Energy Consumption Analysis for Concrete Residences—A Baseline Study in Taiwan

Abstract

:1. Introduction

2. Study Area and Model Descriptions

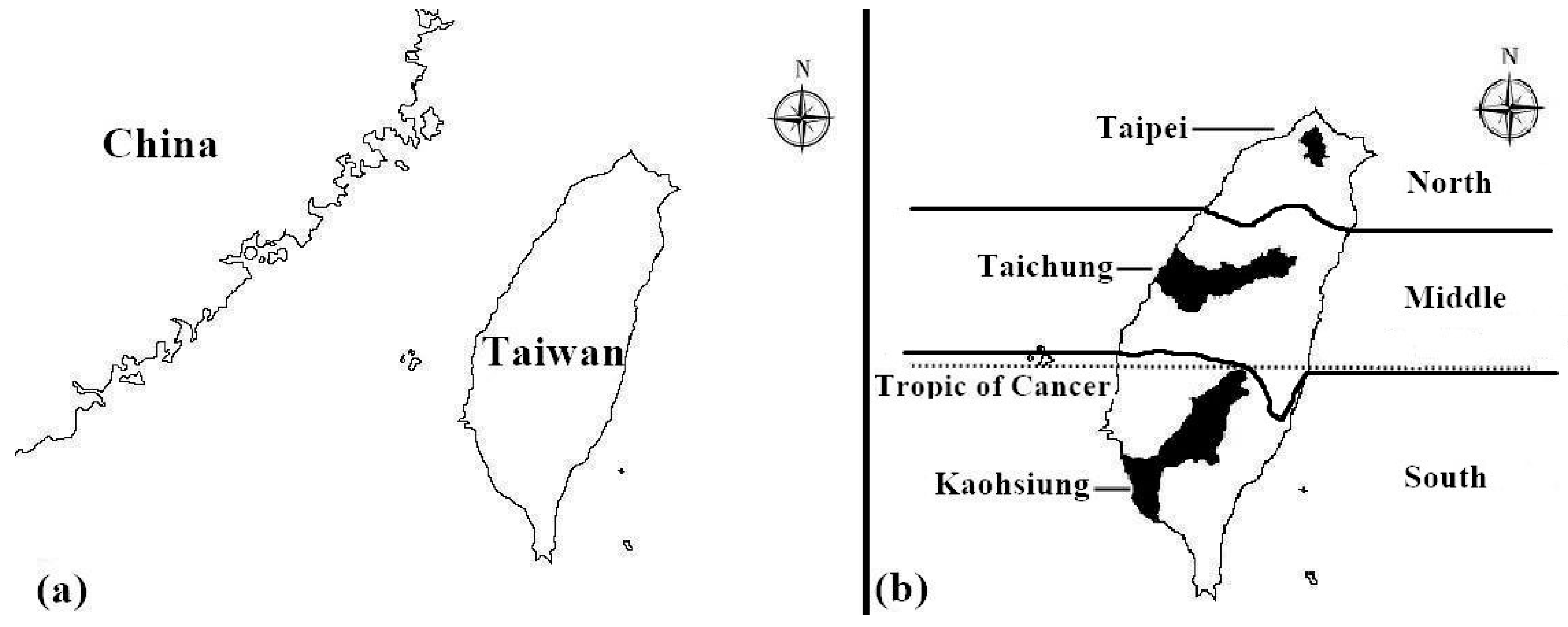

2.1. Study Area

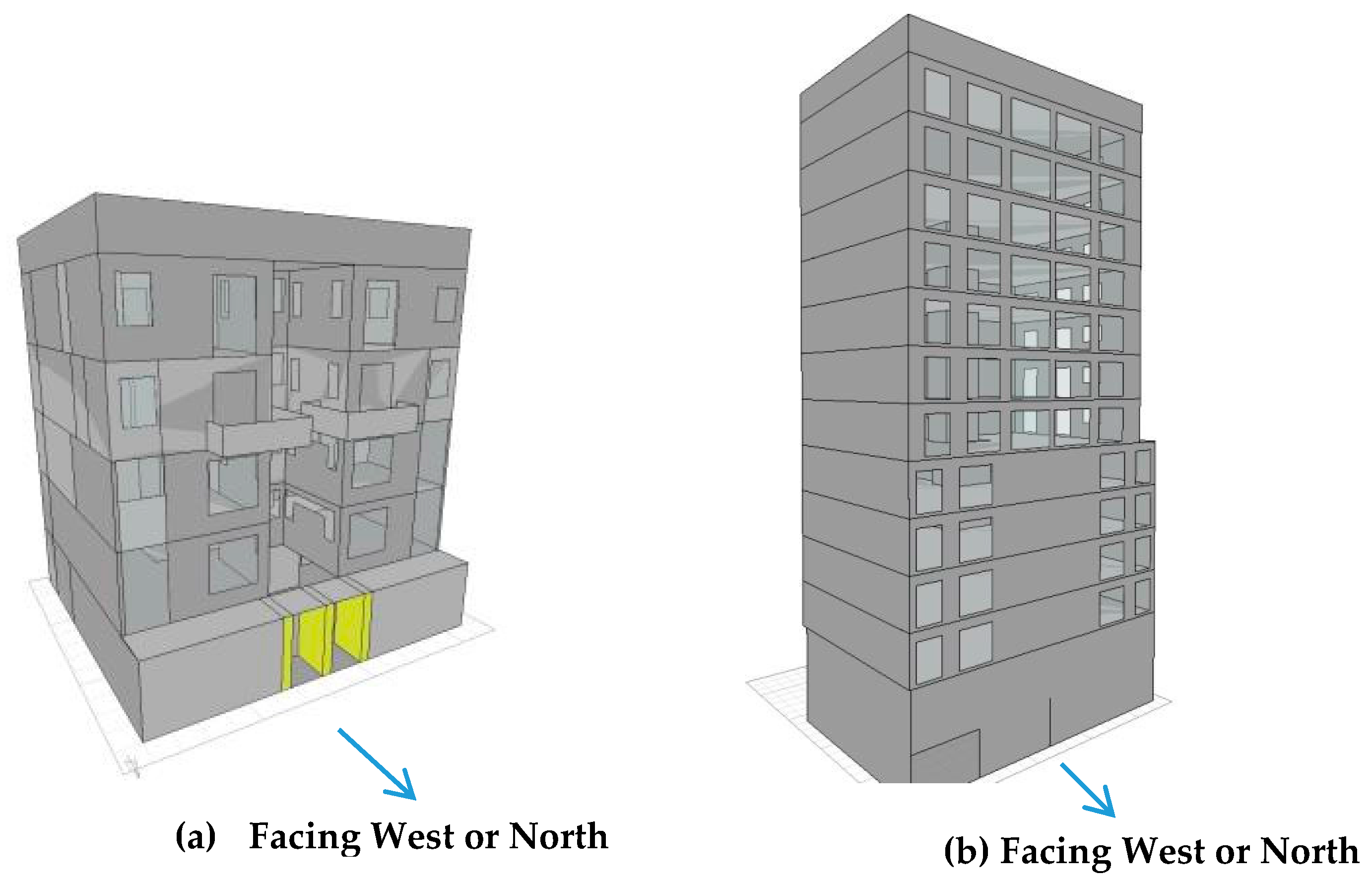

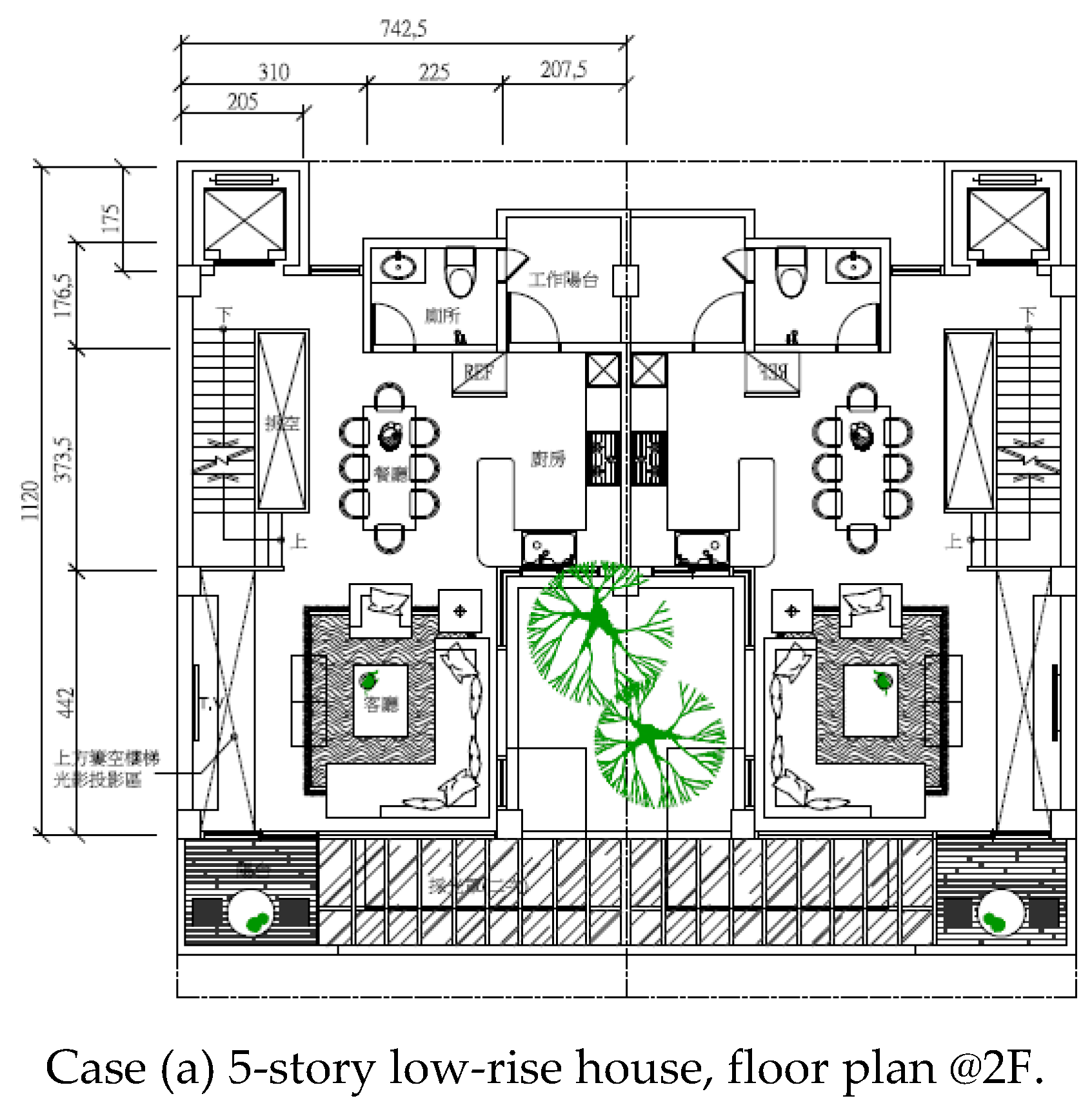

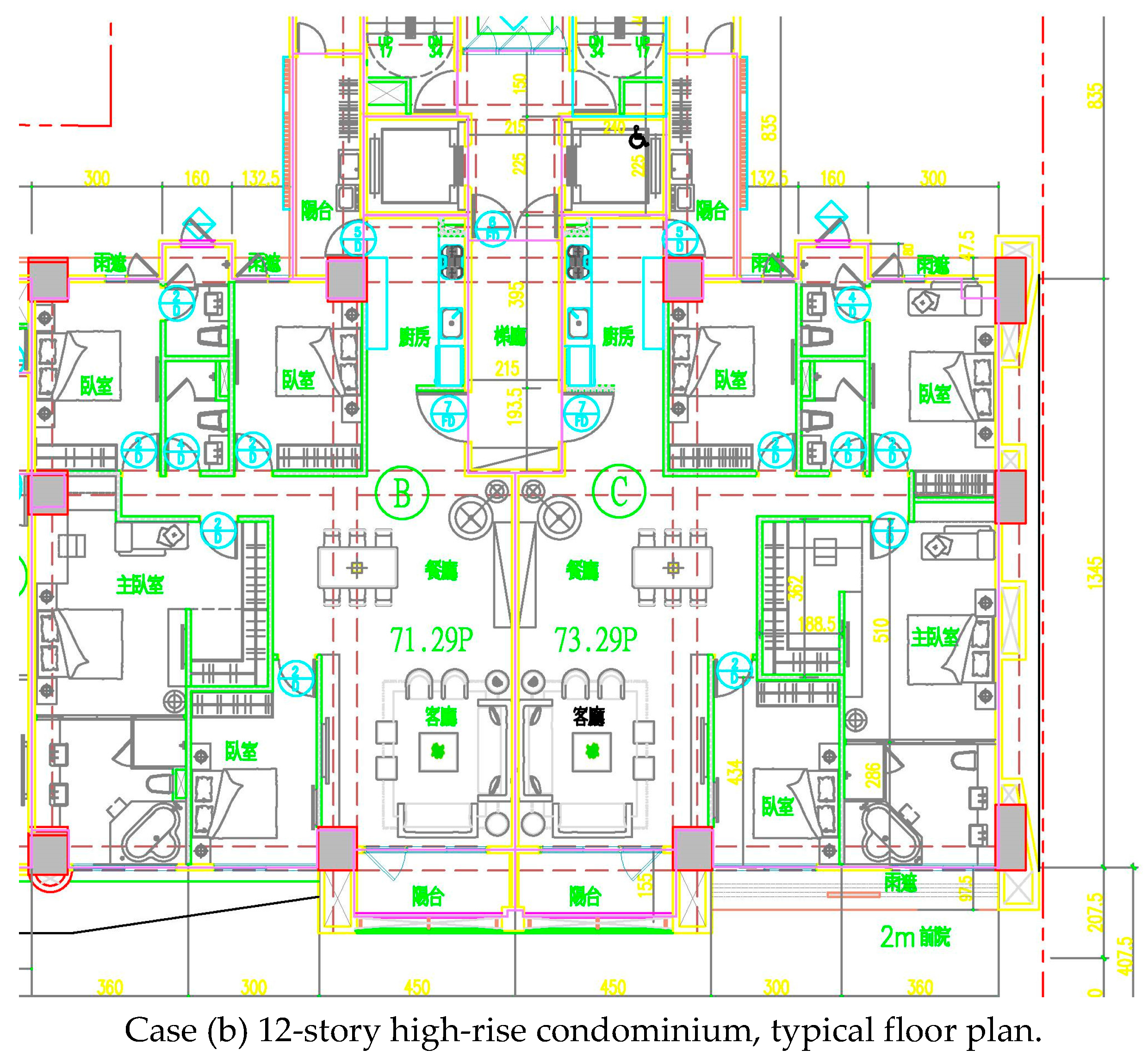

2.2. Model Descriptions

- (1)

- Occupancy and operation setting: the occupancy of each house is set at 6, including grandparents, parents, and a pair of kids. Parents and kids leave home at 8:00 am and come back at 6:00 pm, while grandparents stay at home all day. The occupancy of each unit in the condominium is set at 4 (parents, and a pair of kids), and all four leave home at 8:00 am and come back at 6:00 pm. In both cases, human activity level is in sedentary mode at 70 W;

- (2)

- Air conditioning: air conditioning is turned on when room temperature is above 26 °C in a 24-h setting;

- (3)

- Internal gains (values for both lighting, and small power loads per unit floor area): sensible gain is set at 5 W/m2 (by lighting, and small power loads), and latent gain is 5 W/m2 (by small power loads such as cookers, electric kettle, hot water heaters, etc.) in both cases;

- (4)

- Internal design conditions setting: clothing is set at 1.0, relative humidity at 60%, air velocity at 0.5 m/s, and lighting level at 300 lux; and

- (5)

- Windows setting: windows remain closed all time.

3. Results and Discussion

3.1. Annual Energy Consumption

- Insulation impacts: Annual energy savings from 13.83% to 21.15% are achieved. Average impact is 17.77%. Insulation impacts on the condominium (from 18.57% to 21.15%) appear to be larger than that on the house (from 13.83% to 17.03%).

- Air tightness impacts: Annual energy savings from 36.98% to 42.20% are achieved. Average impact is 39.78%. Different from insulation impacts, air tightness impacts on the condominium (from 36.98% to 40.16%) are smaller than that on house (from 39.72% to 42.20%), but the difference is considered not significant.

- Double impacts (insulation + air tightness): Annual energy savings from 48.19% to 54.68% are achieved. Average impact is 52.63%.

- Orientation impact: Using typical insulation in Taipei as an example ‘facing west’ results in 1.59% (12-story condominium) to 3.11% (5-story house) energy increase. Compared with impacts from insulation and air tightness, orientation impact is small and can almost be neglected.

- Location impact: Houses (facing north) in Kaohsiung require 45.03% more annual energy than the same house in Taipei. Houses (facing north) in Taichung require 12.84% more annual energy than the same house Taipei. Condominiums (facing north) in Kaohsiung and in Taichung require 41.44% and 13.49% more annual energy than the same condo in Taipei, respectively. Houses and condominiums facing west have similar results.

3.2. Baseline Validation and Adjustment Parameters

- Number of residents (Pno_res): 6 residents in house and 4 residents in condominium are assumed in the simulation. Energy consumption is strongly correlated to the number of residents [39]. A linear regression has been used to describe the relationship between occupancy rate and energy consumption [40], suggesting linear relationship a reasonable hypothesis. Hence, a “number of residents” adjustment parameter (Pno_res) in the form of “actual number of residents/6, for house” or “actual number of residents/4, for condominium” is suggested when the number of residents varies.

- Total floor area (Pfl_area): The initial assumption of the house and condominium area are set at 397 m2 and 161 m2 respectively. These are considered typical settings for upper middle class communities in suburban areas in Taiwan. However, floor area may vary in different cases. When calculating energy consumption with the admittance method, the internal gains (W/m2), energy use intensity, and lighting intensity (lm/m2, lux) are defined based on floor area, the resulting energy is directly proportional to floor area. Energy consumption from air conditioning load due to solar gains is calculated based on the respective sunlit area on wall, roof, and glaze (m2) and the solar intensity (M/m2). Sunlit area on roof is the same as floor area, and when both fenestration ratio and floor height are fixed, the envelope area on the wall and glaze is not directly proportional to the floor area but has strong correlation. This study suggests a linear ‘total floor area’ adjustment parameter (Pfl_area) in the form of “actual floor area/397, for house” or “actual floor area/161, for condominium” be asserted in estimation when floor area varies to simplify the estimate.

- Air conditioning comfort level (PAC_comf): The simulation assumed air conditioning (AC) is turned on in the entire floor area when room temperature goes above 26 °C in a 24-h setting, no matter whether residents are home or not. This setting results in the maximum comfort, but is not at all energy efficient. According to the simulation results of such setting, the average daily AC operation time is 7.44 h, and AC accounts for 54.38% of annual energy consumption in concrete residences. That is, when AC is turned off completely, an energy saving of 54.38% can be achieved. However, turning-off AC is not a reasonable scenario in the metropolitan areas in investigated regions, where interior temperature can reach high-30 degrees Celsius in summer. Based on the simulation, a minimum AC energy requirement to secure least comfort level could achieve an energy saving of 43.12% when the AC temperature is turned on at 30 °C and in limited hours between 10:00 PM and 4:00 AM and also in limited cooling areas. From the data derived from simulation, this study suggests a four-level air conditioning comfort level setting (PAC_comf) that could be asserted to meet different AC comfort level requirements: (a) for maximum AC comfort, PAC_comf is set at “1”; (b) for moderate AC comfort, PAC_comf is set at “0.8563”(AC on at 27 °C and operates for 14 h); (c) for less than moderate AC comfort, PAC_comf is set at “0.7125” (AC on at 28 °C and operates for 10 h); and (d) for least AC comfort, PAC_comf is set at “ 0.5688– (1-0.4312) (AC on at 30 °C and operates for 6 h).

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Jim, C.Y. Air-conditioning energy consumption due to green roofs with different building thermal insulation. Appl. Energy 2014, 128, 49–59. [Google Scholar] [CrossRef]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 2016, in press. Available online: http://dx.doi.org/10.1016/j.resconrec (accessed on 14 April 2016). [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving better energy-efficient air conditioning: A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- IEA, International Energy Agency. CO2 Emissions from Fuel Combustion; IEA, International Energy Agency: Paris, France, 2014. [Google Scholar]

- Chen, S.; Yoshino, H.; Li, N. Statistical analyses on summer energy consumption characteristics of residential buildings in some cities of China. Energy Build. 2010, 42, 136–146. [Google Scholar] [CrossRef]

- Zhou, N. Current Status and Future Scenarios of Residential Building Energy Consumption in China; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2010. [Google Scholar]

- Jiang, P. Analysis of national and local energy-efficiency design standards in the public building sector in China. Energy Sustain. Dev. 2011, 15, 443–450. [Google Scholar] [CrossRef]

- Bojic, M.; Yik, F. Cooling energy evaluation for high-rise residential buildings in Hong Kong. Energy Build. 2005, 37, 345–351. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y. Characteristic of cooling load and energy consumption of air conditioning in residential buildings in Beijing. HV & AC 2006, 36, 1–11. [Google Scholar]

- Meier, A.; Lin, J.; Liu, J.; Li, T. Standby power use in Chinese homes. Energy Build. 2004, 36, 1211–1216. [Google Scholar] [CrossRef]

- Geoffrey, K.F.T.; Kelvin, K.W.Y. A study of domestic energy usage patterns in Hong Kong. Energy 2006, 28, 1671–1682. [Google Scholar]

- Hu, T.; Yoshino, H.; Jiang, Z. Analysis on urban residential energy consumption of Hot Summer & Cold Winter Zone in China. Sustain. Cities Soc. 2013, 6, 85–91. [Google Scholar]

- Yoshino, H.; Lou, H. Indoor thermal environment of residential buildings in three cities of China. J. Asian Archit. Build. Eng. 2002, 1, 129–136. [Google Scholar] [CrossRef]

- Zhang, H.; Yoshino, H. Analysis of indoor humidity environment in residential buildings. Build. Environ. 2010, 45, 2132–2140. [Google Scholar] [CrossRef]

- Fumo, N.; Mago, P.; Luck, R. Methodology to estimate building energy consumption using EnergyPlus Benchmark Models. Energy Build. 2010, 42, 2331–2337. [Google Scholar] [CrossRef]

- White, J.A.; Reichmuth, R. Simplified method for predicting building energy consumption using average monthly temperatures. In Proceedings of the 31st Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 11–16 August 1996; Volume 3, pp. 1834–1839.

- Pan, Y.; Huang, Z.; Wu, G. Calibrated building energy simulation and its application n a high-rise commercial building in Shanghai. Energy Build. 2007, 39, 651–657. [Google Scholar] [CrossRef]

- Reddy, A. Literature review on calibration of building energy simulation programs: Uses, problems, procedures, uncertainty, and tools. ASHRAE Trans. 2006, 112, 226–240. [Google Scholar]

- Canyurta, O.E.; Ozturka, H.K.; Hepbaslib, A.; Utlu, Z. Estimating the Turkish residential–commercial energy output based on genetic algorithm (GA) approaches. Energy Policy 2005, 33, 1011–1019. [Google Scholar] [CrossRef]

- Zhao, H.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Ahn, K.U.; Kim, D.W.; Kim, Y.J.; Yoon, S.H.; Park, C.S. Issues to be solved for energy simulation of an existing office building. Sustainability 2016, 8, 345. [Google Scholar] [CrossRef]

- Filippín, C. Benchmarking the energy efficiency and greenhouse gases emissions of school buildings in central Argentina. Build. Environ. 2000, 35, 407–414. [Google Scholar]

- Birtles, A.B.; Grigg, P. Energy efficiency of buildings: Simple appraisal method. Build. Ser. Eng. Res. Technol. 1997, 18, 109–114. [Google Scholar] [CrossRef]

- Chung, W. Review of building energy-use performance benchmarking methodologies. Appl. Energy 2011, 88, 1470–1479. [Google Scholar] [CrossRef]

- Central Weather Bureau. Available online: http://www.cwb.gov.tw/V7/climate/monthlyMean/Taiwan_tx.htm (accessed on 12 August 2016).

- Hsieh, H.Y. The 1990s Taiwan residential construction boom: A supply side interpretation. Constr. Manag. Econ. 2005, 23, 265–284. [Google Scholar] [CrossRef]

- Hsieh, H.-Y. The Taiwanese Residential Construction Peak in the 1990s: Interpreting Industry and Developer Behaviour, Chapter 4 Taiwan’s Residential Construction Industry. Ph.D. Thesis, Griffith University, Nathan, QLD, Australia, 2003. [Google Scholar]

- Wu, N.W.; Fu, C.C. Tile application as the indication of modernization in colonial taiwan, international proceedings of economics development and research. Acad. J. 2012, 54, 215. [Google Scholar]

- Marsh, A.J. Rgermal analysis and the Admittance Method. Nat. Freq. 26 December 2005. Issue No. 100. Available online: https://forums.autodesk.com/autodesk/attachments/autodesk/356/1967/1/D__Square%20One_Documentation_Software%20Help%20Files_Ecotect%20.pdf (accessed on 10 July 2016).

- Construction and Planning Agency Ministry of Interior. Available online: http://www.cpami.gov.tw/chinese/filesys/file/chinese/publication/law/lawdata/1000810233-5.pdf (accessed on 12 July 2016).

- Šadauskienė, J.; Šeduikytė, L.; Paukštys, V.; Banionis, K.; Gailius, A. The role of air tightness in assessment of building energy performance: Case study of Lithuania. Energy Sustain. Dev. 2016, 32, 31–39. [Google Scholar] [CrossRef]

- Thermal Technology of Building Elements; STR 2.05.01:2005; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 2005. (In Lithuanian)

- Chou, B.C; Jiang, C.M.; Mon, W.D; Lee, J.H. Difference of the indoor ventilation aeration efficiency from the various construction of stone-slab house. In Proceedings of the 16th Symposium of Research, Architect Institute of Taiwan, Taipei, Taiwan, 12 June 2004; Available online: http://www.pws.stu.edu.tw/paul/B_Conference/B088.pdf (accessed on 29 October 2016).

- Zhu, D.T.; Hong, D.Y.; Wang, C. A detailed loads comparison of three building energy modeling programs: EnergyPlus, DeST and DOE-2.1 E. Build. Simul. 2013, 6, 323–335. [Google Scholar] [CrossRef]

- Pan, Y.; Huang, Z.; Wu, G.; Chen, C. The application of building energy simulation and calibration in two high-rise commercial buildings in Shanghai. In Proceedings of the 2nd National IBPSA-USA Conference, Cambridge, MA, USA, 2–4 August 2006; pp. 252–261.

- Branco, G.; Lachal, B.; Gallinelli, P.; Weber, W. Predicted versus observed heat consumption of a low energy multifamily complex in Switzerland based on long-term experimental data. Energy Build. 2004, 36, 543–555. [Google Scholar] [CrossRef]

- Groot, E.D.; Spiekman, M.; Opstelten, I. Dutch Research into User Behaviour in Relation to Energy Use of Residences. In PLEA 2008—25th Conference on Passive and Low Energy Architecture, Dublin, Ireland, 22–24 October 2008; Available online: https://www.healthyheating.com/downloads/Thermostats/PLEA_FinalPaper_ref_361.pdf (accessed on 30 October 2016).

- Olivia Guerra Santin, O.G.; Itard, L.; Visscher, H. The effect of occupancy and building characteristics on energy use for space and water heating in Dutch residential stock. Energy Build. 2009, 41, 1223–1232. [Google Scholar] [CrossRef]

- Martani, C.; Lee, D.; Robinson, P.; Britter, R.; Ratti, C. ENERNET: Studying the dynamic relationship between building occupancy and energy consumption. Energy Build. 2012, 47, 584–591. [Google Scholar] [CrossRef]

- Hietanen, P. Paljonko Tilaa Organisaatio Tarvitsee? Työympäristökehittämisen Ympäristövaikutukset. Kiinko Kipa Project Work; Senate Properties: Helsinki, Finland, 2009; p. 33. (In Finnish) [Google Scholar]

| Station | January | February | March | April | May | June | July | August | September | October | November | December | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Taipei | 16.1 | 16.5 | 18.5 | 21.9 | 25.2 | 27.7 | 29.6 | 29.2 | 27.4 | 24.5 | 21.5 | 17.9 | 23.0 |

| Taichung | 16.6 | 17.3 | 19.6 | 23.1 | 26.0 | 27.6 | 28.6 | 28.3 | 27.4 | 25.2 | 21.9 | 18.1 | 23.3 |

| Kaohsiung | 19.3 | 20.3 | 22.6 | 25.4 | 27.5 | 28.5 | 29.2 | 28.7 | 28.1 | 26.7 | 24.0 | 20.6 | 25.1 |

| Layer Name | Width | Density | Sp. Heat | U * | |

|---|---|---|---|---|---|

| Wall Composition, U = 3.23 | Ceramic Tiles | 0.01 | 2.4 | 840 | 1.3 |

| Cement Mortar | 0.015 | 2 | 800 | 1.5 | |

| Reinforced Concrete | 0.15 | 2.2 | 880 | 1.4 | |

| Cement Mortar | 0.01 | 2 | 800 | 1.5 | |

| Roof Composition, U = 1.00 | Cement five-leg tile | 0.05 | 0.7 | 900 | 1.5 |

| Polystyrene Foam | 0.02 | 1.04 | 1130 | 0.04 | |

| Concrete Lightweight | 0.05 | 0.95 | 656.9 | 0.8 | |

| Asphaltic Felt | 0.01 | 1.02 | 900 | 0.11 | |

| Cement Mortar | 0.02 | 2 | 800 | 1.5 | |

| Reinforced Concrete | 0.15 | 2.2 | 880 | 1.4 | |

| Cement Mortar | 0.015 | 2 | 800 | 1.5 | |

| Typical Glass, U = 6.0 | Glass Standard | 0.006 | 2.3 | 836.8 | 1.05 |

| Layer Name | Width | Density | Sp. Heat | U * | |

|---|---|---|---|---|---|

| Wall Composition, U = 1.07 | Ceramic Tiles | 0.01 | 2.4 | 840 | 1.3 |

| EPS | 0.025 | 21.04 | 1300 | 0.04 | |

| Cement Mortar | 0.015 | 2 | 800 | 1.5 | |

| Reinforced Concrete | 0.15 | 2.2 | 880 | 1.4 | |

| Roof Composition, U = 0.75 | Concrete 1-4 Dry | 0.05 | 2.3 | 800 | 1.4 |

| PU Block | 0.025 | 1.05 | 1250 | 0.028 | |

| PU | 0.005 | 1.05 | 1250 | 0.05 | |

| Cement Mortar | 0.015 | 2 | 800 | 1.5 | |

| Reinforced Concrete | 0.15 | 2.2 | 880 | 1.4 | |

| Cement Mortar | 0.015 | 2000 | 800 | 1.5 | |

| Low-e Glass, U = 2.5 | Glass Standard | 0.006 | 2300 | 836.8 | 1.046 |

| Air Gap | 0.03 | 1.3 | 1004 | 5.56 | |

| Glass Standard | 0.006 | 2300 | 836.8 | 1.046 |

| House | Condominium | |||||||

|---|---|---|---|---|---|---|---|---|

| Taipei | Taichung | Kaohsiung | Taipei | Taichung | Kaohsiung | |||

| Air Leak (3.25 ach) | Extended Insulation | Facing West | 68,879.17 | 77,094.65 | 98,015.24 | 287,970.94 | 323,584.38 | 401,207.81 |

| Facing North | 68,059.13 | 75,902.02 | 96,717.30 | 286,335.81 | 320,017.95 | 398,511.36 | ||

| Typical Insulation | Facing West | 81,434.48 * | 92,917.36 * | 118,164.58 * | 357,222.50 * | 410,404.90 * | 506,015.62 * | |

| Facing North | 78,978.82 * | 89,117.29 * | 114,543.31 * | 351,622.05 * | 399,040.54 * | 497,345.66 * | ||

| Air Tight (0.5 ac/h) | Extended Insulation | Facing West | 38,745.79 | 42,109.52 | 53,881.35 | 184,184.72 | 190,285.38 | 236,623.65 |

| Facing North | 37,757.78 | 40,827.71 | 52,460.78 | 182,175.39 | 186,811.36 | 234,554.69 | ||

| Typical Insulation | Facing West | 48,331.52 | 56,010.93 | 70,411.45 | 222,238.40 | 258,618.91 | 306,444.61 | |

| Facing North | 45,650.81 | 52,038.93 | 66,643.06 | 216,380.24 | 247,091.92 | 297,598.66 | ||

| House | Condominium | ||||||

|---|---|---|---|---|---|---|---|

| Taipei | Taichung | Kaohsiung | Taipei | Taichung | Kaohsiung | ||

| Facing West | Total Energy | 81,434.48 | 92,917.36 | 118,164.58 | 357,222.50 | 410,404.90 | 506,015.62 |

| Energy/m2 | 102.56 | 117.02 | 148.82 | 92.42 (−9.88%) | 106.18 (−9.26%) | 130.92 (−12.03%) | |

| Energy/family | 40,717.24 | 46,458.68 | 59,082.29 | 14,884.27 (−63.44%) | 17,100.20 (−63.19%) | 21,083.98 (−64.31%) | |

| Energy/capita | 6786.21 | 7743.11 | 9847.05 | 3721.07 (−45.17%) | 4275.05 (−44.79%) | 5271.00 (−46.47%) | |

| Facing North | Total Energy | 78,978.82 | 89,117.29 | 114,543.31 | 351,622.05 | 399,040.54 | 497,345.66 |

| Energy/m2 | 99.47 | 112.24 | 144.26 | 90.98 (−8.54%) | 103.24 (−8.01%) | 128.68 (−10.80%) | |

| Energy/family | 39,489.41 | 44,558.65 | 57,271.66 | 14,650.92 (−62.90%) | 16,626.69 (−62.69%) | 20,722.74 (−63.82%) | |

| Energy/capita | 6581.57 | 7426.44 | 9545.28 | 3662.73 (−44.35%) | 4156.67 (−44.03%) | 5180.68 (−45.73%) | |

| Taipei | Taichung | Kaohsiung | |||

|---|---|---|---|---|---|

| Insulation Impact (ave. −17.77%) | House | Facing West | −15.42% | −17.03% | −17.05% |

| Facing North | −13.83% * | −14.83% | −15.56% | ||

| Condominium | Facing West | −19.39% | −21.15% ** | −20.71% | |

| Facing North | −18.57% | −19.80% | −19.87% | ||

| Air Tightness Impact (ave. −39.78%) | House | Facing West | −40.65% | −39.72% | −40.41% |

| Facing North | −42.20% ** | −41.61% | −41.82% | ||

| Condominium | Facing West | −37.79% | −36.98% * | −39.44% | |

| Facing North | −38.46% | −38.08% | −40.16% | ||

| Double Impact: Insulation + Air Tightness (ave. −52.63%) | House | Facing West | −52.42% | −54.68% ** | −54.40% |

| Facing North | −52.19% | −54.19% | −54.20% | ||

| Condominium | Facing West | −48.44% | −53.63% | −53.24% | |

| Facing North | −48.19% * | −53.18% | −52.84% |

| 2016 | Energy | 2015 | Energy | 2014 | Energy |

|---|---|---|---|---|---|

| November–December | 1863 | November–December | 1858 | November–December | 1268 |

| September–October | 2878 | September–October | 2477 | September–October | 1995 |

| July–August | 2311 | July–August | 2406 | July–August | 1512 |

| May–June | 1912 | May–June | 1708 | May–June | 1073 |

| March–April | 741 | March–April | 671 | March–April | 673 |

| January–February | 714 | January–February | 630 | January–February | 644 |

| Total Energy | 10,419 | 9750 | 7165 | ||

| Energy/Capita | 3473.00 | 3250.00 | 2388.33 | ||

| Energy/m2 | 56.93 | 53.28 | 39.15 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, K.-L.; Jan, M.-Y.; Liao, C.-S. Energy Consumption Analysis for Concrete Residences—A Baseline Study in Taiwan. Sustainability 2017, 9, 257. https://doi.org/10.3390/su9020257

Lin K-L, Jan M-Y, Liao C-S. Energy Consumption Analysis for Concrete Residences—A Baseline Study in Taiwan. Sustainability. 2017; 9(2):257. https://doi.org/10.3390/su9020257

Chicago/Turabian StyleLin, Kuo-Liang, Ming-Young Jan, and Chien-Sen Liao. 2017. "Energy Consumption Analysis for Concrete Residences—A Baseline Study in Taiwan" Sustainability 9, no. 2: 257. https://doi.org/10.3390/su9020257