Organizational Boundary Change in Industrial Symbiosis: Revisiting the Guitang Group in China

Abstract

:1. Introduction

2. Frameworks

2.1. Theoretical Framework

2.2. Methodology and Data Collection

3. Analysis

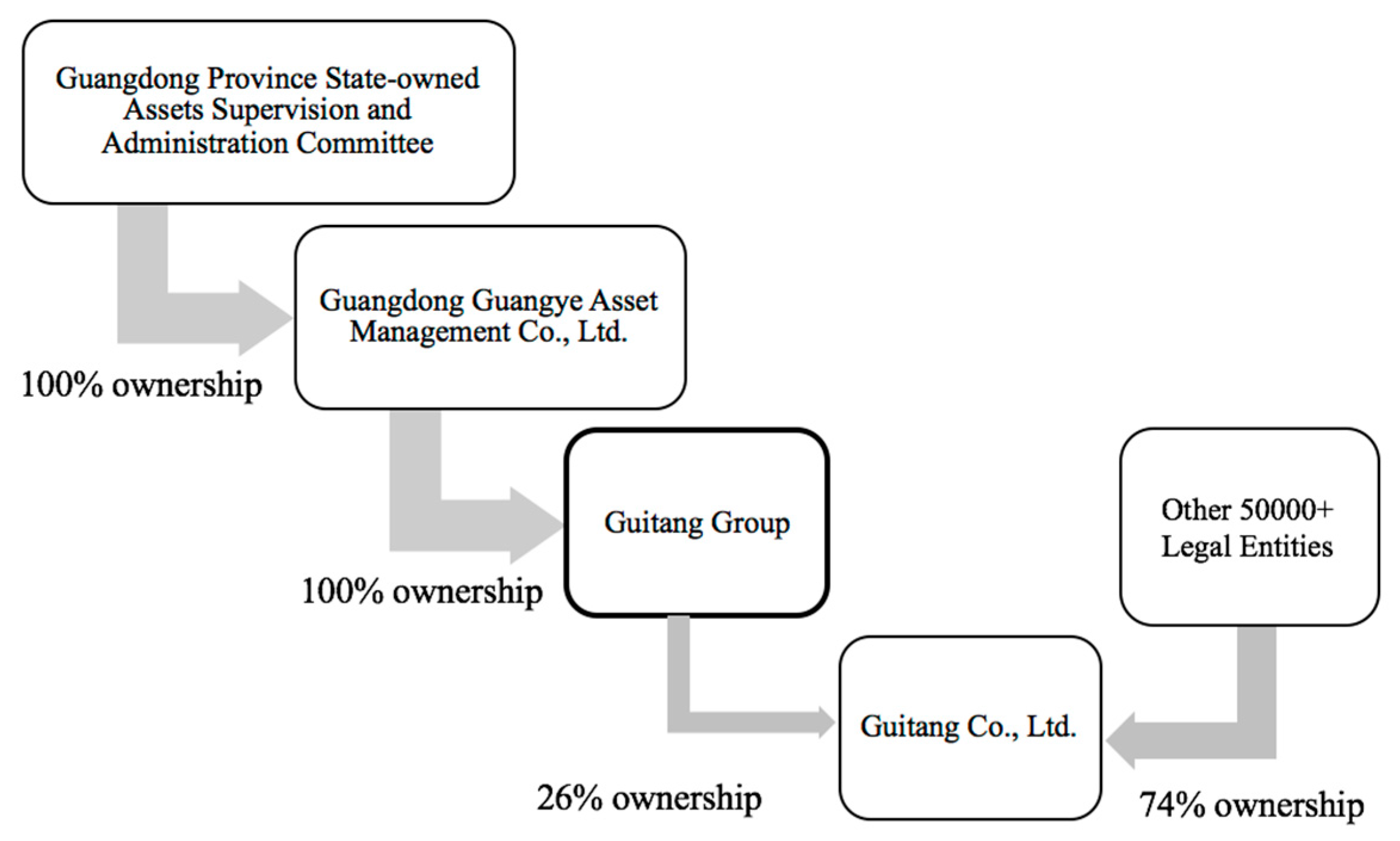

3.1. Definition of Organizational Boundary

3.2. Business Boundary Shift

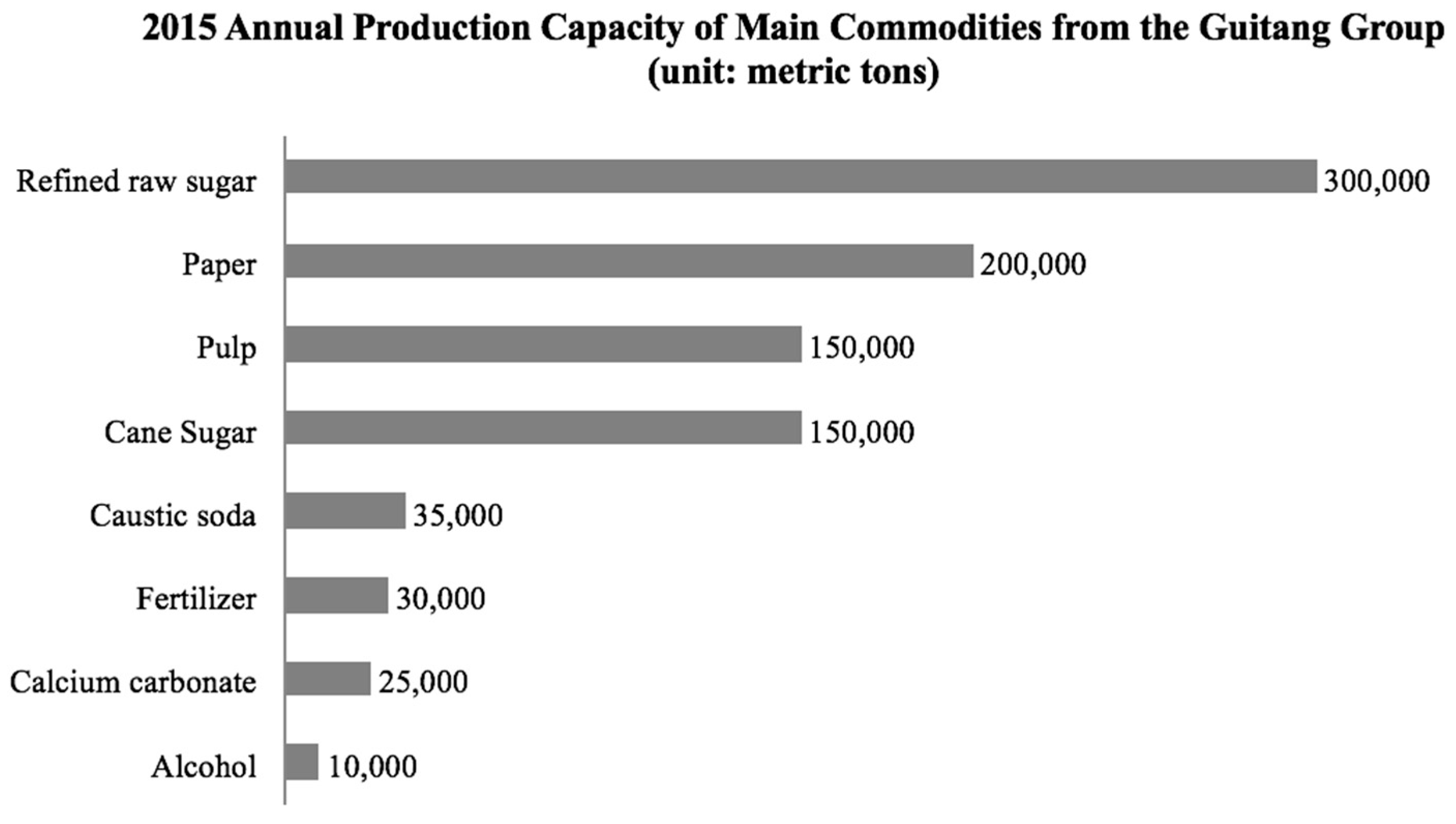

3.2.1. Operational

3.2.2. Management

- (1)

- Socialist infrastructure and cultural heritage as an endowment of social capital: the initial infrastructure of the Guitang factory was designed by Soviet Union experts. In addition to factory buildings, they designed auxiliary facilities including a school, a hospital, a movie theater, a sports stadium, small shopping malls, and residential buildings to support a working community (Figure 4). There was also a hard-working culture created through “Work Emulation Campaigns”, activities that socially acknowledged the diligent workers from the community. Although the infrastructure has gone through changes over the years, the community identity as a working community was shaped from the very beginning. As part of the shared Guitang community, the children of the workers have gone to school together. A number of them got married to each other. The community-centric cultural norm has fostered trust, social linkages, and kinship [29,35,36]. These characteristics also contribute to shaping industrial symbiosis development in Guitang, as previous industrial symbiosis research has found that trust and social ties can be key factors in the emergence of industrial symbiosis [35,38,39].

- (2)

- Transition from bureaucratic to technocratic organizational structure as a premise for innovation: political economist Max Weber states that a bureaucratic organization possesses the following features: (1) Administration is carried out continuously instead of at the pleasure of any individual leader; (2) Tasks within the organization are divided into functionally distinct areas that require authorities and sanctions [40]. Based on this understanding, initial organizational structure of China’s state-owned enterprises, including Guitang, was largely bureaucratic. Bureaucracy could allow organizations to manage intensive administrative tasks and minimize uncertainties in decision making [41]. In Guitang’s case, adopting a bureaucratic management system likely helped to build structure and authority of a brand-new organization under the new-born nation’s institutional resource constraints [19]. While the centralized bureaucratic system reduces management complexity, the Guitang management became technically inclined particularly after the 1990s because of the increasing emphasis on production and efficiency internally [11,36].

- (3)

- The Communist Party system as a critical management and social linkage: similar to any state affiliated enterprise, the Guitang Group has a Communist Party Committee group in parallel with its management team (Figure A2). The Guitang Group Party Committee leads all sub-groups in the subsidiaries depending on the distribution of party members. It advises the management on decisions in all aspects and provides political and social leadership and serves as social ties. Specifically, the Party Committee is heavily involved in human resource management and ideological development of the Guitang Group [42]. The Party Committee not only serves the enterprise but also connects to the provincial and national party system through party meetings. The Party Committee at the Guitang Group has likely reinforced Guitang’s community identity as well as made new ties to other organizations nearby.

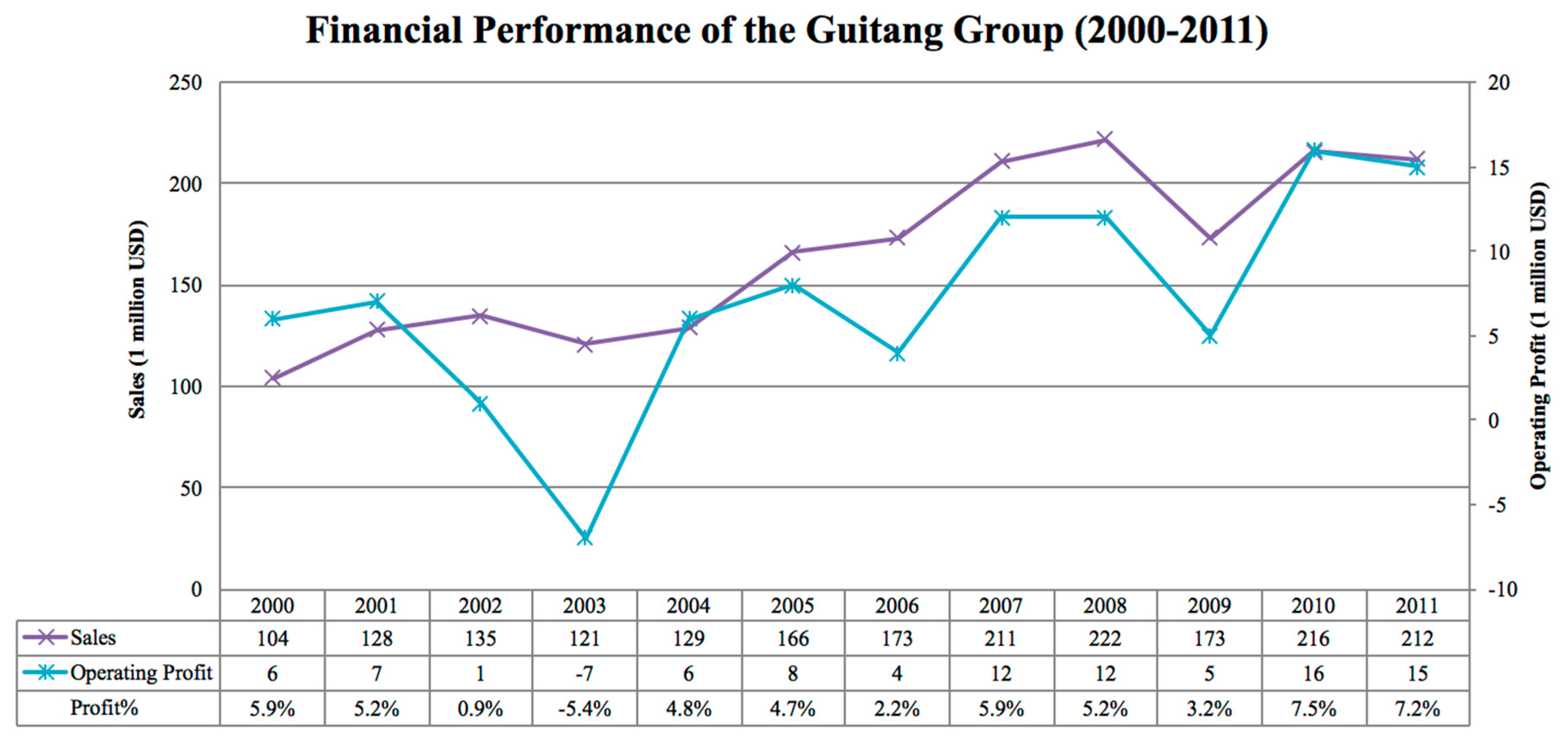

3.2.3. Financial

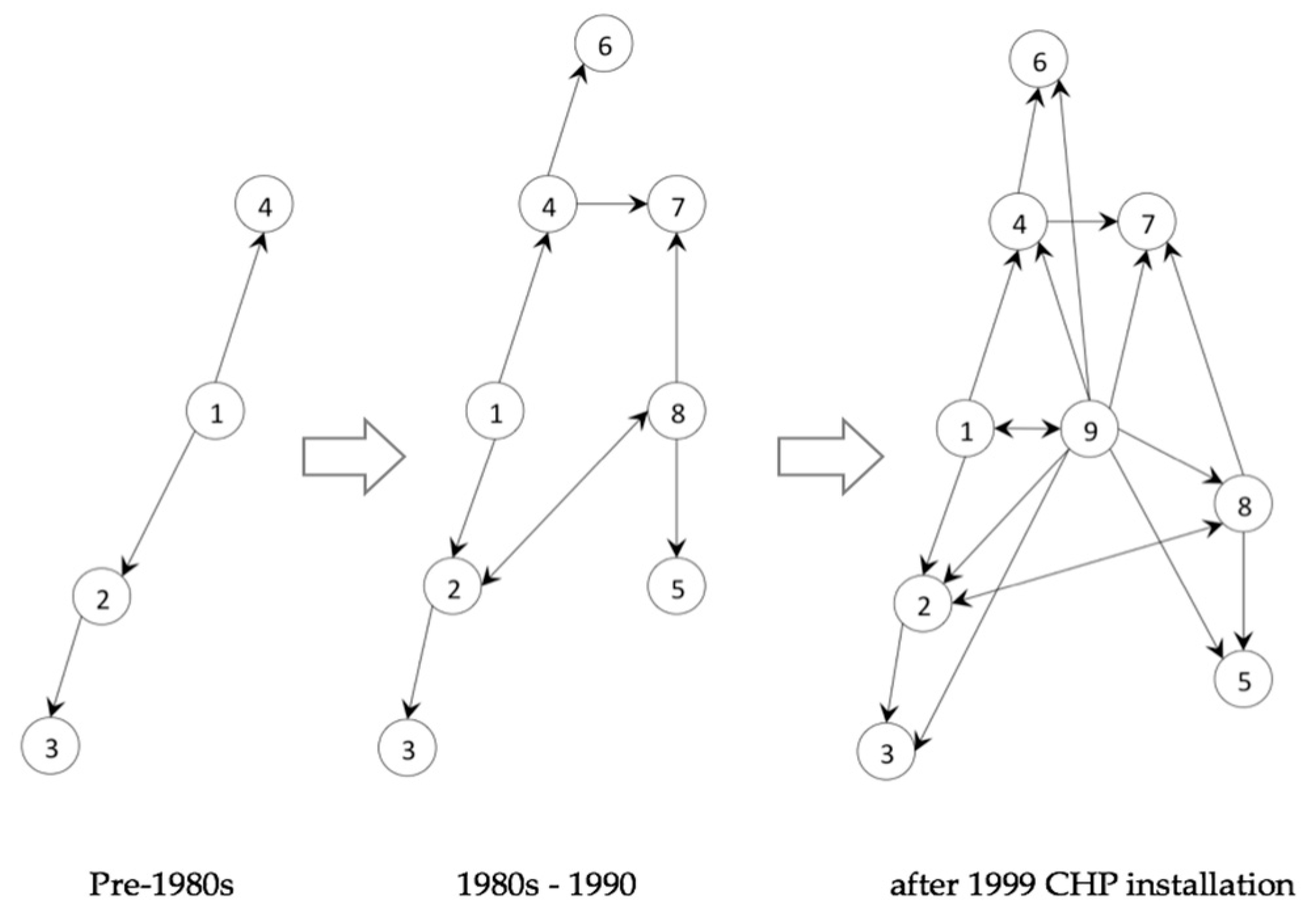

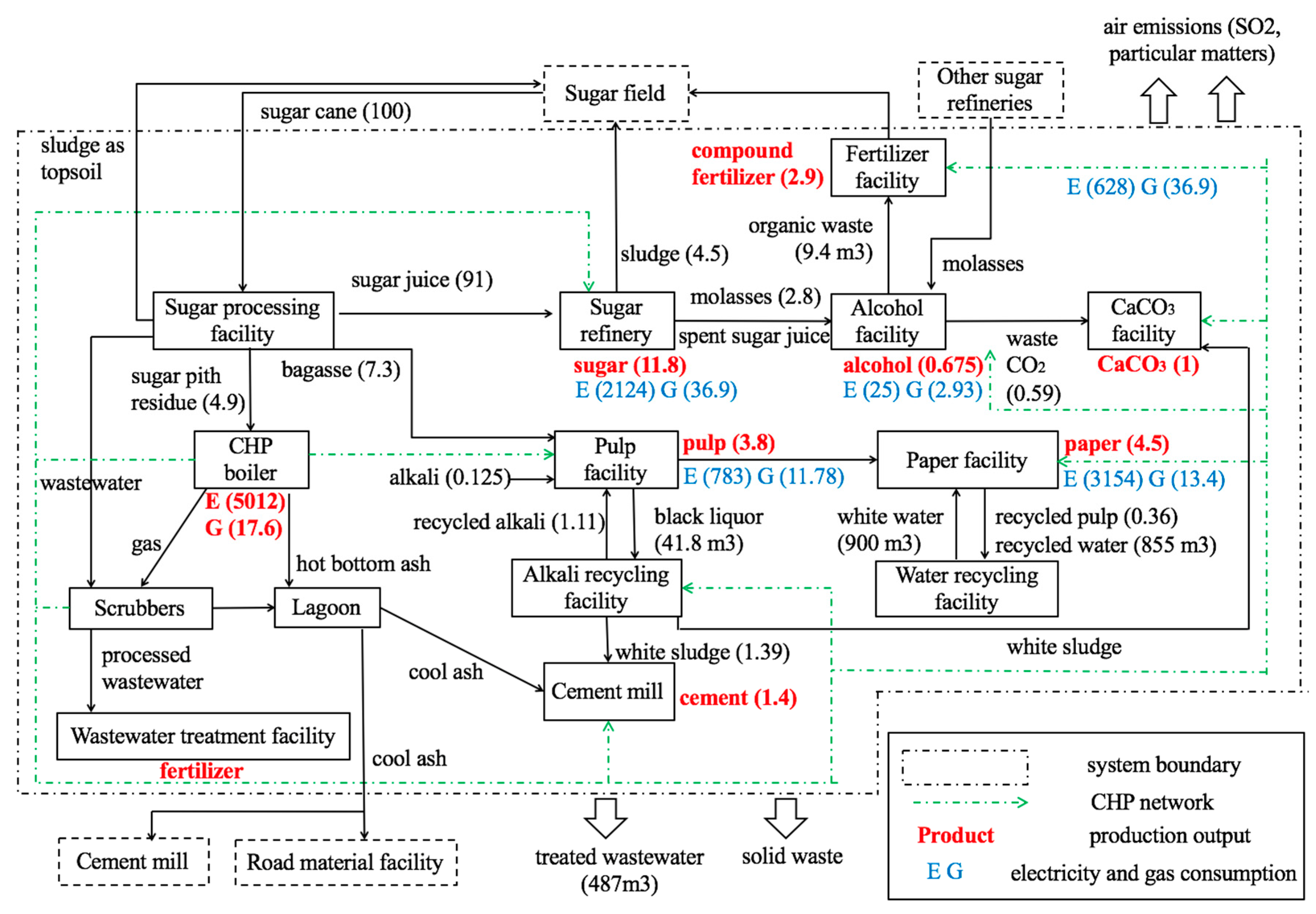

3.3. Industrial Symbiosis Network Boundary Shift

3.3.1. Internal Symbiosis

3.3.2. External Symbiosis

3.4. Policy Context for Boundary Shift

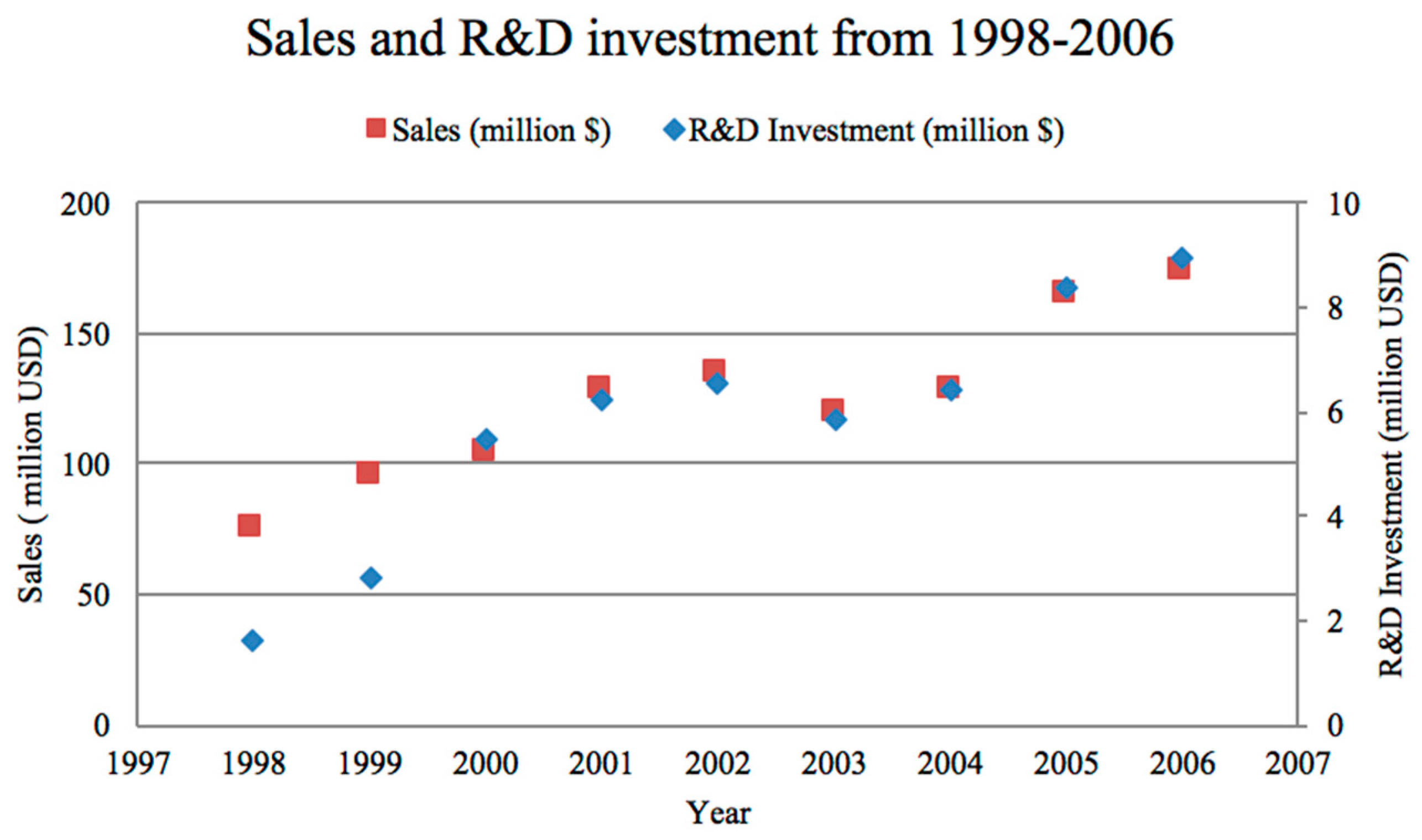

3.4.1. R&D Investment and Innovation

3.4.2. Circular Economy and the Guigang Eco-Industrial Park (EIP)

4. Discussions and Conclusions

4.1. Enabling Context

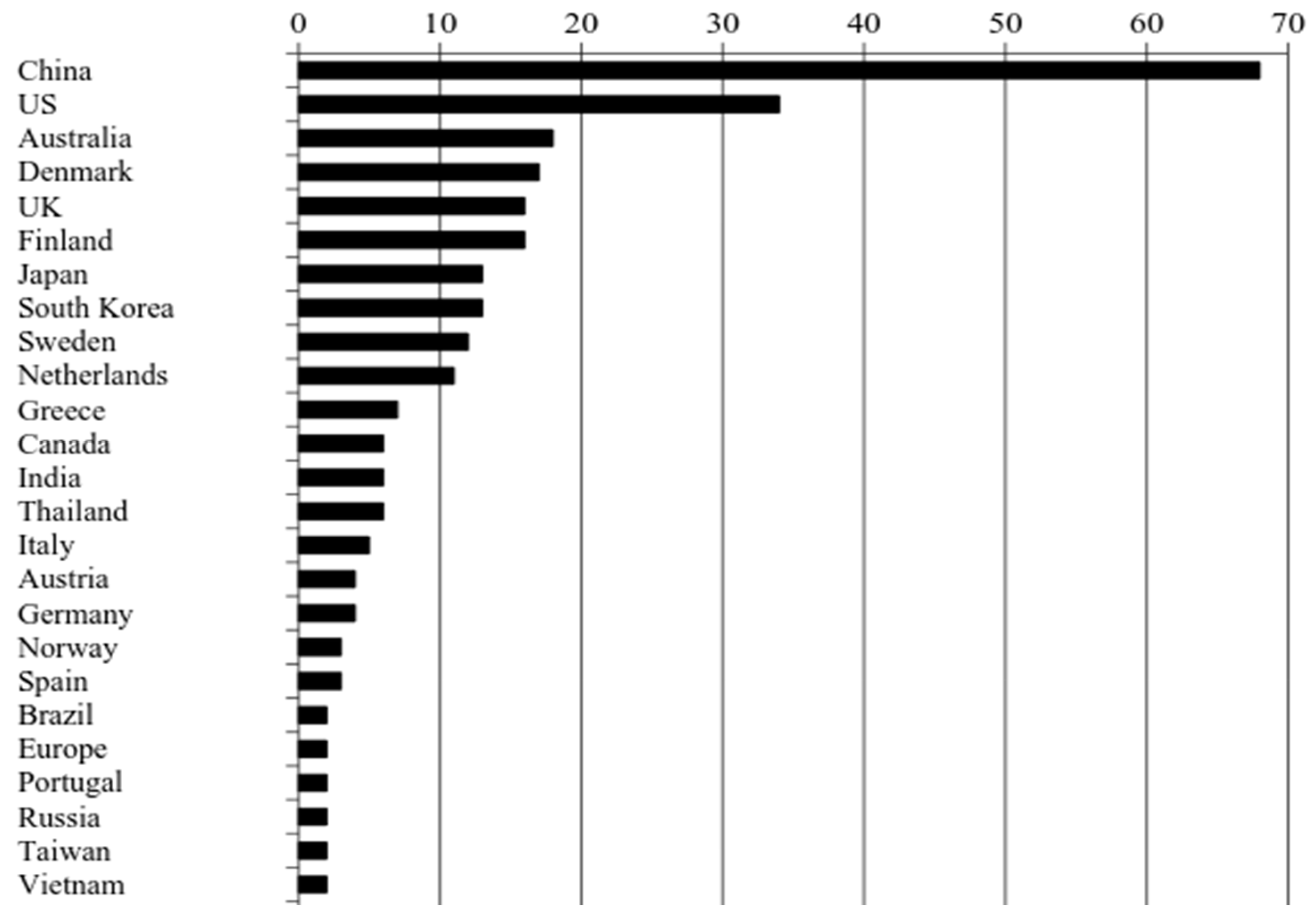

4.2. Comparative Analysis

5. Recommendations for Further Research

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Product | Unit | China | U.S. | India |

|---|---|---|---|---|

| Sugar | metric tons | 200,000 | 1,990,000 | 1,180,000 |

| Coal | metric tons | 3200 | 43,600 | 3200 |

| Electricity | GWh | 4300 | 345,100 | 4900 |

| Oil | metric tons | 120,000 | 248,920,000 | 250,000 |

| Cement | metric tons | 660,000 | 35,940,000 | 2,140,000 |

| Soda | metric tons | 88,000 | 3,550,000 | 18,000 |

| Caustic soda | metric tons | 15,000 | 2,020,000 | 6000 |

| Plant Name | Outdegree | Betweeness | ||||

|---|---|---|---|---|---|---|

| Pre–1980 | 1980s–1990 | After 1999 | Pre–1980 | 1980s–1990 | After 1999 | |

| 1: Sugar | 2 | 2 | 3 | 0 | 0 | 0 |

| 2: Pulp | 1 | 2 | 2 | 1 | 4 | 2 |

| 3: Paper | 0 | 0 | 0 | 0 | 0 | 0 |

| 4: Alcohol | 0 | 2 | 2 | 0 | 2 | 1 |

| 5: Cement | 0 | 0 | 0 | 0 | ||

| 6: Fertilizer | 0 | 0 | 0 | 0 | ||

| 7: Calcium Carbonate | 0 | 0 | 0 | 0 | ||

| 8: Alkali | 3 | 3 | 3 | 2 | ||

| 9: CHP | 8 | 3 | ||||

| Year | By-product Use Amount (Ton/Year) | Total Economic Value 1 | |||||

|---|---|---|---|---|---|---|---|

| Sludge | Sugar Residue | Molasses | Coal Ash | Pith | Yuan (1000s) | USD (1000s) | |

| 2002 | 42,741 | 127,578 | 39,100 | 139,296 | 119,525 | 405,390 | 48,978 |

| 2003 | 57,169 | 157,540 | 41,389 | 113,505 | 159,560 | 504,420 | 60,942 |

| 2004 | 38,122 | 175,024 | 26,686 | 142,887 | 97,174 | 579,300 | 69,991 |

| Time | Activity | Motivations |

|---|---|---|

| 1956 | Use sugar cane residue for fuel | Save fuel cost |

| 1970–1980 | Use waste sugar for alcohol | Improve cost margin, reduce waste |

| Use sugar cane residue for papermaking | Improve cost margin, reduce waste | |

| 1995 | Reuse alkali | Environmental law, technology improvements |

| 1996 | Water reuse | Environmental law, technology improvements (patent) |

| 1999 | Use waste alcohol for fertilizer production | Environmental law, cost margin |

| 1999 | Sludge used for free fertilizer for farmers | Environmental law |

| Alkali used for Calcium Carbonate | Environmental law, cost margin | |

| Use sugar cane residue for CHP | UNEP fund, technology improvements | |

| Reuse alcohol water | Reduce water use | |

| Reuse alkali processing water for CHP | Environmental law, reduce water use, reduce cost | |

| 2001 | Provide sugar cane residue and molasses residue to nearby plants | EIP policy |

References

- Graedel, T.; Allenby, B. Industrial Ecology and Sustainable Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2010; pp. 30–40. [Google Scholar]

- Chertow, M. Industrial Symbiosis: Literature and Taxonomy. Ann. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Chertow, M.; Park, J.Y. Scholarship and Practice in Industrial Symbiosis: 1989–2014. In Taking Stock of Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer: New York, NY, USA, 2016; Chapter 5; pp. 87–116. [Google Scholar]

- Boons, F.; Chertow, M.; Park, J.Y.; Spekkink, W.; Han, S. Industrial Symbiosis Dynamics and the Problem of Equivalence: Proposal for a Comparative Framework. J. Ind. Ecol. 2016. [Google Scholar] [CrossRef]

- Fan, Y.; Bai, B.; Qiao, Q.; Kang, P.; Zhang, Y.; Guo, J. Study on eco-efficiency of industrial parks in China based on data development analysis. J. Environ. Manag. 2017, 192, 107–115. [Google Scholar] [CrossRef] [PubMed]

- The World Bank. DataBank–World Development Indicators. Available online: http://databank.worldbank.org/data/databases.aspx (accessed on 22 May 2017).

- Zhang, L.; Yuan, Z.; Bi, J.; Zhang, B.; Liu, B. Eco-industrial parks: National pilot practices in China. J. Clean. Prod. 2010, 18, 504–509. [Google Scholar] [CrossRef]

- Guo, Y.; Tian, J.; Chertow, M.; Chen, L. Exploring Greenhouse Gas-mitigation Strategies in Chinese Eco-industrial Parks by Targeting Energy Infrastructure Stocks. J. Ind. Ecol. 2017. [Google Scholar] [CrossRef]

- Zhu, Q.; Lowe, E.; Wei, Y.; Barnes, D. Industrial Symbiosis in China: A Case Study of the Guitang Group. J. Ind. Ecol. 2007, 11, 31–42. [Google Scholar] [CrossRef]

- Zhu, Q.; Cote, R. Integrating Green Supply Chain Management into an Embryonic Eco-industrial Development: A Case Study of the Guitang Group. J. Clean. Prod. 2004, 12, 1025–1035. [Google Scholar] [CrossRef]

- Wei, Q. A Study of Circular Economy Technology Innovation Based on the Guangxi Guigang Sugar Corporation. Master’s Thesis, Guangxi University for Nationalities, Nanning, China, 2008. [Google Scholar]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef]

- Schwartz, E.J.; Steininger, K.W. Implementing nature’s lesson: The industrial recycling network enhancing regional development. J. Clean. Prod. 1997, 5, 47–56. [Google Scholar] [CrossRef]

- Jacobsen, N.; Anderberg, S. Understanding the evolution of industrial symbiotic networks: The case of Kalundborg. In Economics of Industrial Ecology: Materials, Structural Change, and Spatial Scales; Van den Bergh, J.C.J.M., Janssen, M.A., Eds.; MIT Press: Cambridge, MA, USA, 2005; pp. 313–336. [Google Scholar]

- Romero, E.; Ruiz, M. Carmen, Framework for Applying a Complex Adaptive System Approach to Model the Operation of Eco-Industrial Parks. J. Ind. Ecol. 2013, 17, 731–741. [Google Scholar]

- Chertow, M. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Fujii, M. Quantitative Assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. Environ. Sci. Technol. 2009, 43, 1271–1281. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Won, J. Ulsan Eco-industrial Park: Challenges and Opportunities. J. Ind. Ecol. 2007, 11, 11–13. [Google Scholar] [CrossRef]

- Bian, M.L. Making of the State Enterprise System in Modern China: The Dynamics of Institutional Change; Harvard University Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Ashton, W. Understanding the organization of industrial ecosystems: A social network approach. J. Ind. Ecol. 2008, 12, 34–51. [Google Scholar] [CrossRef]

- Chertow, M. Quantifying Economic and Environmental Benefits of Co-Located Firms. Environ. Sci. Technol. 2005, 39, 6535–6541. [Google Scholar] [CrossRef] [PubMed]

- Bringezu, S.; Moriguchi, Y. Material flow analysis. In A Handbook of Industrial Ecology; Edward Elgar Publishing Limited: Cheltenham, UK, 2002; pp. 79–80. Available online: https://play.google.com/books/reader?printsec=frontcover&output=reader&id=g1Kb-xizc1wC&pg=GBS.PP1 (accessed on 22 May 2017).

- Wasserman, S.; Faust, K. Social Network Analysis: Methods and Applications; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Boons, F.; Spekkink, W.; Mouzakitis, Y. The Dynamics of Industrial Symbiosis: A Proposal for a Conceptual Framework Based on a Comprehensive Literature Review. J. Clean. Prod. 2010, 19, 905–911. [Google Scholar] [CrossRef]

- Yang, S.; Feng, N. A Case Study of Industrial Symbiosis: Nanning Sugar Co., Ltd. in China. Resour. Conserv. Recycl. 2008, 52, 813–820. [Google Scholar] [CrossRef]

- Bain, A.; Ashton, W.; Chertow, M. Industrial Symbiosis and Residual Recovery in the Nanjangud Industrial Area. Resour. Optim. Initiat. 2010, 54, 1278–1287. [Google Scholar]

- Short, S.; Bocken, N.; Barlow, C.; Chertow, M. From Refining Sugar to Growing Tomatoes: Industrial Ecology and Business Model Evolution. J. Ind. Ecol. 2014, 18, 603–618. [Google Scholar] [CrossRef]

- Fiol, C.M. A semiotic Analysis of Corporate Language: Organizational Boundaries and Joint Venturing. Adm. Sci. Q. 1989, 34, 277–303. [Google Scholar] [CrossRef]

- Li, Z. Guitang, a Factory Watches a City—Large factory, City Planning, and Collectivism. Cities and Towns Construction in Guangxi. pp. 56–63. Available online: http://www.gxcic.net/webeditnew/UploadNews/201407/20140724103715528.pdf (accessed on 1 February 2017).

- The Guitang Group. The Guitang Group Annual Report. Available online: http://www.cninfo.com.cn/information/companyinfo_n.html?fulltext?szmb000833 (accessed on 1 August 2014).

- Slack, N.; Chambers, S.; Johnson, R. Operation Management, 5th ed.; Prentice Hall Press: Harlow, UK, 2007; pp. 4–5. [Google Scholar]

- Ministry of Commerce of the People’s Republic of China Special Commissioner’s Office in Nanning. Guangxi Guitang Group. Available online: http://nntb.mofcom.gov.cn/article/g/n/200606/20060602366804.shtml (accessed on 1 February 2017).

- Flexner, S. Management. In New Oxford American Dictionary; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- North, D. Five Propositions about Institutional Change; University of Michigan Press: Ann Arbor, MI, USA, 1995; pp. 15–26. [Google Scholar]

- Duan, N. Make Sunset Sunrise: Efforts for Construction of the Guigang Eco-Industrial City; Paper Presented at the April 2001 Workshop on Strategies for Industry; Chinese Research Academy of Environmental Sciences: Beijing, China, 2001; Available online: http://www.iephil.com (accessed on 1 August 2014).

- Sun, J. The People’s Republic of China Economic History; China Renmin University Press: Beijing, China, 1992. [Google Scholar]

- Meng, L. An Analysis of the Organizational Structure and the Incentive Mechanism in the State Enterprise. Master’s Thesis, Peking University, Beijing, China, 2000. [Google Scholar]

- Gibbs, D. Trust and networking in inter-firm relations: The case of eco-industrial development. Local Econ. 2003, 18, 222–236. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Do social factors really matter when companies engage in industrial symbiosis? Prog. Ind. Ecol. 2007, 4, 440–462. [Google Scholar] [CrossRef]

- Fry, B.; Raadschelders, J. Mastering Public Administration: From Max Weber to Dwight Waldo; CQ Press: Washington, DC, USA, 2013; pp. 37–38. [Google Scholar]

- Stazyk, E.; Goerdel, H. The Benefits of Bureaucracy: Public Managers’ Perceptions of Political Support, Goal Ambiguity, and Organizational Effectiveness. J. Public Adm. Res. Theory 2010, 21, 645–672. [Google Scholar] [CrossRef]

- The Guitang Group. Advice on the Improvement Plan for Party Organizational Work at the Guitang Group. In Shudao Magazine; No. 5; Guangxi Worker’s Ideological and Political Education Research Group: Nanning, China, 1995. [Google Scholar]

- Chen, X. Eco-Industrial Park Evaluation System and Case Studies. Master’s Thesis, Guangxi Normal University, Guilin, China, 2007. [Google Scholar]

- Csardi, G. Igraph-a Package for Network Analysis. Available online: http://www.r-project.org/conferences/useR-2008/slides/Csardi.pdf (accessed on 1 August 2014).

- Freeman, L.C. A Set of Measures of Centrality Based on Betweeness. Sociometry 1977, 40, 35–41. [Google Scholar] [CrossRef]

- Korhonen, J. Co-production of heat and power: An anchor tenant of a regional industrial ecosystem. J. Clean. Prod. 2001, 9, 509–517. [Google Scholar] [CrossRef]

- Schumpeter, J.A. Business Cycles: A Theoretical, Historical and Statistical Analysis of the Capital Process; McGraw-Hill Book Company: New York, NY, USA, 1939. [Google Scholar]

- Enos, J.L. Invention and Innovation in the Petroleum Refining Industry; National Bureau of Economic Research: Cambridge, MA, USA, 1962; pp. 299–322. Available online: http://www.nber.org/chapters/c2124.pdf (accessed on 1 August 2014).

- Mansfield, E.; Rapoport, J.; Schnee, J.; Wagner, S.; Hamburger, M. Research and Innovation in the Modern Corporation; Lightning Source Incorporated: La Vergne, TN, USA, 1972. [Google Scholar]

- Mueser, R. Identifying Technical Innovations. IEEE Trans. Eng. Manag. 1985, 32, 158–163. [Google Scholar] [CrossRef]

- Guigang National Eco-Industrial Park (Sugar Manufacturing) Project Leadership Committee Office. Design and Development of the Guigang National Eco-Industrial Park (Sugar Manufacturing). Available online: http://d.g.wanfangdata.com.hk/Conference_6886364.aspx (accessed on 1 August 2014).

- Lowe, E.A. Eco-industrial Handbook for Asian Developing Countries. Available online: http://www.indigodev.com/Handbook.html (accessed on 1 August 2014).

| Manufacturing Process | Guitang Group (China) | Nanning Sugar Co. (China) | Nanjangud (India) | British Sugar (the UK) |

|---|---|---|---|---|

| By-Products Use | ||||

| Sampling & cleaning | Soil mix → topsoil | Sludge → fertilizer | Organic material → Compost | Soil mix → topsoil and aggregate |

| Slicing & diffusion & squeezing | Bagasse → pulp and paper production; CHP feed | Bagasse → pulp production | Pulp → animal feed | |

| Purification | Sludge/mud → cement mill; Waste CaCO3 → CaCO3 production | Wet ash → sale; Coal ash → concrete hollow blocks; Stone residue → paving; Dry ash → sale | Press mud → alcohol production | Precipitate → lime |

| Evaporation | Heat → CHP | Steam → craft water tank for reuse | Heat → tomato horticulture | |

| Sugar cooking & molasses separation | Molasses → sale; Molasses → alcohol production | Molasses → alcohol production | Molasses → sale; Molasses → alcohol production | |

| Crystallization & centrifugation | Residual resin → betaine, raffinate | |||

| Sugar storage | Feed → vinasse, bioethanol, and liquefied CO2 through fermentation and distillation | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Chertow, M. Organizational Boundary Change in Industrial Symbiosis: Revisiting the Guitang Group in China. Sustainability 2017, 9, 1085. https://doi.org/10.3390/su9071085

Shi L, Chertow M. Organizational Boundary Change in Industrial Symbiosis: Revisiting the Guitang Group in China. Sustainability. 2017; 9(7):1085. https://doi.org/10.3390/su9071085

Chicago/Turabian StyleShi, Lin, and Marian Chertow. 2017. "Organizational Boundary Change in Industrial Symbiosis: Revisiting the Guitang Group in China" Sustainability 9, no. 7: 1085. https://doi.org/10.3390/su9071085