Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Samples

2.3. Mixture Proportions

3. Results

3.1. Effects of Carbon Fiber on Physical Properties

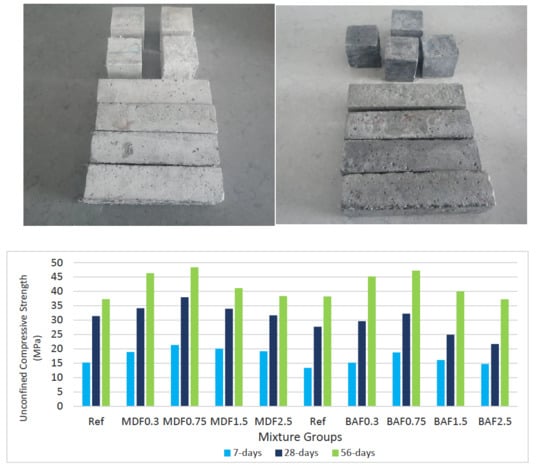

3.2. Effect of Carbon Fiber on the Mechanical Properties

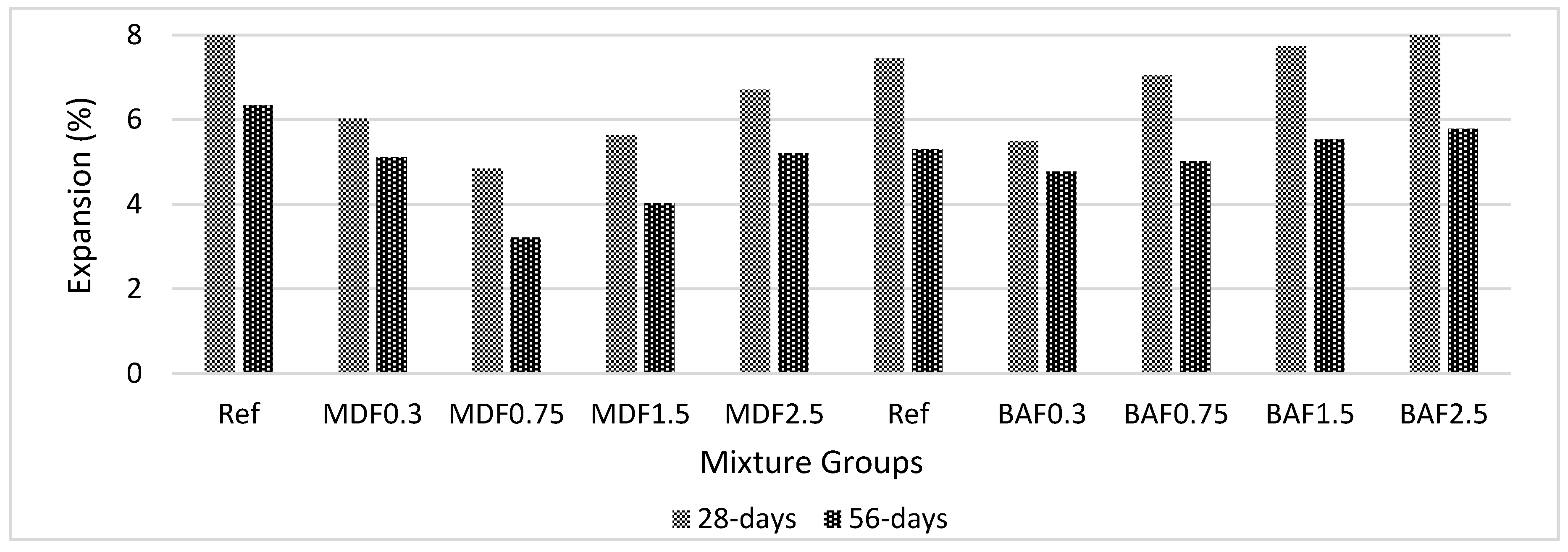

3.3. Effect of Carbon Fiber on the Durability Properties

4. Conclusions

- (1)

- Carbon fiber was effective up to 0.75% for bottom ash, which is 0.30% for bottom ash mixture groups basically when considering the physical properties at the early period of hydration. However, the authors’ advice is to not use beyond a 0.3% carbon fiber dosage. Beyond 28 days, higher dosages cannot be effective, and improper compaction will lead to the formation of voids and reduce the ability of carbon fiber to hold the particles.

- (2)

- Decrease in flow was more notable in marble dust mixture groups compared with bottom ash mixture groups. An approximately 54% reduction was observed in marble dust mixtures when compared with the reference mixture. The reduction is mainly due to the surface characteristics of the carbon fiber with a high-length-to-diameter ratio. The surface of the carbon filaments absorbs more water during mixing and causes a decrease in workability at higher rates. The addition of carbon fiber above 0.75% was associated with significantly reduced flowability of marble dust mixture groups.

- (3)

- Porosity was higher in marble dust mixture groups. The addition of carbon fiber increased porosity values for marble dust and bottom ash mixture groups beyond the 0.75% addition.

- (4)

- Water absorption values decreased with the addition of carbon fiber. However, the addition of carbon fiber beyond 0.75% increased water absorption values for both mixture groups. However, the increase was greater in bottom ash mixture groups. The authors believe that the higher absorption values can possibly create additional water for later ages and the pores acting as a reservoir for providing extra water available for curing. This can be compatible with the mechanical and durability test results. No adverse effect of higher absorption capacity at lower dosages was reported by considering the compressive and flexural strength. Additionally, no loss of resistance against sulfate and seawater environments was observed during this study.

- (5)

- Unconfined compressive and flexural strength values increased with the addition of carbon fiber. However, beyond a 0.75% carbon fiber addition level, both strength values decreased. The decrease in intensity was greater for bottom ash mixture groups. The compressive strength reached 48.4 and 47.2 MPa for marble dust and bottom ash mixture groups, respectively, at 56 days of curing. The strength gain was greater after 28 days for both mixture groups. The laboratory produced carbon-enriched bottom ash; further, marble cement paste composites showed excellent performance at later ages. The composites can be satisfactorily used in various civil engineering works and applications (e.g., manufacturing of bricks, tiles, paving stone). The composites’ weakness against mechanical loading can be reduced with the addition of small carbon fibers. For structural-grade applications, compressive strength values are also appropriate at lower carbon dosages. The mechanical performance for both mixture groups is appropriate for using composites in the building sector as an alternative sustainable material. The use of industrial waste such as bottom ash and marble dust have a positive effect on the economy and sustainability. The authors believed that using 20% waste and reducing the amount of cement in pastes will have a major impact on concrete, especially in highway or other bulk applications. This study considers the cement paste application with lower-scale applications. The impact would be more when used in concrete. The reduction in carbon dioxide amount decreases the negative effect of environmental pollution. Additionally, in this study, 6mm carbon fiber was used. Thus, the effectiveness of long carbon fiber on mechanical performance should be checked before use.

- (6)

- Both composites were resistant to sulfate and seawater attacks. Carbon fiber seemed to be useful for protecting the composites against harsh environments at low volume fraction. The addition of carbon fiber beyond 0.75% adversely affected the composite’s resistance.

- (7)

- It is highly recommended to investigate the effect of carbon fibers on the microstructure of these novel-based composites. Additionally, different water binder ratios might be helpful for better understanding the behavior of such composites. In this study, the length of carbon fiber is 6 mm; further, the authors strongly recommend using different lengths of carbon fiber to investigate the performance of the composites on a large scale.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, G.B.; Subramaniam, K.V.L. Production and characterization of low-energy Portland composite cement from post-industrial waste. J. Clean. Prod. 2019, 239, 118024. [Google Scholar] [CrossRef]

- Scrivener, K.; John, V.M.; Gartner, E. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Nidheesh, P.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production Earth System Science Data. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef] [Green Version]

- Çankaya, S.; Pekey, B. A comparative life cycle assessment for sustainable cement production in Turkey. J. Environ. Manag. 2019, 249, 109362. [Google Scholar] [CrossRef]

- Atiyeh, M.; Aydin, E. Data for bottom ash and marble powder utilization as an alternative binder for sustainable concrete construction. Data Brief 2020, 29, 105160. [Google Scholar] [CrossRef]

- Brundtland, G.H. The Brundtland Report: “Our Common Future”. Med. War 1987, 4, 17–25. [Google Scholar]

- Brito, J.D.; Saikia, N. Recycled Aggregate in Concrete; Springer: Berlin, Germany, 2013. [Google Scholar]

- Bassani, M.; Garcia, J.D.; Meloni, F.; Volpatti, G.; Zampini, D.M. Recycled coarse aggregates from pelletized unused concrete for a more sustainable concrete production. J. Clean. Prod. 2019, 219, 424–432. [Google Scholar] [CrossRef]

- Aydin, E.; Arel, H.Ş. Data for the physical and mechanical properties of high volume fly ash cement paste composites. Data Brief 2017, 16, 321–326. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, A.; Bhunia, D. Long term strength and durability parameters of hardened concrete on partially replacing cement by dried waste marble powder slurry. Constr. Build. Mater. 2019, 198, 553–569. [Google Scholar] [CrossRef]

- Arel, H.Ş.; Aydin, E. Use of industrial and agricultural wastes in construction concrete. ACI Mater. J. 2018, 115, 55–64. [Google Scholar] [CrossRef]

- Singh, N.; Bhardwaj, A. Reviewing the role of coal bottom ash as an alternative of cement. Constr. Build. Mater. 2020, 233, 117276. [Google Scholar] [CrossRef]

- Muthusamy, K.; Rasid, M.H.; Jokhio, G.A.; Budiea, A.M.A.; Hussin, M.W.; Mirza, J. Coal bottom ash as sand replacement in concrete: A review. Constr. Build. Mater. 2020, 236, 117507. [Google Scholar] [CrossRef]

- Pant, A.; Datta, M.; Ramana, G. Bottom ash as a backfill material in reinforced soil structures. Geotext. Geomembr. 2019, 47, 514–521. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattarai, R.; Li, Y.; Li, S.; Fan, Y. Utilization of coal fly and bottom ash pellet for phosphorus adsorption: Sustainable management and evaluation. Resour. Conserv. Recycl. 2019, 149, 372–380. [Google Scholar] [CrossRef]

- Li, X.; Liu, Z.; Lv, Y.; Cai, L.; Jiang, D.; Jiang, W.; Jian, S. Utilization of municipal solid waste incineration bottom ash in autoclaved aerated concrete. Constr. Build. Mater. 2018, 178, 175–182. [Google Scholar] [CrossRef]

- Tang, P.; Chen, W.; Xuan, D.; Zuo, Y.; Poon, C. Investigation of cementitious properties of different constituents in municipal solid waste incineration bottom ash as supplementary cementitious materials. J. Clean. Prod. 2020, 258, 120675. [Google Scholar] [CrossRef]

- Khongpermgoson, P.; Abdulmatin, A.; Tangchirapat, W.; Jaturapitakkul, C. Evaluation of compressive strength and resistance of chloride ingress of concrete using a novel binder from ground coal bottom ash and ground calcium carbide residue. Constr. Build. Mater. 2019, 214, 631–640. [Google Scholar] [CrossRef]

- Argiz, C.; Moragues, A.; Menéndez, E. Use of ground coal bottom ash as cement constituent in concretes exposed to chloride environments. J. Clean. Prod. 2018, 170, 25–33. [Google Scholar] [CrossRef]

- Rani, R.; Jain, M.K. Effect of bottom ash at different ratios on hydraulic transportation of fly ash during mine fill. Powder Technol. 2017, 315, 309–317. [Google Scholar] [CrossRef]

- Abdulmatin, A.; Tangchirapat, W.; Jaturapitakkul, C. An investigation of bottom ash as a pozzolanic material. Constr. Build. Mater. 2018, 186, 155–162. [Google Scholar] [CrossRef]

- Singh, N.; Arya, S. Influence of coal bottom ash as fine aggregates replacement on various properties of concretes: A review. Resour. Conserv. Recycl. 2018, 138, 257–271. [Google Scholar] [CrossRef]

- Le, N.H.; Abriak, N.-E.; Binetruy, C.; Benzerzour, M.; Nguyen, S.-T. Mechanical behavior of municipal solid waste incinerator bottom ash: Results from triaxial tests. Waste Manag. 2017, 65, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Ashish, D. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2019, 211, 716–729. [Google Scholar] [CrossRef]

- Ma, B.; Wang, J.; Tan, H.; Li, X.; Cai, L.; Zhou, Y.; Chu, Z. Utilization of waste marble powder in cement based materials by incorporating nano silica. Constr. Build. Mater. 2019, 211, 139–149. [Google Scholar] [CrossRef]

- Nežerka, V.; Hrbek, V.; Prosek, Z.; Somr, M.; Tesarek, P.; Fladr, J. Micromechanical characterization and modeling of cement pastes containing waste marble powder. J. Clean. Prod. 2018, 195, 1081–1090. [Google Scholar] [CrossRef]

- Kabeer, K.I.S.A.; Vyas, A.K. Utilization of marble powder as fine aggregate in mortar mixes. Constr. Build. Mater. 2018, 165, 321–332. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; Ghalehnovi, M.; Brito, J.D.; Shamsabadi, E.A. Durability performance of structural concrete containing silica fume and marble industry waste powder. J. Clean. Prod. 2018, 170, 42–60. [Google Scholar] [CrossRef]

- Sutcu, M.; Alptekin, H.; Erdoğmuş, E.; Er, Y.; Gencel, O. Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr. Build. Mater. 2015, 82, 1–8. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G.; Naik, T.R. Characterization of marble powder for its use in mortar and concrete. Constr. Build. Mater. 2010, 24, 113–117. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Influence of marble waste as partial replacement of fine aggregates on strength and drying shrinkage of concrete. Constr. Build. Mater. 2019, 228, 116730. [Google Scholar] [CrossRef]

- Pehlivanlı, Z.O.; Uzun, I.; Demir, I. Mechanical and microstructural features of autoclaved aerated concrete reinforced with autoclaved polypropylene, carbon, basalt and glass fiber. Constr. Build. Mater. 2015, 96, 428–433. [Google Scholar] [CrossRef]

- Kimm, M.; Pico, D.; Gries, T. Investigation of surface modification and volume content of glass and carbon fibres from fibre reinforced polymer waste for reinforcing concrete. J. Hazard. Mater. 2019, 390, 121797. [Google Scholar] [CrossRef] [PubMed]

- Pirmohammad, S.; Majd Shokorlou, Y.; Amani, B. Laboratory investigations on fracture toughness of asphalt concretes reinforced with carbon and kenaf fibers. Eng. Fract. Mech. 2020, 226, 106875. [Google Scholar] [CrossRef]

- Sathish, T.; Palanikumar, B.; Karthick, S. Comparative study on addition of carbon fiber in concrete with partial replacement of demolished concrete waste in structural concrete. Mater. Today 2020, in press. [Google Scholar] [CrossRef]

- Ostrowski, K.; Dudek, M.; Sadowski, Ł. Compressive behaviour of concrete-filled carbon fiber-reinforced polymer steel composite tube columns made of high performance concrete. Compos. Struct. 2020, 234, 111668. [Google Scholar] [CrossRef]

- Liu, B.; Guo, J.; Wen, X.; Zhou, J.; Deng, Z. Study on flexural behavior of carbon fibers reinforced coral concrete using digital image correlation. Constr. Build. Mater. 2020, 242, 117968. [Google Scholar] [CrossRef]

- Safiuddin, M.; Yakhlaf, M.; Soudki, K.A. Key mechanical properties and microstructure of carbon fibre reinforced self consolidating concrete. Constr. Build. Mater. 2018, 164, 477–488. [Google Scholar] [CrossRef]

- Song, W.; Yi, J.; Wu, H.; He, X.; Song, Q.; Yin, J. Effect of carbon fiber on mechanical properties and dimensional stability of concrete incorporated with granulated-blast furnace slag. J. Clean. Prod. 2019, 238. [Google Scholar] [CrossRef]

- Yakhlaf, M.; Soudki, K. Properties of freshly mixed carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 2013, 46, 224–231. [Google Scholar] [CrossRef]

- Rangelov, M.; Nassiri, S.; Haselbach, L.; Englund, K. Using carbon fiber composites for reinforcing pervious concrete. Constr. Build. Mater. 2016, 126, 875–885. [Google Scholar] [CrossRef]

- Tanyildizi, H. Effect of temperature, carbon fibers, and silica fume on the mechanical properties of lightweight concretes. Xinxing Tan Cailiao New Carbon Mater. 2008, 23, 339–344. [Google Scholar] [CrossRef]

- Giner, V.; Baeza, F.; Ivorra, S.; Zornoza, E.; Galao, Ó. Effect of steel and carbon fiber additions on the dynamic properties of concrete containing silica fume. Mater. Des. 2012, 34, 332–339. [Google Scholar] [CrossRef]

- Díaz, B.; Guitián, B.; Nóvoa, X.R.; Pérez, C. Analysis of the microstructure of carbon fibre reinforced cement pastes by impedance spectroscopy. Constr. Build. Mater. 2020, 243, 118207. [Google Scholar] [CrossRef]

- Hambach, M.; Möller, H.; Neumann, T.; Volkmer, D. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength (>100 MPa). Cem. Concr. Res. 2016, 89, 80–86. [Google Scholar] [CrossRef]

- Kim, G.M.; Yoon, H.N.; Lee, H.K. Autogenous shrinkage and electrical characteristics of cement pastes and mortars with carbon nanotube and carbon fiber. Constr. Build. Mater. 2018, 177, 428–435. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D. Effects of silica fume, latex, methylcellulose, and carbon fibers on the thermal conductivity and specific heat of cement paste. Cem. Concr. Res. 1997, 27, 1799–1804. [Google Scholar] [CrossRef]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F. Commercial and recycled carbon/steel fibers for fiber reinforced cement mortars with high electrical conductivity. Cem. Concr. Compos. 2020, in press. [Google Scholar] [CrossRef]

- Wei, H.; Wu, T.; Yang, X. Properties of lightweight aggregate concrete reinforced with carbon and/or polypropylene fibers. Materials 2020, 13, 640. [Google Scholar] [CrossRef] [Green Version]

- ASTM International. ASTM C150/C150M 12 Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. ASTM C109/C109M 20a Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2 in. or [50 mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. ASTM C348 19 Standard Test Method for Flexural Strength of Hydraulic Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. ASTM C127 15 Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. ASTM C230/C230M 14 Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. ASTM C88/C88M 18 Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Aydin, E. Staple wire reinforced high volume fly ash cement paste composites. Constr. Build. Mater. 2017, 153, 393–401. [Google Scholar] [CrossRef]

- Aydin, E. Sulphate resistance of high volume fly ash cement paste composites. In Principles of Chemical Engineering Processes; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Aydin, E. Novel coal bottom ash waste composites for sustainable construction. Constr. Build. Mater. 2016, 124, 582–588. [Google Scholar] [CrossRef]

| Oxides (%) | Cement | Bottom Ash | Marble Dust |

|---|---|---|---|

| SiO2 | 20.7 | 56.6 | 10.1 |

| Al2O3 | 5.4 | 26.8 | 0.5 |

| Fe2O3 | 2.7 | 7.4 | 0.9 |

| CaO | 65.2 | 1.3 | 45.3 |

| MgO | 0.4 | 0.1 | 5.7 |

| K2O | 0.1 | 1.2 | 0.04 |

| SO3 | 1.6 | 0.5 | 0.02 |

| LOI a | 2.3 | 3.5 | 36.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atiyeh, M.; Aydin, E. Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability. Materials 2020, 13, 1899. https://doi.org/10.3390/ma13081899

Atiyeh M, Aydin E. Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability. Materials. 2020; 13(8):1899. https://doi.org/10.3390/ma13081899

Chicago/Turabian StyleAtiyeh, Mohamad, and Ertug Aydin. 2020. "Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability" Materials 13, no. 8: 1899. https://doi.org/10.3390/ma13081899