Methodology for the Successful Integration of an Energy Management System to an Operational Environmental System

Abstract

:1. Introduction

- Better access to certain markets and product differentiation. By implementing energy saving strategies, companies can achieve certifications that will improve their social perception, gaining recognition over the competition and allowing their products to enter in more exclusive markets.

- Decrease the risk and market uncertainty. In a manufacturing plant, the focus is on reaching the production goals and the energy efficiency is rarely observed, frequently causing increments in the manufacturing costs and reducing profits. Saving energy promotes healthier finances, helping companies to avoid temporary recessions.

- Environmental protection. Over the last 15 years, many energy regulations and economic incentives have been introduced in the UK, the E-Union, the USA and many other countries. Some of these regulations and incentives introduced are climate change agreements, EU emissions trading, Carbon Reduction Commitments (CRC), energy efficiency directives or renewable energy obligations. The increased number and strengthening of the environmental regulation have forced organizations to mitigate their environmental impact in order to reach or keep their presence in some regions of the world. Moreover, environmental impact is one of the most publicized topics, meaning that improving environmental performance could result in a rise in demand from “green” customers, who appreciate ecological products.

- Energy is not considered as a business strategic opportunity. The International Energy Agency, (IEA) on its report International Energy Outlook 2013 [20] states the following regarding this topic: “In most sectors and countries, energy is a relatively minor component of the calculation of competitiveness, but energy expenditure may be of major importance in energy-intensive industries”. This limited energy vision and its potential influence on business productivity, puts energy out of the strategic context of the business.

- EnMS is not considered as a profitable investment. The time and cost associated with the development, implementation and certification processes of an EnMS are relatively high, and are perceived as an expense, not as an investment. This still common thinking in the global industrial environment, clouds a more accurate and realistic vision, in which many companies are already achieving significant economic benefits through the operation of an EnMS.

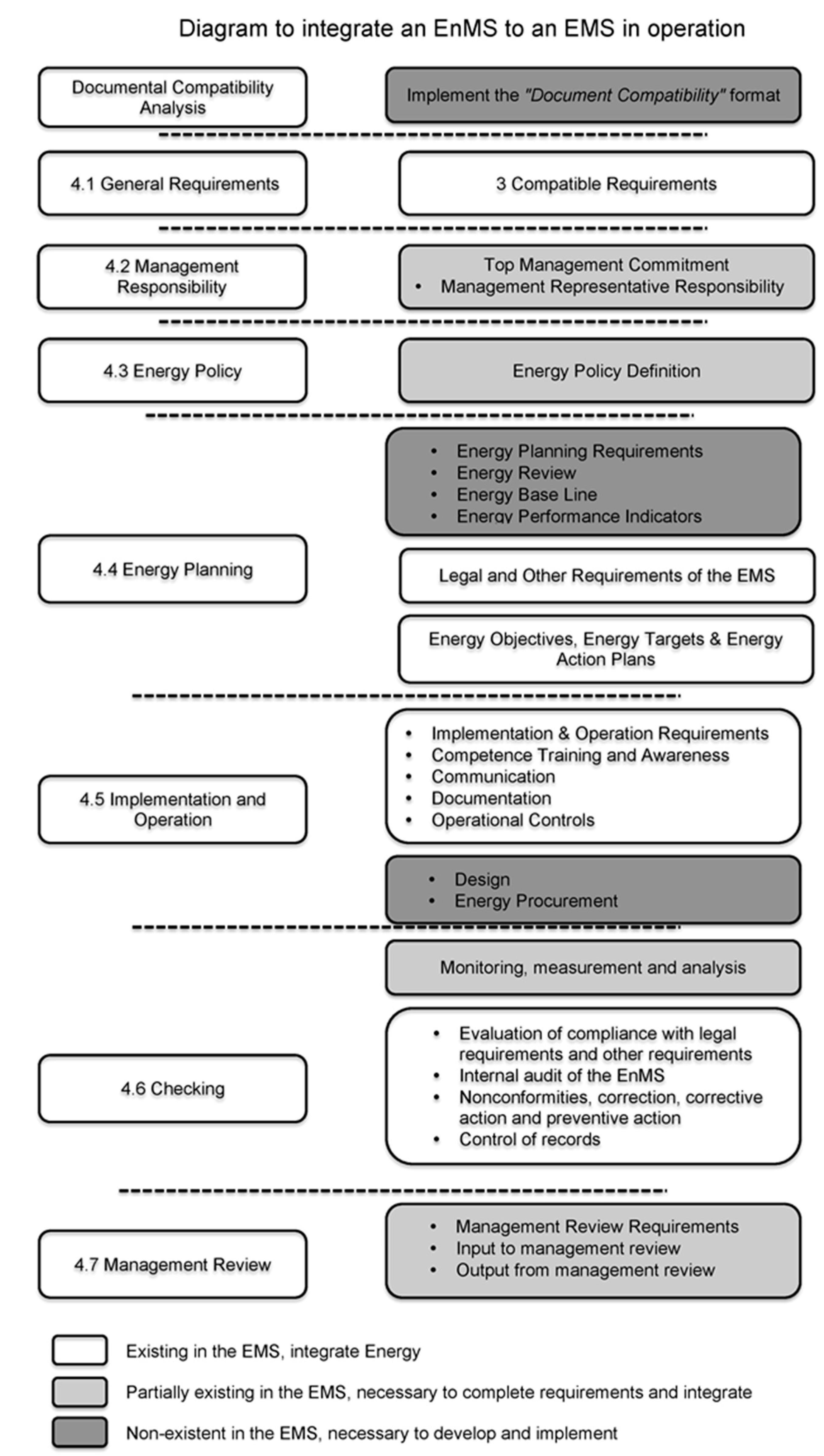

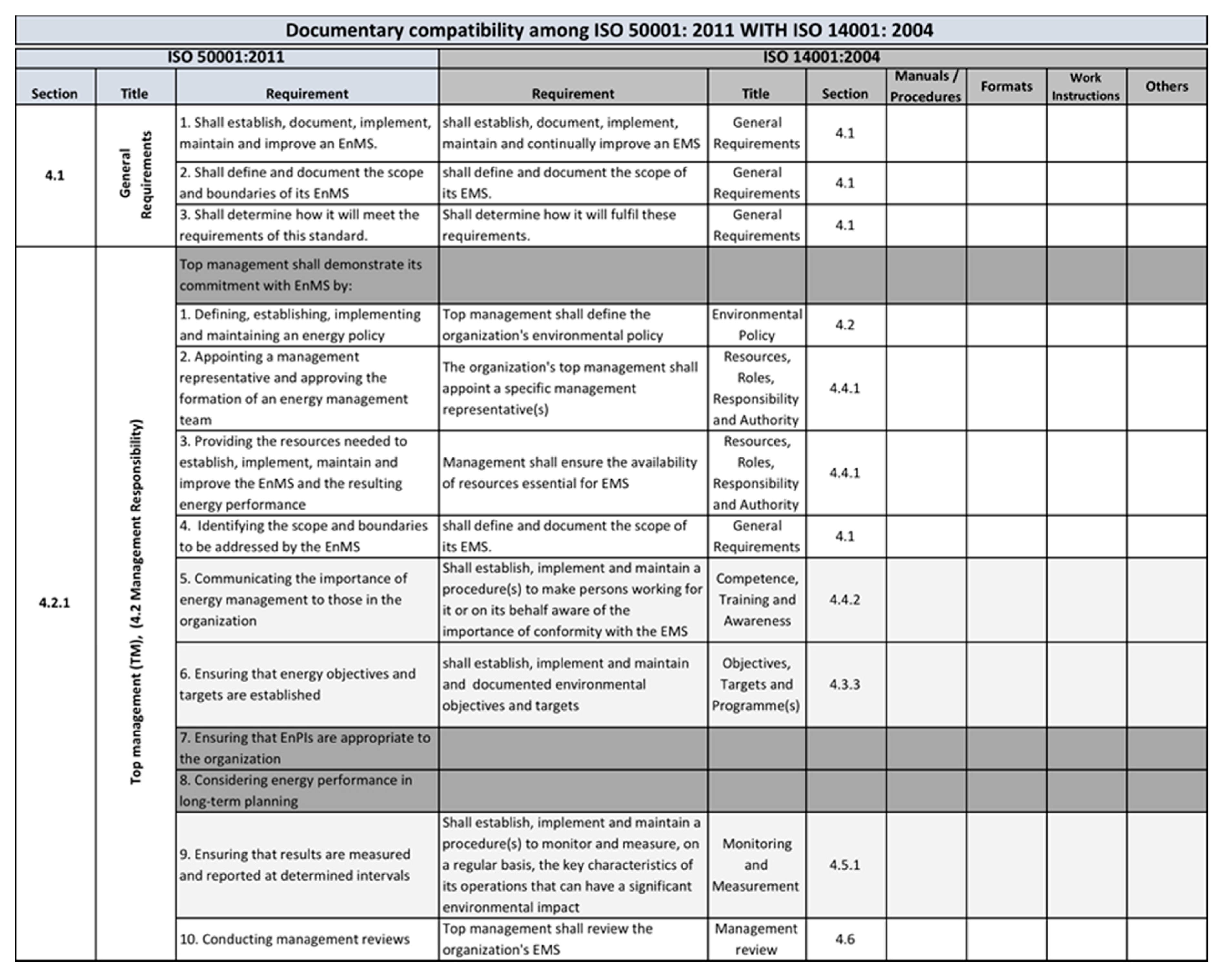

2. Materials and Methods

3. Results and Discussion

- (1)

- Those derived from the maturity of the EMS. Developing and implementing the new EnMS in the structure of a mature EMS, facilitates the deployment, understanding and robustness of the new system.

- (2)

- Advantages in the implementation. Making use of the already functional mechanisms, systems, processes and procedures and in the operation of the EMS significantly facilitates training, awareness, implementation, verification and control of the new EnMS.

- (3)

- Savings in the resources for the administration. Management systems require resources for daily operation in both systems such as trainers, document controllers, internal auditors and management representatives. Having a single integrated system, resources are used more efficiently.

- (4)

- Benefits to avoid duplicity of documentation. The integration of the EnMS into the operating EMS avoids duplication of documentation, especially in the one developed to cover common requirements between both systems. Operating the systems separately generates duplicity.

- (5)

- Reduction of time and resources required for development and implementation. As demonstrated in the enterprise case study, by integrating the EnMS with the operating EMS, a high percentage of the requirements are already developed and in operation.

- (6)

- In the first semester after the ISO 50001 integration, an immediate energy saving of 7.88% was measured when the energy consumption per produced unit decreased from 14.60 to 13.45 kW/h, with an estimated monetary saving of $26,500 USD during that period.

4. Conclusions

- (1)

- The proposed methodology to develop and implement an EnMS integrated into an EMS already in operation is effective and fulfills the function for which it was designed, achieving important benefits for the organizations.

- (2)

- In the company case study, it was shown that, at the document level, a saving of 81.30% of the documentary requirements of the EnMS can be achieved by making use of the proposed methodology, derived from the compatibility with the EMS.

- (3)

- The effectiveness of the methodology was demonstrated when the certification in EnMS ISO 50001:2011 was achieved in four months even with limited resources.

- (4)

- The energy savings accomplished as a result of the integration of the EMS allow the recovery of the costs of implementation and certification in less than a year.

- (5)

- There are currently more than 319,324 ISO 14,001 certificates issued worldwide; the organizations holding such certificates are suitable candidates to make use of the proposed methodology for the integration of the EnMS ISO 50001. These may be interested in knowing the benefits that could be obtained when developing and implementing a new SGEn integrated to its operating GHS and making use of the proposed methodology.

- (6)

- Promoting the advantages associated with the integration of energy and environmental management systems in organizations certified in ISO 14001 could further increase the number of certifications in ISO 50001, especially in those organizations classified as high energy consumers.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

References

- Mohr, S.; Somers, K.; Swartz, S.; Vanthournout, H. Manufacturing Resource Productivity. In McKinsey Quarterly; McKinsey & Company: New York, NY, USA, 2012. [Google Scholar]

- Apostolos, F.; Alexios, P.; Georgios, P.; Panagiotis, S.; George, C. Energy Efficiency of Manufacturing Processes: A Critical Review. Procedia CIRP 2013, 7, 628–633. [Google Scholar] [CrossRef]

- Bottcher, C.; Müller, M. Insights on the impact of energy management systems on carbon and corporate performance. An empirical analysis with data from German automotive suppliers. J. Clean. Prod. 2014, 137, 1449–1457. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook. 2016. Available online: www.eia.gov/outlooks/ieo/ (accessed on 16 September 2016).

- Melichar, M. Energy price shocks and economic activity: Which energy price series should we be using? Energy Econ. 2016, 54, 431–443. [Google Scholar] [CrossRef]

- Pham, T.H.H. Energy management systems and market value: Is there a link? Econ. Model 2015, 46, 70–78. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manag. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Stefan, A.; Paul, L. Does It Pay to Be Green? A Systematic Overview. Acad. Manag. Perspect. 2008, 22, 45–62. [Google Scholar] [CrossRef]

- International Organization for Standardization, ISO 50001:2011 Energy Management Systems, Requirements with Guidance for Use, Genève, Switzerland. 2011. Available online: https://www.iso.org/standard/51297.html (accessed on 10 October 2016).

- Energy Management Systems in Practice: ISO 50001: A Guide for Companies and Organizations. Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, German Federal Environment Agency. 2012. Available online: https://www.adelphi.de (accessed on 10 October 2016).

- Global Energy Management System Implementation: Case Study—Nissan. Clean, Energy Ministerial. 2013. Available online: https://cleanenergysolutions.org (accessed on 15 September 2016).

- Jovanovi, B.; Filipovi, J. ISO 50001 standard-based energy management maturity model e proposal and validation in industry. J. Clean. Prod. 2016, 112, 2744–2755. [Google Scholar] [CrossRef]

- McKane, A. Thinking Globally: How ISO 50001—Energy Management Can Make Industrial Energy Efficiency Standard Practice, Lawrence Berkeley National Laboratory. 2010. Available online: http://escholarship.org/uc/item/92d8q553 (accessed on 15 September 2016).

- Scheihing, P. Save Energy through the Superior Energy Performance Program. Chem. Eng. Prog. 2014, 110, 48–51. [Google Scholar]

- Bergek, A.; Berggren, C. The impact of environmental policy instruments on innovation: A review of energy and automotive industry studies. Ecol. Econ. 2014, 106, 112–123. [Google Scholar] [CrossRef]

- Perlis, M.L. The Climate and Energy Policy Basis for EPA’s First-Ever CO2 Emission Standards for Power Plants. Electr. J. 2014, 27, 35–44. [Google Scholar] [CrossRef]

- Korhonen, J.; Pätäri, S.; Toppinen, A.; Tuppura, A. The role of environmental regulation in the future competitiveness of the pulp and paper industry: The case of the sulfur emissions directive in Northern Europe. J. Clean. Prod. 2015, 108, 864–872. [Google Scholar] [CrossRef]

- Lorek, S.; Spangenberg, J.H. Sustainable consumption within a sustainable economy e beyond green growth and green economies. J. Clean. Prod. 2014, 63, 33–44. [Google Scholar] [CrossRef]

- Charlet, L. ISO Survey. 2016. Available online: http://www.iso.org/iso/iso-survey (accessed on 15 October 2016).

- International Energy Agency. World Energy Outlook 2013, Paris, France. 2013. Available online: www.worldenergyoutlook.org (accessed on 10 October 2016).

- Chiu, T.Y.; Lo, S.L.; Tsai, Y.Y. Establishing an Integration-Energy-Practice Model for Improving Energy Performance Indicators in ISO 50001 Energy Management Systems. Energies 2012, 5, 5324–5339. [Google Scholar] [CrossRef]

- Zobel, T.; Malmgren, C. Evaluating the Management System Approach for Industrial Energy Efficiency Improvements. Energies 2016, 9, 774. [Google Scholar] [CrossRef]

- Laskurain, L.; Saizarbitoria, I.H.; Casadesús, M. Fostering renewable energy sources by standards for environmental and energy management. Renew. Sustain. Energy Rev. 2015, 50, 1148–1156. [Google Scholar] [CrossRef]

- Empresas UPAC, Comision Nacional para el Uso Eficiente de Energia, Mexico. 2016. Available online: http://www.gob.mx/conuee/acciones-y-programas/quien-se-considera-upac (accessed on 28 September 2016).

- ISO 50001:2011, International Standards Organization, Geneva, Switzerland. 2011. Available online: www.iso.org/iso/iso_50001_energy.pdf (accessed on 28 September 2016).

| Compatibility Analysis of ISO 50001:2011 vs. ISO 14001:2004 | |||||

|---|---|---|---|---|---|

| ISO 50001 Requirements | Compatibility with ISO 14001 | ||||

| Section | Title | Requirements | Match | Partial Match | No-Match |

| 4.1 | General requirements | 3 | 3 | 0 | 0 |

| 4.2 | Management Responsibility | 20 | 10 | 6 | 4 |

| 4.3 | Energy Policy | 10 | 8 | 0 | 2 |

| 4.4 | Energy Planning | 42 | 13 | 0 | 29 |

| 4.5 | Implementation and Operation | 38 | 30 | 0 | 8 |

| 4.6 | Checking | 34 | 26 | 2 | 6 |

| 4.7 | Management Review | 16 | 11 | 1 | 4 |

| Total | 163 | 101 | 9 | 53 | |

| Analysis of Changes in the EMS Documents to Integrate the EnMs | ||||

|---|---|---|---|---|

| Quantity | Document | Number of Words in the Document | ||

| Original Document | Integrated Document | Difference | ||

| 1 | Manual | 6763 | 7488 | 725 |

| 23 | Modified procedures | 39,857 | 42,800 | 2943 |

| 16 | Formats | 23,160 | 24,257 | 1097 |

| 3 | Work instructions | 4771 | 5061 | 290 |

| 1 | New procedures | Non-existent | 2053 | 2053 |

| 7 | New formats | Non-existent | 2227 | 2227 |

| 3 | New work instructions | Non-existent | 4608 | 4608 |

| Total | 74,551 | 88,494 | 13,943 | |

| New documents or changes due to integration | 18.7% | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uriarte-Romero, R.; Gil-Samaniego, M.; Valenzuela-Mondaca, E.; Ceballos-Corral, J. Methodology for the Successful Integration of an Energy Management System to an Operational Environmental System. Sustainability 2017, 9, 1304. https://doi.org/10.3390/su9081304

Uriarte-Romero R, Gil-Samaniego M, Valenzuela-Mondaca E, Ceballos-Corral J. Methodology for the Successful Integration of an Energy Management System to an Operational Environmental System. Sustainability. 2017; 9(8):1304. https://doi.org/10.3390/su9081304

Chicago/Turabian StyleUriarte-Romero, Rafael, Margarita Gil-Samaniego, Edgar Valenzuela-Mondaca, and Juan Ceballos-Corral. 2017. "Methodology for the Successful Integration of an Energy Management System to an Operational Environmental System" Sustainability 9, no. 8: 1304. https://doi.org/10.3390/su9081304