In this section, we address a profit maximizing issue regarding the optimization decision for coal power flexibility retrofitting under an assumption of perfect competition.

The flexibility retrofitting marginal cost of a generating enterprise refers to the increased flexibility costs in the total electricity caused by per unit of increased flexible electricity. The flexibility electricity marginal revenue refers to the total revenue increment brought by per unit deal of increased flexible electricity.

As the flexible electricity marginal revenue is greater than its marginal cost, power generation enterprises are profitable, and coal power flexibility retrofitting is feasible; once the marginal cost is greater than the marginal revenue, thermal power flexibility retrofitting is unfeasible. It can be used to judge whether or not the plant operators are willing to carry out coal power flexibility retrofitting, and can also be used to judge the rationality of current compensation standards in China.

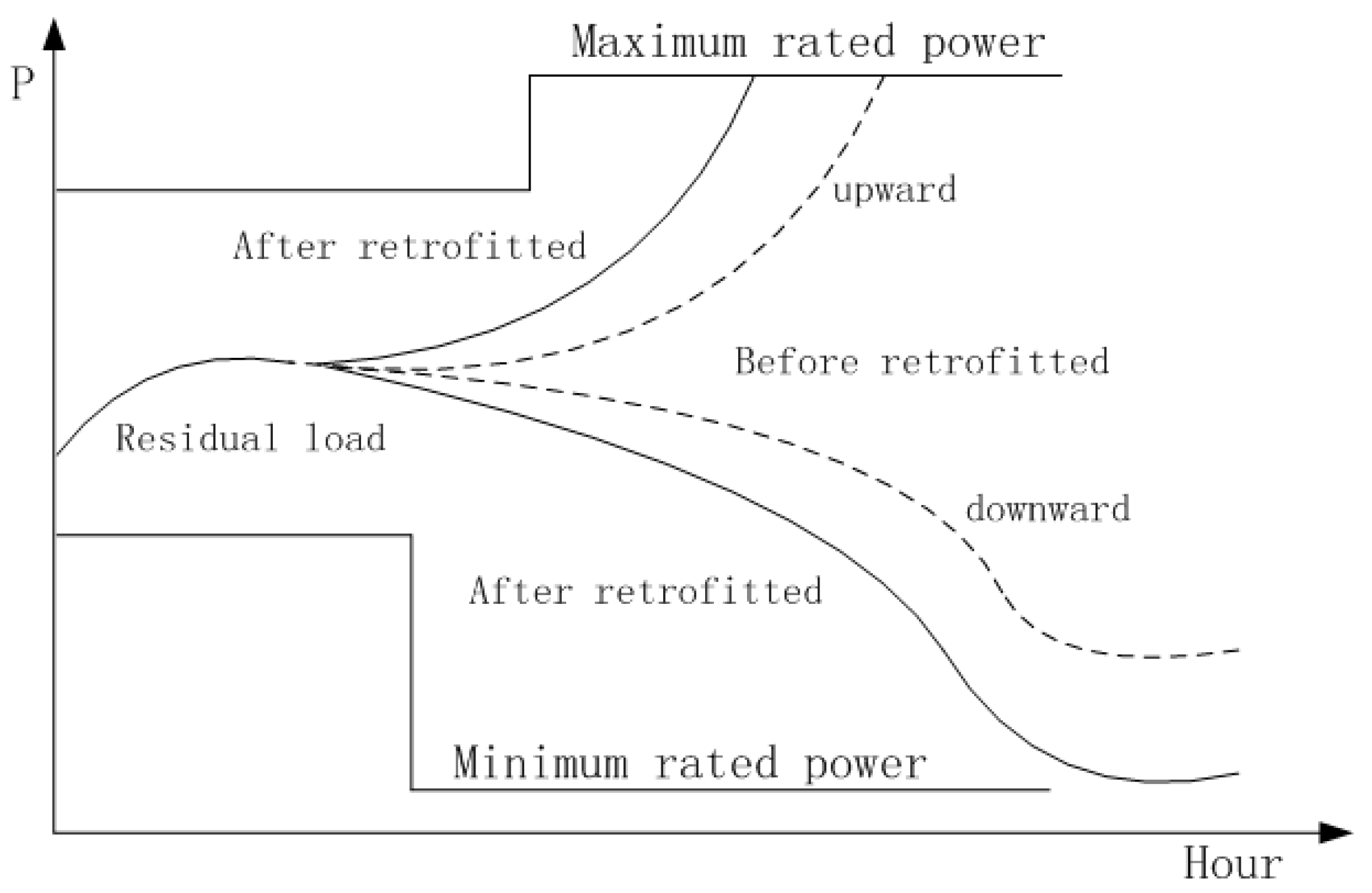

The flexibility requirement has two aspects, an upward flexibility and a downward flexibility requirement. For upward flexibility, the greater the upward ramp rate, the sooner the power output is close to the rated output, and the greater the generation electricity. The ability to ramp up quickly may have extra value to the system beyond just the extra electricity generated. However, in this section we only research the flexible electricity marginal cost and marginal revenue provided by peak shaving depth retrofitting.

Flexible electricity (

) increases with increased depth, and is a function of peak shaving depth (

); flexible electricity cost (

) is also a function of flexible electricity (

), so the cost also can be expressed as a function of the depth. Therefore, the flexibility marginal cost (

MC) can be expressed as:

Power enterprises reduce their power trading through downward load operation, therefore the flexible electricity revenue (

) is the compensation for peak shaving operation, it can be expressed as a function of flexible electricity (

). By the same token, flexible electricity revenue is also a function of the depth (H), so flexibility marginal revenue (

MR) can be expressed as:

5.1. Fixed Cost of Peak Shaving Depth Retrofitting

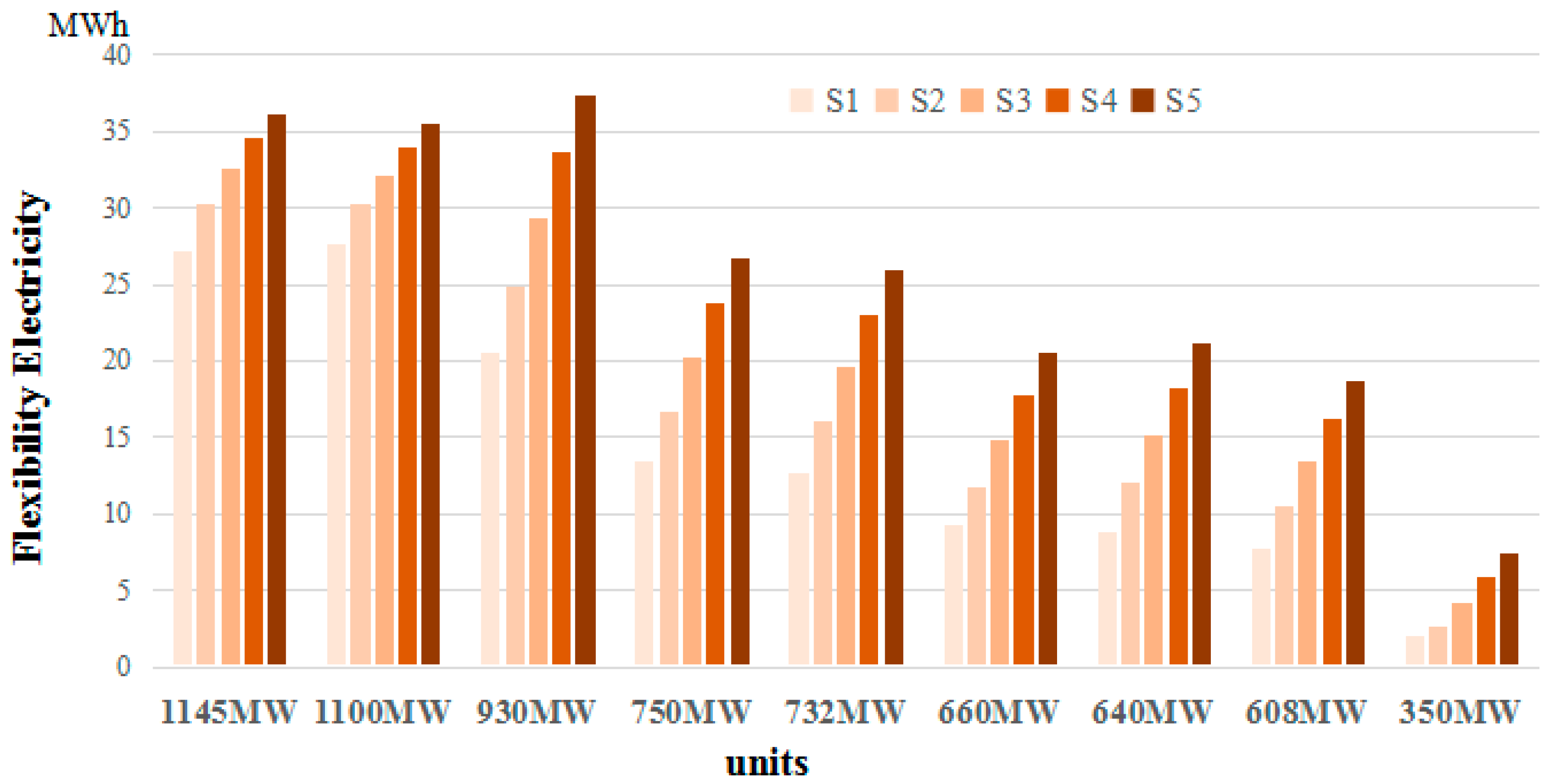

For the fixed cost of peak shaving depth retrofitting, detailed economic indicators need to be clarified gradually in the demonstration pilot project, now there are no official statistics. Thus, according to the prophase research results from National Energy Administration, the per unit of flexibility retrofitting cost is commonly between 50 yuan/kW and 200 yuan/kW [

33]. Taking a 600 MW unit as an example, if the designed minimum output power is 50% of the rated power, we set the scenarios according to different depths with different costs. These are shown in

Table 10.

From

Table 10, the retrofitting cost per MW increases with the increase in depth, because each boiler has a designed lowest stable-combustion depth, if the designed depth is deeper than the running depth, the only retrofitting process is to ensure the normal working of the environmental protection equipment; if it is higher than the running depth, the retrofitting process will become complicated in order to ensure the stable combustion of the boiler and the normal working of the environmental protection equipment.

To estimate

with the quadratic function, then the function between

and

is:

This is the total retrofitting cost. If the unit can serve

years after retrofitted, and the rate of return on investment is

, then the annual cost will be

; if the total time of annual peak shaving operation is

, then the average fixed cost of one time peak shaving operation

will be:

where

is the capital recovery factor. Assuming that in the electrical power investment,

equals 8%, and the service life

of coal power units after being retrofitted is 15 years, then the capital recovery factor

equals 0.1168. Then the average fixed cost of one time peak shaving operation

will be:

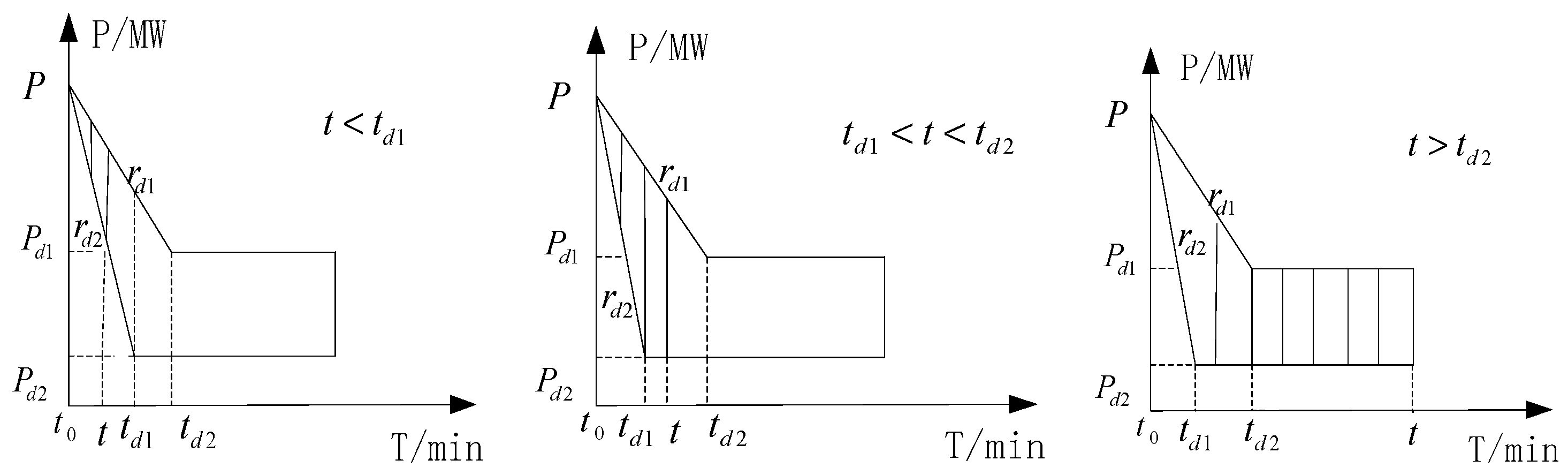

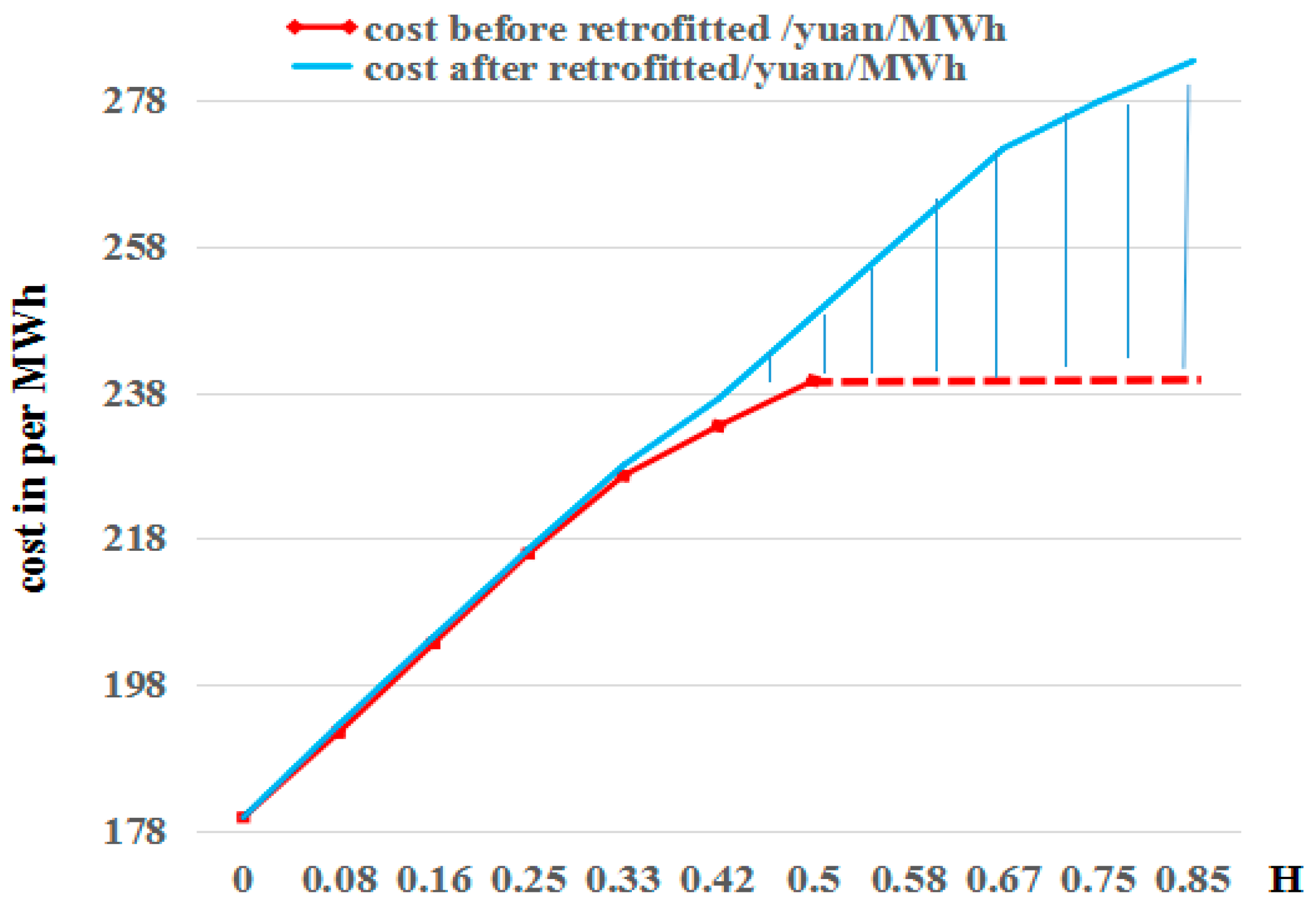

5.2. Variable Cost-Generation Loss Cost from Peak Shaving Depth Retrofitting

Peak shaving depth retrofitting inevitably leads to increasing generation losses. Also taking the 600 MW unit as an example, assuming that the generation heat rate with different active powers before retrofitting is shown in

Table 11 (the depth is from 0 to 50%). The generation heat rate after retrofitting is set according to Germany’s experience [

34] and shown in

Table 11. Assuming that the price of standard coal (5500 kCal/kg) is 600 yuan/ton, the per unit generation cost is also shown in

Table 11.

Before retrofitting, the function between per unit generation cost and the depth can be fitted using the least square method with Equation (18).

After retrofitting, the function between per unit generation cost and the depth can be fitted as follows:

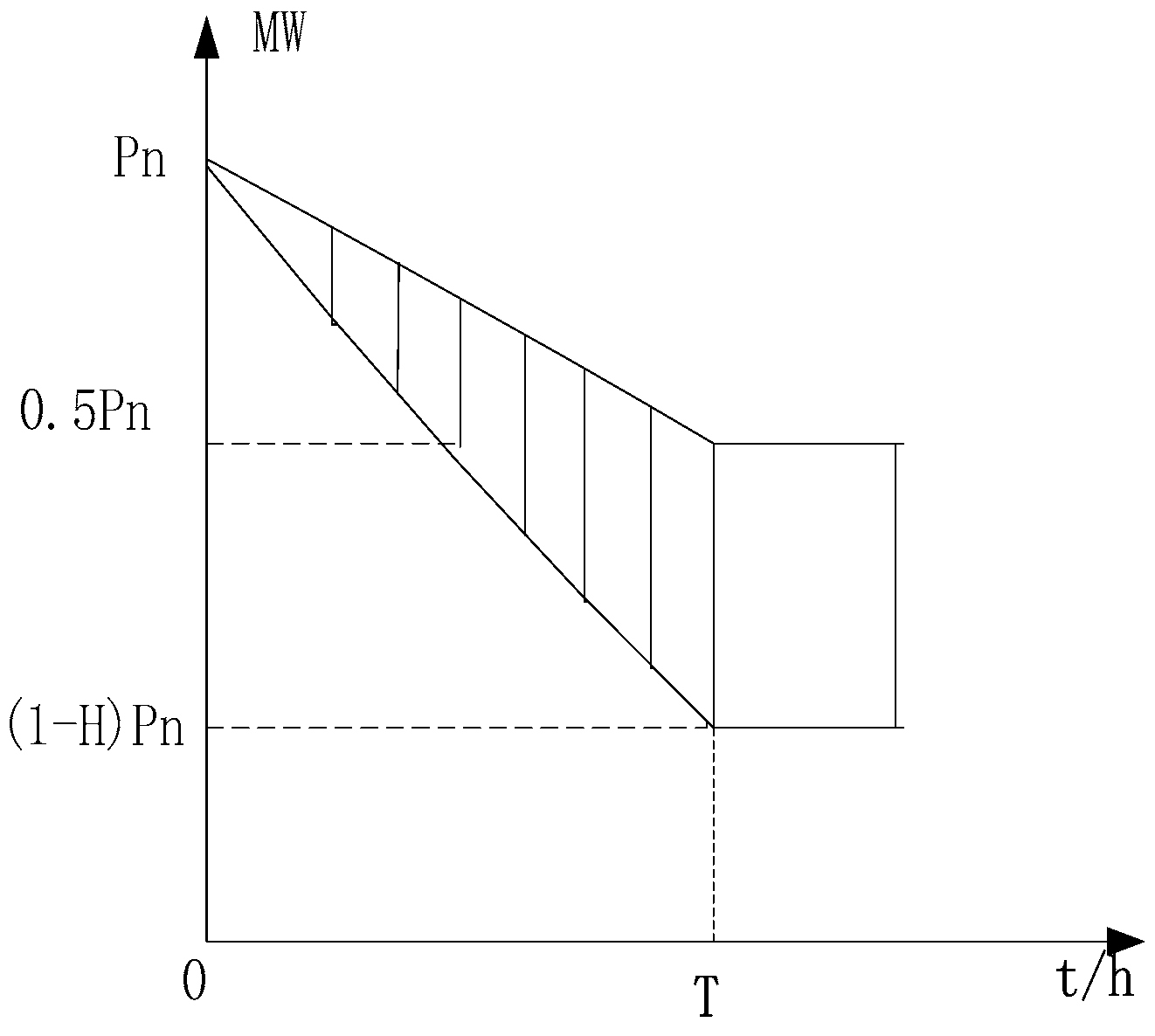

The generation loss cost of per unit is shown in

Figure 7 by a shaded area.

If flexible electricity is

, the total generation loss cost

is:

The total retrofitting cost for one time peak shaving operation should include both the fixed cost and the variable cost. Because the unit of is , the unit of is yuan. After unifying the units of the two kinds of cost, the unit of the total cost is 106 yuan.

Therefore, the total cost

for one time peak shaving operation is:

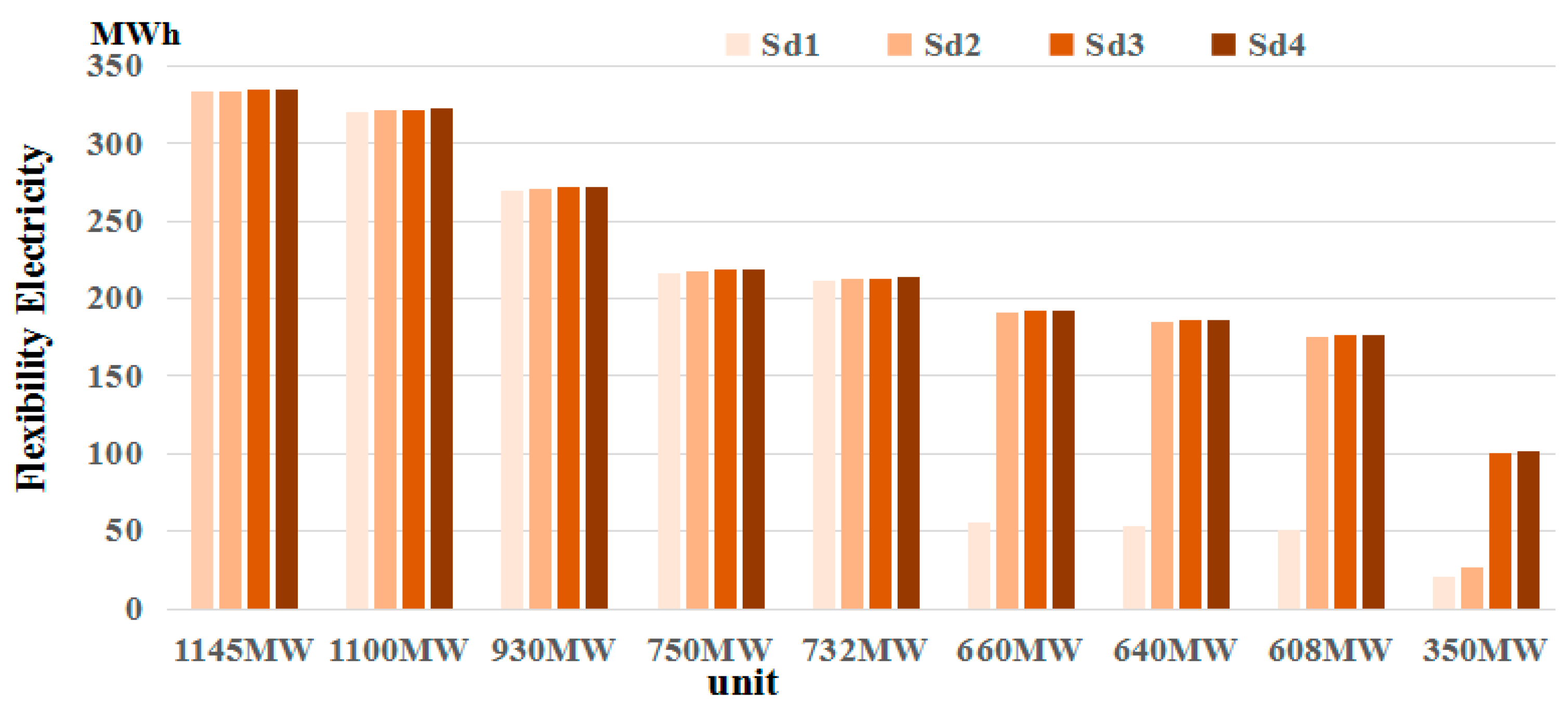

5.3 Revenue from Peak Shaving Depth Operation

According to the Northeast Regional Electricity Market Operation Rules issued by the Northeast NEA [

35], for units with a peak shaving operation, if the depth is higher than 40%, the subsidy for per megawatt hour electricity is 1000 yuan, and if the depth is lower than 40%, the subsidy is 400 yuan, then two scenarios for the compensation standard of per megawatt hour electricity, basic scenario (

) and policy scenario (

), are shown in

Table 12.

According to these two compensation scenarios, the functions between per unit flexible electricity revenue can be expressed as the piecewise function and , respectively. Both of these are always constant in every piecewise range of .

If the flexible electricity of the peak shaving operation is , the per unit flexible electricity revenue is , the flexibility revenue will be , that is, .

5.5. Analysis of Characteristic Roots in Two Scenarios

In economic terms, when , the producers can profit from this transaction and they are willing to continue production and transaction. In power economics, only when coal power plants can benefit from peak shaving operations are they willing to carry out coal power flexibility retrofitting. This means that only when the margin revenues from the peak shaving operation can cover the marginal cost of coal power flexibility retrofitting, are the operators are willing to carry out coal power flexibility retrofitting.

Due to the fact that electricity trading is always in 15 min, we set the response time

T = 0.25 h, 0.50 h, 0.75 h, 1 h, where h equals to one hour, thus the inequality of

is as follows:

As we know, it is difficult to predict the times of peak shaving operation

, as it depends on the wind speed, the changes of power load and other factors in the power system. However, the maximum annual operation hours of coal power units is 5500 h, if the maximum

equals 5500, then the minimum of

will equal 0.0002;

is far less than the minimum of

and

(the minimum of

is 0.0004 in the range of

), in this case the inequality of

is simplified as follows:

The characteristic roots of the inequality of

can reflect the range in which the margin revenue can cover the margin cost with a certain

. For coal power units, which can only run with the depth at which the margin revenue can cover the margin cost, the plant operators are willing to participate in peak shaving operation. The characteristic roots for different

are always

. This is related to the compensation standard and the times of peak shaving operation. If there are characteristic roots in the range of

, then all of the ranges of

and the total annual running hours in two scenarios are show in

Table 13 and

Table 14.

In the basic scenario, the maximum annual peak shaving running hours is 402, as the depth is 0.85; in the policy scenario, the maximum annual peak shaving running hours is 322, as the depth is 0.85.

In fact, in 2016, the most serious wind power curtailment was in four provinces [

36]: Gansu, Xinjiang, Inner Mongolia, and Jilin, and the curtailment rate was 43%, 38%, 21% and 30%, respectively. Among them, the curtailed wind power and the total flexibility retrofitting capacity of coal power units in Jilin province [

37] are show in

Table 15, and we can roughly estimate the peak shaving running hours, also shown in

Table 15.

From

Table 15 we can see that if all of the curtailed wind power is integrated by the peak shaving operation of the total coal power flexibility retrofitting units from

, then the total peak shaving running hours will be 2180 h when the depth is from 0.50 to 0.60, and the total peak shaving running hours will be 727 h when the depth is from 0.50 to 0.85. These are all bigger than the calculated running hours in

Table 13 and

Table 14. This means that in the north areas where the curtailed wind power needs to be integrated through coal power peak shaving operations, the actual times

should be greater than or equal to the calculated

in

Table 13 and

Table 14.

If we roughly set the total times

of peak shaving operations as 100, 300 or 500, then the characteristic roots

for

in these two scenarios are shown in

Table 16.

From

Table 16 we can see that the characteristic roots have a relationship with the compensation standard and the times of peak shaving operation. There are three cases for the characteristic roots:

- (1)

If there is a characteristic root in every piecewise range of , the peak shaving retrofitting decision will be ‘yes’. As the actual running depth is less than or equal to the calculated in every piecewise range of , the margin revenue can cover the margin cost, and the compensation standard is rational and the plant operators are willing to carry out coal power flexibility retrofitting.

- (2)

If there are no roots in every piecewise range of and the calculated is bigger than every piecewise range of , then the peak shaving retrofitting decision will be ‘yes’ and the compensation standard will be high enough for the plant operators to carry out coal power flexibility retrofitting.

- (3)

If there are no roots in every piecewise range of and the calculated is less than every piecewise range of , then the peak shaving retrofitting decision will be ‘no’ and the compensation standard will be too low to carry out coal power flexibility retrofitting.

In the basic scenario, we can conclude that:

- (1)

When the times of peak shaving operation are equal to 100, this compensation standard is not enough for a depth deeper than 0.52.

- (2)

When the times of peak shaving operation are equal to 300, this compensation is good enough for carrying out peak shaving operation.

In the policy scenario, we can conclude that the compensation standard is always good enough for carrying out peak shaving operation. Therefore, from the comparison of the policy scenario with the basic scenario, we suggest that the current compensation standard in China should be set as upward ladders like according to peak shaving depth, so it can make power generation enterprise profitable, and also save compensation costs. This can make the peak shaving compensation mechanism a long-term mechanism in order to promote renewable energy integration sustainably.