Estimating Leaf Bulk Density Distribution in a Tree Canopy Using Terrestrial LiDAR and a Straightforward Calibration Procedure

Abstract

:1. Introduction

2. Material and Methods

2.1. Study Area and Plot Description

| Characteristics | Plot 1 | Plot 2 | Plot 3 | Plot 4 |

|---|---|---|---|---|

| Stem number | 31 | 59 | 42 | 65 |

| Max height (m) | 8.3 | 8.4 | 10.7 | 12 |

| Total basal area (m2·ha−1) | 18 | 30 | 30 | 40 |

| Quercus pubescens % | 94 | 83 | 71 | 85 |

2.2. Calibration Volumes (CV): Description and Measurement

2.3. TLS Instrument and Measurements

2.4. Definition of Density Indices in Spherical Volumes

2.5. Processing TLS Data

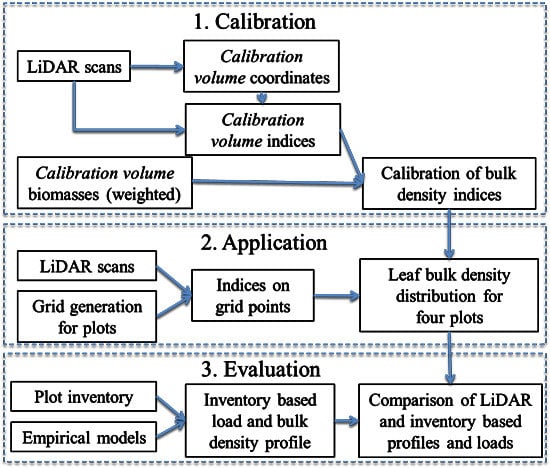

2.5.1. General Framework

2.5.2. Computation of Calibration Volume Locations

2.5.3. Model Calibration over Calibration Volumes

2.5.4. Model Application to Bulk Density Estimation

3. Results

3.1. CV Data

| CV Characteristics | Mean | Min | Max | Standard Deviation |

|---|---|---|---|---|

| Leaf bulk density (kg·m−3) | 0.167 | 0.0388 | 0.313 | 0.0595 |

| Center height (m) | 4.23 | 1.69 | 7.83 | 1.37 |

3.2. Model Calibration

| Index I | Element Distribution | Criteria | Calibration Parameter | Standard Error | R2 | R2 (on CV with Ni > 1000) |

|---|---|---|---|---|---|---|

| I1 | Spherical | (Ni)max | 0.0958 | 0.0035 | 0.60 | −0.19 |

| I1 | Spherical | (Nt − Nb)max | 0.0973 | 0.0043 | 0.42 | −0.16 |

| I2 | Spherical | (Ni)max | 0.0676 | 0.0026 | 0.53 | 0.34 |

| I2 | Spherical | (Nt − Nb)max | 0.0728 | 0.0031 | 0.37 | 0.36 |

| I3 | Spherical | (Ni)max | 0.0723 | 0.0021 | 0.73 | 0.45 |

| I3 | Spherical | (Nt − Nb)max | 0.0740 | 0.0027 | 0.60 | 0.45 |

| I3 | Plagiophile | (Ni)max | 0.0767 | 0.0022 | 0.74 | 0.32 |

| I3 | Uniform | (Ni)max | 0.0776 | 0.0022 | 0.74 | 0.29 |

| I3 | Erectophile | (Ni)max | 0.0782 | 0.0025 | 0.60 | 0.36 |

| I3 | Planophile | (Ni)max | 0.0764 | 0.0039 | 0.22 | −0.78 |

3.3. Model Application and Evaluation

4. Discussion

4.1. Method Performance for LiDAR-Derived Bulk Densities

4.2. Accuracy and Cost Comparison of Inventory- and LiDAR-Based Method

4.3. Benefits and Drawbacks of Calibration vs. Direct Estimation by LiDAR

4.4. Future Work

4.5. Applications

5. Conclusion

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Y.P.; Jarvis, P.G. Description and validation of an array model-MAESTRO. Agric. For. Meteorol. 1990, 51, 257–280. [Google Scholar] [CrossRef]

- Sellers, P.J.; Dickinson, R.E.; Randall, D.A.; Betts, A.K.; Hall, F.G.; Berry, J.A.; Collatz, G.J.; Denning, A.S.; Mooney, H.A.; Nobre, C.A.; et al. Modelling the exchanges of energy, water, and carbon between continents and the atmosphere. Science 1997, 275, 502–509. [Google Scholar] [CrossRef] [PubMed]

- Simioni, G.; Gignoux, J.; le Roux, X. Tree layer spatial structure can affect savanna production and water budget: Results of a 3D model. Ecology 2003, 84, 1879–1894. [Google Scholar] [CrossRef]

- Charbonnier, F.; le Maire, G.; Dreyer, E.; Casnoves, F.; Christina, M.; Dauzat, J.; Eitel, J.U.H.; Vaast, P.; Vierling, L.A.; Roupsard, O. Competition for light in heterogeneous canopies: Application of MAESTRA to a coffee (Coffea arabica L.) agroforestry system. Agric. For. Meteorol. 2013, 181, 152–169. [Google Scholar] [CrossRef]

- Kobayashi, H.; Baldocchi, D.D.; Ryu, Y.; Chen, Q.; Ma, S.; Osuna, J.L.; Ustin, S.L. Modeling energy and carbon fluxes in a heterogeneous oak Woodland: A three dimensional approach. Agric. For. Meteorol. 2012, 152, 83–100. [Google Scholar] [CrossRef]

- Olchev, A.; Radler, K.; Sogachev, A.; Panferov, O.; Gravenhorst, G. Application of a three-dimensional model for assessing effects of small clear-cuttings on radiation and soil temperature. Ecol. Model. 2009, 220, 3046–3056. [Google Scholar] [CrossRef]

- Arroyo, L.A.; Pascual, C.; Manzanera, J.A. Fire models and methods to map fuel types: The role of remote sensing. For. Ecol. Manag. 2008, 256, 1239–1252. [Google Scholar] [CrossRef] [Green Version]

- Weise, D.R.; Wright, C.S. Wildland fire emissions, carbon and climate: Characterizing wildland fuels. For. Ecol. Manag. 2014, 317, 26–40. [Google Scholar] [CrossRef]

- Pimont, F.; Dupuy, J.-L.; Caraglio, Y.; Morvan, D. Effect of vegetation heterogeneity on radiative transfer in forest fires. Int. J. Wildl. Fire 2009, 18, 536–553. [Google Scholar] [CrossRef]

- Pimont, F.; Dupuy, J.-L.; Linn, R.R.; Dupont, S. Impact of tree canopy structure on wind-flows and fire propagation simulated with FIRETEC. Ann. For. Sci. 2011, 68, 523–530. [Google Scholar] [CrossRef]

- Parsons, R.; Mell, W.E.; McCauley, P. Linking 3D spatial models of fuels and fire: Effects of spatial heterogeneity on fire behavior. Ecol. Model. 2011, 222, 679–691. [Google Scholar] [CrossRef]

- Brown, J.K. Weight and Density of Crowns of Rocky Mountains Conifers; USDA Forest Service, Intermountain Forest and Range Experiment Station, Research Paper INT-197; USDA Forest Service: Ogden, UT, USA, 1978; p. 56. [Google Scholar]

- Baldwin, V.C., Jr.; Peterson, K.D.; Burkhart, H.E.; Amatais, R.L.; Dougherty, P.M. Equation for estimating loblolly pine branch and foliage weight and surface area distributions. Can. J. For. Res. 1997, 27, 918–927. [Google Scholar] [CrossRef]

- Monserud, R.A.; Marshall, J.D. Allometric crown relations in three northern Idaho conifer species. Can. J. For. Res. 1999, 29, 521–535. [Google Scholar] [CrossRef]

- Shaiek, O.; Loustau, D.; Trichet, P.; Meredieu, C.; Bachtobji, B.; Garchi, S.; El Aouni, M.H. Generalized biomass equations for the main aboveground biomass components of maritime pine across contrasting environments. Ann. For. Sci. 2011, 68, 443–452. [Google Scholar] [CrossRef]

- Weiss, M.; Baret, F.; Smith, G.J.; Jonckheere, I.; Coppin, P. Review of methods for in-situ LAI determination, Part II: Estimation of LAI, errors and sampling. Agric. For. Meteorol. 2004, 121, 36–53. [Google Scholar]

- Durrieu, S.; Allouis, T.; Fournier, R.A.; Véga, C.; Albrech, L. Spatial quantification of vegetation density from terrestrial laser scanner data for characterization of 3D Forest structure at plot level. In Proceedings of the SilviLaser 2008, Edinburgh, UK, 17–19 September 2008.

- Côté, J.-F.; Fournier, R.A.; Egli, R. An architectural model of trees to estimate forest structural attributes using terrestrial LiDAR. Environ. Model. Softw. 2011, 26, 761–777. [Google Scholar] [CrossRef]

- Béland, M.; Widlowski, J.-L.; Fournier, R.A.; Côté, J.-F.; Verstraete, M. Estimating leaf area distribution in savanna trees from terrestrial LiDAR measurements. Agric. For. Meteorol. 2011, 151, 1252–1266. [Google Scholar] [CrossRef]

- Seielstad, C.; Stonesifer, C.; Rowell, E.; Queen, L. Deriving fuel mass by size class in douglas-fir (Pseudotsuga menziesii) using terrestrial laser scanning. Remote Sens. 2011, 3, 1691–1709. [Google Scholar] [CrossRef]

- Béland, M.; Baldocchi, D.D.; Widlowski, J.-L.; Fournier, R.A.; Verstraete, M.M. On seing the wood from the leaves and the role of voxel size in determining leaf area distribution of forests with terrestrial LiDAR. Agric. For. Meteorol. 2014, 184, 82–97. [Google Scholar] [CrossRef]

- Hosoi, F.; Omasa, K. Voxel based 3D modeling of individual trees for estimating leaf area density using high-resolution portable scanning LiDAR. IEEE Trans. Geosci. Remote Sens. 2006, 44, 3610–3618. [Google Scholar] [CrossRef]

- Hosoi, F.; Omasa, K. Factors contributing to accuracy in the estimation of the woody canopy leaf area density profile using 3D portable LiDAR imaging. J. Exp. Bot. 2007, 58, 3463–3473. [Google Scholar] [CrossRef] [PubMed]

- Skowronski, N.S.; Clark, K.L.; Duveneck, M.; Hom, J. Three-dimensional canopy fuel predicted using upward and downward sensing LiDAR systems. Remote Sens. Environ. 2011, 115, 703–714. [Google Scholar] [CrossRef]

- Hiers, J.K.; O’Brien, J.J.; Mitchell, R.J.; Grego, J.M. The wildland fuel cell concept: An approach to characterize fine-scale variation in fuels and fire in frequently burned longleaf pine forests. Int. J. Wildl. Fire 2009, 18, 315–325. [Google Scholar] [CrossRef]

- Loudermilk, E.L.; O’Brien, J.J.; Mitchell, R.J.; Cropper, W.P.; Hiers, J.K.; Grunwald, S.; Grego, J.; Fernandez-Diaz, J.C. Linking complex forest fuel structure and fire behaviour at fine scales. Int. J. Wildl. Fire 2012, 21, 882–893. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzalez, E.; Estornell, J.; Ruiz, L.A. Dendrometric and dasometric analysis of the bushy biomass in Mediterranean forests. For. Ecol. Manag. 2010, 259, 875–882. [Google Scholar] [CrossRef]

- Rowell, E.; Seielstad, C. Characterizing grass, litter, and shrub fuels in longleaf pine forest pre-and post-fire using terrestrial LiDAR. In Proceedings of the SilivLaser 2012 Conference, Vancouver, BC, Canada, 16–19 September 2012; p. 9.

- Hebert, M.; Kroktov, E. 3-D Measurements from imaging laser radars: How good are they? Int. J. Image Vis. Comput. 1992, 10, 170–178. [Google Scholar] [CrossRef]

- Ross, J. The Radiation Regime and Architecture of Plant Stands. Task for Vegetation Sciences 3; Springer: The Hague, The Netherlands, 1981; p. 391. [Google Scholar]

- Segelstein, D. The Complex Refractive Index of Water. In Master’s Thesis; University of Missouri: Kansas City, MI, USA, 1981. [Google Scholar]

- Goward, S.N.; Huemmrich, K.F.; Waring, R.H. Visible-NearInfrared spectral reflectance of landscape components in western Oregon. Remote Sens. Environ. 1994, 47, 190–203. [Google Scholar] [CrossRef]

- Dagnélie, P. Théorie et Méthodes Statistiques; Les Presses Agronomiques de Gembloux: Gembloux, Belgique, 1975; Volume 2. [Google Scholar]

- Ruel, J.J.; Ayres, M.P. Jensen’s inequality predicts effects of environmental variation. Trends Ecol. Evol. 1999, 14, 361–366. [Google Scholar] [CrossRef]

- Béland, M.; Widlowski, J.-L.; Fournier, R.A. A model for deriving voxel-level tree leaf area density estimates from ground-based LiDAR. Environ. Model. Softw. 2014, 51, 184–189. [Google Scholar] [CrossRef]

- Van Wagner, C.E. Conditions for the start and spread of crown fire. Can. J. For. Res. 1977, 7, 23–24. [Google Scholar] [CrossRef]

- Cruz, M.G.; Alexander, M.E.; Wakimoto, R.H. Development and testing of models for predicting crown fire rate of spread in conifer forest stands. Can. J. For. Res. 2005, 35, 1626–1639. [Google Scholar] [CrossRef]

- Contreras, M.A.; Parsons, R.A.; Chung, W. Modeling tree-level fuel connectivity to evaluate the effectiveness of thinning treatments for reducing crown fire potential. For. Ecol. Manag. 2012, 264, 134–149. [Google Scholar] [CrossRef]

- Taylor, S.W.; Wotton, B.M.; Alexander, M.E.; Dalrymple, G.N. Variation in wind and crown fire behaviour in a northern jack pine—Black spruce forest. Can. J. For. Res. 2004, 34, 1561–1576. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pimont, F.; Dupuy, J.-L.; Rigolot, E.; Prat, V.; Piboule, A. Estimating Leaf Bulk Density Distribution in a Tree Canopy Using Terrestrial LiDAR and a Straightforward Calibration Procedure. Remote Sens. 2015, 7, 7995-8018. https://doi.org/10.3390/rs70607995

Pimont F, Dupuy J-L, Rigolot E, Prat V, Piboule A. Estimating Leaf Bulk Density Distribution in a Tree Canopy Using Terrestrial LiDAR and a Straightforward Calibration Procedure. Remote Sensing. 2015; 7(6):7995-8018. https://doi.org/10.3390/rs70607995

Chicago/Turabian StylePimont, François, Jean-Luc Dupuy, Eric Rigolot, Vincent Prat, and Alexandre Piboule. 2015. "Estimating Leaf Bulk Density Distribution in a Tree Canopy Using Terrestrial LiDAR and a Straightforward Calibration Procedure" Remote Sensing 7, no. 6: 7995-8018. https://doi.org/10.3390/rs70607995

APA StylePimont, F., Dupuy, J.-L., Rigolot, E., Prat, V., & Piboule, A. (2015). Estimating Leaf Bulk Density Distribution in a Tree Canopy Using Terrestrial LiDAR and a Straightforward Calibration Procedure. Remote Sensing, 7(6), 7995-8018. https://doi.org/10.3390/rs70607995