Energy Generation from Horse Husbandry Residues by Anaerobic Digestion, Combustion, and an Integrated Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling of Horse Faeces and Bedding

2.2. Processing of Materials

2.3. Set-Up for the Integrated Generation of Solid Fuel and Biogas from Biomass (IFBB) Process

2.4. Digestion Experiments

2.5. Chemical Analysis and Calculations

2.6. Statistical Analysis

3. Results

3.1. Chemical Properties of Raw Material

3.2. Influence of IFBB Process on Chemical Properties

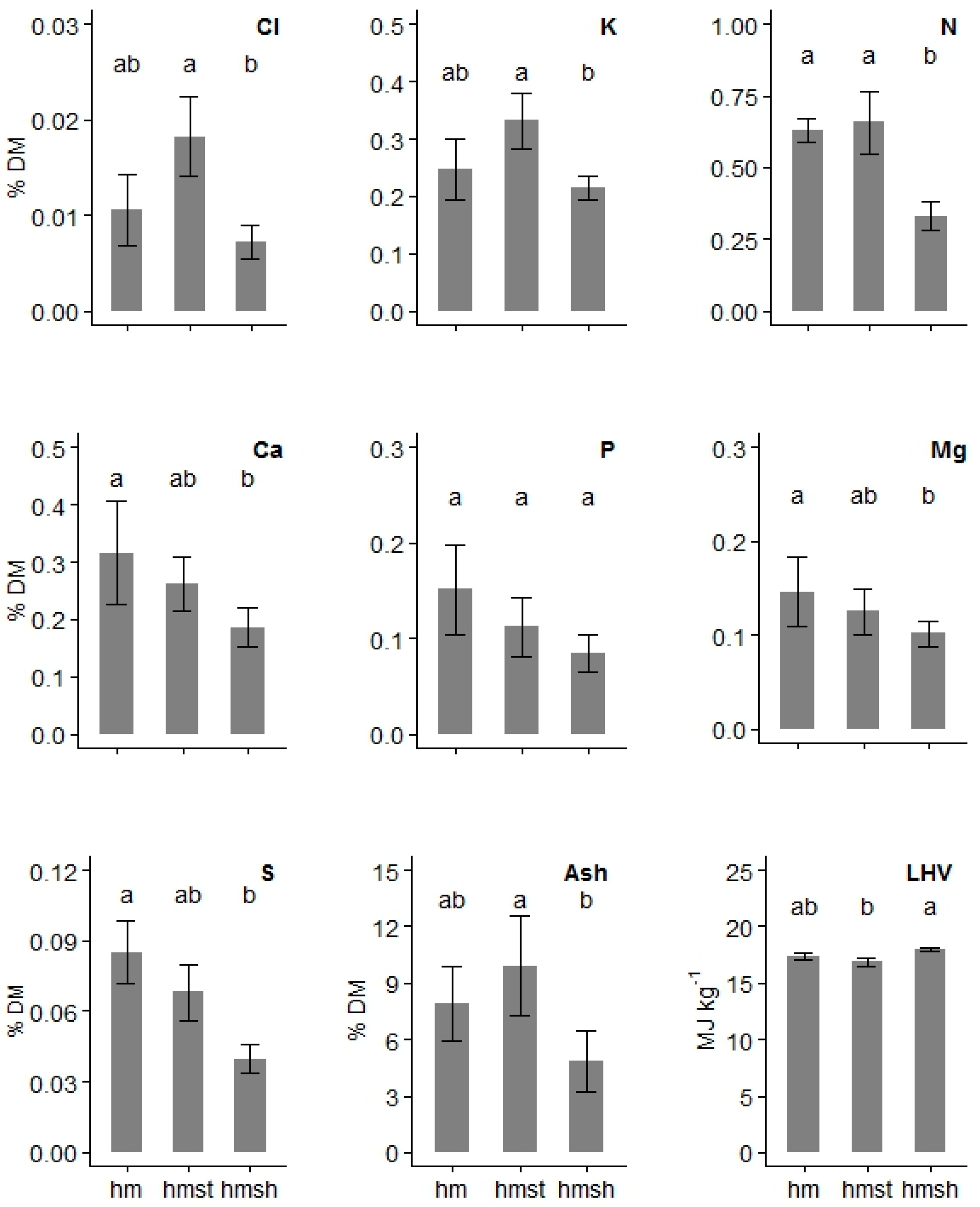

3.3. Chemical Properties of Press Cake

3.4. Methane Yield from Anerobic Digestion of Raw Materials and Press Fluids

3.5. Gross Energy Yields

4. Discussion

4.1. Suitability of Raw Materials and Press Cakes for Combustion

4.2. Suitability of Raw Materials and Press Fluids for Anaerobic Digestion

4.3. Energy Potential

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Häggblom, M.; Rantamäki-Lathinen, L.; Vihinen, H. Equine Sector Comparison between The Netherlands, Sweden and Finland: LIFE04 ENV/FI/000299; Equine Life: Helsinki, Finland, 2008. [Google Scholar]

- Baky, A. Life Cycle Inventory & Assessment Report: Combustion of Horse Manure with Heat Utilisation, Sweden: Baltic Forum for Innovative Technologies for Sustainable Manure Management; Knowledge Report; Swedish Institute of Agricultural and Environmental Engineering: Uppsala, Sweden, 2013. [Google Scholar]

- Kusch, S. Horse Stall Waste: Amounts, Management, Bioenergy Generation. Electron. Int. Interdiscip. Conf. 2013, 2, 423–428. [Google Scholar]

- Wheeler, E.; Zajaczkowski, J.S. Horse Stable Management. Pennsylvania State University, 2009. Available online: http://extension.psu.edu/animals/equine/horse-facilities/horse-stable-manure-management/extension_publication_file (accessed on 20 October 2016).

- Airaksinen, S.; Heinonen-Tanski, H.; Heiskanen, M.-L. Quality of different bedding materials and their influence on the compostability of horse manure. J. Equine Vet. Sci. 2001, 21, 125–130. [Google Scholar] [CrossRef]

- Korries, O.C. Untersuchung Pferdehaltender Betriebe in Niedersachsen: Bewertung unter dem Aspekt der Tiergerechtheit, bei Trennung in Verschiedene Nutzungsgruppen und Beachtung Haltungsbedingter Schäden. Ph.D. Thesis, School of Veterinary Medicine Hannover, Hannover, Germany, 2003. [Google Scholar]

- Lundgren, J.; Pettersson, E. Combustion of horse manure for heat production. Bioresour. Technol. 2009, 100, 3121–3126. [Google Scholar] [CrossRef] [PubMed]

- Swinker, A.M.; Tanner, M.K.; Johnson, D.E.; Benner, L. Composting characteristics of three bedding materials. J. Equine Vet. Sci. 1998, 18, 462–466. [Google Scholar] [CrossRef]

- Kusch, S.; Oechsner, H.; Jungbluth, T. Biogas production with horse dung in solid-phase digestion systems. Bioresour. Technol. 2008, 99, 1280–1292. [Google Scholar] [CrossRef] [PubMed]

- Böske, J.; Wirth, B.; Garlipp, F.; Mumme, J.; van den Weghe, H. Anaerobic digestion of horse dung mixed with different bedding materials in an upflow solid-state (UASS) reactor at mesophilic conditions. Bioresour. Technol. 2014, 158, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Cui, Z.; Shi, J.; Li, Y. Solid-state anaerobic digestion of spent wheat straw from horse stall. Bioresour. Technol. 2011, 102, 9432–9437. [Google Scholar] [CrossRef] [PubMed]

- Li, W. High-Solid Anaerobic Codigestion of Horse Manure and Grass in Batch and Semi-continuous Systems. Energy Fuels 2016, 30, 6419–6424. [Google Scholar] [CrossRef]

- Mönch-Tegeder, M.; Lemmer, A.; Oechsner, H.; Jungbluth, T. Investigation of the methane potential of horse manure. Agric. Eng. Int. 2013, 15, 161–172. [Google Scholar]

- Mönch-Tegeder, M.; Lemmer, A.; Oechsner, H. Enhancement of methane production with horse manure supplement and pretreatment in a full-scale biogas process. Energy 2014, 73, 523–530. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Wachendorf, M.; Richter, F.; Fricke, T.; Graß, R.; Neff, R. Utilization of semi-natural grassland through integrated generation of solid fuel and biogas from biomass. I. Effects of hydrothermal conditioning and mechanical dehydration on mass flows of organic and mineral plant compounds, and nutrient balances. Grass Forage Sci. 2009, 64, 132–143. [Google Scholar] [CrossRef]

- Hensgen, F.; Richter, F.; Wachendorf, M. Integrated generation of solid fuel and biogas from green cut material from landscape conservation and private households. Bioresour. Technol. 2011, 102, 10441–10450. [Google Scholar] [CrossRef] [PubMed]

- Zerr, W. Versuchsanlage zur energetischen Beurteilung von Substraten und Kofermentaten für Biogasanlagen. Umweltwissenschaften und Schadstoff-Forschung 2006, 18, 219–227. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 4630 Vergärung Organischer Stoffe: Substratcharakterisierung, Probenahme, Stoffdatenerhebung, Gärversuche; Beuth: Berlin, Germany, 2006. [Google Scholar]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Wine, R.H. Use of detergents in the analysis of fibrous feeds. IV. Determination of plant cell-wall constituents. J. Assoc. Off. Anal. Chem. 1967, 50, 50–55. [Google Scholar]

- R Core Team. R: A Language and Environment; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Field, A.P.; Miles, J.; Field, Z. Discovering Statistics Using R; Sage: London, UK; Thousand Oaks, CA, USA, 2012. [Google Scholar]

- Giraudoux, P. Pgirmess & Pgirbric, Miscellaneous Functions for Data Handling and Analysis in Ecology. 2014. Available online: http://giraudoux.pagesperso-orange.fr/ (accessed on 30 October 2014).

- Hensgen, F.; Bühle, L.; Donnison, I.; Frasier, M.; Vale, J.; Corton, J.; Heinsoo, K.; Melts, I.; Wachendorf, M. Mineral concentrations in solid fuels from European semi-natural grasslands after hydrothermal conditioning and subsequent mechanical dehydration. Bioresour. Technol. 2012, 332–342. [Google Scholar] [CrossRef] [PubMed]

- Aho, M.; Paakkinen, K.; Taipale, R. Quality of deposits during grate combustion of corn stover and wood chip blends. Fuel 2013, 104, 476–487. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e. V. Feste Biobrennstoffe—Brennstoffspezifikationen und-Klassen—Teil 6: Nicht-Holzartige Pellets für Nichtindustrielle Verwendung; Deutsche Fassung; Beuth: Berlin, 2012. [Google Scholar]

- Piepenschneider, M.; de Moor, S.; Hensgen, F.; Meers, E.; Wachendorf, M. Element concentrations in urban grass cuttings from roadside verges in the face of energy recovery. Environ. Sci. Pollut. Res. 2015, 22, 7808–7820. [Google Scholar] [CrossRef] [PubMed]

- Bühle, L.; Hensgen, F.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Life cycle assessment of the integrated generation of solid fuel and biogas from biomass (IFBB) in comparison to different energy recovery, animal-based and non-refining management systems. Bioresour. Technol. 2012, 111, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Erste Allgemeine Verwaltungsvorschrift zum Bundes-Immissionsschutzgesetz; TA Luft: Berlin, Germany, 2002.

- Kolar, L.; Marsalek, M.; Frelich, J.; Kuzel, S.; Smetana, P.; Zednikova, J.; Svecova, M. Changes in methane release from organic matter passing through the digestive tract of horses. Czech J. Anim. Sci. 2009, 54, 112–120. [Google Scholar]

- Hensgen, F.; Bühle, L.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Energetic conversion of European semi-natural grassland silages through the integrated generation of solid fuel and biogas from biomass: Energy yields and the fate of organic compounds. Bioresour. Technol. 2014, 154, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Yenigün, O.; Demirel, B. Ammonia inhibition in anaerobic digestion: A review. Process Biochem. 2013, 48, 901–911. [Google Scholar] [CrossRef]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

| Chemicals | Straw | Shavings | Horse Faeces | Horse Faeces with Straw | Horse Faeces with Shavings | Coniferous Wood without Bark 1 |

|---|---|---|---|---|---|---|

| DM | — | — | 19.88 ± 1.31 a | 28.36 ± 1.28 a,b | 31.92 ± 2.10 b | — |

| C | 45.11 ± 0.20 | 49.77 ± 0.03 | 46.01 ± 0.42 a,b | 44.36 ± 1.13 a | 47.15 ± 0.97 b | 51 |

| H | 5.40 ± 0.03 | 5.71 ± 0.02 | 5.43 ± 0.04 a,b | 5.63 ± 0.12 a | 5.47 ± 0.13 b | 6.3 |

| Cl | 0.32 ± 0.00 | <0.003 | 0.10 ± 0.05 a,b | 0.22 ± 0.05 a | 0.07 ± 0.02 b | 0.01 |

| K | 1.26 ± 0.01 | 0.04 ± 0.00 | 1.40 ± 0.22 a,b | 1.64 ± 0.17 a | 0.96 ± 0.13 b | 0.04 |

| N | 0.51 ± 0.01 | 0.02 ± 0.00 | 1.24 ± 0.11 a | 1.07 ± 0.11 a,b | 0.70 ± 0.07 b | 0.10 |

| Ca | 0.37 ± 0.03 | 0.08 ± 0.00 | 0.47 ± 0.06 a | 0.40 ± 0.03 a,b | 0.29± 0.06 b | 0.09 |

| Mg | 0.09 ± 0.00 | 0.01 ± 0.00 | 0.30 ± 0.07 a | 0.26 ± 0.03 a | 0.21 ± 0.05 a | 0.015 |

| P | 0.09 ± 0.00 | 35.7 ± 1.20 2 | 0.52 ± 0.10 a | 0.39 ± 0.06 a,b | 0.34 ± 0.09 b | 0.006 |

| S | 0.08 ± 0.00 | <0.004 | 0.16 ± 0.01 a | 0.15 ± 0.01 a,b | 0.09 ± 0.02 b | 0.02 |

| Ash | 7.54 ± 0.70 | — | 11.75 ± 0.62 a | 12.93 ± 2.12 a | 7.86 ± 1.65 b | 0.30 |

| LHV | 16.79 ± 0.08 | 16.73 ± 0.01 | 17.17 ± 0.15 a,b | 16.62 ± 0.34 a | 17.51 ± 0.34 b | 19.18 |

| NDF | 78.50 ± 5.30 | 86.88 ± 2.25 | 66.09 ± 2.14 a | 68.26 ± 4.06 a | 76.68 ± 4.13 b | — |

| ADF | 55.78 ± 12.13 | 74.82 ± 0.63 | 42.30 ± 0.48 a | 46.22 ± 6.45 a | 62.64 ± 5.69 b | — |

| ADL | 13.07 ± 8.08 | 25.97 ± 0.31 | 8.83 ± 0.36 a,b | 8.29 ± 0.50 a | 16.85 ± 1.63 b | — |

| Horse Faeces | Horse Faeces with Straw | Horse Faeces with Shavings | |

|---|---|---|---|

| DM | −105.00 * | −47.33 ** | −46.38 * |

| C | −1.68 ns | −2.19 ns | −2.57 * |

| H | −1.57 ns | −3.46 * | −2.85 * |

| Cl | 89.12 ** | 91.67 * | 90.27 * |

| K | 82.32 * | 79.72 ** | 77.77 ** |

| N | 48.99 * | 38.62 ** | 52.72 * |

| Ca | 32.94 ns | 34.40 ** | 35.23 * |

| P | 70.92 * | 71.42 ** | 74.81 * |

| S | 47.20 * | 55.79 * | 58.14 * |

| Mg | 51.05 * | 51.81 ** | 51.94 * |

| Ash | 32.75 * | 23.43 ns | 38.29 * |

| LHV | −1.19 ns | −1.52 ns | −2.26 * |

| Anaerobic Digestion | Direct Combustion | IFBB 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Horse Faeces | Horse Faeces with Straw | Horse Faeces with Shavings | Horse Faeces | Horse Faeces with Straw | Horse Faeces with Shavings | Horse Man Faeces Ure | Horse Faeces with Straw | Horse Faeces with Shavings | |

| Horse manure (kg·FM·a−1) 1 | 5110 | 11,000 | 11,000 | 5110 | 11,000 | 11,000 | 5110 | 11,000 | 11,000 |

| Horse manure (kg·DM·a−1) | 1022 | 3080 | 3520 | 1022 | 3080 | 3520 | 1022 | 3080 | 3520 |

| Gross energy from methane (GJ·a−1) | 7.0 | 22.0 | 10.8 | — | — | — | 0.5 | 2.8 | 1.8 |

| Gross energy from solid fuel (GJ·a−1) | — | — | — | 16.9 | 51.2 | 61.6 | 13.7 | 41.6 | 50.4 |

| Sum of gross energy (GJ·a−1) | 7.0 | 22.0 | 10.8 | 16.9 | 51.2 | 61.6 | 14.3 | 44.4 | 52.2 |

| Gross energy potential for Europe (EU 27; 5 Mill horses 1, PJ·a−1) 1 | 34.8 | 109.8 | 54.2 | 84.7 | 255.9 | 308.2 | 71.3 | 221.9 | 261.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nitsche, M.; Hensgen, F.; Wachendorf, M. Energy Generation from Horse Husbandry Residues by Anaerobic Digestion, Combustion, and an Integrated Approach. Sustainability 2017, 9, 358. https://doi.org/10.3390/su9030358

Nitsche M, Hensgen F, Wachendorf M. Energy Generation from Horse Husbandry Residues by Anaerobic Digestion, Combustion, and an Integrated Approach. Sustainability. 2017; 9(3):358. https://doi.org/10.3390/su9030358

Chicago/Turabian StyleNitsche, Meike, Frank Hensgen, and Michael Wachendorf. 2017. "Energy Generation from Horse Husbandry Residues by Anaerobic Digestion, Combustion, and an Integrated Approach" Sustainability 9, no. 3: 358. https://doi.org/10.3390/su9030358