Automatic Power Line Inspection Using UAV Images

Abstract

:1. Introduction

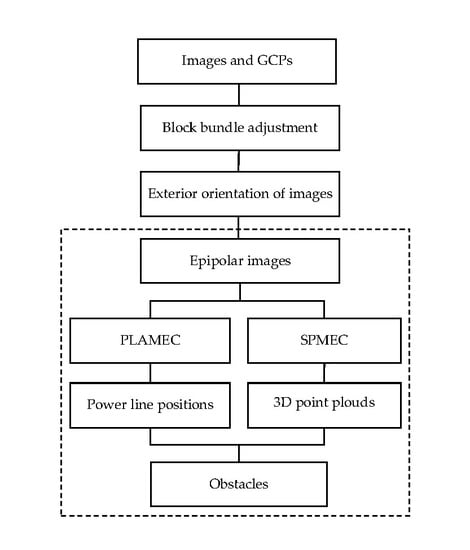

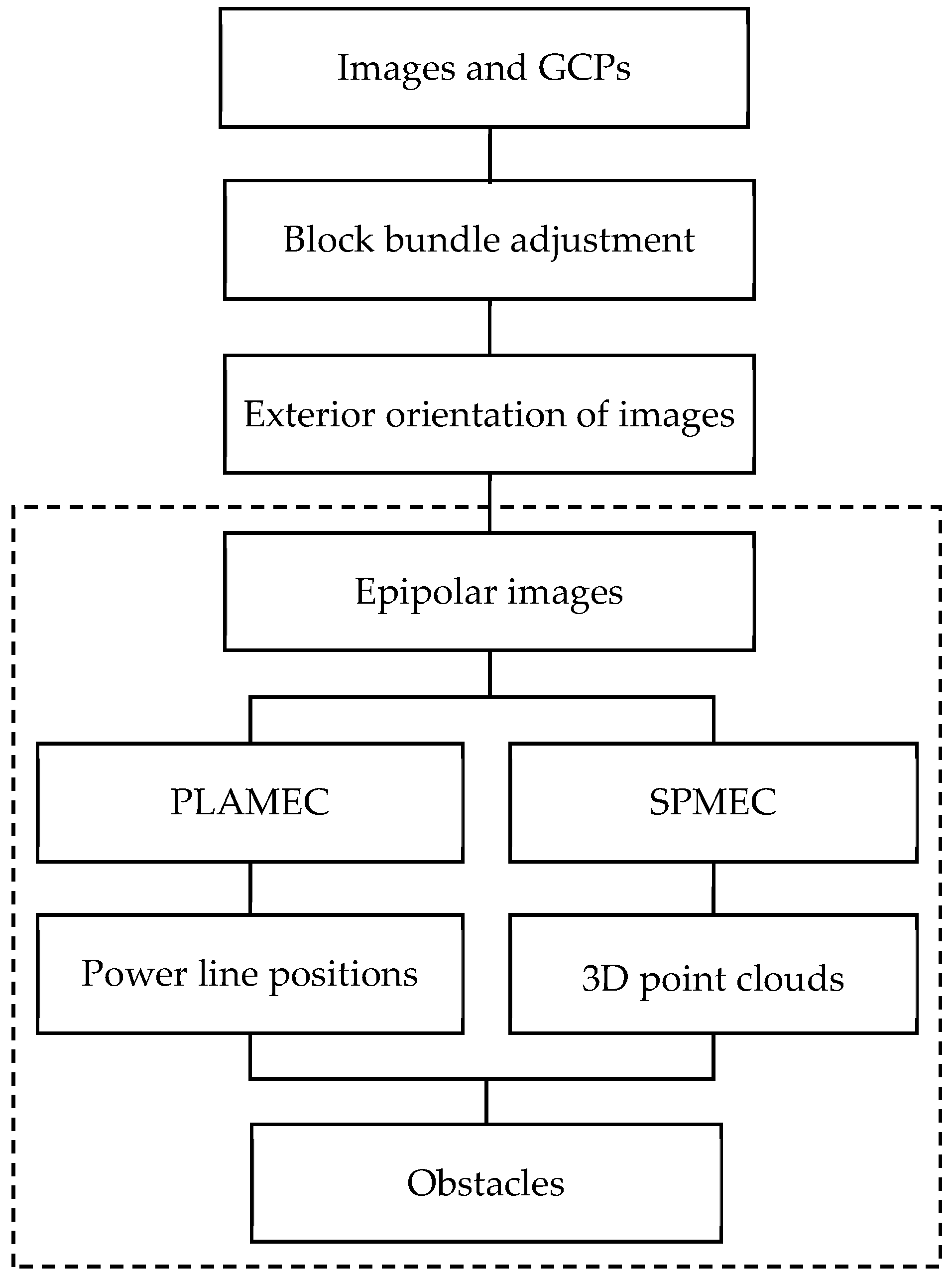

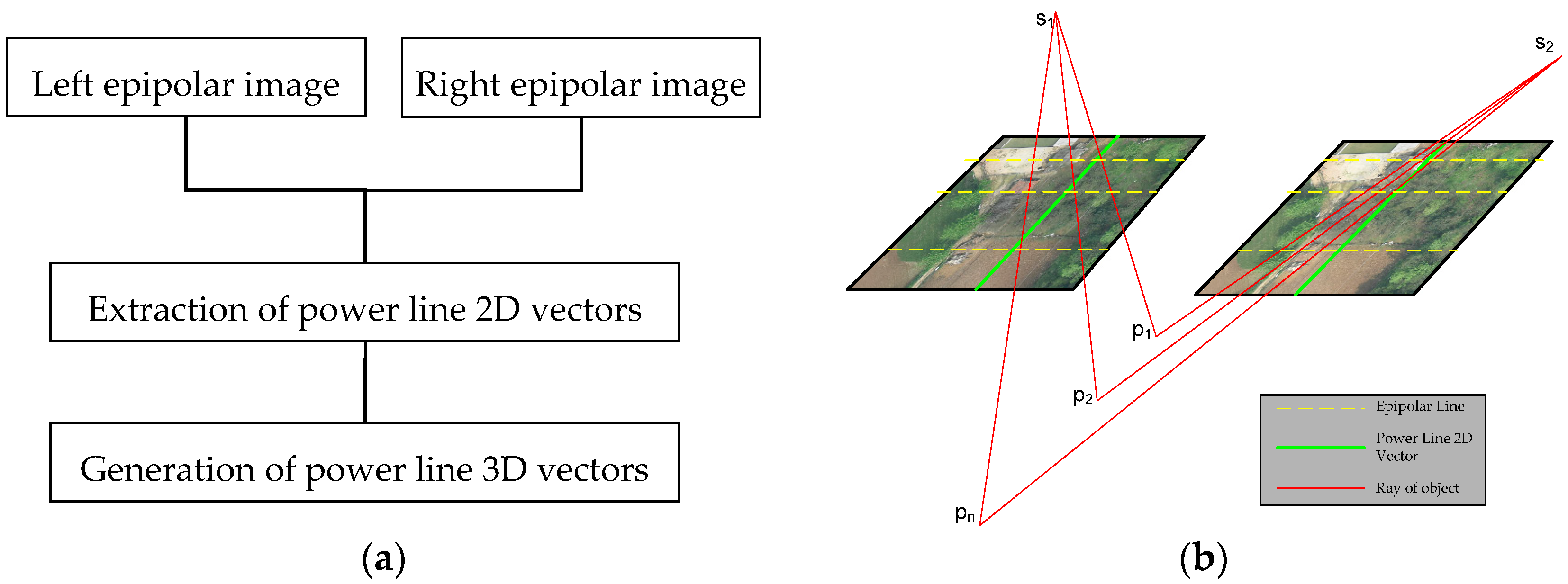

2. Methodology

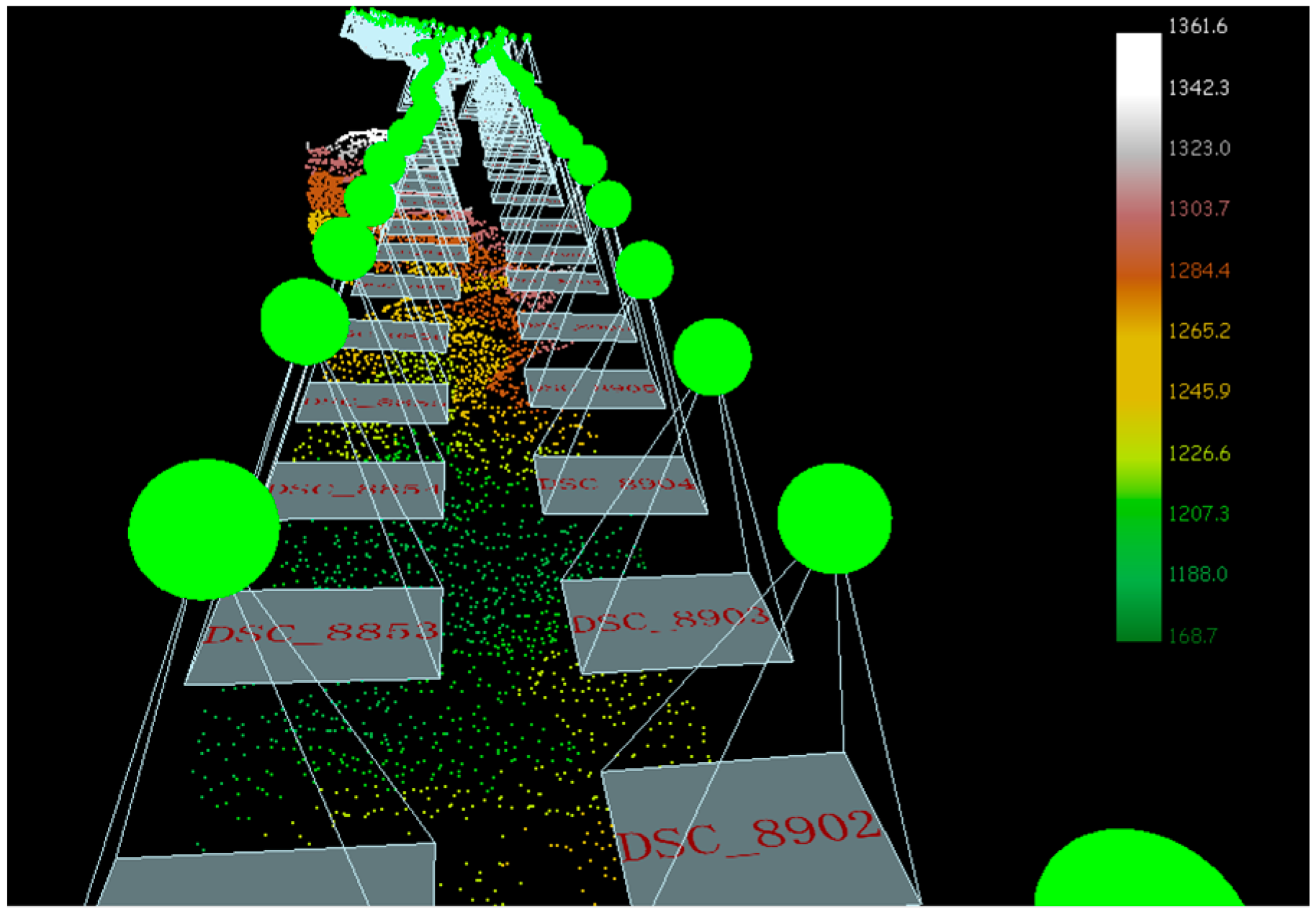

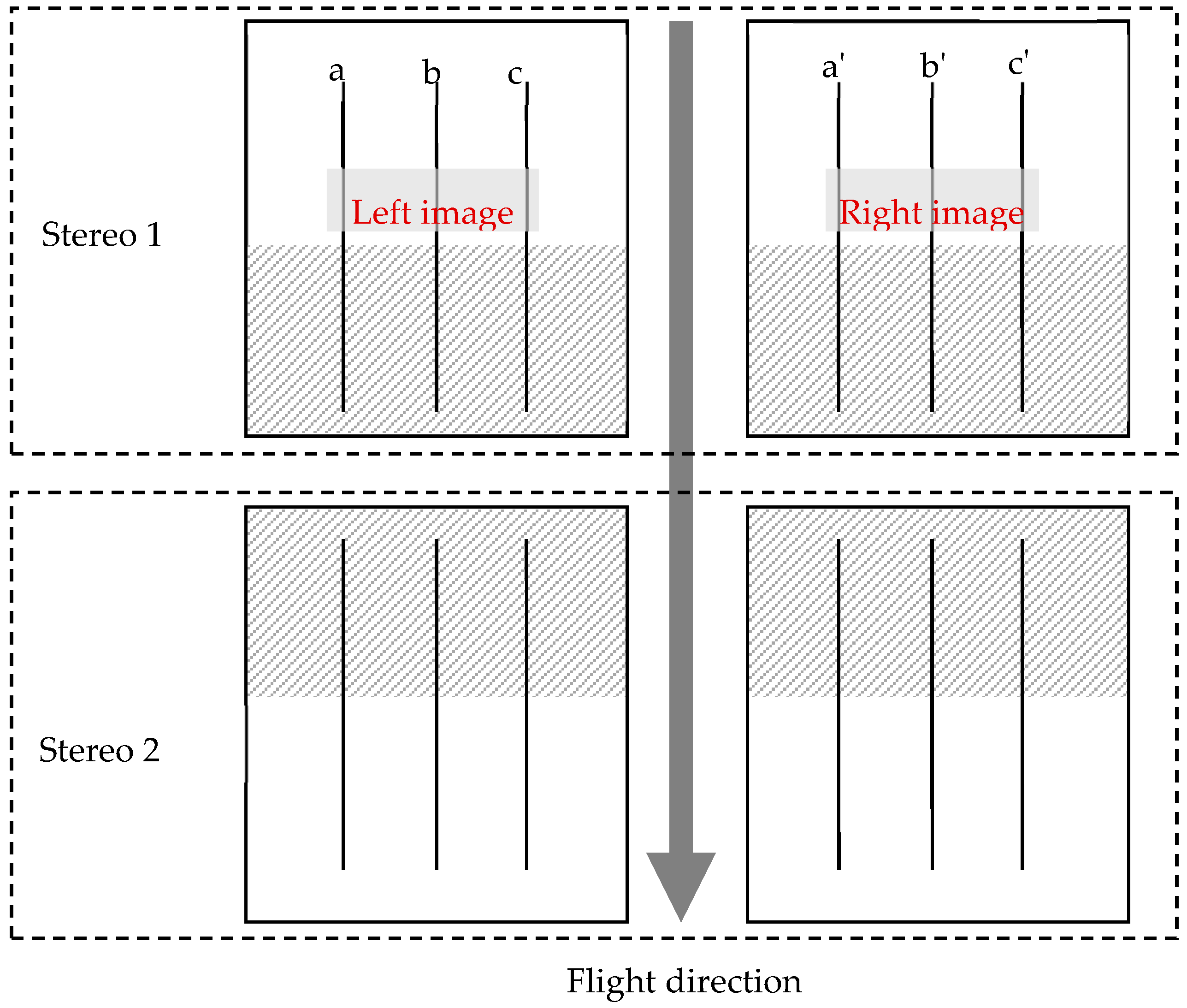

2.1. Power Line Automatic Measurement Method Based on Epipolar Constraints

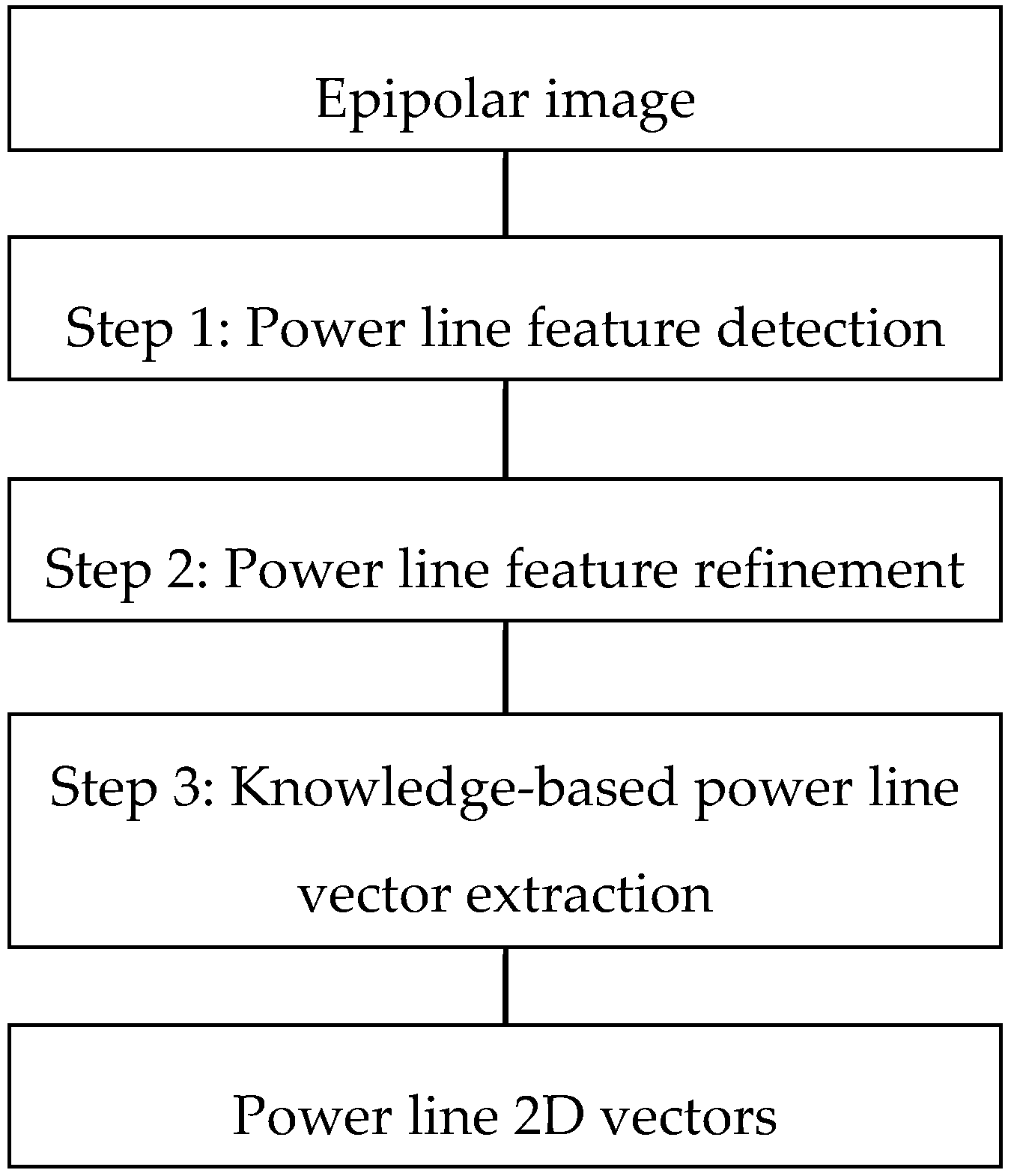

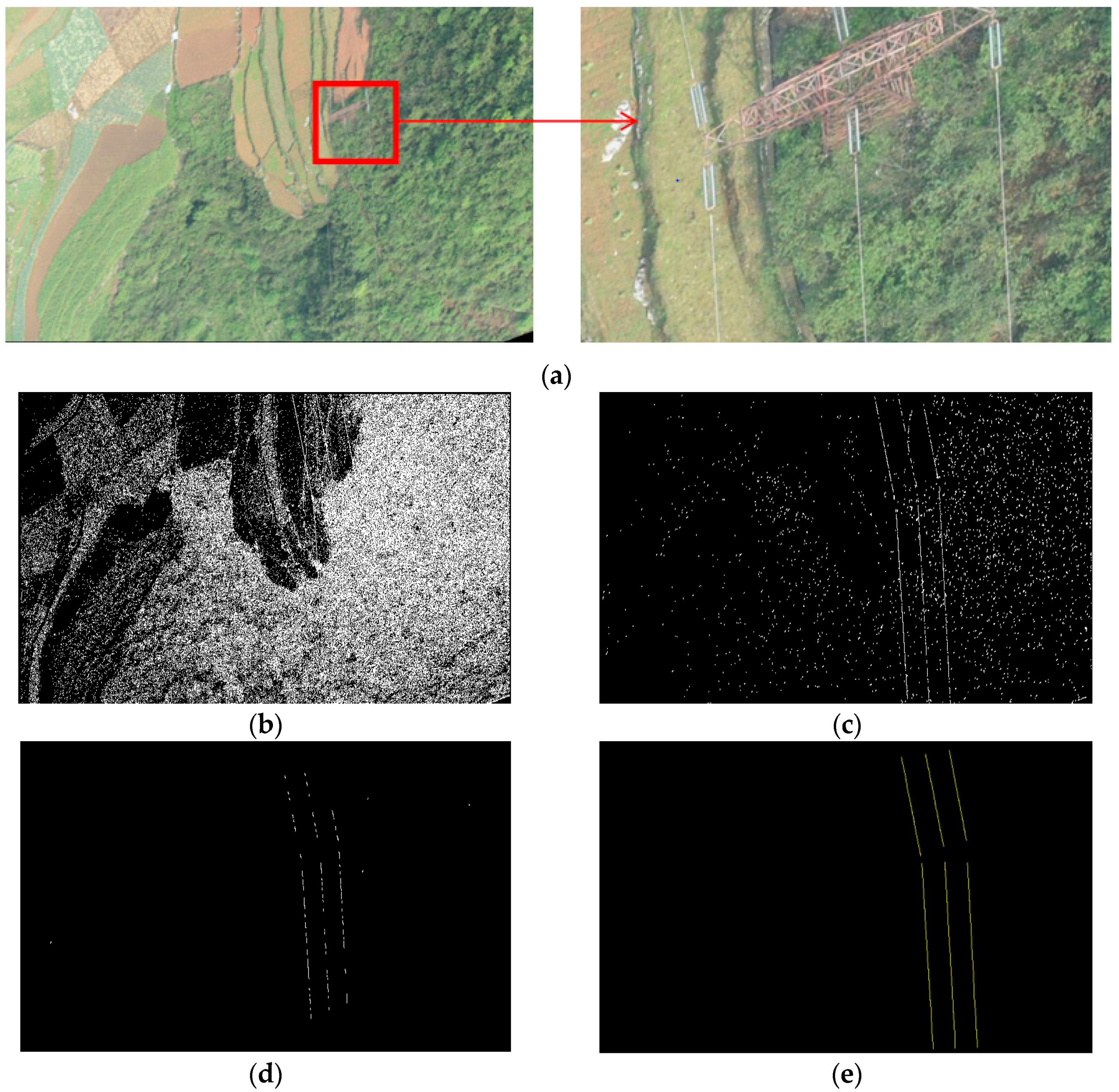

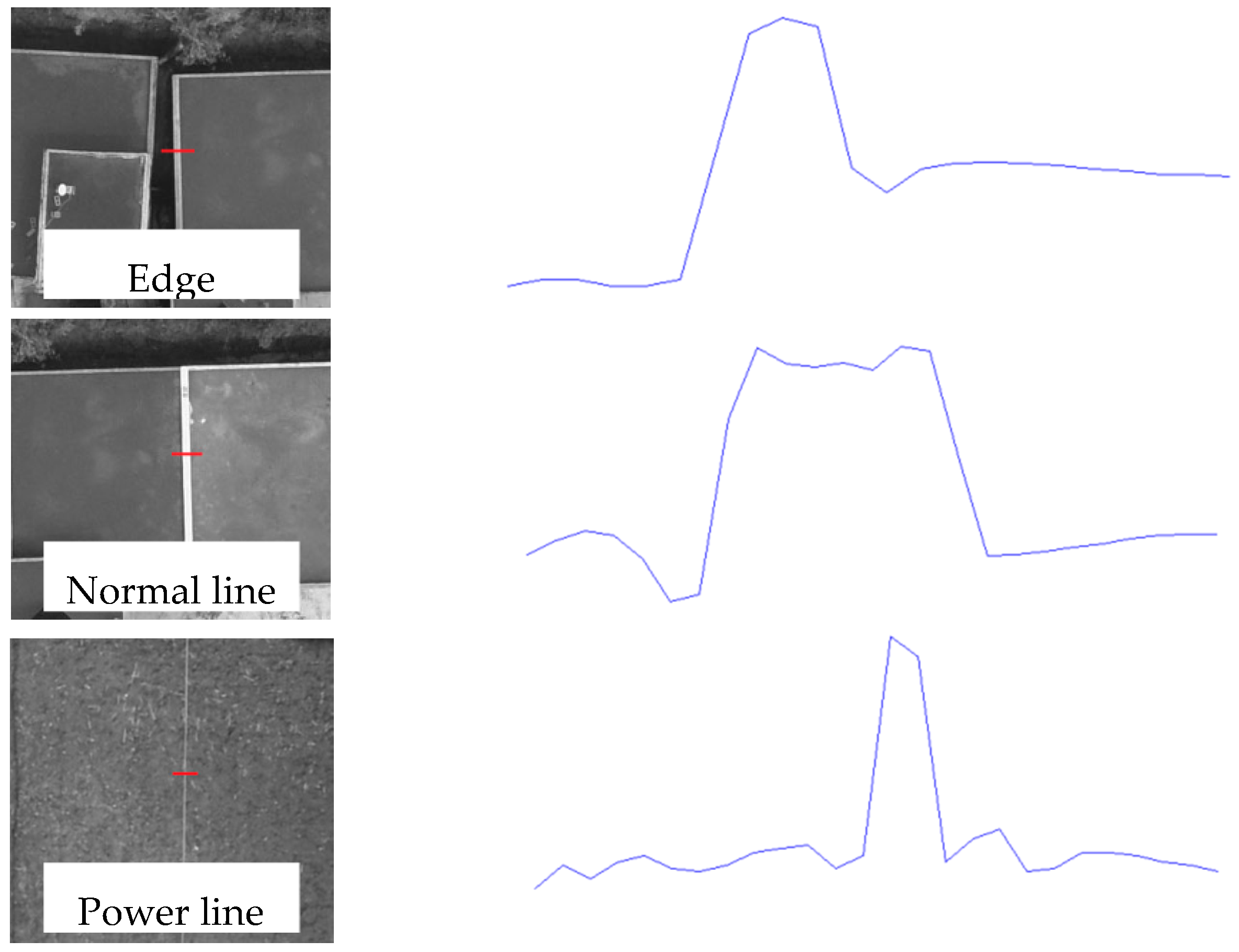

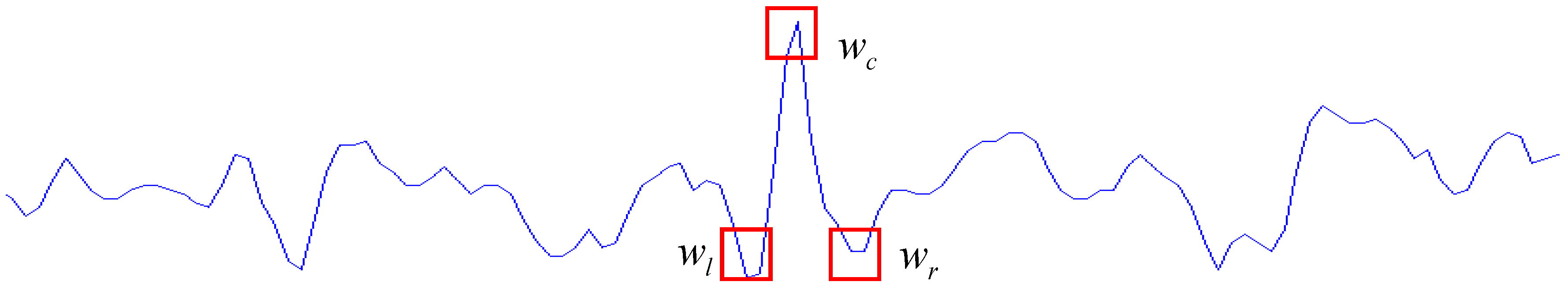

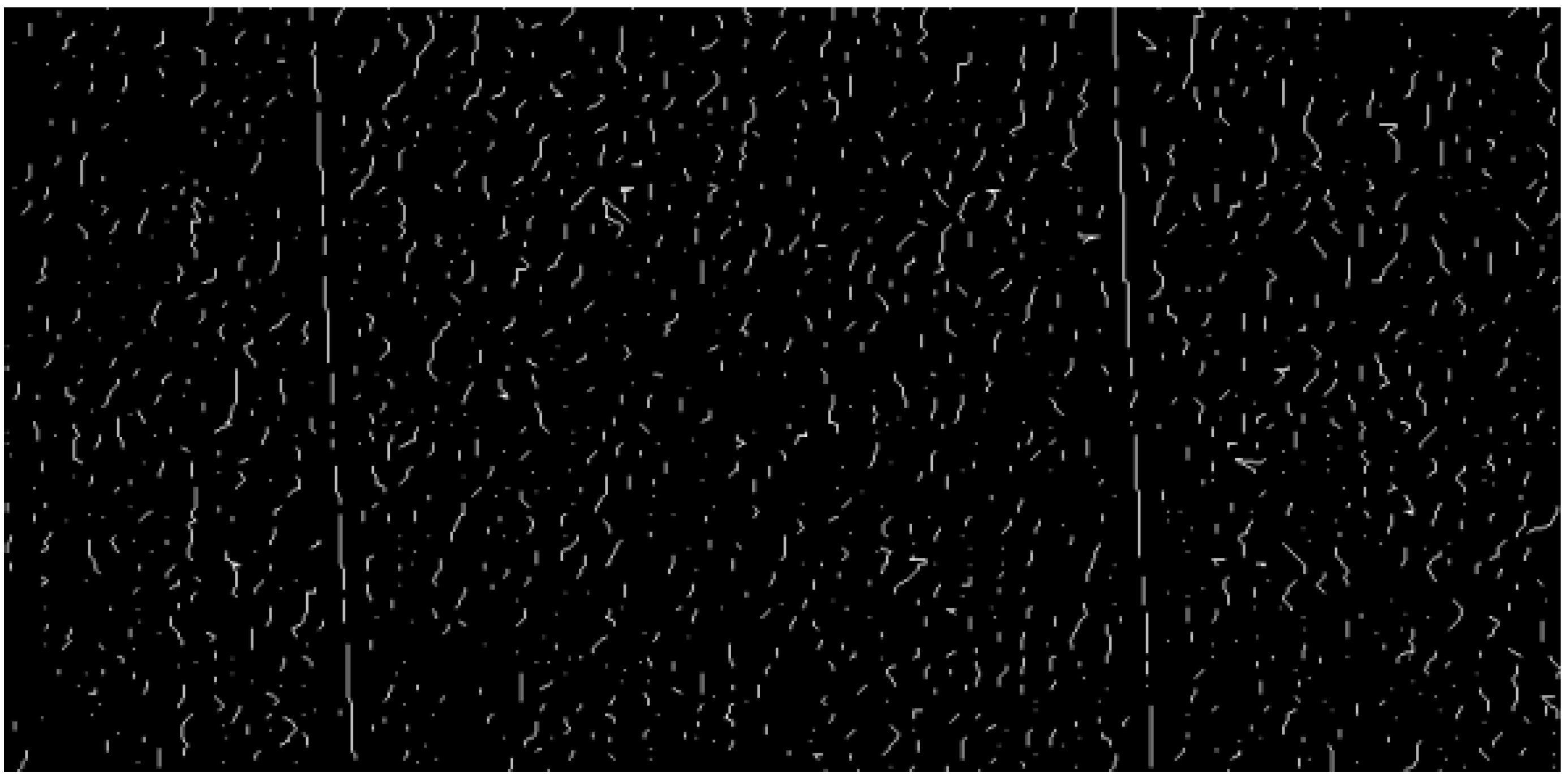

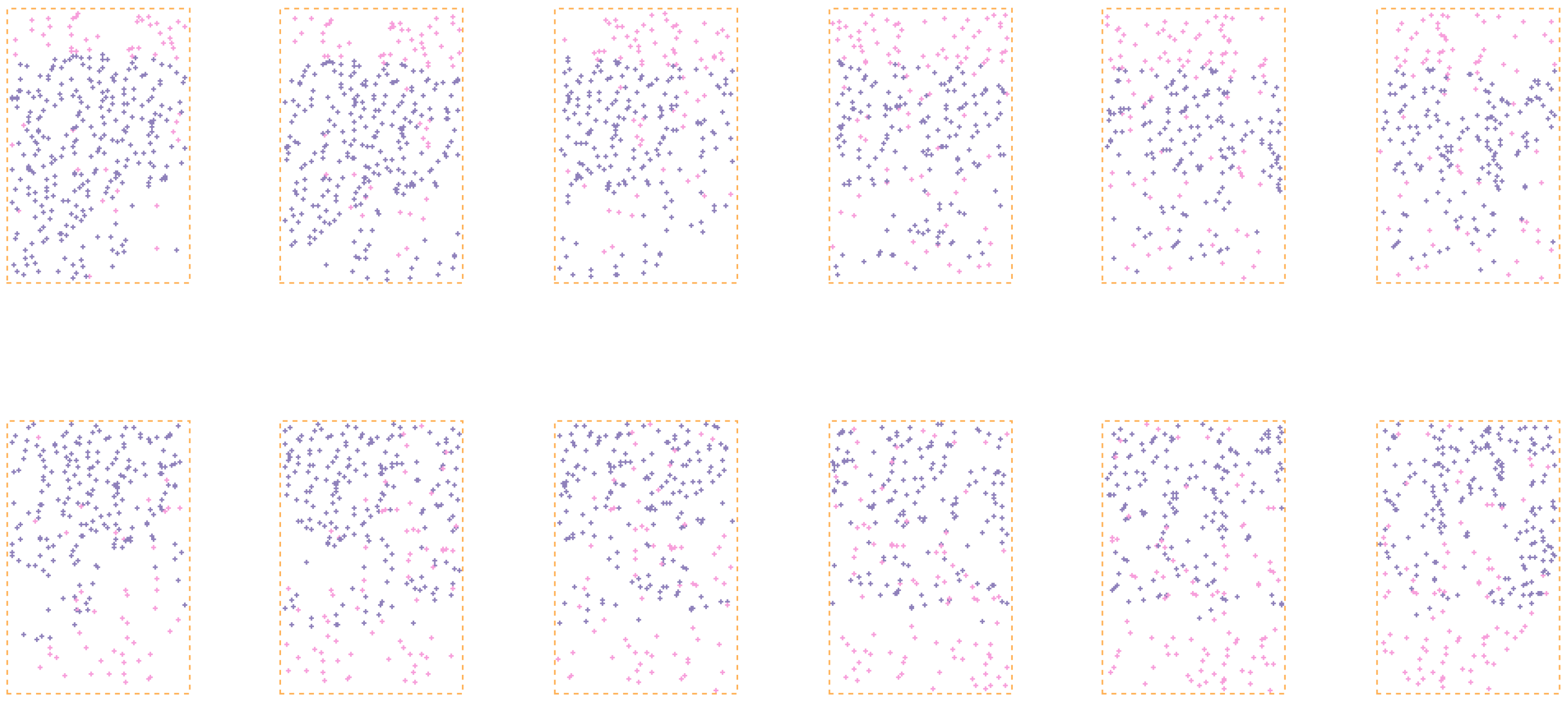

2.1.1. Automatic Extraction of Power Line 2D Vectors from Epipolar Images

2.1.2. Automatic Generation of Power Line 3D Vectors

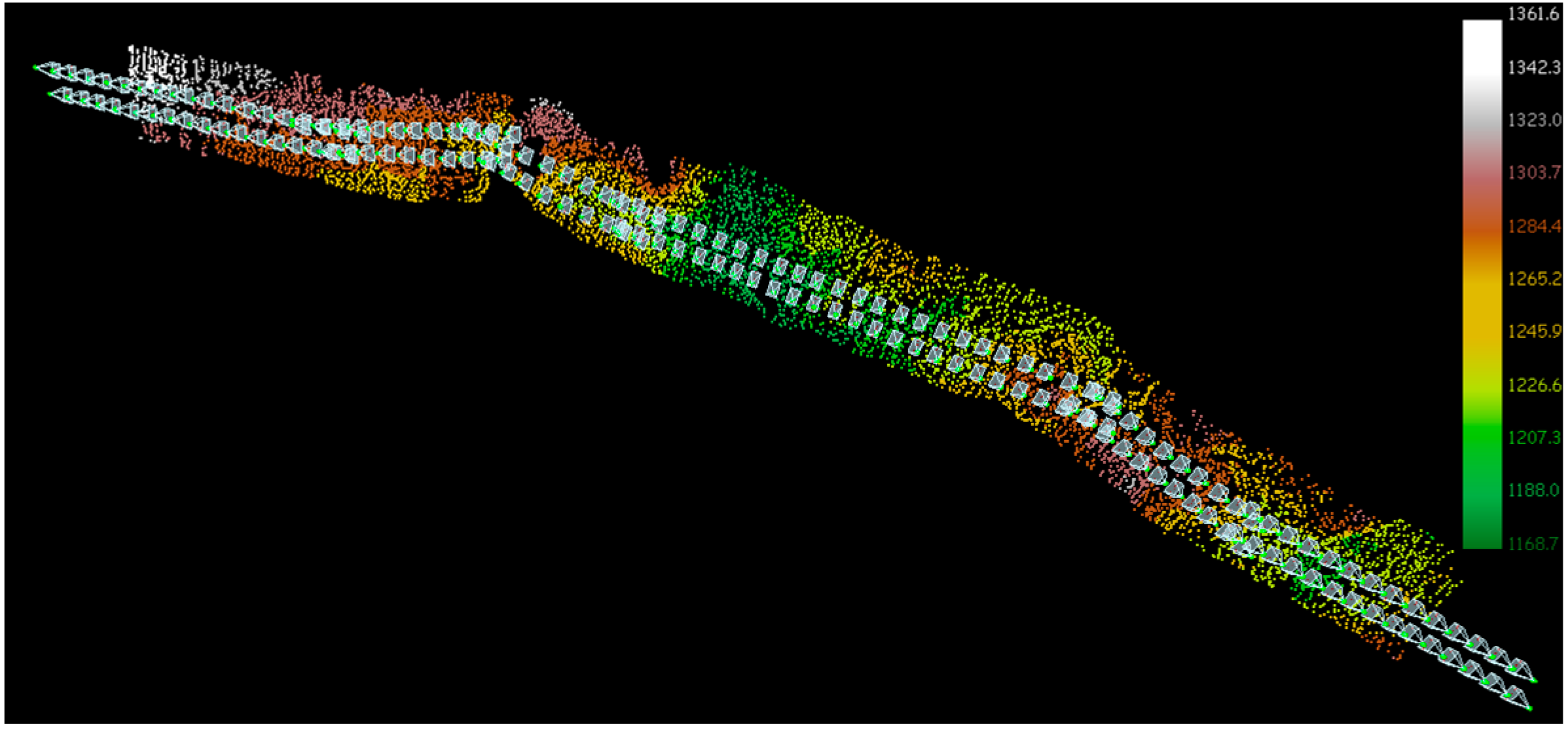

2.2. Power Line Corridor 3D Reconstruction Using the SPMEC

2.3. Automatic Detection of Obstacles within a Power Line Corridor

3. Results and Discussion

3.1. Basic Conditions of the Experimental Data

3.2. Analysis of the Block Bundle Adjustment

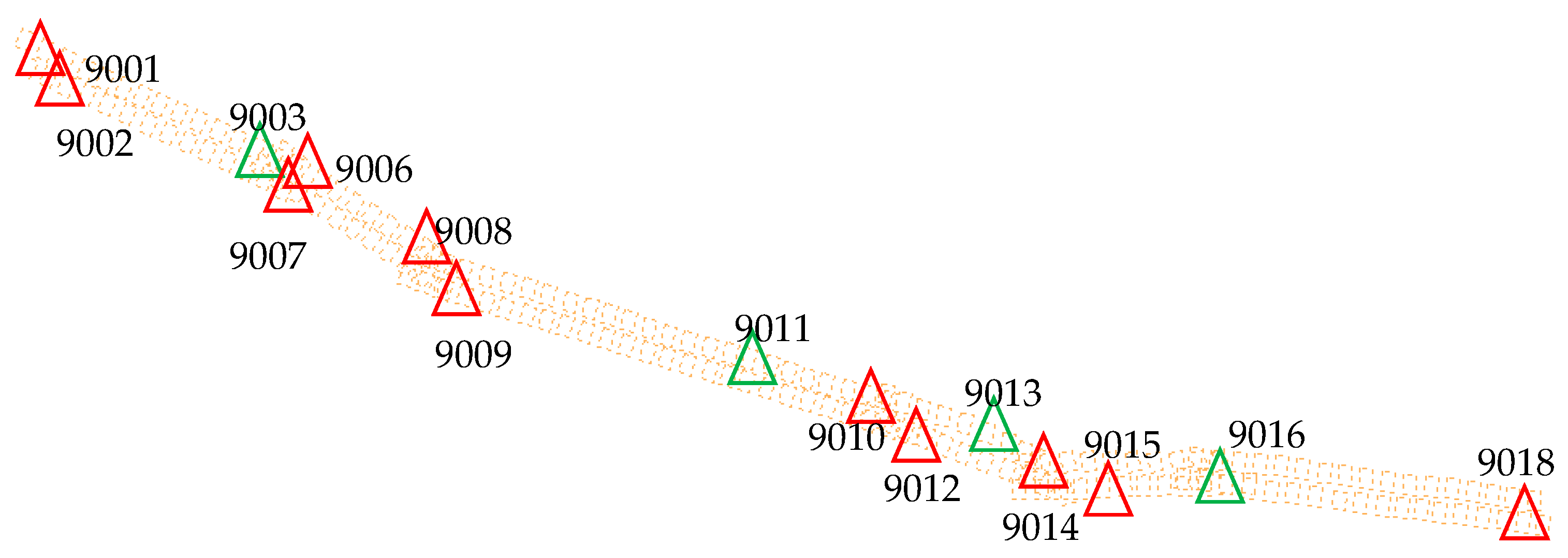

3.3. Analysis of the Results of Automatic Power Line Measurements

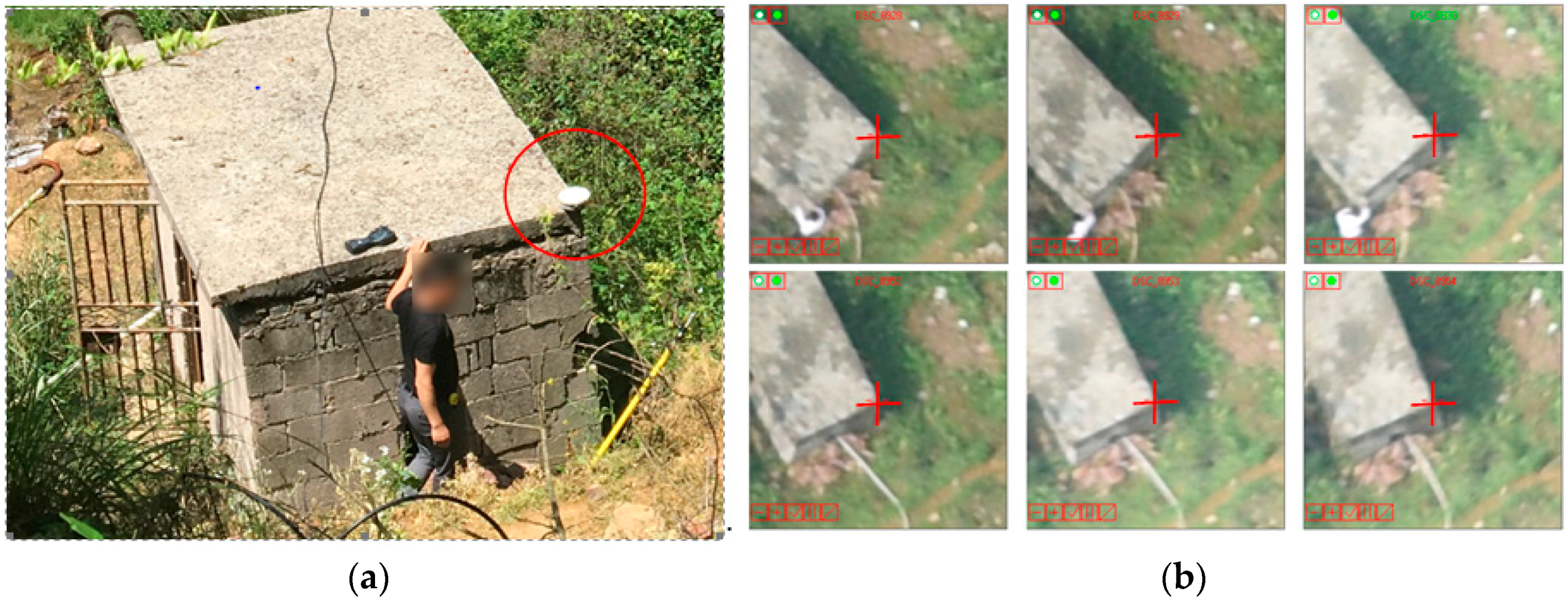

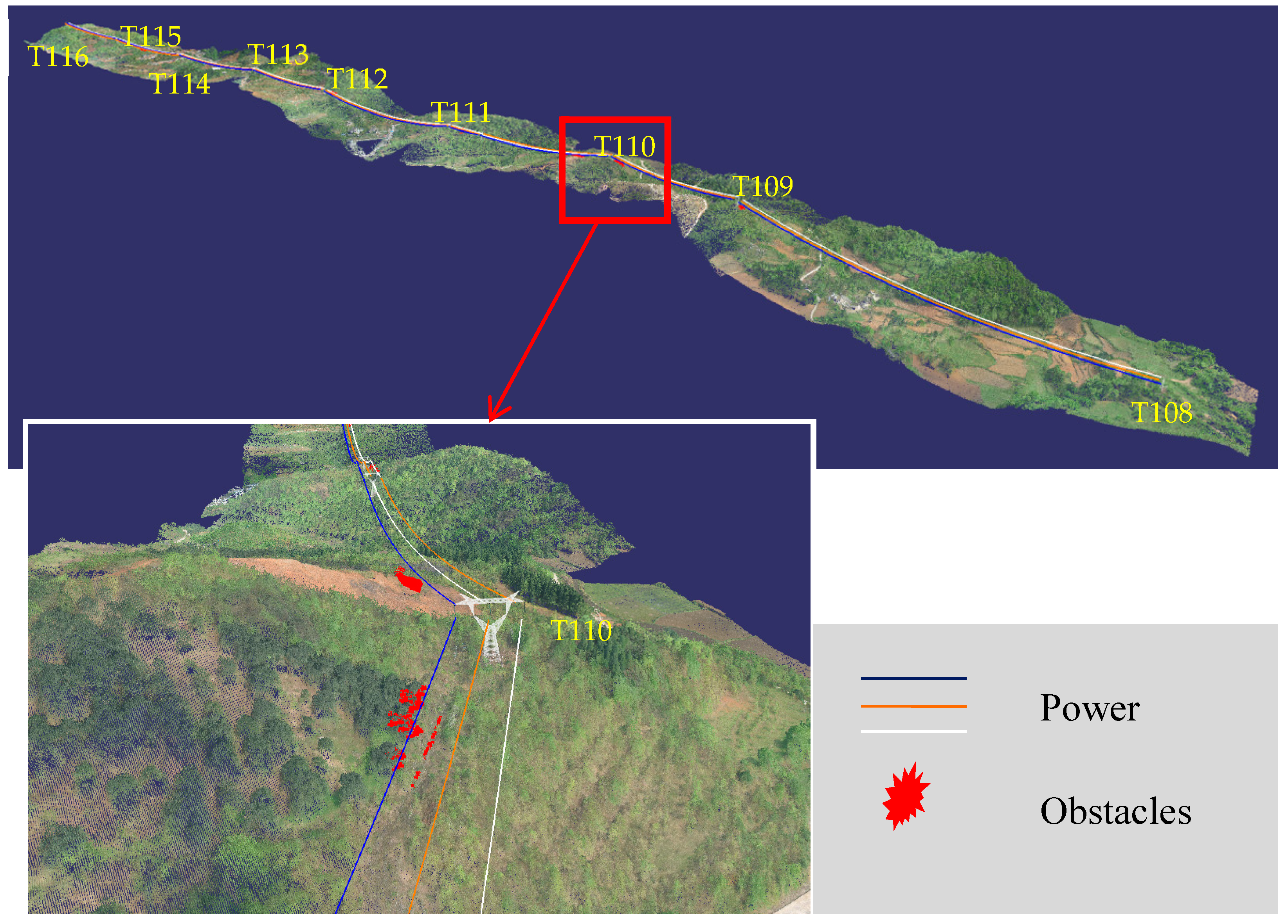

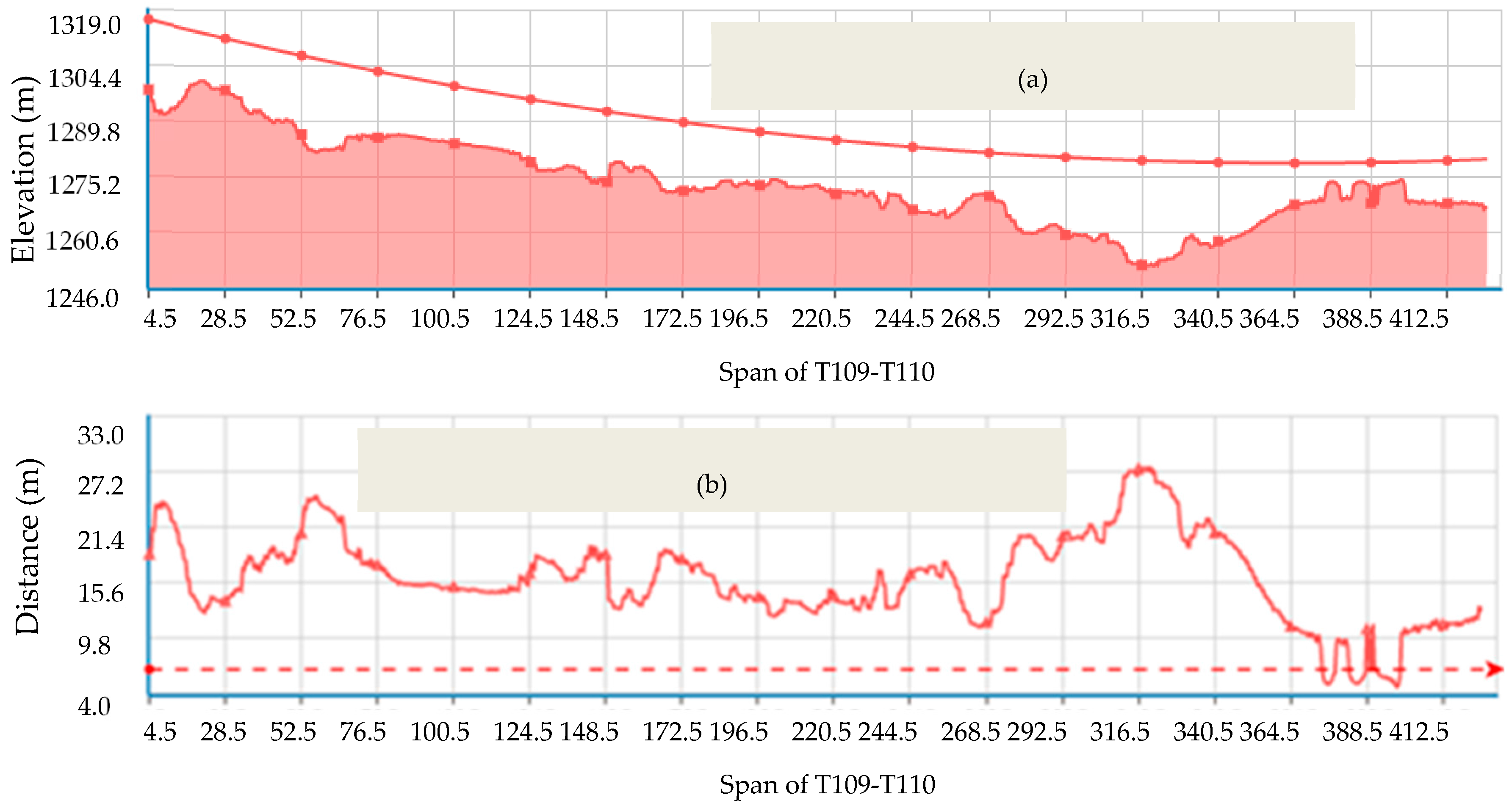

3.4. Detection of Obstacles within the Power Line Corridor

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Miralles, F.; Pouliot, N.; Montambault, S. State-of-the-art review of computer vision for the management of power transmission lines. In Proceedings of the IEEE International Conference on Applied Robotics for the Power Industry (CARPI), Foz do Iguassu, Brazil, 14–16 October 2014. [Google Scholar]

- Ahmad, J.; Malik, A.S.; Abdullah, M.F.; Kamel, N.; Xia, L. A novel method for vegetation encroachment monitoring of transmission lines using a single 2D camera. Pattern Anal. Appl. 2015, 18, 419–440. [Google Scholar] [CrossRef]

- Matikainen, L.; Lehtomäki, M.; Ahokas, E.; Hyyppä, J.; Karjalainen, M.; Jaakkola, A.; Kukko, A.; Heinonen, T. Remote sensing methods for power line corridor surveys. ISPRS J. Photogramm. Remote Sens. 2016, 119, 10–31. [Google Scholar] [CrossRef]

- Zhang, J.X.; Huang, G.M.; Liu, J.P. SAR remote sensing monitoring of the Yushu earthquake disaster situation and the information service system. J. Remote Sens. 2010, 14, 1–046. [Google Scholar]

- Eriksson, L.E.B.; Fransson, J.E.S.; Soja, M.J.; Santoro, M. Backscatter signatures of wind-thrown forest in satellite SAR images. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium (IGARSS), Munich, Germany, 22–27 July 2012. [Google Scholar]

- Kobayashi, Y.; Karady, G.G.; Heydt, G.T.; Olsen, R.G. The utilization of satellite images to identify trees endangering transmission lines. IEEE Trans. Power Deliv. 2009, 24, 1703–1709. [Google Scholar] [CrossRef]

- Mills, S.J.; Castro, M.P.G.; Li, Z.; Cai, J.; Hayward, R.; Mejias, L.; Walker, R.A. Evaluation of aerial remote sensing techniques for vegetation management in power-line corridors. IEEE Trans. Geosci. Remote Sens. 2010, 48, 3379–3390. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Jones, R.; Talbot, H.; Wu, X.; Cheong, K.; Beare, R.; Buckley, M.; Berman, M. Measuring the distance of vegetation from powerlines using stereo vision. ISPRS J. Photogramm. Remote Sens. 2006, 60, 269–283. [Google Scholar] [CrossRef]

- Tabor, A.; Ottesen, B.S. Advances in applications for aerial infrared thermography. Proc. SPIE 2006, 156, 3642–3643. [Google Scholar]

- Guo, B.; Li, Q.; Huang, X.; Wang, C. An improved method for power-line reconstruction from point cloud data. Remote Sens. 2016, 8, 36. [Google Scholar] [CrossRef]

- Zhu, L.; Hyyppä, J. Fully-automated power line extraction from airborne laser scanning point clouds in forest areas. Remote Sens. 2014, 6, 11267–11282. [Google Scholar] [CrossRef]

- Mclaughlin, R.A. Extracting transmission lines from airborne LIDAR data. IEEE Geosci. Remote Sens. Lett. 2006, 3, 222–226. [Google Scholar] [CrossRef]

- Ax, M.; Thamke, S.; Kuhnert, L.; Kuhnert, K.-D. UAV based laser measurement for vegetation control at high-voltage transmission lines. Adv. Mater. Res. 2012, 614–615, 1147–1152. [Google Scholar] [CrossRef]

- RIEGEL. Available online: http://www.riegl.com/products/unmanned%E2%80%90scanning/ (accessed on 20 July 2017).

- Velodyne LiDAR. Available online: http://velodynelidar.com/products.html (accessed on 20 July 2017).

- Toth, J.; Gilpin-Jackson, A. Smart view for a smart grid—Unmanned Aerial Vehicles for transmission lines. In Proceedings of the 2010 1st International Conference on Applied Robotics for the Power Industry (CARPI), Montreal, QC, Canada, 5–7 October 2010. [Google Scholar]

- Cai, J.; Walker, R. Height estimation from monocular image sequences using dynamic programming with explicit occlusions. IET Comput. Vis. 2010, 4, 149–161. [Google Scholar] [CrossRef]

- Jóźków, G.; Vander Jagt, B.; Toth, C. Experiments with UAS imagery for automatic modeling of power line 3D geometry. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, XL-1/W4, 403–409. [Google Scholar]

- Jiang, S.; Jiang, W.; Huang, W.; Yang, L. UAV-based oblique photogrammetry for outdoor data acquisition and offsite visual inspection of transmission line. Remote Sens. 2017, 9, 278. [Google Scholar] [CrossRef]

- Deng, C.; Wang, S.; Huang, Z.; Tan, Z.; Liu, J. Unmanned Aerial Vehicles for power line inspection: A cooperative way in platforms and communications. J. Commun. 2014, 9, 687–692. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, X.; Fang, Y.; Chen, S. UAV low altitude photogrammetry for power line inspection. ISPRS Int. J. Geo-Inf. 2017, 6, 14. [Google Scholar] [CrossRef]

- Ramesh, K.N.; Murthy, A.S.; Senthilnath, J.; Omkar, S.N. Automatic detection of powerlines in UAV remote sensed images. In Proceedings of the 2015 International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Bangalore, India, 10–12 December 2015. [Google Scholar]

- Yan, G.; Li, C.; Zhou, G.; Zhang, W.; Li, X. Automatic extraction of power lines from aerial images. IEEE Geosci. Remote Sens. Lett. 2007, 4, 387–391. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Zhang, J.Q. Digital Photogrammetry; Wuhan University Press: Wuhan, China, 1997. [Google Scholar]

- Serra, J. Image Analysis and Mathematical Morphology; Academic Press: Orlando, FL, USA, 1982. [Google Scholar]

- Ren, M.; Yang, J.; Sun, H. Tracing boundary contours in a binary image. Image Vis. Comput. 2002, 20, 125–131. [Google Scholar] [CrossRef]

- Furukawa, Y.; Ponce, J. Accurate, dense, and robust multi-view stereopsis. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 32, 1362–1376. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Gruen, A. Multi-image matching for DSM generation from IKONOS imagery. ISPRS J. Photogramm. Remote Sens. 2006, 60, 195–211. [Google Scholar] [CrossRef]

- Hirschmuller, H. Accurate and efficient stereo processing by semi-global matching and mutual information. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR), San Diego, CA, USA, 20–26 June 2005. [Google Scholar]

- China Southern Power Grid. Available online: http://www.gz.csg.cn/web/news/43.html (accessed on 6 April 2017).

- k2-Photogrammetry. Available online: http://www.k2-photogrammetry.de/products/patb.html (accessed on 15 June 2017).

- Lowe, D.G. Distincitive image features from scale-invariant keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Gruen, A. Adaptive least squares correlation: A powerful image matching technique. S. Afr. J. Photogramm. Remote Sens. Cartogr. 1985, 14, 175–187. [Google Scholar]

- Teunissen, P.J.G.; Khodabandeh, A. Review and principles of PPP-RTK methods. J. Géod. 2015, 89, 217–240. [Google Scholar] [CrossRef]

- Visiontek Inc. Available online: http://en.visiontek.com.cn/pp1/newsCategoryId=37.html (accessed on 18 July 2017).

- Laser Technology Inc. Available online: http://www.lasertech.com (accessed on 6 June 2017).

- Laser Technology Inc. Available online: http://www.lasertech.com/ftp/techdocs/TruPulse_Height_Performance.pdf (accessed on 20 July 2017).

| Check Point No. | Stereo No. | Coordinate Difference | ||

|---|---|---|---|---|

| Easting | Northing | Elevation | ||

| 9003 | DSC_8780-DSC_8781 | 0.115 | −0.019 | 0.327 |

| DSC_8781-DSC_8782 | −0.080 | 0.043 | 0.324 | |

| DSC_8782-DSC_8783 | 0.082 | −0.038 | 0.294 | |

| DSC_8809-DSC_8810 | 0.125 | 0.052 | 0.212 | |

| DSC_8810-DSC_8811 | 0.046 | 0.070 | −0.183 | |

| DSC_8811-DSC_8812 | −0.052 | −0.106 | −0.280 | |

| 9011 | DSC_8820-DSC_8821 | −0.132 | −0.062 | 0.058 |

| DSC_8821-DSC_8822 | −0.049 | −0.081 | 0.214 | |

| DSC_8842-DSC_8843 | −0.089 | −0.053 | −0.194 | |

| 9013 | DSC_8928-DSC_8929 | 0.072 | 0.154 | 0.255 |

| DSC_8929-DSC_8930 | −0.071 | −0.026 | 0.283 | |

| DSC_8948-DSC_8949 | 0.082 | −0.017 | 0.223 | |

| DSC_8949-DSC_8950 | −0.090 | 0.037 | 0.176 | |

| DSC_8952-DSC_8953 | 0.088 | −0.034 | −0.265 | |

| DSC_8973-DSC_8974 | −0.083 | 0.036 | 0.157 | |

| 9016 | DSC_8960-DSC_8961 | 0.009 | 0.086 | −0.153 |

| DSC_8987-DSC_8986 | 0.011 | 0.166 | −0.298 | |

| DSC_8986-DSC_8985 | −0.004 | −0.097 | −0.385 | |

| DSC_8985-DSC_8984 | −0.039 | 0.058 | −0.185 | |

| DSC_9023-DSC_9022 | −0.017 | −0.115 | 0.090 | |

| DSC_9022-DSC_9021 | −0.017 | −0.057 | 0.275 | |

| DSC_9021-DSC_9020 | −0.004 | −0.122 | 0.078 | |

| Root mean square error of the coordinate difference | 0.073 | 0.081 | 0.233 | |

| Check Point No. | Stereo No. | Coordinate Difference | ||

|---|---|---|---|---|

| Easting | Northing | Elevation | ||

| 9003 | DSC_8780-DSC_8809 | 0.047 | 0.055 | −0.217 |

| DSC_8781-DSC_8810 | 0.038 | 0.046 | −0.205 | |

| DSC_8782-DSC_8811 | 0.065 | 0.063 | −0.250 | |

| DSC_8783-DSC_8812 | 0.080 | 0.121 | −0.209 | |

| 9011 | DSC_8820-DSC_8842 | −0.016 | −0.056 | 0.194 |

| DSC_8821-DSC_8843 | −0.123 | −0.064 | 0.125 | |

| DSC_8822-DSC_8843 | −0.038 | −0.078 | 0.203 | |

| 9013 | DSC_8928-DSC_8948 | −0.156 | 0.058 | 0.305 |

| DSC_8929-DSC_8949 | −0.080 | 0.122 | 0.232 | |

| DSC_8930-DSC_8950 | −0.101 | 0.047 | 0.058 | |

| DSC_8952-DSC_8973 | 0.084 | −0.076 | 0.219 | |

| DSC_8953-DSC_8974 | 0.090 | −0.100 | 0.240 | |

| 9016 | DSC_8960-DSC_8983 | −0.055 | −0.112 | −0.141 |

| DSC_8961-DSC_8983 | −0.040 | 0.097 | −0.286 | |

| DSC_8987-DSC_9023 | 0.094 | −0.110 | −0.225 | |

| DSC_8986-DSC_9022 | −0.018 | 0.068 | −0.166 | |

| DSC_8985-DSC_9021 | 0.009 | 0.079 | −0.187 | |

| DSC_8984-DSC_9020 | 0.004 | −0.109 | 0.050 | |

| Root mean square error of the coordinate difference | 0.075 | 0.085 | 0.205 | |

| Elevation of Manual Measurement | Elevation of the PLAMEC | Elevation Difference |

|---|---|---|

| 1261.858 | 1261.906 | 0.048 |

| 1261.571 | 1261.397 | −0.174 |

| 1315.674 | 1315.705 | 0.031 |

| 1316.065 | 1315.822 | −0.243 |

| 1279.093 | 1279.090 | −0.003 |

| 1278.859 | 1279.044 | 0.185 |

| 1248.168 | 1248.040 | −0.128 |

| 1248.187 | 1248.217 | 0.030 |

| 1248.440 | 1248.560 | 0.120 |

| 1247.950 | 1247.721 | −0.229 |

| 1264.729 | 1264.682 | −0.047 |

| 1264.611 | 1264.793 | 0.182 |

| 1298.366 | 1298.251 | −0.115 |

| 1298.145 | 1298.316 | 0.171 |

| Tower Section | Position of the Obstacles (m) | Distance Between the Obstacles and the Power Line (m) | Distance Difference | |

|---|---|---|---|---|

| Proposed Method | Field Measurement | |||

| T108~T109 | 674.0–679.0 | 5.945 | 6.3 | 0.355 |

| T109~T110 | 375.5–400.0 | 4.626 | 4.8 | 0.174 |

| T110~T111 | 84.0–116.0 | 5.012 | 5.4 | 0.388 |

| 142.0–144.5 | 5.820 | 5.4 | −0.420 | |

| T111~T112 | 93.5–96.0 | 6.021 | 5.9 | −0.121 |

| 112.0–122.5 | 5.161 | 5.3 | 0.139 | |

| T112~T113 | 584.0–600.0 | 6.113 | 5.9 | −0.213 |

| T115~T116 | 235.0–247.0 | 5.889 | 5.5 | −0.389 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yuan, X.; Li, W.; Chen, S. Automatic Power Line Inspection Using UAV Images. Remote Sens. 2017, 9, 824. https://doi.org/10.3390/rs9080824

Zhang Y, Yuan X, Li W, Chen S. Automatic Power Line Inspection Using UAV Images. Remote Sensing. 2017; 9(8):824. https://doi.org/10.3390/rs9080824

Chicago/Turabian StyleZhang, Yong, Xiuxiao Yuan, Wenzhuo Li, and Shiyu Chen. 2017. "Automatic Power Line Inspection Using UAV Images" Remote Sensing 9, no. 8: 824. https://doi.org/10.3390/rs9080824