Clean Technologies in Agriculture—How to Prioritise Measures?

Abstract

:1. Introduction

1.1. Examples of Clean Technologies in Agriculture

1.2. When Is a Technology a Clean Technology?

1.3. Adoption of Clean Technologies

1.4. Knowledge Gap

2. Materials and Methods

2.1. Selection of Clean Technologies

2.2. Purposes and Properties of Selected Clean Technologies

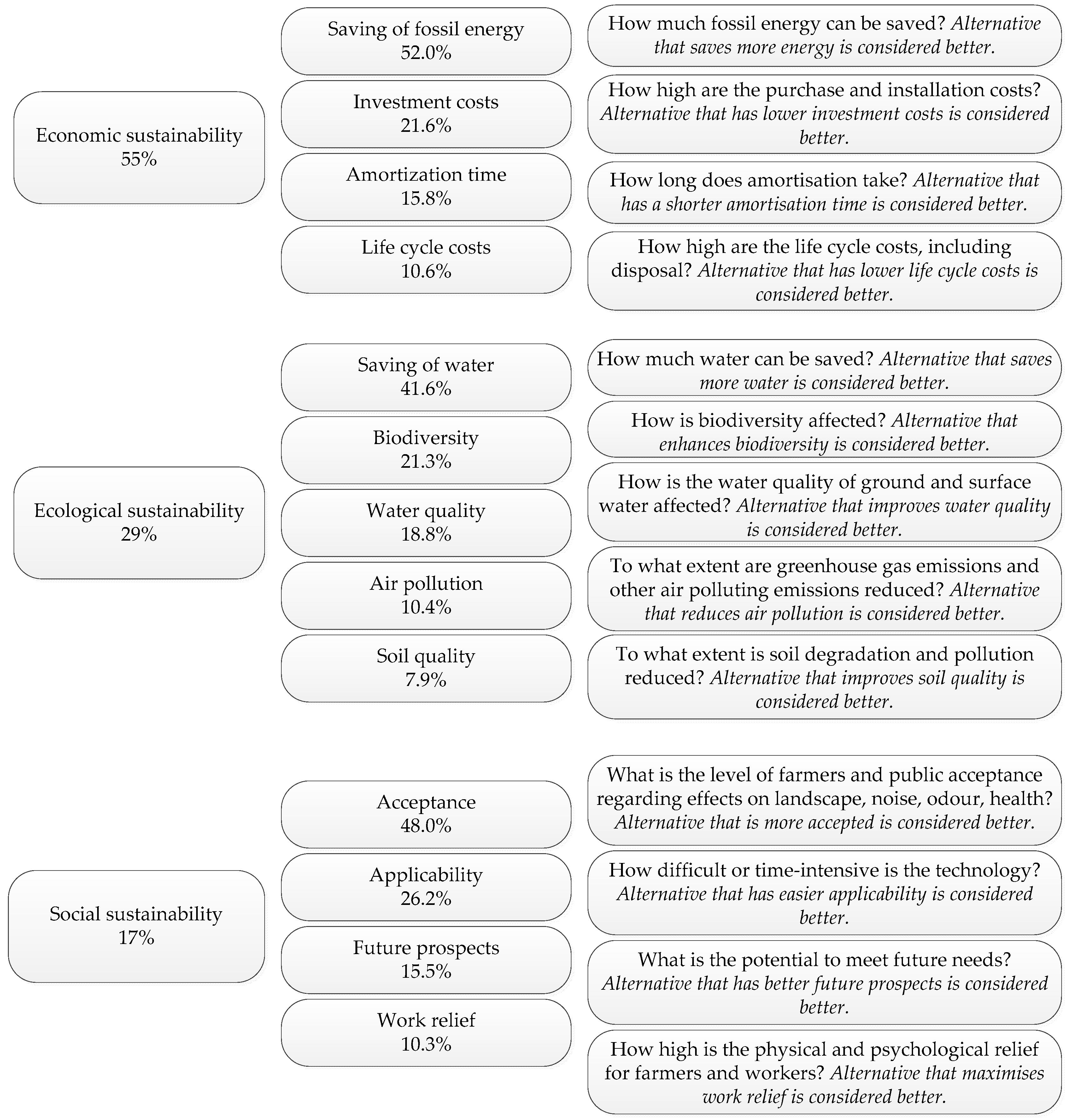

2.3. Design of the MCDA

2.4. Evaluation of Clean Technologies

2.5. Sensitivity Analysis

3. Results

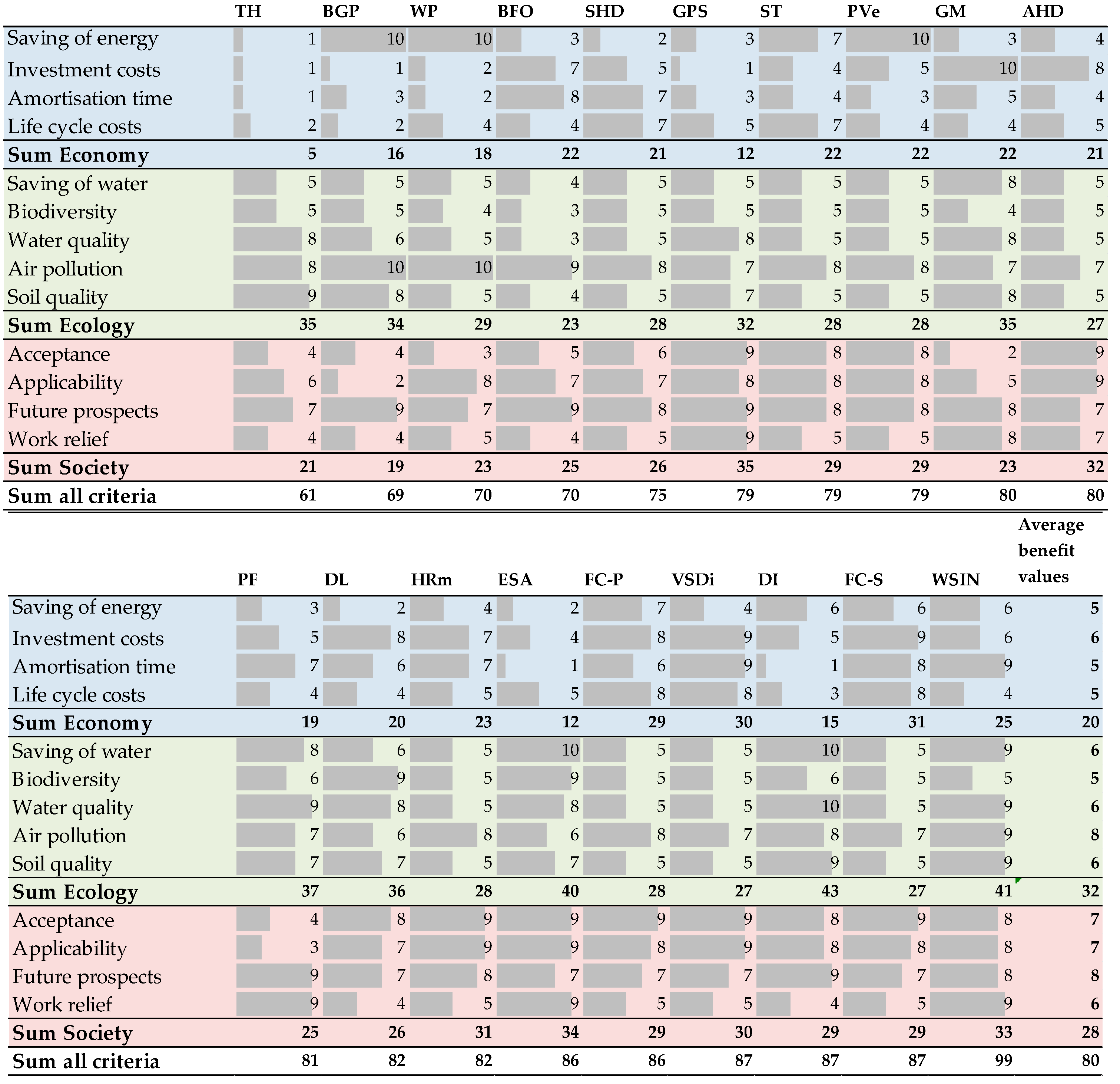

3.1. Sustainability Performance of Clean Technologies

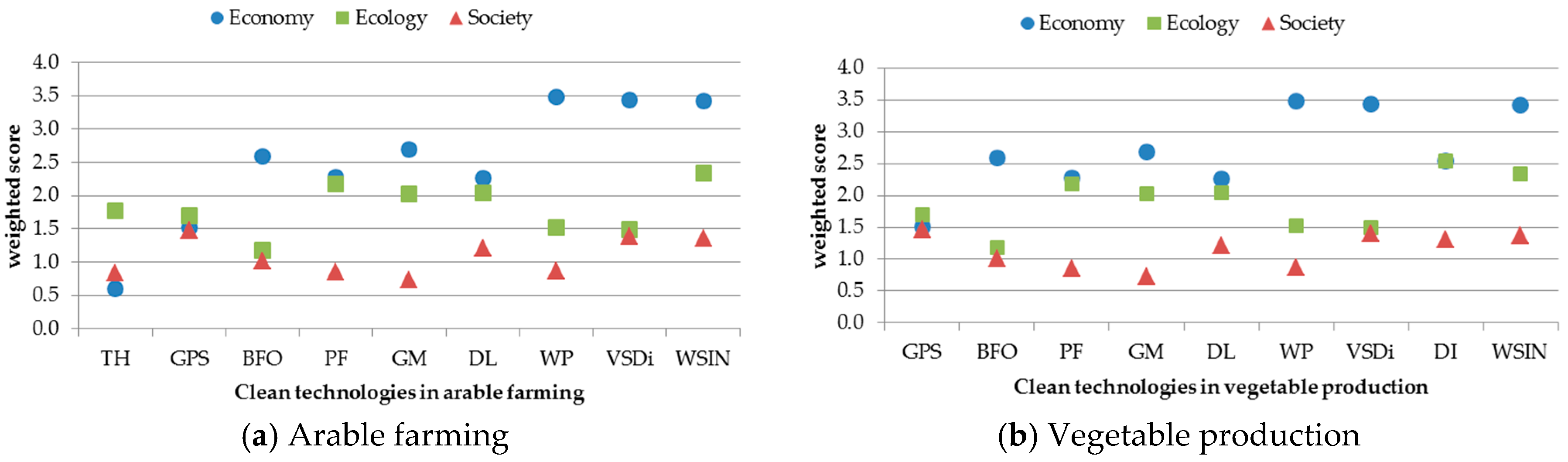

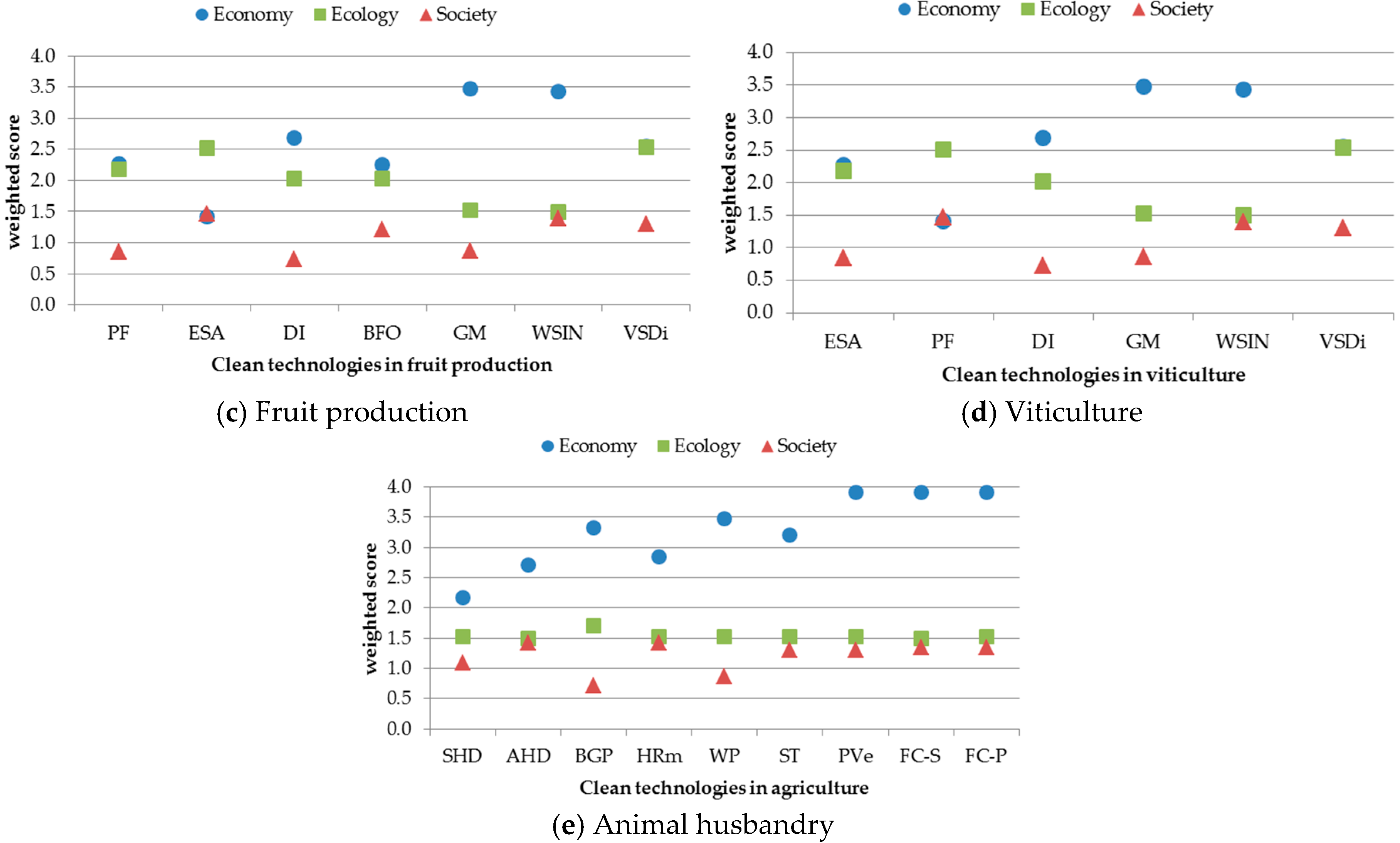

3.2. MCDA Results

3.3. Sensitivity Analysis

4. Discussion

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015; pp. 1–41. [Google Scholar]

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; et al. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; pp. 811–922. [Google Scholar]

- Morawicki, R.O. Handbook of Sustainability for the Food Sciences; John Wiley & Sons: West Sussex, UK, 2012. [Google Scholar]

- Wise, T.A. Can We Feed the World in 2050? A Scoping Paper to Assess the Evidence; Tufts University: Medford, OR, USA, 2013. [Google Scholar]

- Clift, R. Clean technology—An introduction. J. Chem. Technol. Biotechnol. 1995, 62, 321–326. [Google Scholar] [CrossRef]

- Veisi, H. Exploring the determinants of adoption behaviour of clean technologies in agriculture: A case of integrated pest management. Asian J. Technol. Innov. 2012, 20, 67–82. [Google Scholar] [CrossRef]

- Robertson, G.P.; Swinton, S.M. Reconciling agricultural productivity and environmental integrity: A grand challenge for agriculture. Front. Ecol. Environ. 2005, 3, 38–46. [Google Scholar] [CrossRef]

- Urquhart, P. IPM and the Citrus Industry in South Africa; International Institute for Environment and Development (IIED), Sustainable Agriculture and Rural Livelihoods Programme: London, UK, 1999; Volume Gatekeeper Series SA86. [Google Scholar]

- Abbasi, T.; Tauseef, S.; Abbasi, S. A Brief History of Anaerobic Digestion and “Biogas”. In Biogas Energy; Springer: New York, NY, USA, 2012; pp. 11–23. [Google Scholar]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Lebuhn, M.; Munk, B.; Effenberger, M. Agricultural biogas production in Germany-from practice to microbiology basics. Energy Sustain. Soc. 2014, 4, 1–21. [Google Scholar] [CrossRef]

- Dechezleprêtre, A.; Glachant, M.; Ménière, Y. The Clean Development Mechanism and the international diffusion of technologies: An empirical study. Energy Policy 2008, 36, 1273–1283. [Google Scholar] [CrossRef] [Green Version]

- Larson, D.F.; Dinar, A.; Frisbie, J.A. Agriculture and the clean development mechanism. Policy Res. Work. Pap. 2011, 5621, 1–42. [Google Scholar]

- Knothe, G.; Krahl, J.; Van Gerpen, J. The Biodiesel Handbook, 2nd ed.; Elsevier: Urbana, IL, USA, 2015. [Google Scholar]

- Duffield, J.A.; Collins, K. Evolution of Renewable Energy Policy. Choices 2006, 21, 9–14. [Google Scholar]

- Morawicki, R.O. A biobased economy. In Handbook of Sustainability for the Food Sciences; John Wiley & Sons: Chichester, UK, 2012; pp. 343–360. [Google Scholar]

- Randolph, J.; Masters, G.M. Energy for Sustainability: Technology, Planning, Policy; Island Press: Washington, DC, USA, 2008. [Google Scholar]

- Zah, R.; Böni, H.; Gauch, M.; Hischier, R.; Lehmann, M.; Wäger, P. Ökobilanz von Energieprodukten: Ökologische Bewertung von Biotreibstoffen; Bundesamt für Energie, Bundesamt für Umwelt, Bundesamt für Landwirtschaft: Bern, Switzerland, 2007. [Google Scholar]

- Russo, V.; Paola, L.D.; Piemonte, V.; Basile, A.; Falco, M.D.; Giuliani, A. Are biofuels sustainable? An LCA/multivariate perspective on feedstocks and processes. Asia-Pac. J. Chem. Eng. 2016, 11, 650–663. [Google Scholar] [CrossRef]

- Liska, A.J.; Yang, H.S.; Bremer, V.R.; Klopfenstein, T.J.; Walters, D.T.; Erickson, G.E.; Cassman, K.G. Improvements in life cycle energy efficiency and greenhouse gas emissions of corn-ethanol. J. Ind. Ecol. 2009, 13, 58–74. [Google Scholar] [CrossRef]

- Tilman, D.; Socolow, R.; Foley, J.A.; Hill, J.; Larson, E.; Lynd, L.; Pacala, S.; Reilly, J.; Searchinger, T.; Somerville, C.; et al. Energy. Beneficial biofuels—The food, energy, and environment trilemma. Science 2009, 325, 270–271. [Google Scholar] [CrossRef] [PubMed]

- Smulders, S.; Bretschger, L.; Egli, H. Economic Growth and the Diffusion of Clean Technologies: Explaining Environmental Kuznets Curves; ETH Eidgenössische Technische Hochschule Zürich: Zürich, Switzerland, 2005. [Google Scholar]

- Amer, M.; Daim, T.U. Selection of renewable energy technologies for a developing county: A case of Pakistan. Energy Sustain. Dev. 2011, 15, 420–435. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Ghoniem, A.F. Needs, resources and climate change: Clean and efficient conversion technologies. Prog. Energy Combust. Sci. 2011, 37, 15–51. [Google Scholar] [CrossRef]

- Kamel, S.; Dahl, C. The economics of hybrid power systems for sustainable desert agriculture in Egypt. Energy 2005, 30, 1271–1281. [Google Scholar] [CrossRef]

- Hoppe, R.A.; MacDonald, J.M. Updating the ERS Farm Typology; United States Department of Agriculture: Washington, DC, USA, 2013. [Google Scholar]

- Andersen, E.; Verhoog, A.D.; Elbersen, B.S.; Godeschalk, F.E.; Koole, B. A Multidimensional Farming System Typology; SEAMLESS Report No. 12, SEAMLESS Integrated Project, EU 6th Framework Programme; SEAMLESS: Wageningen, The Netherlands, 2006; pp. 1–30. [Google Scholar]

- AgroCleanTech AgroCleanTech. Energie und Klimaschutzagentur für die Landwirtschaft. Available online: http://www.agrocleantech.ch/de/ (accessed on 13 July 2017).

- Hardman, P.; Blignaut, A.; Fuller, S. Confronting Climate Change: Phase III begins. SA Fruit J. 2014, 13, 8–9. [Google Scholar]

- Wettstein, S.; Muir, K.; Scharfy, D.; Stucki, M. The environmental mitigation potential of photovoltaic-powered irrigation in the production of South African maize. 2017; submitted. [Google Scholar]

- Geldermann, J.; Lerche, N. Leitfaden zur Anwendung von Methoden der Multikriteriellen Entscheidungsunterstützung. Methode: Promethee; Georg-August-Universität Göttingen: Göttingen, Germany, 2014. [Google Scholar]

- Suri, K. Political economy of agrarian distress. Econ. Polit. Wkly. 2006, 41, 1523–1529. [Google Scholar]

- Postel, S.L. Entering an era of water scarcity: The challenges ahead. Ecol. Appl. 2000, 10, 941–948. [Google Scholar] [CrossRef]

- Krauss, J.; Bommarco, R.; Guardiola, M.; Heikkinen, R.K.; Helm, A.; Kuussaari, M.; Lindborg, R.; Öckinger, E.; Pärtel, M.; Pino, J. Habitat fragmentation causes immediate and time-delayed biodiversity loss at different trophic levels. Ecol. Lett. 2010, 13, 597–605. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations (FAO). The State of the World’s Land and Water Resources for Food and Agriculture (SOLAW): Managing Systems at Risk; Earthscan: London, UK, 2011. [Google Scholar]

- Gibbs, H.; Salmon, J. Mapping the world’s degraded lands. Appl. Geogr. 2015, 57, 12–21. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food security: The challenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Emmann, C.H.; Arens, L.; Theuvsen, L. Individual acceptance of the biogas innovation: A structural equation model. Energy Policy 2013, 62, 372–378. [Google Scholar] [CrossRef]

- Saaty, R.W. The analytic hierarchy process—What it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Barnard, S. Analytic Hierarchy Process, AHP. Available online: http://www.scbuk.com/ahp.html (accessed on 1 August 2016).

- Sauter, J.; Moriz, C.; Honegger, S.; Anken, T.; Albisser, G. Schleppschlauch-und Breitverteiler im Vergleich; Forschungsanstalt Agroscope Reckenholz Tänikon: Ettenhausen, Switzerland, 2010; pp. 1–8. [Google Scholar]

- Schreiber, M. Kraftstoffverbrauch beim Einsatz von Ackerschleppern im Besonderen Hinblick auf CO2-Emissionen; Universität Hohenheim, Institut für Agrartechnik: Deutschland, Germany, 2006. [Google Scholar]

- Nydegger, F.; Wirleitner, G. Qualitätsheu Durch Effektive und Kostengünstige Belüftung; Forschungsanstalt Agroscope Reckenholz-Tänikon (ART): Tänikon, Switzerland, 2009. [Google Scholar]

- Wieviel Strom wird Eine Kleinwindkraftanlage Gegebener Leistung Erzeugen? Available online: https://www.klein-windkraftanlagen.com/strom-leistung-ertrag-kleinwindkraftanlage/ (accessed on 1 February 2017).

- Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. Landwirtschaft im Umbruch—Herausforderungen und Lösungen. KTBL-Vortragstagung vom 18. bis 19. März 2009 in Goslar; KTBL: Darmstadt, Germany, 2009. [Google Scholar]

- Meyer, M. Solarbauern-Solarrechner Thermisch. Available online: http://www.solarbauern.ch/solarrechner_thermie.php (accessed on 12 July 2017).

- Brookes, G.; Barfoot, P. Key environmental impacts of global genetically modified (GM) crop use 1996–2011. GM Crops Food 2013, 4, 109–119. [Google Scholar] [CrossRef] [PubMed]

- AgroCleanTech AG. Energieagentur St. Gallen, St. Galler Bauernverband Energieeffizienz in der Landwirtschaft. Steuerung bei der Heubelüftung. Available online: http://www.agrocleantech.ch/images/Energieeffizienz/Strom_sparen/Downloads/d/AD_Faktenblatt_FU_Heubelftung.pdf (accessed on 1 February 2017).

- Rüegg, J.; Total, R. Dropleg-Applikationstechnik für Zielgerichteten Pflanzenschutz in Reihenkulturen. Einführung und Hinweise für Produzenten und Berater; Agroscope: Wädenswil, Switzerland, 2013. [Google Scholar]

- AgroCleanTech AG. Wärmerückgewinnung aus der Milchkühlung. Available online: http://www.agrocleantech.ch/images/Energieeffizienz/Strom_sparen/Downloads/d/151103%20WRGM%20-%20Faktenblatt%20DE.pdf (accessed on 1 February 2017).

- AgroCleanTech AG. Leistungsgesteuerte Vakuumpumpen bei Melkmaschinen. Available online: http://www.agrocleantech.ch/images/Energieeffizienz/Strom_sparen/Downloads/d/150722%20Faktenblatt%20Leistungsgesteuerte%20Vakuumpumpe%20mit%20FU.pdf (accessed on 1 February 2017).

- Upton, J.; Murphy, M.; French, P.; Dillon, P. Dairy farm energy consumption. In Proceedings of the Teagasc National Dairy Conference 2010, Charleville and MullingarIreland, 17–18 December 2010; pp. 87–97. [Google Scholar]

- Hebeisen, T.; Ballmer, T. Potential der Tröpfchenbewässerung bei Kartoffeln. Available online: https://www.agroscope.admin.ch/dam/agroscope/de/dokumente/aktuell/Veranstaltungen/a-nachhaltigkeitstagung/2014/08-hebeisen.pdf.download.pdf/08_Praesentation_Thomas_Hebeisen_20140123.pdf (accessed on 1 February 2017).

- Teitel, M.; Levi, A.; Zhao, Y.; Barak, M.; Bar-lev, E.; Shmuel, D. Energy saving in agricultural buildings through fan motor control by variable frequency drives. Energy Build. 2008, 40, 953–960. [Google Scholar] [CrossRef]

- AgroCleanTech AG. Energieagentur St. Gallen, St. Galler Bauernverband Frequenzumformer bei der Stallklimatisierung. Available online: http://www.agrocleantech.ch/images/Energieeffizienz/Strom_sparen/Downloads/d/AD_Faktenblatt_FU_Stallklimatisierung.pdf (accessed on 1 February 2017).

- Majsztrik, J.C.; Price, E.W.; King, D.M. Environmental benefits of wireless sensor-based irrigation networks: Case-study projections and potential adoption rates. HortTechnology 2013, 23, 783–793. [Google Scholar]

- Ernst Basler + Partner AG. Finanzierung von Biogasanlagen in der Landwirtschaft. Finanzierungslösungen und Finanzierungsquellen; Ernst Basler + Partner AG: Zollikon, Switzerland, 2007; pp. 1–44. [Google Scholar]

- Breinesberger, J. Pflanzenöl-ein interessanter Treibstoff für die Landwirtschaft. In Biotreibstoffe auf dem Prüfstand; Österreichischer Biomasseverband: Vienna, Austria, 2012; pp. 48–51. [Google Scholar]

- Pöllinger, A. Heutrocknungsverfahren im Vergleich. Alpenländisches Expertenforum 2014, 19, 35–44. [Google Scholar]

- Preise für Kleinwindkraftanlagen—So Investiert Man Richtig. Available online: https://www.klein-windkraftanlagen.com/allgemein/preise-fuer-kleinwindkraftanlagen-fehlinvestitionen-vermeiden/ (accessed on 1 February 2017).

- Rüegg, J.; Total, R.; Holpp, M.; Bachmann, T. Satelliten-Gesteuerte Lenksysteme im Feldgemüsebau. Stand der Technik, Praktische Erfahrungen und Empfehlungen; Flugschrift GPS; Forschungsanstalt Agroscope Changins-Wädenswil ACW: Wädenswil, Switzerland, 2011; pp. 1–14. [Google Scholar]

- Bundesamt für Energie Wie viel Kostet Eine Solaranlage? Available online: https%3A%2F%2Fwww.energieschweiz.ch%2Fpage%2Fde-ch%2Fkosten-einer-solaranlage (accessed on 12 July 2017).

- O. KOHLER AG. Merkblatt Photovoltaik. Available online: http://www.kohler-ag.ch/bilder/Merkblatt_Photovoltaik.pdf (accessed on 1 February 2017).

- Schiefer, C.; Schubert, R.; Pölitz, B.; Kühne, A.; Westphal, K.; Steinhöfel, O.; Schaerff, A. Untersuchungen zum Anbau von GVO in Sachsen; Sächsische Landesanstalt für Landwirtschaft: Dresden, Germany, 2008; pp. 1–121. [Google Scholar]

- eBee: A $12,000 Foamie (!). Available online: http://www.modelairplanenews.com/ebee-12000-foamie/ (accessed on 1 February 2017).

- Dropleg Schlepprohre von Lechler. Available online: http://www.spritzenteile.de/Fluessigduengung/Schleppschlaeuche-Schlepprohr/Dropleg/ (accessed on 12 July 2017).

- Pregler, B. Product Review: Electrostatic Sprayers. Available online: https://www.winebusiness.com/content/file/Sep09_ElectroStatic-Spray.pdf (accessed on 12 July 2017).

- CONRAD Frequenzumrichter. Available online: http://www.conrad.ch/ce/de/overview/1101123/Frequenzumrichter (accessed on 12 July 2017).

- Belau, T.; Fröba, N. Investitionen und Verfahrenskosten für die Feldbewässerung—Ergebnisse der KTBL-Arbeitsgruppe,, Feldbewässerung “. Landbauforsch-Sonderheft 2009, 328, 69–72. [Google Scholar]

- Keshtgary, M.; Deljoo, A. An efficient wireless sensor network for precision agriculture. Can. J. Multimed. Wirel. Netw. 2012, 3, 1–5. [Google Scholar]

- Baumgartner, H. Gülle auf die Felder statt in die Luft. Umwelt Mag. 2014, 2, 22–27. [Google Scholar]

- Rechnet Sich Eine Kleinwindkraftanlage? Available online: https://www.klein-windkraftanlagen.com/allgemein/rechnet-sich-eine-kleinwindkraftanlage/ (accessed on 1 February 2017).

- Sidler, A.U.; Merz, A. Praktischer Leitfaden Solarenergie Landwirtschaft. Der Weg zur Nachhaltigen Nutzung Vorhandener EnergieRessourcen; Schweizerischer Bauernverband: Brugg, Switzerland, 2008; pp. 1–20. [Google Scholar]

- May, M.J. Economic consequences for UK farmers of growing GM herbicide tolerant sugar beet. Ann. Appl. Biol. 2003, 142, 41–48. [Google Scholar] [CrossRef]

- Seiler, E.; Bilitewski, B.; Woidasky, J. Recycling von Windkraftanlagen. Available online: https://www.ict.fraunhofer.de/content/dam/ict/de/documents/ue_klw_Poster_Recycling%20von%20Windkraftanlagen.pdf (accessed on 12 July 2017).

- Lutz, H.-P. Thermische Solaranlagen zur Warmwasserbereitung und Heizungsunterstützung; Wirtschaftsministerium Baden-Württemberg: Stuttgart, Deutschland, 2008; pp. 1–40. [Google Scholar]

- Solar Thermal Panels System Lifespan, Maintenance and Warranties. Available online: https://www.renewableenergyhub.co.uk/solar-thermal-information/solar-thermal-system-lifespan-maintenance-and-warranties.html (accessed on 12 July 2017).

- Der Bundesrat. Bericht zu Kosten-Nutzen von Gentechnisch Veränderten Pflanzen; Der Bundesrat: Berne, Switzerland, 2014; pp. 1–100. [Google Scholar]

- Inverters-FR-E700. Available online: https://gb3a.mitsubishielectric.com/fa/en/products/drv/inv/local/e700 (accessed on 12 July 2017).

- Kabashima, J.; Giles, D.; Parrella, M. Electrostatic sprayers improve pesticide efficacy in greenhouses. Calif. Agric. 1995, 49, 31–35. [Google Scholar] [CrossRef]

- Ballmer, T.; Hebeisen, T.; Wüthrich, R.; Gut, F. Potenzial der Tröpfchenbewässerung im Kartoffelbau bei veränderten Klimabedingungen. Agrar Schweiz 2012, 3, 244–251. [Google Scholar]

- Erickson, W.P.; Johnson, G.D.; David, P., Jr. A Summary and Comparison of Bird Mortality from Anthropogenic Causes with an Emphasis on Collisions; United States Department of Agriculture, Forest Service, Pacific Southwest Research Station: Albany, CA, USA, 2005. [Google Scholar]

- Kunz, T.H.; Arnett, E.B.; Erickson, W.P.; Hoar, A.R.; Johnson, G.D.; Larkin, R.P.; Strickland, M.D.; Thresher, R.W.; Tuttle, M.D. Ecological impacts of wind energy development on bats: Questions, research needs, and hypotheses. Front. Ecol. Environ. 2007, 5, 315–324. [Google Scholar] [CrossRef]

- Hilbeck, A. Implications of transgenic, insecticidal plants for insect and plant biodiversity. Perspect. Plant Ecol. Evol. Syst. 2001, 4, 43–61. [Google Scholar] [CrossRef]

- Postel, S.; Polak, P.; Gonzales, F.; Keller, J. Drip irrigation for small farmers: A new initiative to alleviate hunger and poverty. Water Int. 2001, 26, 3–13. [Google Scholar] [CrossRef]

- Möller, K.; Stinner, W. Effects of different manuring systems with and without biogas digestion on soil mineral nitrogen content and on gaseous nitrogen losses (ammonia, nitrous oxides). Eur. J. Agron. 2009, 30, 1–16. [Google Scholar] [CrossRef]

- Law, S.E. Agricultural electrostatic spray application: A review of significant research and development during the 20th century. J. Electrost. 2001, 51, 25–42. [Google Scholar]

- Hübener, R. Improved water application in irrigated agriculture. Verbesserte Methoden der Wasserverteilung im Bewässerungslandbau. Tropenlandwirt Z. Für Landwirtsch. Trop. Subtrop. 1988, 89, 143–163. [Google Scholar]

- Bundesamts für Umwelt. Leitfaden zur Vermeidung und Verringerung von Ammoniakemissionen aus landwirtschaftlichen Quellen; BAFU: Bern, Switzerland, 2014. [Google Scholar]

- Smith, P.; Martino, D.; Cai, Z.; Gwary, D.; Janzen, H.; Kumar, P.; McCarl, B.; Ogle, S.; O’Mara, F.; Rice, C.; et al. Greenhouse gas mitigation in agriculture. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2008, 363, 789–813. [Google Scholar] [CrossRef] [PubMed]

- Beratergruppe Boden Dünguing Umwelt BDU; Beratungszentrale LBL; Lindau, Service romand de vulgarisation SRVA. Ammoniakverluste bei der Hofdünger-Ausbringung; UFA-Revue: Winterthur, Switzerland, 2005. [Google Scholar]

- Möller, K. Influence of different manuring systems with and without biogas digestion on soil organic matter and nitrogen inputs, flows and budgets in organic cropping systems. Nutr. Cycl. Agroecosyst. 2009, 84, 179–202. [Google Scholar] [CrossRef]

- Fargione, J.; Hill, J.; Tilman, D.; Polasky, S.; Hawthorne, P. Land clearing and the biofuel carbon debt. Science 2008, 319, 1235–1238. [Google Scholar] [CrossRef] [PubMed]

- Bell, D.; Gray, T.; Haggett, C. The “social gap” in wind farm siting decisions: Explanations and policy responses. Environ. Polit. 2005, 14, 460–477. [Google Scholar] [CrossRef]

- Rogers, A.L.; Manwell, J.F.; Wright, S. Wind Turbine Acoustic Noise. Renewable Energy Research Laboratory; University of Massachusetts at Amherst: Amherst, MA, USA, 2006. [Google Scholar]

- Brudermann, T.; Reinsberger, K.; Orthofer, A.; Kislinger, M.; Posch, A. Photovoltaics in agriculture: A case study on decision making of farmers. Energy Policy 2013, 61, 96–103. [Google Scholar] [CrossRef]

- Lucht, J.M. Public acceptance of plant biotechnology and GM crops. Viruses 2015, 7, 4254–4281. [Google Scholar] [CrossRef] [PubMed]

- Aubert, B.A.; Schroeder, A.; Grimaudo, J. IT as enabler of sustainable farming: An empirical analysis of farmers’ adoption decision of precision agriculture technology. Decis. Support Syst. 2012, 54, 510–520. [Google Scholar] [CrossRef]

- Patel, M.K. Technological improvements in electrostatic spraying and its impact to agriculture during the last decade and future research perspectives—A review. Eng. Agric. Environ. Food 2016, 9, 92–100. [Google Scholar] [CrossRef]

- Hoyer Alternative Kraftstoffe. Produktinformation. Available online: https://www.hoyer-energie.de/sitefiles/finke/downloads/prospekte/broschuere_pflanzenoel.pdf (accessed on 1 September 2016).

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

| Be useful in at least one of the farming specialisations: arable farming, vegetable production, fruit production, viticulture or animal husbandry |

| Established and already in use in agriculture |

| Potential to be deployed in large parts of the world |

| Technology in the meaning of a technical solution, excluding methods |

| Ain Purpose | Clean Technology | Abbreviation | Properties | Applied in |

|---|---|---|---|---|

| Reduced energy use; Sustainable energy use | Automatic regulation of hay ventilation | AHD | Producing quality hay needs a regulated drying process. With conventional drying installations, hay is ventilated for too long or initiated at the wrong time. Automatic control systems initiate ventilation depending on humidity and temperature thresholds, measured by sensors. Thereby electricity can be saved. | Animal husbandry |

| Solar collectors for warm air production in hay ventilation | SHD | Hay production is mostly carried out with ambient air ventilation. In order to accelerate the drying process and avoid mould growth, SHD can be instead of air heaters fuelled by heating oil. This enables drying when the ambient air is humid or even during the night. Air collectors beneath the roof transport the solar heated air to the ventilator. | Animal husbandry | |

| Frequency converter for vacuum pumps | FC-V | FC-V in dairy production reduces electricity demand. The frequency converter can be coupled with a vacuum sensor and adjust the pump motor speed according to the degree of vacuum needed. By adjusting the speed, electricity can be saved compared to constant speed pumping. | Animal husbandry | |

| Frequency converter for stable air conditioning | FC-S | Stable air conditioning refers to the control of temperature and humidity in stables, the supply of fresh air and the removal of exhaust air. In pig production in particular, ventilation is commonly controlled by transformers using maximum capacity. FC-S adjusts the speed of ventilation systems according to the need for air supply and removal. FC-S improves the electricity demand even when compared to on-off-control ventilation systems. | Animal husbandry | |

| Heat recovery from milk cooling | HRm | Cooling and cool storage of milk requires large quantities of energy. Fresh milk has a temperature of around 35 °C and needs to be cooled down to 4 °C. Installing a HRm system with a heat exchanger coupled to the cooling system generates warm water for direct use or in a boiler. Less energy is needed for hot water preparation, which is needed e.g., to clean the milking equipment. | Animal husbandry | |

| energy production, economic efficiency climate change | Photovoltaic plants | PVe | PVe modules can be installed on stable roofs or processing plant roofs. The generated electricity can be used for a variety of electricity needs in agriculture and, if financial reward systems exist, excess electricity can be fed into the grid. | Animal husbandry |

| Solar Thermal collectors | ST | ST modules can e.g., be installed on the farm house and the production of service water (warm water) can be used for house or stable heating or cleaning purposes on the farm. | Animal husbandry | |

| Wind energy plants | WP | WP plants can be used for electricity-intensive processes in agriculture. The generated electricity can be used for a variety of electricity needs in agriculture and, if financial reward systems exist and if regulations permitting it are in place, excess electricity can be fed into the grid, as is valid for PV electricity. | Animal husbandry, arable farming, vegetable production | |

| Agricultural biogas plants | BGP | Biomass from agricultural production can be used to produce biogas, either from so-called energy plants or from agricultural waste products (or both). Here we considered a BGP running on agricultural waste. Ideally, in a combined heat and power plant, heat as well as electricity can be produced. The biogas can be used as vehicle fuel, the heat and electricity as needed in farm processes. | Animal husbandry | |

| climate change, reduction of inputs | Direct use of plant oils as biofuel | BFO | The use of fossil fuels for machinery use in agriculture can be reduced with BFO produced from oil plants such as canola (Brassica napus), either by modifying agricultural machines with a tank for oil fuel and using diesel only to start machines or by directly using machines built for running on BFO. | arable farming, vegetable production, fruiticulture, viticulture |

| Trail hose | TH | Conventional slurry spreading can lead to nitrogen losses of up to 25% in the form of ammonia. Spreading manure with TH reduces ammonia emissions by evenly distributing the slurry and bringing it closer to the soil than with a baffle plate. | arable farming | |

| reduction of inputs; protection of water resources | Genetic Engineering | GM | GM crops such as cotton and maize can reduce pesticide applications and, by reducing these applications, also reduce fuel use. In addition, crop yields can be increased. | arable farming, vegetable production, fruiticulture |

| GPS Power steering | GPS | When applying fertiliser or plant protection products in agriculture, precision on the field is necessary. GPS power steering systems help the farmer stay in the correct lane and avoid overlaps by showing and correcting the route based on GPS data, thereby reducing inputs. | arable farming, vegetable production | |

| Precision farming | PF | PF can be practiced with GPS-steered drones. With these drones, aerial photographs can be taken of fields. When combined with infrared sensors and synchronised with normalised vegetation indices, reflection data of crops can indicate stress symptoms due to water or fertiliser shortage or pests and diseases. The stressed areas identified by the drone can then be inspected by the farmer. PF increases information reaching the farmer, enables the reduction of inputs and can help increase yields. | arable farming, vegetable production, fruiticulture, viticulture | |

| Dropleg application of plant protection products | DL | DL helps spray plant protection products (PPP) with higher efficiency rates. With DL, the application of PPP can be adjusted with flexible injectors, sprayed on leaf surfaces and additionally from the underside. Thereby the products adhere to the crops better and lower amounts are needed. Better yields can be achieved by higher efficiency in PPP application. | arable farming, vegetable production | |

| Electrostatic application of plant protection products | ESA | Electrostatic injectors generate an electrostatic field which helps to direct the PPP spray on the crops and distribute it more evenly. Reduced drift, fewer applications and reduced water demand are the environmental benefits. | fruiticulture, viticulture | |

| protection of water resources, reduced energy use | Drip irrigation | DI | Drip irrigation is based on pressure compensation, distributing water evenly in DI systems. PVC or PE tubes of relatively small diameters are equipped with drip heads, delivering small amounts of water constantly to the crops. Reduced water and energy demands, reduction of diseases, reduction of eutrophication and erosion through well-directed irrigation and fertilisation are among the benefits. | vegetable production, fruiticulture, viticulture |

| Wireless sensor irrigation networks | WSIN | WSIN is a sensor-based control system of water demand in crops. According to soil moisture measurements, irrigation can be initiated automatically or manually when the farmer analyses the sensor data. The benefits include reduced water and fertiliser use, reduced energy demand for irrigation pumps and reduced time investment due to remote control. | arable farming, vegetable production, fruiticulture, viticulture | |

| Frequency converter for irrigation pumps | VSDi | Irrigation pumps need large amounts of energy. VSDi reduces the energy demand of irrigation pumps by adjusting the speed drive and thereby also the water quantity. Reduced electricity demand and costs are further benefits. | arable farming, vegetable production, fruiticulture, viticulture |

| Benefit Value | Energy Saving Potential (%) | Investment Costs ($) | Amortisation Time (a) | Life Cycle Costs | Ecological & Social Criteria |

|---|---|---|---|---|---|

| 1 | 0–10 | >30,000 | >18 | Very high | Very negative impact |

| 2 | 10–20 | 25,000–30,000 | 16–18 | Markedly higher | |

| 3 | 20–30 | 20,000–25,000 | 14–16 | high | Negative impact |

| 4 | 30–40 | 15,000–20,000 | 12–14 | Slightly higher | |

| 5 | 40–50 | 10,000–15,000 | 10–12 | normal | No impact |

| 6 | 50–60 | 8000–10,000 | 8–10 | Slightly lower | Slightly better |

| 7 | 60–70 | 6000–8000 | 6–8 | Moderately lower | |

| 8 | 70–80 | 4000–6000 | 4–6 | lower | Positive impact |

| 9 | 80–90 | 2000–4000 | 2–4 | Markedly lower | |

| 10 | 90–100 | 0–2000 | 0–2 | Very low | Very positive impact |

| TH | BGP | BFO | SHD | WP | GPS | ST | PVe | GM | AHD | PF | DL | HRm | ESA | FC-P | VSDi | DI | FC-S | WSIN | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Saving of fossil fuel energy | [42] | Energy production | [43] | [44] | Energy production [45] | [46] | [47] | Energy production | [48] | [49] | No data | [50] | [51] | No data | [52,53] | [30] | [54] | [55,56] | [57] |

| Investment costs | [42] | [58] | [59] | [60] | [61] | [62] | [63] | [64] | [65] | [49] | [66] | [67] | [51] | [68] | [52,53] | [69] | [70] | [56] | [71] |

| Amortisation time | [72] | [58] | [59] | [60] | [73] | No data | [74] | [74] | [75] | [49] | No data | No data | [51] | [68] | [52,53] | [30] | No data | [55] | [57] |

| Life cycle costs | [42] | [58] | [43] | [44] | [45,76] | No data | [77,78] | [74] | [79] | No data | No data | No data | No data | [68] | [80] | [80] | [54] | [80] | No data |

| Saving of water | No impact | No impact | No impact | No impact | No impact | No impact | No impact | No impact | [48] | No impact | No data | No data | No impact | [81] | No impact | No impact | [82] | No impact | [57] |

| Biodiversity | No impact | No impact | [59] | No impact | [83,84] | No impact | No impact | No impact | [85] | No impact | No data | No data | No impact | No data | No impact | No impact | [86] | No impact | No impact |

| Water quality | [42] | [87] | [18] | No impact | No impact | [46] | No impact | No impact | [48] | No impact | No data | [50] | No impact | [88] | No impact | No impact | [89] | No impact | [57] |

| Air pollution | [90] | [91] | [43] | [44] | [45] | [46] | [47] | [74] | [48] | [49] | No data | [50] | [51] | [68] | [52] | [30] | [54] | [55,56] | [57] |

| Soil quality | [92] | [93] | [43] | No impact | No impact | [46] | No impact | No impact | [48] | No impact | No data | [50] | No impact | [68] | No impact | No impact | [89] | No impact | [57] |

| Acceptance | [42] | [39] | [94] | No data | [95,96] | [46] | No data | [97] | [98] | [49] | [99] | [50] | [51] | No data | [52] | [30] | [70] | [55] | [57] |

| Applicability | [42] | [58] | [43,59] | No data | No data | [46,62] | [74] | [74,97] | No impact | [49] | [99] | [50] | [51] | [88] | [52] | No data | [86] | [56] | [57] |

| Future prospects | [42] | No data | No data | No data | No data | [62] | No data | No data | No data | No data | No data | [50] | No data | [100] | No data | No data | [86] | No data | [57] |

| Work relief | [42] | [58] | [101] | No impact | No impact | [62] | No impact | No impact | No data | [49] | [99] | [50] | No impact | [88] | No impact | No impact | [89] | No impact | [57] |

| Ranks | Rank Level Changes | ||||

|---|---|---|---|---|---|

| Clean Technology | MCDA Rank Original | MCDA Rank Sensitivity Main Goals | MCDA Rank Sensitivity Main and Criteria | MCDA Sensitivity Main Goals | MCDA Sensitivity Main and Criteria |

| WSIN | 1 | 1 | 1 | 0 | 0 |

| FC-P | 2 | 3 | 4 | −1 | −2 |

| FC-S | 3 | 4 | 3 | −1 | 0 |

| PVe | 4 | 5 | 11 | −1 | −7 |

| DI | 5 | 2 | 5 | +3 | 0 |

| VSDi | 6 | 7 | 2 | −1 | +4 |

| ST | 7 | 9 | 11 | −2 | −4 |

| WP | 8 | 13 | 17 | −5 | −9 |

| HRm | 9 | 8 | 7 | +1 | +2 |

| BGP | 10 | 16 | 18 | −6 | −8 |

| AHD | 11 | 10 | 9 | +1 | +2 |

| DL | 12 | 11 | 8 | +1 | +4 |

| GM | 13 | 15 | 13 | −2 | 0 |

| ESA | 14 | 6 | 6 | +8 | +8 |

| PF | 15 | 14 | 10 | +1 | +5 |

| BFO | 16 | 18 | 16 | −2 | 0 |

| SHD | 17 | 17 | 15 | 0 | +2 |

| GPS | 18 | 12 | 14 | +6 | +4 |

| TH | 19 | 19 | 19 | 0 | 0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scharfy, D.; Boccali, N.; Stucki, M. Clean Technologies in Agriculture—How to Prioritise Measures? Sustainability 2017, 9, 1303. https://doi.org/10.3390/su9081303

Scharfy D, Boccali N, Stucki M. Clean Technologies in Agriculture—How to Prioritise Measures? Sustainability. 2017; 9(8):1303. https://doi.org/10.3390/su9081303

Chicago/Turabian StyleScharfy, Deborah, Norman Boccali, and Matthias Stucki. 2017. "Clean Technologies in Agriculture—How to Prioritise Measures?" Sustainability 9, no. 8: 1303. https://doi.org/10.3390/su9081303