Processing Point Clouds Using Simulated Physical Processes as Replacements of Conventional Mathematically Based Procedures: A Theoretical Virtual Measurement for Stem Volume

Abstract

:1. Introduction

2. Artificial Ground Truth

2.1. Regular Shape Objects

2.2. Artificial Stems

2.3. Ideal Point Cloud and Ideal Tree Model

3. Virtual Water Displacement Method

3.1. Analysis of Physical Basis

3.2. VWD Method Description

3.2.1. Primary Mechanism

3.2.2. The Establishment of the VGE

3.2.3. Virtual Water Molecule

3.2.4. Point Cloud as Object

3.2.5. Diminishing the Modeling Complexity by Making Models No Longer

3.3. Sphere Packing Problem

3.4. Workflow Using VWD Application

3.5. Virtual Experiments Using VWD Application

4. Results

4.1. Theoretical and Actual Filling of VWMs

4.2. Regular Shape Objects

4.3. Artificial Stems

5. Discussion

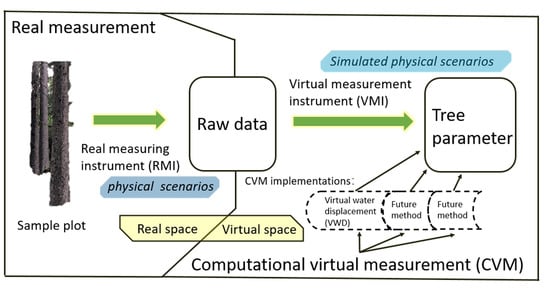

5.1. Computational Virtual Measurement

5.2. Computer Performance and the VWD Feasibility in the Future

5.3. Scale Effect for VWMs

5.4. Objectivity, Current Limitations and Further Development

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Water Displacement Method

Appendix A.2. Technical Detail of the VWM Physics

Appendix A.3. Development Environment

References

- Purves, D.; Pacala, S. Predictive models of forest dynamics. Science 2008, 320, 1452–1453. [Google Scholar] [CrossRef] [PubMed]

- Breidenbach, J.; Granhus, A.; Hylen, G.; Eriksen, R.; Astrup, R. A century of National Forest Inventory in Norway–informing past, present, and future decisions. For. Ecosyst. 2020, 7, 46. [Google Scholar] [CrossRef]

- Hiley, W. The Forests of Suomi (Finland): Results of the General Survey of the Forests of the Country carried out during the Years 1921–1924. Emp. For. J. 1927, 6, 316–318. [Google Scholar]

- Hackenberg, J.; Morhart, C.; Sheppard, J.; Spiecker, H.; Disney, M. Highly accurate tree models derived from terrestrial laser scan data: A method description. Forests 2014, 5, 1069–1105. [Google Scholar] [CrossRef] [Green Version]

- Wang, C. Biomass allometric equations for 10 co-occurring tree species in Chinese temperate forests. For. Ecol. Manag. 2006, 222, 9–16. [Google Scholar] [CrossRef]

- Fang, R.; Strimbu, B.M. Comparison of mature douglas-firs’ crown structures developed with two quantitative structural models using TLS point clouds for neighboring trees in a natural regime stand. Remote Sens. 2019, 11, 1661. [Google Scholar] [CrossRef] [Green Version]

- Henry, M.; Bombelli, A.; Trotta, C.; Alessandrini, A.; Birigazzi, L.; Sola, G.; Vieilledent, G.; Santenoise, P.; Longuetaud, F.; Valentini, R. GlobAllomeTree: International platform for tree allometric equations to support volume, biomass and carbon assessment. iForest 2013, 6, 326–330. [Google Scholar] [CrossRef] [Green Version]

- Zeng, W.; Tomppo, E.; Healey, S.P.; Gadow, K.V. The national forest inventory in China: History-results-international context. For. Ecosyst. 2015, 2, 23. [Google Scholar] [CrossRef] [Green Version]

- Erez, T.; Tassa, Y.; Todorov, E. Simulation tools for model-based robotics: Comparison of bullet, havok, mujoco, ode and physx. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 25–30 May 2015; pp. 4397–4404. [Google Scholar]

- Hongpan, N.; Yong, G.; Zhongming, H. Application research of PhysX engine in virtual environment. In Proceedings of the 2010 International Conference on Audio, Language and Image Processing, Shanghai, China, 23–25 November 2010; pp. 587–591. [Google Scholar]

- Saarinen, N.; Kankare, V.; Vastaranta, M.; Luoma, V.; Pyörälä, J.; Tanhuanpää, T.; Liang, X.; Kaartinen, H.; Kukko, A.; Jaakkola, A.; et al. Feasibility of Terrestrial laser scanning for collecting stem volume information from single trees. ISPRS J. Photogramm. Remote Sens. 2017, 123, 140–158. [Google Scholar] [CrossRef]

- Liang, X.L.; Kankare, V.; Hyyppa, J.; Wang, Y.S.; Kukko, A.; Haggren, H.; Yu, X.W.; Kaartinen, H.; Jaakkola, A.; Guan, F.Y.; et al. Terrestrial laser scanning in forest inventories. ISPRS J. Photogramm. Remote Sens. 2016, 115, 63–77. [Google Scholar] [CrossRef]

- Fan, G.; Nan, L.; Dong, Y.; Su, X.; Chen, F. AdQSM: A New Method for Estimating Above-Ground Biomass from TLS Point Clouds. Remote Sens. 2020, 12, 3089. [Google Scholar] [CrossRef]

- Pueschel, P.; Newnham, G.; Rock, G.; Udelhoven, T.; Werner, W.; Hill, J. The influence of scan mode and circle fitting on tree stem detection, stem diameter and volume extraction from terrestrial laser scans. ISPRS J. Photogramm. Remote Sens. 2013, 77, 44–56. [Google Scholar] [CrossRef]

- Jiang, A.; Liu, J.; Zhou, J.; Zhang, M. Skeleton extraction from point clouds of trees with complex branches via graph contraction. Vis. Comp. 2021, 37, 2235–2251. [Google Scholar] [CrossRef]

- Lecigne, B.; Delagrange, S.; Taugourdeau, O. Annual Shoot Segmentation and Physiological Age Classification from TLS Data in Trees with Acrotonic Growth. Forests 2021, 12, 391. [Google Scholar] [CrossRef]

- Xie, D.; Wang, X.; Qi, J.; Chen, Y.; Mu, X.; Zhang, W.; Yan, G. Reconstruction of single tree with leaves based on terrestrial lidar point cloud data. Remote Sens. 2018, 10, 686. [Google Scholar] [CrossRef] [Green Version]

- Bournez, E.; Landes, T.; Saudreau, M.; Kastendeuch, P.; Najjar, G. From TLS point clouds to 3D models of trees: A comparison of existing algorithms for 3D tree reconstruction. In Proceedings of the 3D Virtual Reconstruction and Visualization of Complex Architectures, Nafplio, Greece, 1–3 March 2017; pp. 113–120. [Google Scholar]

- Zianis, D.; Muukkonen, P.; Mäkipää, R.; Mencuccini, M. Biomass and Stem Volume Equations for Tree Species in Europe; Silva Fennica Monographs: Helsinki, Finland, 2005. [Google Scholar]

- Bienert, A.; Hess, C.; Maas, H.; Von Oheimb, G. A voxel-based technique to estimate the volume of trees from terrestrial laser scanner data. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, 40, 101. [Google Scholar] [CrossRef] [Green Version]

- Raumonen, P.; Kaasalainen, M.; Åkerblom, M.; Kaasalainen, S.; Kaartinen, H.; Vastaranta, M.; Holopainen, M.; Disney, M.; Lewis, P. Fast automatic precision tree models from terrestrial laser scanner data. Remote Sens. 2013, 5, 491–520. [Google Scholar] [CrossRef] [Green Version]

- Calders, K.; Newnham, G.; Burt, A.; Murphy, S.; Raumonen, P.; Herold, M.; Culvenor, D.; Avitabile, V.; Disney, M.; Armston, J.; et al. Nondestructive estimates of above-ground biomass using terrestrial laser scanning. Methods Ecol. Evol. 2015, 6, 198–208. [Google Scholar] [CrossRef]

- Delagrange, S.; Jauvin, C.; Rochon, P. PypeTree: A tool for reconstructing tree perennial tissues from point clouds. Sensors 2014, 14, 4271–4289. [Google Scholar] [CrossRef] [Green Version]

- Du, S.; Lindenbergh, R.; Ledoux, H.; Stoter, J.; Nan, L. AdTree: Accurate, detailed, and automatic modelling of laser-scanned trees. Remote Sens. 2019, 11, 2074. [Google Scholar] [CrossRef] [Green Version]

- Unity Technologies. Unity User Manual (2018.2). Available online: https://docs.unity3d.com/Manual/UnityManual.html (accessed on 23 November 2019).

- Boeing, A.; Bräunl, T. Evaluation of real-time physics simulation systems. In Proceedings of the 5th International Conference on Computer Graphics and Interactive Techniques in Australia and Southeast Asia, Perth, Australia, 1–4 December 2007; pp. 281–288. [Google Scholar]

- Zhang, C.; Chen, T. Efficient feature extraction for 2d/3d objects in mesh representation. In Proceedings of the IEEE 2001 International Conference on Image Processing (Cat. No. 01CH37205), Thessaloniki, Greece, 7–10 October 2001; pp. 935–938. [Google Scholar]

- Åkerblom, M. Quantitative Tree Modeling from Laser Scanning Data. Master’s Thesis, Tampere University, Tampere, Finland, 2012. [Google Scholar]

- Unity Technologies. Tree Editor. Available online: https://docs.unity3d.com/Manual/class-Tree.html (accessed on 23 November 2019).

- Rusu, R.B.; Cousins, S. Point cloud library (PCL). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1–4. [Google Scholar]

- Schroeder, W.J.; Martin, K.M.; Lorensen, W.E. The design and implementation of an object-oriented toolkit for 3d graphics and visualization. In Proceedings of the Seventh Annual IEEE Visualization’96, San Francisco, CA, USA, 27 October–1 November 1996; pp. 93–100. [Google Scholar]

- Hackenberg, J.; Spiecker, H.; Calders, K.; Disney, M.; Raumonen, P. Simpletree-an efficient open source tool to build tree models from tls clouds. Forests 2015, 6, 4245–4294. [Google Scholar] [CrossRef]

- Batty, M. Virtual geography. Futures 1997, 29, 337–352. [Google Scholar] [CrossRef]

- Lin, H.; Gong, J. Exploring virtual geographic environments. Geogr. Inf. Sci. 2001, 7, 1–7. [Google Scholar] [CrossRef]

- Mekni, M. Automated Generation of Geometrically-Precise and Semantically-Informed Virtual Geographic Environments Populated with Spatially-Reasoning Agents; Universal-Publishers: Irvine, CA, USA, 2010. [Google Scholar]

- Lin, H.; Chen, M.; Lu, G.; Zhu, Q.; Gong, J.; You, X.; Wen, Y.; Xu, B.; Hu, M. Virtual geographic environments (vges): A new generation of geographic analysis tool. Earth-Sci. Rev. 2013, 126, 74–84. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Gong, J.; Li, Y. Realistic rendering for physically based shallow water simulation in virtual geographic environments (vges). Ann. GIS 2015, 21, 301–312. [Google Scholar] [CrossRef]

- Machado, S.d.A.; Nadolny, M. Comparação de métodos de cubagem de árvores e de diversos comprimentos de seção. In Anais do III Congresso Florestal e do Meio Ambiente do Paraná; Associaçáo Parananense de Engenheiros Florestais: Curitiba, Brazil, 1991; pp. 89–104. [Google Scholar]

- Mestre, S.; Veye, F.; Perez-Martin, A.; Behar, T.; Triboulet, J.; Berron, N.; Demattei, C.; Quéré, I. Validation of lower limb segmental volumetry with hand-held, self-positioning three-dimensional laser scanner against water displacement. J. Vasc. Surg. Venous Lymphat. Disord. 2014, 2, 39–45. [Google Scholar] [CrossRef]

- Damstra, R.J.; Glazenburg, E.J.; Hop, W.C.J. Validation of the inverse water volumetry method: A new gold standard for arm volume measurements. Breast Cancer Res. Treat. 2006, 99, 267. [Google Scholar] [CrossRef] [PubMed]

- Maniatis, D.; Saint André, L.; Temmerman, M.; Malhi, Y.; Beeckman, H. The potential of using xylarium wood samples for wood density calculations: A comparison of approaches for volume measurement. iForest 2011, 4, 150. [Google Scholar] [CrossRef]

- Unity Technologies. Scenes. Available online: https://docs.unity3d.com/Manual/CreatingScenes.html (accessed on 18 June 2018).

- Hifi, M.; M’hallah, R. A literature review on circle and sphere packing problems: Models and methodologies. Adv. Oper. Res. 2009, 2009, 150624. [Google Scholar] [CrossRef]

- Archer, T.; Whitechapel, A. Inside c#; Microsoft Press: Redmond, MA, USA, 2002; Volume 1. [Google Scholar]

- Scherzer, D.; Bagar, F.; Mattausch, O. Volumetric real-time water and foam rendering. In GPU Pro 360 Guide to Rendering; AK Peters/CRC Press: Boca Raton, FL, USA, 2018; pp. 189–201. [Google Scholar]

- Horvath, C.J. Empirical directional wave spectra for computer graphics. In Proceedings of the 2015 Symposium on Digital Production, Los Angeles, CA, USA, 8 August 2015; ACM: New York, NY, USA, 2015; pp. 29–39. [Google Scholar]

- Bridson, R. Fluid Simulation for Computer Graphics; AK Peters/CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Dullweber, A.; Leimkuhler, B.; McLachlan, R. Symplectic splitting methods for rigid body molecular dynamics. J. Chem. Phys. 1997, 107, 5840–5851. [Google Scholar] [CrossRef] [Green Version]

- Unity Technologies. Physics. Available online: https://docs.unity3d.com/Manual/PhysicsSection.html (accessed on 24 December 2018).

- Nvidia Corporation. Rigid Body Dynamics. Available online: https://docs.nvidia.com/gameworks/content/gameworkslibrary/physx/guide/Manual/RigidBodyDynamics.html#applying-forces-and-torques (accessed on 24 December 2018).

- Unity Technologies. Rigidbody. Available online: https://docs.unity3d.com/ScriptReference/Rigidbody.html (accessed on 24 December 2018).

- Nvidia Corporation. Rigid Body Collision. Available online: https://docs.nvidia.com/gameworks/content/gameworkslibrary/physx/guide/Manual/RigidBodyCollision.html#broad-phase-algorithms (accessed on 25 December 2018).

- Nvidia Corporation. Geometry Queries. Available online: https://docs.nvidia.com/gameworks/content/gameworkslibrary/physx/guide/Manual/GeometryQueries.html (accessed on 25 December 2018).

- Unity Technologies. Mesh Collider. Available online: https://docs.unity3d.com/Manual/class-MeshCollider.html (accessed on 1 July 2021).

- Huang, W.; Yu, L. Serial symmetrical relocation algorithm for the equal sphere packing problem. arXiv 2012, arXiv:1202.4149. [Google Scholar]

| Model | Equation | Geometric Parameters | Theoretical Volume | Mesh Volume | Absolute Difference | Calibration Coefficient |

|---|---|---|---|---|---|---|

| Cube | r = 20 | 8000 | 7999.99 | 0.01 | none | |

| Sphere | r = 10 | 4188.79 | 4098.68 | 90.11 | 97.85% | |

| Cylinder | r = 10 h = 40 | 12,566.37 | 12,360.69 | 206.68 | 98.36% |

| Parameters | S.1 | S.2 | S.3 | S.4 | S.5 | S.6 | S.7 | S.8 | S.9 | S.10 | S.11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | 1.634 | 1.647 | 1.626 | 1.622 | 1.626 | 1.632 | 1.619 | 1.645 | 1.630 | 1.630 | 1.630 |

| P.2 | 0.048 | 0.047 | 0.049 | 0.049 | 0.049 | 0.049 | 0.047 | 0.049 | 0.047 | 0.047 | 0.049 |

| P.3 | 0.052 | 0.051 | 0.051 | 0.051 | 0.051 | 0.053 | 0.051 | 0.053 | 0.051 | 0.053 | 0.053 |

| P.4 | 0.030 | 0.029 | 0.031 | 0.031 | 0.029 | 0.029 | 0.031 | 0.031 | 0.029 | 0.029 | 0.031 |

| P.5 | 173 | 174 | 172 | 173 | 173 | 173 | 175 | 174 | 172 | 173 | 171 |

| P.6 | 10,000 | 9915 | 9967 | 10,042 | 9913 | 9975 | 9953 | 10,053 | 9907 | 9957 | 10,052 |

| P.7 | 3 | 4 | 3 | 4 | 3 | 3 | 4 | 3 | 4 | 3 | 4 |

| P.8 | 5 | 6 | 6 | 4 | 4 | 6 | 6 | 4 | 4 | 4 | 4 |

| P.9 | 0.094 | 0.095 | 0.095 | 0.093 | 0.093 | 0.093 | 0.093 | 0.095 | 0.093 | 0.093 | 0.09 |

| P.10 | 0.063 | 0.062 | 0.064 | 0.062 | 0.064 | 0.062 | 0.062 | 0.062 | 0.062 | 0.062 | 0.062 |

| Vol (dm3) | 26.44 | 24.97 | 26.32 | 26.31 | 26.96 | 25.58 | 26.81 | 26.44 | 25.86 | 25.86 | 26.16 |

| Accuracy (%) * | 4.0 | 10.1 | 5.8 | 5.9 | 3.5 | 8.5 | 4.1 | 5.4 | 7.5 | 7.5 | 6.4 |

| R.1 | R.2 | R.3 | R.4 | R.5 | STDEV | AVG | DIFF | VWD V (cm3) | True V (cm3) | Adjusted V (cm3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vessel | 2294 | 2305 | 2294 | 2298 | 2295 | 4.66 | 2297 | ||||

| Stem | 2259 | 2256 | 2247 | 2250 | 2252 | 4.76 | 2253 | 44 | 41,376 | 23,709 | |

| Stem with Branches | 2244 | 2237 | 2247 | 2241 | 2243 | 3.71 | 2242 | 55 | 51,720 | 27,946 | 29,636 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Shen, Y.-J.; Zhang, X.; Zhao, Y.; Schmullius, C. Processing Point Clouds Using Simulated Physical Processes as Replacements of Conventional Mathematically Based Procedures: A Theoretical Virtual Measurement for Stem Volume. Remote Sens. 2021, 13, 4627. https://doi.org/10.3390/rs13224627

Wang Z, Shen Y-J, Zhang X, Zhao Y, Schmullius C. Processing Point Clouds Using Simulated Physical Processes as Replacements of Conventional Mathematically Based Procedures: A Theoretical Virtual Measurement for Stem Volume. Remote Sensing. 2021; 13(22):4627. https://doi.org/10.3390/rs13224627

Chicago/Turabian StyleWang, Zhichao, Yan-Jun Shen, Xiaoyuan Zhang, Yao Zhao, and Christiane Schmullius. 2021. "Processing Point Clouds Using Simulated Physical Processes as Replacements of Conventional Mathematically Based Procedures: A Theoretical Virtual Measurement for Stem Volume" Remote Sensing 13, no. 22: 4627. https://doi.org/10.3390/rs13224627