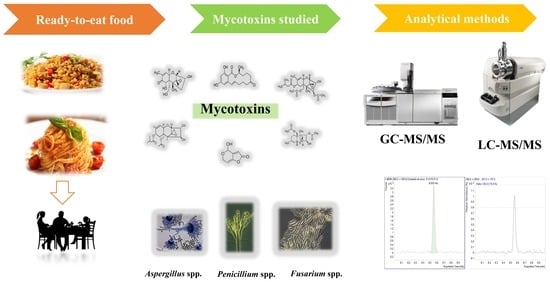

Evaluation of Mycotoxin Residues on Ready-to-Eat Food by Chromatographic Methods Coupled to Mass Spectrometry in Tandem

Abstract

:1. Introduction

2. Results

2.1. Analytical Method Validation

2.2. Sample Analysis

2.3. Mycotoxin Occurrence in Ready-to-Eat Food Samples

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Chemicals and Reagents

5.2. Standards and Solutions

5.3. Procedures

5.3.1. Samples

5.3.2. Extraction Procedure

5.4. GC–MS/MS Analysis

5.5. LC–MS/MS Analysis

5.6. Method Validation

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yang, J.; Li, J.; Jiang, Y.; Duan, X.; Qu, H.; Yang, B.; Sivakumar, D. Natural occurrence, analysis, and prevention of mycotoxins in fruits and their processed products. Crit. Rev. Food Sci. Nutr. 2014, 54, 64–83. [Google Scholar] [CrossRef] [PubMed]

- Alshannaq, A.; Yu, J.H. Occurrence, toxicity, and analysis of major mycotoxins in food. Int. J. Environ. Res. Public Health 2017, 14, 632. [Google Scholar] [CrossRef] [PubMed]

- Juan-García, A.; Manyes, L.; Ruiz, M.J.; Font, G. Applications of flow cytometry to toxicological mycotoxin effects in cultured mammalian cells: A review. Food Chem. Toxicol. 2013, 56, 40–59. [Google Scholar] [CrossRef] [PubMed]

- Marin, S.; Ramos, A.J.; Cano-Sancho, G.; Sanchis, V. Mycotoxins: Occurrence, toxicology, and exposure assessment. Food Chem. Toxicol. 2013, 60, 218–237. [Google Scholar] [CrossRef] [PubMed]

- Prosperini, A.; Berrada, H.; Ruiz, M.J.; Caloni, F.; Coccini, T.; Spicer, L.J.; Perego, M.C.; Lafranconi, A. A Review of the Mycotoxin enniatin B. Front. Public Health 2017, 5, 304. [Google Scholar] [CrossRef] [PubMed]

- Prosperini, A.; Meca, G.; Font, G.; Ruiz, M.J. Study of the cytotoxic activity of beauvericin and fusaproliferin and bioavailability in vitro on Caco-2 cells. Food Chem. Toxicol. 2012, 50, 2356–2361. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Commission Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off. J. Eur. Union 2006, L364, 5–24. [Google Scholar]

- Juan, C.; Covarelli, L.; Beccari, G.; Colasante, V.; Mañes, J. Simultaneous analysis of twenty-six mycotoxins in durum wheat grain from Italy. Food Control 2016, 62, 322–329. [Google Scholar] [CrossRef]

- García-Moraleja, A.; Font, G.; Mañes, J.; Ferrer, E. Development of a new method for the simultaneous determination of 21 mycotoxins in coffee beverages by liquid chromatography tandem mass spectrometry. Food Res. Int. 2015, 72, 247–255. [Google Scholar] [CrossRef]

- Rodríguez-Carrasco, Y.; Mañes, J.; Berrada, H.; Juan, C. Development and Validation of a LC-ESI-MS/MS Method for the Determination of Alternaria Toxins Alternariol, Alternariol Methyl-Ether and Tentoxin in Tomato and Tomato-Based Products. Toxins 2016, 8, 328. [Google Scholar] [CrossRef] [PubMed]

- Danezis, G.P.; Anagnostopoulos, C.J.; Liapis, K.; Koupparis, M.A. Multi-residue analysis of pesticides, plant hormones, veterinary drugs and mycotoxins using HILIC chromatography–MS/MS in various food matrices. Anal. Chim. Acta 2016, 942, 121–138. [Google Scholar] [CrossRef] [PubMed]

- Milani, J.; Maleki, G. Effects of processing on mycotoxin stability in cereals. J. Sci. Food Agric. 2014, 94, 2372–2375. [Google Scholar] [CrossRef] [PubMed]

- Visconti, A.; Haidukowski, E.M.; Pascale, M.; Silvestri, M. Reduction of deoxynivalenol during durum wheat processing and spaghetti cooking. Toxicol. Lett. 2004, 153, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Serrano, A.B.; Font, G.; Mañes, J.; Ferrer, E. Effects of technological processes on enniatin levels in pasta. J. Sci. Food Agric. 2016, 96, 1756–1763. [Google Scholar] [CrossRef] [PubMed]

- Sakuma, H.; Watanabe, Y.; Furusawa, H.; Yoshinari, T.; Akashi, H.; Kawakami, H.; Saito, S.; Sugita-Konishi, Y. Estimated dietary exposure to mycotoxins after taking into account the cooking of staple foods in Japan. Toxins 2013, 5, 1032–1042. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Contaminants in the Food Chain. Scientific Opinion on the risks to human and animal health related to the presence of beauvericin and enniatins in food and feed. EFSA J. 2014, 12, 3802. [Google Scholar]

- Saladino, F.; Quiles, J.M.; Mañes, J.; Fernández-Franzón, M.; Luciano, F.B.; Meca, G. Dietary exposure to mycotoxins through the consumption of commercial bread loaf in Valencia, Spain. LWT-Food Sci. Technol. 2017, 75, 697–701. [Google Scholar] [CrossRef]

- Juan, C.; Berrada, H.; Mañes, J.; Oueslati, S. Multi-mycotoxin determination in barley and derived products from Tunisia and estimation of their dietary intake. Food Chem. Toxicol. 2017, 103, 148–156. [Google Scholar] [CrossRef] [PubMed]

- Anastassiades, M.; Maštovská, K.; Lehotay, S.J. Evaluation of analyte protectants to improve gas chromatographic analysis of pesticides. J. Chromatogr. A 2003, 1015, 163–184. [Google Scholar] [CrossRef]

- Pereira, V.L.; Fernandes, J.O.; Cunha, S.C. Comparative assessment of three cleanup procedures after QuEChERS extraction for determination of trichothecenes (type A and type B) in processed cereal-based baby foods by GC–MS. Food Chem. 2015, 182, 143–149. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Commission Decision (EC) No 657/2002 of 12 August 2002 concerning the performance of analytical methods and the interpretation of results. Off. J. Eur. Union 2002, L221, 8–36. [Google Scholar]

- López, P.; De Rijk, T.; Sprong, R.C.; Mengelers, M.J.B.; Castenmiller, J.J.M.; Alewijn, M. A mycotoxin-dedicated total diet study in The Netherlands in 2013: Part II—Occurrence. World Mycotoxin J. 2016, 9, 89–108. [Google Scholar] [CrossRef]

- Yau, A.T.C.; Chen, M.Y.Y.; Lam, C.H.; Ho, Y.Y.; Xiao, Y.; Chung, S.W.C. Dietary exposure to mycotoxins of the Hong Kong adult population from a Total Diet Study. Food Addit. Contam. Part A 2016, 33, 1026–1035. [Google Scholar] [CrossRef] [PubMed]

- Raad, F.; Nasreddine, L.; Hilan, C.; Bartosik, M.; Parent-Massin, D. Dietary exposure to aflatoxins, ochratoxin A and deoxynivalenol from a total diet study in an adult urban Lebanese population. Food Chem. Toxicol. 2014, 73, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Sirot, V.; Fremy, J.; Leblanc, J. Dietary exposure to mycotoxins and health risk assessment in the second french total diet study. Food Chem. Toxicol. 2013, 52, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Beltrán, E.; Ibáñez, M.; Portolés, T.; Ripollés, C.; Sancho, J.V.; Yusà, V.; Marin, S.; Hernández, F. Development of sensitive and rapid analytical methodology for food analysis of 18 mycotoxins included in a total diet study. Anal. Chim. Acta 2013, 783, 39–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leblanc, J.C.; Tard, A.; Volatier, J.L.; Verger, P. Estimated dietary exposure to principal food mycotoxins from the first French Total Diet Study. Food Addit. Contam. 2005, 22, 652–672. [Google Scholar] [CrossRef] [PubMed]

- Covarelli, L.; Beccari, G.; Prodi, A.; Generotti, S.; Etruschi, F.; Juan, C.; Ferrer, E.; Mañes, J. Fusarium species, chemotype characterisation and trichothecene contamination of durum and soft wheat in an area of central Italy. J. Sci. Food Agric. 2015, 95, 540–551. [Google Scholar] [CrossRef] [PubMed]

- Tolosa, J.; Font, G.; Mañes, J.; Ferrer, E. Mitigation of enniatins in edible fish tissues by thermal processes and identification of degradation products. Food Chem. Toxicol. 2017, 101, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Han, Z.; Aerts, J.; Nie, D.; Jin, M.; Shi, W.; Zhao, Z.; De Saeger, S.; Zhao, Y.; Wu, A. A reliable liquid chromatography–tandem mass spectrometry method for simultaneous determination of multiple mycotoxins in fresh fish and dried seafoods. J. Chromatogr. A 2015, 1387, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Cano-Sancho, G.; Valle-Algarra, F.M.; Jiménez, M.; Burdaspal, P.; Legarda, T.M.; Ramos, A.J.; Sanchis, V.; Marín, S. Presence of trichothecenes and co-occurrence in cereal-based food from Catalonia (Spain). Food Control 2011, 22, 490–495. [Google Scholar] [CrossRef]

- Tolosa, J.; Graziani, G.; Gaspari, A.; Chianese, D.; Ferrer, E.; Mañes, J.; Ritieni, A. Multi-Mycotoxin Analysis in Durum Wheat Pasta by Liquid Chromatography Coupled to Quadrupole Orbitrap Mass Spectrometry. Toxins 2017, 9, 59. [Google Scholar] [CrossRef] [PubMed]

- Stanciu, O.; Juan, C.; Miere, D.; Loghin, F.; Mañes, J. Presence of Enniatins and Beauvericin in Romanian Wheat Samples: From Raw Material to Products for Direct Human Consumption. Toxins 2017, 9, 189. [Google Scholar] [CrossRef] [PubMed]

- Sifou, A.; Meca, G.; Serrano, A.B.; Mahnine, N.; El Abidi, A.; Mañes, J.; El Azzouzi, M.; Zinedine, A. First report on the presence of emerging Fusarium mycotoxins enniatins (A, A1, B, B1), beauvericin and fusaproliferin in rice on the Moroccan retail markets. Food Control 2011, 22, 1826–1830. [Google Scholar] [CrossRef]

- Makun, H.A.; Dutton, M.F.; Njobeh, P.B.; Mwanza, M.; Kabiru, A.Y. Natural multi-occurrence of mycotoxins in rice from Niger State, Nigeria. Mycotoxin Res. 2011, 27, 97–104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, X.D.; Su, P.; Shan, H. Mycotoxin Contamination of Rice in China. J. Food Sci. 2017, 82, 573–584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cano-Sancho, G.; Sanchis, V.; Ramos, A.J.; Marín, S. Effect of food processing on exposure assessment studies with mycotoxins. Food Addit. Contam. Part A 2013, 30, 867–875. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Carrasco, Y.; Mañes, J.; Berrada, H.; Font, G. Preliminary estimation of deoxynivalenol excretion through a 24 h pilot study. Toxins 2015, 7, 705–718. [Google Scholar] [CrossRef] [PubMed]

- Nijs, M.; van den Top, H.; de Stoppelaar, J.; Lopez, P.; Mol, H. Fate of enniatins and deoxynivalenol during pasta cooking. Food Chem. 2016, 213, 763–767. [Google Scholar] [CrossRef] [PubMed]

- Serrano, A.B.; Font, G.; Mañes, J.; Ferrer, E. Development a mitigation strategy of enniatins in pasta under home-cooking conditions. LWT-Food Sci. Technol. 2016, 65, 1017–1024. [Google Scholar] [CrossRef]

- Castells, M.; Marín, S.; Sanchis, V.; Ramos, A.J. Reduction of Aflatoxins by Extrusion-Cooking of Rice Meal. J. Food Sci. 2006, 71, 369–377. [Google Scholar] [CrossRef]

- Sani, A.M.; Azizi, E.G.; Salehi, E.A.; Rahimi, K. Reduction of aflatoxin in rice by different cooking methods. Toxicol. Ind. Health 2014, 30, 546–550. [Google Scholar] [CrossRef] [PubMed]

- Park, J.W.; Kim, Y.B. Effect of pressure cooking on aflatoxin B1 in rice. J. Agric. Food Chem. 2006, 54, 2431–2435. [Google Scholar] [CrossRef] [PubMed]

- CIHEAM/FAO Centre International de Hautes Agronomiques Méditerranéennes/Food and Agriculture Organization of the United Nations. Mediterranean Food Consumption Patterns: Diet, Environment, Society, Economy and Health. A White Paper Priority 5 of Feeding Knowledge Programme, Expo Milan 2015. Available online: http://www.fao.org/3/a-i4358e.pdf (accessed on 10 February 2017).

- European Commission. Commission Regulation (EC) No 401/2006 of 23 February 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off. J. Eur. Union 2006, L70, 12–34. [Google Scholar]

| Mycotoxin | Food Product | Maximum Levels (µg/kg) |

|---|---|---|

| AFB1 | Processed cereal-based foods and baby foods for infants and young children, dietetic food destined for physical treatment, cereals and cereal products, dried fruit, groundnuts and nuts, and spices | 0.1–8.0 |

| Sum of AFs | Cereal and cereal-based products, dried fruit, coffee, groundnuts, and nuts | 4.0–15.0 |

| OTA | Processed cereal-based foods and baby foods for infants and young children, dietetic food destined for physical treatment, cereals and cereal products, dried vine fruit, wine, coffee, grape juice | 0.5–10 |

| DON | Processed cereal-based products and baby foods for infants and young children, cereals intended for direct human consumption, cereal flour, bran and germ as end product marketed for direct human consumption, pasta dry, bread, pastries, biscuits, cereal snacks, and breakfast cereals | 200–750 |

| ZEA | Processed maize-based products and baby foods for infants and young children, maize and maize-based products, bread, and other unprocessed cereal | 20–200 |

| Sum of FBs | Processed maize-based products and baby foods for infants and young children, maize-based products, and unprocessed maize | 200–2000 |

| Mycotoxin | Transitions | Cereals | Legumes | Fish | Vegetables | Meats | ME | Recovery | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quantitative | Qualitative | LOD | LOQ | LOD | LOQ | LOD | LOQ | LOD | LOQ | LOD | LOQ | (%) | (%) | |

| Q | Q | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | µg/kg | |||

| OTA | 404 > 102 a | 404 > 239 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 73–121 | 71–91 |

| AFB1 | 313 > 241 a | 313 > 289 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.3 | 1 | 65–106 | 67–98 |

| AFB2 | 315 > 286 a | 315 > 259 | 0.3 | 1 | 0.3 | 1 | 0.3 | 1 | 0.3 | 1 | 0.3 | 1 | 63–77 | 67–116 |

| AFG1 | 329 > 243 a | 329 > 311 | 0.3 | 1 | 1.5 | 5 | 0.3 | 1 | 0.3 | 1 | 0.15 | 0.5 | 58–117 | 79–102 |

| AFG2 | 331 > 313 a | 331 > 245 | 0.15 | 0.5 | 0.3 | 1 | 0.3 | 1 | 0.3 | 1 | 0.3 | 1 | 58–97 | 67–90 |

| FB1 | 722 > 334 a | 722 > 352 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 0.3 | 1 | 1.5 | 5 | 61–141 | 69–114 |

| FB2 | 706 > 336 a | 706 > 318 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 0.3 | 1 | 1.5 | 5 | 59–102 | 65–116 |

| ENA | 699 > 228 a | 699 > 210 | 0.15 | 0.5 | 0.3 | 0.5 | 0.3 | 1 | 0.15 | 0.5 | 0.15 | 0.5 | 65–117 | 74–114 |

| ENA1 | 685 > 214 a | 685 > 210 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 91–125 | 62–104 |

| ENB | 657 > 196 a | 657 > 214 | 0.15 | 0.5 | 0.3 | 1 | 0.15 | 0.5 | 0.15 | 0.5 | 0.3 | 1 | 68–101 | 69–111 |

| ENB1 | 671 > 214 a | 671 > 228 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 74–96 | 69–119 |

| BEA | 801 > 784 a | 801 > 244 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.3 | 1 | 58–103 | 78–99 |

| STG | 325 > 281 a | 325 > 310 | 1.5 | 5 | 1.5 | 5 | 0.3 | 1 | 1.5 | 5 | 1.5 | 5 | 70–116 | 71–102 |

| DON | 392 > 259 b | 407 > 197 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 82–114 | 75–107 |

| 3-ADON | 392 > 287 b | 467 > 147 | 0.75 | 2.5 | 0.15 | 0.5 | 0.15 | 0.5 | 1.5 | 5 | 0.15 | 0.5 | 78–173 | 89–117 |

| 15-ADON | 392 > 217 b | 392 > 184 | 0.75 | 2.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 77–148 | 73–98 |

| NIV | 289 > 73 b | 379 > 73 | 1.5 | 5 | 0.75 | 2.5 | 1.5 | 5 | 1.5 | 5 | 0.75 | 2.5 | 82–153 | 60–79 |

| NEO | 252 > 195 b | 252 > 167 | 0.15 | 0.5 | 0.15 | 0.5 | 0.75 | 2.5 | 0.15 | 0.5 | 0.15 | 0.5 | 77–175 | 91–114 |

| DAS | 350 > 229 b | 378 > 124 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 0.15 | 0.5 | 60–144 | 60–102 |

| FUS-X | 450 > 260 b | 450 > 245 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 1.5 | 5 | 0.15 | 0.5 | 78–151 | 68–106 |

| T-2 | 350 > 244 b | 350 > 229 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 0.75 | 2.5 | 96–151 | 73–107 |

| HT-2 | 347 > 157 b | 347 > 185 | 0.15 | 0.5 | 0.15 | 0.5 | 0.15 | 0.5 | 0.75 | 2.5 | 0.15 | 0.5 | 73–137 | 73–113 |

| ZEA | 462 > 151 b | 462 > 333 | 0.15 | 0.5 | 0.15 | 0.5 | 1.5 | 5 | 0.15 | 0.5 | 1.5 | 5 | 65–158 | 67–104 |

| α-ZAL | 433 > 309 b | 433 > 295 | 0.15 | 0.5 | 0.15 | 0.5 | 0.75 | 2.5 | 0.15 | 0.5 | 0.15 | 0.5 | 73–155 | 66–117 |

| β-ZAL | 307 > 292 b | 307 > 277 | 0.75 | 2.5 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 62–132 | 70–89 |

| α-ZOL | 305 > 289 b | 305 > 73 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 1.5 | 5 | 0.75 | 2.5 | 58–145 | 63–77 |

| β-ZOL | 536 > 446 b | 536 > 333 | 0.15 | 0.5 | 1.5 | 5 | 1.5 | 5 | 0.75 | 2.5 | 1.5 | 5 | 71–128 | 63–79 |

| Samples | Concentration µg/kg RSD (%) | |||

|---|---|---|---|---|

| DON | ENB | HT-2 | AFG2 | |

| Cereals | ||||

| Lasagne | 2.84 ± 2.2 | 12.25 ± 3.2 | 34.43 ± 0.6 | n.d. |

| Macaroni | 5.27 ± 4.2 | 9.83 ± 1.0 | n.d. | n.d. |

| Spaghetti pesto | 21.59 ± 1.0 | 11.51 ± 6.2 | 7.23 ± 4.5 | n.d. |

| Noodles | 4.75 ± 10.5 | 86.32 ± 12.2 | 18.85 ± 1.6 | n.d. |

| Rice (Paella) | n.d. | n.d. | n.d. | 2.84 |

| Rice salad | 2.61 ± 0.2 | n.d. | n.d. | n.d. |

| Pizza | 3.39 ± 4.8 | n.d. | 9.06 | n.d. |

| Quiche | 4.1 ± 1.0 | 14.68 ± 4.2 | n.d. | n.d. |

| Vegetable | ||||

| Vegetable soup | n.d. | n.d. | n.d. | n.d. |

| Garlic soup | 6.19 ± 0.2 | n.d. | n.d. | n.d. |

| Cream of leek | n.d. | n.d. | n.d. | n.d. |

| Gratin broccoli | n.d. | n.d. | n.d. | n.d. |

| Scrambled spinach | n.d. | n.d. | n.d. | n.d. |

| Sauteed artichoke | n.d. | n.d. | n.d. | n.d. |

| Fish | ||||

| Grilled salmon | n.d. | n.d. | n.d. | n.d. |

| Grilled tuna | n.d. | n.d. | n.d. | n.d. |

| Baked perch fillets | n.d. | n.d. | n.d. | n.d. |

| Hake in white wine | n.d. | n.d. | n.d. | n.d. |

| Grilled sole | n.d. | n.d. | n.d. | n.d. |

| Legume | ||||

| Lentils | n.d. | n.d. | n.d. | n.d. |

| Broad beans | 6.98 ± 0.2 | n.d. | n.d. | n.d. |

| Red beans | n.d. | n.d. | n.d. | n.d. |

| Cream of chickpeas | n.d. | n.d. | n.d. | n.d. |

| Meats | ||||

| Grilled chicken breast | n.d. | n.d. | n.d. | n.d. |

| Grilled pork loin | n.d. | n.d. | n.d. | n.d. |

| Mycotoxin | Parameter | Cereals | Vegetables | Legumes | Total |

|---|---|---|---|---|---|

| (n = 8) | (n = 6) | (n = 4) | (n = 25) | ||

| DON | Occurrence (%) | 7 (88) | 1 (17) | 1 (25) | 9 (36) |

| Mean µg/kg | 6.36 | 6.19 | 6.98 | 6.51 | |

| Range (min-max) µg/kg | 2.61–21.59 | 6.19 | 6.98 | 2.61–21.59 | |

| ENB | Occurrence (%) | 5 (63) | - | - | 5 (20) |

| Mean µg/kg | 26.91 | n.d. | n.d. | 26.91 | |

| Range (min-max) µg/kg | 9.83–86.32 | n.d. | n.d. | 9.83–86.32 | |

| HT-2 | Occurrence (%) | 4 (50) | - | - | 4 (16) |

| Mean µg/kg | 17.39 | n.d. | n.d. | 17.39 | |

| Range (min-max) µg/kg | 9.06–34.43 | n.d. | n.d. | 9.06–34.43 | |

| AFG2 | Occurrence (%) | 1 (13) | - | - | 1 (4) |

| Mean µg/kg | 2.84 | n.d. | n.d. | 2.84 | |

| Range (min-max) µg/kg | 2.84 | n.d. | n.d. | 2.84 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carballo, D.; Font, G.; Ferrer, E.; Berrada, H. Evaluation of Mycotoxin Residues on Ready-to-Eat Food by Chromatographic Methods Coupled to Mass Spectrometry in Tandem. Toxins 2018, 10, 243. https://doi.org/10.3390/toxins10060243

Carballo D, Font G, Ferrer E, Berrada H. Evaluation of Mycotoxin Residues on Ready-to-Eat Food by Chromatographic Methods Coupled to Mass Spectrometry in Tandem. Toxins. 2018; 10(6):243. https://doi.org/10.3390/toxins10060243

Chicago/Turabian StyleCarballo, Dionisia, Guillermina Font, Emilia Ferrer, and Houda Berrada. 2018. "Evaluation of Mycotoxin Residues on Ready-to-Eat Food by Chromatographic Methods Coupled to Mass Spectrometry in Tandem" Toxins 10, no. 6: 243. https://doi.org/10.3390/toxins10060243