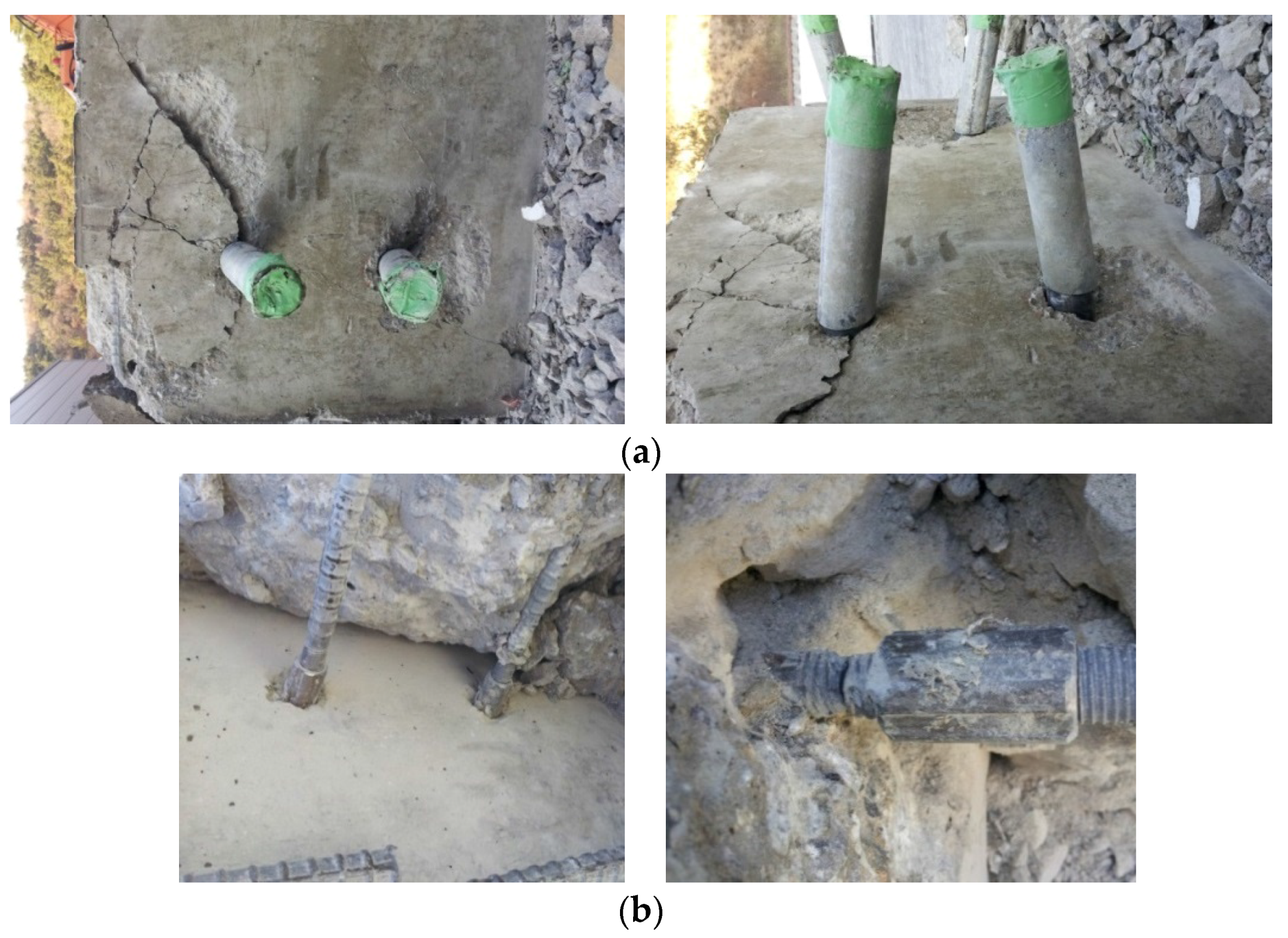

Figure 1.

Installation overview of loop bars: (a) front view; (b) plan view.

Figure 1.

Installation overview of loop bars: (a) front view; (b) plan view.

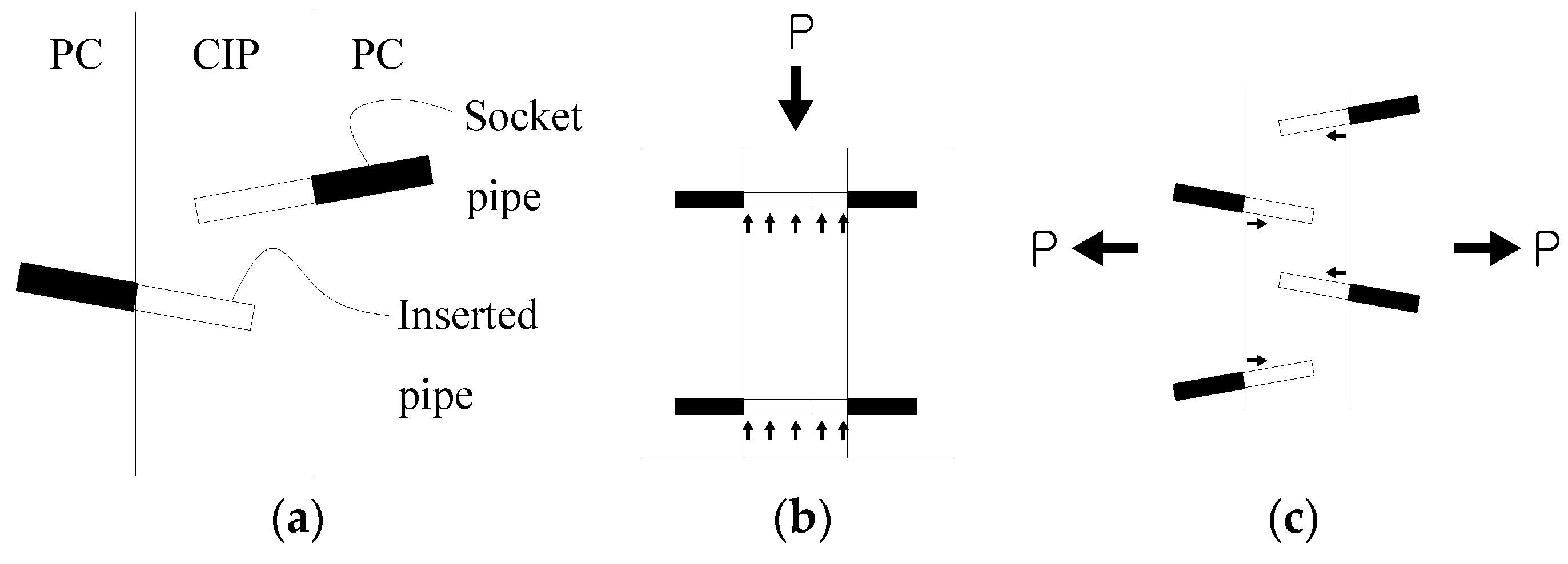

Figure 2.

Installation overview and resistance mechanisms of skewed pipe shear connectors: (a) installation overview (plan view); (b) shear resistance (front view); (c) pull-out resistance (plan view).

Figure 2.

Installation overview and resistance mechanisms of skewed pipe shear connectors: (a) installation overview (plan view); (b) shear resistance (front view); (c) pull-out resistance (plan view).

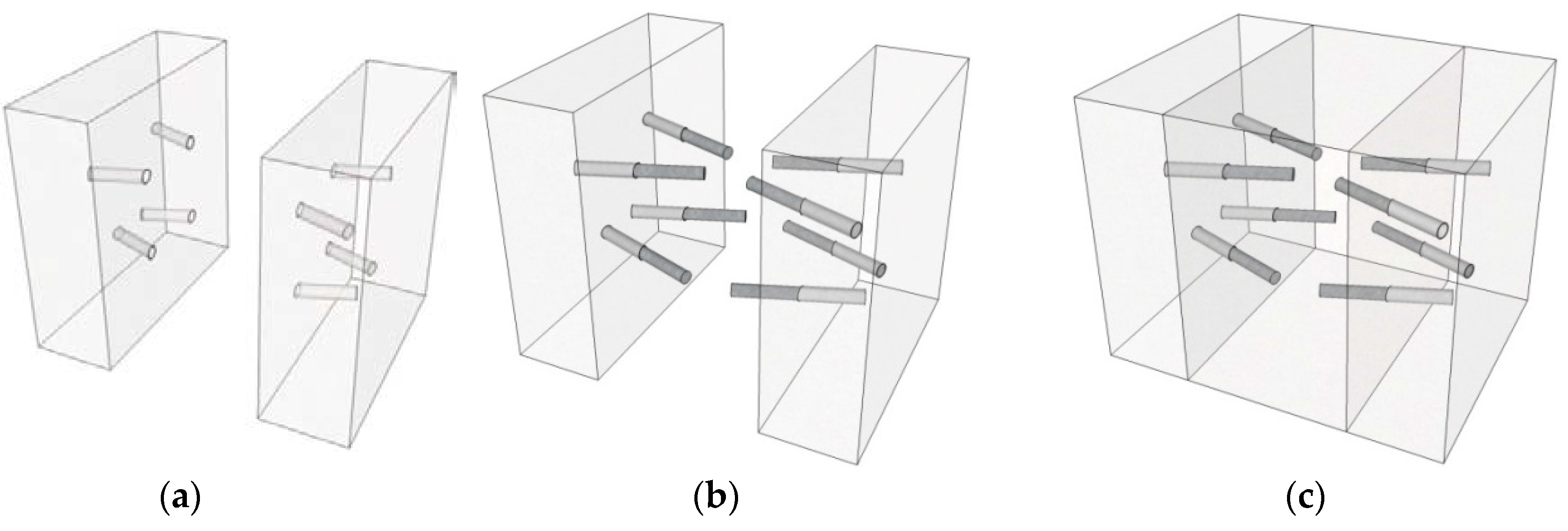

Figure 3.

Installation process of skewed pipe shear connectors: (a) socket pipe installation, formwork, and concrete cast; (b) mold removal and pipe insertion; (c) pouring concrete (CIP).

Figure 3.

Installation process of skewed pipe shear connectors: (a) socket pipe installation, formwork, and concrete cast; (b) mold removal and pipe insertion; (c) pouring concrete (CIP).

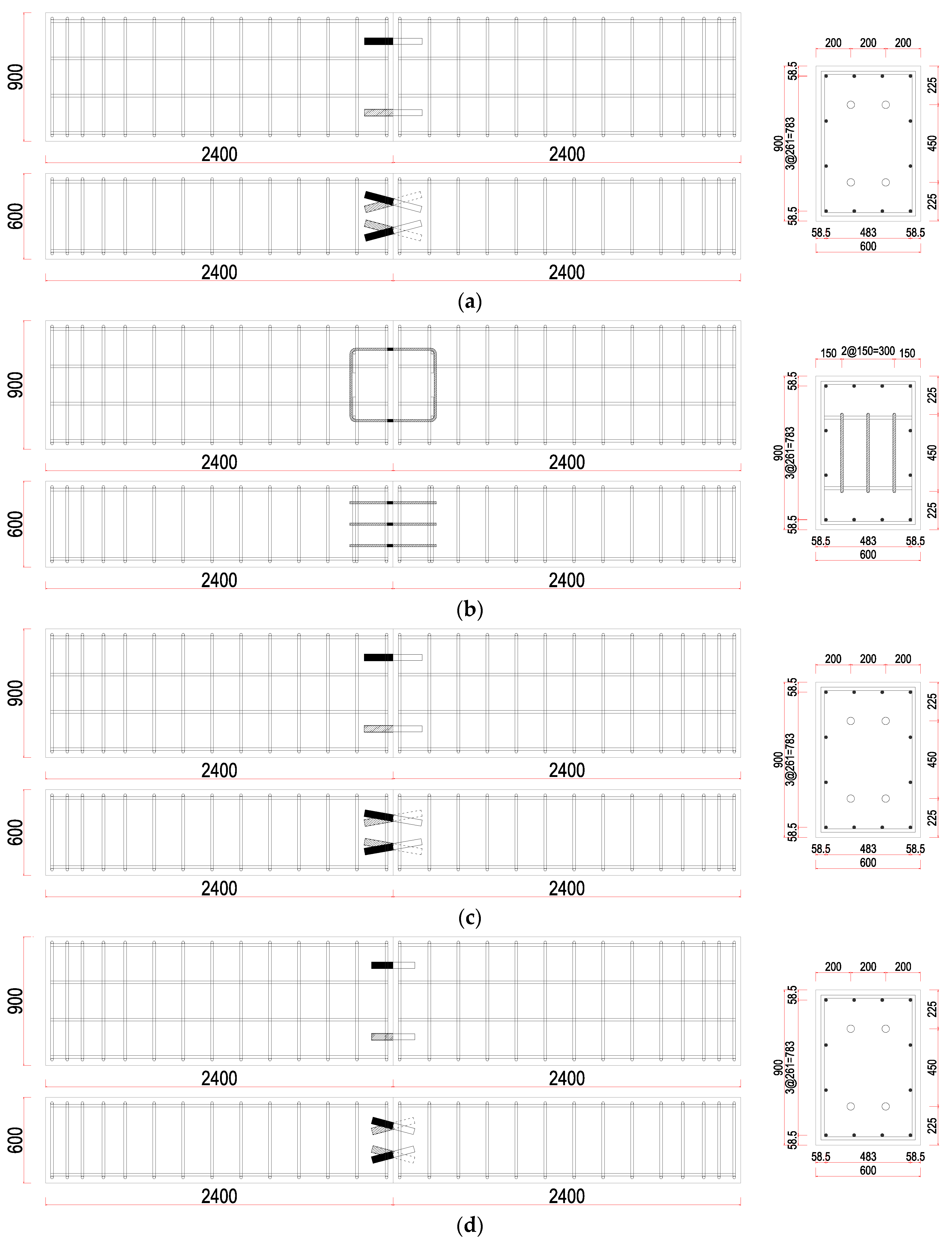

Figure 4.

Layout of specimens for push-out tests (unit: mm): (a) skewed pipe shear connector (Reference); (b) loop bar; (c) skewed pipe shear connector (D = 21.7); (d) skewed pipe shear connector (L = 150).

Figure 4.

Layout of specimens for push-out tests (unit: mm): (a) skewed pipe shear connector (Reference); (b) loop bar; (c) skewed pipe shear connector (D = 21.7); (d) skewed pipe shear connector (L = 150).

Figure 5.

Layout of specimens for pull-out tests (unit: mm): (a) skewed pipe shear connector (Reference); (b) loop bar; (c) skewed pipe shear connector (A = 10); (d) skewed pipe shear connector (L = 150).

Figure 5.

Layout of specimens for pull-out tests (unit: mm): (a) skewed pipe shear connector (Reference); (b) loop bar; (c) skewed pipe shear connector (A = 10); (d) skewed pipe shear connector (L = 150).

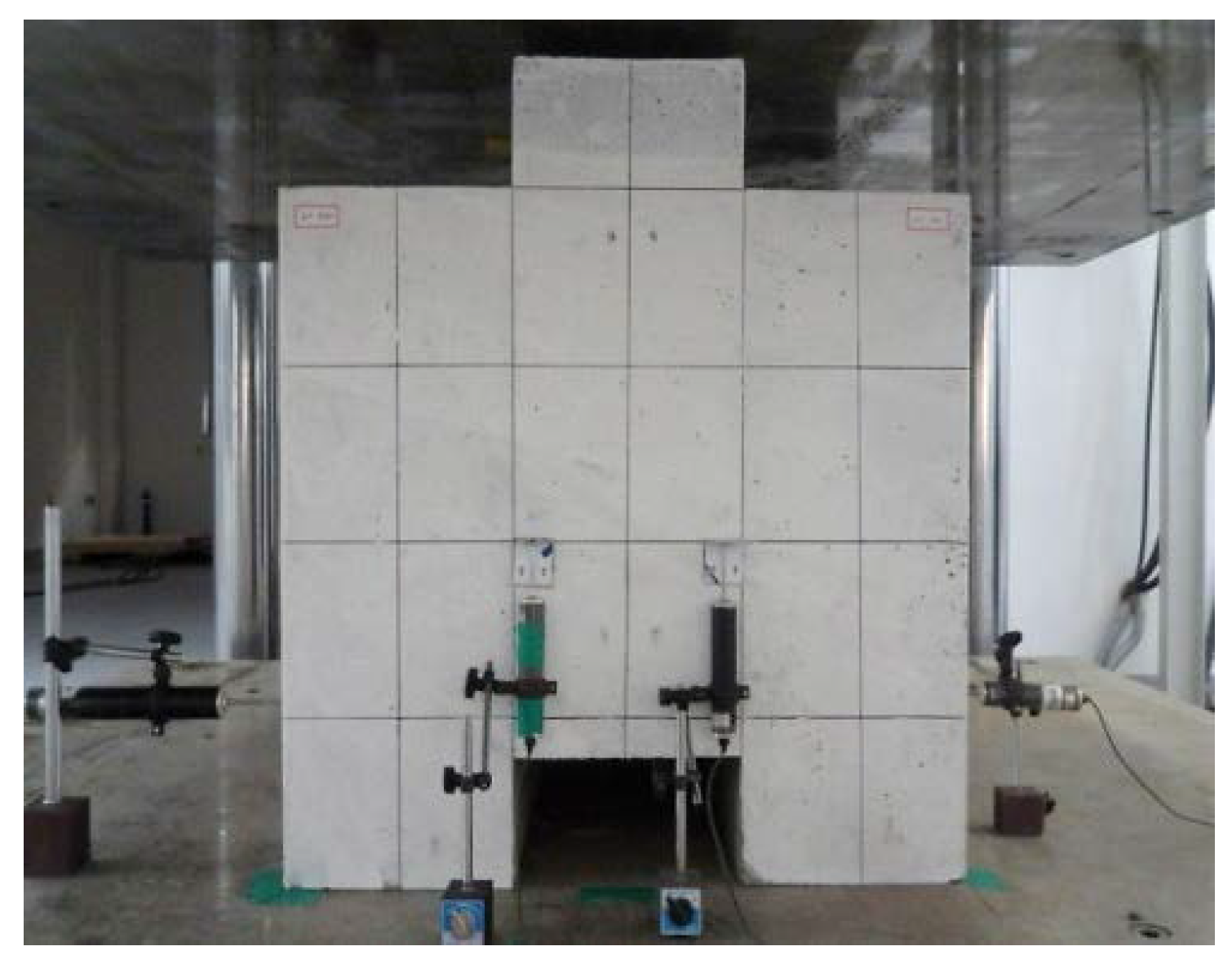

Figure 6.

Push-out test set-up.

Figure 6.

Push-out test set-up.

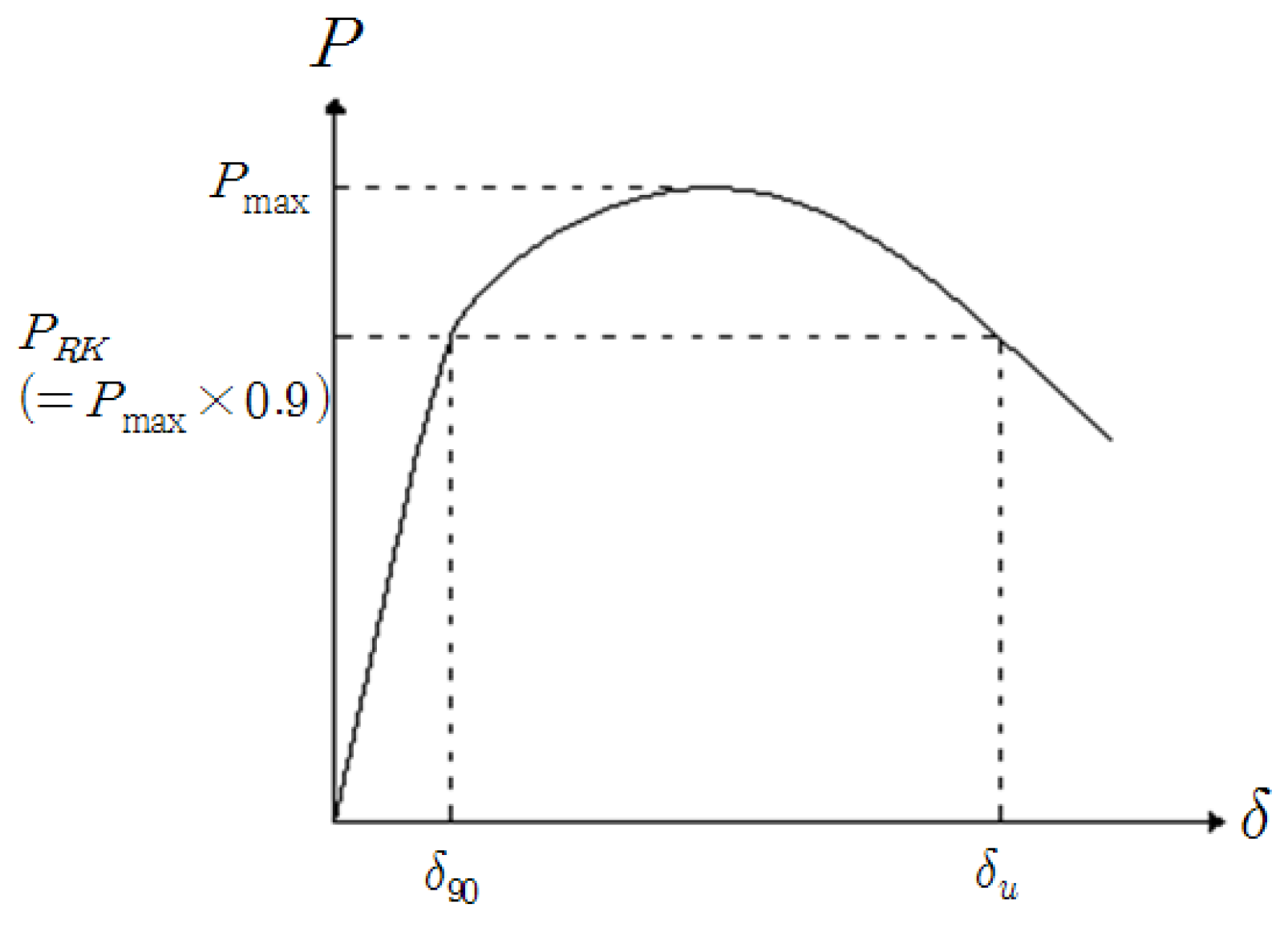

Figure 7.

Evaluation method of test results.

Figure 7.

Evaluation method of test results.

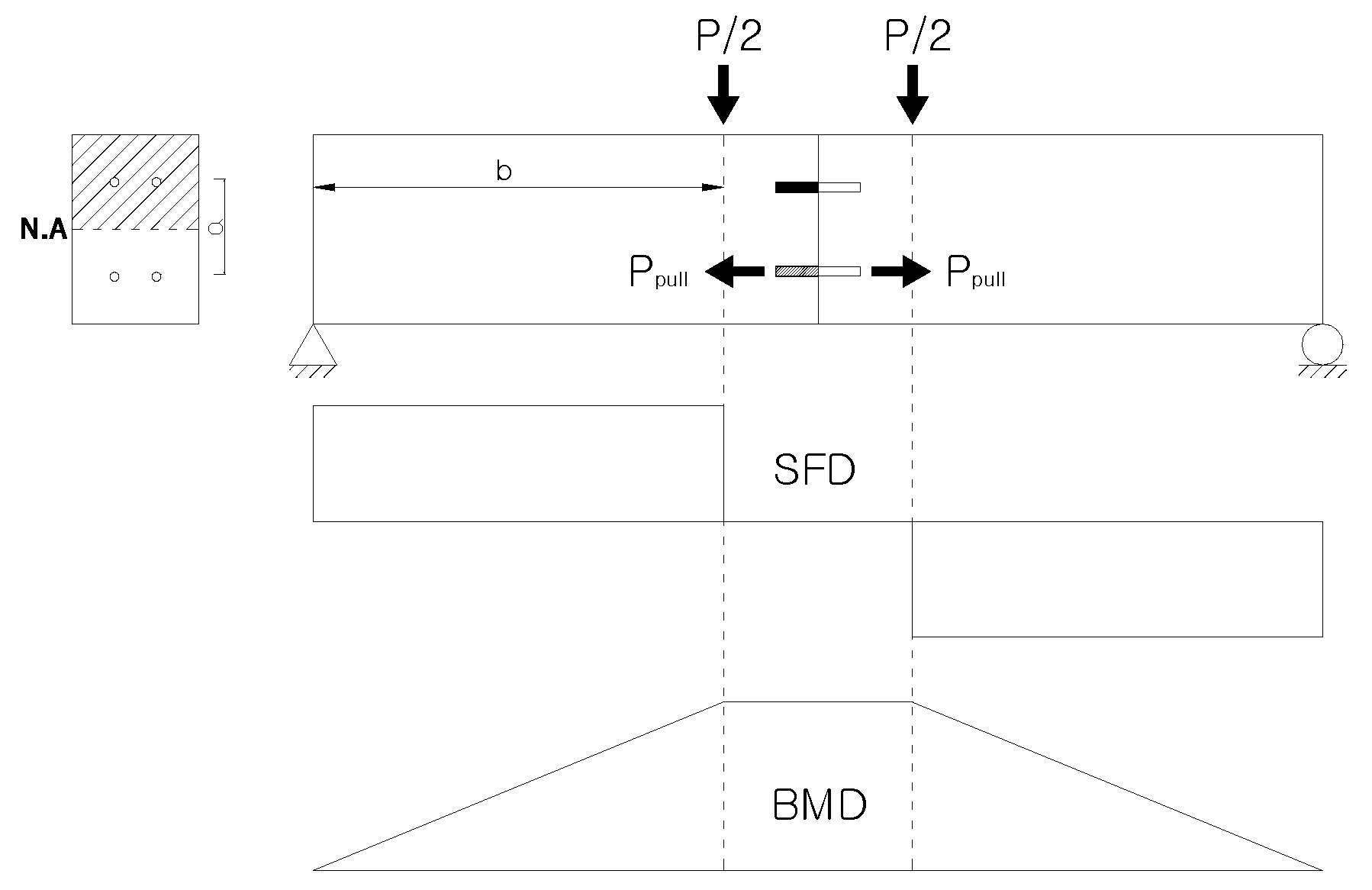

Figure 8.

Overview of pull-out test.

Figure 8.

Overview of pull-out test.

Figure 9.

Pull-out test setup.

Figure 9.

Pull-out test setup.

Figure 10.

Comparison of load-relative slip relationships in pipe shear connectors and loop bars (push-out test).

Figure 10.

Comparison of load-relative slip relationships in pipe shear connectors and loop bars (push-out test).

Figure 11.

Comparison of load-relative slip relationships of different inserted pipe diameter specimens (push-out test).

Figure 11.

Comparison of load-relative slip relationships of different inserted pipe diameter specimens (push-out test).

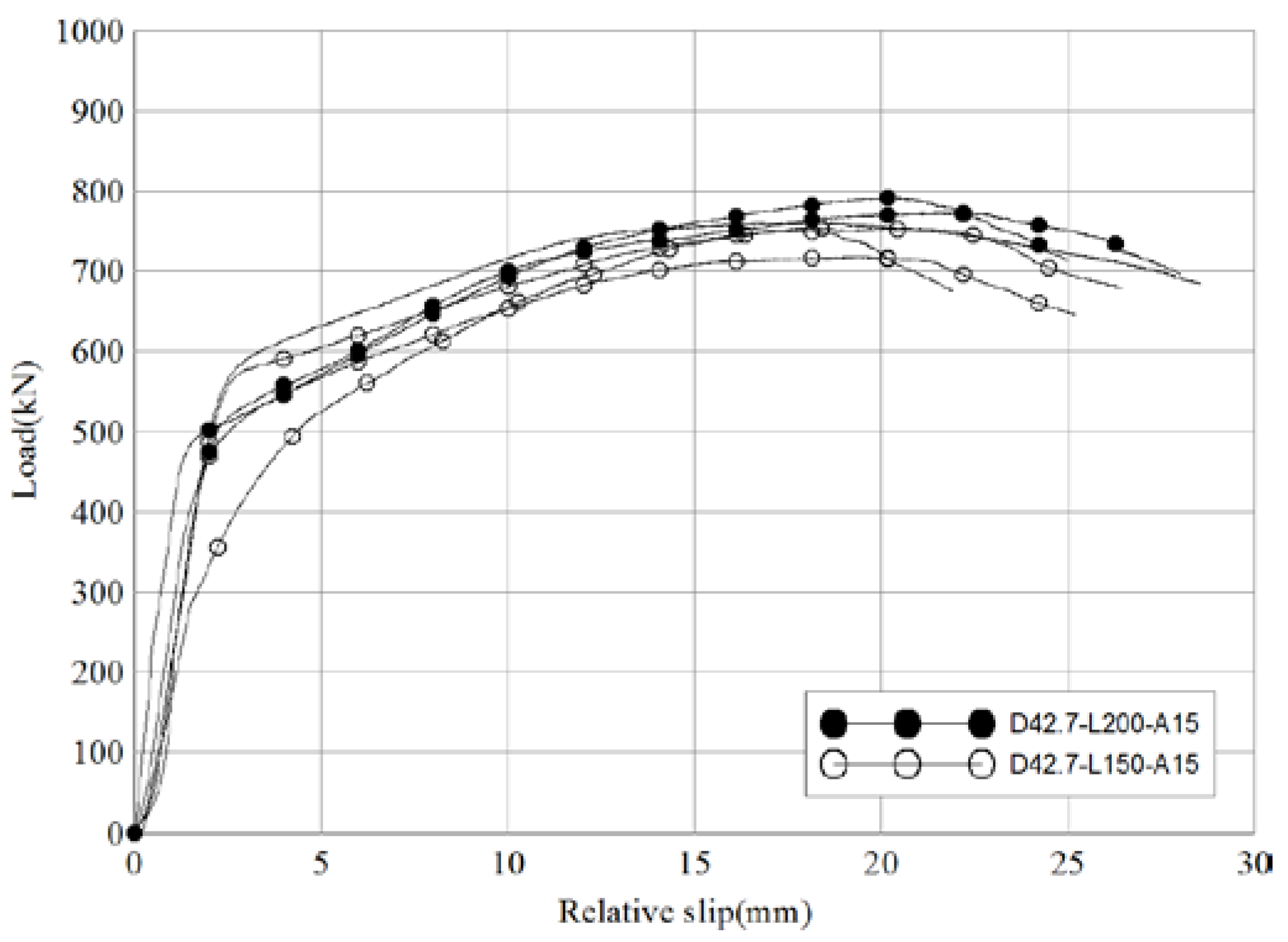

Figure 12.

Comparison of load-relative slip relationships of different pipe length specimens (push-out test).

Figure 12.

Comparison of load-relative slip relationships of different pipe length specimens (push-out test).

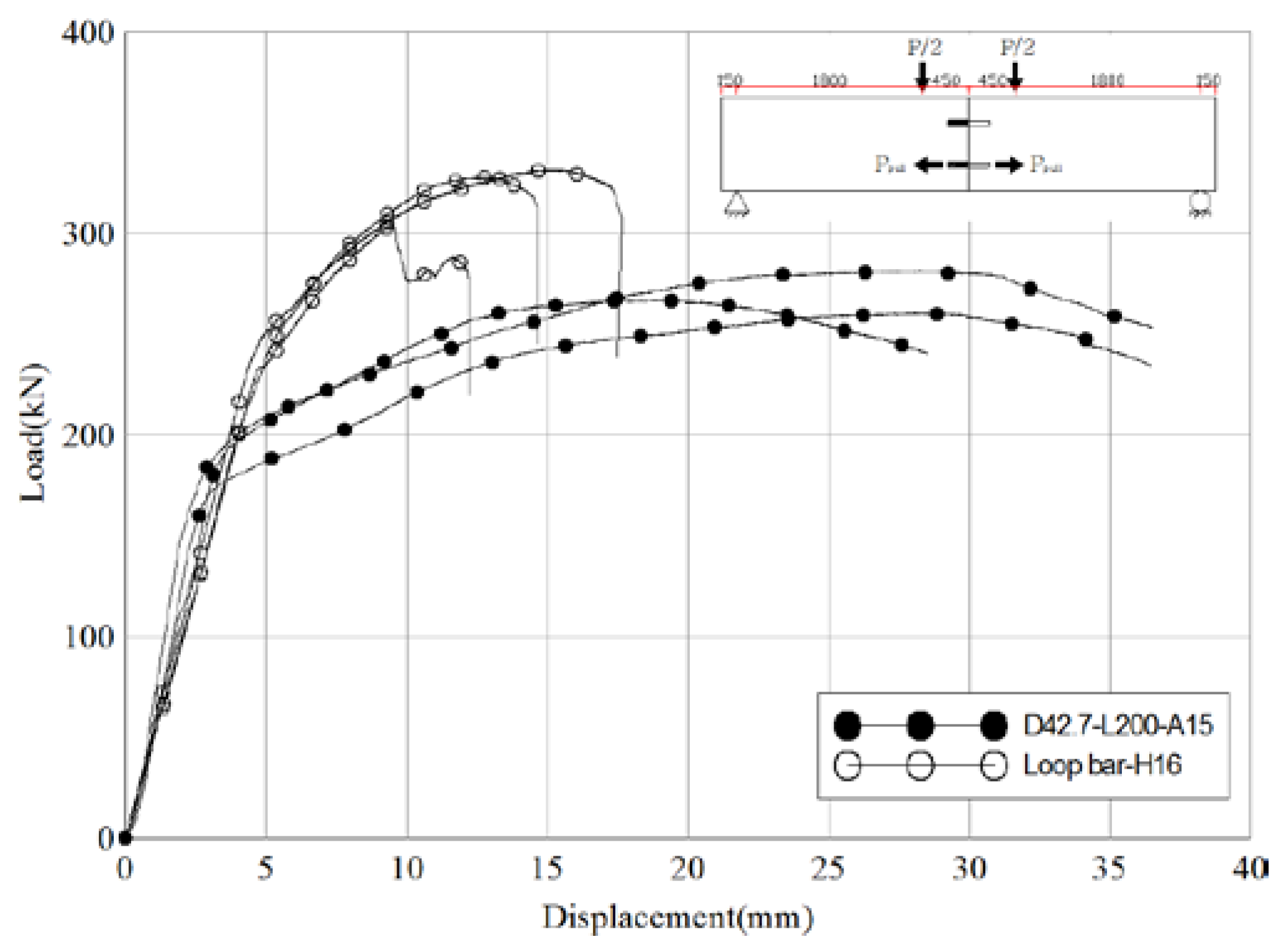

Figure 13.

Comparison of load-displacements of different shear connector types (pull-out test).

Figure 13.

Comparison of load-displacements of different shear connector types (pull-out test).

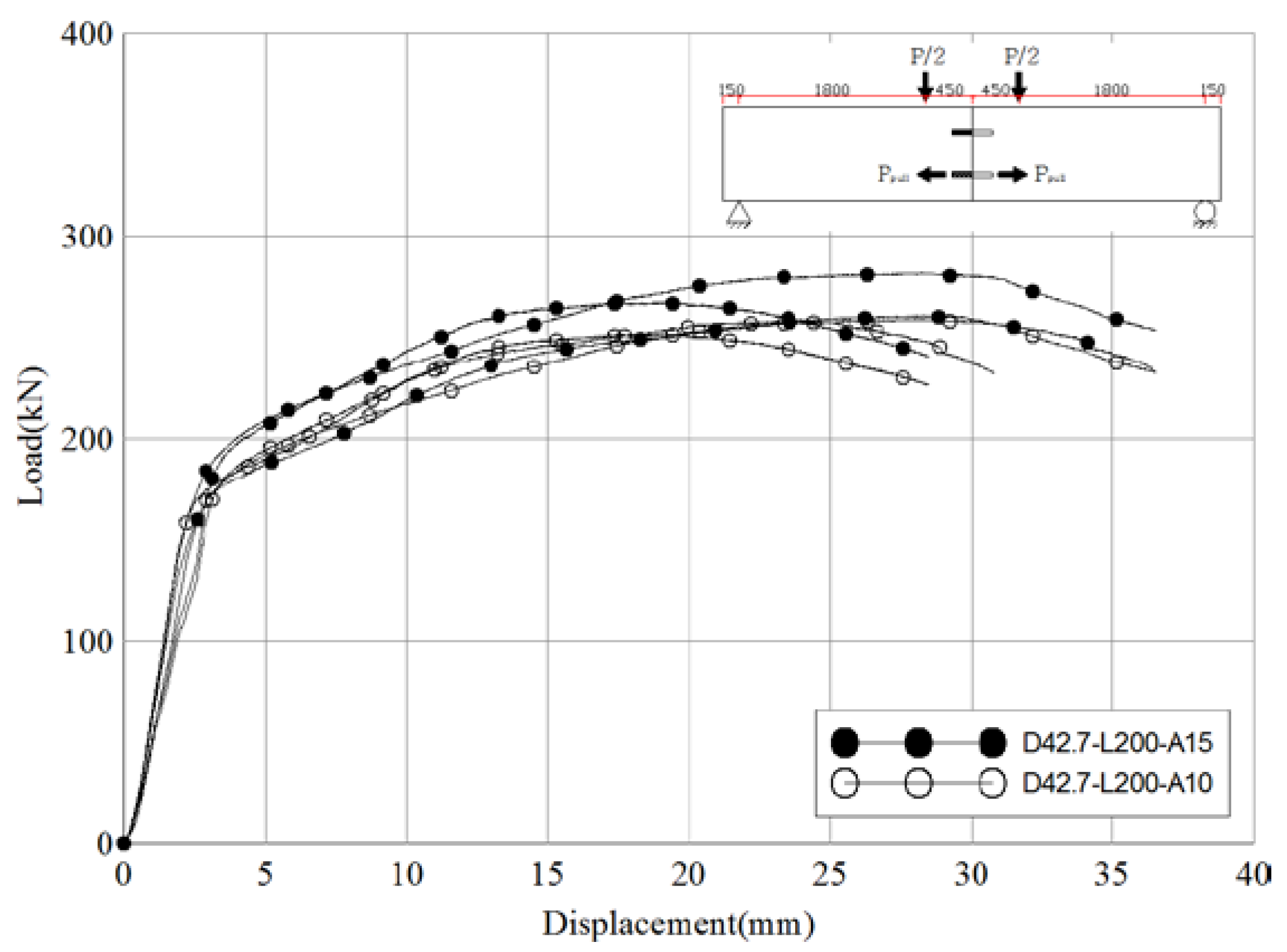

Figure 14.

Comparison of load-displacement of different pipe insertion angle specimens (pull-out test).

Figure 14.

Comparison of load-displacement of different pipe insertion angle specimens (pull-out test).

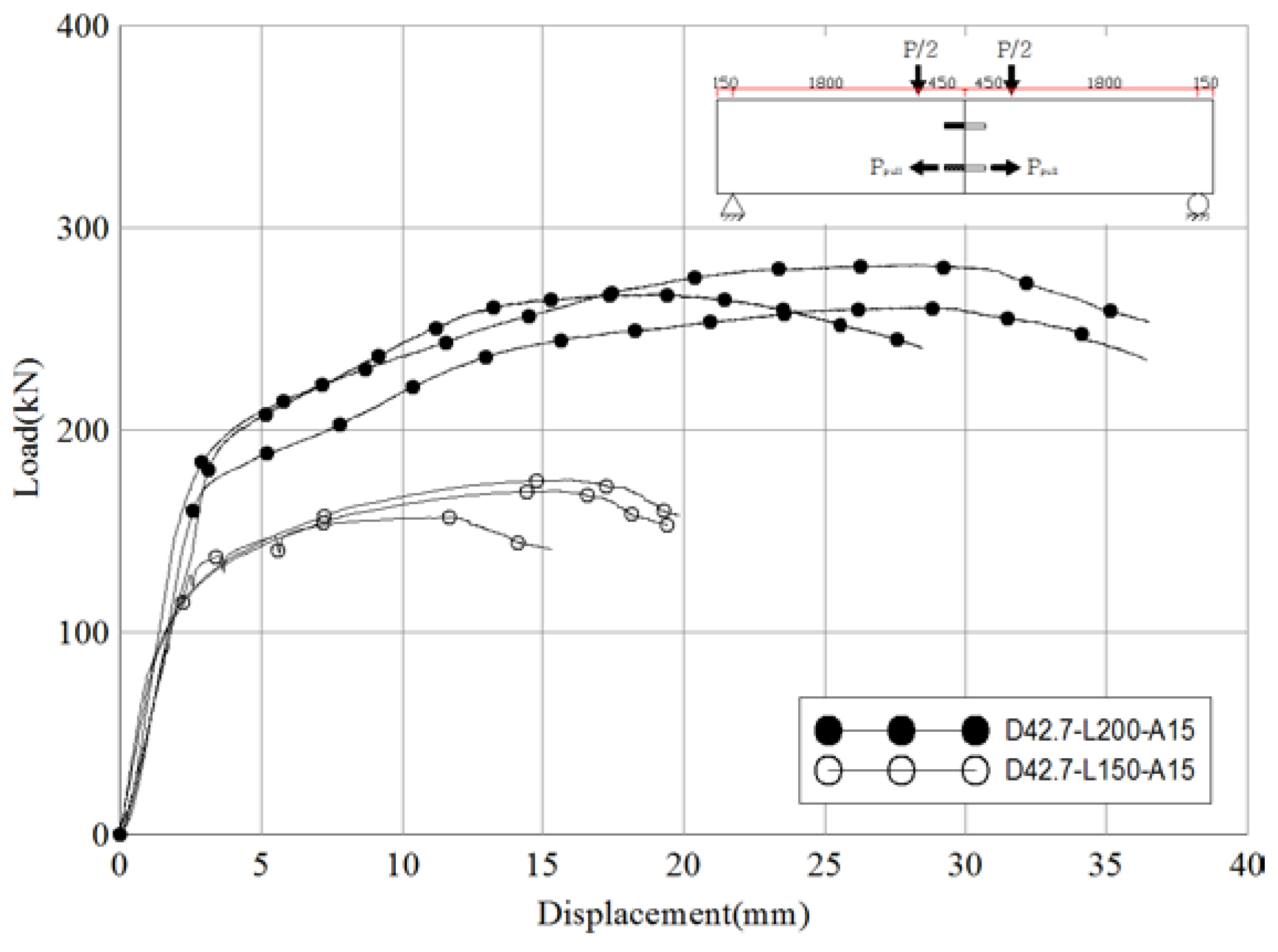

Figure 15.

Comparison of load-displacement of different pipe length specimens (pull-out test).

Figure 15.

Comparison of load-displacement of different pipe length specimens (pull-out test).

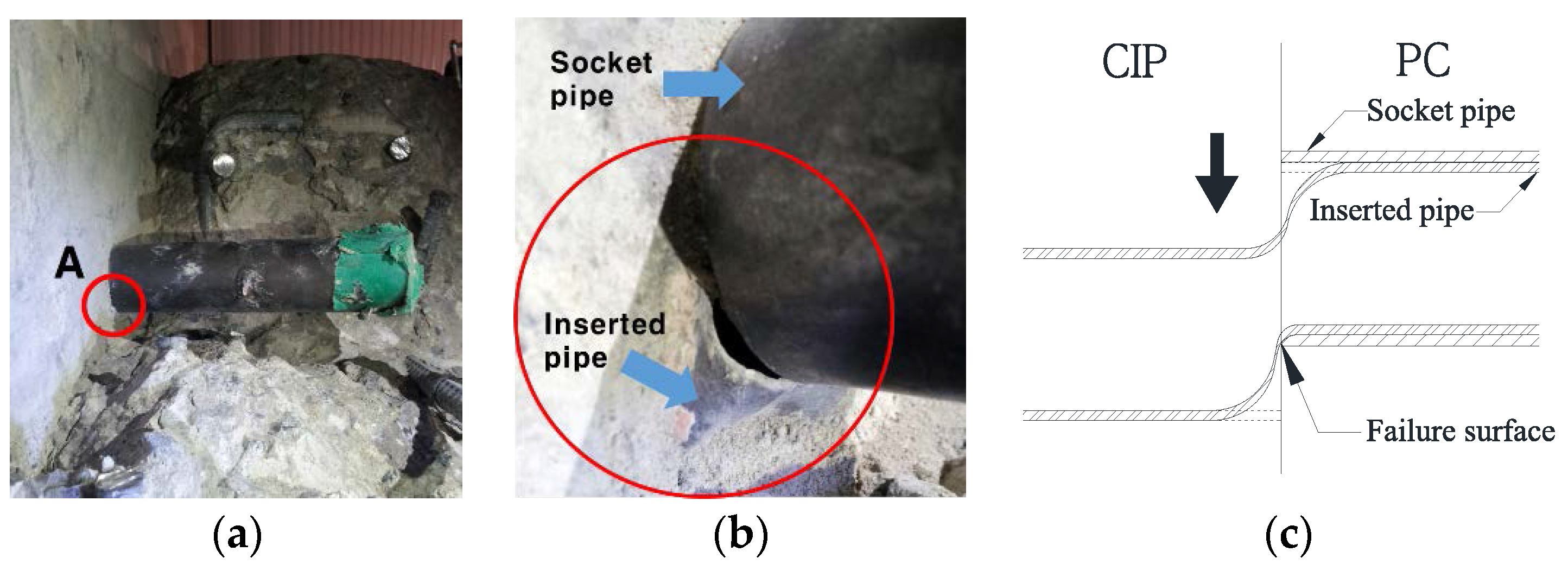

Figure 16.

Shear failure of a skewed pipe shear connector: (a) shape of failure; (b) close-up: part A; (c) overview of shear failure.

Figure 16.

Shear failure of a skewed pipe shear connector: (a) shape of failure; (b) close-up: part A; (c) overview of shear failure.

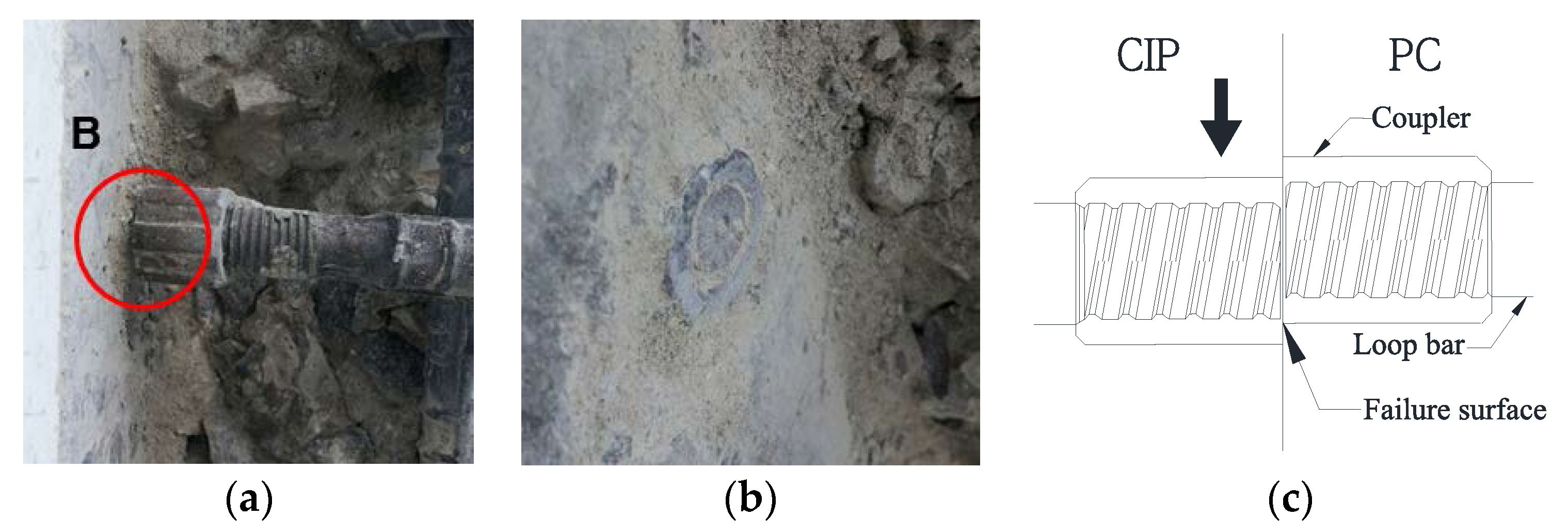

Figure 17.

Shear failure of a loop bar: (a) shape of failure; (b) close-up: part B; (c) overview of shear failure.

Figure 17.

Shear failure of a loop bar: (a) shape of failure; (b) close-up: part B; (c) overview of shear failure.

Figure 18.

Crack shape after pull-out test: (a) skewed pipe shear connector specimen; (b) loop bar specimen.

Figure 18.

Crack shape after pull-out test: (a) skewed pipe shear connector specimen; (b) loop bar specimen.

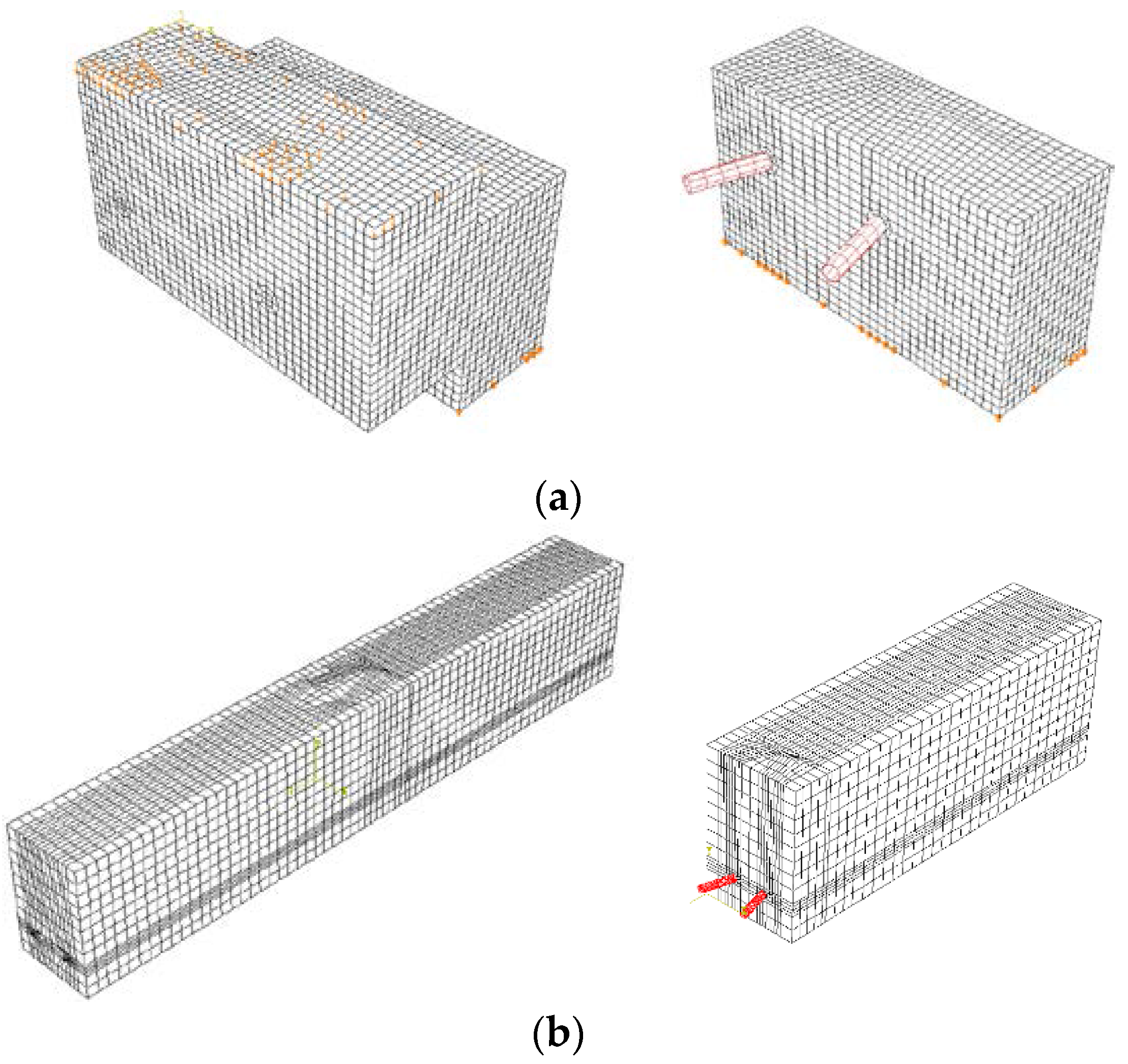

Figure 19.

Finite element mesh: (a) model of push-out test specimen; (b) model of pull-out test specimen.

Figure 19.

Finite element mesh: (a) model of push-out test specimen; (b) model of pull-out test specimen.

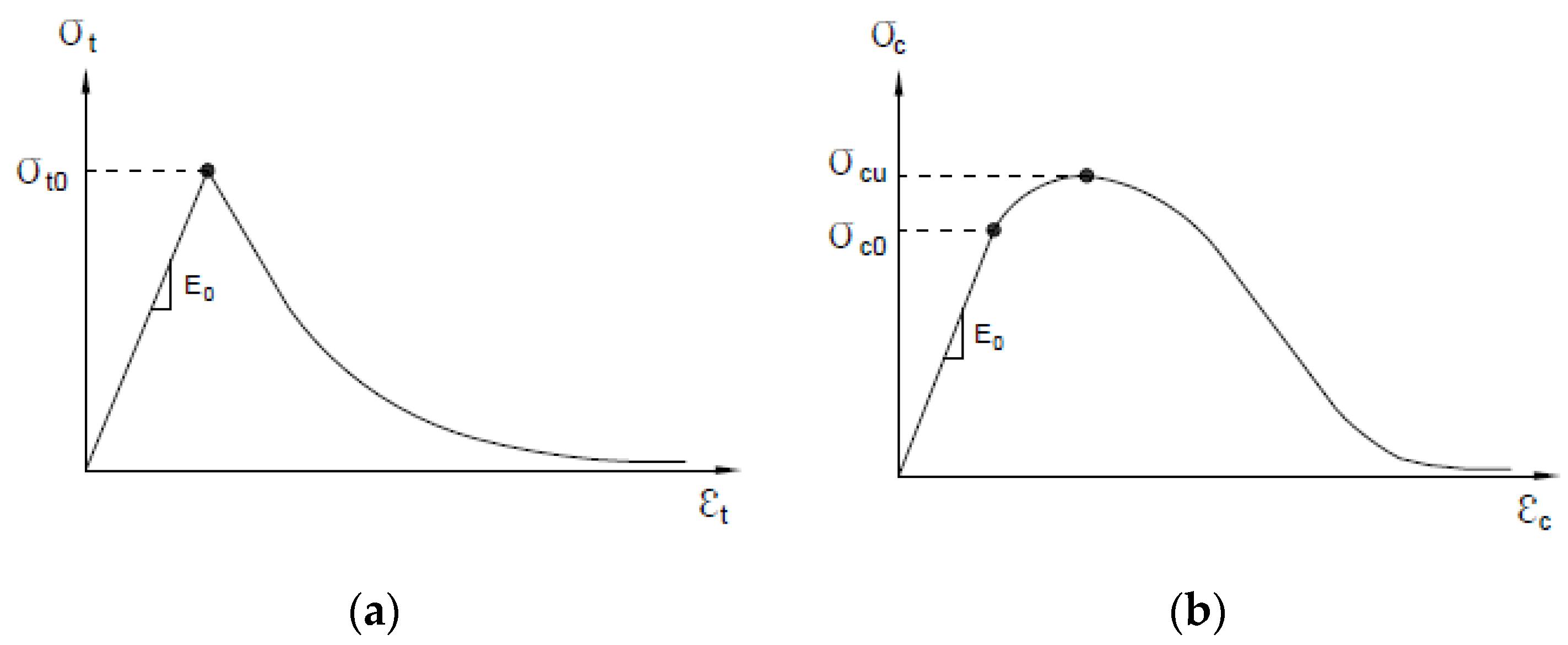

Figure 20.

Stress–strain relationship of the concrete damaged plasticity model: (a) uniaxial tension model; (b) uniaxial compression model.

Figure 20.

Stress–strain relationship of the concrete damaged plasticity model: (a) uniaxial tension model; (b) uniaxial compression model.

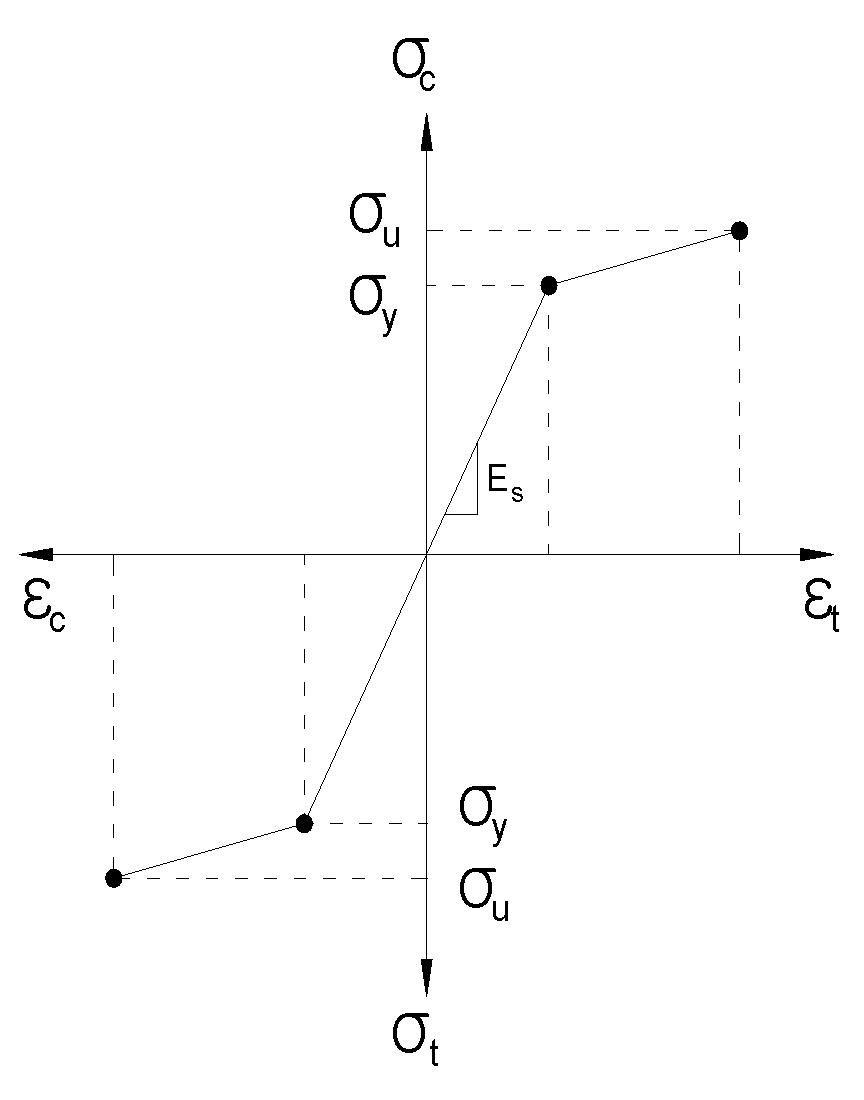

Figure 21.

Stress–strain relationship of classical metal plastic model.

Figure 21.

Stress–strain relationship of classical metal plastic model.

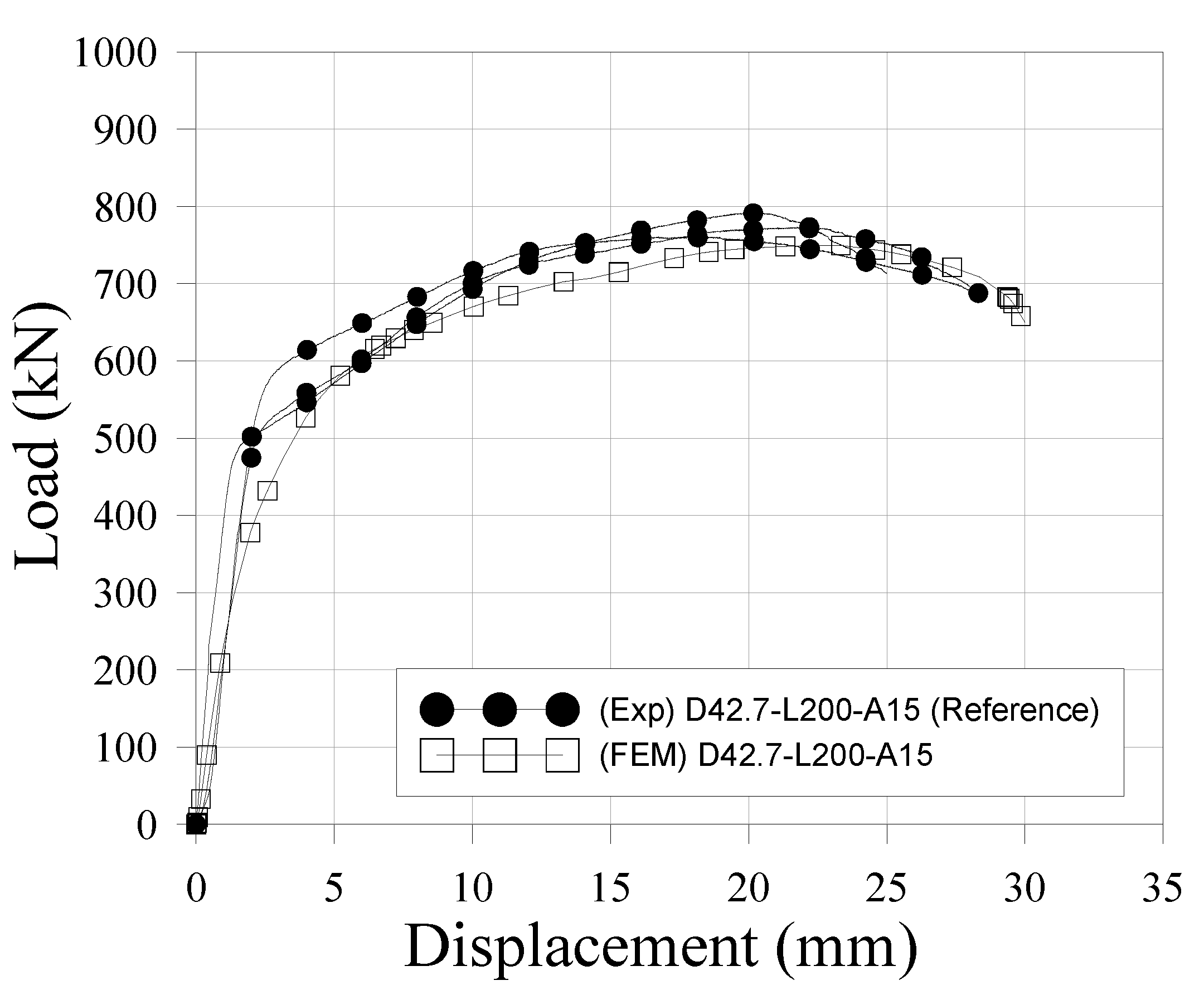

Figure 22.

Load-relative slip characteristics of push-out test.

Figure 22.

Load-relative slip characteristics of push-out test.

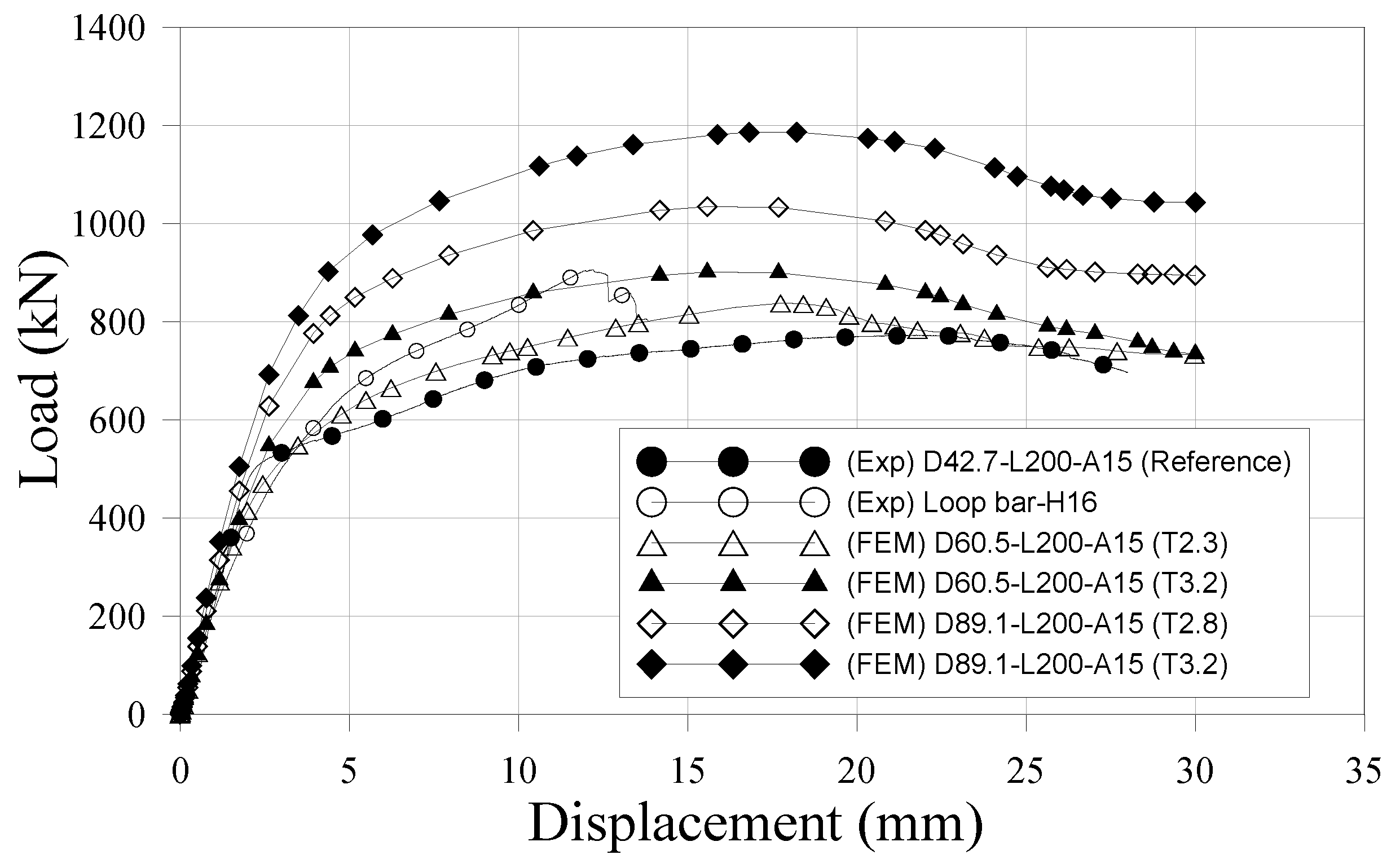

Figure 23.

Comparison of experimental and numerical results (push-out test).

Figure 23.

Comparison of experimental and numerical results (push-out test).

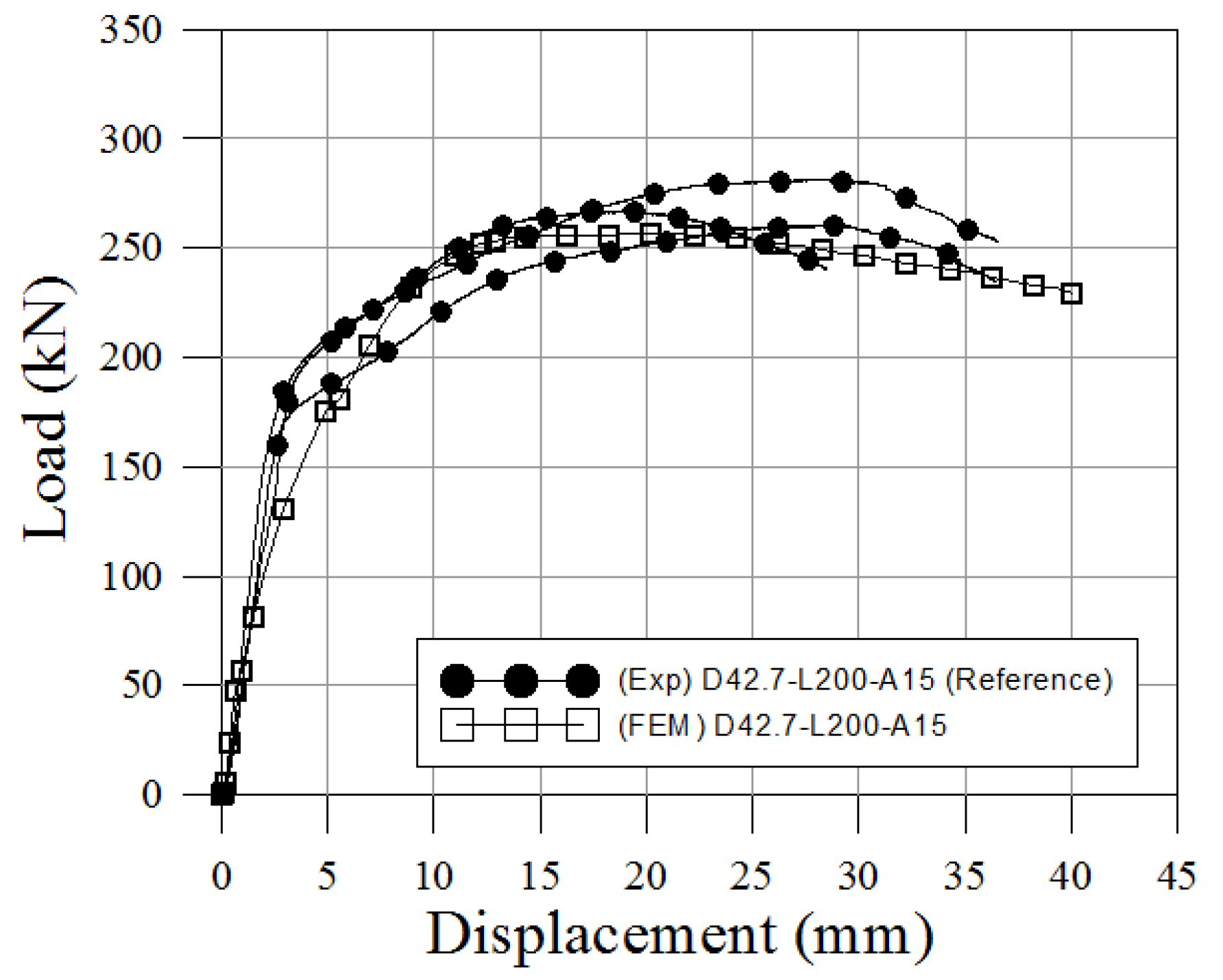

Figure 24.

Load-displacements of the pull-out test.

Figure 24.

Load-displacements of the pull-out test.

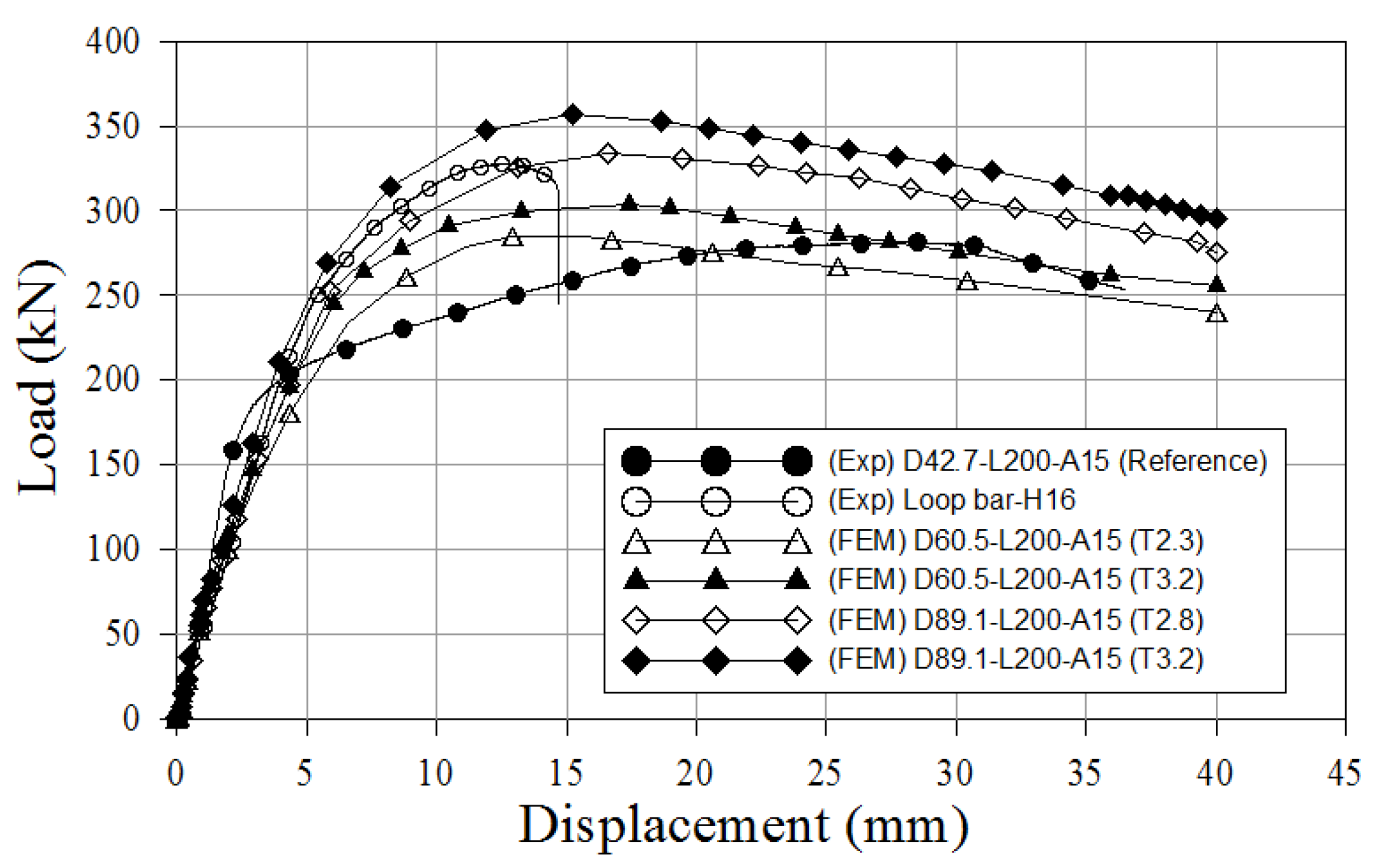

Figure 25.

Comparison of experimental and numerical results (pull-out test).

Figure 25.

Comparison of experimental and numerical results (pull-out test).

Table 1.

Material properties of the connectors [

12].

Table 1.

Material properties of the connectors [

12].

| Connectors | Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|

| Loop bar | SD 400 | 400 | 560 |

| Skewed pipe shear connector | STK 400 | 235 | 400 |

Table 2.

Dimensions of the structural steel pipe.

Table 2.

Dimensions of the structural steel pipe.

| Pipe Type | External Diameter (mm) | Thickness (mm) | Internal Diameter (mm) | Cross-Section Area (mm2) |

|---|

| Inserted | 21.7 | 2.3 | 17.1 | 140.2 |

| Socket | 27.2 | 2.3 | 22.6 | 179.9 |

| Inserted | 42.7 | 2.3 | 38.1 | 291.9 |

| Socket | 48.6 | 2.3 | 44.0 | 334.5 |

Table 3.

Variation in the skewed pipe shear connectors for push- and pull-out test specimens.

Table 3.

Variation in the skewed pipe shear connectors for push- and pull-out test specimens.

| Specimens | Socket Length (mm) | Inserted Pipe Length (mm) | Insertion Angle (°) | No. of Connectors ** Installed | Concrete Comp. Strength (MPa) | Quantity of Specimens |

|---|

| Into the Socket | Into the CIP | Push-Out | Pull-Out |

|---|

| D42.7-L200-A15 * (Reference) | 200 | 200 | 200 | 15 | 8/4 | 45 | 3 | 3 |

| Loop bar-H16 | N.A. *** (dia. of loop bar = 16 mm) | 12/6 | 45 | 3 | 3 |

| D21.7-L200-A15 | 200 | 200 | 200 | 15 | 8/N.A. | 45 | 3 | N.A. |

| D42.7-L150-A15 | 150 | 150 | 150 | 15 | 8/4 | 45 | 3 | 3 |

| D42.7-L200-A10 | 200 | 200 | 200 | 10 | N.A./10 | 45 | N.A. | 3 |

Table 4.

Results of push-out test (D42.7-L200-A15).

Table 4.

Results of push-out test (D42.7-L200-A15).

| Specimens | No. | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| D42.7-L200-A15 (Reference) | 1 | 773.3 | 488.2 | 696.0 | 9.8 | 28.0 | 2.9 | 1.6 |

| 2 | 792.0 | 405.9 | 712.8 | 11.0 | 25.0 | 2.3 | 2.0 |

| 3 | 761.2 | 551.9 | 685.1 | 8.2 | 28.5 | 3.5 | 1.4 |

| Avg. | 775.5 | 482.0 | 698.0 | 9.6 | 27.2 | 2.8 | 1.6 |

Table 5.

Results of push-out test (loop bar).

Table 5.

Results of push-out test (loop bar).

| Specimens | No. | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Loop bar-H16 | 1 | 906.0 | 579.2 | 815.4 | 9.4 | 13.5 | 1.4 | 1.6 |

| 2 | 894.3 | 552.2 | 804.8 | 9.8 | 14.6 | 1.5 | 1.6 |

| 3 | 956.1 | 648.8 | 860.5 | 11.3 | 14.4 | 1.3 | 1.5 |

| Avg. | 918.8 | 593.4 | 826.9 | 10.2 | 14.2 | 1.4 | 1.5 |

Table 6.

Comparison of the characteristic values of different types of shear connector specimens (push-out test).

Table 6.

Comparison of the characteristic values of different types of shear connector specimens (push-out test).

| Specimens | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| (A) Loop bar-H16 | 918.8 | 593.4 | 826.9 | 10.2 | 14.2 | 1.4 | 1.5 |

| (B) D42.7-L200-A15 (Reference) | 775.5 | 482.0 | 698.0 | 9.5 | 27.2 | 2.8 | 1.6 |

| Ratio (A/B) | 1.19 | 1.23 | - | - | - | 0.49 | 0.94 |

Table 7.

Results of push-out test (D21.7-L200-A15).

Table 7.

Results of push-out test (D21.7-L200-A15).

| Specimens | No. | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| D21.7-L200-A15 | 1 | 539.5 | 394.3 | 485.6 | 7.3 | 15.9 | 2.2 | 1.4 |

| 2 | 528.3 | 338.0 | 475.5 | 8.1 | 15.2 | 1.9 | 1.6 |

| 3 | 546.0 | 376.8 | 491.4 | 9.1 | 17.3 | 1.9 | 1.4 |

| Avg. | 537.9 | 369.7 | 484.1 | 8.2 | 16.1 | 2.0 | 1.5 |

Table 8.

Comparison of characteristic values of different inserted pipe diameter specimens (push-out test).

Table 8.

Comparison of characteristic values of different inserted pipe diameter specimens (push-out test).

| Specimens | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| (A) D21.7-L200-A15 (external diameter = 21.7 mm) | 537.9 | 369.7 | 484.1 | 8.2 | 16.1 | 2.0 | 1.5 |

| (B) D42.7-L200-A15 (Reference, external diameter = 42.7 mm) | 775.5 | 482.0 | 698.0 | 9.5 | 27.2 | 2.8 | 1.6 |

| Ratio (A/B) | 0.69 | 0.77 | - | - | - | 0.70 | 0.94 |

Table 9.

Results of push-out test (D42.7-L150-A15).

Table 9.

Results of push-out test (D42.7-L150-A15).

| Specimens | No. | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| D42.7-L150-A15 | 1 | 750.2 | 535.4 | 675.2 | 9.6 | 21.9 | 2.3 | 1.4 |

| 2 | 754.8 | 395.1 | 679.3 | 11.2 | 26.4 | 2.4 | 1.9 |

| 3 | 718.6 | 462.3 | 646.7 | 9.5 | 25.2 | 2.6 | 1.6 |

| Avg. | 741.2 | 464.3 | 667.1 | 10.1 | 24.5 | 2.4 | 1.6 |

Table 10.

Comparison of characteristic values of different pipe length specimens (push-out test).

Table 10.

Comparison of characteristic values of different pipe length specimens (push-out test).

| Specimens | Pmax (kN) | Py (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| (A) D42.7-L150-A15 | 741.2 | 464.3 | 667.1 | 10.1 | 24.5 | 2.4 | 1.6 |

| (B) D42.7-L200-A15 (Reference) | 775.5 | 482.0 | 698.0 | 9.5 | 27.2 | 2.8 | 1.6 |

| Ratio (A/B) | 0.96 | 0.96 | - | - | - | 0.86 | 1.00 |

Table 11.

Results of pull-out test (D42.7-L200-A15).

Table 11.

Results of pull-out test (D42.7-L200-A15).

| Specimens | No. | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| D42.7-L200-A15 (Reference) | 1 | 267.2 | 190.1 | 534.5 | 380.2 | 9.7 | 28.5 | 2.9 | 1.4 |

| 2 | 260.5 | 166.0 | 521.0 | 332.0 | 12.6 | 36.4 | 2.9 | 1.6 |

| 3 | 281.6 | 180.0 | 563.1 | 359.9 | 13.7 | 36.4 | 2.7 | 1.6 |

| Avg. | 269.8 | 178.7 | 539.5 | 357.4 | 12.0 | 33.8 | 2.8 | 1.5 |

Table 12.

Results of pull-out test (loop bar).

Table 12.

Results of pull-out test (loop bar).

| Specimens | No. | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| Loop bar-H16 | 1 | 304.7 | 231.6 | 609.4 | 463.2 | 7.1 | 12.2 | 1.7 | 1.3 |

| 2 | 331.7 | 242.1 | 663.5 | 484.3 | 8.6 | 17.5 | 2.0 | 1.4 |

| 3 | 327.8 | 240.7 | 655.5 | 481.4 | 8.0 | 14.7 | 1.8 | 1.4 |

| Avg. | 321.4 | 238.1 | 642.8 | 476.3 | 7.9 | 14.8 | 1.9 | 1.3 |

Table 13.

Comparison of characteristic values of different types of shear connector specimens (pull-out test).

Table 13.

Comparison of characteristic values of different types of shear connector specimens (pull-out test).

| Specimens | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| (A) Loop bar-H16 | 321.4 | 238.1 | 642.8 | 476.3 | 7.9 | 14.8 | 1.9 | 1.3 |

| (B) D42.7-L200-A15 (Reference) | 269.8 | 178.7 | 539.5 | 357.4 | 12.0 | 33.8 | 2.8 | 1.5 |

| Ratio (A/B) | 1.19 | 1.33 | 1.19 | 1.33 | - | - | 0.68 | 0.87 |

Table 14.

Results of pull-out test (D42.7-L200-A10).

Table 14.

Results of pull-out test (D42.7-L200-A10).

| Specimens | No. | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| D42.7-L200-A10 | 1 | 251.6 | 178.1 | 503.1 | 356.2 | 9.7 | 28.5 | 2.9 | 1.4 |

| 2 | 258.0 | 162.0 | 516.0 | 323.9 | 10.7 | 30.8 | 2.9 | 1.6 |

| 3 | 258.7 | 154.7 | 517.4 | 309.4 | 13.8 | 36.5 | 2.6 | 1.7 |

| Avg. | 256.1 | 164.9 | 512.2 | 329.8 | 11.4 | 31.9 | 2.8 | 1.6 |

Table 15.

Comparison of characteristic values of different pipe insertion angle specimens (pull-out test).

Table 15.

Comparison of characteristic values of different pipe insertion angle specimens (pull-out test).

| Specimens | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| (A) D42.7-L200-A10 (angle = 10°) | 256.1 | 164.9 | 512.2 | 329.8 | 11.4 | 31.9 | 2.8 | 1.6 |

| (B) D42.7-L200-A15 (Reference, angle = 15°) | 269.8 | 178.7 | 539.5 | 357.4 | 12.0 | 33.8 | 2.8 | 1.5 |

| Ratio (A/B) | 0.95 | 0.92 | 0.95 | 0.92 | - | - | 1.00 | 1.07 |

Table 16.

Results of pull-out test (D42.7-L150-A15).

Table 16.

Results of pull-out test (D42.7-L150-A15).

| Specimens | No. | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| D42.7-L150-A15 | 1 | 169.6 | 102.2 | 339.2 | 204.4 | 6.9 | 19.4 | 2.8 | 1.7 |

| 2 | 175.1 | 96.5 | 350.1 | 192.9 | 7.3 | 19.8 | 2.7 | 1.8 |

| 3 | 156.5 | 126.2 | 312.9 | 252.4 | 4.2 | 15.3 | 3.7 | 1.2 |

| Avg. | 167.0 | 108.3 | 334.1 | 216.6 | 6.1 | 18.2 | 3.1 | 1.5 |

Table 17.

Comparison of characteristic value of different pipe length specimens (pull-out test).

Table 17.

Comparison of characteristic value of different pipe length specimens (pull-out test).

| Specimens | P (kN) | Ppull (kN) | δ90 (mm) | δu (mm) | δu/δ90 | Pmax/Py |

|---|

| Max | Yielding | Max | Yielding |

|---|

| (A) D42.7-L150-A15 | 167.0 | 108.3 | 334.1 | 216.6 | 6.1 | 18.2 | 3.1 | 1.5 |

| (B) D42.7-L200-A15 (Reference) | 269.8 | 178.7 | 539.5 | 357.4 | 12.0 | 33.8 | 2.8 | 1.5 |

| Ratio (A/B) | 0.62 | 0.61 | 0.62 | 0.61 | - | - | 1.11 | 1.00 |

Table 18.

Results of push-out test and numerical results.

Table 18.

Results of push-out test and numerical results.

| Name | No. | Pmax (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 |

|---|

| D42.7-L200-A15 | 1 | 773.3 | 696.0 | 9.8 | 28.0 | 2.9 |

| 2 | 792.0 | 712.8 | 11.0 | 25.0 | 2.3 |

| 3 | 761.2 | 685.1 | 8.2 | 28.5 | 3.5 |

| Avg. | 775.5 | 698.0 | 9.6 | 27.2 | 2.8 |

| D42.7-L200-A15 (FEM) | - | 749.9 | 674.9 | 10.3 | 29.6 | 2.9 |

Table 19.

Shear behavior characteristic of experimental and numerical results.

Table 19.

Shear behavior characteristic of experimental and numerical results.

| Name | Pmax (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 |

|---|

| D42.7-L200-A15 (Reference) | 749.9 | 674.9 | 10.2 | 29.5 | 2.9 |

| D60.5-L200-A15 (T2.3) | 837.8 | 754.0 | 10.5 | 24.1 | 2.3 |

| D60.5-L200-A15 (T3.2) | 901.2 | 811.1 | 7.8 | 23.9 | 3.1 |

| D89.1-L200-A15 (T2.8) | 1034.7 | 931.3 | 7.8 | 24.5 | 3.1 |

| D89.1-L200-A15 (T3.2) | 1186.5 | 1067.9 | 8.2 | 26.1 | 3.2 |

| Loop bar-H16 (Loop bar) | 918.8 | 826.9 | 10.2 | 14.2 | 1.4 |

Table 20.

Results of pull-out test and numerical results.

Table 20.

Results of pull-out test and numerical results.

| Name | No. | Pmax (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 |

|---|

| D42.7-L200-A15 (Reference) | 1 | 267.2 | 534.5 | 9.7 | 28.5 | 2.9 |

| 2 | 260.5 | 521.0 | 12.6 | 36.4 | 2.9 |

| 3 | 281.6 | 563.1 | 13.7 | 36.4 | 2.7 |

| Avg. | 269.8 | 539.5 | 12.0 | 33.8 | 2.8 |

| D42.7-L200-A15 (FEM) | - | 256.4 | 512.8 | 8.5 | 39.2 | 4.6 |

Table 21.

Pull-out behavior characteristic of experimental and numerical results.

Table 21.

Pull-out behavior characteristic of experimental and numerical results.

| Name | Pmax (kN) | PRK (kN) | δ90 (mm) | δu (mm) | δu/δ90 |

|---|

| D42.7-L200-A15 (Reference) | 256.4 | 512.8 | 8.7 | 38.5 | 4.4 |

| D60.5-L200-A15 (T2.3) | 285.1 | 570.2 | 7.2 | 31.4 | 4.4 |

| D60.5-L200-A15 (T3.2) | 304.0 | 608.0 | 8.1 | 32.2 | 3.9 |

| D89.1-L200-A15 (T2.8) | 334.3 | 668.6 | 9.6 | 33.1 | 3.4 |

| D89.1-L200-A15 (T3.2) | 356.6 | 713.2 | 9.3 | 32.3 | 3.5 |

| Loop-H16 (Loop bar) | 321.4 | 642.8 | 7.9 | 14.8 | 1.9 |