A Bi-Objective Green Closed Loop Supply Chain Design Problem with Uncertain Demand

Abstract

:1. Introduction

- To tackle the uncertainty in the demand, this paper propose a bi-objective model with the chance constraint.

- The model in this study considers customer satisfaction including the speed of logistics, the quality of products and recycling used products.

- An exact -constraint method is adapted to obtain the exact Pareto front for small-scale problems after approximation.

- An approximation method is introduced to handle the chance constraint.

- A multi-objective simulated annealing method (MOSA) and non-dominated sorting genetic algorithm (NSGA-II) are proposed for medium- and large-scale problems.

2. Literature Review

2.1. The Literature of Supply Chain

2.2. Related Research on the Closed-Loop Supply Chain

2.3. The Studies on the Green Closed-Loop Supply Chain

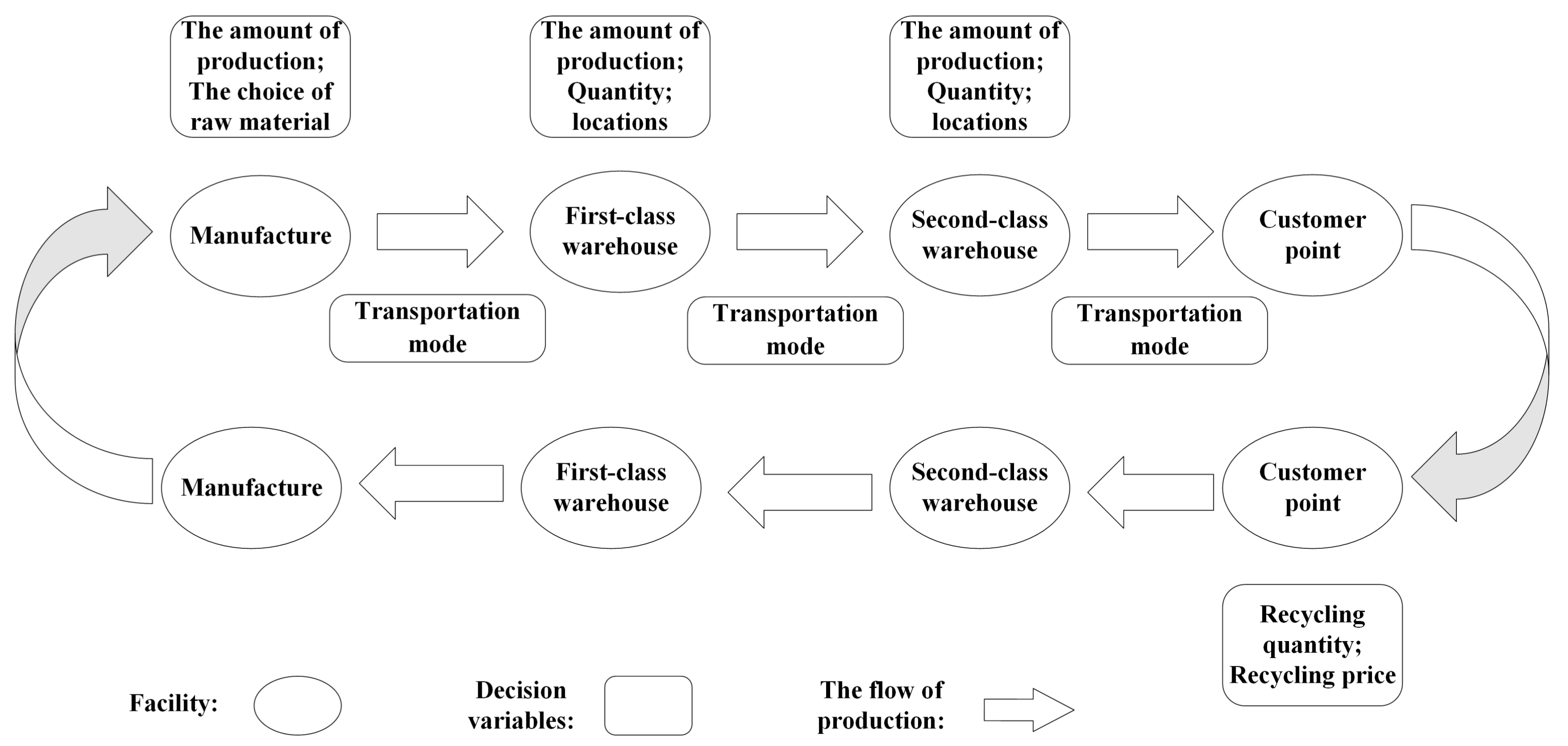

3. Problem Statement

- Our study mainly focuses on the choice of warehouses. Therefore, we assume that manufacturer and customer locations are fixed and known.

- The potential locations of all entities in the network are identified, and the numbers of facilities that can be opened are limited.

- We do not consider the transshipment of goods between the same echelon. We assume that there are only flows between two different echelons. For example, the production cannot be transported from one first-class warehouse to another first-class house, but can be transported from a first-class warehouse to a second-class warehouse.

- In order to simplify the model, the price of recycled products is consistent regardless of quality.

4. Mathematical Formulation

4.1. Notation

- i:

- index of manufacturer;

- j:

- index of first-class warehouse;

- k:

- index of second-class warehouse;

- l:

- index of customer demand point;

- r:

- index of raw material;

- o:

- index of operation;

- q:

- index of transportation method;

- I:

- set of manufacturers;

- J:

- set of first-class warehouses;

- K:

- set of second-class warehouses;

- L:

- set of customer demand points;

- R:

- set of raw materials;

- O:

- set of operations;

- Q:

- set of transportation methods;

- :

- the products’ maximum quantity of customer demand point l;

- :

- the products’ mean quantity of customer demand point l;

- :

- the maximum probability the second-class warehouses fail to meet customer demand l

- :

- the defect coefficient of raw material r to product quality of manufacturer i;

- u:

- the upper bound of recycling price;

- v:

- the lower bound of recycling price;

- :

- the unit transportation cost when recycling;

- :

- the operation cost of manufacturer i using operation system o, non-negative;

- :

- the operation cost of first-class warehouse j using operation system o, non-negative;

- :

- the operation cost of second-class warehouse k using operation system o, non negative;

- :

- the unit transportation cost from manufacturer i to first-class warehouse j by vehicle q, non-negative;

- :

- the unit transportation cost from first-class warehouse j to second-class warehouse k by vehicle q, non-negative;

- :

- the unit transportation cost from second-class warehouse k to customer demand point l by vehicle q, non-negative;

- :

- the production of manufacturer i cost using raw material r, non-negative;

- :

- the stay time of products with the manufacturer i under the operation cost , non-negative;

- :

- the stay time of products in the first-class warehouse j under the operation cost , non-negative;

- :

- the stay time of products in the second-class warehouse k under the operation cost , non-negative;

- :

- the transportation time from manufacturer i to first-class warehouse j under the transportation cost , non-negative;

- :

- the transportation time from first-class warehouse j to second-class warehouse k under the transportation cost , non-negative;

- :

- the transportation time from second-class warehouse k to customer demand point l under the transportation cost , non-negative;

- :

- the recycling price;

- b:

- parameter denoting the incentive sensitivity of return amounts;

- :

- parameter between zero and one, depending on the proportion of products that are possible to recycle;

- :

- parameter denoting the coefficient of the amounts of recycling products, which changes with the recycling price;

- :

- a scaling parameter to adjust the dimension of time;

- :

- a scaling parameter to adjust the dimension of product quality;

- :

- a scaling parameter to adjust the dimension of the amounts of recycling products;

- a:

- positive integer, denoting the minimal traffic volume;

- s:

- positive integer, denoting the minimal production of manufacturer i;

- f:

- positive integer;

- c:

- positive number, and ;

- h:

- positive integer, and ;

- M:

- a sufficiently large positive number;

- :

- the production yield of manufacturer i using raw material r;

- :

- the amounts of products shipped from manufacturer i to first-class warehouse j using transportation vehicle q;

- :

- the amounts of products shipped from first-class warehouse j to second-class warehouse k using transportation vehicle q;

- :

- the amounts of products shipped from second-class warehouse k to customer demand point l using transportation vehicle q;

- :

- binary variable; equals one if constructing first-class warehouse j, zero otherwise;

- :

- binary variable; equals one if constructing second-class warehouse k, zero otherwise;

- :

- binary variable; equals one if manufacturer i uses operation system o, zero otherwise;

- :

- binary variable; equals one if first-class warehouse j uses operation system o, zero otherwise;

- :

- binary variable; equals one if second-class warehouse k uses operation system o, zero otherwise;

- :

- binary variable; equals one if using transportation vehicle q between manufacturer i and first-class warehouse j, zero otherwise;

- :

- binary variable; equals one if using transportation vehicle q between first-class warehouse j and second-class warehouse k, zero otherwise;

- :

- binary variable; equals one if using transportation vehicle q between second-class warehouse k and customer demand point l, zero otherwise;

- :

- binary variable; equals one if manufacturer i uses raw material r to produce products, zero otherwise;

- :

- binary variable; equals one if recycling used products with price m, zero otherwise;

4.2. Problem Model

5. Solution Approach

5.1. -Constraint Method

5.1.1. The -Constraint Method Framework

- Compute the ideal point = (,) and nadir point = (,).

- Set = {(,)} and = (△ = 2000 for this problem).

- While ≥, do:

- (a)

- solve the -constraint problem with as a constraint and the Obj2as the single objective function to optimality, and add the optimal solution value (,) to .

- (b)

- set = .

- Obtain the Pareto front by removing dominated points from , if existing.

5.1.2. An Example with the -Constraint Method

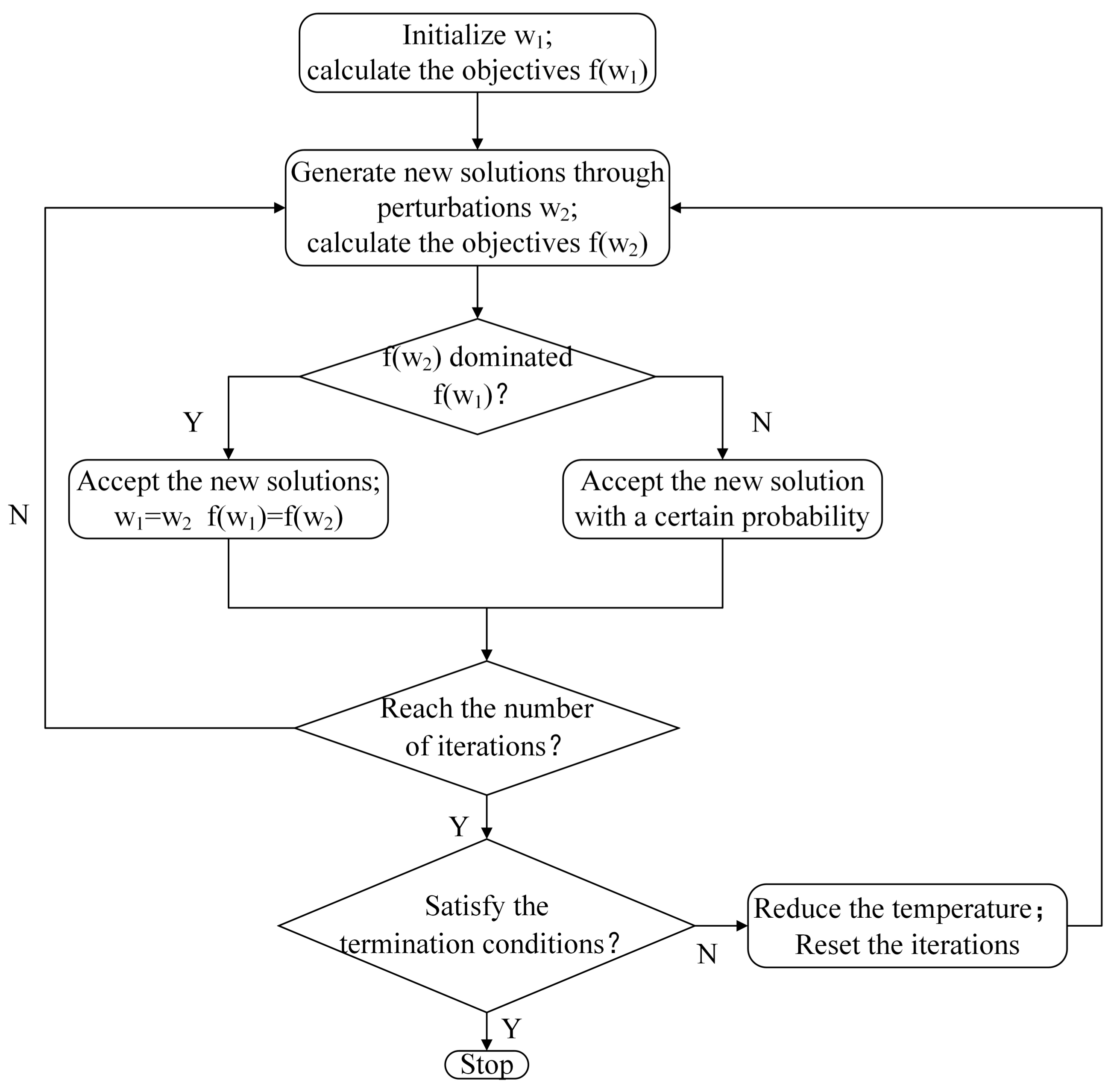

5.2. Multi-Objective Simulated Annealing Method

5.3. Non-Dominated Solution Genetic Algorithm

- Genetic Operator 1:

- Randomly select two chromosomes;

- Exchange the facility locations of the two chromosomes;

- Change the second and third parts accordingly;

- Recalculate the objectives.

- Genetic Operator 2:

- Randomly select two chromosomes;

- Exchange the facility operation system of the two chromosomes;

- Change the first and third parts accordingly;

- Recalculate the objectives.

- Genetic Operator 3:

- Randomly select a chromosome;

- Change the number of transportation production;

- Change the first and second parts accordingly;

- Recalculating the objectives.

6. Performance Measurement

6.1. Introduction of Indicators

6.2. Parameter Tuning

6.3. Comparison of the Proposed Algorithms

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lambert, D.M.; Cooper, M.C. Issues in supply chain management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef] [Green Version]

- Elbounjimi, M. Green closed-loop supply chain network design a literature review. Int. J. Oper. Logist. Manag. 2014, 3, 275–286. [Google Scholar]

- Wei, J.; Govindan, K.; Li, Y. Pricing and collecting decisions in a closed-loop supply chain with symmetric and asymmetric information. Comput. Oper. Res. 2015, 54, 257–265. [Google Scholar] [CrossRef]

- Zhang, L. A nonlinear complementarity model for supply chain network equilibrium. J. Ind. Manag. Optim. 2007, 3, 727–737. [Google Scholar] [CrossRef]

- Cardona-Valdés, Y.; Álvarez, A.; Ozdemir, D. A bi-objective supply chain design problem with uncertainty. Transp. Res. Part C 2011, 19, 821–832. [Google Scholar] [CrossRef]

- Pereira, J.; Vilá, M. A new model for supply chain network design with integrated assembly line balancing decisions. Int. J. Prod. Res. 2015, 54, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Eskandarpour, M.; Dejax, P.; Péton, O. A large neighborhood search heuristic for supply chain network design. Comput. Oper. Res. 2017, 80, 23–37. [Google Scholar] [CrossRef]

- Habibi, M.K.K.; Battaia, O.; Cung, V.D. Collection-disassembly problem in reverse supply chain. Int. J. Prod. Econ. 2017, 183, 334–344. [Google Scholar] [CrossRef]

- Kannan, G.; Noorul, A.; Devika, M. Analysis of closed loop supply chain using genetic algorithm and particle swarm optimization. Int. J. Prod. Res. 2009, 47, 1175–1200. [Google Scholar] [CrossRef]

- Turki, S.; Didukh, S.; Sauvey, C.; Rezg, N. Optimization and analysis of a manufacturing remanufacturing transport warehousing system within a closed-loop supply chain. Sustainability 2017, 9, 561. [Google Scholar] [CrossRef]

- Bottani, E.; Casella, G. Minimization of the environmental emissions of closed-loop supply chains: A case study of returnable transport assets management. Sustainability 2018, 10, 329. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, Z.; Guo, S.; Tseng, M.; Wu, K. Enhancing Eco-Efficiency of Agro-Products’ Closed-Loop Supply Chain under the Belt and Road Initiatives: A System Dynamics Approach. Sustainability 2018, 10, 668. [Google Scholar] [CrossRef]

- Huynh, C.H.; So, K.C.; Gurnani, H. Managing a closed-loop supply system with random returns and a cyclic delivery schedule. Eur. J. Oper. Res. 2016, 255, 787–796. [Google Scholar] [CrossRef]

- Zohal, M.; Soleimani, H. Developing an ant colony approach for green closed-loop supply chain network design: A case study in gold industry. J. Clean. Prod. 2016, 133, 314–337. [Google Scholar] [CrossRef]

- Soleimani, H.; Govindan, K.; Saghafi, H.; Jafari, H. Fuzzy multi-objective sustainable and green closed-loop supply chain network design. Comput. Ind. Eng. 2017, 109, 191–203. [Google Scholar] [CrossRef]

- Liu, S.; Chang, Y. Manufacturers’ closed-loop orientation for green supply chain management. Sustainability 2017, 9, 222. [Google Scholar] [CrossRef]

- Kaya, O.; Urek, B. A mixed integer nonlinear programming model and heuristic solutions for location, inventory and pricing decisions in a closed loop supply chain. Comput. Oper. Res. 2016, 65, 93–103. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Thierry, M.; Salomon, M.; Van Nunen, J. Strategie issues in product recovery management. Calif. Manag. Rev. 1995, 37, 114–135. [Google Scholar] [CrossRef]

- Lu, Z.; Bostel, N. A facility location model for logistics systems including reverse flows: The case of remanufacturing activities. Comput. Oper. Res. 2007, 34, 299–323. [Google Scholar] [CrossRef]

- Franca, R.B.; Jones, E.C.; Richards, C.N. Multi-objective stochastic supply chain modeling to evaluate tradeoffs between profit and quality. Int. J. Prod. Econ. 2010, 127, 292–299. [Google Scholar] [CrossRef]

- Ng, M.W. Distribution-free vessel deployment for liner shipping. Eur. J. Oper. Res. 2014, 238, 858–862. [Google Scholar] [CrossRef]

- Hillermeier, C. Nonlinear multiobjective optimization. J. Oper. Res. Soc. 1999, 51, 246–256. [Google Scholar]

- Liu, M.; Yang, D.; Su, Q.; Xu, L. Bi-objective approaches for home healthcare medical team planning and scheduling problem. Computat. Appl. Math. 2018, 1–32. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, J.; Vecchi, M.P. Optimization by simulated annealing. Read. Comput. Vis. 1987, 220, 606–615. [Google Scholar]

- Bandyopadhyay, S.; Saha, S.; Maulik, U.; Deb, K. A simulated annealing-based multiobjective optimization algorithm: Amosa. IEEE Trans. Evolut. Comput. 2008, 12, 269–283. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Cortés, N.C. Solving multiobjective optimization problems using an artificial immune system. Genet. Progr. Evolvable Mach. 2005, 6, 163–190. [Google Scholar] [CrossRef]

- Zitzler, E.; Thiele, L.; Laumanns, M.; Fonseca, C.M.; Fonseca, V.G.D. Performance assessment of multiobjective optimizers: An analysis and review. IEEE Trans. Evolut. Comput. 2003, 7, 117–132. [Google Scholar] [CrossRef]

- Zitzler, E.; Deb, K.; Thiele, L. Comparison of multiobjective evolutionary algorithms: Empirical results. Evolut. Comput. 2000, 8, 173–195. [Google Scholar] [CrossRef] [PubMed]

| Solution ID | Objective 1 | Objective 2 | ||

|---|---|---|---|---|

| Cost | Satisfaction | |||

| (1) min Obj.2 | 84,995 | 0.00% | 31,913 | −54.89% |

| (2) Obj.1 ≤ 87177 | 85,292 | 0.35% | 48,263 | −31.78% |

| (3) Obj.1 ≤ 89177 | 87,292 | 2.70% | 54,593 | −22.83% |

| (4) Obj.1 ≤ 91177 | 89,394 | 5.18% | 56,103 | −20.70% |

| (5) Obj.1 ≤ 93177 | 91,394 | 7.53% | 57,621 | −18.55% |

| (6) Obj.1 ≤ 95177 | 93,393 | 9.88% | 58,951 | −16.67% |

| (7) Obj.1 ≤ 97177 | 95,394 | 12.23% | 60,111 | −15.04% |

| (8) Obj.1 ≤ 99177 | 97,395 | 14.59% | 61,386 | −13.23% |

| (9) Obj.1 ≤ 101177 | 99,395 | 16.94% | 62,521 | −11.63% |

| (10) Obj.1 ≤ 103177 | 101,395 | 19.30% | 63,578 | −10.13% |

| (11) Obj.1 ≤ 105177 | 103,395 | 21.65% | 64,358 | −9.03% |

| (12) Obj.1 ≤ 107177 | 105,395 | 24.00% | 64,928 | −8.23% |

| (13) Obj.1 ≤ 109177 | 107,395 | 26.35% | 65,738 | −7.08% |

| (14) Obj.1 ≤ 111177 | 109,412 | 28.73% | 66,368 | −6.19% |

| (15) Obj.1 ≤ 113177 | 111,412 | 31.08% | 66,848 | −5.51% |

| (16) Obj.1 ≤ 115177 | 113,411 | 33.43% | 67,328 | −4.83% |

| (17) Obj.1 ≤ 117177 | 115,412 | 35.79% | 67,808 | −4.16% |

| (18) Obj.1 ≤ 119177 | 117,412 | 38.14% | 68,258 | −3.52% |

| (19) Obj.1 ≤121177 | 119,412 | 40.49% | 68,678 | −2.93% |

| (20) Obj.1 ≤ 123177 | 121,451 | 42.89% | 69,068 | −2.37% |

| (21) Obj.1 ≤ 125177 | 123,452 | 45.25% | 69,398 | −1.91% |

| (22) Obj.1 ≤ 127177 | 125,453 | 47.60% | 69,728 | −1.44% |

| (23) Obj.1 ≤ 129177 | 127,547 | 50.06% | 70,058 | −0.98% |

| (24) Obj.1 ≤ 143177 | 141,617 | 66.62% | 70,268 | −0.68% |

| (25) Obj.1 ≤ 147177 | 145,638 | 71.35% | 70,328 | −0.59% |

| (26) Obj.1 ≤ 157177 | 156,399 | 84.01% | 70,478 | −0.38% |

| (27) Obj.1 ≤ 161177 | 160,408 | 88.73% | 70,538 | −0.30% |

| (28) Obj.1 ≤ 171177 | 171,157 | 101.37% | 70,688 | −0.08% |

| Ideal | 84,995 | 0.00% | 70,748 | 0.00% |

| Nadir | 175,177 | 106.10% | 31,913 | −54.89% |

| {200, 200, 20, 0.94} | 0.2382 | {250, 200, 20, 0.94} | 0.2308 |

| {200, 200, 20, 0.96} | 0.2184 | {250, 200, 20, 0.96} | 0.2390 |

| {200, 200, 20, 0.97} | 0.2175 | {250, 200, 20, 0.97} | 0.2243 |

| {200, 200, 25, 0.94} | 0.2473 | {250, 200, 25, 0.94} | 0.2535 |

| {200, 200, 25, 0.96} | 0.2243 | {250, 200, 25, 0.96} | 0.2236 |

| {200, 200, 25, 0.97} | 0.2343 | {250, 200, 25, 0.97} | 0.2210 |

| {200, 200, 30, 0.94} | 0.2594 | {250, 200, 30, 0.94} | 0.2359 |

| {200, 200, 30, 0.96} | 0.2251 | {250, 200, 30, 0.96} | 0.2300 |

| {200, 200, 30, 0.97} | 0.2149 | {250, 200, 30, 0.97} | 0.2103 |

| {200, 250, 20, 0.94} | 0.2183 | {250, 250, 20, 0.94} | 0.2467 |

| {200, 250, 20, 0.96} | 0.2289 | {250, 250, 20, 0.96} | 0.2169 |

| {200, 250, 20, 0.97} | 0.2028 | {250, 250, 20, 0.97} | 0.1961 |

| {200, 250, 25, 0.94} | 0.2433 | {250, 250, 25, 0.94} | 0.2588 |

| {200, 250, 25, 0.96} | 0.2340 | {250, 250, 25, 0.96} | 0.2513 |

| {200, 250, 25, 0.97} | 0.2396 | {250, 250, 25, 0.97} | 0.2052 |

| {200, 250, 30, 0.94} | 0.2341 | {250, 250, 30, 0.94} | 0.2255 |

| {200, 250, 30, 0.96} | 0.2028 | {250, 250, 30, 0.96} | 0.2196 |

| {200, 250, 30, 0.97} | 0.2140 | {250, 250, 30, 0.97} | 0.2022 |

| {150, 100, 0.8, 0.2} | 0.2335 | {200, 100, 0.8, 0.2} | 0.2159 |

| {150, 100, 0.8, 0.5} | 0.2220 | {200, 100, 0.8, 0.5} | 0.1939 |

| {150, 100, 0.8, 0.8} | 0.2060 | {200, 100, 0.8, 0.8} | 0.2076 |

| {150, 100, 0.5, 0.2} | 0.2228 | {200, 100, 0.5, 0.2} | 0.2286 |

| {150, 100, 0.5, 0.5} | 0.2318 | {200, 100, 0.5, 0.5} | 0.2030 |

| {150, 100, 0.5, 0.8} | 0.2047 | {200, 100, 0.5, 0.8} | 0.2148 |

| {150, 100, 0.2, 0.2} | 0.2682 | {200, 100, 0.2, 0.2} | 0.2277 |

| {150, 100, 0.2, 0.5} | 0.2398 | {200, 100, 0.2, 0.5} | 0.2471 |

| {150, 100, 0.2, 0.8} | 0.2550 | {200, 100, 0.2, 0.8} | 0.2288 |

| {150, 150, 0.8, 0.2} | 0.2161 | {200, 150, 0.8, 0.2} | 0.2035 |

| {150, 150, 0.8, 0.5} | 0.2027 | {200, 150, 0.8, 0.5} | 0.1896 |

| {150, 150, 0.8, 0.8} | 0.2078 | {200, 150, 0.8, 0.8} | 0.2086 |

| {150, 150, 0.5, 0.2} | 0.2227 | {200, 150, 0.5, 0.2} | 0.2066 |

| {150, 150, 0.5, 0.5} | 0.2027 | {200, 150, 0.5, 0.5} | 0.2011 |

| {150, 150, 0.5, 0.8} | 0.2141 | {200, 150, 0.5, 0.8} | 0.2099 |

| {150, 150, 0.2, 0.2} | 0.2291 | {200, 150, 0.2, 0.2} | 0.2346 |

| {150, 150, 0.2, 0.5} | 0.2374 | {200, 150, 0.2, 0.5} | 0.2362 |

| {150, 150, 0.2, 0.8} | 0.2384 | {200, 150, 0.2, 0.8} | 0.2359 |

| Instance | NSGA-II (Referred to as A) | MOSA (Referred to as B) | ||||||

|---|---|---|---|---|---|---|---|---|

| C (AR) | MS | Time | C (BR) | MS | Time | |||

| {1, 3, 5, 12} | 0.0100 | 0.5226 | 1.3780 | 101.35 | 0.0122 | 0.3516 | 1.3382 | 72.18 |

| {1, 3, 5, 14} | 0.0098 | 0.7102 | 1.3916 | 105.45 | 0.0121 | 0.1864 | 1.2971 | 92.58 |

| {1, 3, 5, 16} | 0.0087 | 0.7758 | 1.4097 | 102.90 | 0.0120 | 0.1506 | 1.3378 | 161.64 |

| {1, 3, 6, 12} | 0.0095 | 0.6097 | 1.3816 | 107.83 | 0.0131 | 0.2388 | 1.3111 | 126.57 |

| {1, 3, 6, 14} | 0.0116 | 0.6521 | 1.4026 | 113.09 | 0.0149 | 0.2356 | 1.2812 | 125.13 |

| {1, 3, 6, 16} | 0.0077 | 0.6776 | 1.4003 | 108.02 | 0.0123 | 0.1969 | 1.2890 | 178.31 |

| {1, 3, 7, 12} | 0.0119 | 0.5649 | 1.3784 | 115.05 | 0.0146 | 0.3560 | 1.3562 | 88.83 |

| {1, 3, 7, 14} | 0.0074 | 0.5552 | 1.3763 | 121.84 | 0.0159 | 0.3320 | 1.3151 | 219.94 |

| {1, 3, 7, 16} | 0.0114 | 0.6031 | 1.3634 | 115.28 | 0.0120 | 0.3089 | 1.3592 | 205.14 |

| {1, 4, 5, 12} | 0.0061 | 0.3688 | 1.3985 | 104.74 | 0.0124 | 0.4832 | 1.3527 | 82.54 |

| {1, 4, 5, 14} | 0.0076 | 0.6874 | 1.3919 | 109.45 | 0.0118 | 0.2127 | 1.3039 | 105.54 |

| {1, 4, 5, 16} | 0.0113 | 0.5518 | 1.3738 | 103.75 | 0.0140 | 0.3601 | 1.3243 | 147.02 |

| {1, 4, 6, 12} | 0.0096 | 0.4977 | 1.3643 | 112.40 | 0.0130 | 0.2636 | 1.3638 | 75.85 |

| {1, 4, 6, 14} | 0.0081 | 0.5834 | 1.3940 | 117.15 | 0.0118 | 0.1564 | 1.3031 | 188.61 |

| {1, 4, 6, 16} | 0.0107 | 0.5454 | 1.3879 | 112.12 | 0.0140 | 0.3347 | 1.3327 | 194.39 |

| {1, 4, 7, 12} | 0.0122 | 0.7435 | 1.3474 | 120.78 | 0.0177 | 0.1640 | 1.2944 | 152.60 |

| {1, 4, 7, 14} | 0.0103 | 0.5582 | 1.3901 | 126.80 | 0.0129 | 0.2876 | 1.3510 | 182.62 |

| {1, 4, 7, 16} | 0.0122 | 0.7437 | 1.3684 | 121.01 | 0.0158 | 0.1206 | 1.3168 | 292.99 |

| {2, 3, 5, 12} | 0.0104 | 0.7024 | 1.3780 | 103.64 | 0.0202 | 0.1916 | 1.3272 | 57.68 |

| {2, 3, 5, 14} | 0.0093 | 0.7931 | 1.3718 | 103.94 | 0.0182 | 0.1313 | 1.3063 | 79.99 |

| {2, 3, 5, 16} | 0.0095 | 0.7972 | 1.3728 | 103.51 | 0.0183 | 0.2283 | 1.3173 | 131.24 |

| {2, 3, 6, 12} | 0.0104 | 0.7547 | 1.3912 | 106.48 | 0.0204 | 0.1547 | 1.2772 | 95.36 |

| {2, 3, 6, 14} | 0.0099 | 0.5850 | 1.3312 | 112.28 | 0.0192 | 0.3182 | 1.3198 | 73.52 |

| {2, 3, 6, 16} | 0.0089 | 0.6870 | 1.3809 | 112.62 | 0.0184 | 0.2066 | 1.3359 | 109.62 |

| {2, 3, 7, 12} | 0.0167 | 0.8011 | 1.3563 | 114.90 | 0.0235 | 0.1620 | 1.3316 | 105.89 |

| {2, 3, 7, 14} | 0.0119 | 0.5546 | 1.3791 | 117.38 | 0.0232 | 0.2494 | 1.3151 | 178.35 |

| {2, 3, 7, 16} | 0.0104 | 0.7362 | 1.3674 | 119.16 | 0.0172 | 0.1670 | 1.3453 | 185.41 |

| {2, 4, 5, 12} | 0.0135 | 0.5919 | 1.3251 | 104.55 | 0.0233 | 0.3522 | 1.3210 | 83.03 |

| {2, 4, 5, 14} | 0.0119 | 0.6937 | 1.3522 | 107.57 | 0.0217 | 0.2098 | 1.2818 | 107.09 |

| {2, 4, 5, 16} | 0.0106 | 0.6750 | 1.3548 | 109.36 | 0.0221 | 0.2688 | 1.3081 | 73.63 |

| {2, 4, 6, 12} | 0.0117 | 0.7808 | 1.3515 | 111.51 | 0.0186 | 0.2068 | 1.3365 | 128.20 |

| {2, 4, 6, 14} | 0.0131 | 0.6378 | 1.3580 | 116.10 | 0.0202 | 0.2124 | 1.3300 | 156.43 |

| {2, 4, 6, 16} | 0.0148 | 0.8224 | 1.3638 | 117.14 | 0.0235 | 0.0895 | 1.2997 | 184.92 |

| {2, 4, 7, 12} | 0.0130 | 0.8044 | 1.3779 | 119.57 | 0.0255 | 0.1459 | 1.2758 | 141.30 |

| {2, 4, 7, 14} | 0.0116 | 0.6986 | 1.3314 | 124.44 | 0.0220 | 0.2338 | 1.3377 | 146.16 |

| {2, 4, 7, 16} | 0.0121 | 0.7887 | 1.3862 | 125.07 | 0.0229 | 0.1726 | 1.3130 | 223.88 |

| Average | 0.0107 | 0.6627 | 1.3730 | 112.45 | 0.0172 | 0.2345 | 1.3196 | 137.62 |

| Instance | NSGA-II (Referred to as A) | MOSA (Referred to as B) | ||||||

|---|---|---|---|---|---|---|---|---|

| C (AR) | MS | Time | C (BR) | MS | Time | |||

| {2, 5, 8, 18} | 0.0115 | 0.7638 | 1.3794 | 168.05 | 0.0332 | 0.1743 | 1.2044 | 166.79 |

| {2, 5, 8, 20} | 0.0135 | 0.6159 | 1.3462 | 162.56 | 0.0312 | 0.2883 | 1.2577 | 297.51 |

| {2, 5, 8, 22} | 0.0164 | 0.9437 | 1.3561 | 170.55 | 0.0264 | 0.0270 | 1.2994 | 336.88 |

| {2, 5, 9, 18} | 0.0111 | 0.4888 | 1.3810 | 167.92 | 0.0247 | 0.4312 | 1.2873 | 286.48 |

| {2, 5, 9, 20} | 0.0184 | 0.7109 | 1.3638 | 175.74 | 0.0254 | 0.2256 | 1.3096 | 297.37 |

| {2, 5, 9, 22} | 0.0112 | 0.7458 | 1.3456 | 184.84 | 0.0226 | 0.1199 | 1.2834 | 343.98 |

| {2, 5, 10, 18} | 0.0127 | 0.6460 | 1.3829 | 180.20 | 0.0238 | 0.3029 | 1.2502 | 479.56 |

| {2, 5, 10, 20} | 0.0149 | 0.6520 | 1.3141 | 188.44 | 0.0230 | 0.1896 | 1.3165 | 418.46 |

| {2, 5, 10, 22} | 0.0188 | 0.7224 | 1.3286 | 196.97 | 0.0278 | 0.1469 | 1.3177 | 503.24 |

| {2, 6, 8, 18} | 0.0173 | 0.8583 | 1.3028 | 161.83 | 0.0283 | 0.1150 | 1.3225 | 317.92 |

| {2, 6, 8, 20} | 0.0171 | 0.7302 | 1.3831 | 171.46 | 0.0382 | 0.2119 | 1.2709 | 429.53 |

| {2, 6, 8, 22} | 0.0148 | 0.4792 | 1.2774 | 177.64 | 0.0277 | 0.3553 | 1.2837 | 415.91 |

| {2, 6, 9, 18} | 0.0175 | 0.8452 | 1.3112 | 175.90 | 0.0275 | 0.0766 | 1.2536 | 392.62 |

| {2, 6, 9, 20} | 0.0147 | 0.7081 | 1.3529 | 183.90 | 0.0388 | 0.2099 | 1.2561 | 398.30 |

| {2, 6, 9, 22} | 0.0147 | 0.7445 | 1.3947 | 191.79 | 0.0252 | 0.0740 | 1.2567 | 476.39 |

| {2, 6, 10, 18} | 0.0105 | 0.7796 | 1.3936 | 190.11 | 0.0289 | 0.0654 | 1.2302 | 459.14 |

| {2, 6, 10, 20} | 0.0170 | 0.6724 | 1.3733 | 199.59 | 0.0326 | 0.2308 | 1.2338 | 517.90 |

| {2, 6, 10, 22} | 0.0217 | 0.9453 | 1.3682 | 228.69 | 0.0460 | 0.0453 | 1.2156 | 402.23 |

| {3, 5, 8, 18} | 0.0185 | 0.8342 | 1.3292 | 170.68 | 0.0374 | 0.1462 | 1.1944 | 234.35 |

| {3, 5, 8, 20} | 0.0154 | 0.7669 | 1.2929 | 180.07 | 0.0291 | 0.1356 | 1.3191 | 251.36 |

| {3, 5, 8, 22} | 0.0178 | 0.7820 | 1.3631 | 195.66 | 0.0404 | 0.1127 | 1.2365 | 351.81 |

| {3, 5, 9, 18} | 0.0119 | 0.8291 | 1.4044 | 193.84 | 0.0415 | 0.1375 | 1.1971 | 305.07 |

| {3, 5, 9, 20} | 0.0079 | 0.6072 | 1.4040 | 206.17 | 0.0234 | 0.2614 | 1.2466 | 462.42 |

| {3, 5, 9, 22} | 0.0131 | 0.6965 | 1.3766 | 217.64 | 0.0392 | 0.1750 | 1.1405 | 383.77 |

| {3, 5, 10, 18} | 0.0111 | 0.6226 | 1.3055 | 221.22 | 0.0375 | 0.3092 | 1.2879 | 309.20 |

| {3, 5, 10, 20} | 0.0093 | 0.6916 | 1.3861 | 225.92 | 0.0299 | 0.2059 | 1.2501 | 453.90 |

| {3, 5, 10, 22} | 0.0112 | 0.7246 | 1.3671 | 215.32 | 0.0284 | 0.1739 | 1.2863 | 466.66 |

| {3, 6, 8, 18} | 0.0185 | 0.8622 | 1.3412 | 497.96 | 0.0434 | 0.0309 | 1.2928 | 315.60 |

| {3, 6, 8, 20} | 0.0101 | 0.8339 | 1.3027 | 173.53 | 0.0304 | 0.1372 | 1.2529 | 309.32 |

| {3, 6, 8, 22} | 0.0135 | 0.8259 | 1.3898 | 180.01 | 0.0408 | 0.1159 | 1.1954 | 352.42 |

| {3, 6, 9, 18} | 0.0058 | 0.5509 | 1.3948 | 178.04 | 0.0269 | 0.1759 | 1.1632 | 393.94 |

| {3, 6, 9, 20} | 0.0102 | 0.6675 | 1.2766 | 182.85 | 0.0352 | 0.1705 | 1.2190 | 353.93 |

| {3, 6, 9, 22} | 0.0182 | 0.9771 | 1.3945 | 190.94 | 0.0479 | 0.0000 | 1.2074 | 414.19 |

| {3, 6, 10, 18} | 0.0175 | 0.8455 | 1.3340 | 193.24 | 0.0447 | 0.1178 | 1.2712 | 224.56 |

| {3, 6, 10, 20} | 0.0164 | 0.5859 | 1.3144 | 212.44 | 0.0410 | 0.3086 | 1.2279 | 401.46 |

| {3, 6, 10, 22} | 0.0143 | 0.8788 | 1.2704 | 225.04 | 0.0378 | 0.0698 | 1.2865 | 427.43 |

| Average | 0.0143 | 0.7399 | 1.3501 | 198.24 | 0.0330 | 0.1687 | 1.2534 | 370.88 |

| Instance | NSGA-II (Referred to as A) | MOSA (Referred to as B) | ||||||

|---|---|---|---|---|---|---|---|---|

| C (AR) | MS | Time | C (BR) | MS | Time | |||

| {2, 5, 9, 24} | 0.0208 | 0.8480 | 1.3020 | 185.78 | 0.0353 | 0.1116 | 1.3027 | 291.55 |

| {2, 5, 9, 26} | 0.0159 | 0.7381 | 1.3560 | 193.37 | 0.0332 | 0.1353 | 1.2413 | 438.01 |

| {2, 5, 9, 28} | 0.0120 | 0.7386 | 1.3648 | 199.57 | 0.0289 | 0.1144 | 1.2652 | 503.86 |

| {2, 5, 10, 24} | 0.0125 | 0.5849 | 1.3274 | 198.00 | 0.0262 | 0.3069 | 1.2574 | 441.82 |

| {2, 5, 10, 26} | 0.0164 | 0.6745 | 1.3577 | 206.27 | 0.0286 | 0.2453 | 1.3129 | 491.11 |

| {2, 5, 10, 28} | 0.0152 | 0.5364 | 1.3613 | 224.37 | 0.0256 | 0.3591 | 1.2763 | 530.42 |

| {2, 5, 11, 24} | 0.0199 | 0.7814 | 1.3271 | 222.04 | 0.0246 | 0.1697 | 1.3011 | 540.14 |

| {2, 5, 11, 26} | 0.0267 | 0.8926 | 1.3170 | 233.84 | 0.0397 | 0.0781 | 1.2840 | 531.98 |

| {2, 5, 11, 28} | 0.0101 | 0.7059 | 1.3839 | 242.92 | 0.0265 | 0.2386 | 1.2957 | 640.47 |

| {2, 6, 9, 24} | 0.0158 | 0.7523 | 1.3826 | 194.49 | 0.0290 | 0.1382 | 1.2593 | 476.12 |

| {2, 6, 9, 26} | 0.0112 | 0.6075 | 1.3189 | 201.12 | 0.0246 | 0.2200 | 1.2975 | 463.04 |

| {2, 6, 9, 28} | 0.0162 | 0.8251 | 1.3521 | 209.27 | 0.0394 | 0.0692 | 1.1945 | 440.44 |

| {2, 6, 10, 24} | 0.0114 | 0.7019 | 1.3551 | 207.88 | 0.0278 | 0.1611 | 1.2404 | 591.58 |

| {2, 6, 10, 26} | 0.0134 | 0.6143 | 1.3423 | 216.56 | 0.0298 | 0.1410 | 1.2860 | 464.02 |

| {2, 6, 10, 28} | 0.0222 | 0.6362 | 1.3341 | 226.15 | 0.0320 | 0.1470 | 1.2786 | 744.03 |

| {2, 6, 11, 24} | 0.0156 | 0.7165 | 1.3543 | 223.49 | 0.0309 | 0.2354 | 1.2624 | 576.32 |

| {2, 6, 11, 26} | 0.0232 | 0.8749 | 1.3110 | 233.66 | 0.0449 | 0.0567 | 1.2649 | 603.27 |

| {2, 6, 11, 28} | 0.0205 | 0.5352 | 1.3151 | 245.32 | 0.0404 | 0.4110 | 1.2916 | 662.85 |

| {3, 5, 9, 24} | 0.0096 | 0.7493 | 1.3123 | 188.10 | 0.0292 | 0.1870 | 1.2786 | 361.94 |

| {3, 5, 9, 26} | 0.0123 | 0.8378 | 1.2840 | 206.80 | 0.0318 | 0.0767 | 1.3151 | 460.95 |

| {3, 5, 9, 28} | 0.0128 | 0.6184 | 1.3509 | 206.19 | 0.0313 | 0.2687 | 1.2126 | 510.66 |

| {3, 5, 10, 24} | 0.0174 | 0.6621 | 1.3612 | 201.38 | 0.0410 | 0.2218 | 1.2301 | 485.29 |

| {3, 5, 10, 26} | 0.0151 | 0.4228 | 1.2622 | 210.86 | 0.0323 | 0.4506 | 1.3129 | 526.35 |

| {3, 5, 10, 28} | 0.0099 | 0.8439 | 1.3591 | 220.27 | 0.0304 | 0.1188 | 1.2751 | 530.91 |

| {3, 5, 11, 24} | 0.0146 | 0.8410 | 1.3088 | 216.80 | 0.0469 | 0.1239 | 1.2809 | 539.27 |

| {3, 5, 11, 26} | 0.0147 | 0.6601 | 1.3197 | 228.60 | 0.0402 | 0.2437 | 1.3063 | 577.52 |

| {3, 5, 11, 28} | 0.0121 | 0.6361 | 1.3844 | 239.59 | 0.0324 | 0.2553 | 1.2630 | 598.84 |

| {3, 6, 9, 24} | 0.0146 | 0.8087 | 1.3377 | 195.46 | 0.0403 | 0.1666 | 1.2761 | 450.28 |

| {3, 6, 9, 26} | 0.0136 | 0.8042 | 1.3520 | 202.87 | 0.0402 | 0.0428 | 1.2094 | 509.48 |

| {3, 6, 9, 28} | 0.0158 | 0.8969 | 1.3518 | 211.26 | 0.0440 | 0.0419 | 1.2602 | 515.24 |

| {3, 6, 10, 24} | 0.0187 | 0.8761 | 1.3509 | 212.39 | 0.0604 | 0.0501 | 1.2194 | 76.46 |

| {3, 6, 10, 26} | 0.0175 | 0.8285 | 1.2685 | 220.61 | 0.0398 | 0.1734 | 1.2286 | 89.00 |

| {3, 6, 10, 28} | 0.0176 | 0.9089 | 1.3618 | 230.55 | 0.0673 | 0.0869 | 1.1285 | 49.08 |

| {3, 6, 11, 24} | 0.0246 | 0.9521 | 1.3407 | 227.82 | 0.0746 | 0.0258 | 1.1803 | 79.01 |

| {3, 6, 11, 26} | 0.0234 | 0.8519 | 1.3065 | 239.19 | 0.0599 | 0.0981 | 1.2557 | 67.59 |

| {3, 6, 11, 28} | 0.0129 | 0.7744 | 1.3402 | 250.23 | 0.0463 | 0.1992 | 1.2193 | 86.22 |

| Average | 0.0160 | 0.7427 | 1.3365 | 215.92 | 0.0377 | 0.1714 | 1.2601 | 442.92 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Liu, R.; Zhu, Z.; Chu, C.; Man, X. A Bi-Objective Green Closed Loop Supply Chain Design Problem with Uncertain Demand. Sustainability 2018, 10, 967. https://doi.org/10.3390/su10040967

Liu M, Liu R, Zhu Z, Chu C, Man X. A Bi-Objective Green Closed Loop Supply Chain Design Problem with Uncertain Demand. Sustainability. 2018; 10(4):967. https://doi.org/10.3390/su10040967

Chicago/Turabian StyleLiu, Ming, Rongfan Liu, Zhanguo Zhu, Chengbin Chu, and Xiaoyi Man. 2018. "A Bi-Objective Green Closed Loop Supply Chain Design Problem with Uncertain Demand" Sustainability 10, no. 4: 967. https://doi.org/10.3390/su10040967