Friction Stir Processing of Particle Reinforced Composite Materials

Abstract

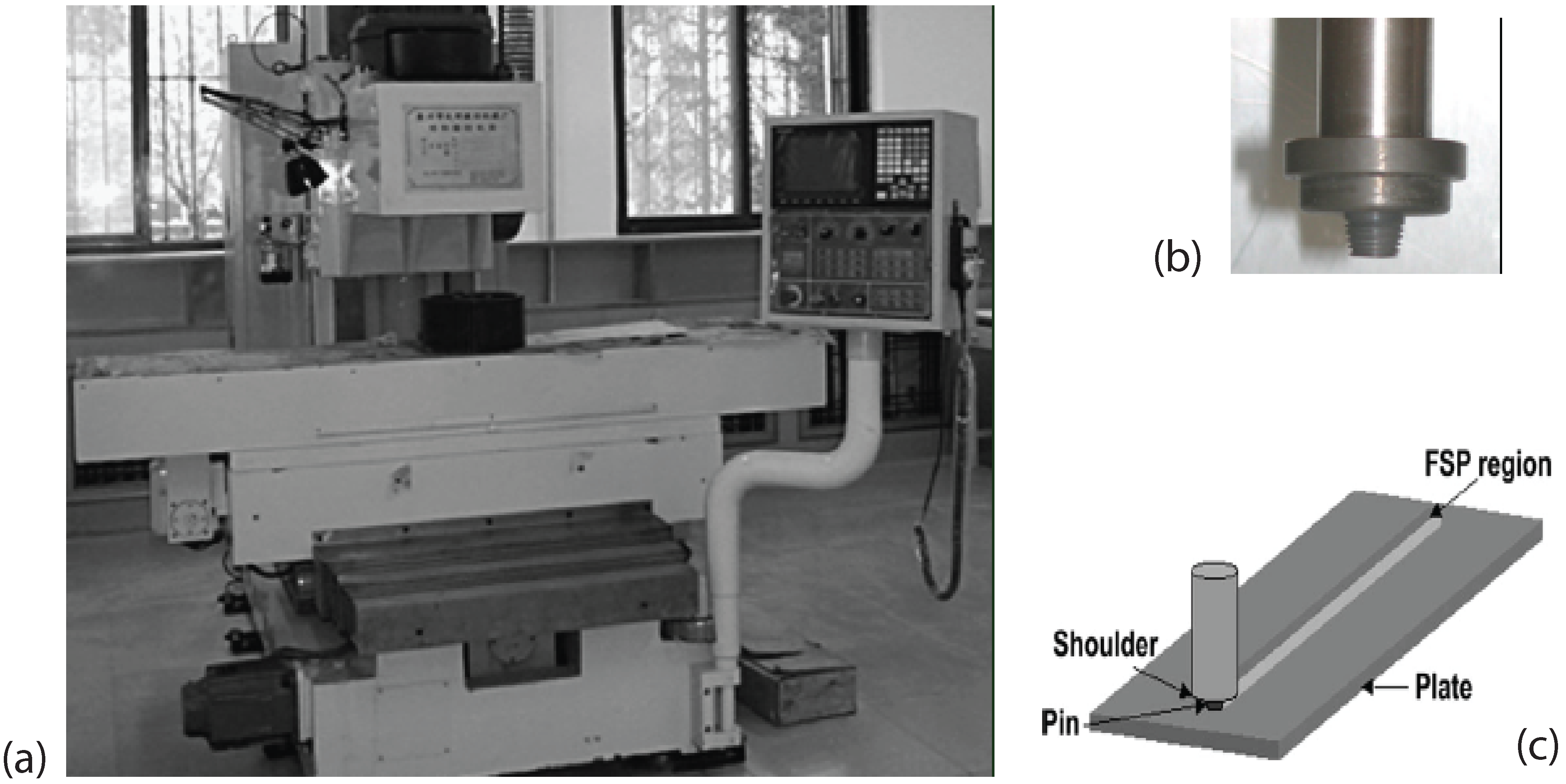

:1. Introduction

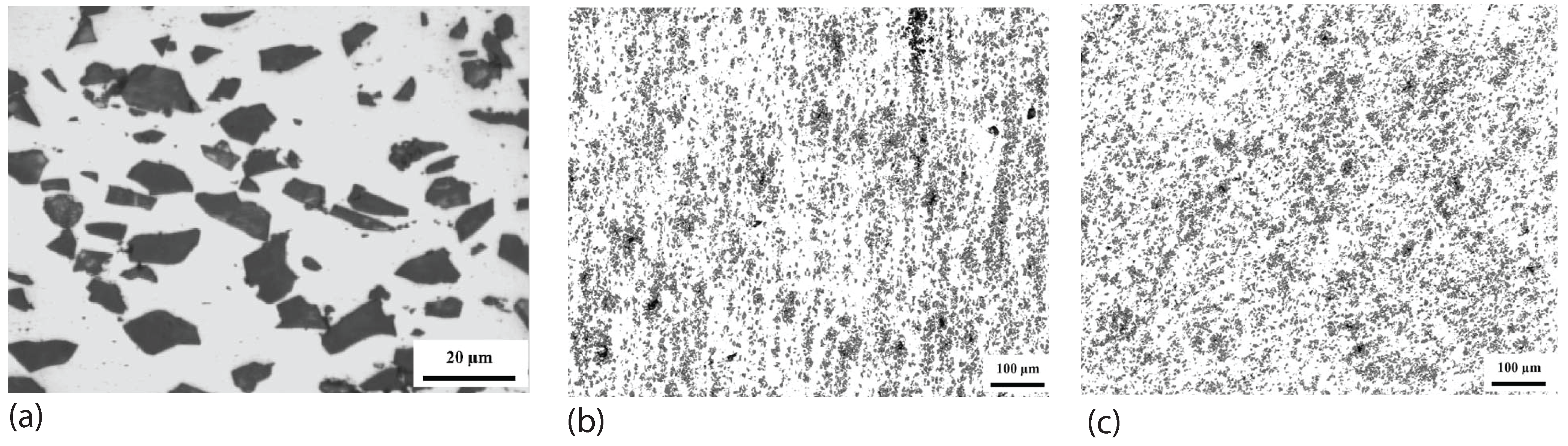

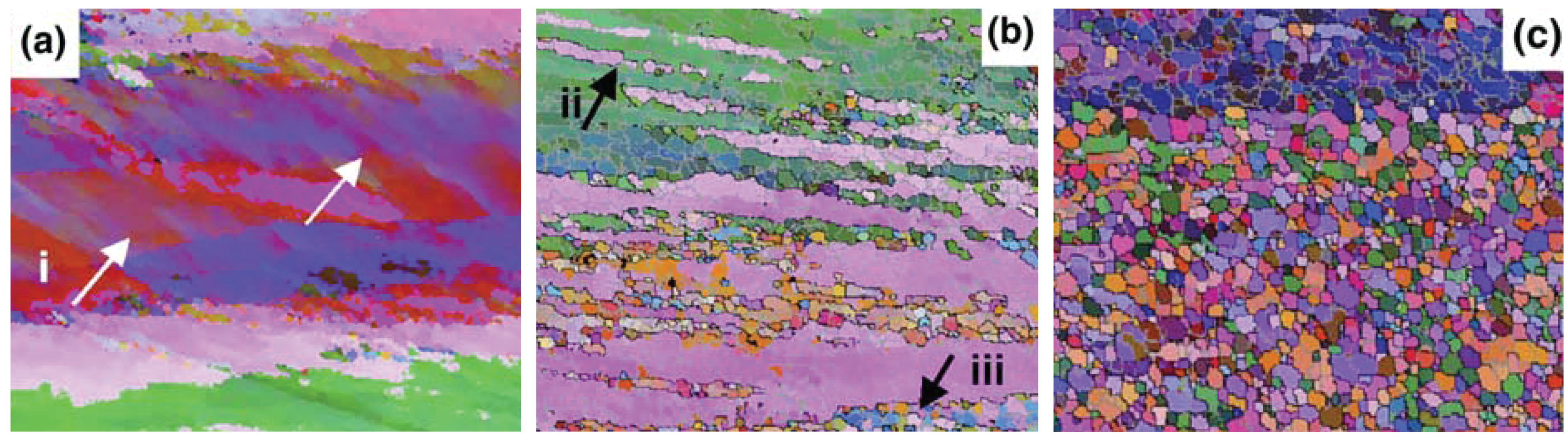

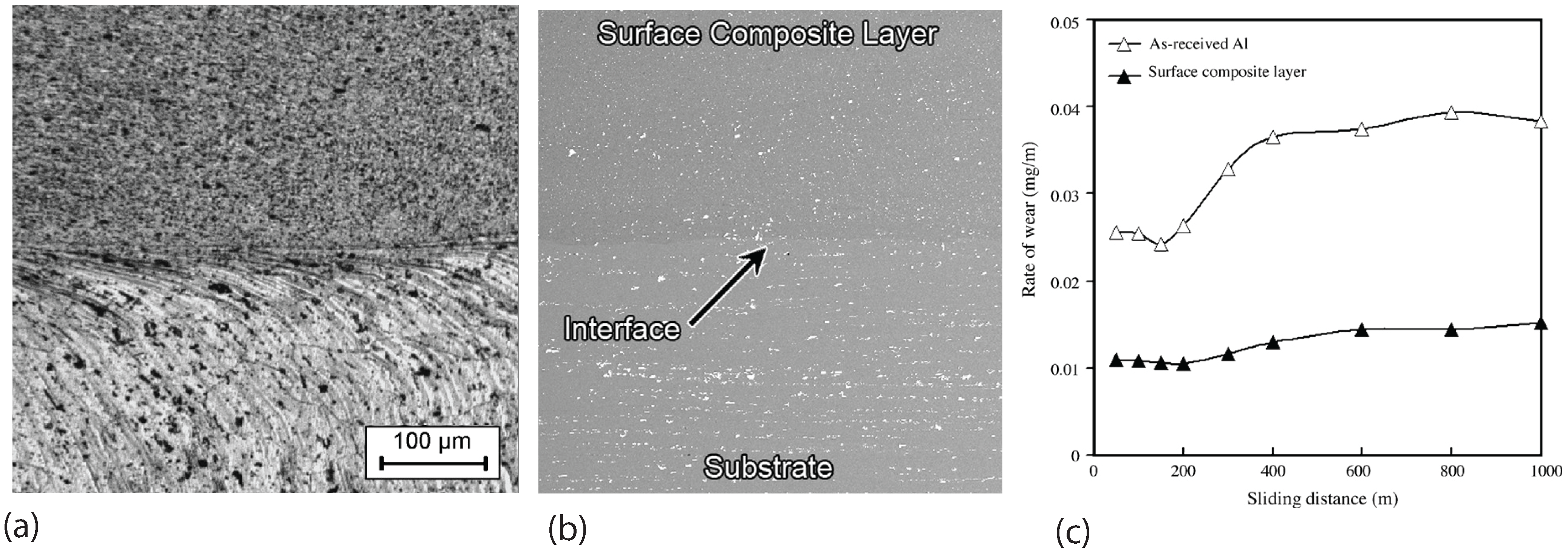

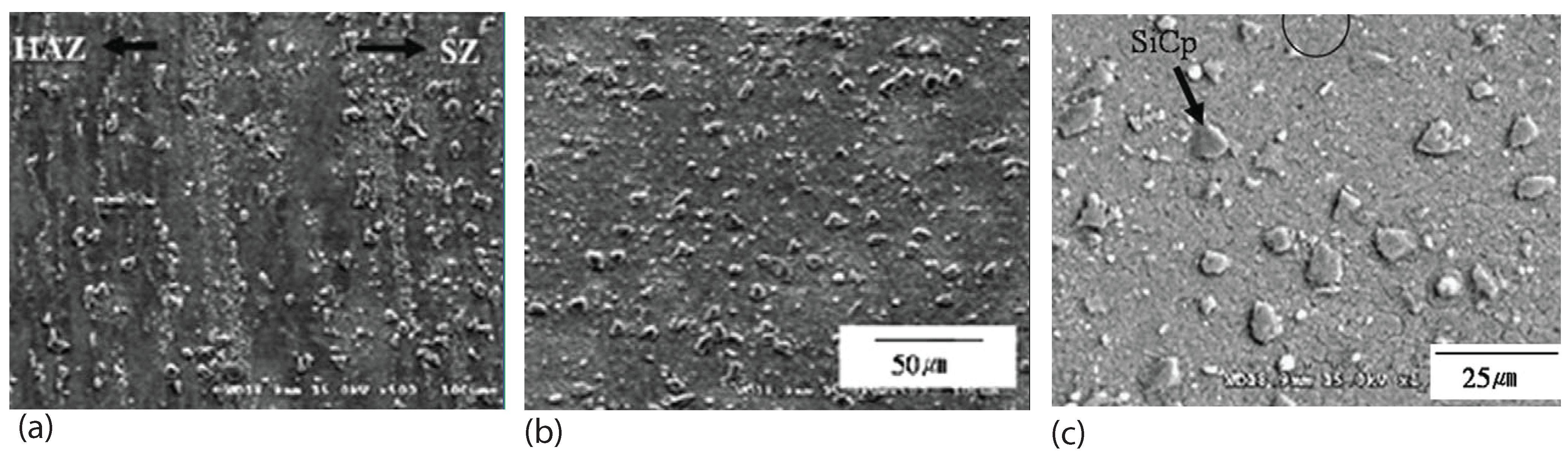

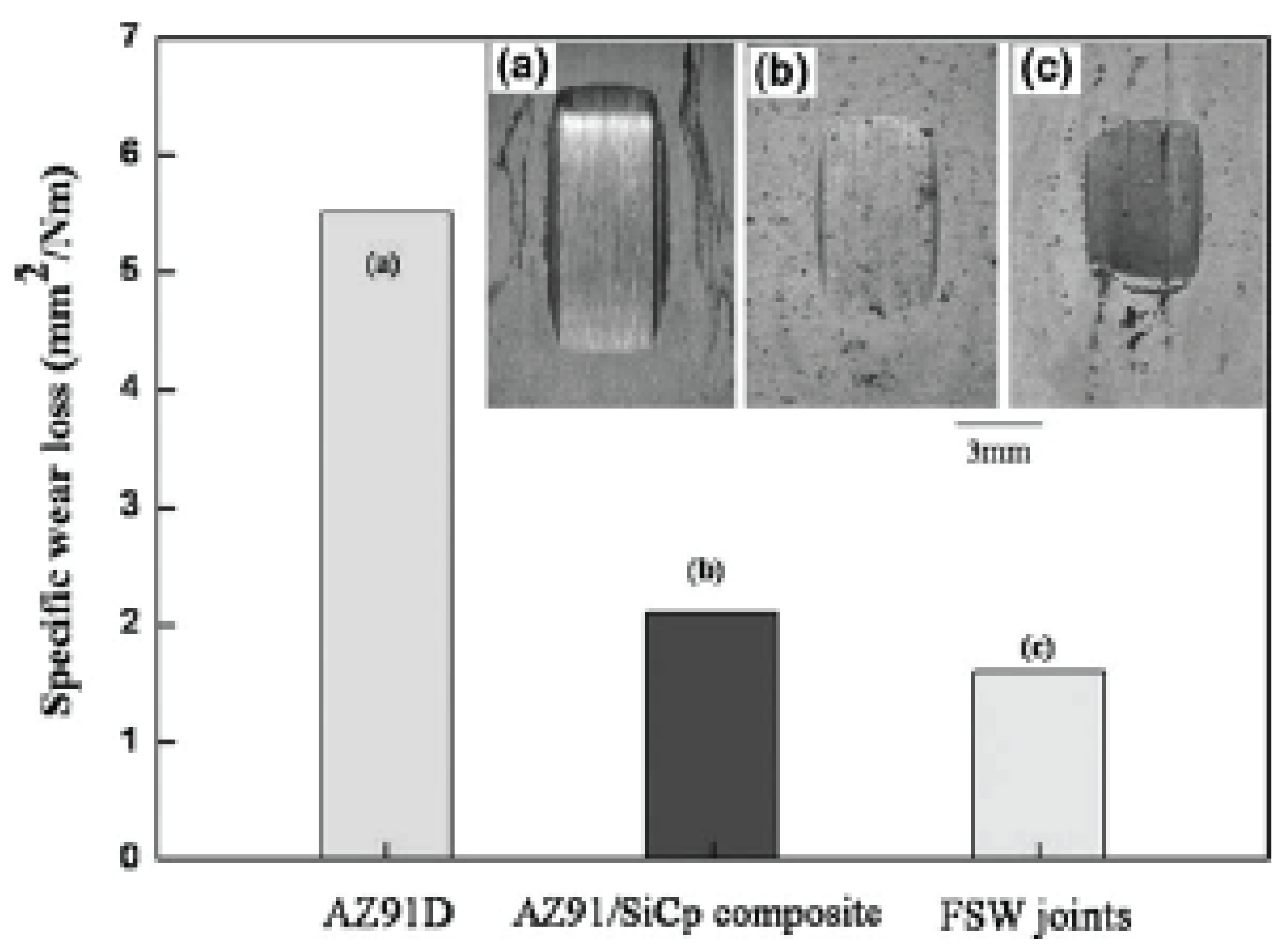

2. Friction Stir Processing of Aluminum Matrix Composites

3. Friction Stir Processing of Magnesium Matrix Composites

4. Perspectives on Friction Stir Processing

4.1. Application for Processing New Metallic Alloys/Composites

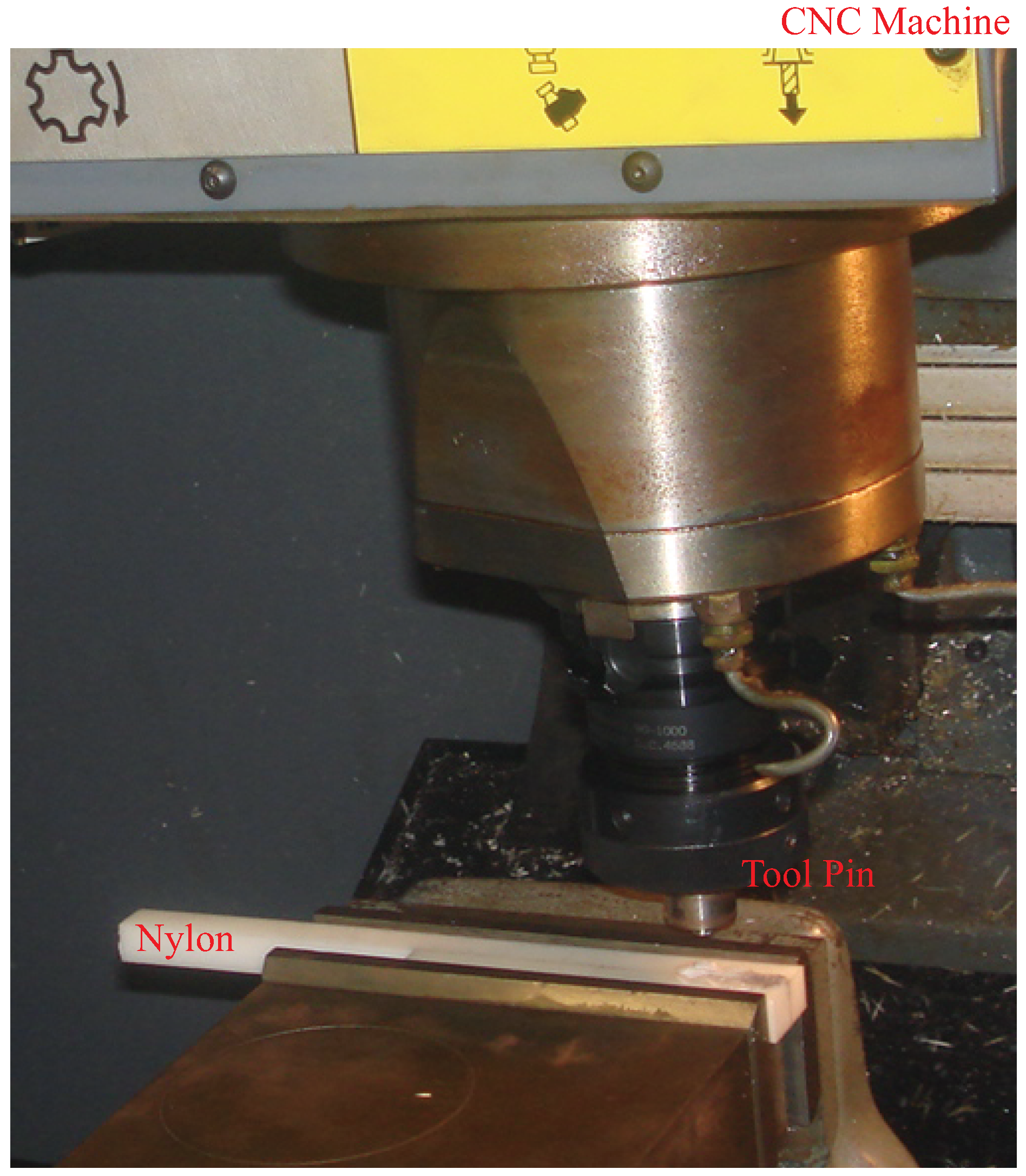

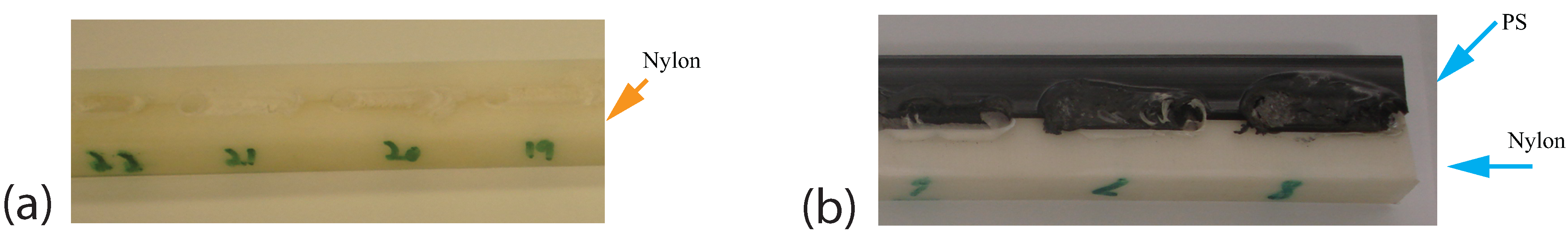

4.2. Application for Processing Polymeric Materials and Composites

4.3. Issues on the Challenges and Improvements Needed

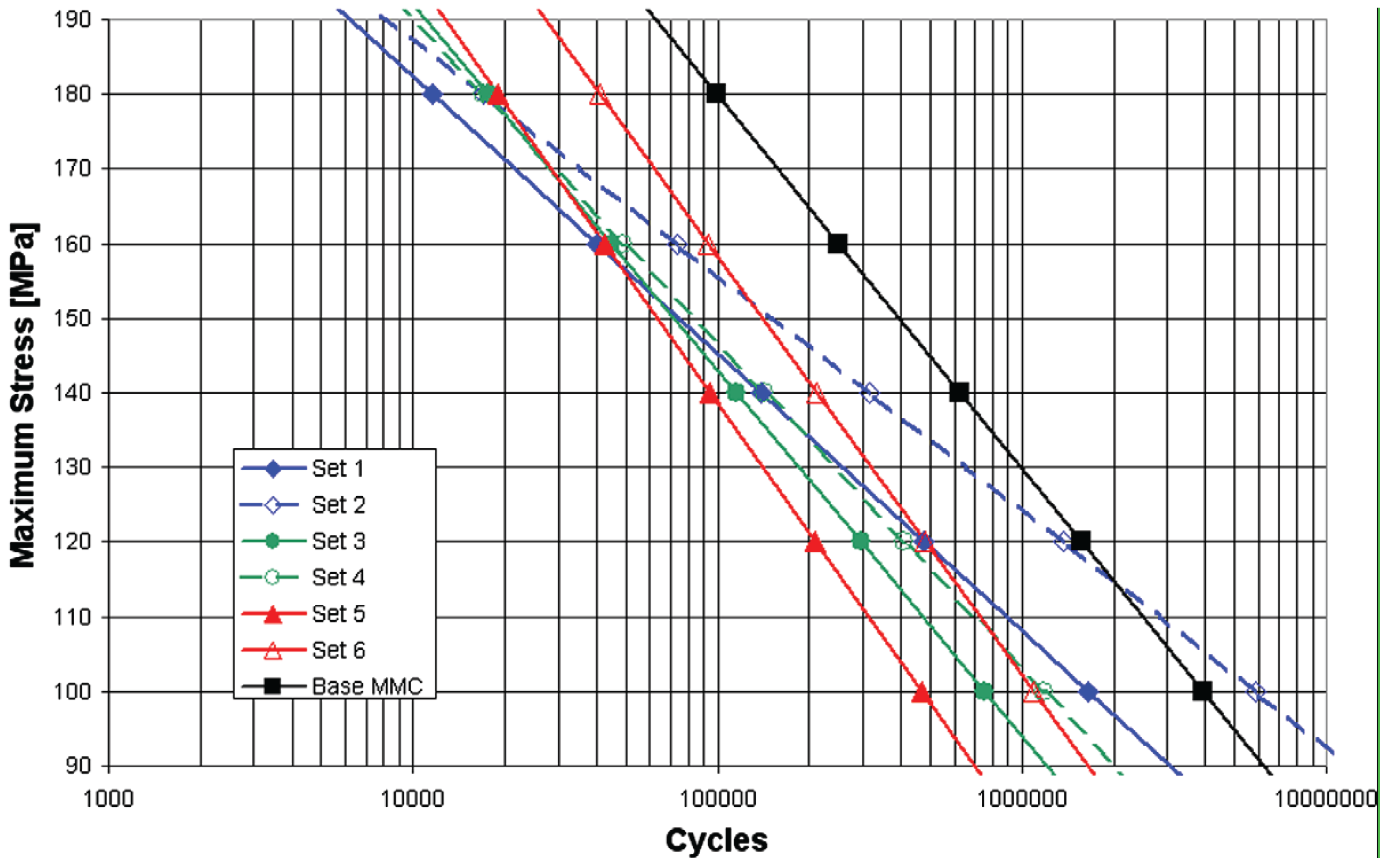

| Specimen set | 1 | 2 | 3 | 4 | 5 | 6 |

| Rotation rate (rpm) | 630 | 630 | 630 | 880 | 880 | 880 |

| Tool speed (mm/min) | 115 | 170 | 260 | 115 | 170 | 260 |

5. Summary and Conclusions

Acknowledgements

References

- Liechty, B.C.; Webb, B.W. Flow field characterization of friction stir processing using a particle-grid method. J. Mater. Process. Technol. 2008, 208, 431–443. [Google Scholar] [CrossRef]

- Darras, B.M.; Khraisheh, M.K.; Abu-Farha, F.K.; Omar, M.A. Friction stir processing of commercial AZ31 magnesium alloy. J. Mater. Process. Technol. 2007, 191, 77–81. [Google Scholar] [CrossRef]

- Wang, W.; Shi, Q.; Liu, P.; Li, H.; Li, T. A novel way to produce bulk SiCp reinforced aluminum metal matrix composites by friction stir processing. J. Mater. Process. Technol. 2009, 209, 2099–2103. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Senthilkumar, V.S.; Padmanabhan, K.A. On the role of process variables in the friction stir processing of cast aluminum A319 alloy. Mater. Des. 2010, 31, 761–771. [Google Scholar] [CrossRef]

- Sinha, P.; Muthukumaran, S.; Mukherjee, S.K. Analysis of first mode of metal transfer in friction stir welded plates by image processing technique. J. Mater. Process. Technol. 2008, 197, 17–21. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Senthilkumar, V.S.; Balasubramanian, V.; Natarajan, S. Mechanical property and microstructural changes during friction stir processing of cast aluminum 2285 alloy. Mater. Des. 2009, 30, 2237–2242. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Pilchak, A.L.; Juhas, M.C.; Williams, J.C. Microstructural refinement and property enhancement of cast light alloys via friction stir processing. Scr. Mater. 2008, 58, 361–366. [Google Scholar]

- Du, X.; Wu, B. Using friction stir processing to produce ultrafine-grained microstructure in AZ61 magnesium alloy. Trans. Nonferrous Met. Soc. China 2008, 19, 562–565. [Google Scholar] [CrossRef]

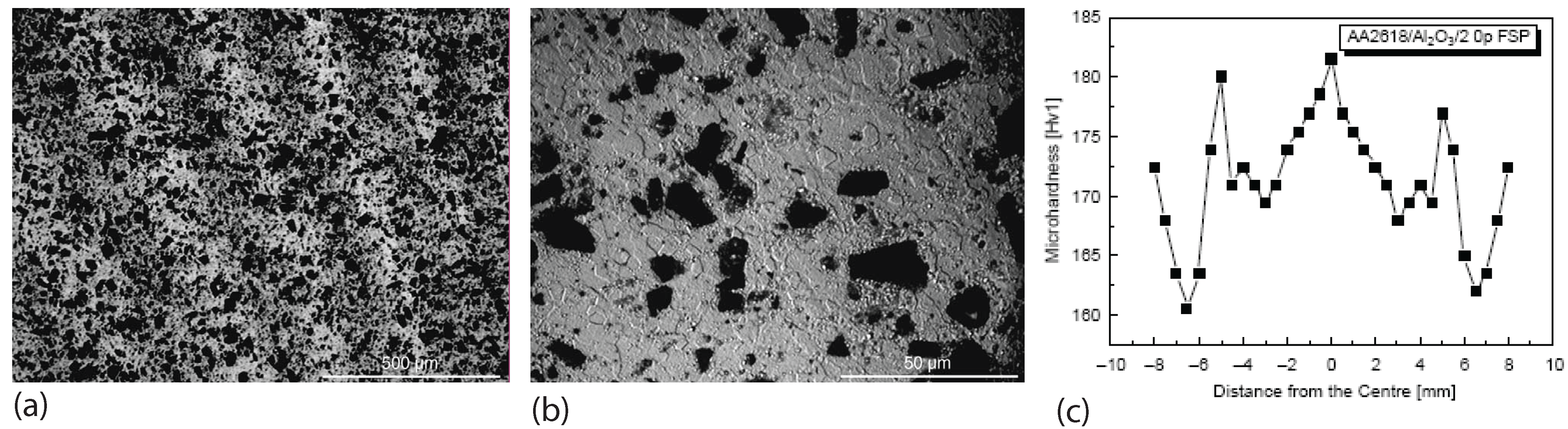

- Shafiei-Zarghani, A.; Kashani-Bozorg, S.F.; Zarei-Hanzaki, A. Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng., A 2009, 500, 84–91. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.S.; Kokawa, H. Microstructural evolution during friction stir-processing of pure iron. Acta Mater. 2008, 56, 2602–2614. [Google Scholar] [CrossRef]

- Ceschini, L.; Boromei, I.; Minak, G.; Morri, A.; Tarterini, F. Microstructure, tensile and fatigue properties of AA6061/20 vol %Al2O3p friction stir welded joints. Composites: Part A 2007, 38, 1200–1210. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y.; Charit, I. Friction stir processing: a novel technique for fabrication of surface composite. Mater. Sci. Eng., A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Liu, F.C. Achieving exceptionally high superplasticity at high strain rates in a micrograined Al-Mg-Sc alloy produced by friction stir processing. Scr. Mater. 2008, 59, 882–885. [Google Scholar]

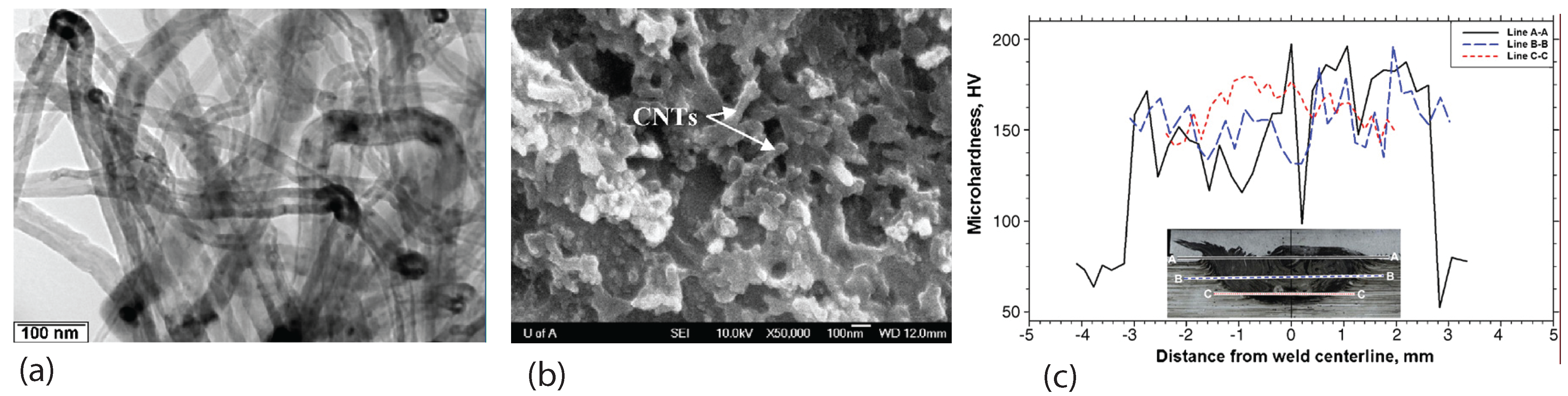

- Lim, D.K.; Shibayanagi, T.; Gerlich, A.P. Synthesis of multi-walled CNT reinforced aluminium alloy composite via friction stir processing. Mater. Sci. Eng., A 2009, 507, 194–199. [Google Scholar] [CrossRef]

- Surekha, K.; Murty, B.S.; Rao, K.P. Effect of processing parameters on the corrosion behaviour of friction stir processed AA 2219 aluminum alloy. Solid State Sci. 2009, 11, 907–917. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Sharma, S.R.; Mishra, R.S. Effect of multiple-pass friction stir processing on microstructure and tensile properties of a cast aluminum-silicon alloy. Scr. Mater. 2006, 54, 1623–1626. [Google Scholar] [CrossRef]

- McNelley, T.R.; Swaminathan, S.; Su, J.Q. Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr. Mater. 2008, 58, 349–354. [Google Scholar] [CrossRef] [Green Version]

- Johannes, L.B.; Mishra, R.S. Multiple passes of friction stir processing for the creation of superplastic 7075 aluminum. Mater. Sci. Eng., A 2007, 464, 255–260. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Marco, P.P. Friction stir processing of a Zr-modified 2014 aluminium alloy. Mater. Sci. Eng., A 2007, 462, 206–210. [Google Scholar]

- Yazdipour, A.; Shafiei, A.; Dehghani, M.K. Modeling the microstructural evolution and effect of cooling rate on the nanograins formed during the friction stir processing of Al5083. Mater. Sci. Eng., A 2009, 527, 192–197. [Google Scholar] [CrossRef]

- Liu, F.C.; Ma, Z.Y.; Chen, L.Q. Low-temperature superplasticity of Al-Mg-Sc alloy produced by friction stir processing. Scr. Mater. 2009, 60, 968–971. [Google Scholar] [CrossRef]

- Johannes, L.B.; Charit, I.; Mishra, R.S.; Verma, R. Enhanced superplasticity through friction stir processing in continuous cast AA5083 aluminum. Mater. Lett. 2007, 464, 351–357. [Google Scholar] [CrossRef]

- Fuller, M.D.; Swaminathan, S.; Zhilyaev, A.P.; McNelley, T.R. Microstructural transformations and mechanical properties of cast NiAl bronze: Effects of fusion welding and friction stir processing. Mater. Sci. Eng., A 2007, 463, 128–137. [Google Scholar] [CrossRef]

- Kobata, J.; Takigawa, Y.; Chung, S.W.; Tsuda, H.; Kimura, H.; Higashi, K. Nanoscale amorphous “band-like" structure induced by friction stir processing in Zr55Cu30Al10Ni5 bulk metallic glass. Mater. Lett. 2007, 61, 3771–3773. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Mizuno, T.; Abe, G.; Nagaoka, T.; Fukusumi, M. Nanostructured tool steel fabricated by combination of laser melting and friction stir processing. Mater. Sci. Eng., A 2009, 505, 157–162. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Mizuno, T.; Abe, G.; Nagaoka, T.; Fukusumi, M. Modification of nitride layer on cold-work tool steel by laser melting and friction stir processing. Surf. Coat. Technol. 2009, 204, 368–390. [Google Scholar] [CrossRef]

- Feng, A.H.; Ma, Z.Y. Microstructural evolution of cast Mg-Al-Zn during friction stir processing and subsequent aging. Acta Mater. 2009, 57, 4248–4260. [Google Scholar] [CrossRef]

- Ni, D.R.; Wang, D.; Feng, A.H.; Yao, G.; Ma, Z.Y. Enhancing the high-cycle fatigue strength of Mg-9Al-1Zn casting by friction stir processing. Scr. Mater. 2009, 61, 568–571. [Google Scholar] [CrossRef]

- Chang, C.I.; Du, X.H.; Huang, J.C. Producing nanograined microstructure in Mg-Al-Zn alloy by two-step friction stir processing. Scr. Mater. 2008, 59, 356–359. [Google Scholar] [CrossRef]

- Chang, C.I.; Lee, C.J.; Huang, J.C. Relationship between grain size and Zener-Holloman parameter during friction stir processing in AZ31 Mg alloys. Scr. Mater. 2004, 51, 509–514. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Marco, P.P. Friction stir processing of AM60B magnesium alloy sheets. Mater. Sci. Eng., A 2007, 462, 393–397. [Google Scholar] [CrossRef]

- Chang, C.I.; Du, X.H.; Huang, J.C. Achieving ultrafine grain size in Mg-Al-Zn alloy by friction stir processing. Scr. Mater. 2007, 57, 209–212. [Google Scholar] [CrossRef]

- Commin, L.; Dumont, M.; Masse, J.E.; Barrallier, L. Friction stir welding of AZ31 magnesium alloy rolled sheets: Influence of processing parameters. Acta Mater. 2009, 57, 326–334. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.Y.; Mishra, R.S.; Liu, F.C. Superplastic behavior of micro-regions in two-pass friction stir processed 7075Al alloy. Mater. Sci. Eng., A 2009, 505, 70–78. [Google Scholar] [CrossRef]

- Lakshminarayanan, A.K.; Balasubramanian, V. Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique. Trans. Nonferrous Met. Soc. China 2008, 18, 548–554. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; de Oliveira, F.M.F.; de Castro, P.M.S.T. Fatigue behavior of notched specimens of friction stir welded aluminium alloy 6063-T6. J. Mater. Process. Technol. 2008, 207, 283–292. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng., A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Vecchio, K.S. Thermal history analysis of friction stir processed and submerged friction stir processed aluminum. Mater. Sci. Eng., A 2009, 465, 165–175. [Google Scholar] [CrossRef]

- Cui, G.R.; Ma, Z.Y.; Li, S.X. Periodical plastic flow pattern in friction stir processed Al-Mg alloy. Scr. Mater. 2008, 58, 1082–1085. [Google Scholar]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater. Des. 2008, 29, 362–373. [Google Scholar]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy. J. Mater. Process. Technol. 2008, 200, 163–175. [Google Scholar]

- Buffa, G.; Fratini, L.; Pasta, S.; Shivpuri, R. On the thermo-mechanical loads and the resultant residual stresses in friction stir processing operations. CIRP Ann. - Manuf. Technol. 2008, 57, 287–290. [Google Scholar]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. Effect of friction stir processing with SiC particles on microstructure and hardness of AZ31. Mater. Sci. Eng., A 2006, 433, 50–54. [Google Scholar] [CrossRef]

- Liechty, B.C.; Webb, B.W. Modeling the frictional boundary condition in friction stir welding. Int. J. Mach. Tool. Manuf. 2008, 48, 1474–1485. [Google Scholar]

- Elangovan, K.; Balasubramanian, V.; Babu, S. Predicting tensile strength of friction stir welded AA6061 aluminium alloy joints by a mathematical model. Mater. Des. 2009, 30, 188–193. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.W. Numerical studies on controlling of process parameters in friction stir welding. J. Mater. Process. Technol. 2009, 209, 241–270. [Google Scholar] [CrossRef]

- Wang, Y.; Mishra, R.S. Finite element simulation of selective superplastic forming of friction stir processed 7075 Al alloy. Mater. Sci. Eng., A 2007, 463, 245–248. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of welding parameters on mechanical and microstructural properties of dissimilar AA6082-AA2024 joints produced by friction stir welding. Mater. Des. 2009, 30, 609–616. [Google Scholar] [CrossRef]

- Cavaliere, P.; Cabibbo, M.; Panella, F.; Squillace, A. 2198 Al-Li plates joined by Friction Stir Welding: Mechanical and microstructural behavior. Mater. Des. 2009, 30, 3622–3631. [Google Scholar] [CrossRef]

- Cui, G.R.; Ma, Z.Y.; Li, S.X. The origin of non-uniform microstructure and its effects on the mechanical properties of a friction stir processed Al-Mg alloy. Acta Mater. 2009, 57, 5718–5729. [Google Scholar]

- Hirata, T.; Tanaka, T.; Chung, S.W.; Takigawa, Y.; Higashi, K. Relationship between deformation behavior and microstructural evolution of friction stir processed Zn-22 wt.% Al alloy. Scr. Mater. 2007, 56, 477–480. [Google Scholar]

- Cavaliere, P.; Squillace, A.; Panella, F. Effect of welding parameters on mechanical and microstructural properties of AA6082 joints produced by friction stir welding. J. Mater. Process. Technol. 2008, 200, 364–372. [Google Scholar] [CrossRef]

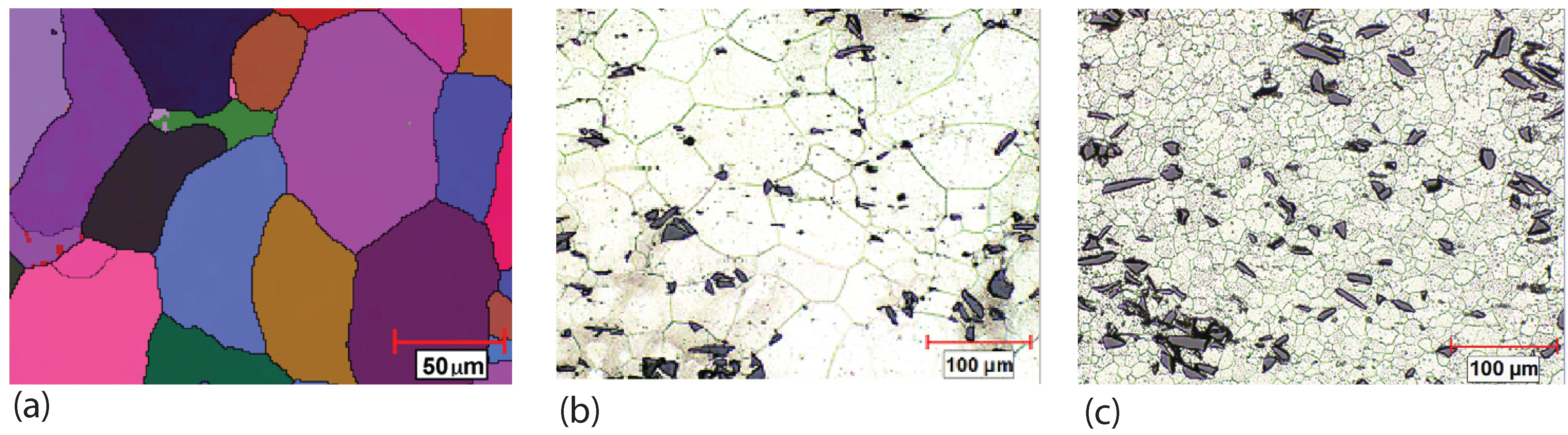

- Tewari, A.; Spowart, J.E.; Gokhale, A.M.; Mishra, R.S.; Miracle, D.B. Characterization of the effects of friction stir processing on microstructural changes in DRA composites. Mater. Sci. Eng., A 2006, 428, 80–90. [Google Scholar] [CrossRef]

- Fernandez, G.J.; Murr, L.E. Characterization of tool wear and weld optimization in the friction-stir welding of cast aluminum 359+20% SiC metal-matrix composite. Mater. Charact. 2004, 52, 65–75. [Google Scholar] [CrossRef]

- Uzun, H. Friction stir welding of SiC particulate reinforced AA2124 aluminium alloy matrix composite. Mater. Des. 2007, 28, 1440–1446. [Google Scholar] [CrossRef]

- Feng, A.H.; Xiao, B.L.; Ma, Z.Y. Effect of microstructural evolution on mechanical properties of friction stir welded AA2009/SiCp composite. Compos. Sci. Technol. 2008, 68, 2141–2148. [Google Scholar]

- Prangnell, P.B.; Heason, C.P. Grain structure formation during friction stir welding observed by the ‘stop action technique’. Acta Mater. 2005, 53, 3179–3192. [Google Scholar]

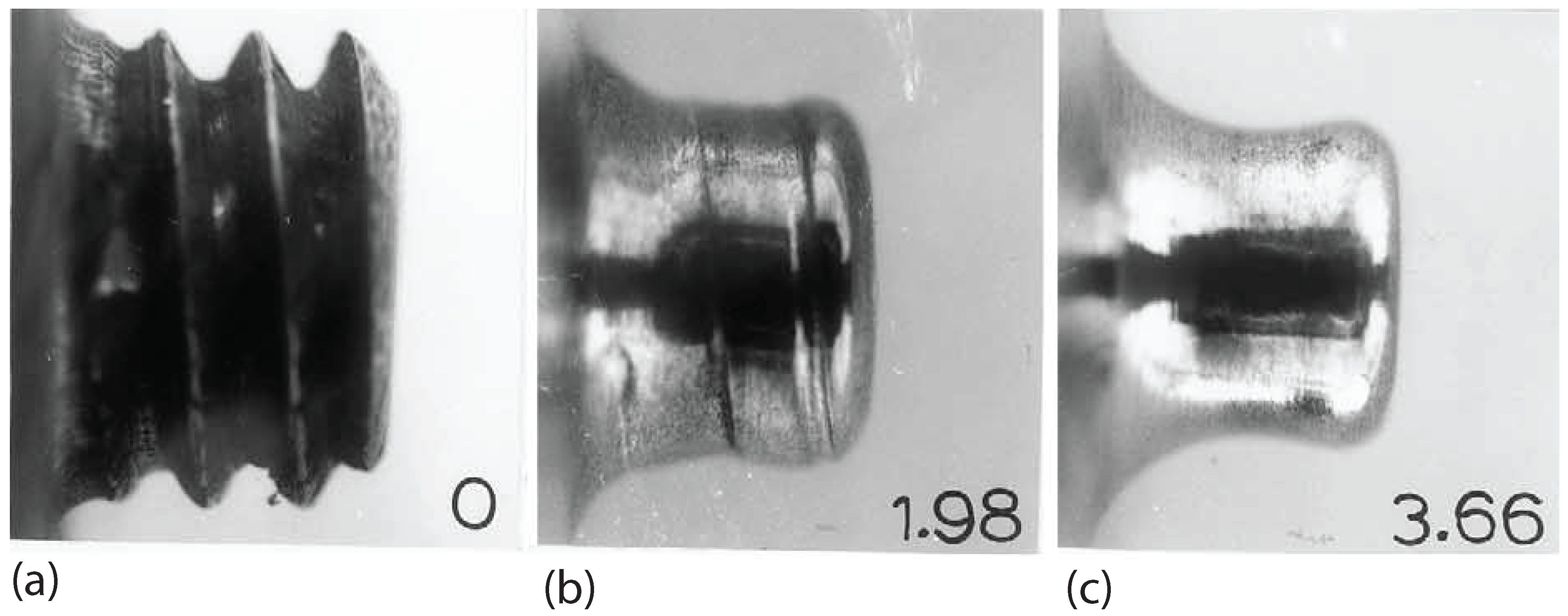

- Prado, R.A.; Murr, L.E.; Soto, K.F.; McClure, J.C. Self-optimization in tool wear for friction-stir welding of Al 6061+20% Al2O3 MMC. Mater. Sci. Eng. A 2003, 349, 156–165. [Google Scholar] [CrossRef]

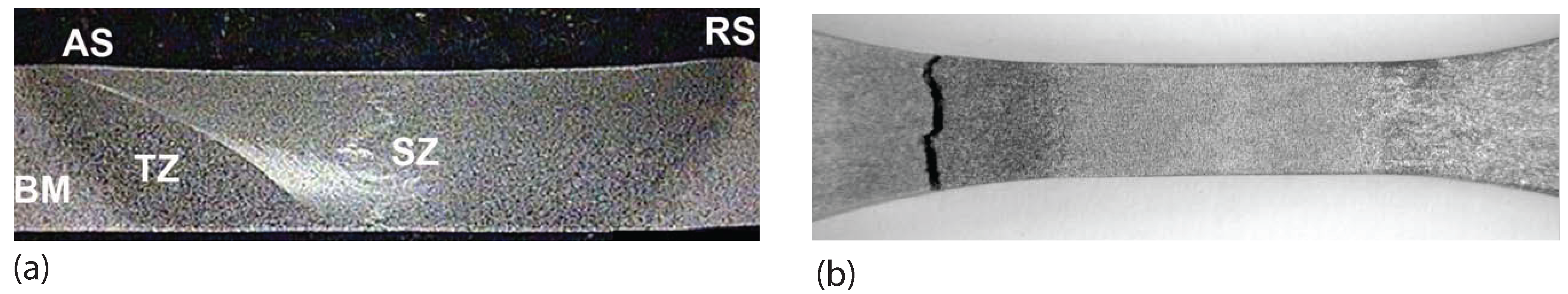

- Pirondi, A.; Collini, L. Analysis of crack propagation resistance of AlAl2O3 particulate-reinforced composite friction stir welded butt joints. Int. J. Fatigue 2009, 31, 111–121. [Google Scholar] [CrossRef]

- Marzoli, L.M.; Strombeck, A.V.; Dos Santos, J.F.; Gambaro, C.; Volpone, L.M. Friction stir welding of an AA6061/Al2O3/20p reinforced alloy. Compos. Sci. Technol. 2006, 66, 363–371. [Google Scholar] [CrossRef]

- Cavaliere, P. Mechanical properties of Friction Stir Processed 2618/Al2O3/20p metal matrix composite. Composites: Part A 2005, 36, 1657–1665. [Google Scholar]

- Chen, X.-G.; da Silvaa, M.; Gougeonb, P.; St-Georges, L. Microstructure and mechanical properties of friction stir welded AA6063B4C metal matrix composites. Mater. Sci. Eng. A 2009, 518, 174–184. [Google Scholar] [CrossRef]

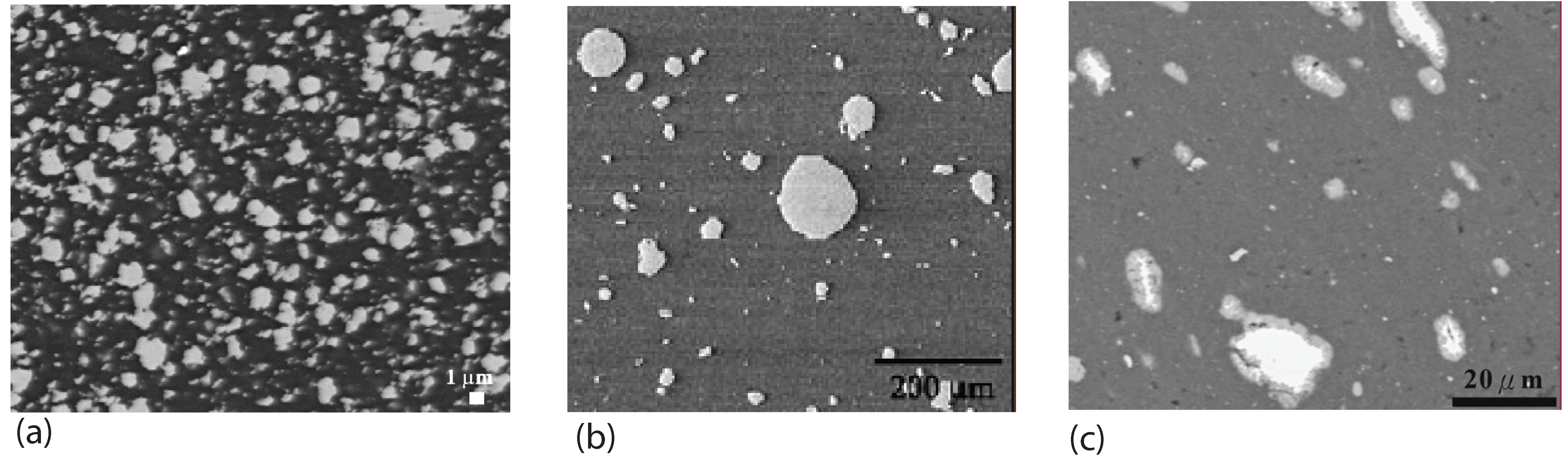

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Intermetallic-reinforced aluminum matrix composites produced in situ by friction stir processing. Mater. Lett. 2007, 61, 1315–1318. [Google Scholar]

- Dixit, M.; Newkirk, J.W.; Mishra, R.S. Properties of friction stir-processed Al 1100NiTi composite. Scr. Mater. 2007, 56, 541–544. [Google Scholar]

- Lee, I.S.; Kao, P.W.; Ho, N.J. Microstructure and mechanical properties of AlFe in situ nanocomposite produced by friction stir processing. Intermetallics 2008, 16, 1104–1108. [Google Scholar] [CrossRef]

- Callister, W.D. Materials Science and Engineering An Introduction, 6th ed.; John Wiley: New York, NY, USA, 2005; pp. 349–350. [Google Scholar]

- Lee, C.J.; Huang, J.C.; Hsieh, P.J. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. MWCNTs/AZ31 surface composites fabricated by friction stir processing. Mater. Sci. Eng., A 2006, 419, 344–348. [Google Scholar] [CrossRef]

- Lee, W.B.; Lee, C.Y.; Kim, M.K.; Yoon, J.I.; Kim, Y.J.; Yoen, Y.M.; Jung, S.B. Microstructures and wear property of friction stir welded AZ91 Mg/SiC particle reinforced composite. Compos. Sci. Technol. 2006, 66, 1513–1520. [Google Scholar] [CrossRef]

- Suhuddin, U.F.H.R.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Lee, C.-W. Grain structure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater. 2009, 57, 5406–5418. [Google Scholar] [CrossRef]

- Zinkle, S.J. Overview of the US fusion materials sciences program. Fusion Eng. Des. 2005, 47, 821–828. [Google Scholar]

- Kohyama, A. Current status of fusion reactor structural materials R & D. Mater. Trans. 2005, 46, 384–393. [Google Scholar]

- Muroga, T. Vanadium alloys for fusion blanket applications. Mater. Trans. 2005, 46, 405–411. [Google Scholar] [CrossRef]

- Kohyama, A.; Abe, K.; Kimura, A.; Muroga, T.; Jitsukawa, S. Recent accomplishments and future prospects of materials R & D in Japan. Fusion Eng. Des. 2005, 47, 836–843. [Google Scholar]

- Muroga, T.; Nagasaka, T.; Nishimura, A.; Chen, J.M. Improvement of vanadium alloys by precipitate control for structural components of fusion reactors. Mater. Sci. Forum 2005, 475~479, 1449–1453. [Google Scholar] [CrossRef]

- Yao, Z.Y.; Suzuki, A.; Nakasaka, T.; Muroga, T. Behavior of oxygen in fusion candidate vanadium alloysduring oxidation and annealing. Mater. Sci. Forum 2005, 475–479, 1445–1448. [Google Scholar] [CrossRef]

- Watanabe, H.; Nagamine, M.; Yamasaki, K.; Yoshida, N.; Heo, N.J.; Nagasaka, T.; Muroga, T. The microstructure of laser welded V-4Cr-4Ti alloy after ion irradiation. Mater. Sci. Forum 2005, 475–479, 1491–1495. [Google Scholar] [CrossRef]

- Chung, H.M.; Strain, R.V.; Tsai, H.C.; Park, J.H.; Smith, D.L. Impact properties and hardening behaviour of laser and electron-beam welds of V-4Cr-4Ti. Fusion Mater., Semiann. Prog. Rep. 1996, 55–58. [Google Scholar]

- Loomis, B.A.; Koicek, C.F.; Nowicki, L.J.; Smith, D.L. Tensile properties of vanadium-base alloys with a tungsten/inert-gas weld zone. Fusion Mater., Semiann. Prog. Rep. 1993, 187–191. [Google Scholar]

- Fukumoto, K.; Takahashi, K.; Anma, Y.; Matsui, H. Effects of impurities on microstructural evolution and deformation process of ion-irradiated V-Cr-Ti alloys. Mater. Trans. 2005, 46, 503–510. [Google Scholar] [CrossRef]

- Hatano, Y.; Hayakawa, R.; Nishino, K.; Ikeno, S.; Nagasaka, T.; Muroga, T.; Watanabe, K. Surface segregation of Ti in a V-4Cr-4Ti alloy and its influence on the surface reaction rates of hydrogen isotopes. Mater. Trans. 2005, 46, 511–516. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203 and GB Patent Application No. 9125978, 1991. [Google Scholar]

- Arici, A.; Sinmazcelik, T. Effects of double passes of the tool on friction stir welding of polyethylene. J. Mater. Sci. 2005, 40, 3313–3316. [Google Scholar] [CrossRef]

- Cho, J.H.; Boyce, D.E.; Dawson, P.R. Effects of impurities on microstructural evolution and deformation process of ion-irradiated V-Cr-Ti alloys. Mater. Sci. Eng., A 2005, 398, 146–163. [Google Scholar] [CrossRef]

- Sato, Y.; Nelson, T.W.; Sterling, C.J.; Steel, R.J.; Pettersson, C.O. Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel. Mater. Sci. Eng., A 2005, 397, 376–384. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, S.B.; Wu, L.; Feng, J.C.; Ma, S.L. Defects formation procedure and mathematic model for defect free friction stir welding of magnesium alloy. Mater. Des. 2006, 27, 805–809. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Hood, E.; Tang, W. Texture in friction stir welds of Timetal 21S. Scr. Mater. 2005, 52, 491–494. [Google Scholar] [CrossRef]

- Lee, W.B.; Jung, S.B. The joint properties of copper by friction stir welding. Mater. Lett. 2004, 58, 1041–1046. [Google Scholar] [CrossRef]

- Park, H.S.; Kimura, T.; Murakami, T.; Nagano, Y.; Nakata, K.; Ushio, M. Microstructures and mechanical properties of friction stir welds of 60% Cu-40% Zn copper alloy. Mater. Sci. Eng., A 2004, 371, 160–169. [Google Scholar] [CrossRef]

- Prado, R.A.; Murr, L.E.; Shindo, D.J.; Soto, K.F. Tool wear in the friction-stir welding of aluminum alloy 6061+20% Al2O3: A preliminary study. Scr. Mater. 2001, 45, 75–80. [Google Scholar] [CrossRef]

- Santella, M.L.; Engstrom, T.; Storjohann, D.; Pan, T.Y. Effects of friction stir processing on mechanical properties of the cast aluminum alloys A319 and A356. Scr. Mater. 2005, 45, 201–206. [Google Scholar] [CrossRef]

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Ultrafine-grained Al–Al2Cu composite produced in situ by friction stir processing. Scr. Mater. 2005, 53, 341–345. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar]

- Williams, S.W. Welding of airframes using friction stir. Air Space Eur. 2001, 3, 64–66. [Google Scholar] [CrossRef]

- Sanderson, A.; Punshon, C.S.; Russell, J.D. Advanced welding processes for fusion reactor fabrication. Fusion Eng. Des. 2000, 49–50, 77–87. [Google Scholar] [CrossRef]

- Arici, A.; Mert, S. Friction stir spot welding of polypropylene. J. Reinf. Plast. Compos. 2008, 27, 2001–2004. [Google Scholar] [CrossRef]

- Arici, A.; Selale, S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Joining 2007, 12, 536–539. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Minak, G.; Ceschini, L.; Boromei, I.; Ponte, M. Fatigue properties of friction stir welded particulate reinforced aluminium matrix composites. Int. J. Fatigue 2010, 32, 218–226. [Google Scholar] [CrossRef]

- McClure, J.C.; Tang, W.; Murr, L.E.; Guo, X.; Feng, Z.; Gould, J.E. A thermal model of friction-stir welding. In Trends in Welding Research; Vitak, J.M., David, S.A., Johnson, J.A., Smartt, H.B., Deb Roy, T., Eds.; Am Welding Soc/ASM Int: Materials Park, OH, USA, 1999; pp. 590–595. [Google Scholar]

- Mishra, R.S.; Mahoney, M.W. Friction stir processing: A new grain refinement technique to achieve high strain rate superplasticity in commercial alloys. Mater. Sci. Forum 2001, 357–359, 507–512. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effect of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Liu, G.; Murr, L.E.; Niou, C.-S.; McClure, J.C.; Vega, F.R. Microstructural aspect of the friction stir welding of 6061-T6 aluminum. Scr. Mater. 1997, 37, 355–361. [Google Scholar] [CrossRef]

- Murr, L.E.; Li, Y.; Flores, R.D.; Trillo, E.A.; McClure, J.C. Intercalation vortices and related microstructural features in the friction-stir welding of dissimilar metals. Mater. Res. Innovations 1998, 293, 150–163. [Google Scholar] [CrossRef]

- Li, Y.; Murr, L.E.; McClure, J.C. Flow visualization and residual microstructures associated with the friction-stir welding of 2024 aluminum to 6061 aluminum. Mater. Sci. Eng., A 1999, 271, 213–223. [Google Scholar] [CrossRef]

- Guerra, M.; McClure, J.C.; Murr, L.E.; Nunes, A.C. Metal flow during friction stir welding. In Friction Stir Welding and Processing; Jata, K.V., Mahoney, M.W., Mishra, R.S., Semiatin, S.L., Field, D.P., Eds.; TMS (The Minerals, Metals and Materials Society): Warrendale, PA, USA, 2001; pp. 25–34. [Google Scholar]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license http://creativecommons.org/licenses/by/3.0/.

Share and Cite

Gan, Y.X.; Solomon, D.; Reinbolt, M. Friction Stir Processing of Particle Reinforced Composite Materials. Materials 2010, 3, 329-350. https://doi.org/10.3390/ma3010329

Gan YX, Solomon D, Reinbolt M. Friction Stir Processing of Particle Reinforced Composite Materials. Materials. 2010; 3(1):329-350. https://doi.org/10.3390/ma3010329

Chicago/Turabian StyleGan, Yong X., Daniel Solomon, and Michael Reinbolt. 2010. "Friction Stir Processing of Particle Reinforced Composite Materials" Materials 3, no. 1: 329-350. https://doi.org/10.3390/ma3010329