1. Introduction

The construction industry has unique characteristics that differentiate it from other industry sectors [

1]. It has order-based production, fixed production times, established locations for operations, non-repetitive tasks, and low productivity compared to other industries [

2,

3]. These unique characteristics have acted as barriers to enacting a new paradigm. To overcome this problem, construction firms around the US have performed research since 1980 in order to apply information technology (IT) to the construction industry. Recently, as a result of this research, a mobile IT application [

4] has been developed for use in the construction industry. These new IT technologies that are being applied to the construction industry contribute to productivity improvement and technological enhancement and their importance is ever increasing [

5].

The Korean construction industry has also expressed the need for technological development and national policies for construction information standardization in order to improve the construction techniques and to implement IT environments. Through the basic construction industry law (1996), the development of a comprehensive construction information system and the use of IT systems in the construction industry were legalized, contributing to the development of construction techniques and the promotion of the construction market. As the construction market started being promoted in the early 2000s, the construction management (CM) market achieved a rapid growth of 630%, going from US$10,469 million in 2001, to US$660,469 million in 2012 [

6]. Contributing to this growth, many CM firms began to emerge. According to research conducted by the Ministry of Land, Infrastructure and Transport [

7], by 2013, 32% of CM firms held more than 300 regular employees, 25% had assets of more than US$5 million, and their size and assets were continuously growing. However, after the global financial crisis in 2008, the amount of orders in CM market decreased by more than US$97 million, intensifying the competition between CM firms, in turn resulting in decreases of profit rates and increases in the uncertainty of the construction industry [

8]. For these reasons, the need for risk management in CM firms was presented in order to minimize firms’ losses.

However, according to an analysis performed by Park et al. [

9] on the risk management situation of Korean CM firms, most Korean CM firms have no risk departments, managers, or risk management procedures; moreover, it was confirmed that they did not invest in risk management training, and they could not systematically and effectively manage the risks owing to the lack of risk management systems. Thus, this analysis presents the need to develop and implement standard operating systems and risk management systems. The absence of a risk management system has a negative impact on CM firms and prevents them from responding systematically and reasonably to risks that occur during field operations [

10]. Considering that managing potential risks can reduce uncertainty and minimize losses [

11], it is essential to develop new countermeasures by creating effective risk management systems and implementing them in construction sites so that risk management can play a central role in achieving stable earnings.

Thus, in this study, the main risk factors that must be managed were defined by deducing risk factors that could occur during field operation management at CM firms and performing an assessment of risks. Additionally, a system functional block diagram is presented and its functions are defined based on main risk factors. Based upon this data, an analysis on both the date flow diagram (DFD) and the entity relationship diagram (ERD) was performed, resulting in the development of the construction management risk system (CMRS). As for the effects of developing CMRS as proposed in this study, the risk management of CM firms identified various issues such as confusion in response procedures, inability to recognize responsible entity, and difficulty in initial reaction due to lack of clear management standards and systematic manuals. However, the efficiency of risk management tasks by CM firms can be improved by providing a clear response process for each risk factor by applying CMRS, which enables initial reaction, clarifies who is responsible by confirming the relevant staff, and takes prompt measures for contract revocation by managing the records. Additionally, this field operation risk management system is capable of performing systematic and effective management of risks, resulting in workload reduction, countermeasure-related decision support, countermeasure-related results checking, and database management of records.

2. Literature Review and Research Steps

2.1. Literature Review

Since the end of 1984, application service providers (ASP)-based project information management systems (PIMSs) have been developed for implementation in the construction industry [

12]. Since 1990, studies on the implementation of mobile IT in the construction industry have been performed [

13]. Recently, mobile IT application studies [

14] have been performed, and mobile PIMSs equipped with some PIMS module functions are being constantly implemented in the field. In addition, building information modeling (BIM) offers support for structural analysis and design works [

15,

16], construction and building energy simulations [

17,

18], and applicability to leadership in energy and environmental design (LEED) and integrated design process (IPD) projects. For these reasons, BIM has led to many changes in the construction industry [

19,

20], and it is also being actively used in green building design [

21,

22]. Likewise, as the construction industry changes, the exchange and utilization of information via IT devices is becoming very important, and such importance will continue [

23].

In order to effectively manage the risks that occur during construction works, Al-Bahar and Crandall [

24] proposed a process framework intended for developing a risk management system (RMS) after establishing countermeasures for each of the risk factors. Jannadi and Almishari [

25] proposed a risk assessor model (RAM) intended for evaluating and measuring the time of occurrence and degree of impact for safety risks that occur during construction work processes. Liang et al. [

26] analyzed the safety management practices implemented in Chinese public mega-buildings, which are currently being built continuously. From this analysis, problems with construction laws and government regulators were observed, and a plan for improving safety management methods and procedures was presented. Based on this, a plan for developing a mega public building safety risk assessment system was proposed. Staneff et al. [

27] proposed risk management measures with regard to the aging of ocean platforms and the implementation of a software-based ocean risk management system that included data management functions for ocean wind probability, waves, and earthquakes. Instead of showing only graphics and results, Zhou et al. [

28] showed the reciprocal relationship between risk occurrence and risk management processes by applying an existing risk management system to the Chinese city gas line project through the geographic information system (GIS). Essamin et al. [

29] proposed a prototype of the prestressed concrete cylinder pipeline (PCCP) risk management system that used colors to represent five risk levels, making possible its implementation on the internet. Kim et al. [

30] identified actual conditions of risk management at construction worksites and presented an improvement plan for problems of risk management and analysis. To develop a risk management system, this plan was classified into four steps: risk management preparation, risk check, risk analysis, and risk response. Then, an integrated computational building model was presented that enabled risk management for each process.

Likewise, studies on risk management systems are being performed principally centered on project risk management (PRM). However, more studies are still required for the development of effective risk management systems for the field operations of CM firms.

2.2. Research Method and Scope

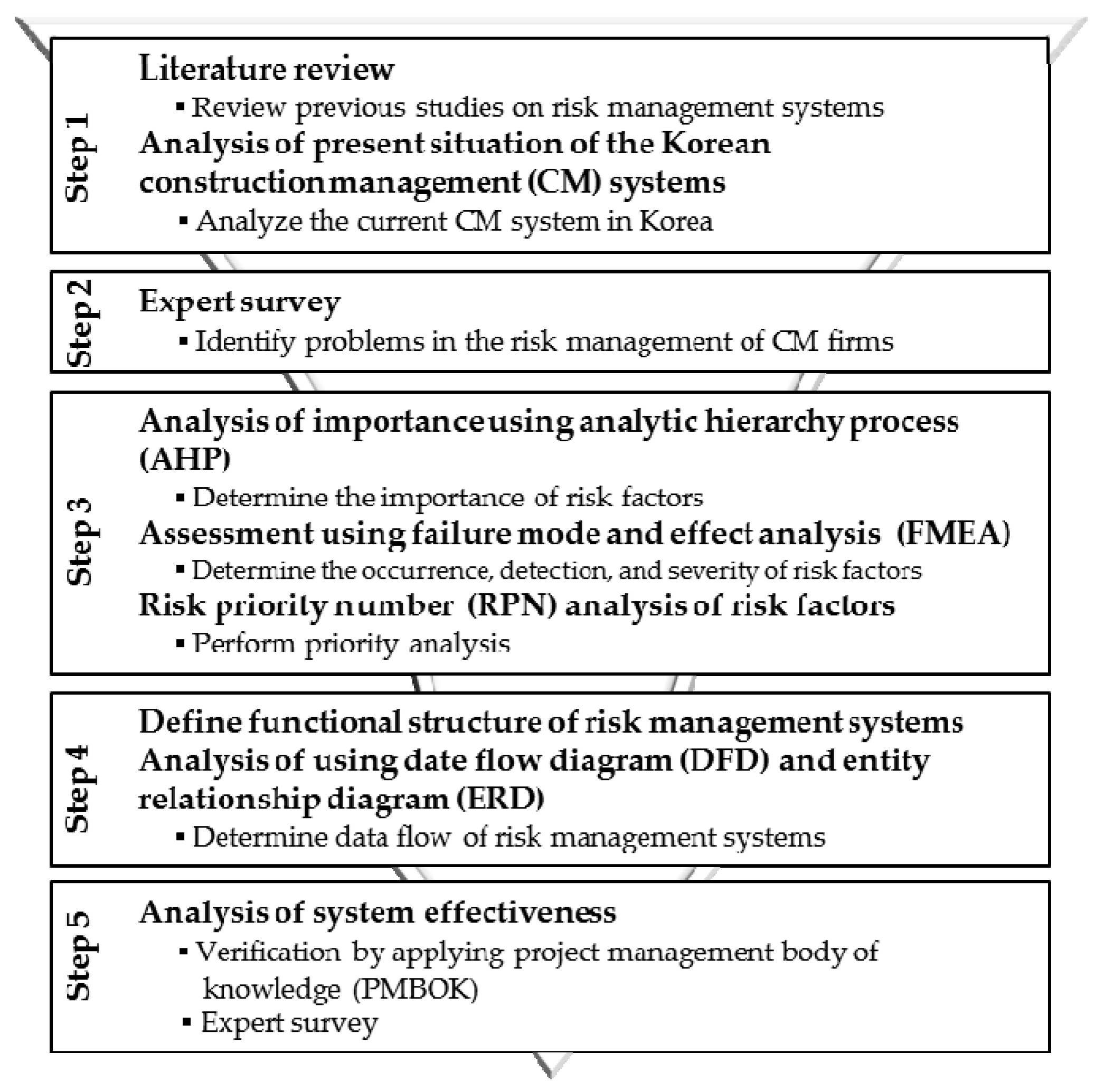

The main research objectives were achieved through a five-stage research methodology that is summarized in

Figure 1. In summary, during Step 3, six risk factors were defined by performing one-on-one interviews with the directors in charge of field operation from 15 firms whose CM for-fee orders exceeded US$880 billion in 2015. From each firm, 75 field operation managers were surveyed with regard to the previously defined risk factors, and 58 copies were collected. The importance of each risk factor was analyzed using Expert Choice 11.5, and their occurrence, detection, and severity were evaluated through a failure mode and effect analysis (FMEA), which is a widely used as a risk analysis technique. The system functional block diagram and functions were defined around the six risk factors defined through Step 3.

Step 4 accounted for system design and included DFD and ERD analyses. The system was designed so that it would be connected to the flow of information according to risk management procedures. When a risk occurs, it can be managed by countermeasure processes. The processed work content is then saved inside the system database (DB). Additionally, screenshots of each module are presented in detail.

Lastly, during Step 5, the field operation directors of 15 CM firms were interviewed with regard to five categories, assessing the system through a Likert 5-point scale analysis.

3. Analysis of Risk Factors and System Functions According to Field Operation Management of CM Firms

3.1. Risk Management System in Korean CM Firms

To analyze the risk management system of Korean CM firms, field operation managers from 15 firms were surveyed from 20 February to 10 March in 2015. This survey had a total of five main categories: risk management necessity, risk management training status for employees, availability of risk management procedures, availability of risk management procedures systems, and the need for introducing risk management systems.

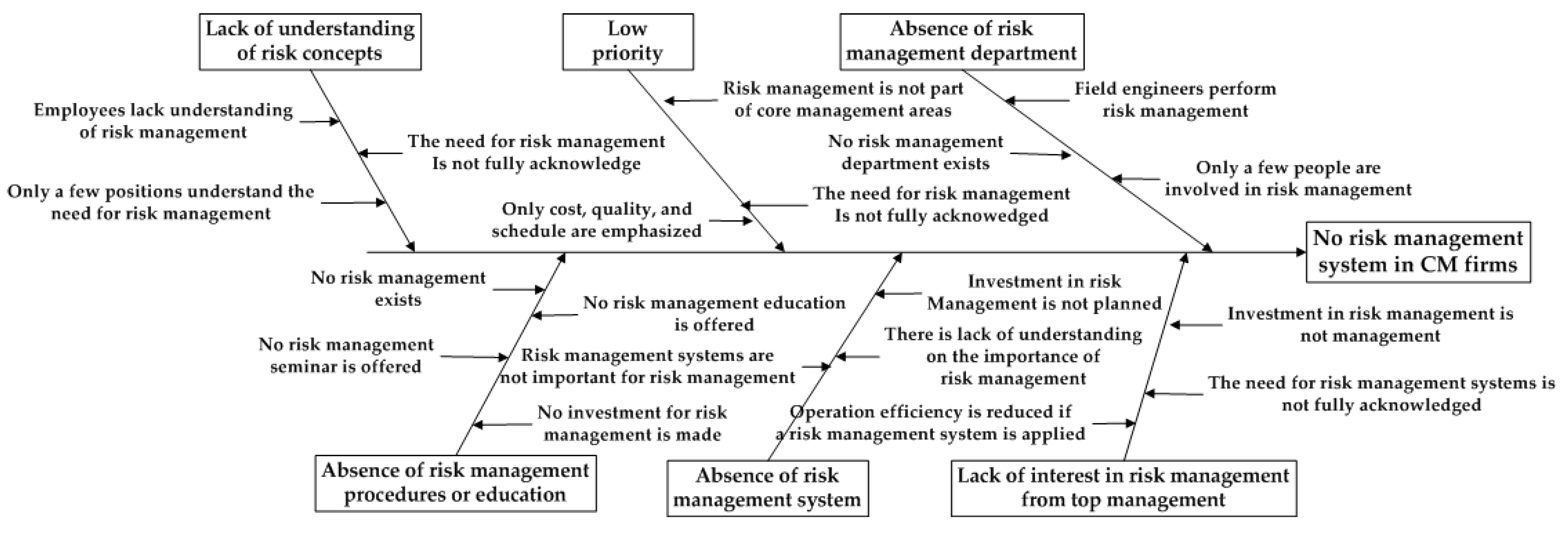

Figure 2 shows the results of this survey.

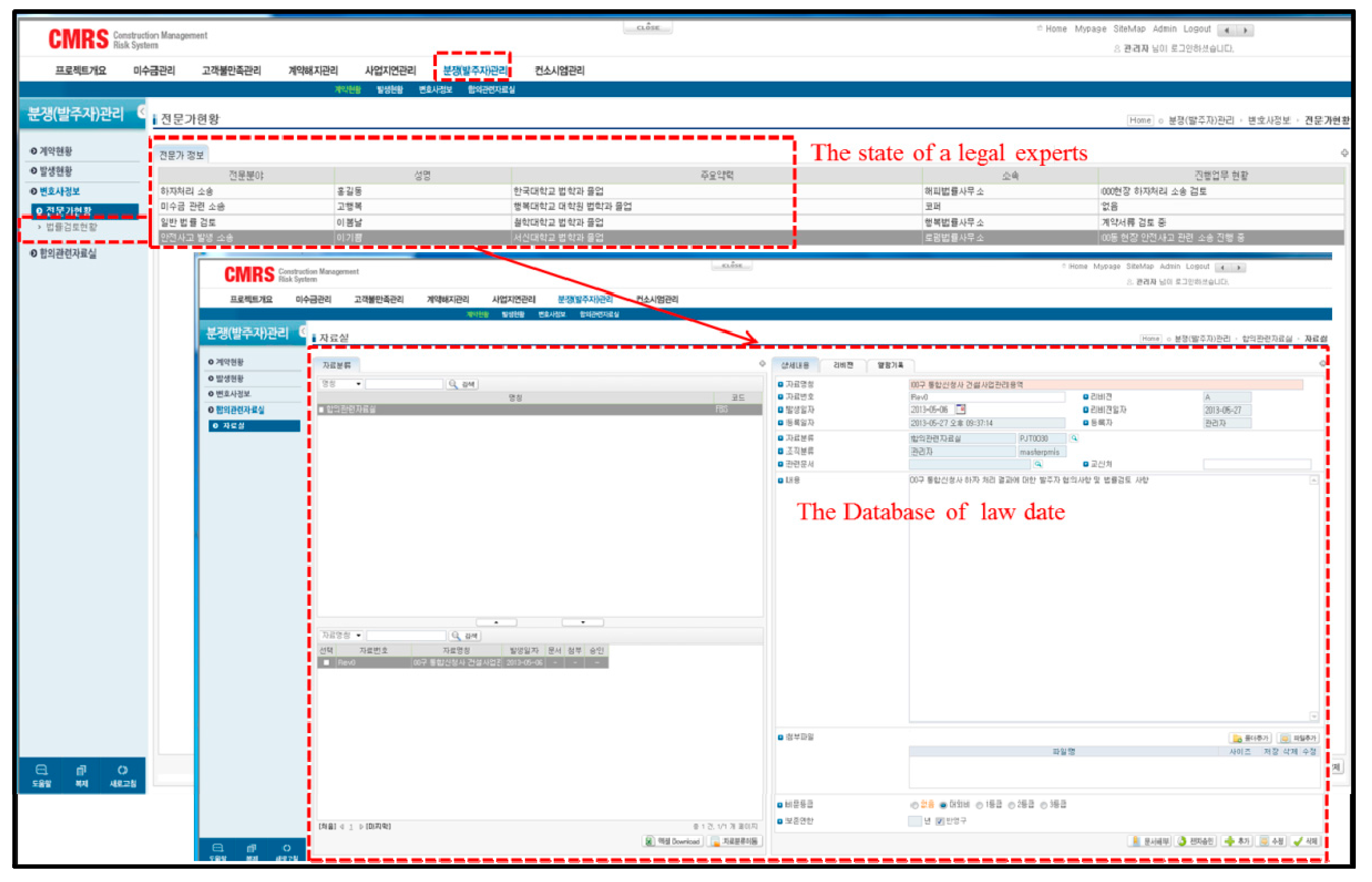

The absence of risk management training, procedures, and systems were some of the factors identified as problems in Korean CM firms. As a consequence, these factors prevent Korean CM firms from taking effective risk countermeasures. Although most CM firms acknowledge the need for managing risks, they instead prioritize time management, cost management, quality management, and safety management; in addition, most lack risk management departments or directors. For these reasons, risk factors are not being managed through systematical methods. This, in turn, causes problems such as decreased customer satisfaction, difficulty in providing early response to risks, uncertain accountability of risk factors, and difficulty in managing records of risk factors. Thus, as shown in

Figure 3, it becomes difficult to make use of DBs when legal disputes with clients occur.

3.2. Deduction of Risk Factors and Evaluation of Risks for System Development

To deduce the risk factors that occur when managing field operations, 15 directors in charge of field operation management at different companies were interviewed one-on-one, obtaining a 100% response rate. After deducing the risk factors, a risk evaluation was performed. For this, field operation managers from 15 different firms were surveyed on a Likert 10-point-scale basis: 75 survey copies were distributed, and 58 copies were collected, obtaining a 77% collection rate. The importance of each risk factor was analyzed using Expert Choice 11.5, and their occurrence, detection, and severity were evaluated through a FMEA, which is a widely used risk analysis technique. The risk priority number (RPN) is evaluated by multiplying values obtained from the FMEA [

31]. Six risk factors that occur during field operation management were deduced and defined.

Table 1 shows the risk evaluation results.

The risk evaluation results revealed that payment delay was the greatest risk factor that CM firms could deal with during field operation management, followed by project delay, legal disputes with clients, customer dissatisfaction with field services, contract revocation, and legal disputes with partner companies. The reason why payment delay appears to be the biggest risk factor is that CM firms receive the contractor’s payment on the date agreed by the contract after manpower has been deployed. Thus, the degree of risk faced by CM firms with insufficient financial resources when the contractor’s payment is delayed by several months due to financial conditions is significantly large. Project delays were also found to be a significant risk as they generate receivables. That is, when projects are delayed (due to financial conditions, occurrence of field accidents, licensing delays, etc.) after concluding a contract with the contractor, CM firms are unable to receive payment regarding manpower deployment upon the agreed date. The impact of legal disputes with clients is reduced when they are solved through consultation and mediation; however, if they must be solved by a court, additional expenses are generated, manpower has to be deployed to handle the case, and the company image falls. For such problems, the degree of risk of legal disputes with clients was found to be significant. Customer dissatisfaction with field services was found to be a high risk under analysis because it could generate customer claims which, in turn, deteriorate the company image and could have a negative impact on future order-receiving activities. Contract revocation was found to have a negative impact on CM firms. That is, when projects are canceled because the contractor considers CM services to be unnecessary or has financial problems, it causes a decline in revenues and difficulties in personnel relocation to other sites. Legal disputes with partner companies were found to have a negative impact (albeit small compared to the other risks) because when disagreements occur between consortiums when executing a project, disputes between companies arise and work productivity declines. Therefore, a construction risk management system for CM firms that considers the aforementioned risks factors (payment delay, project delay, legal disputes with clients, customer dissatisfaction, contract revocation, and legal disputes with partner companies) should be proposed.

3.3. System Architecture

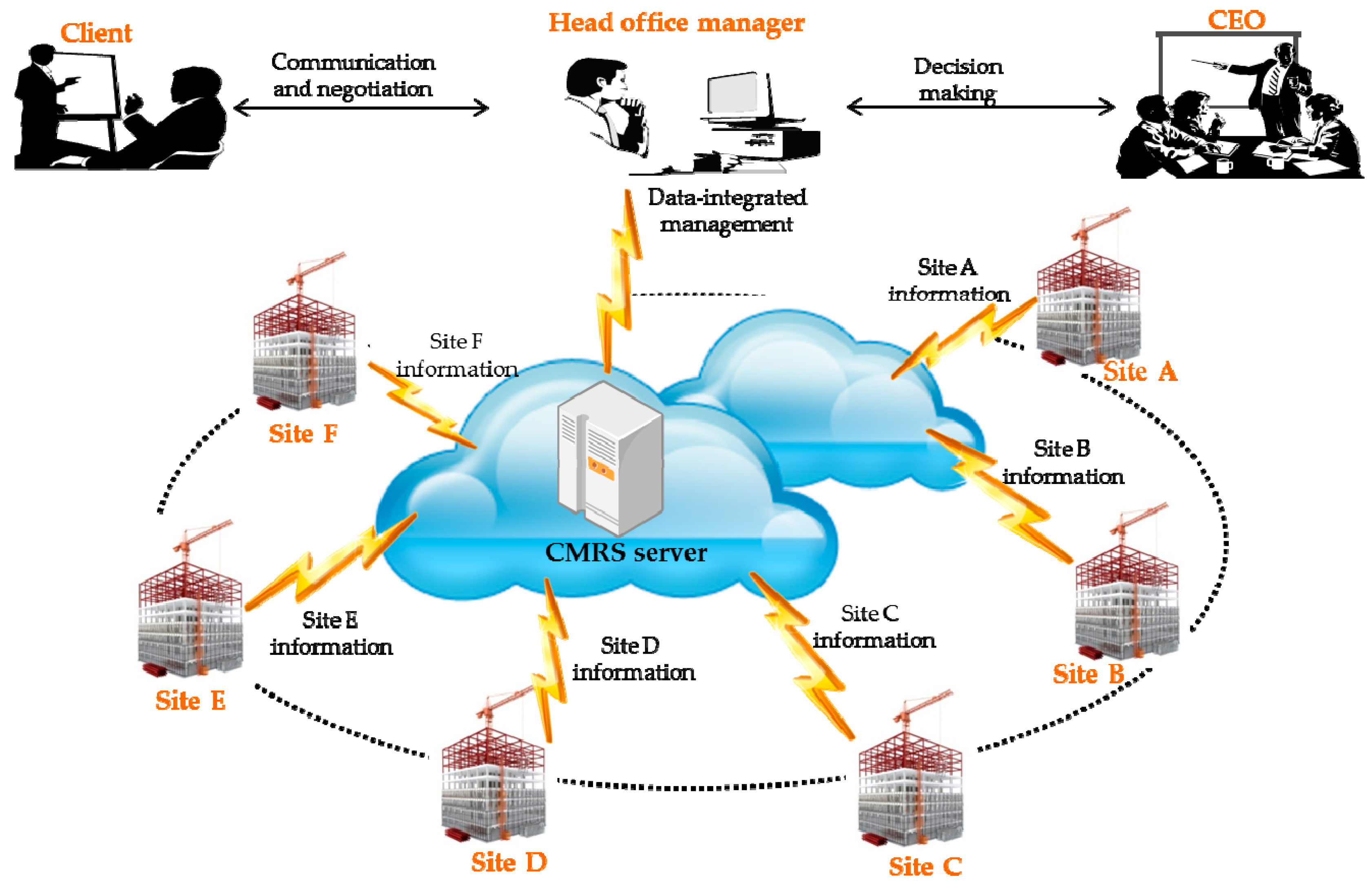

The CRMS inputs risk occurrence information and status into the server, allowing for a systematical management of risk factors that occur in the field. This information is provided as guidelines for administrative control and, as shown in

Figure 4, can be used as a resource for knowledge management of the company.

3.4. System Functional Block Diagram

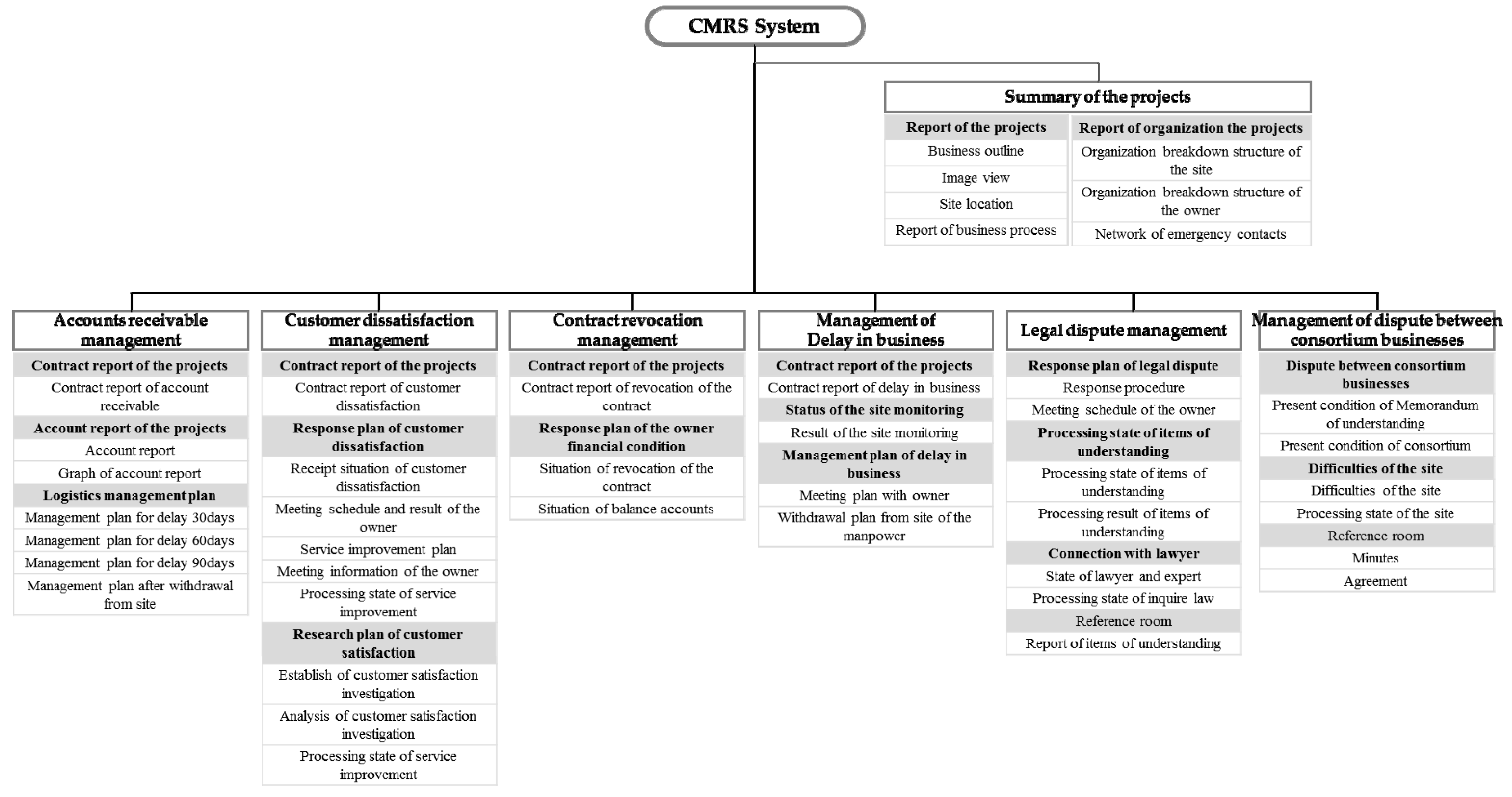

As shown in

Figure 5, the CRMS functional block diagram comprises seven modules (project overview, payment delay management, customer dissatisfaction management, contract revocation management, project delay management, legal dispute management, and consortium management) and 20 sub-modules.

The functions of each module are as follows:

The project overview module comprises two sub-modules and seven functions. This module provides detailed information about the status and organization of each project;

The payment delay management module comprises three sub-modules and seven functions. This module provides graphical information about the status of contracts whose payment has been delayed and information regarding the payment progress of all projects. Additionally, it allows for the establishment of different management plans for projects with payment delays of 30, 60, and 90 days. When the payment delay exceeds 90 days, a field evacuation plan can be made;

The customer dissatisfaction management module comprises three sub-modules and 10 functions. This module provides information regarding reception status of customer dissatisfactions, information on interviews with the contractor, service improvement status, etc. Additionally, it provides information regarding customer satisfaction surveying plans;

The contract revocation management module comprises two sub-modules and three functions. This module provides information about contract revocations caused by financial conditions of the contractor and payment status of service charges generated by contract revocations;

The project delay management module comprises three sub-modules and four functions. This module provides monitoring information of all projects, allowing the establishment of countermeasures regarding project delays. Furthermore, it gives information related to interview schedules with contractors and site evacuation plans;

The legal dispute management module comprises four sub-modules and seven functions. This module provides information regarding response procedures and interview schedules of the contractor; this information can be used as preparation for legal disputes. Additionally, when consultations with contractors are done, this module can monitor the current status and results of such consultations. Furthermore, when disputes with contractors occur, this module provides information on lawyers specializing in specific dispute types and legal reviews of each lawyer;

The consortium management module comprises three sub-modules and seven functions. This module provides information regarding the current status of partner companies, errors committed by the construction site staff, and the processing status of such errors. Additionally, it allows for record management of minutes and agreements made during consortium meetings.

3.5. Analysis of the System Data Flow Diagram (DFD)

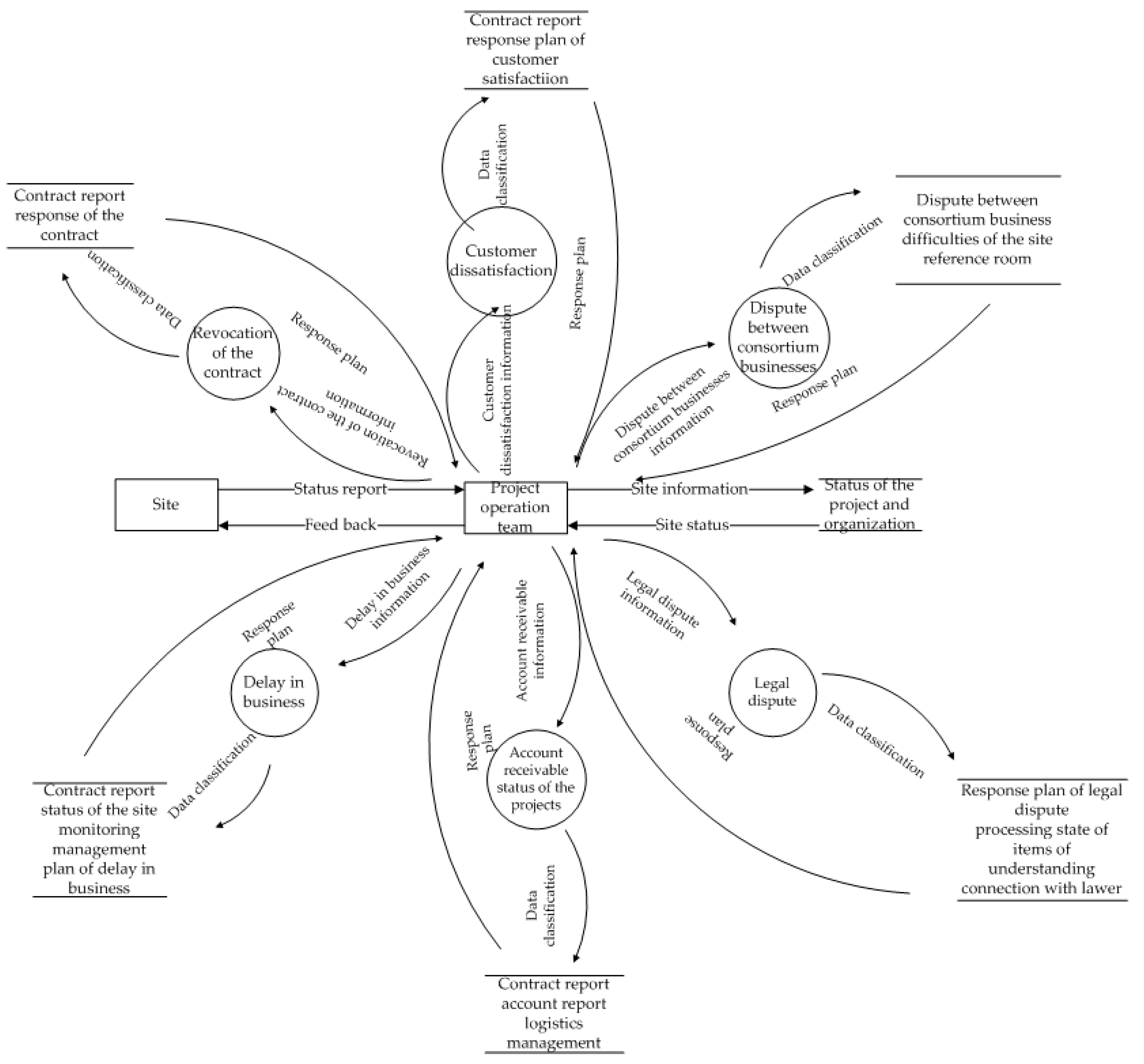

A DFD defines the role of each function by identifying the flow and relation between data in order to create or make possible the creation of a system [

32,

33]. The definition of the functions and data flow with each of the seven modules and 20 sub-modules is shown in

Figure 6.

3.6. Analysis of the System Entity Relationship Diagram (ERD)

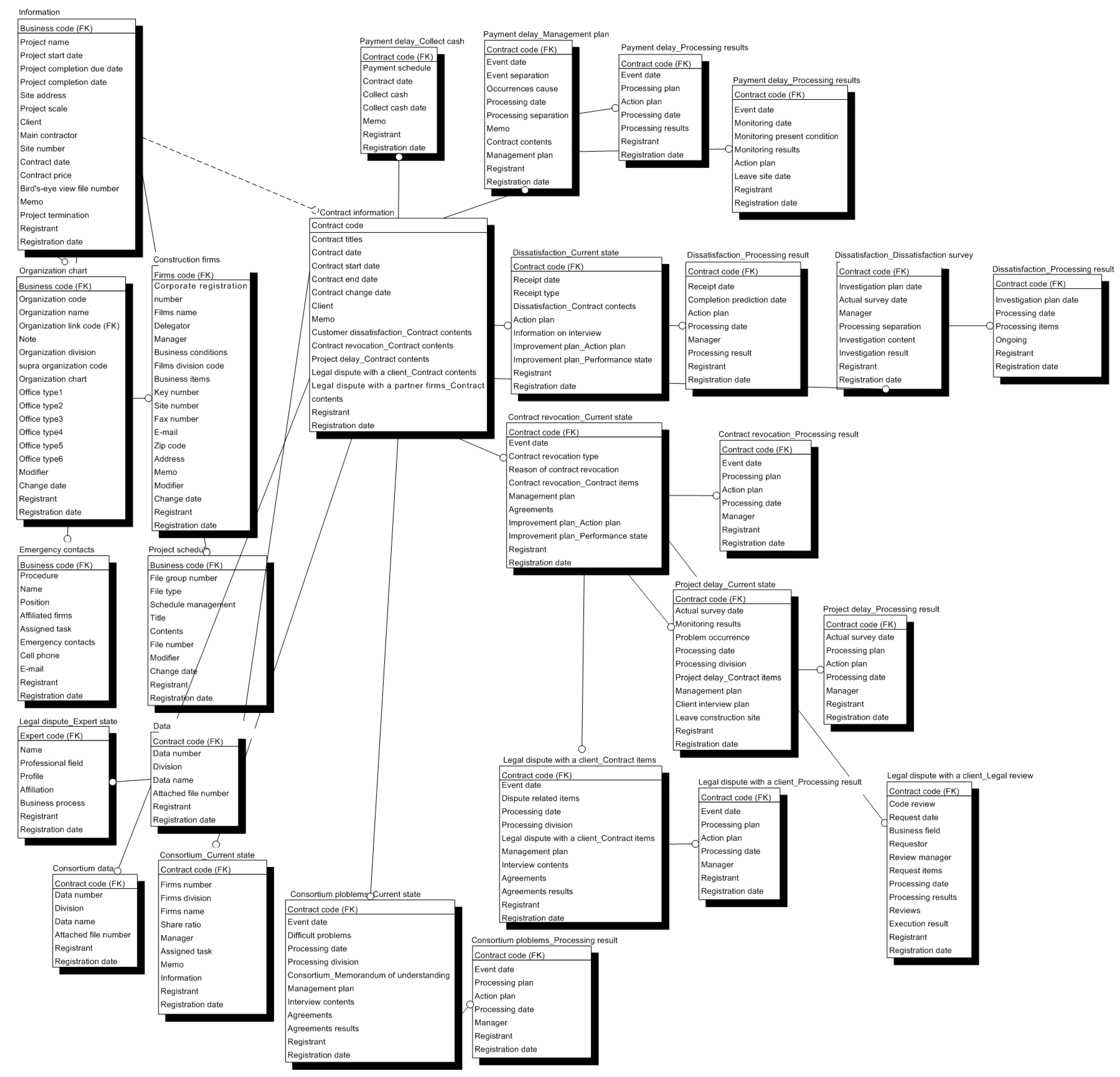

The ERD is a method for illustrating the relation between entity types deduced through business process analyses and other entity types, i.e., it shows the correlation between data flow and processes regarding a system’s development [

34].

Figure 7 shows an ERD analysis of the items required for this study’s CRMS design. The information flow of the seven modules and 20 sub-modules of the CRMS was divided into two parts: (1) data exchange and flow between contractors, construction sites, and CM firms; (2) system and data flow in accordance with business procedures implemented for effectively and systematically managing risks that occur in CM firms. This system allows business management through the implementation of risk response processes. The processed business contents are stored in the system, allowing project records to be managed. Each piece of information is specifically classified by its function in risk occurrence status, processing results, and future management plan, so that it can be used accordingly. This system helps risk managers perform their work effectively and allows executives and staff members to make rapid decisions.

4. CRMS Development

4.1. CRMS Main Screen

Figure 8 shows the CRMS main screen, which can be seen right after accessing the system. By installing plug-ins located in the lower right corner of the main screen, all programs required to operate the system are automatically downloaded. After finishing the program installation, the system can be accessed by inputting the user’s individual identification (ID) and password (PW).

4.1.1. Project Selection

After accessing the system, the desired project can be selected from the field list. Summary information about the contract date, commencement date, expected completion date, construction period, and construction progress can be checked regarding the selected project. The progress status can easily be checked and understood through a color labeling system: green means that the status is normal, yellow means that the plan preparation is lower than 70%, and red means that the plan preparation is lower than 50%.

Figure 9 shows the project selection screen.

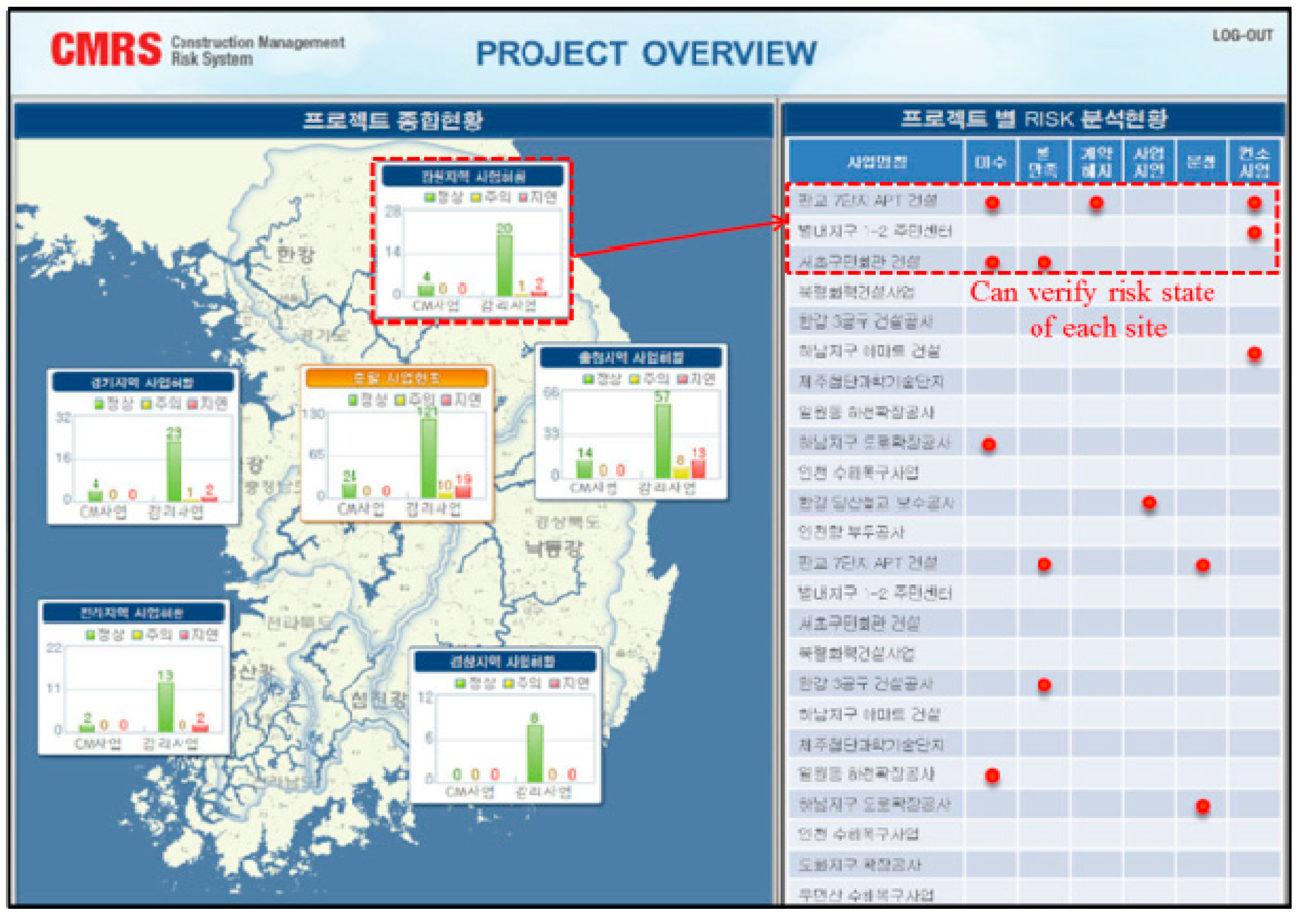

4.1.2. Project Overview Screen

Through the project overview screen, national CM sites are classified by region, and some brief information about project risks can be obtained for each region. The right side of the screen shows detailed project information by region and provides risk information regarding payment delays, client dissatisfaction, contract revocations, project delays, legal disputes with clients, and legal disputes with partner companies. The risk status of each project is classified by color to allow for easy checking.

Figure 10 shows the project overview screen.

4.1.3. Project Overview

The project overview provides information regarding business outline, aerial view, site organization, and progress status. The business outline provides special and significant information about the project such as commencement date, completion date, construction designer, construction status. In the progress status section, historical information about the main particulars of a project’s progress can be input, allowing the main project information to be managed after its completion. The organization status section provides information about participants from each institution involved in the project, allowing staff data to be checked.

4.1.4. Participant Firms and Emergency Contacts

The system provides information about emergency contacts and detailed information of firms involved in specific projects. Information provided on participant firms includes detailed contract status, contact number, and information about firm representatives.

4.1.5. Payment Delay Management and Work Completion Status

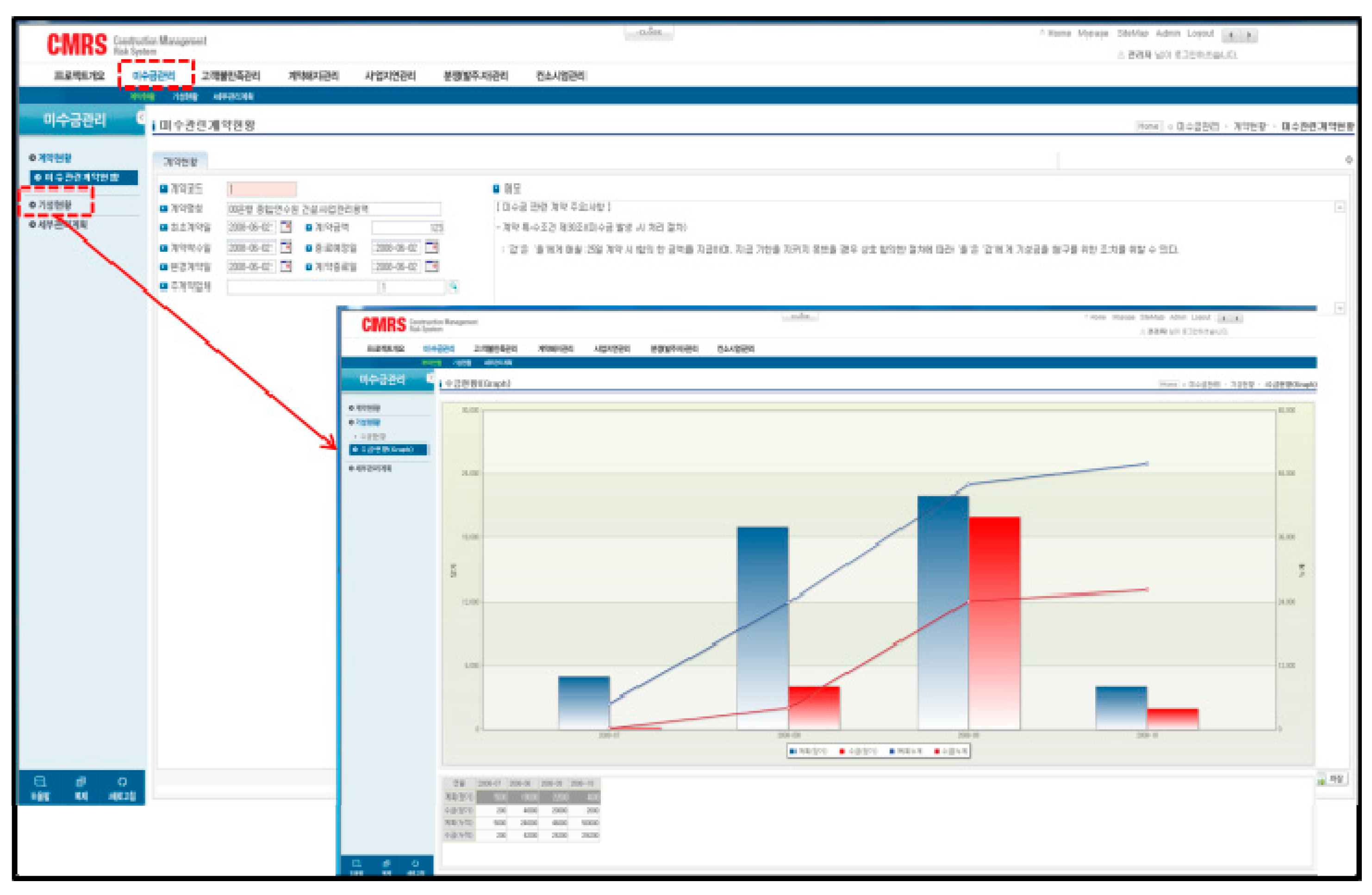

As shown in

Figure 11, the receivables management status comprises three detailed modules (contract status, work completion status, and detailed management plan). The contract status gives information related to the receivables’ processing procedures. The work completion status provides information about the payment collection status for completed works; it also provides graphical information through which payments of completed works can easily be checked. Furthermore, through this status, detailed management plans for delayed construction works can be established in stages in relation to the delay time.

4.1.6. Customer Dissatisfaction Management and Countermeasures

When customer dissatisfaction problems arise, detailed information on the corresponding contract can be viewed. Additionally, up-to-date information on cases of customer dissatisfaction can be input and viewed. Furthermore, service improvement plans and processing plans for customer dissatisfaction cases can be established, and their results and implementation status can be viewed, together with information on interviews with contractors.

4.1.7. Contract Revocation Management and Countermeasures

When contract revocation cases occur, this module provides detailed information about contracts. Additionally, information about the causes of such problems can be input and viewed. This feature provides information about countermeasures that were implemented to solve problems and caused contract revocation issues such as agreements, improvement plans, processing results, and planning. This information can be continuously managed.

4.1.8. Project Delay Management and Site Monitoring

This module provides detailed information about contracts to be viewed when projects are delayed and offers input and viewing of site-monitoring results. Additionally, it provides information about countermeasures taken to fix the causes of project delays such as response programs, processing results, and site management plans. All data related to project delays can be continuously updated, managed, and used as resources for solving future disputes that could occur as a result of project delays.

4.1.9. Status of Legal Disputes and Legal Reviews

This module allows for management of legal disputes with clients during the progress of a project. It provides detailed information about the project progress and specific information about disputes with clients, which can be input and managed. Additionally, information regarding the measures taken to solve disputes, such as processing plans, results, contractor interview contents, and agreements, can be input and managed. Tasks are given to advisory lawyers in accordance with their specialization based on the nature of the legal dispute, and the legal review status can also be viewed. All this information can be used as resources for solving future problems that may occur during legal disputes.

Figure 12 shows the screen of this module.

4.1.10. Joint Supply Agreement with Partner Companies and Company Information

This module allows for the establishment of site management standards through the creation of joint supply agreements when carrying out projects in partnership with other CM firms and provides information about the main conditions of joint supply agreements made. Information on companies (headquarters’ director, staff relocated to the construction field, share ratio of each company, assigned responsibilities, etc.) involved in specific projects is available, allowing the current status of consortiums to be checked with one view. Additionally, errors committed in the construction field by members of the consortium can be recorded and managed, providing information (such as processing plans, results, interview contents, agreements, etc.) that can be used for solving problems. All of this information can be constantly updated, managed, stored in archives, and consequently used as resources for manpower management of consortiums.

4.2. Verification of CRMS

To verify the anticipated outcomes of applying the CMRS system, the efficiency of CMRS was verified by comparing with the six procedures of risk management of the project management body of knowledge (PMBOK) and surveying the field operation managers of 15 firms.

4.2.1. Verification by Applying PMBOK

The risk management procedures of PMBOK require efficient risk plans and management through the six following steps: risk management planning, risk identification, qualitative risk analysis, quantitative risk analysis, risk response planning, and risk monitoring and control [

35]. Based on this, the efficiency of the system will be verified in comparison with the development process of CMRS, and the results are shown in

Table 2.

The CMRS system proposed in this study is developed based on the management plan of each of the six risk management steps in PMBOK, through which risks of CM firms can be systematically managed.

4.2.2. Verification of Expected Effect by Applying CRMS

Field operation managers of different CM firms were surveyed in order to verify the practical applicability of the CRMS and to prove that it can effectively be used to solve field operation management problems faced by CM firms. The CRMS proposed in this study is aimed at improving the systematic risk management processes and further at improving business effectiveness and productivity. Thus, the expected effectiveness of this system has been examined by providing explanatory videos and explanations to field operation managers from 15 firms (15 survey copies were distributed and collected).

The CRMS assessing categories were “Ease of use”, “Adequacy of risk response measures”, “Adequacy of system architecture” “Degree of completion of system”, and “Practical applicability”. These five categories were evaluated on a Likert 5-point-scale (1: Very low; 5: Very high).

Table 3 shows the results of expert verification.

The average rating of the system was 4.09, and the average scores for each evaluation category were 4.27 (practical applicability and adequacy of the risk response measures), 4.13 (degree of completion of the system), 3.93 (adequacy of the system architecture), and 3.87 (ease of use).

4.3. Contribution

As revealed by the investigation results, CM firms are currently unable to manage risk effectively owing to the absence of field operation management risk definitions and analyses and the lack of systematical countermeasures to such risks. This not only increases the work burden of coordinators due to the absence of risk management departments and directors, but also generates difficulties in responding to disputes and lawsuits that are actually caused by late response to risks and risk management hindrances.

To solve these issues, the CMRS presented in this study provides a systematic and rational work process for performing risk management through its seven modules and 20 sub-modules. The project overview module provides data on the current state of each project. The accounts receivable management module provides contract status related to payment delays and collection of payments for each project. The customer dissatisfaction management module provides investigation plans, submissions of customer dissatisfaction, client interviews, and improvement and fulfillment of services. The contract revocation management module provides data on the financial conditions of the client as well as the calculation of service fees according to termination. The project delay management module provides data on establishing measures for each project delay. The legal dispute management module offers response procedures for clients and schedules for interview plans to prepare for legal disputes. The consortium management module provides information on the current state of consortiums and difficulties of members as well as the state of handling these issues and means for resolution. The CRMS proposed in this study is expected to offer effective response to risks, decision-making support, and future knowledge management resources.

4.3.1. Comparing Characteristics of the CRMS with Existing Risk Management Systems

Considering the fact that the effectiveness of risk management for overseas constructions is higher during the early stages of projects from both case studies and literature review, the fully integrated risk management system (FIRMS) subdivides the early stages of projects and presents a tool for managing the risks in procedures by classifying the total life cycle of projects in five stages: establishment of ordering plans, bid preparation period, contract conclusion, construction, completion, and maintenance. This allows the risks to be systematically managed. Additionally, by means of a portfolio cash flow analysis, it provides practical cash flow and contract management guidelines including main check points. However, since the system is focused on the early stages of domestic and overseas construction projects, it cannot be easily applied to the national construction industry. Furthermore, it also presents difficulties in performing multiple analyses because it cannot easily process all characteristics related to the project and its environment, which are essential to analyzing the variety of risks that may occur during overseas construction projects.

The risk management plan (RMP) and risk-based estimate system (RBES) used by the Washington State Department of Transportation [

36] were designed so that it could be more easily used and accessed by users. Their major significance is that they can be downloaded from the internet without charge. The RMP has a checklist form through which risk management processes, including risk recognition, analysis, countermeasures, monitoring, and control, can easily be viewed. Additionally, specific information about each process can be input, enabling effective risk management. In contrast, the RBES, which is based on the RMP, offers functions such as calculation of expenses incurred by risks during the entire project, and calculation of total expenses incurred by basic risk countermeasures (e.g., gain, avoidance, bypass). Furthermore, the degree of risk can be obtained through Excel-based Monte Carlo simulation. However, users have difficulties using and accessing the system due to its complex architecture that comprises multiple menus.

The Simple Risk Management Process (TSRMP) is a risk management process designed with the support of the Royal Society of London for the Promotion of Natural Knowledge [

37]. It has major significance as an Excel-based user-friendly process. Through this integrated web-based construction risk management system, construction practitioners can easily understand the many risks that occur during construction projects and establish effective countermeasures to minimize losses caused by them. However, although the architecture of this system is comparatively simpler than that of the RMP or RBES, its system analysis techniques such as construction industry research and information association (CIRIA) are weak, and it can only be used by Royal Society members.

The CRMS proposed in this study is capable of analyzing the importance, incidence, detection, and severity of risks factors that occur in CM firms through AHP and FMEA techniques, which yielded the six main risk factors that have to be prioritized. The CRMS comprises seven modules and 20 sub-modules in which detailed risk management status information is available and through which information about future construction plans can also be obtained. Additionally, information regarding the risk factors of projects is stored in the database, and it can be used as a resource for processing future claims or disputes. Finally, all the information provided can easily and conveniently be visualized through this system. Therefore, the CRMS proposed herein is suitable for use by all users—from construction managers to executives—and it provides optimal risk management information for national CM firms.

Table 4 compares the characteristics of CRMS to the aforementioned existing risk management systems.

4.3.2. Advantages of CRMS in Comparison with Existing Risk Management Systems

• Decreased work burden for field managers:

Existing risk management systems lack standardized operating systems, which delays decision-making processes. Owing to this, it is difficult to apply early countermeasures to risk factors, which in turn causes an increase in the work load of managers and directors. However, CRMS allows work progress planning through early response processes, which allows work to progress effectively and minimizes additional task increments by reducing business confusion.

• Decision-making support and results checking:

Since existing risk management systems lack standardized operating systems, decision making processes are delayed and future business progress procedures regarding previously taken decisions cannot be confirmed. However, CRMS allows such information to be viewed at any time. Additionally, responsibilities and authorities can be granted to decision makers, easing risk response processes.

• Records management:

Existing risk management systems present disadvantages at managing data related to countermeasures taken against risks factors. Instead, the CRMS proposed herein stores data on risk response procedures. This data can be used in the future as preparation for lawsuits and legal disputes. Such information can also be used as knowledge management resources that may contribute to the company’s technological improvement.

4.3.3. Limitations and Future Research

Because most CM firms still prioritize process management, cost management, quality management, and safety management, investment in risk management is deficient.

To apply the CRMS proposed herein in field operations, it is necessary to perform quantitative studies of the system implementation. This should be preceded by active interest and investment from directors, executives, and staff members in the inclusion of risk management in CM firms, including the development of risk management manuals for each risk factor and the improvement of risk management processes. Furthermore, there is insufficient research on project risk management in the CM field. To perform this kind of research, it is especially important to gather the risk cases classified by application, size, and nature of the project and store them in a database for use as a resource for developing the risk management system.

5. Conclusions

In 2007, the Korean CM market experienced dramatic growth, reaching US$386.526 billion. However, after the global financial crisis of 2008, the amount of orders decreased, and CM firms were forced to compete, accepting excessively low-priced orders in order to survive in the market. The consequences of such competition are still being suffered: e.g., deterioration of CM services, decline of industry competitiveness, and degradation of risk responding ability. In particular, the degradation of risk responding ability is caused by insufficient investment in risk management training, system development, and research, which is in turn caused by a decrease in corporate profitability. Such risk management insufficiency prevents CM firms from responding systematically and reasonably to the risks that occur during field operations, which has a negative impact on them.

Thus, in this study, main factors that must be considered for developing a risk management system for CM firms were selected by defining and evaluating the risks that can occur during field operation management at CM firms. Centered on these main factors, an effective field operation risk management system was proposed by presenting a functional block diagram and performing DFD and ERD analyses. This system was evaluated by experts on five categories using a Liker 5-point-scale. The categories evaluated were practical applicability (4.27), adequacy of the response measures (4.27), degree of completion of the system (4.13), adequacy of the system architecture (3.93) and ease of use (3.87). The average rating of the system evaluation was 4.09, which is a high-ranking score.

Owing to a lack of clear management standards and systematic manuals, existing risk management systems used by CM firms present problems such as late response to risks, confusion regarding the response procedures, and accountability uncertainty. However, the CRMS proposed herein offers clear accountability by allowing early response to risks, verification of the person in charge of risk management, clear risk response processes, and rapid response to legal disputes by managing risk records. For these reasons, it is expected to improve risk management effectiveness in CM firms.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation (NRF) of Korea funded by the Ministry of Science, ICT & Future Planning (Grant No. 2015R1A5A1037548)

Author Contributions

Kyungmo Park, Sanghyo Lee, and Yonghan Ahn conceived and designed the experiments; Sanghyo Lee and Yonghan Ahn performed the experiments; Kyungmo Park analyzed the data; Kyungmo Park wrote the paper. All authors reviewed and commented on the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liberda, M.; Ruwanpura, J.; Jergeas, G. Construction Productivity Improvement: A Study of Human, Management and External Issues. In Proceedings of the 2003 Construction Research Congress, Honolulu, HI, USA, 19–21 March 2003; pp. 1–8.

- Arditi, D. Construction Productivity Improvement. J. Constr. Eng. Manag. 1985, 111, 1–14. [Google Scholar] [CrossRef]

- Allmon, E.; Haas, C.T.; Borcherding, J.D.; Goodrum, P.M.U.S. Construction Labor Productivity Trends, 1970–1998. J. Constr. Eng. Manag. 2000, 126, 97–104. [Google Scholar] [CrossRef]

- Ibbs, C.W.; Wong, C.K.; Kwak, Y.H. Project Change Management System. J. Manag. Eng. 2001, 17, 159–165. [Google Scholar] [CrossRef]

- Breuer, J.; Fischer, M. Managerial Aspects of Information-Technology Strategies for A/E/C Firms. J. Manag. Eng. 1994, 10, 52–59. [Google Scholar] [CrossRef]

- The Construction Management Association of Korea (CMAK). Available online: http://www.cmak.or.kr/html/cmdata/cmreport.asp (accessed on 14 November 2013).

- The Ministry of Land, Infrastructure and Transport (MOLIT). Available online: http://www.kiscon.net/pcm/content.asp?num=36? (accessed on 30 August 2013).

- Kim, J. Risk Management Determines the Future of Companies, 2nd ed.; Won & Won Books: Seoul, Korea, 2009; pp. 157–161. [Google Scholar]

- Park, K.; Lee, H.W.; Kim, C.D. Assessment of Risk Management Practices of CM Enterprise: The Need for an Enterprise-level Risk Management Framework. Korea J. Constr. Eng. Manag. 2014, 15, 66–73. [Google Scholar] [CrossRef]

- Abdelgawad, M.; Fayek, A.R. Risk Management in the Construction Industry Using Combined Fuzzy FMEA and Fuzzy AHP. J. Constr. Eng. Manag. 2010, 136, 1028–1036. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Aslam, M.A.; Hinze, J.W.; Arain, F.M. Cost and Schedule Risk Analysis of Bridge Construction in Pakistan Establishing Risk Guidelines. J. Constr. Eng. Manag. 2014, 140, 04014020. [Google Scholar] [CrossRef]

- Giannotti, A.C.; Fisher, D.J. Project Information Management System—Another Approach. J. Manag. Eng. 1998, 9, 52–63. [Google Scholar] [CrossRef]

- Bowden, S.L. Application of Mobile IT in Construction. Ph.D. Thesis, Loughborough University, Leicestershire, UK, 2005. [Google Scholar]

- Kim, C.; Lim, H.; Kim, H. Mobile computing platform for construction site management. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Korea, 29 June–1 July 2011; pp. 1164–1169.

- Nawari, N. Standardization of Structural BIM. In Proceedings of the 2011 ASCE International Workshop on Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; pp. 405–412.

- Nawari, N. The Challenge of Computerizing Building Codes in a BIM Environment. In Proceedings of the 2012 ASCE International Conference on Computing in Civil Engineering, Clearwater Beach, FL, USA, 17–20 June 2012; pp. 285–292.

- Jiang, Y.; Ming, J.; Wu, D.; Yen, J.; Mitra, P.; Messner, J.I.; Leicht, R. BIM Server Requirements to Support the Energy Efficient Building Lifecycle. In Proceedings of the 2012 ASCE International Conference on Computing in Civil Engineering, Clearwater Beach, FL, USA, 17–20 June 2012; pp. 365–372.

- Forgues, D.; Iordanova, I. An IDP-BIM Framework for Reshaping Professional Design Practices. In Innovation for Reshaping Construction Practice, Proceedings of the 2010 Construction Research Congress, Banff, AB, Canada, 8–10 May 2010; Ruwanpura, J., Mohamed, Y., Lee, S.H., Eds.; ASCE: Reston, VA, USA, 2010; pp. 172–182. [Google Scholar]

- Catalina, T.; Virgone, J.; Blanco, E. Development and validation of regression models to predict monthly heating demand for residential building. Energy Build. 2008, 40, 1825–1832. [Google Scholar] [CrossRef]

- Kim, H.; Anderson, K. Energy Simulation System Using BIM (Building Information Modeling). In Proceedings of the 2011 ASCE International Workshop on Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; pp. 635–640.

- Wu, W.; Issa, R. BIM Facilitated Web Service for LEED Automation. In Proceedings of the 2011 ASCE International Workshop on Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; pp. 673–681.

- Succar, B. Building information modeling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2008, 18, 357–375. [Google Scholar] [CrossRef]

- Chan, S.-L.; Leung, N.-N. Prototype Web-Based Construction Project Management System. J. Constr. Eng. Manag. 2004, 130, 935–943. [Google Scholar] [CrossRef]

- Al-Bahar, J.F.; Crandall, K.C. Systematic Risk Management Approach for Construction Projects. J. Constr. Eng. Manag. 1990, 116, 533–546. [Google Scholar] [CrossRef]

- Jannadi, O.A.; Almishari, S. Risk Assessment in Construction. J. Constr. Eng. Manag. 2003, 129, 492–500. [Google Scholar] [CrossRef]

- Liang, C.; Longquan, M.; Ye, F.; Hu, C. Research on the Establishment of Mega Public Building Safety Risk Assessment System in China. In Vulnerability, Uncertainty, and Risk: Analysis, Modeling, and Management, Proceedings of the International Conference on Vulnerability and Risk Analysis and Management (ICVRAM 2011) and the International Symposium on Uncertainty Modeling and Analysis (ISUMA 2011), Hyattsville, MD, USA, 11–13 April, 2011; Ayyub, B.M., Ed.; ASCE: Reston, VA, USA, 2011; pp. 316–325. [Google Scholar]

- Staneff, S.T.; Ibbs, C.W.; Bea, R.G. Risk-Management System for Infrastructure-Condition Assessment. J. Infrastruct. Syst. 1995, 1, 221–229. [Google Scholar] [CrossRef]

- Zhou, N.; Xu, S.; Liu, X.; Wang, K.; Zhao, H. Risk Information Management System of City Gas Line Based on GIS. In Better Pipeline Infrastructure for a Better Life, Proceedings of the International Conference on Pipelines and Trenchless Technology (ICPTT), Wuhan, China, 19–22 October 2012; Ma, B., Najafi, M., Jiang, G., Slavin, L., Eds.; ASCE: Reston, VA, USA, 2012; pp. 298–309. [Google Scholar]

- Essamin, O.; El-Sahli, K.; Hovhanessian, G.; Le Diouron, T. Risk Management System for Prestressed Concrete Cylinder Pipeline: Practical Results and Experience on the Great Man Made River. In Pipelines 2005: Optimizing Pipeline Design, Operations, and Maintenance in Today’s Economy, Proceedings of the ASCE Pipeline Division Specialty Conference, Houston, TX, USA, 21–24 August, 2005; Vipulanandan, C., Ortega, R., Eds.; ASCE: Reston, VA, USA, 2005; pp. 241–251. [Google Scholar]

- Kim, C.H.; Park, S.Y.; Kang, I.S. A Development of Integrated Prototype Model for Risk Management of Construction Projects. J. Korea Soc. Civ. Eng. 2006, 26, 469–480. [Google Scholar]

- Abdelgawad, M.; Fayek, A. Comprehensive Hybrid Framework for Risk Analysis in the Construction Industry Using Combined Failure Mode and Effect Analysis, Fault Trees, Event Trees, and Fuzzy Logic. J. Constr. Eng. Manag. 2012, 138, 642–651. [Google Scholar] [CrossRef]

- Phan, D.H.; Howard, H.C. Functional Analysis Using Partitioned Engineering Data Flow Model. J. Comput. Civ. Eng. 1994, 8, 2–19. [Google Scholar] [CrossRef]

- Whitten, J.L.; Bentley, L.D.; Barlow, V.M. System Analysis and Design Methods, 3rd ed.; Irwin: Burr Ridge, IL, USA, 1994. [Google Scholar]

- Rojas, E.M.; Songer, A.D. Web-Centric Systems A New Paradigm for Collaborative Engineering. J. Manag. Eng. 1999, 15, 39–45. [Google Scholar] [CrossRef]

- Project Management Institute (PMI). Project Management Body of Knowledge (PMBOK), 3rd ed.; PMI: Newton Square, PA, USA, 2004; pp. 237–268. [Google Scholar]

- Washington State Department of Transportation (WSDT). Available online: http://www.wsdot.wa.gov/Projects/ProjectMgmt/RiskAssessment/Information.htm (accessed on 23 June 2014).

- Royal Society of London for the Promotion of Natural Knowledge (RSLPNK). Available online: https://royalsociety.org (accessed on 23 June 2014).

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).