As described above, the geometric calibration established during the Landsat 8 commissioning period has required very little refinement since routine operations began. The exceptions to this have been the two small adjustments to the OLI-to-spacecraft alignment noted in

Table 2 above. The second of these, though effective as of 1 October 2013, was not implemented into the product generation system until February 2014 to support the planned complete reprocessing of all Landsat 8 Level 1 products. Small magnitude adjustments with limited impact on product accuracy will typically be deferred until one of the scheduled reprocessing campaigns to avoid introducing discontinuities into the calibration history that are not justified by improved product performance. The geometric performance results presented below reflect the calibration adjustments described in the previous section, applied during the February 2014 reprocessing effort. The accumulated trending data are analyzed at least quarterly, in preparation for the release of a new CPF, but none of these analyses have indicated a need for further calibration adjustments.

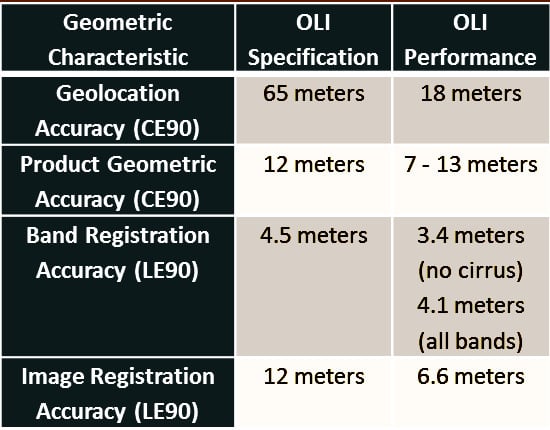

3.1. Geodetic Accuracy

Geodetic accuracy refers to the absolute geolocation accuracy of OLI imagery and is measured using ground control points. The effects of terrain are compensated in the geodetic accuracy analysis so it reflects horizontal positional accuracy and is specified and measured in terms of 90% circular error (CE90). As noted in

Table 1, the required accuracy is 65 meters (CE90) or better.

Geodetic accuracy statistics are collected when ground control points are correlated with OLI imagery as part of Level 1T product generation processing (using the GLS control) and also for the geometric calibration sites where higher accuracy DOQ and SPOT-derived control points are available. Every available control point of the selected type is correlated with a Level 1T OLI image generated using the spacecraft ephemeris (position and velocity) and attitude information provided in the Level 0 data stream. The control points that correlate successfully are analyzed to select a consistent set. The selected points are then used to compute ephemeris and attitude corrections. These corrections are applied to the geometric model and the final Level 1T product is then generated using the refined control-corrected model. As a byproduct of this procedure the computed correction values are stored in the IAS trending database for subsequent use in OLI-to-spacecraft alignment calibration. The control point statistics are also stored in the database to provide a record of the measured geolocation accuracy of the original OLI image. These statistics are analyzed to assess Landsat 8 geodetic accuracy.

The accuracy of the ground control used to evaluate the accuracy of the imagery is a concern if the control is less than an order of magnitude or so more accurate than the imagery. This is the case with the GLS control which is less than two-times more accurate (38 meter CE90) than the Landsat 8 geodetic accuracy specification (65 meter CE90). This problem is highlighted by comparing the geodetic accuracy results observed for the operational GLS control versus the calibration site control. It would be tempting to dismiss the GLS control for accuracy evaluation purposes on this basis, but it is important to recall that although the calibration site control provides better accuracy than the GLS control, it does not provide a global distribution of test sites. Relying solely on the calibration sites could mask the effects of systematic errors such as within-orbit thermally induced alignment variations. It is thus important to analyze both the highly accurate DOQ and the globally distributed GLS results.

Figure 8 shows the measured CE90 geodetic accuracy performance, summarized by calendar quarter, using three classes of ground control: (1) the GLS control used operationally to create Level 1T data products; (2) the DOQ/SPOT control used at calibration sites for geometric analyses; and (3) a subset of the GLS control referred to as anchor site control. The anchor sites are the Landsat Worldwide Reference System 2 (WRS-2) path/row locations that were controlled, with the assistance of the National Geospatial Intelligence Agency (NGA), during the global Landsat image triangulation that established the geometric framework for the GLS [

8]. Since the NGA-provided control was not available everywhere around the world (e.g., not for many isolated islands), the GLS is not of uniform accuracy. Selecting sites that were used as the original GLS positional constraints ought to provide a globally distributed subset of sites that is more reliable than the overall GLS population.

Figure 8.

OLI absolute geodetic/geolocation accuracy by calendar quarter. Anchor sites are the subset of Global Land Survey (GLS) scenes that contained control points provided by the National Geospatial Intelligence Agency (NGA).

Figure 8.

OLI absolute geodetic/geolocation accuracy by calendar quarter. Anchor sites are the subset of Global Land Survey (GLS) scenes that contained control points provided by the National Geospatial Intelligence Agency (NGA).

As expected, the calibration site DOQ/SPOT-derived control reports much better accuracy than does the less accurate GLS control and the GLS anchor sites produce consistently better results than the remainder of the GLS control. Given the divergence in the results yielded by the different classes of ground control, establishing a single, defensible, estimate for Landsat 8 OLI geolocation accuracy requires separating the error components that are attributable to the OLI imagery from those that are due to the ground control itself. Consider the measured geolocation accuracy to be composed of four components:

where:

- (1)

is static calibration error resulting from residual alignment calibration bias;

- (2)

is dynamic calibration error that varies with position due to within-orbit alignment changes;

- (3)

is random pointing error including spacecraft position and attitude knowledge, sensor internal line-of-sight stability, and alignment instability;

- (4)

is ground control point error, including ~0.1 pixel GCP mensuration error.

If we can estimate the first three terms on the right hand side of Equation (4) we can produce an estimate of geolocation accuracy that is independent of the control point effects. We estimate the static calibration error by computing the mean geodetic offsets for all test scenes. This error component is treated as a constant offset. Dynamic calibration errors, in the form of within-orbit thermally induced alignment changes, are modeled as a linear trend in the mean offsets with position in orbit, using WRS row location as a proxy for orbit position. This error component can then be treated as a uniform error distribution varying between the maximum and minimum values it can attain across a given WRS row range.

Since the ground control point errors are fixed for a given site whereas the pointing errors should vary randomly for that site, we can estimate the random pointing error by analyzing the repeatability of the measured geodetic offsets at each WRS path/row. The standard deviations of the mean geodetic errors for all scenes over each path/row were computed for all scenes where there was more than one successful acquisition. The root-mean-squares of the site-specific standard deviations in each direction were taken to be estimates of the low frequency pointing error. Higher frequency within-scene pointing errors were estimated from the standard deviations of the scene-by-scene control point measurements at calibration sites. The low- and high-frequency estimates are root-sum-squared to yield a combined random pointing error estimate.

This error estimation approach was applied to both the GLS and calibration site/DOQ ground control point results collected during L1T processing, yielding the results shown in

Table 3. In the GLS case, the residual calibration error terms (calibration bias and trend with WRS row) were estimated using only the anchor sites as there is some evidence of the presence of latitude-dependent systematic errors in the broader GLS. The pointing repeatability analysis included the entire GLS data set to obtain a larger sample. The implied GLS GCP error, however, applies only to the anchor sites.

The variance of a uniformly distributed random variable, X, that takes on values between min(X) and max(X) is [

9]:

Table 3.

Landsat 8 global geolocation accuracy performance estimate. The final estimate is highlighted in bold in the table.

Table 3.

Landsat 8 global geolocation accuracy performance estimate. The final estimate is highlighted in bold in the table.

| Source | GLS Scenes | DOQ Scenes | All Scenes |

|---|

| Static Calibration Error | Along-Track Mean (m) | 2.9 | 0.2 | 2.9 |

| Across-Track Mean (m) | −2.0 | −0.1 | −2.0 |

| Dynamic Calibration Trend | Along-Track Trend (m/row) | −0.076 | −0.030 | −0.076 |

| Across-Track Trend (m/row) | 0.177 | 0.132 | 0.177 |

| Calibration Trend Lever Arm | Row Range (rows) | 94 | 57 | 124 |

| Dynamic Calibration Error | Along-Track (m) | 2.1 | 0.5 | 2.7 |

| Across-Track (m) | 4.8 | 2.2 | 6.4 |

| Random Pointing Error | Along-Track (m) | 8.0 | 6.4 | 6.4 |

| Across-Track (m) | 7.9 | 7.4 | 7.4 |

| L8 Geolocation Error | CE90 (m) | 19.0 | 15.1 | 18.1 |

| Measured Geodetic Error | CE90 (m) | 34.9 | 15.3 | - |

| Implied GCP Error | CE90 (m) | 29.2 | 2.3 | - |

Since the dynamic calibration term is being modeled as a linear trend with position in orbit, the range of values that it takes on is the trend, in terms of meters per WRS row, times the number of rows spanned by the data. The dynamic calibration contribution was thus computed as:

The final Landsat 8 CE90 geolocation error was calculated from the individual components as follows:

The along- and across-track static calibration error terms are root-sum-squared along with the average of the along- and across-track terms for the dynamic calibration and pointing components, both of the latter being scaled by a factor of 2.146 to convert a root-mean-square value to 90% circular error. The implied control point error is computed as the root-sum-square difference between the measured CE90 geodetic error (shown in

Table 3 and plotted in

Figure 8) and the Landsat 8 geolocation error estimate. Note from

Table 3 that the GLS and DOQ Landsat 8 geolocation accuracy estimates are reasonably close although the DOQ results exhibit smaller within-orbit effects due to their more restricted geographic distribution. Both analyses yielded reasonable values for the implied control point error based upon the expected accuracy of these control sources. The final estimate of global Landsat 8 geolocation error (the “All Scenes” column in

Table 3) was calculated using the GLS estimates for static and dynamic calibration error (which require a global distribution of data to estimate accurately), the DOQ estimates for pointing error (which should be the same everywhere), and a WRS row range of 124, spanning a full daylight half-orbit. The result is an estimate of Landsat 8 geodetic accuracy of just over 18 meters (CE90), which is well below the 65 meter requirement. It is also better than the implied accuracy of the GLS control. This excellent geolocation accuracy leads to the somewhat unexpected conclusion that Level 1Gt products that do not use the GLS ground control will, in many cases, have better absolute accuracy, though poorer multi-temporal consistency, than L1T products.

3.2. Geometric Accuracy

The Landsat 8 geometric accuracy requirement refers to the accuracy of Level 1T products, after the application of ground control. This 12-meter CE90 requirement was intended to control the internal geometric accuracy of OLI images and was specified to be based upon GPS-quality ground control points and digital elevation data with accuracy commensurate with the Shuttle Radar Topography Mission (SRTM). From the previous section it should be apparent that ground control point accuracy will be a more important driver of operational Level 1T product accuracy than will Landsat 8 image geometry. This requirement has thus come to be considered in two contexts: (1) verification of the original 12-meter CE90 geometric accuracy requirement using calibration sites; and (2) characterization of Level 1T product accuracy relative to the GLS ground control framework, which is itself nominally accurate to 25 meters net root-mean-squared error (RMSE) or, equivalently, 38 meters CE90 [

5]. It is worth noting that the excellent geolocation accuracy of Landsat 8 has made it possible to identify regions where the GLS control has substantially larger than expected errors. The worst of these are in the process of being improved, as is briefly described below.

At the time the GLS control point database was created, sites that contained a sufficiently large number of control points had a subset of the points identified as verification points. These verification points, which are not used in control point correction, are correlated with the final Level 1T product to measure its accuracy relative to the GLS geometric framework. These statistics are collected in the IAS trending database for every Level 1T product for which verification points are available.

Landsat 8 system internal geometric accuracy is evaluated at calibration sites using both high precision DOQ/SPOT-derived control and the GLS verification point results for those sites.

Figure 9 shows a plot of the Level 1T geometric accuracy results by calendar quarter for four different combinations of control point source and scene type: (1) DOQ/SPOT control at calibration sites; (2) GLS verification points at calibration sites; (3) GLS verification points at anchor sites; and (4) the global set of GLS verification points.

Table 4 shows the summary results for these four cases.

Table 4.

Landsat 8 Level 1T product accuracy estimates.

Table 4.

Landsat 8 Level 1T product accuracy estimates.

| Control Source | Scene Type | Number of Scenes | Level 1T Accuracy (CE90 Meters) |

|---|

| DOQ (post-fit residuals) | Calibration Site | 352 | 6.7 |

| GLS (verification points) | Calibration Site | 640 | 7.8 |

| GLS (verification points) | Anchor Site | 6804 | 11.7 |

| GLS (verification points) | All | 78,962 | 12.6 |

Figure 9.

Level 1T product accuracy by calendar quarter. The accuracy estimates are highly sensitive to the quality of the ground control used to measure the accuracy.

Figure 9.

Level 1T product accuracy by calendar quarter. The accuracy estimates are highly sensitive to the quality of the ground control used to measure the accuracy.

The calibration site results derived from high-quality control points span the first year of operations and are well below the requirement threshold of 12 meters. It should be noted that these scenes are screened for cloud cover prior to being processed whereas GLS results are generated for every scene that achieves an acceptable control point fit, regardless of cloud cover which could impact the ability to correlate verification points. The GLS results show both a seasonal variation in accuracy, believed to be due to increased cloud and snow interference in the northern hemisphere winter, and performance across the full global database that exceeds the 12-meter requirement. These results show that, as was the case with geolocation accuracy, the accuracy of the GLS control limits the accuracy of the final Landsat 8 Level 1T data products. This further justifies the ongoing effort to improve the quality of the GLS control.

3.3. Band Registration Accuracy

Band-to-band registration accuracy characterizes the alignment of the nine OLI spectral bands contained in each Level 1T product. Band-to-band registration performance is measured by cross-correlating all pair-wise subsets of the spectral bands using cloud-free acquisitions of characterization sites selected to minimize inter-band spectral differences. These are mostly desert sites with little vegetation and high altitude sites where the cirrus band is able to see ground features.

It was originally believed that the cirrus band signal from the Earth’s surface would be so attenuated by atmospheric water vapor absorption that it would never provide a usable image signal for band registration. The Landsat 8 IAS was thus equipped with processing software that performs the band registration assessment measurements using lunar scan data. Each lunar scan provides usable data for only a portion of one FPM. The lack of coverage for the full FPM field of view makes the lunar data less desirable for band alignment calibration purposes than Earth-view data. Band alignment in the lunar data can also be biased by residual scan rate errors, making it less reliable than Earth-view data for band registration characterization. When spectral simulations of the OLI cirrus band showed that usable Earth signals could be expected for high altitude sites under dry atmospheres, the OLI calibration plan was modified to use Earth-image band registration measurements for all spectral bands.

OLI band registration accuracy performance for Level 1T products is required to be better than 4.5 meters (LE90) in both the line and sample directions, for all spectral band-pairs.

Figure 10 shows that the measured performance is below the requirement threshold for all band-pair combinations, and is well below the threshold for all band-pairs that do not include the cirrus band.

Table 5 summarizes the OLI band registration accuracy results for all bands except the cirrus band and for the complete set of OLI bands, including the cirrus band. Note that although the number of scenes available for cirrus band characterization is limited, it is still larger than the number of lunar scans conducted during the same time period. Even in scenes that are usable for cirrus band characterization the signal levels are relatively low, so the registration uncertainty is greater for the cirrus band that it is for the other bands.

Figure 10.

OLI band-to-band registration accuracy by band pair. Pairs including the cirrus band are grouped at the right end of the plot.

Figure 10.

OLI band-to-band registration accuracy by band pair. Pairs including the cirrus band are grouped at the right end of the plot.

Table 5.

OLI band registration accuracy, with and without the cirrus band. Both all-band average and worst case band-pair results are shown.

Table 5.

OLI band registration accuracy, with and without the cirrus band. Both all-band average and worst case band-pair results are shown.

| | Band RMS (LE90 Meters) | Worst Band Pair (LE90 Meters) |

|---|

| Band Set | Number of Scenes | Line | Sample | Line | Sample |

|---|

| Excluding Cirrus Band | 482 | 2.7 | 2.6 | 3.4 | 3.3 |

| All Bands | 29 | 3.7 | 3.4 | 4.1 | 4.0 |

3.4. Image Registration Accuracy

In addition to characterizing the geometric accuracy of Level 1T products as described above, the internal geometric accuracy of OLI images is evaluated by measuring the alignment of Level 1T products acquired over the same site over time. Image-to-image registration accuracy, which is specified to be 12 meters (LE90) or better in the line and sample directions, is characterized by correlating pairs of Level 1T products over the same WRS path/row. The earliest-acquired cloud-free image of a given test site is chosen as a reference image that is compared to subsequent acquisitions. The resulting registration accuracy assessment is less sensitive to the quality of the ground control and verification points since it is a direct comparison of two OLI images, albeit images that have both been corrected using the GLS ground control. This characterization uses cloud-free images over a set of test sites selected to provide a good north-south geographic distribution in order to look for performance differences associated with position in orbit.

Figure 11 shows a graphical depiction of the measured image registration accuracy results from 128 scenes acquired over 10 test sites. Note that even the worst-case scene measured as of March 2014 was well within the required accuracy.

Figure 11.

OLI image-to-image registration accuracy; blue bars—average over all test scenes; red bars—worst-case test scene.

Figure 11.

OLI image-to-image registration accuracy; blue bars—average over all test scenes; red bars—worst-case test scene.

Table 6 shows the accuracy values corresponding to the plot. It should be noted that these results, derived from 15-meter ground sample distance panchromatic band data, are approaching the accuracy limitations (0.1 to 0.2 pixel) of the image correlation tools used to measure the image-to-image displacements.

Table 6.

OLI multi-temporal image-to-image registration accuracy results.

Table 6.

OLI multi-temporal image-to-image registration accuracy results.

| All Scene RMS (LE90 Meters) | Worst Scene (LE90 Meters) | Specification (LE90 Meters) |

|---|

| Line | Sample | Line | Sample | Line | Sample |

|---|

| 3.052 | 2.250 | 6.623 | 5.051 | 12 | 12 |