Rev. 2014, 30, 337–355. [Google Scholar] [CrossRef]

- Radousky, H.B.; Liang, H. Energy harvesting: An integrated view of materials, devices and applications. Nanotechnology 2013, 23, 502001. [Google Scholar] [CrossRef] [PubMed]

- Terasaki, I.; Sasago, Y.; Uchinokura, K. Large thermoelectric power in NaCo2O4 single crystals. Phys. Rev. B 1997, 56, R12685–R12687. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, B.; Fang, J.; Ang, R.; Sun, Y. Tunning of microstructure and thermoelectric properties of Ca3Co4O9 ceramics by high-magnetic-field sintering. J. Appl. Phys. 2011, 110, 123713. [Google Scholar] [CrossRef]

- Sotelo, A.; Constantinescu, G.; Rasekh, S.; Torres, M.A.; Diez, J.C.; Madre, M.A. Improvement of thermoelectric properties of Ca3Co4O9 using soft chemistry synthetic methods. J. Eur. Ceram. Soc. 2012, 32, 2415–2422. [Google Scholar] [CrossRef] [Green Version]

- Rubesova, K.; Hlasek, T.; Jakes, V.; Huber, S.; Hejtmanek, J.; Sedmidubsky, D. Effect of a powder compaction process on the thermoelectric properties of Bi2Sr2Co1.8Ox ceramics. J. Eur. Ceram. Soc. 2015, 35, 525–531. [Google Scholar] [CrossRef]

- Madre, M.A.; Rasekh, S.; Diez, J.C.; Sotelo, A. New solution method to produce high performance thermoelectric ceramics: A case study of Bi-Sr-Co-O. Mater. Lett. 2010, 64, 2566–2568. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, W.; Hebert, S.; Muguerra, H.; Grebille, D.; Pelloquin, D.; Maignan, A. Thermoelectric properties in the misfit-layered-cobalt oxides [Bi2A2O4][CoO2]b1/b2 (A = Ca, Sr, Ba, b1/b2 = 1.65, 1.82, 1.98) single crystals. In Proceedings of the 26th International Conference on Thermoelectrics, Jeju, Korea, 3–5 June 2007; Kim, I., Ed.; IEEE: Piscataway, NJ, USA, 2008; pp. 117–120. [Google Scholar]

- Sotelo, A.; Rasekh, S.; Madre, M.A.; Guilmeau, E.; Marinel, S.; Diez, J.C. Solution-based synthesis routes to thermoelectric Bi2Ca2Co1.7Ox. J. Eur. Ceram. Soc. 2011, 31, 1763–1769. [Google Scholar] [CrossRef] [Green Version]

- Hao, H.; Yang, H.; Liu, Y.; Hu, X. High-temperature Thermoelectric Properties of Cu-substituted Bi2Ba2Co2−xCuxOy Oxides. J. Mater. Sci. Technol. 2011, 27, 525–528. [Google Scholar] [CrossRef]

- Constantinescu, G.; Rasekh, S.; Torres, M.A.; Madre, M.A.; Diez, J.C.; Sotelo, A. Enhancement of the high-temperature thermoelectric performance of Bi2Ba2Co2Ox. Scr. Mater. 2013, 68, 75–78. [Google Scholar] [CrossRef] [Green Version]

- Maignan, A.; Hebert, S.; Hervieu, M.; Michel, C.; Pelloquin, D.; Khomskii, D. Magnetoresistance and magnetothermopower properties of Bi/Ca/Co/O and Bi(Pb)/Ca/Co/O misfit layer cobaltites. J. Phys. Condens. Matter 2003, 15, 2711–2723. [Google Scholar] [CrossRef]

- Butt, S.; Liu, Y.-C.; Lan, J.-L.; Shehzad, K.; Zhan, B.; Li, Y.; Nan, C.-W. High-temperature thermoelectric properties of La and Fe co-doped Ca-Co-O misfit-layered cobaltites consolidated by spark plasma sintering. J. Alloys Compd. 2014, 588, 277–283. [Google Scholar] [CrossRef]

- Wang, H.; Sun, X.; Yan, X.; Huo, D.; Li, X.; Li, L.-G.; Ding, X. Fabrication and thermoelectric properties of highly textured Ca9Co12O28 ceramic. J. Alloys Compd. 2014, 582, 294–298. [Google Scholar] [CrossRef]

- Diez, J.C.; Rasekh, S.; Madre, M.A.; Guilmeau, E.; Marinel, S.; Sotelo, A. Improved Thermoelectric Properties of Bi-M-Co-O (M = Sr, Ca) Misfit Compounds by Laser Directional Solidification. J. Electron. Mater. 2010, 39, 1601–1605. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, N.M.; Rasekh, S.; Costa, F.M.; Madre, M.A.; Sotelo, A.; Diez, J.C.; Torres, M.A. New method to improve the grain alignment and performance of thermoelectric ceramics. Mater. Lett. 2012, 83, 144–147. [Google Scholar] [CrossRef] [Green Version]

- Vogel-Schauble, N.; Dujardin, R.; Weidenkaff, A.; Aguirre, M.H. Influence of Thermal Aging Phenomena on Thermoelectric Properties of Al-Substituted ZnO. J. Electron. Mater. 2012, 41, 1606–1614. [Google Scholar] [CrossRef]

- Park, K.; You, S.; Ur, S.; Kim, I.; Choi, S.; Seo, W. High-Temperature Stability of Thermoelectric Skutterudite In0.25Co3FeSb12. J. Electron. Mater. 2012, 4, 1051–1056. [Google Scholar] [CrossRef]

- Diez, J.C.; Rasekh, S.; Constantinescu, G.; Madre, M.A.; Torres, M.A.; Sotelo, A. Effect of annealing on the thermoelectric properties of directionally grown Bi2Sr2Co1.8Ox ceramics. Ceram. Int. 2012, 38, 5419–5424. [Google Scholar] [CrossRef] [Green Version]

- Costa, F.M.; Ferreira, N.M.; Rasekh, S.; Fernandes, A.J.S.; Torres, M.A.; Madre, M.A.; Diez, J.C.; Sotelo, A. Very Large Superconducting Currents Induced by Growth Tailoring. Cryst. Growth Des. 2015, 15, 2094–2101. [Google Scholar] [CrossRef]

- Kennedy, B.J.; Howard, C.J.; Knight, K.S.; Zhang, Z.; Zhou, Q. Structures and phase transitions in the ordered double perovskites Ba2BiIIIBiVO6 and Ba2BiIIISbVO6. Acta Cryst. B 2006, 62, 537–546. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, F.; Diez, J.C.; Rasekh, S.; Madre, M.A.; Torres, M.A.; Sotelo, A. The effect of environmental conditions on the mechanical and thermoelectric properties of Bi2Ca2Co1.7Ox textured materials. Ceram. Int. 2015, 41, 6358–6363. [Google Scholar] [CrossRef]

- Kahraman, F.; Sotelo, A.; Madre, M.A.; Rasekh, S.; Torres, M.A.; Diez, J.C. Mechanical and thermoelectric environmental evolution properties of Bi2Sr2Co1.8Ox ceramics textured by laser floating zone technique. J. Mater. Sci. Mater. Electron. 2015, 26, 1461–1465. [Google Scholar] [CrossRef]

- Kahraman, F.; Madre, M.A.; Rasekh, S.; Salvador, C.; Bosque, P.; Torres, M.A.; Diez, J.C.; Sotelo, A. Enhancement of mechanical and thermoelectric properties of Ca3Co4O9 by Ag addition. J. Eur. Ceram. Soc. 2015, 35, 3835–3841. [Google Scholar] [CrossRef]

- Noudem, J.G.; Kenfaui, D.; Chateigner, D.; Gomina, M. Granular and Lamellar Thermoelectric Oxides Consolidated by Spark Plasma Sintering. J. Electron. Mater. 2011, 40, 1100–1106. [Google Scholar] [CrossRef]

- Rogl, G.; Rogl, P. Mechanical Properties of Skutterudites. Sci. Adv. Mater. 2011, 3, 517–538. [Google Scholar] [CrossRef]

- Bathula, S.; Gahtori, B.; Jayasimhadri, M.; Tripathy, S.K.; Tyagi, K.; Srivastava, A.K.; Dhar, A. Microstructure and mechanical properties of thermoelectric nanostructured n-type silicon-germanium alloys synthesized employing spark plasma sintering. Appl. Phys. Lett. 2014, 105, 061902. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Gürth, M.; Tavassoli, A.; Ebner, C.; Wünschek, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Bauer, E.; et al. Mechanical properties of half-Heusler alloys. Acta Mater. 2016, 107, 178–195. [Google Scholar] [CrossRef]

- Gahlawat, S.; He, R.; Chen, S.; Wheeler, L.; Ren, Z.; White, K. Elastic constants determined by nanoindentation for p-type thermoelectric half-Heusler. J. Appl. Phys. 2014, 116, 083516. [Google Scholar] [CrossRef]

- He, R.; Gahlawat, S.; Guo, C.; Chen, S.; Dahal, T.; Zhang, H.; Liu, W.; Zhang, Q.; Chere, E.; White, K. Studies on mechanical properties of thermoelectric materials by nanoindentation. Phys. Status Solidi A 2015, 212, 2191–2195. [Google Scholar] [CrossRef]

- Rasekh, S.; Constantinescu, G.; Torres, M.A.; Madre, M.A.; Diez, J.C.; Sotelo, A. Growth rate effect on microstructure and thermoelectric properties of melt grown Bi2Ba2Co2Ox textured ceramics. Adv. Appl. Ceram. 2012, 111, 490–495. [Google Scholar] [CrossRef]

- Motohashi, T.; Nonaka, Y.; Sakai, K.; Karppinen, M.; Yamauchi, H. Fabrication and thermoelectric characteristics of [(Bi,Pb)2Ba2O4±w]0.5CoO2 bulks with highly aligned grain structure. J. Appl. Phys. 2008, 103, 033705. [Google Scholar] [CrossRef]

- Madre, M.A.; Costa, F.M.; Ferreira, N.M.; Costa, S.I.R.; Rasekh, S.; Torres, M.A.; Diez, J.C.; Amaral, V.S.; Amaral, J.S.; Sotelo, A. High thermoelectric performance in Bi2−xPbxBa2Co2Oy promoted by directional growth and annealing. J. Eur. Ceram. Soc. 2016, 36, 67–74. [Google Scholar] [CrossRef]

- Luo, X.G.; Chen, H.; Wang, G.Y.; Wu, G.; Wu, T.; Zhao, L.; Chen, X.H. Transport properties and magnetic-field-induced localization in the misfit cobaltite [Bi2Ba1.3K0.6Co0.1O4]RS[CoO2]1.97 single crystal. J. Phys. Condens. Matter 2008, 20, 215221. [Google Scholar] [CrossRef]

- Koshibae, W.; Tsutsui, S.; Maekawa, S. Thermopower in cobalt oxides. Phys. Rev. B 2000, 62, 6869–6872. [Google Scholar] [CrossRef]

- Hao, H.; Yu, H.; Zhao, L. Thermoelectric characteristics of Pb- and La-doped Bi2Ba2Co2Oy ceramics. Adv. Mater. Res. 2011, 228–229, 804–808. [Google Scholar] [CrossRef]

- Ang, R.; Sun, Y.P.; Luo, X.; Song, W.H. A narrow band contribution with Anderson localization in Ag-doped layered cobaltites Bi2Ba3Co2Oy. J. Appl. Phys. 2007, 102, 073721. [Google Scholar] [CrossRef]

- Hervieu, M.; Maignan, A.; Michel, C.; Hardy, V.; Creon, N.; Raveau, B. Metallicity and thermopower of the misfit cobaltite [Bi2Ba1.8Co0.2O4]RS[CoO2]2. Phys. Rev. B 2003, 67, 045112. [Google Scholar] [CrossRef]

- Sakai, K.; Motohashi, T.; Karppinen, M.; Yamauchi, H. Enhancement in thermoelectric characteristics of the misfit-layered cobalt oxide, [(Bi,Pb)2Ba1.8Co0.2O4±ω]0.5CoO2, through Pb-for-Bi substitution. Thin Solid Films 2005, 486, 58–62. [Google Scholar] [CrossRef]

- Sakai, K.; Karppinen, M.; Chen, J.M.; Liu, R.S.; Sugihara, S.; Yamauchi, H. Pb-for-Bi substitution for enhancing thermoelectric characteristics of [(Bi,Pb)2Ba2O4±ω]0.5CoO2. Appl. Phys. Lett. 2006, 88, 232102. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diez, J.C.; Madre, M.A.; Torres, M.A.; Rasekh, S.; Sotelo, A. Long-Term High-Temperature Stability of Directionally Grown [Bi2Ba2O4]p[CoO2] Rods. Materials 2017, 10, 146. https://doi.org/10.3390/ma10020146

Diez JC, Madre MA, Torres MA, Rasekh S, Sotelo A. Long-Term High-Temperature Stability of Directionally Grown [Bi2Ba2O4]p[CoO2] Rods. Materials. 2017; 10(2):146. https://doi.org/10.3390/ma10020146

Chicago/Turabian StyleDiez, Juan C., María A. Madre, Miguel A. Torres, Shahed Rasekh, and Andrés Sotelo. 2017. "Long-Term High-Temperature Stability of Directionally Grown [Bi2Ba2O4]p[CoO2] Rods" Materials 10, no. 2: 146. https://doi.org/10.3390/ma10020146