Can Legislation Promote a Circular Economy? A Material Flow-Based Evaluation of the Circular Degree of the Chinese Economy

Abstract

:1. Introduction

2. Methods and Data

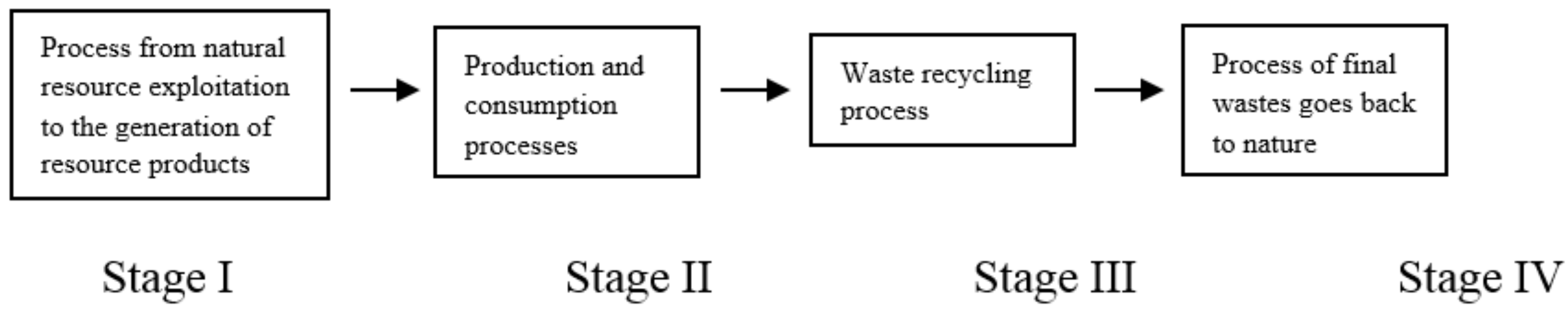

2.1. Indicators Characterizing the Circular Degree of the National Economy

2.2. Evaluation Model for the Circular Degree of the National Economy

2.3. Data Sources

3. Results

3.1. Individual Estimation for the Four Stages of Natural Resource Utilization

3.1.1. Stage 1: Mineral Resource Comprehensive Utilization Rate

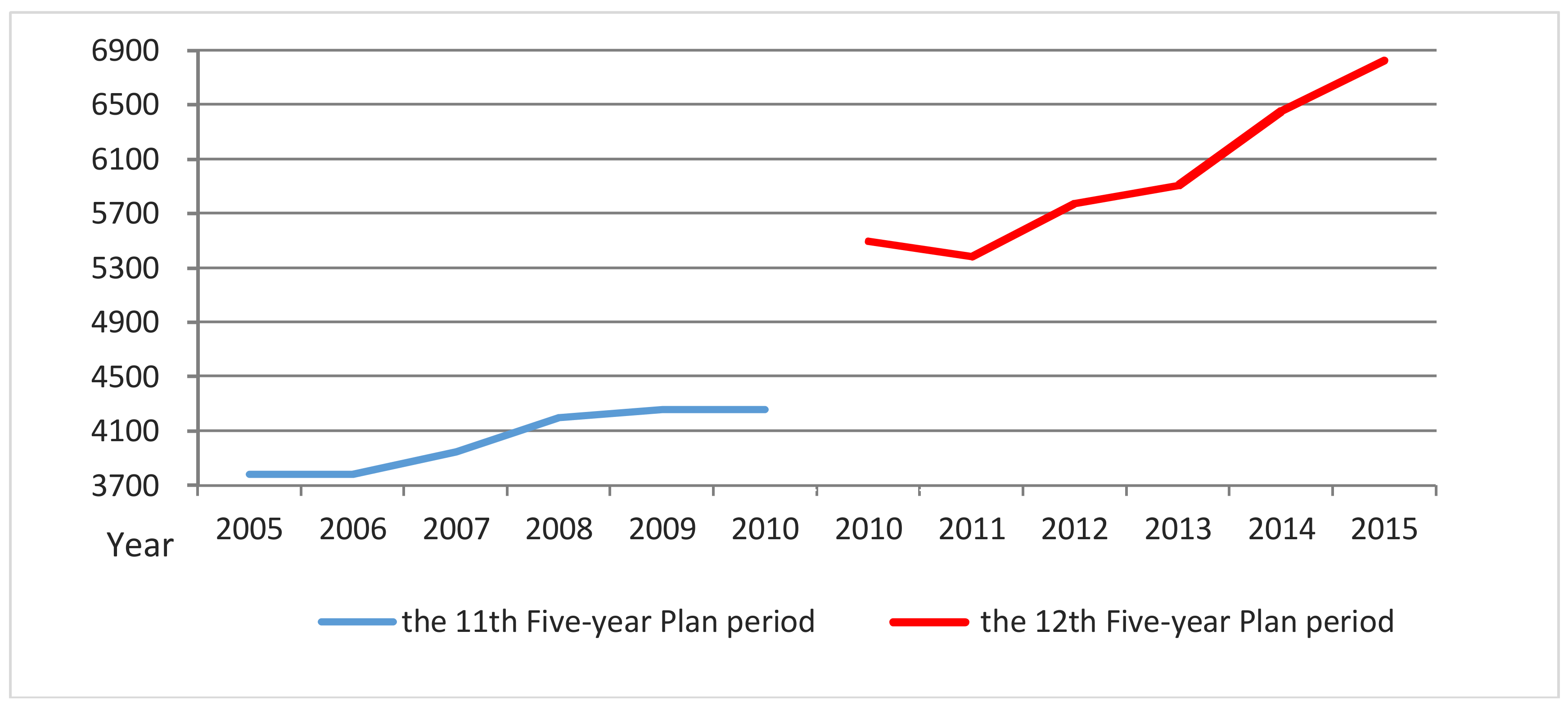

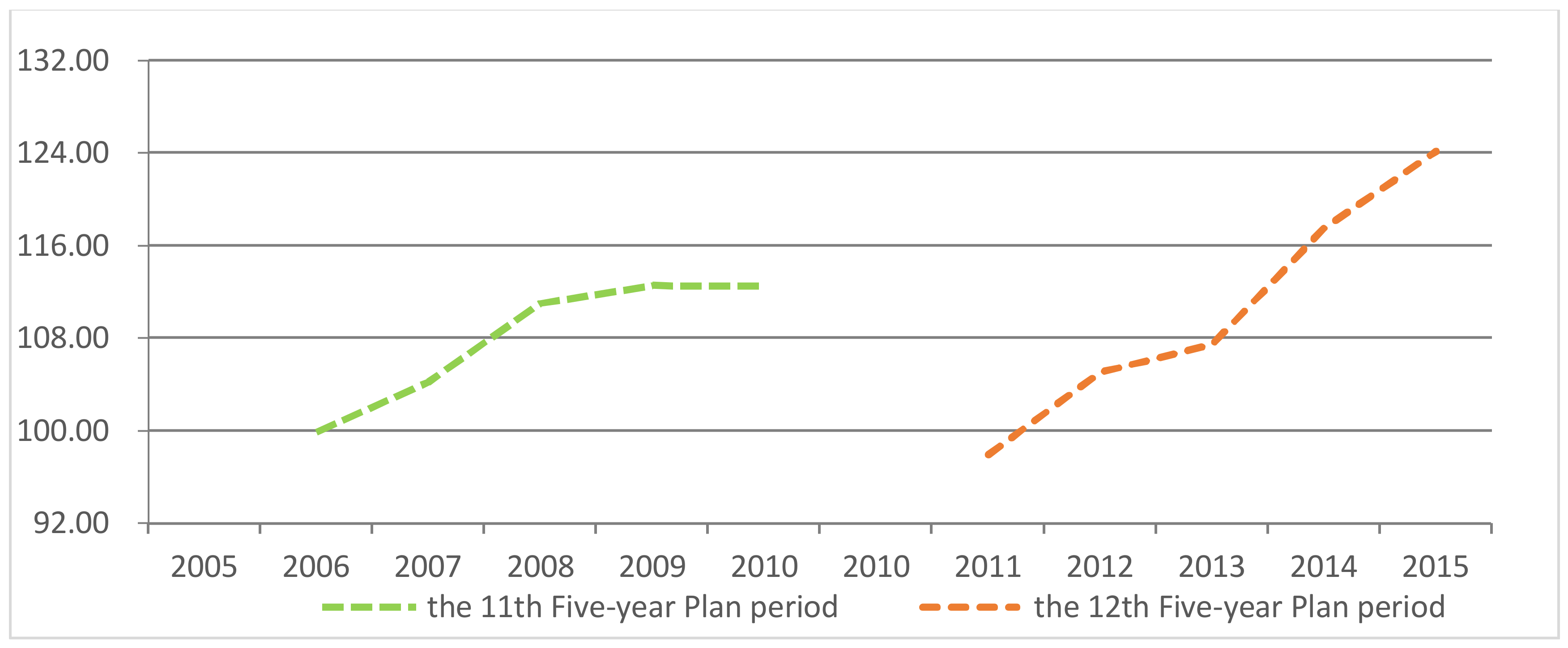

3.1.2. Stage 2: Primary Resource Productivity

3.1.3. Stage 3: Secondary Resource Recycling Rate

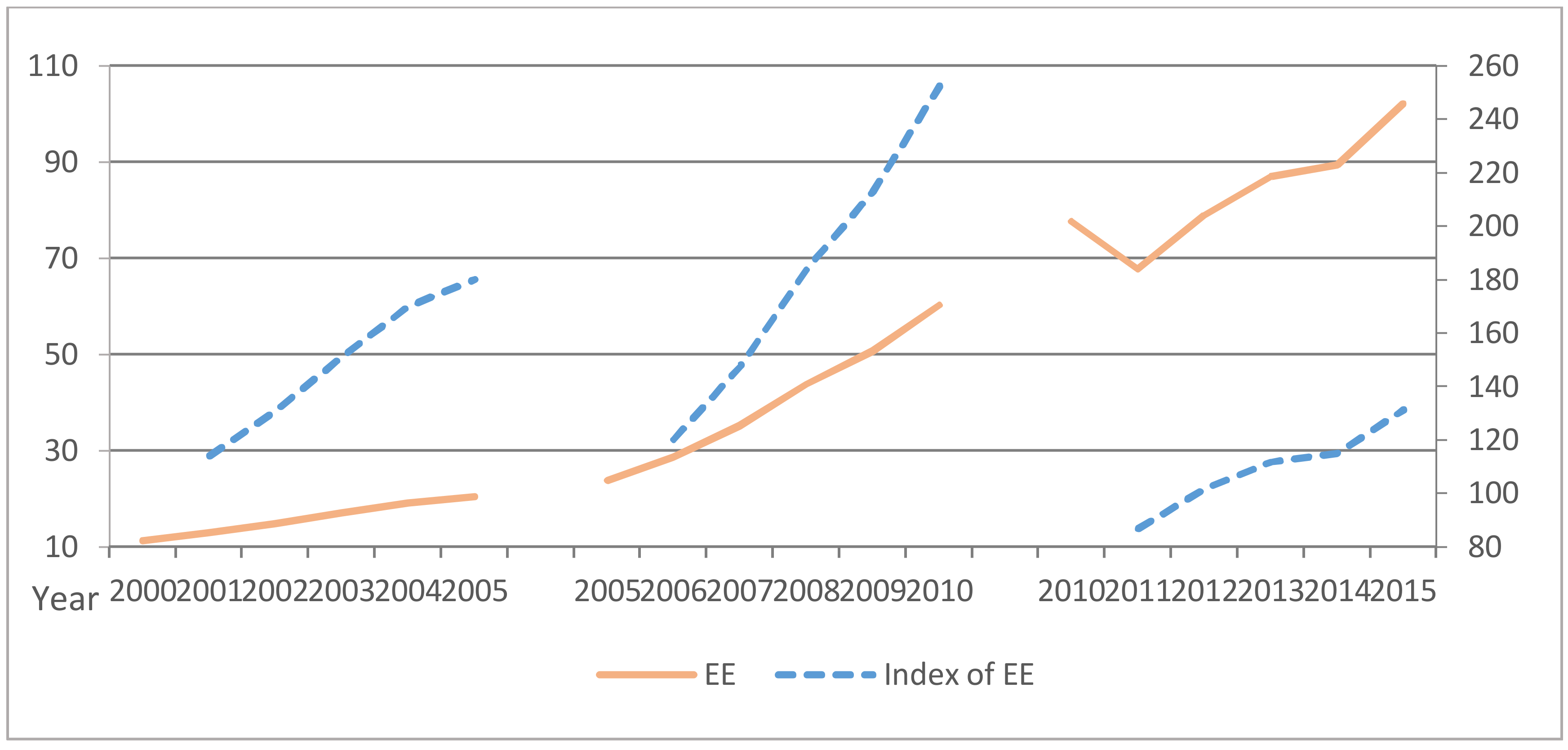

3.1.4. Stage 4: Environmental Efficiency

3.2. Comprehensive Evaluation of the Circular Degree of the National Economy

3.2.1. Resource-Environmental Efficiency

3.2.2. Comprehensive Circular Degree (CCD) of the National Economy

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United Nations (UN). Report of the UN Conference on Environment and Development, Rio de Janeiro, 3–14 June 1992; UN Doc A/CONF.151/26/Rev.1; United Nations: Rio de Janeiro, Brazil, 1992; Volume I–III. [Google Scholar]

- Robinson, N.A.; Hassan, P.; Burhenne-Guilmin, F. Agenda 21 and the UNCED Proceedings; Oceana Publications: New York, NY, USA, 1993. [Google Scholar]

- Geng, Y.; Fu, J.; Sarkis, J. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Zhu, D.J. Sustainable development calls for circular economy. Sci. Technol. Rev. 1998, 9, 39–42. (In Chinese) [Google Scholar]

- Su, Y.; Zhou, H.C. Discussion on some issues concerning the development of circular economy in China. Econ. Res. Ref. 2005, 10, 15–20. (In Chinese) [Google Scholar]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The Circular Economy: A New Development Strategy in China. J. Ind. Ecol. 2010, 10, 4–8. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Wang, Y.Q. How to promote circular economy in environmental protection department. Environ. Prot. 2004, 9, 3–7. (In Chinese) [Google Scholar]

- Geng, Y.; Zhu, Q.; Doberstein, B. Implementing China’s circular economy concept at the regional level: A review of progress in Dalian, China. Waste Manag. 2009, 29, 996–1002. [Google Scholar] [CrossRef] [PubMed]

- The Standing Committee of the National People’s Congress China. Circular Economy Promotion Law of the People’s Republic of China. 2008. Available online: http://www.fdi.gov.cn/1800000121_39_597_0_7.html (accessed on 23 August 2017). (In Chinese)

- Mathews, J.A.; Tan, H. Progress toward a Circular Economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Ying, F.; Zhao, W.P. Circular economy development phase research based on the IPAT equation: The case of Shaanxi. Econ. Horiz. 2015, 17, 33–44. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Schneider, P.; Anh, L.H.; Wagner, J.; Reichenbach, J.; Hebner, A. Solid waste management in Ho Chi Minh City, Vietnam: Moving towards a circular economy? Sustainability 2017, 9, 286. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving 'leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Zhang, H.B. Environmental legislation should not focus on the purpose of establishing the concept model but on the actual effect of environmental and economic benefits: The view of a legislative expert on revising the “Circular Economy Promotion Law of the People’s Republic of China”. Resour. Regen. 2015, 8, 22–27. (In Chinese) [Google Scholar]

- China Energy Network. Available online: http://www.cnenergy.org/hb/201611/t20161129_409270.html (accessed on 18 June 2017). (In Chinese).

- Yu, J.X. The confusion and the way out of the law on the promotion of circular economy: Rational reflection for eight years’ practice. Environ. Econ. 2017, 3, 56–61. (In Chinese) [Google Scholar]

- West, J.; Schandl, H.; Heyenga, S. Resource Efficiency: Economics and Outlook for China (Chinese Version). United Nations Environment Programme, Research Report, 2013. Available online: https://www.researchgate.net/publication/255723165_Resource_Efficiency_Economics_and_Outlook_for_China_Chinese_Version (accessed on 23 September 2017). (In Chinese).

- National Development and Reform Commission of the PRC (NDRC). Notice of the Evaluation Index System for the Development of Circular Economy, 2007, No. 1815 [2007] of the NDRC Environmental and Resource Division. Available online: http://ishare.iask.sina.com.cn/f/33945394.html (accessed on 16 December 2017). (In Chinese).

- National Development and Reform Commission of the PRC (NDRC). Notice of the Evaluation Index System for the Development of Circular Economy, 2017, No. 2749 [2016] of the NDRC Environmental and Resource Division. Available online: http://www.ndrc.gov.cn/zcfb/zcfbtz/201701/t20170112_834922.html (accessed on 7 December 2017). (In Chinese)

- Liu, Z.; Geng, Y.; Park, H.S.; Dong, H.J.; Dong, L.; Fujita, T. An emergy-based hybrid method for assessing industrial symbiosis of an industrial park. J. Clean. Prod. 2016, 114, 132–140. [Google Scholar]

- Pan, H.Y.; Zhang, X.H.; Wang, Y.Q.; Qi, Y.; Wu, J.; Lin, L.L. Emergy evaluation of an industrial park in Sichuan Province, China: A modified emergy approach and its application. J. Clean. Prod. 2016, 135, 105–118. [Google Scholar] [CrossRef]

- Jiang, J. The compiling method and empirical study of circular economy development index. Res. Dev. 2013, 1, 89–92. (In Chinese) [Google Scholar]

- Liu, C.; Côté, R. A Framework for Integrating Ecosystem Services into China’s Circular Economy: The Case of Eco-Industrial Parks. Sustainability 2017, 9, 1510. [Google Scholar] [CrossRef]

- Bringezu, S.; Schutz, H.; Mooll, S. Rationale for and interpretation of economy-wide materials flow analysis and derived indicators. Ind. Ecol. 2003, 7, 43–64. [Google Scholar] [CrossRef]

- Wang, N.; Lee, J.C.K.; Zhang, J.; Chen, H.; Li, H. Evaluation of urban circular economy development: An empirical research of 40 cities in china. J. Clean. Prod. 2018, 180, 876–887. [Google Scholar] [CrossRef]

- Chen, S.J.; Hwang, C.L.; Hwang, F.P. Fuzzy multiple attribute decision making: Methods and applications. Eur. J. Oper. Res. 1992, 4, 287–288. [Google Scholar]

- Ulukan, Z.; Kahraman, C.; Cebeci, U. Multi-criteria supplier selection using fuzzy AHP. Logist. Inf. Manag. 2003, 16, 382–394. [Google Scholar]

- Ofcen, English Section. The Twelfth Five-Year Plan for National Economic and Social Development of the People’s Republic China Central Compilation & Tr. 2011. Available online: http://www.gbv.de/dms/zbw/720612306.pdf (accessed on 23 August 2017).

- National Development and Reform Commission of the PRC (NDRC). Notice on the Guidance of the Comprehensive Utilization of Resource of the 12th Five-Year Plan and the Implementation Plan of Comprehensive Utilization of Bulk Solid Wastes. No. 2919 [2011] of the NDRC Environmental and Resource Division. Available online: http://zfxxgk.ndrc.gov.cn/PublicItemView.aspx?ItemID=%7becba8923-08ac-4949-bf55-b9c65bc7dede%7d (accessed on 23 August 2017). (In Chinese)

- State Council. Notice of the State Council on Issuing the Circular Economy Development Strategy and Near-Term Action Plan, 2013. No. 5 [2013] of the State Council. Available online: http://www.gov.cn/zwgk/2013-02/05/content_2327562.htm (accessed on 23 August 2017). (In Chinese)

- Wikipedia. Five-Year Plans of China. Available online: https://en.wikipedia.org/wiki/Five-year_plans_of_China (accessed on 7 September 2017).

- Cai, S.F.; Yang, D. Comprehensive utilization research of mineral resources. Compr. Util. Chin. Resour. 2000, 2, 3–5. (In Chinese) [Google Scholar]

- Editorial Office of China Mining Yearbook. China Mining Yearbooks, 2002–2015; China Earthquake Press: Beijing, China, 2002–2016. (In Chinese) [Google Scholar]

- National Bureau of Statistics. China Statistical Yearbooks, 2000–2016; China Statistics Press: Beijing, China, 2000–2016. (in Chinese) [Google Scholar]

- National Bureau of Statistics and Ministry of Environmental Protection. China Environmental Statistical Yearbook, 2000–2016; China Statistics Press: Beijing, China, 2000–2016. (In Chinese) [Google Scholar]

- Department of Circulation Industry Development Division of Ministry of Commerce. Renewable Resource Collection Sector Development Report 2013–2015. Government Report. Available online: http://ltfzs.mofcom.gov.cn/article/ztzzn/an/201406/20140600629599.shtml (accessed on 15 July 2017). (In Chinese)

- Ministry of Commerce. Midterm and Long-term Plan for the Construction of Renewable Resource Collection System (2015–2020). Government Document, No. 21 [2015] of the Department of Circulation Industry Development Division of Ministry of Commerce. Available online: http://www.mofcom.gov.cn/article/h/redht/201501/20150100878083.shtml (accessed on 15 July 2017). (In Chinese)

- Xie, Z.H.; Zhang, Y. China Circular Economy Yearbook 2008–2010; 2011–2013; 2014–2015; Chinese Financial and Economic Publishing House: Beijing, China; Metallurgical Industry Press: Beijing, China. (In Chinese)

- National Bureau of Statistics. Note of the Environmental Statistical Data 2013. Available online: http://www.stats.gov.cn/ztjc/ztsj/hjtjzl/2013/201412/t20141219_655870.html (accessed on 15 October 2017). (In Chinese)

- European Environmental Agency (EEA). Circular Economy in Europe—Developing the Knowledge Base (No. 2). European Environmental Agency, 2016; Available online: https://www.eea.europa.eu/publications/circular-economy-in-europe (accessed on 9 August 2017).

- State Council. Several Opinions of the State Council on Speeding up the Development of Circular Economy; Interpretation of Administrative Regulations; No. 22 [2005] of the State Council. Available online: http://www.lawinfochina.com/display.aspx?id=4559&lib=law (accessed on 5 June 2017).

- Zhai, Y. Research on circular economy and circular economy legislation. J. Shanghai Univ. Political Sci. Law (Rule Law Rev.) 2017, 6, 11–20. (In Chinese) [Google Scholar]

- Peng, F.; Chen, S.Q. EU “circular economy” legislation: Origin, concept and evolution. J. Shanghai Univ. Political Sci. Law (Rule Law Rev.) 2017, 6, 21–28. (In Chinese) [Google Scholar]

- Peng, F. Resource, waste or industry promotion—China’s “Circular Economy Promotion Law” revision path rethinking. Politics Law 2017, 9, 98–109. (In Chinese) [Google Scholar]

- Guo, Y.J. The legislation is to promote circular economy or regulate the comprehensive utilization of material resources: A perspective on the revision of China’s Circular Economy Promotion Law. Politics Law 2017, 8, 130–141. (In Chinese) [Google Scholar]

- Xue, S.L. Research on the difficulties and countermeasures in the implementation of the Circular Economy Promotion Law. Leg. Expo. 2017, 27, 50–51. (In Chinese) [Google Scholar]

- Qu, Y. Comparison and reconstruction of the legal system of circular economy. J. Shanghai Univ. Political Sci. Law (Rule Law Rev.) 2017, 6, 29–37. (In Chinese) [Google Scholar]

- Moriguchi, Y. Material flow indicators to measure progress toward a sound material-cycle society. J. Mater. Cycles Waste Manag. 2007, 9, 112–120. [Google Scholar] [CrossRef]

- Geng, Y.; Zhang, P. Measuring China’s circular economy. Science 2013, 339, 1526–1527. [Google Scholar] [CrossRef] [PubMed]

- Despeisse, M.; Kishita, Y.; Nakano, M.; Barwood, M. Towards a circular economy for end-of-life vehicles: A comparative study UK—Japan. Procedia CIRP 2015, 29, 668–673. [Google Scholar] [CrossRef]

- Hiratsuka, J.; Sato, N.; Yoshida, H. Current status and future perspectives in end-of-life vehicle recycling in Japan. J. Mater. Cycles Waste Manag. 2014, 16, 21–30. [Google Scholar] [CrossRef]

- Environment Agency Japan. Basic Law for Establishing a Sound Material-Cycle Society (Tentative translation). Law No. 110 of 2000. March, 2008.

- Dong, H.L. The enlightenment of the legislation of circular economy in Japan on environmental legislation in China. Mod. Jurisprud. 2006, 1, 177–184. (In Chinese) [Google Scholar]

- Iacovidou, E.; Velis, C.A.; Purnell, P.; Zwirner, O.; Brown, A.; Hahladakis, J. Metrics for optimising the multi-dimensional value of resources recovered from waste in a circular economy: A critical review. J. Clean. Prod. 2017, 166, 910–938. [Google Scholar] [CrossRef]

- Silva, A.; Stocker, L.; Mercieca, P.; Rosano, M. The role of policy labels, keywords and framing in transitioning waste policy. J. Clean. Prod. 2016, 115, 224–237. [Google Scholar] [CrossRef]

- Crang, M. Interrogating the circular economy: The moral economy of resource recovery in the EU. Econ. Soc. 2015, 44, 218–243. [Google Scholar]

- Van Rooij, B. Implementation of Chinese Environmental Law: Regular Enforcement and Political Campaigns. Dev. Chang. 2006, 37, 57–74. [Google Scholar] [CrossRef]

- Wang, A. The Search for Sustainable Legitimacy: Environmental Law and Bureaucracy in China. Harv. Environ. Law Rev. 2013, 37, 365–440. [Google Scholar] [CrossRef]

- The National People’s Congress. Available online: http://www.npc.gov.cn/wxzl/gongbao/2017-03/30/content_2019527.htm (accessed on 20 September 2017).

| Indicators | Sub-Indicators | |

|---|---|---|

| EIS 2007 (macro level) | (1) Resource productivity | Output of main mineral resource; output of energy |

| (2) Resource consumption rate | Energy consumption per unit GDP; energy consumption per added industrial value; energy consumption of per unit product in key industrial sectors; water withdrawal per unit of GDP; water withdrawal per added industrial value; water consumption of per unit product in key industrial sectors; coefficient of irrigation water utilization | |

| (3) Integrated resource utilization rate (secondary resource recycling rate) | Recycling rate of industrial solid waste; industrial water reuse ratio; recycling rate of reclaimed municipal wastewater; safe treatment rate of domestic solid wastes; recycling rate of iron scrap; recycling rate of non-ferrous metals; recycling rate of waste paper; recycling rate of plastic; recycling rate of rubber | |

| (4) Waste disposal and pollutant emission | Total amount of industrial solid waste for final disposal; total amount of industrial wastewater discharge; total amount of SO2 emission; total amount of chemical oxygen demand (COD) discharge | |

| EIS 2017 | (1) Comprehensive Indicator | Primary resource productivity; |

| Major secondary resource recycling rate | ||

| (2) Single indicator | Comprehensive utilization rate of general industrial solid waste; recovery rate of major renewable resources; comprehensive utilization rate of crop straw; city food and kitchen waste recycling rate; urban construction waste resource processing rate; energy productivity; water resources productivity; Construction land productivity; repeated water use rate of above-scale industrial enterprises; urban reclaimed water utilization rate; resource recycling industry output value | |

| (3) Reference indicator | The amount of industrial solid waste disposal; industrial waste water emissions; processing capacity of urban solid waste; major pollutants emissions |

| Indicator | Calculation Methods |

|---|---|

| 1. Single indicator | |

| (1) MRCUR (mineral resource comprehensive utilization rate) | MRCUR = 0.7 × total recovery rate of major mineral resource + 0.3 × comprehensive utilization rate of associated mineral resources |

| (2) PRP (primary resource productivity) | PRP = GDP (constant prices)/total consumption amount of major primary resources (petroleum, natural gas, coal, iron ore, non-ferrous metal ore, non-metallic resources and biomass resources, among which petroleum, natural gas and coal are all fossil fuels, in apparent consumption) |

| (3) SRRR (Secondary resource recycling rate) | SRRR = 0.5 × industrial solid waste comprehensive utilization rate + 0.3 × renewable resource recycling rate + 0.2 × industrial water recycling rate |

| (4) EE (environmental efficiency) | EE = GDP (constant prices)/total discharges of major pollutants (the sum of COD, ammonia nitrogen, SO2, smoke, dust and solid waste) |

| 2. Comprehensive indicator | |

| (5) CCD (comprehensive circular degree) | CCD = ∑(MRCUR + REE + SRRR)/3 |

| 3. Supplementary indicator | |

| (6) Total recovery rate of major mineral resource | The data are obtained from governmental reports and published articles |

| (7) Comprehensive utilization rate of associated mineral resources | The data are obtained from governmental reports and published articles |

| (8) Comprehensive utilization rate of industrial solid wastes | Comprehensive utilization rate of industrial solid waste = volume of comprehensive utilization of industrial solid waste/produced volume of industrial solid waste × 100% |

| (9) Recycling rate of major renewable resources | Recycling rate of major renewable resources = (domestic waste iron and steel recovery amount/crude steel production + domestic waste non-ferrous metals recovery amount/production of 10 major non-ferrous metals + domestic waste plastic recovery amount/primary plastic production + domestic waste paper recovery amount/machine-made paper production + scrap cars recovery amount/production of cars + waste electronic and electric products recovery amount/production of electronic and electric products) × 1/6 × 100% |

| (10) Industrial water recycling rate | Industrial water recycling rate = recycling amount of industrial water/(new industrial water consumption+ recycling amount of industrial water) × 100% |

| (11) Resource-environmental efficiency (REE) (This is a semi- comprehensive indicator) | Resource-environmental efficiency = (total consumption amount of major primary resources − total discharge of major industrial pollutants)/total consumption amount of major primary resources × 100% |

| (12) Index of mineral resource comprehensive utilization rate | Index of mineral resource comprehensive utilization rate = current year mineral resource comprehensive utilization rate/base year mineral resource comprehensive utilization rate × 100% |

| (13) Index of primary resource productivity | Index of primary resource productivity = current year primary resource productivity/base year primary resource productivity × 100% |

| (14) Index of the secondary resource recycling rate | Index of the secondary resource recycling rate = 0.5 × index of industrial solid waste comprehensive utilization rate + 0.3 × index of renewable resource recycling rate + 0.2 × index of industrial water recycling rate |

| (15) Index of industrial solid waste comprehensive utilization rate | Index of industrial solid waste comprehensive utilization rate = current year industrial solid waste comprehensive utilization rate/base year industrial solid waste comprehensive utilization rate × 100% |

| (16) Index of renewable resource recycling rate | Index of renewable resource recycling rate = current year renewable resource recycling rate/base year renewable resource recycling rate × 100% |

| (17) Index of industrial water recycling rate | Index of industrial water recycling rate = current year industrial water recycling rate/base year industrial water recycling rate × 100% |

| (18) Index of environmental efficiency | Index of environmental efficiency = current year environmental efficiency/base year environmental efficiency × 100% |

| Year | Raw Coal (Standard Coal) | Crude Oil (Standard Coal) | Natural Gas (Standard Coal) | Iron Ore | Non-ferrous Metal Ores | Non-Metallic Resources | Biomass Resources | Total |

|---|---|---|---|---|---|---|---|---|

| 2001 | 105,771.96 | 32,975.96 | 3733.13 | 28,901.65 | 13,278.16 | 111,799.02 | 43,112.45 | 339,572.34 |

| 2002 | 116,160.25 | 35,611.17 | 3900.27 | 33,549.52 | 12,245.94 | 119,505.67 | 42,945.73 | 363,918.55 |

| 2003 | 138,352.27 | 39,613.68 | 4532.91 | 37,748.88 | 10,367.25 | 163,778.24 | 40,037.42 | 434,430.65 |

| 2004 | 161,657.26 | 45,825.92 | 5296.46 | 51,880.98 | 14,429.14 | 126,358.22 | 46,495.91 | 451,943.90 |

| 2005 | 189,231.16 | 46,523.68 | 6272.86 | 62,520.92 | 12,577.39 | 130,228.30 | 47,580.53 | 494,934.84 |

| 2006 | 207,402.11 | 50,131.73 | 7734.61 | 75,066.06 | 15,419.31 | 152,155.20 | 50,697.21 | 558,606.23 |

| 2007 | 225,795.45 | 52,945.14 | 9343.26 | 87,924.76 | 19,519.39 | 164,647.48 | 51,098.16 | 611,273.64 |

| 2008 | 229,236.87 | 53,542.04 | 10,900.77 | 97,863.67 | 19,436.53 | 164,188.74 | 54,301.30 | 629,469.92 |

| 2009 | 240,666.22 | 55,124.66 | 11,764.41 | 108,648.48 | 19,097.67 | 189,592.93 | 54,118.23 | 679,012.60 |

| 2010 | 249,568.42 | 62,752.75 | 14,425.92 | 129,221.48 | 25,154.27 | 213,995.65 | 56,726.81 | 751,845.29 |

| 2011 | 271,704.19 | 65,023.22 | 17,803.98 | 156,524.7 | 28,761.38 | 241,190.78 | 59,511.48 | 840,519.73 |

| 2012 | 275,464.53 | 68,363.46 | 19,302.62 | 147,252.33 | 32,717.77 | 240,043.26 | 62,122.09 | 845,266.06 |

| 2013 | 280,999.36 | 71,292.12 | 22,096.39 | 154,494.18 | 37,931.81 | 259,585.45 | 64,030.46 | 890,429.77 |

| 2014 | 279,328.74 | 74,090.24 | 24,270.94 | 161,844.37 | 32,955.99 | 236,173.88 | 65,266.31 | 873,930.47 |

| 2015 | 273,849.49 | 78,672.62 | 25,364.40 | 147,721.60 | 32,783.60 | 259,055.75 | 66,754.97 | 884,202.43 |

| Year | Amount of Resource Consumption (0.1 Billion Ton) | GDP (0.1 Billion Yuan RMB) | PRP (Yuan/Ton) | Index of PRP (%) |

|---|---|---|---|---|

| 2005 Constant price | ||||

| 2005 | 49.49 | 187,318.9 | 3784.72 | |

| 2006 | 55.86 | 211,147.7 | 3779.90 | 99.87 |

| 2007 | 61.13 | 241,195.8 | 3945.79 | 104.26 |

| 2008 | 62.95 | 264,472.8 | 4201.52 | 111.01 |

| 2009 | 67.90 | 289,329.9 | 4261.04 | 112.59 |

| 2010 | 75.18 | 320,102.6 | 4257.56 | 112.49 |

| Average for the 11th Five-year Plan period | 4089.16 | |||

| 2010 Constant price | ||||

| 2010 | 75.18 | 413,030.3 | 5493.55 | |

| 2011 | 84.05 | 452,429.9 | 5382.74 | 97.98 |

| 2012 | 84.53 | 487,976.2 | 5773.05 | 105.09 |

| 2013 | 89.04 | 525,835.4 | 5905.41 | 107.50 |

| 2014 | 87.39 | 564,194.4 | 6455.83 | 117.52 |

| 2015 | 88.42 | 603,212.1 | 6822.10 | 124.18 |

| Average for the 12th Five-year Plan period | 6067.83 | |||

| Year | Produced Volume of Industrial Solid Waste (10 Thousand Ton) | Volume of Comprehensive Utilization of Industrial Solid Waste (10 Thousand Ton) | Comprehensive Utilization Rate of Industrial Solid Waste (%) | Industrial Solid Waste Comprehensive Utilization Index |

|---|---|---|---|---|

| 2000 | 81,608 | 37,451 | 45.9 | |

| 2001 | 88,840 | 47,290 | 52.1 | 113.51 |

| 2002 | 94,509 | 50,061 | 51.9 | 113.07 |

| 2003 | 100,428 | 56,040 | 54.8 | 119.39 |

| 2004 | 120,030 | 67,796 | 55.7 | 121.35 |

| 2005 | 134,449 | 76,993 | 56.1 | 122.22 |

| 2006 | 151,541 | 92,601 | 60.2 | 107.31 |

| 2007 | 175,632 | 110,311 | 62.1 | 110.70 |

| 2008 | 190,127 | 123,482 | 64.3 | 114.62 |

| 2009 | 203,943 | 138,186 | 67 | 119.43 |

| 2010 | 240,944 | 161,772 | 66.7 | 118.89 |

| 2011 | 326,204 | 196,988 | 59.8 | 89.66 |

| 2012 | 332,509 | 204,467 | 60.9 | 91.30 |

| 2013 | 330,859 | 207,616 | 62.2 | 93.25 |

| 2014 | 329,254 | 206,392 | 62.1 | 93.10 |

| 2015 | 331,055 | 200,857 | 60.2 | 90.25 |

| Year | Recycling Rate of Waste Iron and Steel | Recycling Rate of Waste Non-Ferrous Metals (%) | Recycling Rate of Waste Plastic (%) | Recycling Rate of Waste Paper (%) | Recycling Rate of Scrap Cars (%) | Recycling Rate of Waste Electronic and Electrical Products (%) | Recycling Rate of Major Renewable Resources (%) | Index of Recycling Rate of Major Renewable Resources |

|---|---|---|---|---|---|---|---|---|

| 2008 | 14.03 | 7.78 | 24.45 | 37.22 | 9.55 | 22.79 | 19.30 | |

| 2009 | 13.32 | 13.63 | 27.55 | 38.18 | 5.13 | 25.75 | 20.59 | |

| 2010 | 13.04 | 12.98 | 27.07 | 37.58 | 8.10 | 20.24 | 19.83 | |

| 2011 | 13.28 | 13.24 | 27.04 | 39.48 | 6.44 | 21.82 | 20.22 | 101.93 |

| 2012 | 11.60 | 14.34 | 30.01 | 40.82 | 5.71 | 11.44 | 18.99 | 93.91 |

| 2013 | 18.55 | 15.09 | 21.71 | 38.66 | 6.10 | 14.71 | 19.14 | 100.79 |

| 2014 | 18.52 | 16.53 | 28.21 | 37.49 | 5.39 | 17.07 | 20.54 | 107.32 |

| 2015 | 17.89 | 16.99 | 23.05 | 41.15 | 6.94 | 20.27 | 21.05 | 102.49 |

| Year | New Industrial Water Consumption (10 Thousand m3) | Recycling Amount (10 Thousand m3) | Industrial Water Recycling Rate (%) | Index of Industrial Water Recycling Rate |

|---|---|---|---|---|

| 2004 | 1,028,202 | 4,183,937 | 80.27 | |

| 2005 | 1,112,285 | 5,670,096 | 83.60 | |

| 2006 | 1,200,287 | 5,535,492 | 82.18 | 98.30 |

| 2007 | 1,177,176 | 6,026,048 | 83.66 | 100.07 |

| 2008 | 1,064,104 | 6,547,258 | 86.02 | 102.89 |

| 2009 | 1,028,179 | 6,130,645 | 85.64 | 102.44 |

| 2010 | 1,094,686 | 6,872,928 | 86.26 | 103.18 |

| 2011 | 702,724 | 6,334,101 | 90.01 | 104.35 |

| 2012 | 858,143 | 6,913,391 | 88.96 | 103.13 |

| 2013 | 888,536 | 6,526,517 | 88.02 | 102.04 |

| 2014 | 874,086 | 6,930,588 | 88.80 | 102.94 |

| 2015 | 827,433 | 7,160,130 | 89.64 | 103.92 |

| Year | Industrial Solid Waste Comprehensive Utilization Rate | Renewable Resource Recycling Rate | Industrial Water Recycling Rate | Secondary Resource Recycling Rate |

|---|---|---|---|---|

| 2010 | 66.70 | 19.83 | 86.26 | 56.55 |

| 2011 | 59.80 | 20.22 | 90.01 | 53.97 |

| 2012 | 60.90 | 18.99 | 88.96 | 53.94 |

| 2013 | 62.20 | 19.14 | 88.02 | 54.44 |

| 2014 | 62.10 | 20.54 | 88.80 | 54.97 |

| 2015 | 60.20 | 21.05 | 89.64 | 54.34 |

| Year | GDP (0.1 Billion RMB) | Total Discharges of Major Pollutants (10 Thousand Ton) | Environmental Efficiency (10 Thousand Yuan RMB/Ton) | Index of EE |

|---|---|---|---|---|

| 2000 constant price | ||||

| 2000 | 100,280.1 | 8883.7 | 11.29 | |

| 2001 | 108,639.2 | 8431.4 | 12.89 | 114.15 |

| 2002 | 118,561.9 | 8011.2 | 14.80 | 131.11 |

| 2003 | 130,463.2 | 7632.7 | 17.09 | 151.42 |

| 2004 | 143,657.8 | 7488.89 | 19.18 | 169.94 |

| 2005 | 160,027 | 7861.78 | 20.36 | 180.32 |

| Average for the 10th Five-year Plan period | 16.86 | |||

| 2005 constant price | ||||

| 2005 | 187,318.9 | 7861.78 | 23.83 | |

| 2006 | 211,147.7 | 7357.63 | 28.70 | 120.44 |

| 2007 | 241,195.8 | 6864.14 | 35.14 | 147.48 |

| 2008 | 264,472.8 | 6036.97 | 43.81 | 183.87 |

| 2009 | 289,329.9 | 5695.91 | 50.80 | 213.19 |

| 2010 | 320,102.6 | 5319.39 | 60.18 | 252.56 |

| Average for the 11th Five-year Plan period | 43.72 | |||

| 2010 constant price | ||||

| 2010 | 413,030.3 | 5319.39 | 77.65 | |

| 2011 | 452,429.9 | 6690.33 | 67.62 | 87.09 |

| 2012 | 487,976.2 | 6175.56 | 79.02 | 101.77 |

| 2013 | 525,835.4 | 6049.70 | 86.92 | 111.94 |

| 2014 | 564,194.4 | 6307.68 | 89.45 | 115.20 |

| 2015 | 603,212.1 | 5906.32 | 102.13 | 131.53 |

| Average for the 12th Five-year Plan period | 85.03 | |||

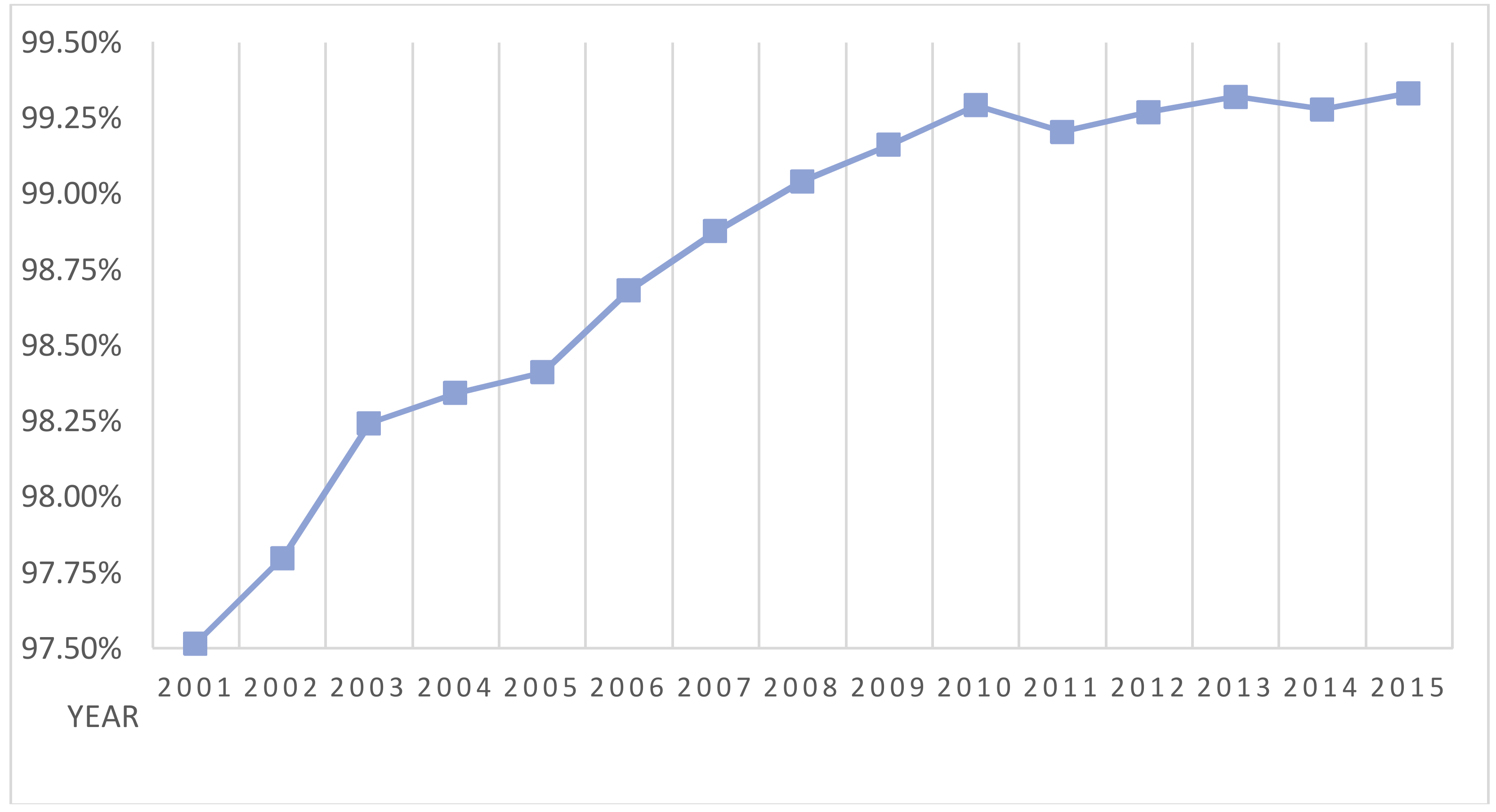

| Year | Total Consumed Resource (10 Thousand Ton) | Total Discharged Pollutants (10 Thousand Ton) | REE (%) |

|---|---|---|---|

| 2001 | 339,572.34 | 8431.40 | 97.52 |

| 2002 | 363,918.55 | 8011.20 | 97.80 |

| 2003 | 434,430.65 | 7632.70 | 98.24 |

| 2004 | 451,943.90 | 7488.89 | 98.34 |

| 2005 | 494,934.84 | 7861.78 | 98.41 |

| 2006 | 558,606.23 | 7357.63 | 98.68 |

| 2007 | 611,273.64 | 6864.14 | 98.88 |

| 2008 | 629,469.92 | 6036.97 | 99.04 |

| 2009 | 679,012.60 | 5695.91 | 99.16 |

| 2010 | 751,845.29 | 5319.39 | 99.29 |

| 2011 | 840,519.73 | 6690.33 | 99.20 |

| 2012 | 845,266.06 | 6175.56 | 99.27 |

| 2013 | 890,429.77 | 6049.70 | 99.32 |

| 2014 | 873,930.47 | 6307.68 | 99.28 |

| 2015 | 884,202.43 | 5906.32 | 99.33 |

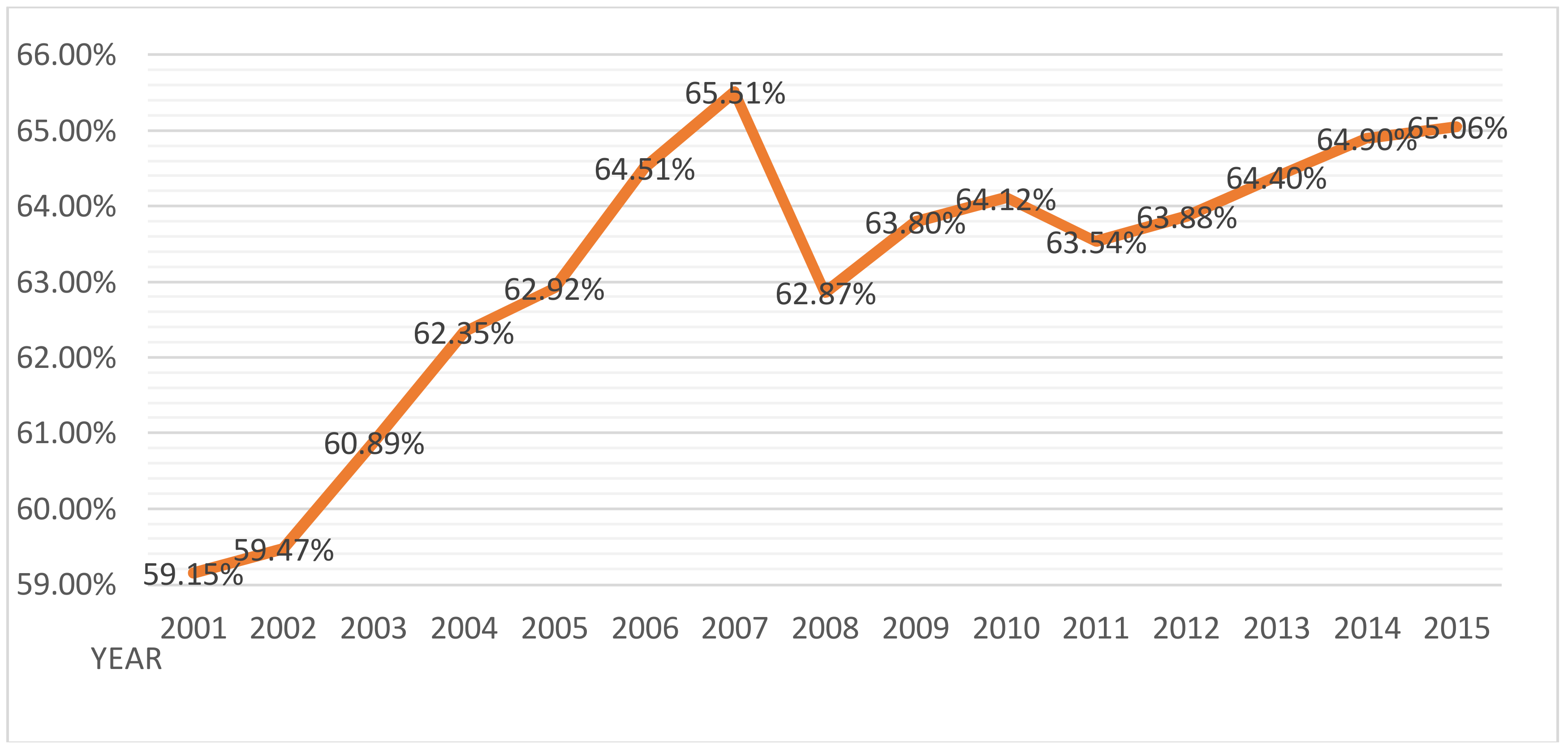

| Year | MRCUR (%) | REE (%) | SRRR (%) | CCD (%) |

|---|---|---|---|---|

| 2001 | 27.85 | 97.52 | 52.10 | 59.15 |

| 2002 | 28.72 | 97.80 | 51.90 | 59.47 |

| 2003 | 29.62 | 98.24 | 54.80 | 60.89 |

| 2004 | 30.54 | 98.34 | 58.16 | 62.35 |

| 2005 | 31.50 | 98.41 | 58.85 | 62.92 |

| 2006 | 32.44 | 98.68 | 62.40 | 64.51 |

| 2007 | 33.41 | 98.88 | 64.26 | 65.51 |

| 2008 | 34.41 | 99.04 | 55.14 | 62.87 |

| 2009 | 35.44 | 99.16 | 56.81 | 63.80 |

| 2010 | 36.50 | 99.29 | 56.55 | 64.12 |

| 2011 | 37.45 | 99.20 | 53.97 | 63.54 |

| 2012 | 38.42 | 99.27 | 53.94 | 63.88 |

| 2013 | 39.42 | 99.32 | 54.44 | 64.40 |

| 2014 | 40.45 | 99.28 | 54.97 | 64.90 |

| 2015 | 41.50 | 99.33 | 54.34 | 65.06 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; He, X.; Poustie, M. Can Legislation Promote a Circular Economy? A Material Flow-Based Evaluation of the Circular Degree of the Chinese Economy. Sustainability 2018, 10, 990. https://doi.org/10.3390/su10040990

Hu Y, He X, Poustie M. Can Legislation Promote a Circular Economy? A Material Flow-Based Evaluation of the Circular Degree of the Chinese Economy. Sustainability. 2018; 10(4):990. https://doi.org/10.3390/su10040990

Chicago/Turabian StyleHu, Yuan, Xuan He, and Mark Poustie. 2018. "Can Legislation Promote a Circular Economy? A Material Flow-Based Evaluation of the Circular Degree of the Chinese Economy" Sustainability 10, no. 4: 990. https://doi.org/10.3390/su10040990