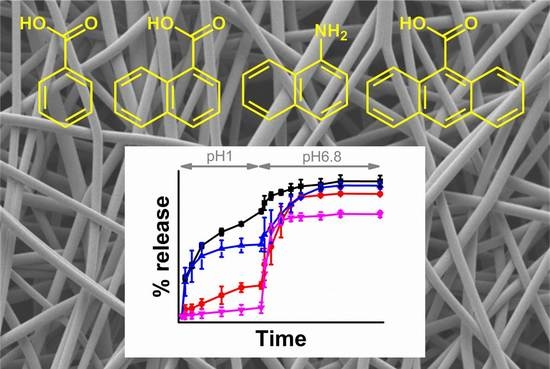

The Effect of Molecular Properties on Active Ingredient Release from Electrospun Eudragit Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Monoaxial Electrospinning

2.2.2. Coaxial Electrospinning

2.3. Characterisation

2.3.1. Electron Microscopy

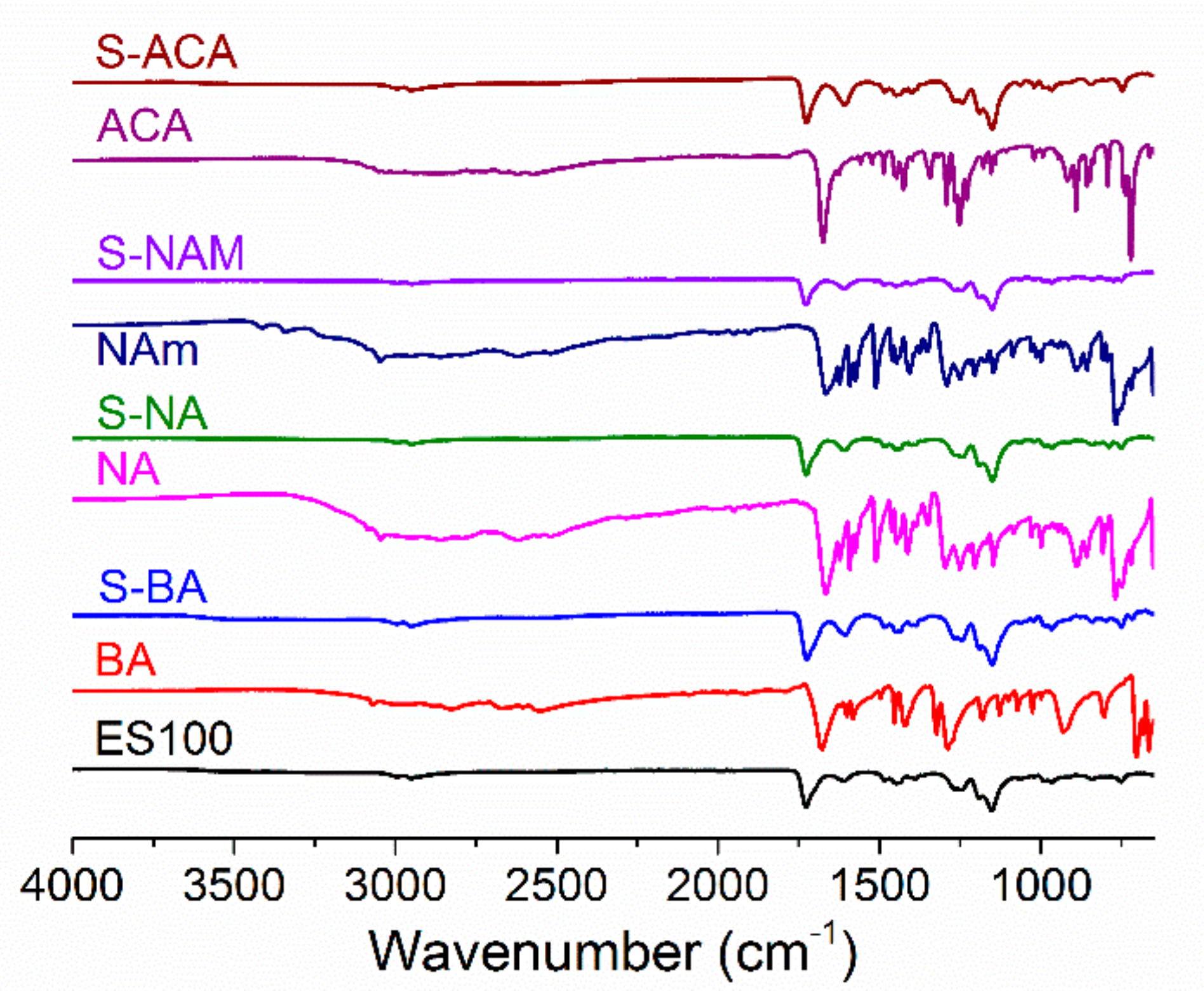

2.3.2. Physical Form Characterisation

2.3.3. Active Ingredient Loading

2.4. Dissolution Studies

3. Results

3.1. Monolithic Fibers

3.2. Core/Shell Fibers

3.3. AI Release

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sebe, I.; Szabo, P.; Kallai-Szabo, B.; Zelko, R. Incorporating small molecules or biologics into nanofibers for optimized drug release: A review. Int. J. Pharm. 2015, 494, 516–530. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Jiang, J.; Davoodi, P.; Srinivasan, M.P.; Wang, C.H. Electrohydrodynamic atomization: A two-decade effort to produce and process micro-/nanoparticulate materials. Chem. Eng. Sci. 2015, 125, 32–57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, D.G.; Shen, X.X.; Branford-White, C.; White, K.; Zhu, L.M.; Bligh, S.W. Oral fast-dissolving drug delivery membranes prepared from electrospun polyvinylpyrrolidone ultrafine fibers. Nanotechnology 2009, 20, 055104. [Google Scholar] [CrossRef] [PubMed]

- Illangakoon, U.E.; Gill, H.; Shearman, G.C.; Parhizkar, M.; Mahalingam, S.; Chatterton, N.P.; Williams, G.R. Fast dissolving paracetamol/caffeine nanofibers prepared by electrospinning. Int. J. Pharm. 2014, 477, 369–379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, H.; Wang, Q.; Li, G.; Qiu, Y.; Wei, Q. Electrospun water-stable zein/ethyl cellulose composite nanofiber and its drug release properties. Mater. Sci. Eng. C 2017, 74, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.X.; Zheng, W.; Li, L.; Zheng, Y.F. Fabrication, characterization and in vitro drug release behavior of electrospun PLGA/chitosan nanofibrous scaffold. Mater. Chem. Phys. 2011, 125, 606–611. [Google Scholar] [CrossRef]

- Jia, X.; Zhao, C.; Li, P.; Zhang, H.; Huang, Y.; Li, H.; Fan, J.; Feng, W.; Yuan, X.; Fan, Y. Sustained release of VEGF by coaxial electrospun dextran/PLGA fibrous membranes in vascular tissue engineering. J. Biomater. Sci. Polym. Ed. 2011, 22, 1811–1827. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Wang, C.H. Electrospun micro- and nanofibers for sustained delivery of paclitaxel to treat C6 glioma in vitro. Pharm. Res. 2006, 23, 1817–1826. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Williams, G.R.; Wu, J.; Lv, Y.; Sun, X.; Wu, H.; Zhu, L.M. Thermosensitive nanofibers loaded with ciprofloxacin as antibacterial wound dressing materials. Int. J. Pharm. 2017, 517, 135–147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Williams, G.R.; Wu, J.; Wang, H.; Sun, X.; Zhu, L.M. Poly(N-isopropylacrylamide)/poly(l-lactic acid-co-caprolactone) fibers loaded with ciprofloxacin as wound dressing materials. Mater. Sci. Eng. C 2017, 79, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Li, H.-Y.; Williams, G.R.; Yang, H.-H.; Tao, L.; Zhu, L.-M. Electrospun poly(N-isopropylacrylamide)/ethyl cellulose nanofibers as thermoresponsive drug delivery systems. J. Pharm. Sci. 2016, 105. [Google Scholar] [CrossRef]

- Lin, X.; Tang, D.; Cui, W.; Cheng, Y. Controllable drug release of electrospun thermoresponsive poly(N-isopropylacrylamide)/poly(2-acrylamido-2-methylpropanesulfonic acid) nanofibers. J. Biomed. Mater. Res. A 2012, 100, 1839–1845. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yu, D.G.; Li, X.Y.; Bligh, S.W.; Williams, G.R. Electrospun medicated shellac nanofibers for colon-targeted drug delivery. Int. J. Pharm. 2015, 490, 384–390. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salehi, R.; Irani, M.; Eskandani, M.; Nowruzi, K.; Davaran, S.; Haririan, I. Interaction, controlled release, and antitumor activity of doxorubicin hydrochloride from pH-sensitive p(NIPAAm-MAA-VP) nanofibrous scaffolds prepared by green electrospinning. Int. J. Polym. Mater. 2014, 63, 609–619. [Google Scholar] [CrossRef]

- Shen, X.; Yu, D.; Zhu, L.; Branford-White, C.; White, K.; Chatterton, N.P. Electrospun diclofenac sodium loaded Eudragit(R) L 100-55 nanofibers for colon-targeted drug delivery. Int. J. Pharm. 2011, 408, 200–207. [Google Scholar] [CrossRef] [PubMed]

- Illangakoon, U.E.; Nazir, T.; Williams, G.R.; Chatterton, N.P. Mebeverine-loaded electrospun nanofibers: Physicochemical characterization and dissolution studies. J. Pharm. Sci. 2014, 103, 283–292. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.-G.; Williams, G.R.; Wang, X.; Liu, X.-K.; Li, H.-L.; Bligh, S.W.A. Dual drug release nanocomposites prepared using a combination of electrospraying and electrospinning. RSC Adv. 2013, 3, 4652. [Google Scholar] [CrossRef]

- Akhgari, A.; Heshmati, Z.; Afrasiabi Garekani, H.; Sadeghi, F.; Sabbagh, A.; Sharif Makhmalzadeh, B.; Nokhodchi, A. Indomethacin electrospun nanofibers for colonic drug delivery: In vitro dissolution studies. Colloids Surf. B 2017, 152, 29–35. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, D.-G.; Liu, F.; Cui, L.; Liu, Z.-P.; Wang, X.; Bligh, S.W.A. Coaxial electrospinning using a concentric Teflon spinneret to prepare biphasic-release nanofibers of helicid. RSC Adv. 2013, 3, 17775–17783. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Guhathakarta, S.; Rajaram, R.; Korrapati, P.S. Electrospun zein/eudragit nanofibers based dual drug delivery system for the simultaneous delivery of aceclofenac and pantoprazole. Int. J. Pharm. 2012, 438, 117–122. [Google Scholar] [CrossRef] [PubMed]

- Balogh, A.; Farkas, B.; Domokos, A.; Farkas, A.; Démuth, B.; Borbás, E.; Nagy, B.; Marosi, G.; Nagy, Z.K. Controlled-release solid dispersions of Eudragit® FS 100 and poorly soluble spironolactone prepared by electrospinning and melt extrusion. Eur. Polym. J. 2017, 95, 406–417. [Google Scholar] [CrossRef]

- Illangakoon, U.E.; Yu, D.G.; Ahmad, B.S.; Chatterton, N.P.; Williams, G.R. 5-Fluorouracil loaded Eudragit fibers prepared by electrospinning. Int. J. Pharm. 2015, 495, 895–902. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, M.; Yu, D.G.; Wang, X.; Geraldes, C.F.; Williams, G.R.; Bligh, S.W. Electrospun contrast-agent-loaded fibers for colon-targeted MRI. Adv. Healthcare Mater. 2016, 5, 977–985. [Google Scholar] [CrossRef] [PubMed]

- Jin, M.; Yu, D.G.; Geraldes, C.F.; Williams, G.R.; Bligh, S.W. Theranostic fibers for simultaneous imaging and drug delivery. Mol. Pharm. 2016, 13, 2457–2465. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Gao, Y.; Williams, G.R. Core/shell poly(ethylene oxide)/Eudragit fibers for site-specific release. Int. J. Pharm. 2017, 523, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.G.; Li, X.Y.; Wang, X.; Yang, J.H.; Bligh, S.W.; Williams, G.R. Nanofibers fabricated using triaxial electrospinning as zero order drug delivery systems. ACS Appl. Mater. Interfaces 2015, 7, 18891–18897. [Google Scholar] [CrossRef] [PubMed]

| ID | Active Ingredient (AI) | Theoretical Fiber AI Loading (% w/w) a | Observed Fiber AI Loading (% w/w) b | Entrapment Efficiency (%) c | Fiber Diameter (nm) |

|---|---|---|---|---|---|

| Monoaxial electrospinning | |||||

| S-BA | Benzoic acid | 7.69 | 9.04 ± 0.13 | 118 ± 2 | 483 ± 145 |

| S-NA | 1-Naphthoic acid | 7.69 | 7.05 ± 1.02 | 92 ± 13 | 129 ± 102 |

| S-NAM | 1-Naphthylamine | 7.69 | 6.69 ± 0.27 | 91 ± 4 | 214 ± 105 |

| S-ACA | 9-Anthracene carboxylic acid | 7.69 | 6.54 ± 0.38 | 85 ± 5 | 585 ± 158 |

| Coaxial electrospinning | |||||

| C-BA | Benzoic acid | 2.70 | 3.42 ± 0.27 | 127 ± 10 | 591 ± 189 |

| C-NA | 1-Naphthoic acid | 2.70 | 2.38 ± 0.07 | 88 ± 2 | 664 ± 171 |

| C-NAM | 1-Naphthylamine | 2.70 | 2.20 ± 0.37 | 81 ± 14 | 547 ± 124 |

| C-ACA | 9-Anthracene carboxylic acid | 2.70 | 2.45 ± 0.16 | 91 ± 6 | 621 ± 140 |

| Formulation | n | k (min−1) |

|---|---|---|

| S-BA | 0.14 | 0.48 |

| S-NA | 0.28 | 0.16 |

| S-NAM | 0.10 | 0.51 |

| S-ACA | 0.36 | 0.055 |

| C-BA | 0.11 | 0.47 |

| C-NA | 0.25 | 0.18 |

| C-NAM | 0.22 | 0.27 |

| C-ACA | NC | NC |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burgess, K.; Li, H.; Abo-zeid, Y.; Fatimah; Williams, G.R. The Effect of Molecular Properties on Active Ingredient Release from Electrospun Eudragit Fibers. Pharmaceutics 2018, 10, 103. https://doi.org/10.3390/pharmaceutics10030103

Burgess K, Li H, Abo-zeid Y, Fatimah, Williams GR. The Effect of Molecular Properties on Active Ingredient Release from Electrospun Eudragit Fibers. Pharmaceutics. 2018; 10(3):103. https://doi.org/10.3390/pharmaceutics10030103

Chicago/Turabian StyleBurgess, Kieran, Heyu Li, Yasmin Abo-zeid, Fatimah, and Gareth R. Williams. 2018. "The Effect of Molecular Properties on Active Ingredient Release from Electrospun Eudragit Fibers" Pharmaceutics 10, no. 3: 103. https://doi.org/10.3390/pharmaceutics10030103

APA StyleBurgess, K., Li, H., Abo-zeid, Y., Fatimah, & Williams, G. R. (2018). The Effect of Molecular Properties on Active Ingredient Release from Electrospun Eudragit Fibers. Pharmaceutics, 10(3), 103. https://doi.org/10.3390/pharmaceutics10030103