1. Introduction

The rapid increase in energy consumption and greenhouse gas (GHG) emission in the building sector has led to the amendment of energy policies in many countries. Globally, the building sector consumes over 30% of total final energy, having increased by more than 35% since 1990. At the same time, it also accounts for 30% of CO

2 gas emission [

1]. According to the International Energy Outlook 2016, global final energy consumption is expected to increase by an average of 1.8% per annum from 2012 to 2040 [

2]. This is as a result of the transition of many emerging economies from traditional sources of energy to modern marketable sources such as electricity. The final energy consumption includes energy consumed through space heating and cooling, domestic activities, lighting and household utilization [

3].

Despite the increasing energy consumption, energy poverty is still a major issue in some parts of the world. Energy poverty can be defined as a state whereby occupants or households lack access or resource to afford basic energy services. Over two billion people worldwide live without electricity and rely on solid fuels such as biomass fuels and coal for their energy needs [

4]. According to the World Health Organization (WHO), indoor air pollution increases the risk of pneumonia among children and chronic respiratory diseases for adults. Annually, it is responsible for more than 1.5 million deaths. Two-thirds of which occur in Sub-Saharan Africa and Southeast Asia [

5]. Across Europe and other parts of the world that experience winter season, cold housing as a result of energy poverty leads to morbidity conditions, such as circulatory, respiratory, and mental illness; flu; arthritis; rheumatism; etc. The Marmot Review indicates that more than one in four adolescents living in cold housing are at risk of multiple mental health problems compared to 1 in 20 adolescents who have always lived in warm houses. In addition, excessive winter deaths are attributed to the coldest quarter of housing and account for 21.5% of the death toll during the season. Nevertheless, countries with profound energy efficiency housing policies have experienced lower excess winter deaths [

6]. The recommended indoor temperature by the WHO is 21 °C in the living room and 18 °C in the bedrooms for at least 9 h of the day [

7]. Studies [

8,

9] show that there are three main drivers of energy poverty: low-income, high energy costs, and poor thermal efficiency and housing.

Locally, energy poverty in South Africa is primarily driven by accessibility to energy sources, low-income and poor thermal efficiency and housing. In a bid to eliminate the historical inequalities in South Africa, the government embarked on rapid construction of low-cost housing (LCH) and electrification of rural areas. Between 1994 and 2001, approximately 1.2 million LCH were constructed or under construction [

10]. Despite the housing progress, housing demand still increases. Documented by the Financial Fiscal Commission, the housing backlog increased from 1.8 million in 1996 to an estimated 2.1 million in 2013 [

11]. On the other hand, electrification of formal households (includes low-cost housing) increased from 36% in 1994 to 87% in 2012, i.e., 5.7 million formal households were electrified. These values indicate households connected to the national grid and renewable sources of energy [

12]. However, the backlog of electrified household still remains about three million, with a target to electrify 97% by 2025 [

13]. In addition, the government argued that the average poor household does not consume more than 50 kWh per month. Hence, this amount of electricity should be provided for free per month for their basic needs, such as water heating, ironing, lighting, powering of small television set and radio. In 2003, Free Basic Electricity (FBE) policy that provides free 50 kWh of electricity per month to poor household was lunched [

14]. However, FBE is not reaching all its intended beneficiaries. As of 2015, only 77% of customers were documented as collecting their FBE tokens [

15]. The energy poverty level in South Africa is estimated to be between 40% and 49% in 2015 [

16]. FBE policy never took into consideration the thermal needs of the household, given the conditions of LCH.

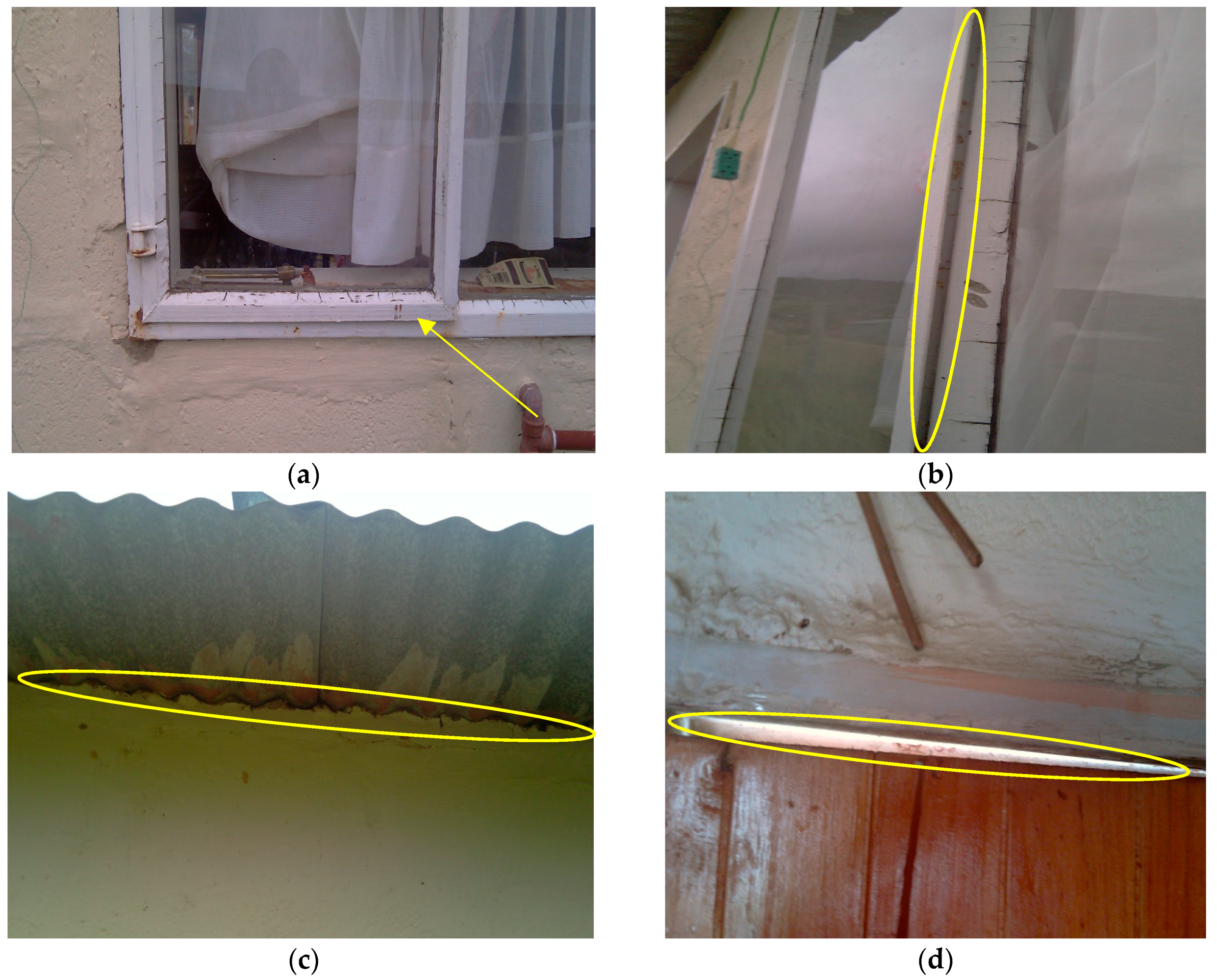

Over the years, LCH has been characterized by poor indoor air quality and harsh thermal conditions. Occupants finding their homes excessively hot in summer and extremely cold in winter [

17,

18]. This is as a result of poor building design and use of inferior building materials. Despite the high amount of solar radiation in South Africa, LCH lacks the capacity to utilize solar energy for space heating. Cracks, openings and poor thermal properties of the thermal envelope of LCH, results in uncontrolled heat exchange between indoor and the ambient environment. Thereby, creating a thermally discomfort environment indoors. Having exhausted the monthly FBE, households will spend a significant amount of their income on space heating to achieve indoor thermal comfort [

19]. Alternatively, these households use coal, paraffin heaters or clothing to keep warm. This leads to poor indoor air quality, cold-related illness, CO

2 emission, etc. According to the Department of Minerals and Energy (DME) 2009, the residential sector represents the third largest energy demanding sector in South Africa, accounting for 20% of energy demand [

12]. South Africa’s dependence on coal has resulted in the country being the leading CO

2 emitter in Africa, accounting for 40% of emissions. On a global scale, South Africa is the 13th largest CO

2 emitter according to Energy Information Administration (EIA) estimates [

20].

Three-quarters of the total energy consumption in the building sector is residential, with great opportunity for energy improvement [

21]. The building design and components of the thermal envelope are the main determining factor of energy consumption in residential buildings. Mari-Louise et al. investigated the influence of window size on the energy required to maintain the indoor temperature in between 23 °C and 26 °C. They used a dynamic building simulation tool (DEROB-LTH). They found that the size of the window is relevant for cooling energy in the summer but has no significant impact in the winter season. Mari-Louise et al. concluded that a smaller window was recommended on south elevation for minimum cooling energy needs [

22]. The impact of opaque building envelope configuration on the heating and cooling energy needed in a cold climate was studied by Francesco et al. They argued that thermal transmittance and inertia are traditionally connected to two different energy demands. While thermal transmittance is crucial to reduce heating energy demand, thermal inertia has an impact on cooling energy demand. They discovered that the influence of thermal inertia on heating energy need is limited while periodic thermal transmittance has an impact on heating load [

23]. In addition, Wang and Wong analyzed the impact of ventilation strategies and façade designs on indoor thermal environment of a residential building. They evaluated four ventilation strategies: nighttime only, daytime only, full-day and no ventilation. Parametric studies of façade designs on orientations, window to wall radio and shading device were performed using the building simulation tool (FLUENT). They found that full-day ventilation provides better indoor thermal comfort.

The above-cited research demonstrates the significance of building design and component of the thermal envelope on energy consumption. They also hinted at various energy efficiency measures for residential buildings via building design and thermal envelope. However, similar to most energy and sustainability research, economic and environmental impact of building energy consumption are not taken into consideration. In other words, these concepts (economic and environment) are not treated in detail. This study is focused on the thermal load, and economic and environmental impact of a low-cost house. Furthermore, the study portrays the social economic welfare of a LCH occupant as well as the environmental impact with respect the house thermal performance.

2. Thermal Comfort

The definition and control of indoor thermal comfort in buildings is difficult to establish due to the variation in the parameters involved [

24]. Commonly, thermal comfort is defined as the condition of mind in which satisfaction is expressed with the thermal environment [

25]. Thermal dissatisfaction is caused by the temperature of a body as a whole. This is as a result of unwanted heating or cooling of the body [

26]. Sensible and latent heat losses from the skin are typically expressed in terms of environmental factors, skin temperature, and skin conditions (dry or wet). It also accounts for the thermal insulation and moisture permeability of clothing. The environmental variables can be summarized as air temperature, radiant temperature, relative air speed and humidity. The operative personal variables that influence thermal comfort are human activity and clothing [

27].

The human perception of thermal comfort analysis conducted by Fanger in 1982 shows that the sensation of thermal comfort was most significantly determined by narrow ranges of skin temperature and sweat evaporation rate, depending on activity level. More active people were comfortable at low skin temperatures and higher evaporation rates. By combining this information with the ASHRAE thermal sensation scale, shown in

Table 1, Fanger developed a comfort index called PMV [

26,

28].

PMV is an index that predicts the mean value of the votes of a large group of persons on a seven-point thermal sensation scale [

29]. The PMV index can be determined when the activity (metabolic rate) and the clothing (thermal resistance) are estimated, and the following environmental parameters are measured: air temperature, mean radiant temperature, relative air velocity and partial water vapor pressure. The PMV is given by the equation [

26];

where

M = Metabolic rate (W/m2);

w = External work (W/m2);

Pa = Partial water pressure (Pa);

ta = Air temperature;

fcl = Ratio of clothed surface to nude surface area;

tr = Mean radiant temperature; and

hc = Convective heat transfer coefficient (W/m2.K).

PPD is a predicted value calculated from PMV. It predicts the percentage of people dissatisfied with the thermal conditions of their surroundings [

30], people who felt more than slightly warm or slightly cold (i.e., the percentage of the people who inclined to complain about the environment). Using the thermal sensation scale in

Table 1, Fanger postulated: people who respond ±2 and ±3 are uncomfortable, while those who respond ±1 and 0 are comfortable. The relationship between PPD and PMV is given by Equation (2);

Owing to individual differences, it is impossible to specify a thermal environment that will satisfy everybody: if the PMV is zero, 5% of people are dissatisfied. It is possible, however, to specify environment known to be acceptable by a certain percentage of the occupants. The ISO standard 7730, for example, recommends that the PPD should be lower than 10%, i.e., PMV within the range of ±0.5 [

31].

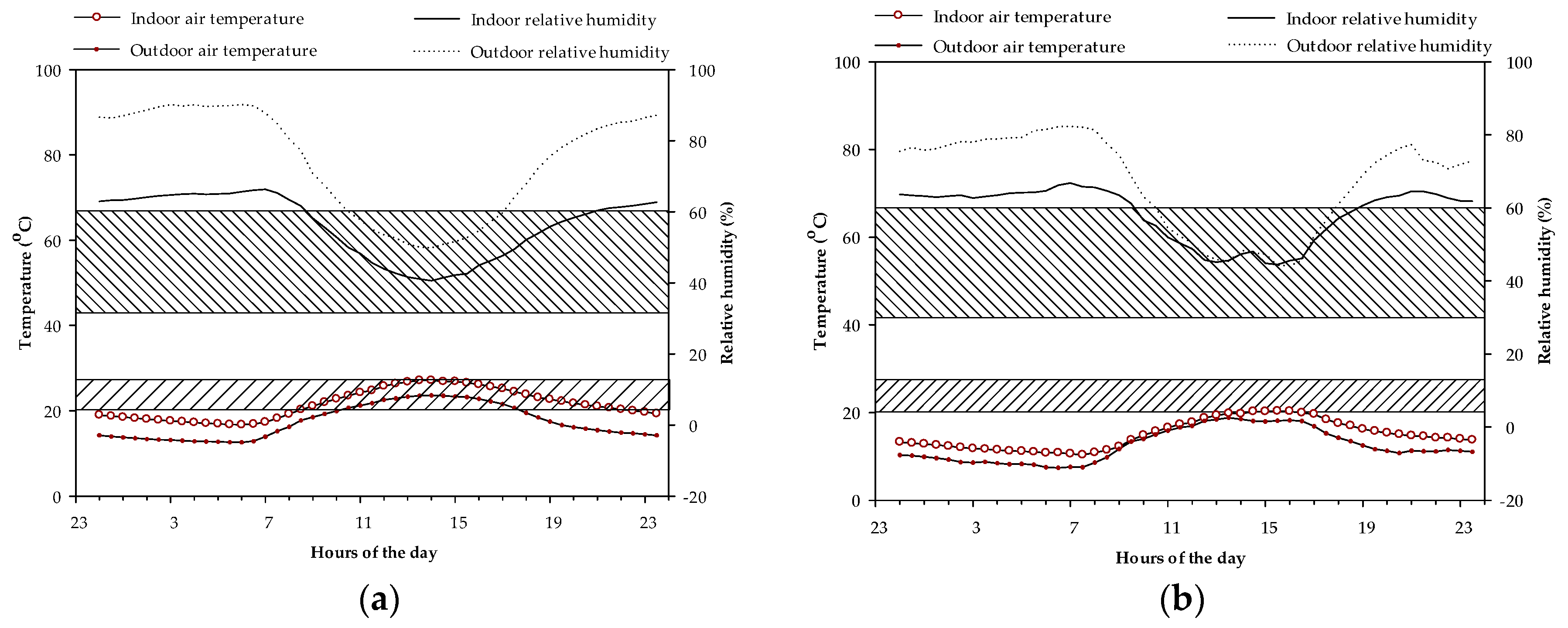

Another approach for analyzing thermal comfort was done by the American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) standard 55 and ISO standard 7730. In this method, thermal comfort depends on indoor temperature and relative humidity. A fix and uniform temperature range and a lower and upper humidity level were set for winter and summer seasons. Low humidity (dew point less than 0 °C) results in dry skin and mucous surfaces leading to comfort complaints such as dry nose, throat, eyes, and skin. High humidity also results in discomfort due to increased moisture, friction between skin and clothing, increased skin moisture, etc. To prevent thermal discomfort, the recommended lower and upper relative humidity levels should not exceed 30% and 60%, respectively [

25,

32], whilst the indoor temperature is kept at 20 °C to 23 °C in the winter and 24 °C to 26 °C in the summer season. The South African National Standards (SANS) 204 recommend 20 °C to 24 °C indoor temperature in both seasons and 30% to 60% relative humidity [

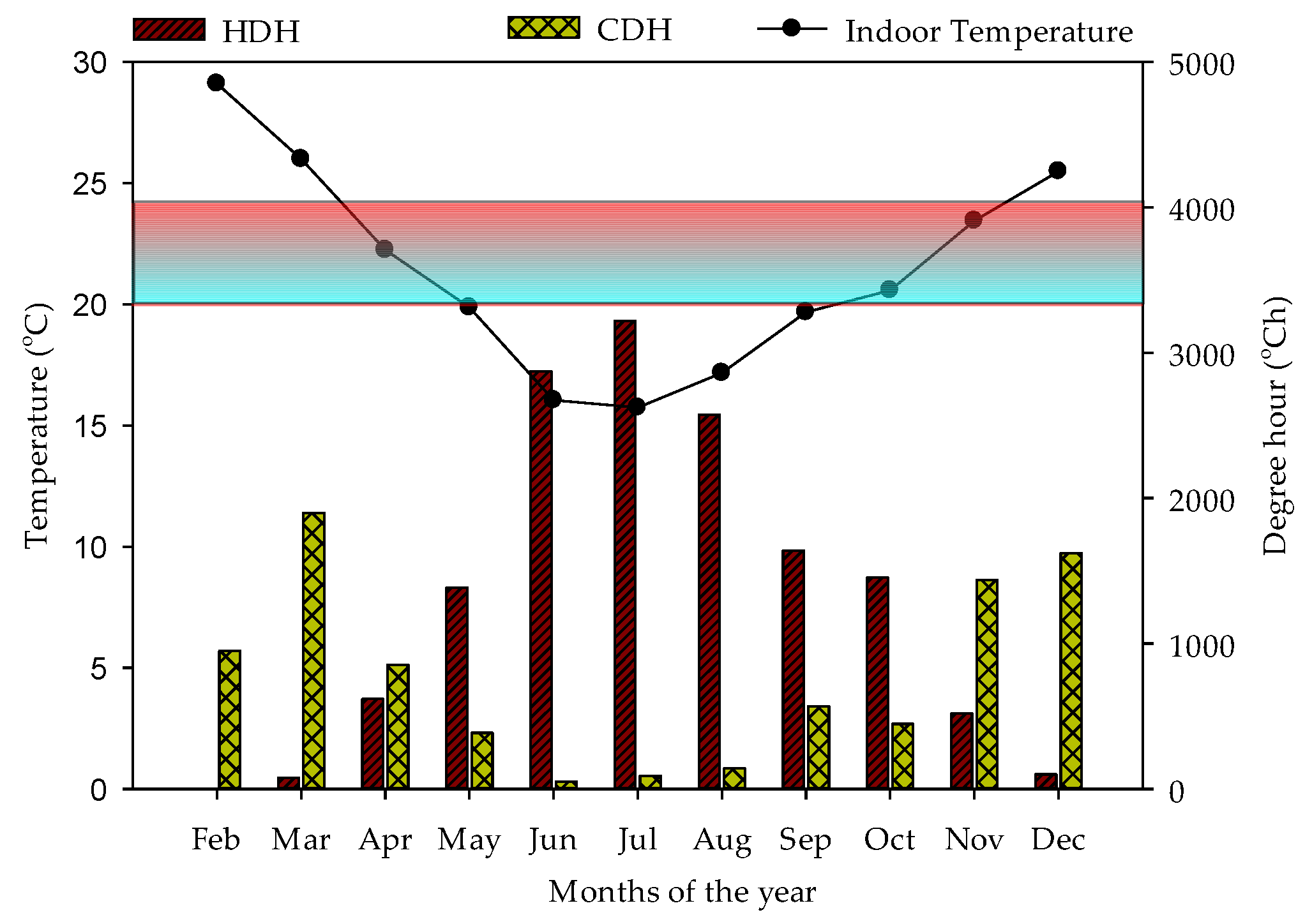

33].

3. Thermal Load Estimation

Reliable and sufficient results can be achieved when using steady-state heat transfer analysis to estimate building thermal load [

34]. However, various methods can be used to estimate building thermal load: radiant time series, thermal network, heat balance, degree hours, etc. Degree-hours is an easy to use, and well-established tool for energy consumption analysis in buildings [

35]. Degree-hours is the sum of the difference between hourly average temperatures and a reference temperature. The numbers of heating (HDH) and cooling (CDH) degree-hours are given as:

and

represent the average hourly and reference based temperature, respectively. The positive sign implies that only positive values are considered. In addition,

m indicates monthly degree-hours. That is, the sum of daily degree-hours in a given month. It could also be extended or reduced to yearly or daily degree-hours, respectively. The monthly or seasonal thermal load can be determined by

where

is cooling or heating load (kWh/m

2);

is the total heating or cooling degree-hours (°C·h); and

is the overall heat transfer coefficient (W/m

2·K) of the opaque components of the thermal envelope. It is the sum of the thermal transmittance (U-value) of all opaque components of the thermal envelope that experience temperature change from inside to outside of the building. According to the First law of thermodynamics, the net change in the total energy of a system is the total energy entering and leaving the system. Therefore, to maintain a stable thermal condition indoors, the equivalent amount of heat gain or loss has to be removed (cooling) or supplied (heating), respectively. Hence, the heating or cooling energy required to maintain a stable indoor thermal condition is given by:

where

is the monthly heating or cooling energy (kWh),

A is the total floor surface area of the house and

is the efficiency of the heating or cooling system. The monthly cost of energy consumed for heating or cooling can be determined from Equation (7):

represents energy charge per unit (c/kWh). In South Africa, energy charges vary with tariff structure. Tariff structures are designed based on customer’s consumption, and they include urban (maximum load > 1 MW), residential (maximum load ≤ 0.1 MW) and rural (maximum load of 0.025 MW) [

36].

Greenhouse Gas Emission

Coal-fired power stations are the main source of electricity in South Africa. This implies that domestic energy consumption contributes to greenhouse gas emission of the country. The greenhouse gas emission and other environmental impact due to the total energy generated and supplied per annum (financial year) are determined by the national power authority (Eskom). This is done using the IPCC 2006 guidelines for the UNFCCC methodology [

37,

38]:

where

is cumulative monthly heating or cooling energy (MWh),

, is the emission of

x gas per annum and

is emission coefficient of

x gas, which could be CO

2, CH

4, NO

x, SO

x, etc. Emission factors are usually determined per annum and they vary from one country to another as they are influenced by the primary means of energy production.

4. Description of the House and Its Location

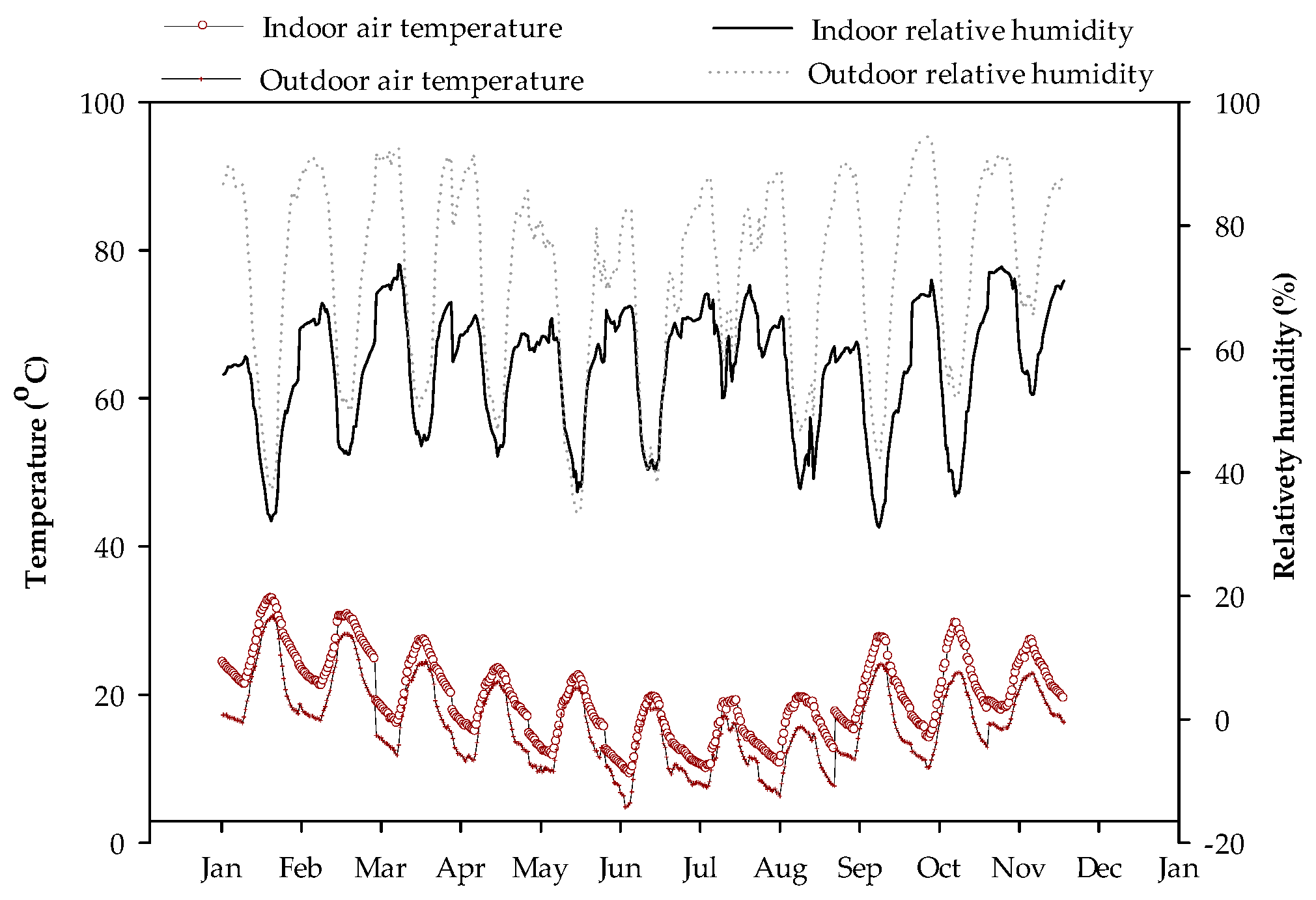

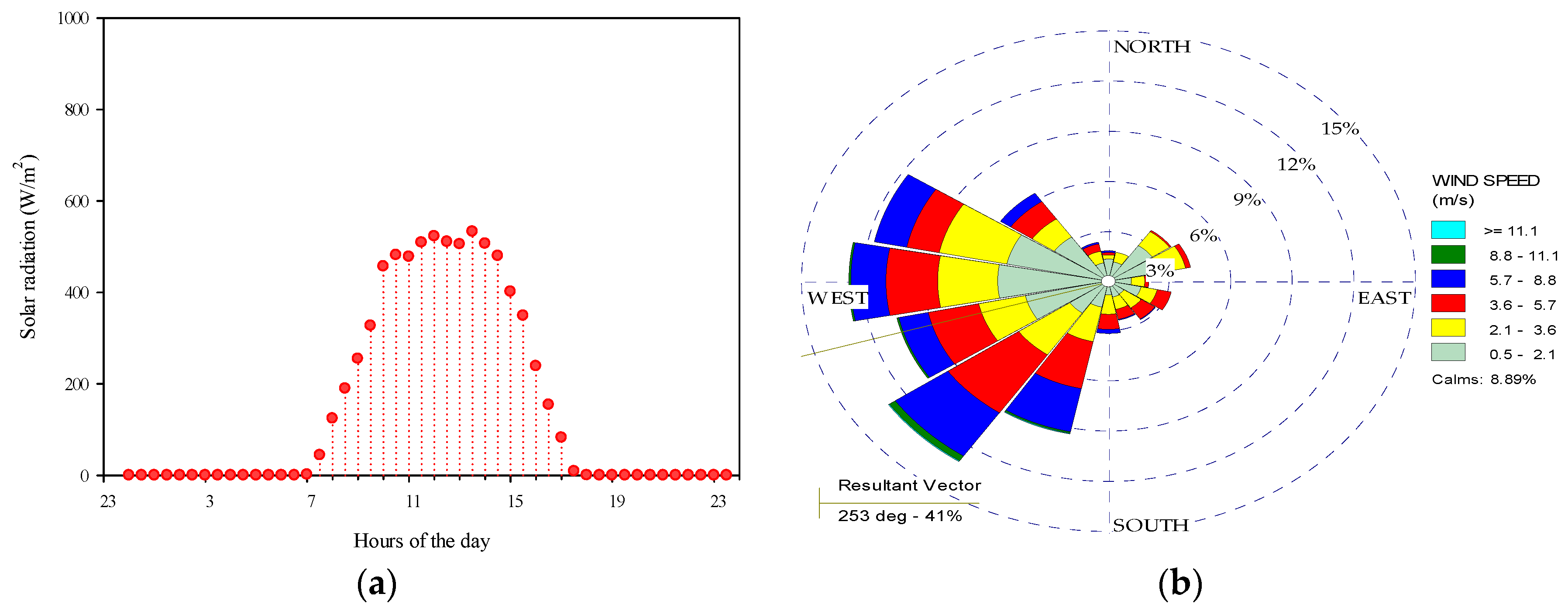

The house used as case study is located in the Golf Course settlement Alice under the Raymond Mhlaba Municipality, Eastern Cape. Golf Course is geographically located at 32°S latitude and 26°E longitude, at an altitude of 493 m. According to the Köppen–Geiger climate classification, Alice has a BSh Arid, Steppe, Hot arid climate. Such climate is characterized by annual precipitation greater than 5 P

th. The annual temperature is greater than or equal to +18 °C [

39]. Locally, Alice is in the temperate interior (Zone 2) climate of South Africa [

40]. The climatic conditions are characterized by a hot summer and mild (no snow) winter, with an average dry bulb temperature of 29 °C and 15 °C, respectively. Rainfall usually occurs in the summer season while winter season is characterized by dry, dusty and windy conditions. The east wind is predominant in summer while the winter is dominated by the west wind [

41]. An average wind speed of 2.5 m/s is experienced in Golf Course throughout the year. Similar to most LCH settlements in the country, Golf Course is a rural settlement primarily occupied by senior citizens, children and low-income earners. The LCH used in this study and its floor plan are shown in

Figure 1a,b.

The passive solar features of the house such as the orientation (16° east of north) and large North facing windows were the major reasons the house was selected. The house comprises of a bedroom, bathroom, open plan living room and kitchen. The total floor dimension is 7.20 m × 5.70 m, approximately 41 m2 floor area. The height of the house at the mid-wall and perimeter walls is 2.89 m and 2.44 m, respectively. The roof is made of galvanized, corrugated iron sheets with no ceiling or any form of roof insulation. The walls are made of M6 (0.39 × 0.19 × 0.14 m) hollow concrete blocks, with no plaster or insulation. Thus, the thickness of the walls assumed the width (0.14 m) of the blocks. More than 97% of the houses in this settlement share the same design.

5. Methodology

To monitor the weather parameters of the house, a series of meteorological sensors were installed. These include type K thermocouple, HMP50 temperature–humidity probes, Li-Cor pyranometer and 03001 wind sentry anemometer and vane.

Type K thermocouple is made of two dissimilar metals joined near the measurement point. It consists of a measurement and reference junction. The reference junction is created where the two metals connect to the measuring point. Type K thermocouple produces a micro-voltage signal which is related to the temperature difference between the measurement and reference junctions. With an error of 2.20 °C, type K thermocouple has a temperature measurement range of −200 °C to 1250 °C [

42]. The HMP50 temperature and relative humidity probe contains a platinum resistance temperature detector (PRT) and a capacitive relative humidity sensor. It has a temperature and relative humidity range of −26 °C to 60 °C and 0% to 98%, respectively. It has an accuracy of ±3% with a response time of 15 s. To ensure precise measurement of the ambient temperature and humidity, the HMP50 was housed in a solar radiation shield in outdoor measurement [

43]. Li-Cor pyranometer is used to measure the global solar radiation, i.e., the sum of direct and diffuse radiation. The Li-Cor pyranometer employs a silicon photovoltaic sensor which is mounted in a cosine-corrected head. The current measured by the detector is converted to a voltage signal by a shunt resistor in the sensor cable [

44]. The wind sentry anemometer and vane measure the horizontal wind speed and wind direction. The anemometer has a range of 0 to 50 m/s. The cup wheel rotation produces an AC sine wave voltage with frequency directly proportional to wind speed. This AC signal is induced in a stationary coil by a two-pole ring magnet mounted on the cup wheel shaft. One complete sine wave cycle is produced for each cup wheel revolution. On the other hand, Wind vane position is transmitted by a 10 K ohm precision conductive plastic potentiometer, which requires a regulated excitation voltage. With a constant excitation voltage applied to the potentiometer, the output signal is an analogue voltage directly proportional to azimuth angle [

45].

A total of 13 thermocouples were used to measure the indoor air, roof, floor, walls inner and outer surface temperatures. The indoor air thermocouple was placed at a height of 1.80 m to have good indoor air temperature variation patterns that are not influenced by the roof temperature and stack warm air. The same height was adopted for the thermocouples measuring the walls surface temperature. They were mounted such that their sentry terminals are in a direct contact with the walls’ surface. One thermocouple on each side of the wall was used to measure the inner and outer surface temperature of the north, east, west and south walls. Indoor relative humidity was measured by a temperature–humidity probe placed at same height as the indoor air thermocouple. Conversely, outdoor air temperature and relative humidity were measured via a solar radiation shielded temperature–humidity probe. The Campbell Scientific 41303-5A 6-plate radiation shield was used [

43]. It is designed to allow ventilation, while at the same time preventing solar radiation from affecting the probe (sensor). The wind sentry anemometer/vane and pyranometer were used to measure wind speed/direction and global solar radiation, respectively. The outdoor metrological sensors were installed at a height of 0.44 m above the roof of the house. The entire sensors were then connected to a Campbell Scientific CR1000 datalogger supported by an AM 16/32 relay multiplexer, powered by a 20 V battery charged by a 20 W solar panel.

7. Conclusions

The good intention of the South Africa government to provide decent homes for low-income earners and homeless people has been overshadowed by the poor thermal performance of the houses. Despite the regulations of energy efficiency in buildings in South Africa, most low-cost housing is built ignoring energy efficiency features. As a result, low-cost householders find their homes extremely cold in winter, as revealed in the findings of this study.

In the winter season, the indoor temperature was either out or below the SANS recommended temperature range. It was also revealed that the thermal envelope and building design play significant roles in the indoor weather conditions of the house. The components of the thermal envelope show little or no resistance to the outdoor weather conditions. As a result, the indoor temperature closely follows the outdoor temperature with a time lag of 2 h. The findings of this study also indicate that occupants (SASSA child grant dependence) will spend approximately twice their monthly income to achieve thermal comfort indoors. The poor thermal behavior of the low-cost housing also has a negative impact on the country’s carbon footprint. An average of 0.51 ton of CO2 gas will be emitted to supply the monthly heating energy that is required in the winter seasons. Likewise, 4.30 kg and 2.08 kg of SO2 and NO2, respectively, will also be emitted.

A lasting solution to the poor thermal performance of low-cost housing is required. This can be achieved through strict practice of the SANS regulation of energy efficiency in building. A formal training to inform local builders about the SANS building regulation is also encouraged. In addition, promoting and enforcing the use of thermal insulation materials in houses (low-cost housing) will not only bring about energy savings but will also provide year-round indoor thermal comfort.