Transition towards Sustainable Solutions: Product, Service, Technology, and Business Model

Abstract

:1. Introduction

2. Literature Review

2.1. Sustainability

2.2. Approaches to Sustainable Solutions

2.2.1. Products, Services, and Technologies

2.2.2. Sustainable Business Models

Product-Service-System (PSS)

Circular Economy (CE)

Industrial Symbiosis (IS)

3. Methods

3.1. Empirical Setting

3.2. Sample and Data Collection

3.3. Measures

4. Results

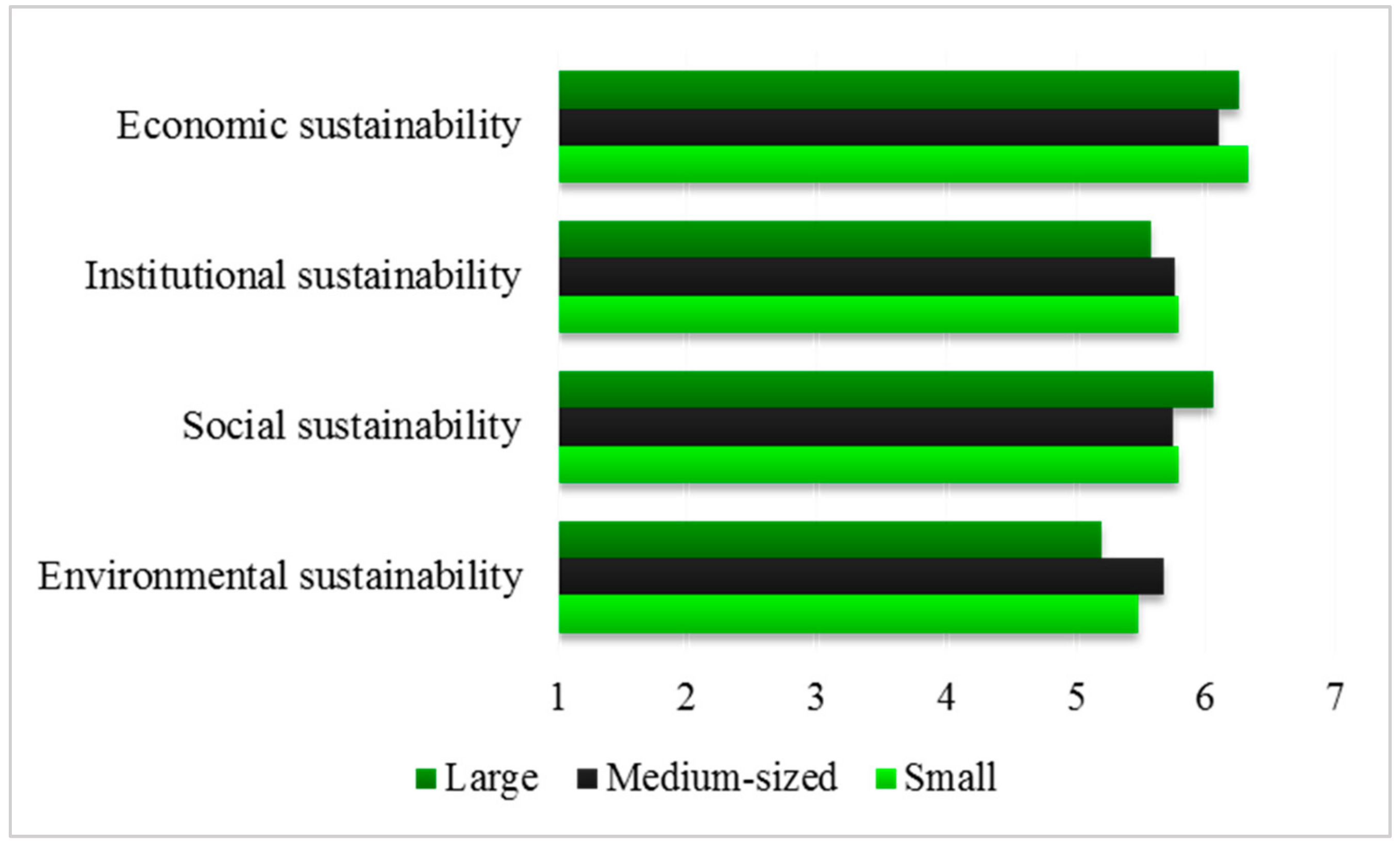

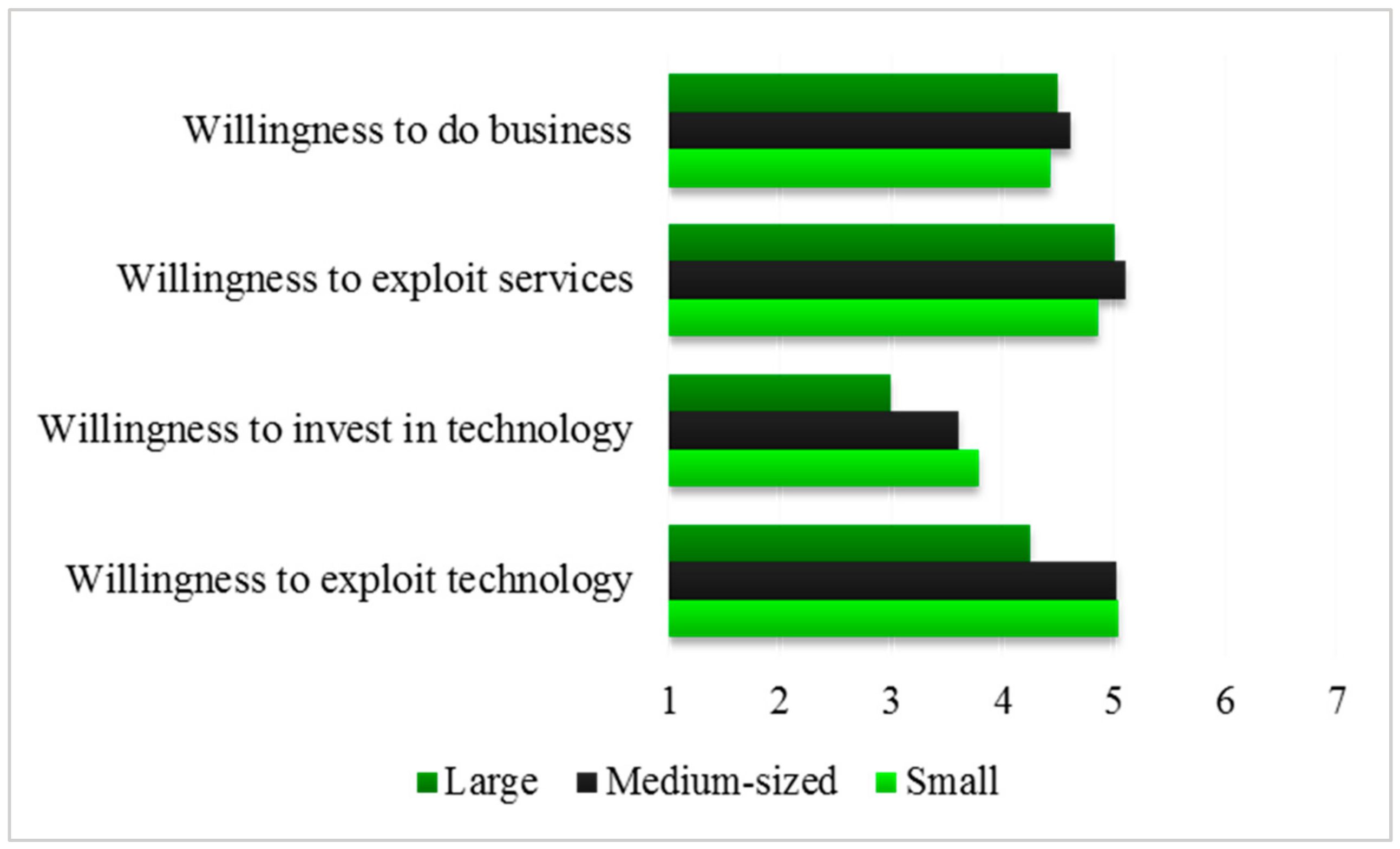

4.1. Quantitative Analysis of the Survey

4.2. Qualitative Analysis of the Survey

4.2.1. Small Operators

4.2.2. Medium Operators

4.2.3. Large Operators

5. Discussion

6. Conclusions

6.1. Theoretical Implications

6.2. Practical Implications

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liljenstolpe, C. Horses in Europe. In Proceedings of the EU Equus, Uppsala, Sweden, 29–30 October 2009; p. 23. [Google Scholar]

- Smith, P.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; Masera, O.; Mbow, C. Agriculture, Forestry and Other Land Use (AFOLU); Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- De Freitas, J.G.; Costa, H.G.; Ferraz, F.T. Impacts of Lean Six Sigma over organizational sustainability: A survey study. J. Clean. Prod. 2017, 156, 262–275. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and green—A systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Gunasekaran, A.; Irani, Z.; Papadopoulos, T. Modelling and analysis of sustainable operations management: Certain investigations for research and applications. J. Oper. Res. Soc. 2014, 65, 806–823. [Google Scholar] [CrossRef]

- Wong, W.P.; Wong, K.Y. Synergizing an ecosphere of lean for sustainable operations. J. Clean. Prod. 2014, 85, 51–66. [Google Scholar] [CrossRef]

- Bebbington, J.; Brown, J.; Frame, B. Accounting technologies and sustainability assessment models. Ecol. Econ. 2007, 61, 224–236. [Google Scholar] [CrossRef]

- Yang, M.; Evans, S.; Vladimirova, D.; Rana, P. Value uncaptured perspective for sustainable business model innovation. J. Clean. Prod. 2017, 140, 1794–1804. [Google Scholar] [CrossRef]

- Shrivastava, P.; Ivanaj, S.; Ivanaj, V. Strategic technological innovation for sustainable development. Int. J. Technol. Manag. 2016, 70, 76–107. [Google Scholar] [CrossRef]

- Anadon, L.D.; Chan, G.; Harley, A.; Matus, K.; Moon, S.; Murthy, S.L.; Clark, W.C. Making Technological Innovation Work for Sustainable Development; Harvard Kennedy School: Cambridge, MA, USA, 2015. [Google Scholar]

- Tim, J. Prosperity without Growth: Economics for a Finite Planet; Earthscan Publications Ltd.: London, UK, 2009. [Google Scholar]

- Markard, J.; Raven, R.; Truffer, B. Sustainability transitions: An emerging field of research and its prospects. Res. Policy 2012, 41, 955–967. [Google Scholar] [CrossRef]

- Meadows, D.; Randers, J.; Meadows, D. Limits to Growth: The 30-Year Update; Chelsea Green Publishing: Hartford, VT, USA, 2004; ISBN 1-60358-155-3. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.; Lenton, T.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 292. [Google Scholar]

- Seiffert, M.E.B.; Loch, C. Systemic thinking in environmental management: Support for sustainable development. J. Clean. Prod. 2005, 13, 1197–1202. [Google Scholar] [CrossRef]

- McLellan, R.; Iyengar, L.; Jeffries, B.; Oerlemans, N. Living Planet Report 2014: Species and Spaces, People and Places; World Wide Fund for Nature: Morges, Switzerland, 2014. [Google Scholar]

- Weidinger, C. Business Success through Sustainability. In Sustainable Entrepreneurship; Springer: Berlin, Germany, 2014; pp. 287–301. [Google Scholar]

- Epstein, M.J.; Roy, M.-J. Sustainability in action: Identifying and measuring the key performance drivers. Long Range Plan. 2001, 34, 585–604. [Google Scholar] [CrossRef]

- Garetti, M.; Taisch, M. Sustainable manufacturing: Trends and research challenges. Prod. Plan. Control 2012, 23, 83–104. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our common future—Call for action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Martens, M.L.; Carvalho, M.M. Key factors of sustainability in project management context: A survey exploring the project managers’ perspective. Int. J. Proj. Manag. 2017, 35, 1084–1102. [Google Scholar] [CrossRef]

- Székely, F.; Knirsch, M. Responsible leadership and corporate social responsibility: Metrics for sustainable performance. Eur. Manag. J. 2005, 23, 628–647. [Google Scholar] [CrossRef]

- Choi, S.; Ng, A. Environmental and economic dimensions of sustainability and price effects on consumer responses. J. Bus. Ethics 2011, 104, 269–282. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Zink, K.J.; Steimle, U.; Fischer, K. Human factors, business excellence and corporate sustainability: Differing perspectives, joint objectives. In Corporate Sustainability as a Challenge for Comprehensive Management; University of Kaiserslauter: Kaiserslauter, Germany, 2008; pp. 3–18. [Google Scholar]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Fiksel, J.; McDaniel, J.; Mendenhall, C. Measuring progress towards sustainability principles, process, and best practices. In Greening of Industry Network Conference Best Practice Proceedings; Wiley, University of North Carolina: Chapel Hill, NC, USA, 1999; Volume 19, p. 2012. Available online: http://eco-nomics.com/images/Sustainability%20Measurement%20GIN.pdf (accessed on 5 January 2018).

- Sheth, J.N.; Sethia, N.K.; Srinivas, S. Mindful consumption: A customer-centric approach to sustainability. J. Acad. Mark. Sci. 2011, 39, 21–39. [Google Scholar] [CrossRef]

- Cruz, J.M.; Wakolbinger, T. Multiperiod effects of corporate social responsibility on supply chain networks, transaction costs, emissions, and risk. Int. J. Prod. Econ. 2008, 116, 61–74. [Google Scholar] [CrossRef]

- Al-Saleh, Y.M.; Taleb, H.M. The integration of sustainability within value management practices: A study of experienced value managers in the GCC countries. Proj. Manag. J. 2010, 41, 50–59. [Google Scholar] [CrossRef]

- Bakker, A.; Schaveling, J.; Nijhof, A. Governance and microfinance institutions. Corp. Gov. 2014, 14, 637–652. [Google Scholar] [CrossRef]

- Kolk, A. Sustainability, accountability and corporate governance: Exploring multinationals’ reporting practices. Bus. Strategy Environ. 2008, 17, 1–15. [Google Scholar] [CrossRef]

- García-Pérez, I.; Muñoz-Torres, M.-J.; Fernández-Izquierdo, M.-Á. Microfinance literature: A sustainability level perspective survey. J. Clean. Prod. 2017, 142, 3382–3395. [Google Scholar] [CrossRef]

- Lozano, R. A holistic perspective on corporate sustainability drivers. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 32–44. [Google Scholar] [CrossRef]

- Mamede, P.; Gomes, C.F. Corporate Sustainability Measurement in Service Organizations: A Case Study from Portugal. Environ. Qual. Manag. 2014, 23, 49–73. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; Van Erck, R.P. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef]

- Talbot, J.; Venkataraman, R. Integration of sustainability principles into project baselines using a comprehensive indicator set. Int. Bus. Econ. Res. J. 2011, 10, 29–40. [Google Scholar] [CrossRef]

- Pope, J.; Annandale, D.; Morrison-Saunders, A. Conceptualising sustainability assessment. Environ. Impact Assess. Rev. 2004, 24, 595–616. [Google Scholar] [CrossRef]

- Wilkins, H. The need for subjectivity in EIA: Discourse as a tool for sustainable development. Environ. Impact Assess. Rev. 2003, 23, 401–414. [Google Scholar] [CrossRef]

- Rauter, R.; Jonker, J.; Baumgartner, R.J. Going one’s own way: Drivers in developing business models for sustainability. J. Clean. Prod. 2017, 140, 144–154. [Google Scholar] [CrossRef]

- International Institute for Sustainable Development; Deloitte & Touche & Business Council for Sustainable Development. Business Strategy for Sustainable Development: Leadership and Accountability for the 90s; Diane Publishing: Collingdale, PA, USA, 1992. [Google Scholar]

- Sadovnikova, A.; Pujari, A. The effect of green partnerships on firm value. J. Acad. Mark. Sci. 2017, 45, 251–267. [Google Scholar] [CrossRef]

- Das, S.; Sen, P.K.; Sengupta, S. Impact of strategic alliances on firm valuation. Acad. Manag. J. 1998, 41, 27–41. [Google Scholar] [CrossRef]

- Mowery, D.C. Collaborative ventures between US and foreign manufacturing firms. Res. Policy 1989, 18, 19–32. [Google Scholar] [CrossRef]

- McCormick, K.; Neij, L.; Mont, O.; Ryan, C.; Rodhe, H.; Orsato, R. Advancing sustainable solutions: An interdisciplinary and collaborative research agenda. J. Clean. Prod. 2016, 123, 1–4. [Google Scholar] [CrossRef]

- Bülbül, H.; Ömürbek, N.; Paksoy, T.; Bektaş, T. An empirical investigation of advanced manufacturing technology investment patterns: Evidence from a developing country. J. Eng. Technol. Manag. 2013, 30, 136–156. [Google Scholar] [CrossRef]

- Chesbrough, H. Business model innovation: Opportunities and barriers. Long Range Plan. 2010, 43, 354–363. [Google Scholar] [CrossRef]

- Zott, C.; Amit, R.; Massa, L. The business model: Recent developments and future research. J. Manag. 2011, 37, 1019–1042. [Google Scholar]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef]

- Legnani, E.; Cavalieri, S.; Ierace, S. A framework for the configuration of after-sales service processes. Prod. Plan. Control 2009, 20, 113–124. [Google Scholar] [CrossRef]

- Pezzotta, G.; Cavalieri, S. A methodological approach to engineer a product-service system. In Proceedings of the International Conference on Advances in Production Management Systems (APMS), Cernobbio, Italy, 11–13 October 2010. [Google Scholar]

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Furrer, O.F.G. A Customer Relationship Typology of Product Services Strategies; Edward Elgar: Broadheath, UK, 2010; pp. 701–721. [Google Scholar]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Geels, F.W. The multi-level perspective on sustainability transitions: Responses to seven criticisms. Environ. Innov. Soc. Transit. 2011, 1, 24–40. [Google Scholar] [CrossRef]

- Hart, S.L.; Milstein, M.B. Global sustainability and the creative destruction of industries. Sloan Manag. Rev. 1999, 41, 23–33. [Google Scholar]

- Jacobsson, S.; Bergek, A. Innovation system analyses and sustainability transitions: Contributions and suggestions for research. Environ. Innov. Soc. Transit. 2011, 1, 41–57. [Google Scholar] [CrossRef]

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boër, C.R.; Westkamper, E.; Williams, D.; Tseng, M.; Seliger, G.; Paci, A.M. The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Ann. Manuf. Technol. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Markard, J.; Stadelmann, M.; Truffer, B. Prospective analysis of technological innovation systems: Identifying technological and organizational development options for biogas in Switzerland. Res. Policy 2009, 38, 655–667. [Google Scholar] [CrossRef]

- Seliger, G.; Kim, H.J.; Kernbaum, S.; Zettl, M. Approaches to sustainable manufacturing. Int. J. Sustain. Manuf. 2008, 1, 58–77. [Google Scholar] [CrossRef]

- Waggoner, P.E.; Ausubel, J.H. A framework for sustainability science: A renovated IPAT identity. Proc. Natl. Acad. Sci. USA 2002, 99, 7860–7865. [Google Scholar] [CrossRef] [PubMed]

- Pacala, S.; Socolow, R. Stabilization wedges: Solving the climate problem for the next 50 years with current technologies. Science 2004, 305, 968–972. [Google Scholar] [CrossRef] [PubMed]

- Hart, S.L. Capitalism at the Crossroads: Next Generation Business Strategies for a Post-Crisis World; FT Press: Upper Saddle River, NJ, USA, 2010; ISBN 0-13-216165-6. [Google Scholar]

- Greve, H.R. Fast and expensive: The diffusion of a disappointing innovation. Strateg. Manag. J. 2011, 32, 949–968. [Google Scholar] [CrossRef]

- Girotra, K.; Netessine, S. OM forum—Business model innovation for sustainability. Manuf. Serv. Oper. Manag. 2013, 15, 537–544. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Johannsdottir, L. Transforming the linear insurance business model to a closed-loop insurance model: A case study of Nordic non-life insurers. J. Clean. Prod. 2014, 83, 341–355. [Google Scholar] [CrossRef]

- Chertow, M.R. “Uncovering” industrial symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Manzini, E.; Vezzoli, C. A strategic design approach to develop sustainable product service systems: Examples taken from the ‘environmentally friendly innovation’Italian prize. J. Clean. Prod. 2003, 11, 851–857. [Google Scholar] [CrossRef]

- Mont, O.K. Clarifying the concept of product—Service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Morelli, N. Developing new product service systems (PSS): Methodologies and operational tools. J. Clean. Prod. 2006, 14, 1495–1501. [Google Scholar] [CrossRef]

- Geum, Y.; Park, Y. Designing the sustainable product-service integration: A product-service blueprint approach. J. Clean. Prod. 2011, 19, 1601–1614. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; Van Halen, C.J.; Te Riele, H.R.; Rommens, P.J. Product service systems, ecological and economic basics. Rep. Dutch Minist. Environ. VROM Econ. Aff. EZ 1999, 36, 1–122. [Google Scholar]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product-Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Sousa-Zomer, T.T.; Miguel, P.A.C. Sustainable business models as an innovation strategy in the water sector: An empirical investigation of a sustainable product-service system. J. Clean. Prod. 2016, 171, S119–S129. [Google Scholar] [CrossRef]

- Maxwell, D.; Van der Vorst, R. Developing sustainable products and services. J. Clean. Prod. 2003, 11, 883–895. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Edbring, E.G.; Lehner, M.; Mont, O. Exploring consumer attitudes to alternative models of consumption: Motivations and barriers. J. Clean. Prod. 2016, 123, 5–15. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Sakai, S.; Yoshida, H.; Hirai, Y.; Asari, M.; Takigami, H.; Takahashi, S.; Tomoda, K.; Peeler, M.V.; Wejchert, J.; Schmid-Unterseh, T. International comparative study of 3R and waste management policy developments. J. Mater. Cycles Waste Manag. 2011, 13, 86–102. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Jun, H.; Xiang, H. Development of circular economy is a fundamental way to achieve agriculture sustainable development in China. Energy Procedia 2011, 5, 1530–1534. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, Z.; Zhou, R.; Deng, W.; Wang, M.; Ma, S. Ecological utilization of leather tannery waste with circular economy model. J. Clean. Prod. 2011, 19, 221–228. [Google Scholar] [CrossRef]

- Han, L.; Li, B.; Song, T.; Tong, L. Circular-economy models of animal husbandry industry in Jilin Province. Chin. Geogr. Sci. 2006, 16, 148–153. [Google Scholar] [CrossRef]

- Chertow, M.; Ehrenfeld, J. Organizing Self-Organizing Systems. J. Ind. Ecol. 2012, 16, 13–27. [Google Scholar] [CrossRef]

- Erkman, S. Industrial ecology: An historical view. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Peck, D.; Kandachar, P.; Tempelman, E. Critical materials from a product design perspective. Mater. Des. 1980–2015 2015, 65, 147–159. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Clean. Prod. 2011, 19, 1865–1875. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Boix, M.; Montastruc, L.; Azzaro-Pantel, C.; Domenech, S. Optimization methods applied to the design of eco-industrial parks: A literature review. J. Clean. Prod. 2015, 87, 303–317. [Google Scholar] [CrossRef]

- Allenby, B. Clean production in context: An information infrastructure perspective. J. Clean. Prod. 2004, 12, 833–839. [Google Scholar] [CrossRef]

- Allenby, B. The ontologies of industrial ecology? Prog. Ind. Ecol. Int. J. 2006, 3, 28–40. [Google Scholar] [CrossRef]

- Veleva, V.; Todorova, S.; Lowitt, P.; Angus, N.; Neely, D. Understanding and addressing business needs and sustainability challenges: Lessons from Devens eco-industrial park. J. Clean. Prod. 2015, 87, 375–384. [Google Scholar] [CrossRef]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Côté, R. Diversity in industrial ecosystems. Int. J. Sustain. Dev. World Ecol. 2007, 14, 329–335. [Google Scholar] [CrossRef]

- Korhonen, J. Theory of industrial ecology: The case of the concept of diversity. Prog. Ind. Ecol. Int. J. 2005, 2, 35–72. [Google Scholar] [CrossRef]

- Harper, E.M.; Graedel, T.E. Industrial ecology: A teenager’s progress. Technol. Soc. 2004, 26, 433–445. [Google Scholar] [CrossRef]

- Lowe, E.A. Eco-Industrial Park Handbook for Asian Developing Countries; Report; Asian Development Bank: Mandaluyong, Philippines, 2001. [Google Scholar]

- Lowe, E.A. Creating by-product resource exchanges: Strategies for eco-industrial parks. J. Clean. Prod. 1997, 5, 57–65. [Google Scholar] [CrossRef]

- Pakarinen, S.; Mattila, T.; Melanen, M.; Nissinen, A.; Sokka, L. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resour. Conserv. Recycl. 2010, 54, 1393–1404. [Google Scholar] [CrossRef]

- Mirata, M.; Emtairah, T. Industrial symbiosis networks and the contribution to environmental innovation: The case of the Landskrona industrial symbiosis programme. J. Clean. Prod. 2005, 13, 993–1002. [Google Scholar] [CrossRef]

- Karlsson, M.; Wolf, A. Using an optimization model to evaluate the economic benefits of industrial symbiosis in the forest industry. J. Clean. Prod. 2008, 16, 1536–1544. [Google Scholar] [CrossRef]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Koppelmäki, K.; Eerola, M.; Kivelä, J.V.; Hagolani-Albov, S.E.; Helenius, J.P.; Winquist, E.; Virkkunen, E. Palopuro Agroecological Symbiosis. In Proceedings of the 7th International Conference on Localized Agri-Food Systems: Challenges for the New Rurality in a Changing World, Stockholm, Sweden, 8–10 May 2016. [Google Scholar]

- Mol, A.P.J.; Dieu, T.T.M. Analysing and governing environmental flows: The case of Tra Co tapioca village, Vietnam. NJAS-Wagening. J. Life Sci. 2006, 53, 301–317. [Google Scholar] [CrossRef]

- Desrochers, P. Regional development and inter-industry recycling linkages: Some historical perspectives. Entrep. Reg. Dev. 2002, 14, 49–65. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Reflections on implementing industrial ecology through eco-industrial park development. J. Clean. Prod. 2007, 15, 1683–1695. [Google Scholar] [CrossRef]

- Martin, M.A. First generation biofuels compete. New Biotechnol. 2010, 27, 596–608. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Liu, W.; Lai, B.; Li, X.; Chen, L. Study of the performance of eco-industrial park development in China. J. Clean. Prod. 2014, 64, 486–494. [Google Scholar] [CrossRef]

- Delai, I.; Takahashi, S. Sustainability measurement system: A reference model proposal. Soc. Responsib. J. 2011, 7, 438–471. [Google Scholar] [CrossRef]

- Khan, E.A.; Dewan, M.N.A.; Chowdhury, M.M.H. Reflective or formative measurement model of sustainability factor? A three industry comparison. Corp. Ownersh. Control 2016, 13, 84–89. [Google Scholar] [CrossRef]

- Svensson, G.; Wagner, B. Implementing and managing economic, social and environmental efforts of business sustainability: Propositions for measurement and structural models. Manag. Environ. Qual. Int. J. 2015, 26, 195–213. [Google Scholar] [CrossRef]

| No | % | ||

|---|---|---|---|

| Size | Less than 20 horses | 68 | 48.9 |

| 20–50 horses | 62 | 44.6 | |

| Over 50 horses | 4 | 2.9 | |

| No answer | 5 | 3.6 | |

| Type of operation | Horserace | 26 | 18.7 |

| Horse-riding | 98 | 70.5 | |

| Other | 13 | 9.4 | |

| No answer | 2 | 1.4 |

| Dimensions | Aspects | References |

|---|---|---|

| Environmental sustainability | Nutrient cycling, Commitment to environmental cause, Waste management, Hygienic factors, Land occupied | [113,114] |

| Social sustainability | Social recognition, Human capital development, Job creation, Health and safety | [113,114] |

| Institutional sustainability | Incomes, Indirect jobs, New business | [35,113] |

| Economic sustainability | Ease of material handling, Energy consumption, Cost reduction | [113,115] |

| Sustainable Solutions | Willingness to Adopt | Examples | Focus/Motivation |

|---|---|---|---|

| Product e.g., [49,50,51,52] | High | Making fuel out of the manure, such as pellets, biogas. | Energy production, Reducing energy consumption |

| Service e.g., [49,50,51,53] | High | Collecting manure from the farms and stables by a service provider Delivering the litters in exchange | Ease, Cost-effectiveness (especially small sized operators) |

| Technology e.g., [9,54,56,57,58,59,60,61] | High (to exploit), Low (to invest) | Utilizing manure as a fuel Burning manure in small-level units (Incinerators, Drum composters, Added heat recovery ventilation) | Energy production, Reducing energy consumption (small sized, medium sized and large operators) |

| Business model e.g., [8,19,66,67,68] | High | Collecting manure from multiple operators and burning it in shared facilities (such as incinerators and bigger-scale drum composting units) Returning the horse manure back to fields. Turning current landfills into gas recovery activities and utilizing manure as a part of the process | Energy production (especially in urban areas) Improving of the land use, Supporting farming (especially in countryside) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasiri, M.; Rantala, T.; Saunila, M.; Ukko, J.; Rantanen, H. Transition towards Sustainable Solutions: Product, Service, Technology, and Business Model. Sustainability 2018, 10, 358. https://doi.org/10.3390/su10020358

Nasiri M, Rantala T, Saunila M, Ukko J, Rantanen H. Transition towards Sustainable Solutions: Product, Service, Technology, and Business Model. Sustainability. 2018; 10(2):358. https://doi.org/10.3390/su10020358

Chicago/Turabian StyleNasiri, Mina, Tero Rantala, Minna Saunila, Juhani Ukko, and Hannu Rantanen. 2018. "Transition towards Sustainable Solutions: Product, Service, Technology, and Business Model" Sustainability 10, no. 2: 358. https://doi.org/10.3390/su10020358