1. Introduction

Adaptive optics (AO) is a technology that enables us to achieve complex aberration corrections for a wide range of applications [

1,

2]. Conventional AO systems utilize spatial light modulators [

3,

4] or solid deformable mirrors (DM) [

5,

6] to compensate for the phase fluctuations that result from non-uniformity in the properties of the medium through which light travels or imperfections in the geometry of the optical components. The spatial light modulators are available in both reflective as well as transparent modes. This type of wavefront corrector has the advantage of very high spatial resolution provided by extremely small liquid crystals. However, they are limited by the relatively small magnitude of correction that they can provide, usually in the range of a few micrometers. Solid deformable mirrors have evolved as the most widely used wavefront correction elements in optics systems, which can offer relatively high strokes. Generally, solid deformable mirrors consist of a solid reflecting membrane or plate surface to which an actuator structure is attached. Through manipulation of the actuators, the shape of the mirror can be modified to fulfill the compensation of distorted wavefronts. The common drawbacks of the solid deformable mirrors are the high cost per actuator channel and the complex fabrication process. Most of the currently available solid deformable mirrors offer small inter-actuator strokes and the maximum deflection magnitudes are limited to tens of micrometers.

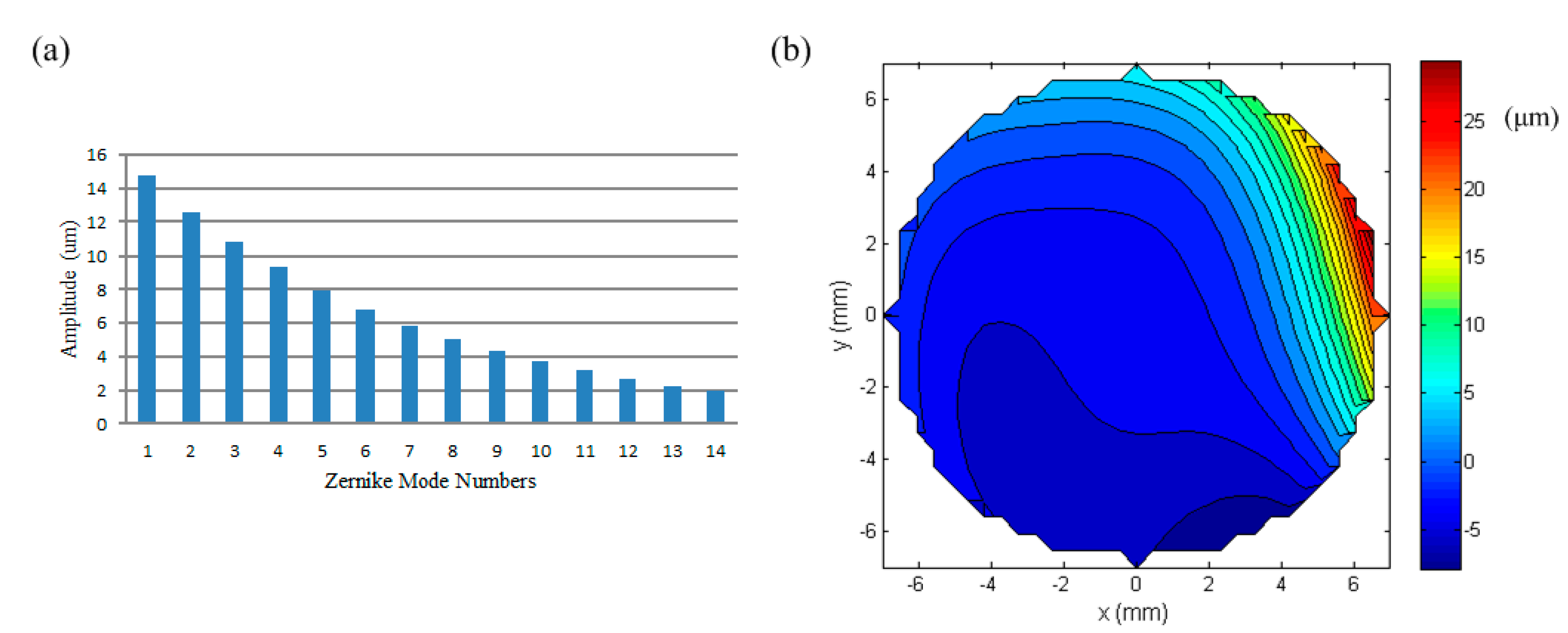

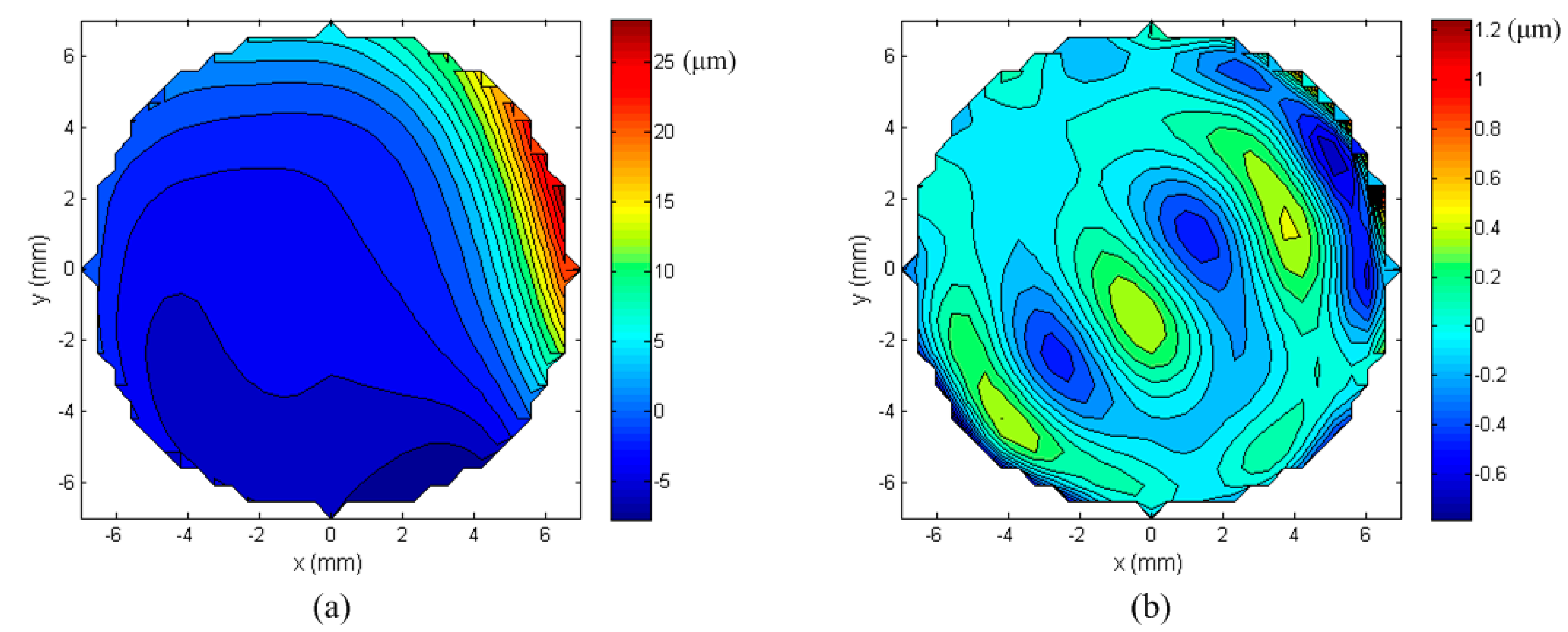

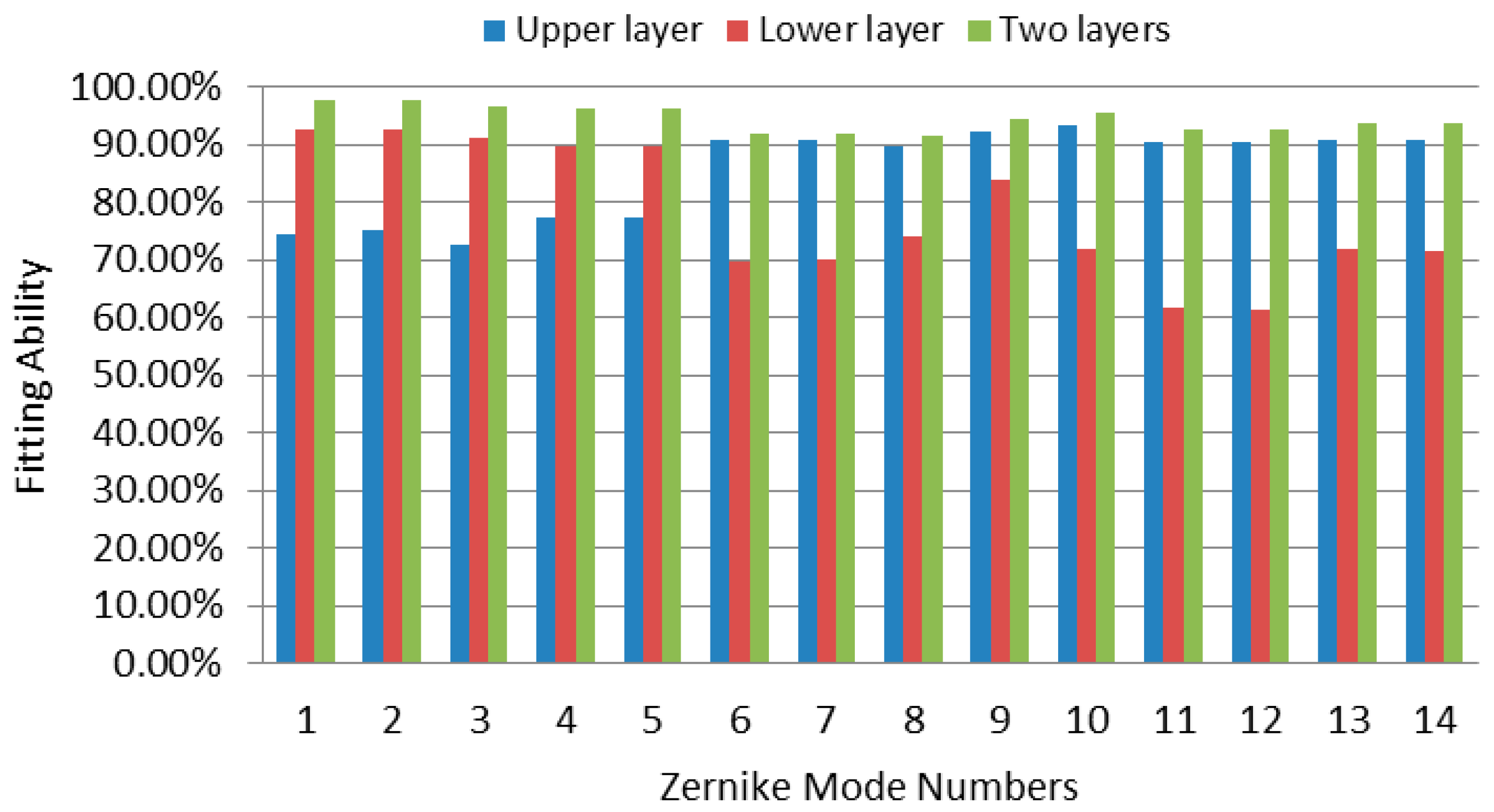

In practice, studies have shown that in many applications such as laser beam shaping [

7,

8,

9] and ophthalmic imaging systems [

10,

11,

12], AO system needs to effectively deal with the low-amplitude high-order aberrations along with some low-order aberrations that come with very high amplitudes simultaneously. For instance, high-resolution retinal imaging technology based on AO plays an important role in vision science and will aid in the early clinical diagnosis of retinal diseases. In view of the characteristics of ocular aberrations for a large and diverse population, e.g., myopic eyes, a set of adaptive optics systems using two deformable mirrors have been designed [

10,

11,

12]. The first large-stroke DM with a limited number of actuators is used to correct large-amplitude low-order aberrations, and the second one with a low stroke but a high spatial correction resolution is used to compensate for the small-amplitude high-order aberrations. However, its practical application in ophthalmology is restricted by the complexity and the high price.

In [

13,

14,

15], a new type of liquid deformable mirror is proposed based on the actuation of the magnetic fluid. Though the disadvantage of the liquid mirror is that the mirror is constrained to remaining horizontal, the magnetic fluid deformable mirror (MFDM) has major advantages such as large strokes, low cost per actuator and easy scalability. The strokes of the single actuator or inter-actuator can both easily reach more than 100 μm with limited power consumption. However, in order to produce a large mirror surface deformation, the size of the electromagnetic coils is normally designed to be large, which results in a low density of actuators and thus is unfavorable for the correction of high-order aberrations. In order to realize the correction of full-order aberrations with high spatial resolution, the design of a two-layer layout of the miniature electromagnetic coils is adopted in this paper. The dynamics model of the mirror is established, and the aberration correction performance is verified by the simulation and experimental results. As a new kind of wavefront corrector, the proposed MFDM has major advantages such as large stroke, low cost, easy scalability and a simple fabrication process, and thus can be easily customized for different applications.

2. Design of Magnetic Fluid Deformable Mirror (MFDM)

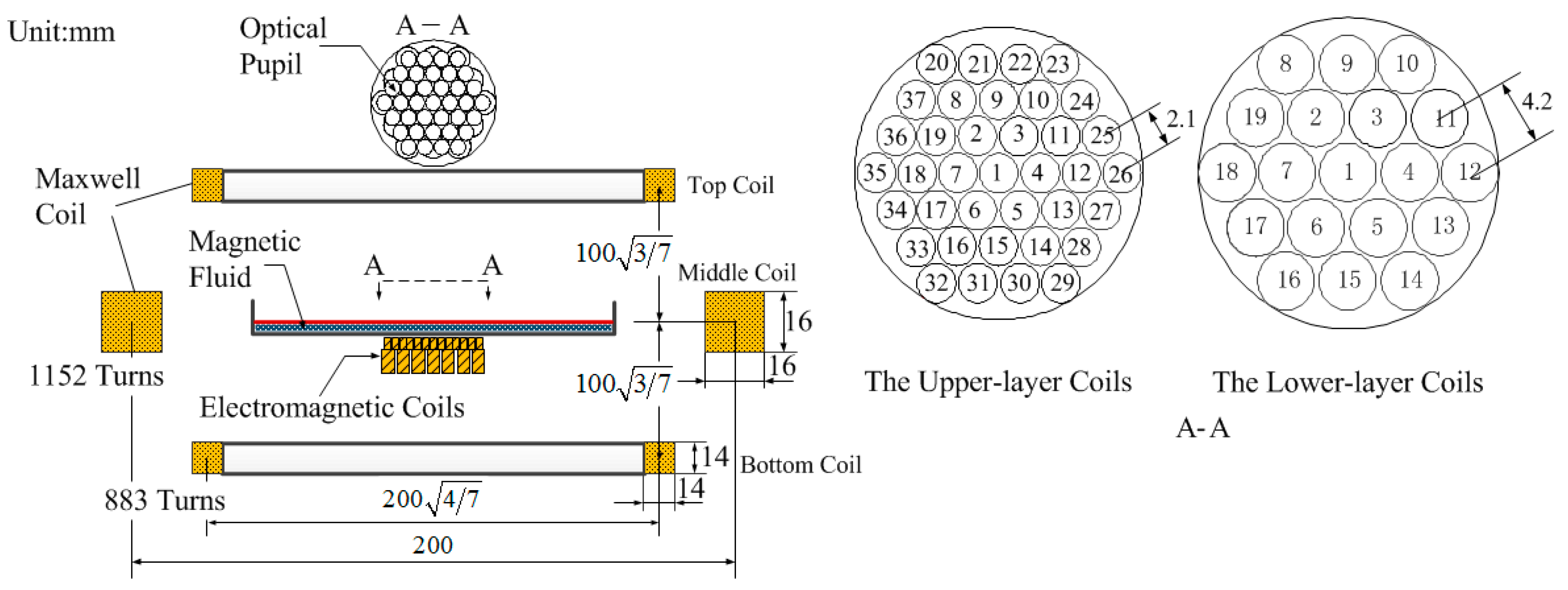

As shown in

Figure 1, the primary elements of the MFDM are a layer of magnetic fluid, a thin film of a reflective material coated on the free surface of the fluid, a two-layer layout of the miniature electromagnetic coils placed underneath the fluid layer, and a Maxwell coil. The properties of the magnetic fluid used in this paper are given in

Table 1, and they are stable colloidal suspensions of nano-sized, single-domain ferri/ferromagnetic particles and can be coated with a silver liquid-like thin film to improve the reflectance.

In order to realize the correction of full-order aberrations with a high spatial resolution, the design of a two-layer layout of the miniature electromagnetic coils is adopted. As shown in

Figure 1, the upper-layer actuators with a small size and high density are used to compensate for small-amplitude high-order aberrations and the lower-layer actuators with a big size and low density are used to correct large-amplitude low-order aberrations. The electromagnetic coils are conventional circular coils wound on a cylindrical bobbin, and the physical parameters are given in

Table 2. Each layer of the coils is disposed in a hexagonal array. The upper-layer coils are radially spaced at 2.1 mm from center to center and the lower-layer coils are radially spaced at 4.2 mm, respectively.

In order to linearize the response of the actuators, an external uniform magnetic field is produced by the Maxwell coil. As shown in

Figure 1, the Maxwell coil consists of three separated coils, where each of the top and bottom coils should be of radius

, and distance

from the plane of the middle coil of radius

R = 100 mm [

16]. The parameters are given in

Table 3. The three separated coils wound with American wire gauge (AWG) 25 magnet wire follow the turn ratio of 64:49 for the top and bottom coil relative to the middle coil [

16]. In addition, magnetic fluids typically show low reflectance to light and can be coated with silver liquid-like thin films to improve the reflectance [

17,

18]. In this paper, the self-assembly method is used to prepare the silver liquid-like thin film for the MFDM. Firstly, the solution of silver nano-particles was dissociated by centrifugation to remove the supernatant, and ethanol was then infused to purify the silver nano-particles. The obtained silver nano-particles were added into the mixed solution of ethanol and dodecanethiol, and then centrifuged after being kept at room temperature for 24 h. Finally, the ethyl acetate was added to the silver nano-particles obtained from the above step, and this solution was then added drop by drop to the surface of the magnetic fluid. After the ethyl acetate evaporated, the hydrophobic dodecanethiol encapsulated silver nano-particles automatically stacked and spread on the surface of the magnetic fluid to form a large-scale domain of silver liquid-like film.

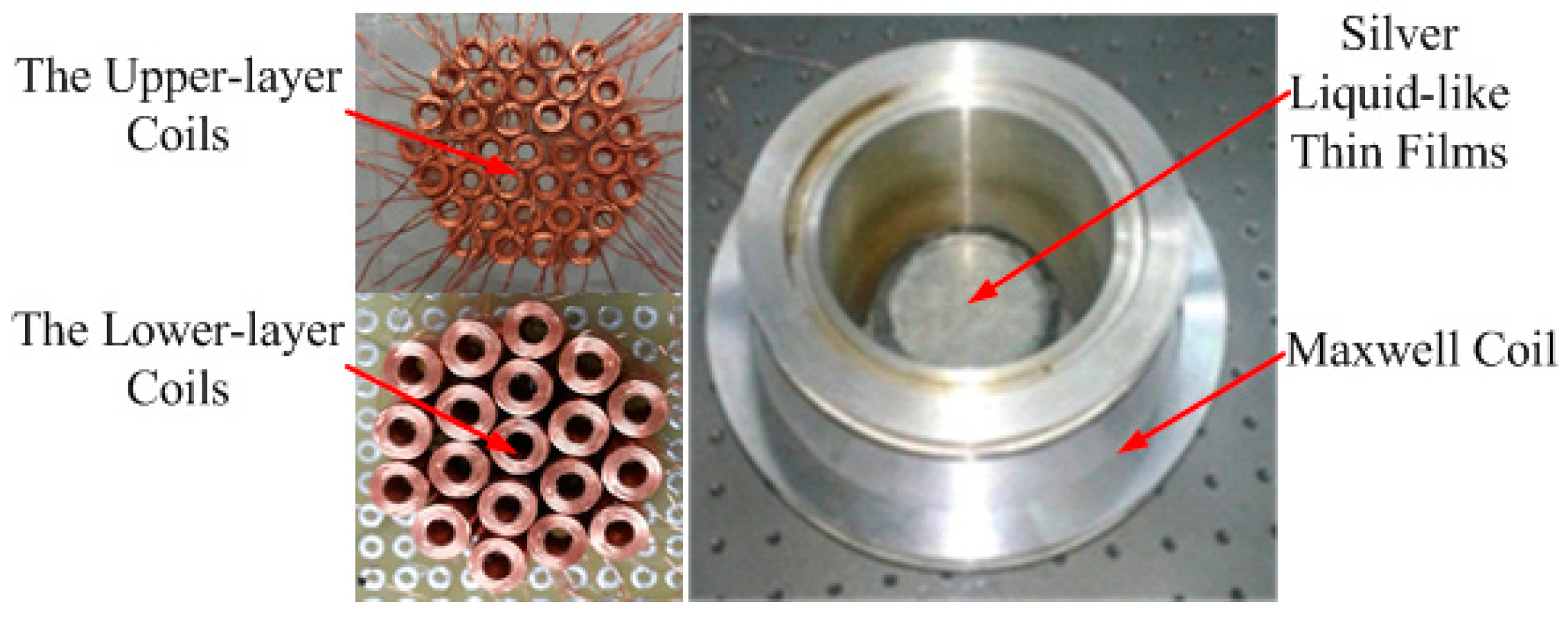

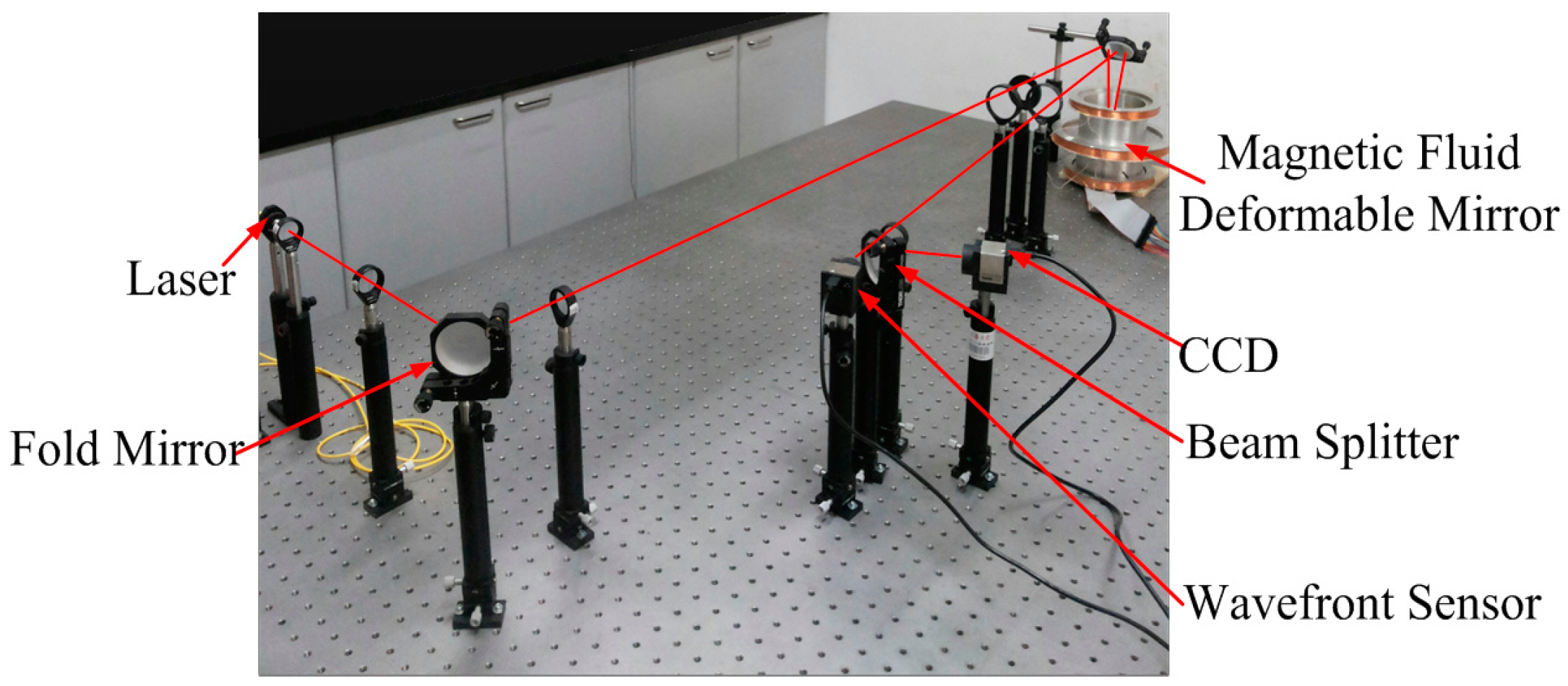

A snapshot of the assembly of the mirror is shown in

Figure 2. The two-layer layout of the miniature electromagnetic coils is placed within the Maxwell coil and a container filled with a 1-mm-deep layer of ferrofluid sits on top of the miniature coils, which are coated with the thin silver liquid-like film.

3. Analytical Surface Dynamics Model of MFDM

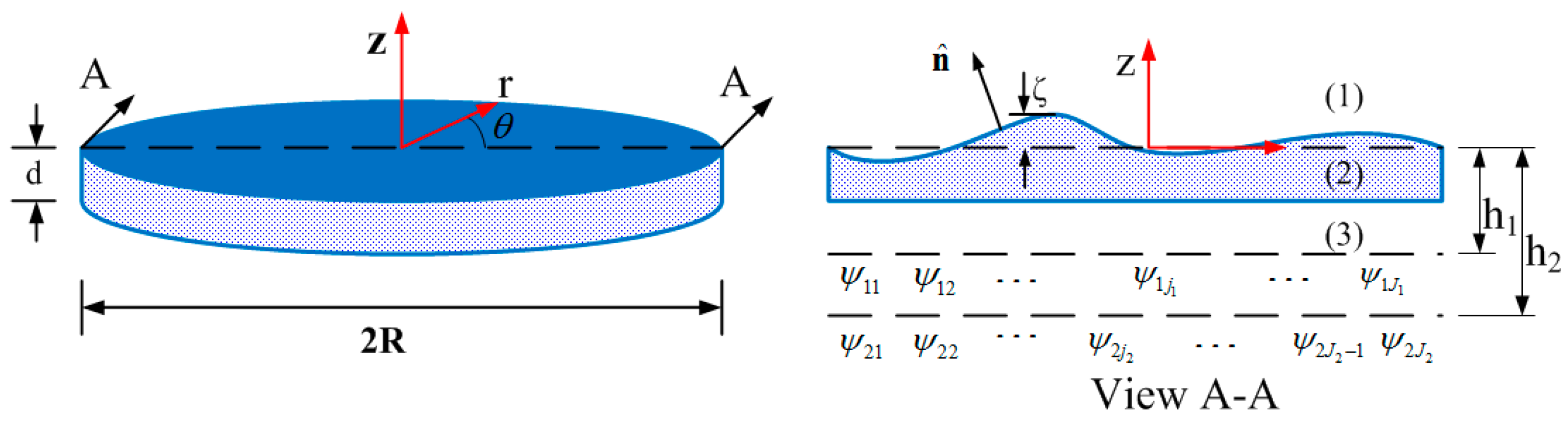

The proposed MFDM is represented by a cylindrical horizontal layer of a magnetic fluid as shown in

Figure 3. The top free surface of the fluid layer is coated with a reflective film and serves as the deformable surface of the mirror. The deflection of the mirror surface at point (

rk, θ

k) is denoted by ζ(

rk, θ

k,

t), where

k = 1,2,3,…,

K is a discrete number of surface locations. The magnetic field generated by any given coil, centered at the horizontal location (

rij, θ

ij), is idealized as that of a point source of magnetic potential ψ

ij(

t), where

i = 1,2 is the

ith layer of actuators, and

j,

j = 1,2,3,…,

Ji is the

jth coil of each layer.

The magnetic field itself is governed by Maxwell’s equations. Since the magnetic field of the miniature coils is idealized as that of point sources of magnetic potential located at the fluid domain boundary, a current-free electromagnetic field can be assumed. Using this assumption and further assuming that the displacement currents in the fluid are negligible, Maxwell’s equations can be written as:

where

B is the magnetic flux density, which is related to the magnetic field

H and the magnetization

M by the following constitutive relationship:

where μ is the magnetic permeability of the magnetic fluid, μ

0 is the magnetic permeability of free space. Assuming the magnetic fluid is linearly magnetized by the applied field, the magnetization vector

M can be written as

where

is considered to be a constant. Considering that the magnetic field extends into the space above and below the fluid layer, Maxwell’s equations are applied to all three sub-domains marked in

Figure 3 as (1)–(3). The scalar potentials ψ

(l),

l = 1,2,3 describe the magnetic field vectors

H(l) in these sub-domains as follows:

Using Equations (2)–(4), the magnetic flux density

B(l) in these sub-domains can be written in terms of the scalar potentials ψ

(l),

l = 1,2,3 as

The magnetic flux density

B meets the principle of superposition. Assume the fluid is irrotational, then based on the principles of conservation of mass and momentum and the theories of magnetic fields, the perturbation part of the surface dynamic governing equations can be written as [

19]:

where ρ is the density of the fluid, σ is the surface tension, φ and ψ

(l),

l = 1,2,3 are the perturbation components of the fluid velocity potential and the magnetic potential, respectively. Using the following two boundary conditions:

The solutions with respect to the input ψ

ij(

t) thus are obtained as follows:

where

is the Bessel function of the first kind, λ is the separation constant, and

Considering that the miniature coils are located far from the walls of the fluid container, so at r = R yields Jm(λR) = 0, which can be solved numerically and yields an infinite number of solutions εmn = λR, m = 0,1,2,…, n = 1,2,3,…, providing the eigenvalue λmn for each mode as λmn = εmn/R. Combining Jm(λr) and , we define the following mode shapes as Hmnc = Jm(λmnr)cosmθ and Hmns = Jm(λmnr)sinmθ.

For any coil ψ

ij(

t) on each layer, based on Equation (8) and the damping effect associated with the fluid viscosity η, the following surface dynamic equation with respect to the mode shape

Hmnc can then be obtained as:

where

m = 0,1,2,… and

n = 1,2,3,…

The main idea of derivation of Equation (12) is similar to the result of MFDM with a single-layer layout of actuators and more details can be found in [

19]. A similar set of equations can be obtained with respect to the mode shape

Hmns as:

where

m and

n = 1,2,3,…

The generalized displacements

and

, obtained from the solution of the second-order differential Equations (12) and (13) respectively, and the corresponding mode shapes

Hmnc and

Hmns evaluated at any desired location (

rk, θ

k), give the total surface displacement at the location as

Based on Equations (12)–(14), it can be seen that the surface response ζ(rk, θk, t) is linearly dependent on the input ψij(t) introduced by each electromagnetic coil.

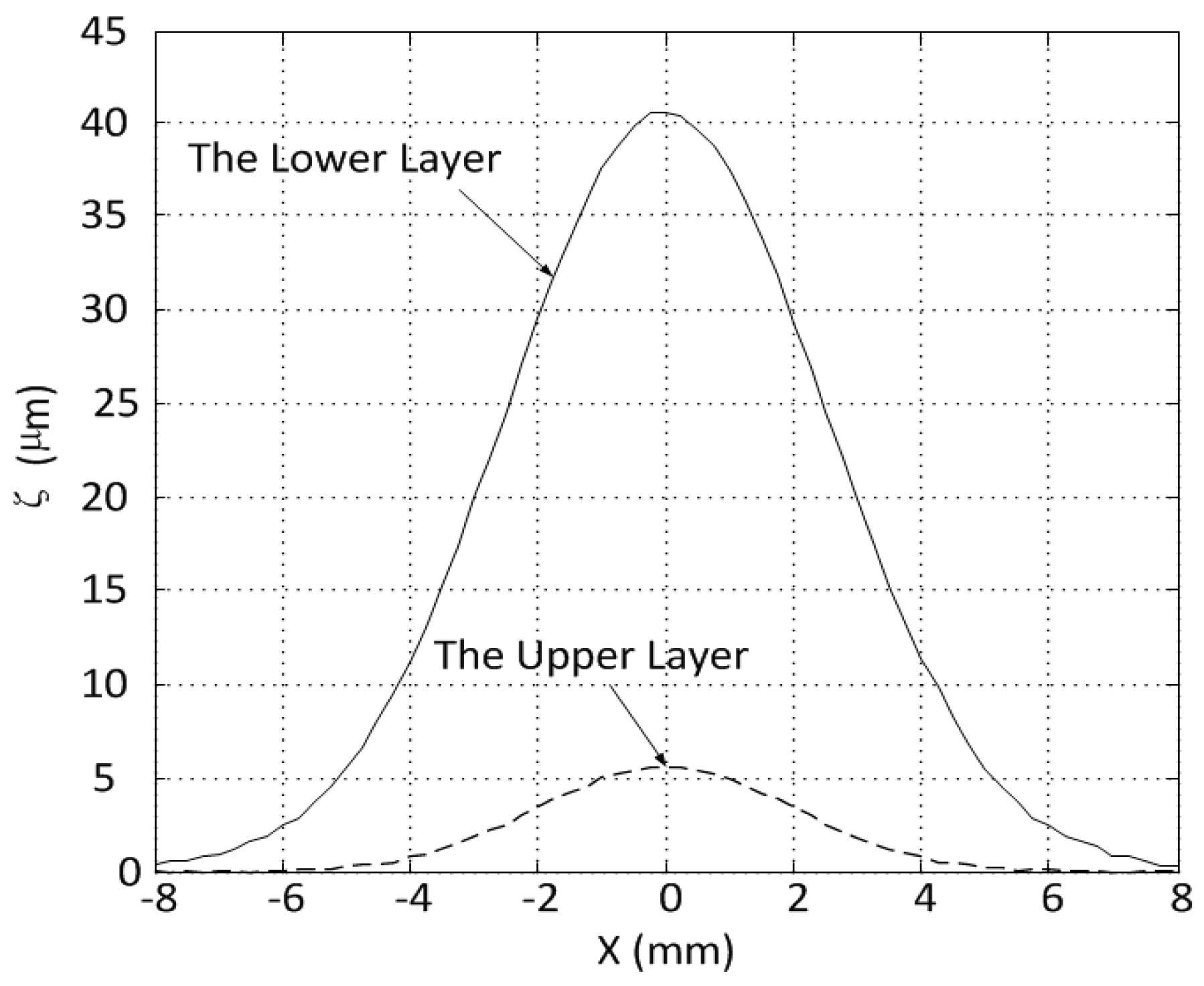

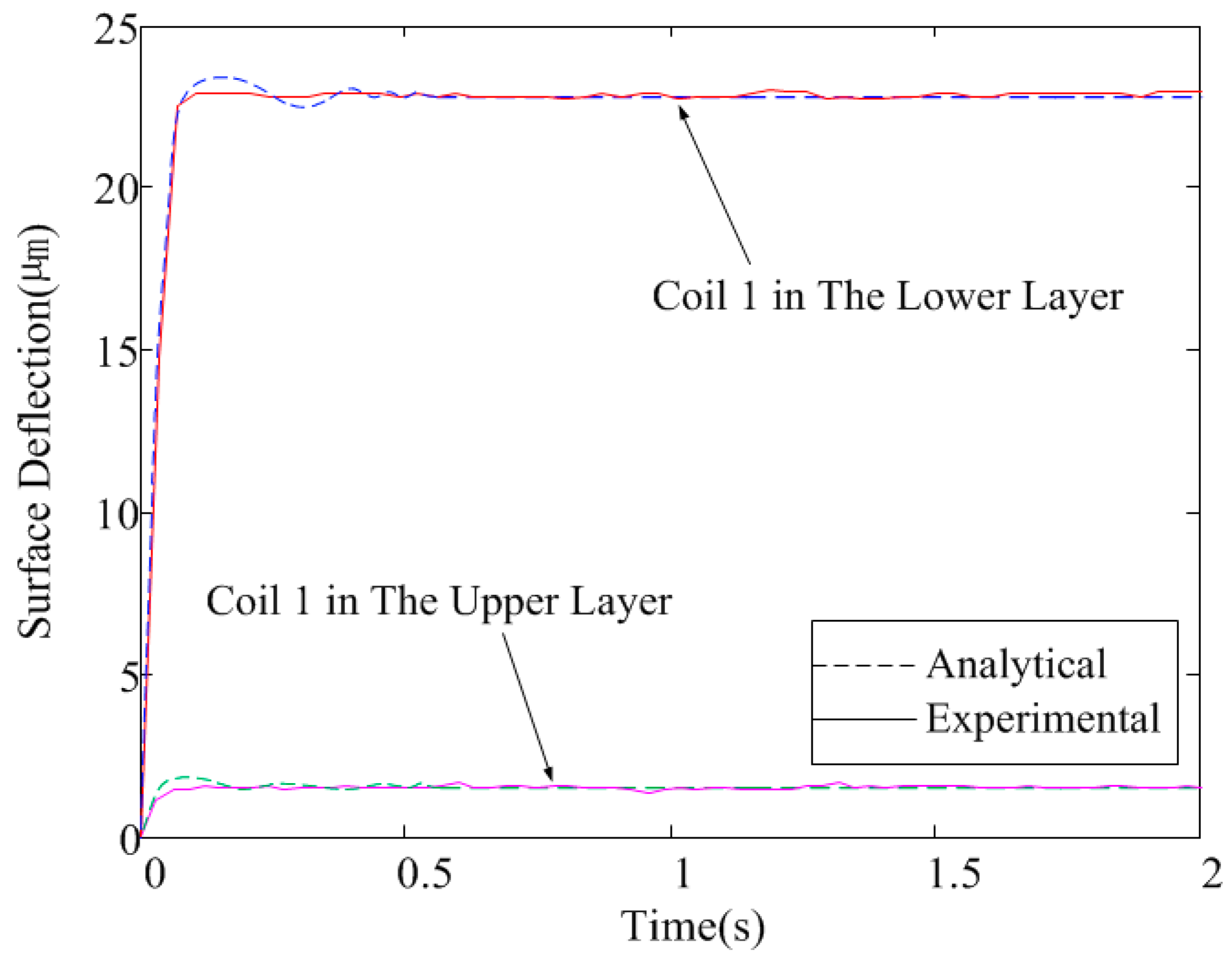

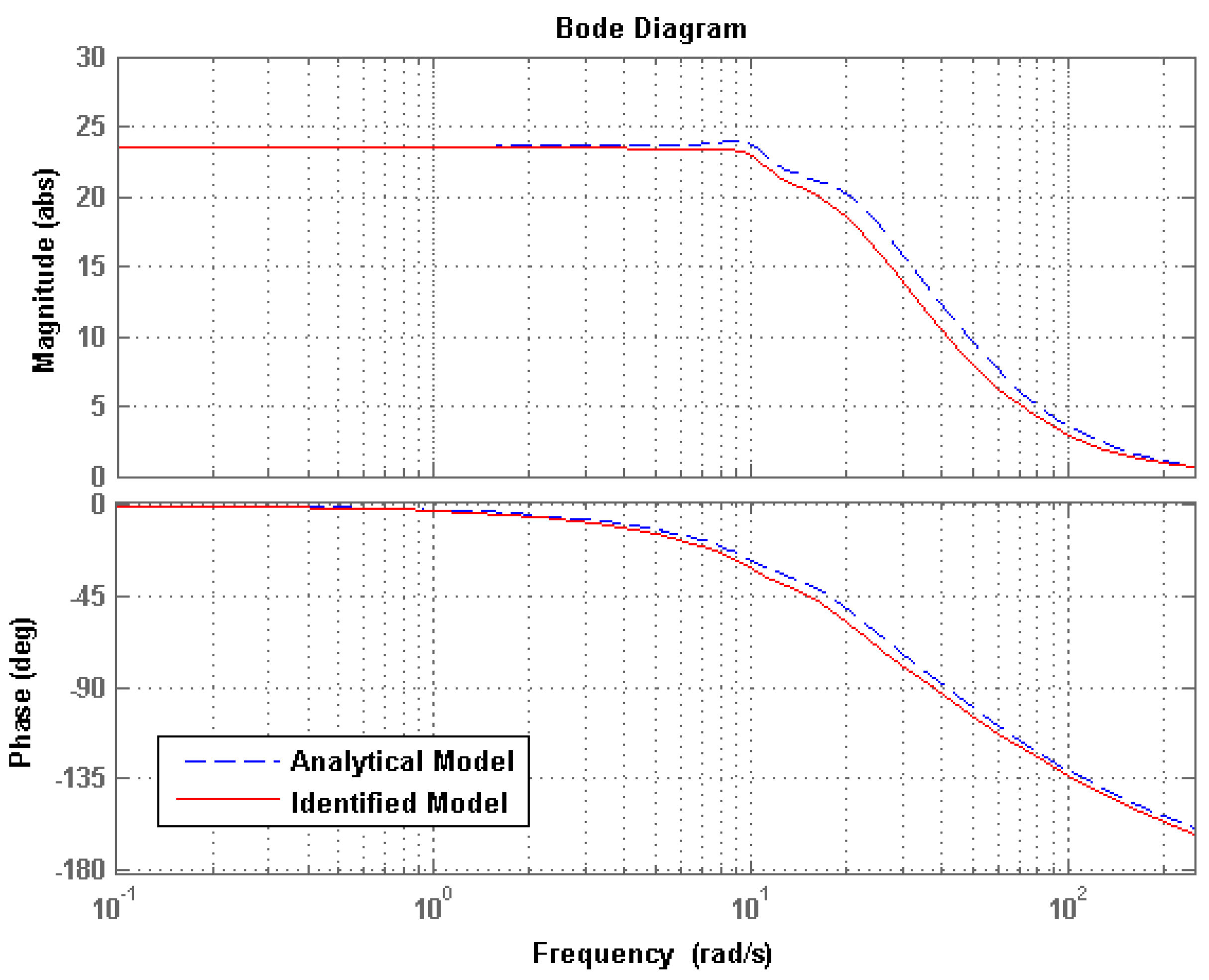

It should be noted that using Equations (12)–(14), the static surface response model of the mirror with respect to the perturbed magnetic field produced by each actuator can be obtained. Then the parameters of the coils in both layers as listed in

Table 2 are designed based on the static model of MFDM so that the desired surface deflection of 5 µm by the single actuator in the upper layer and the deflection of 40 µm by the one in lower layer can be both produced. The ratio of the diameters of the coils in the lower and upper layers is finally rounded to have a factor of two so that the same pupil can be covered by the actuators in each layer.

4. Static Simulation of MFDM

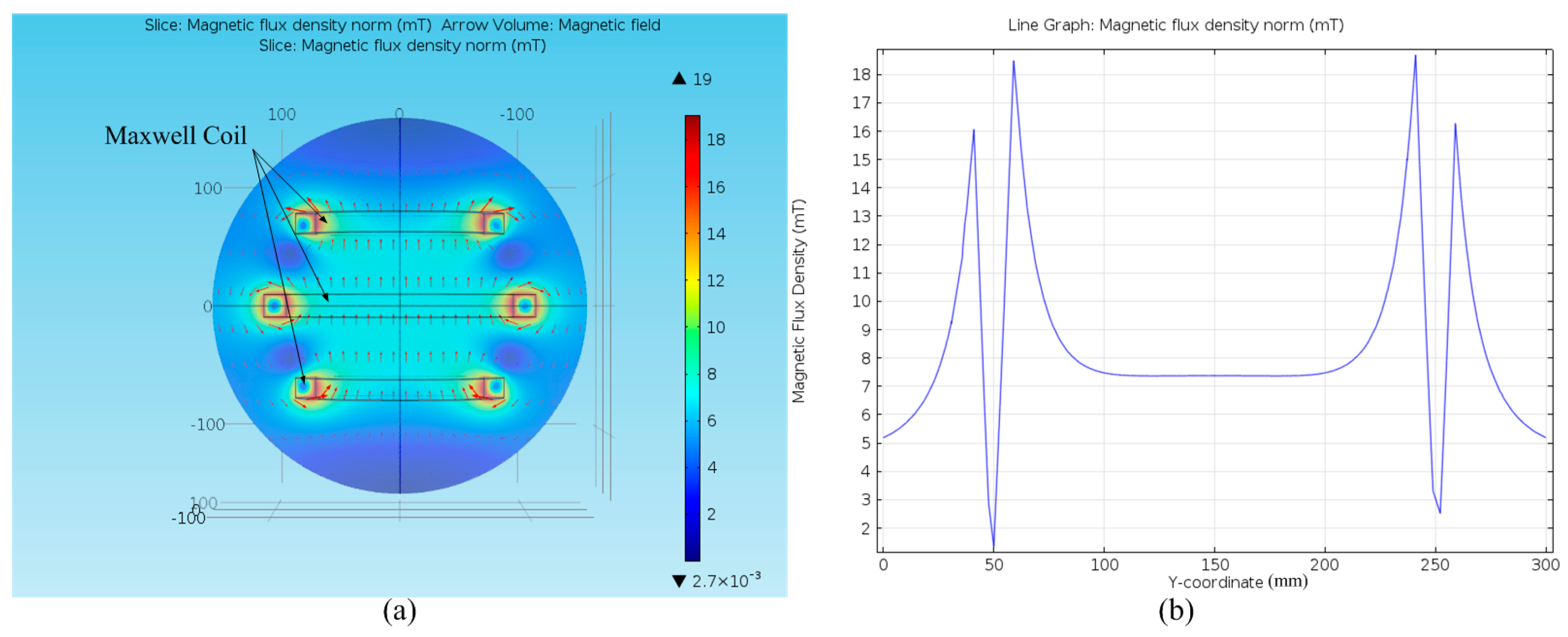

Based on the parameters listed in

Table 1,

Table 2 and

Table 3, the magnetic fields of the Maxwell coil and the two layer coils are simulated using COMSOL Multiphysics (version 4.4, COMSOL Inc., Stockholm, Sweden). As shown in

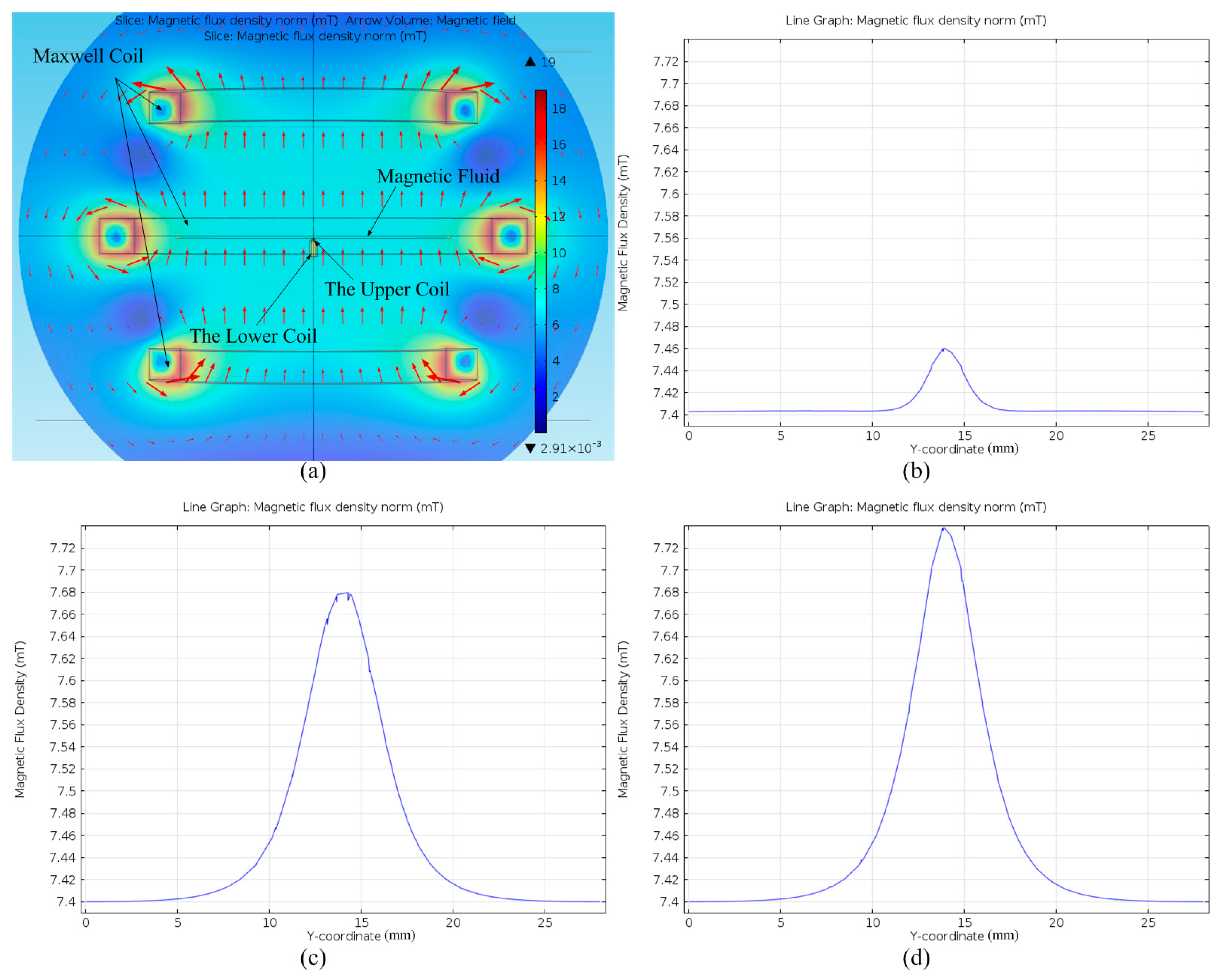

Figure 4a, the magnetic field inside the Maxwell coil is uniformly distributed. When the input current of the Maxwell coil is 500 mA, the uniform magnetic field intensity at the center plane can reach 7.4 mT (see in

Figure 4b).

Figure 5a shows the geometric model of the Maxwell coil, the center coils in the upper layer and lower layer and the magnetic fluid in COMSOL.

Figure 5b,c show the superposition of the magnetic field distribution curve generated by the two center coils along with the Maxwell coil on the mirror surface, respectively. It is indicated that the maximum perturbed magnetic field intensity produced by the coil in the upper layer with a current of 35 mA can reach 0.06 mT on the mirror surface, whereas the maximum perturbed magnetic field intensity produced by the coil in the lower layer with a current of 50 mA can reach up to 0.28 mT. Based on the dynamics model of Equation (14), it can be derived that the maximum mirror surface displacements driven by the center coil in the upper layer or lower layer can reach up to 5 µm and 40 µm, respectively.

Figure 5d shows the superposition result of the magnetic field driven by the two center coils and the Maxwell coil together, and the maximum magnetic field intensity on the mirror surface reaches 7.74 mT.

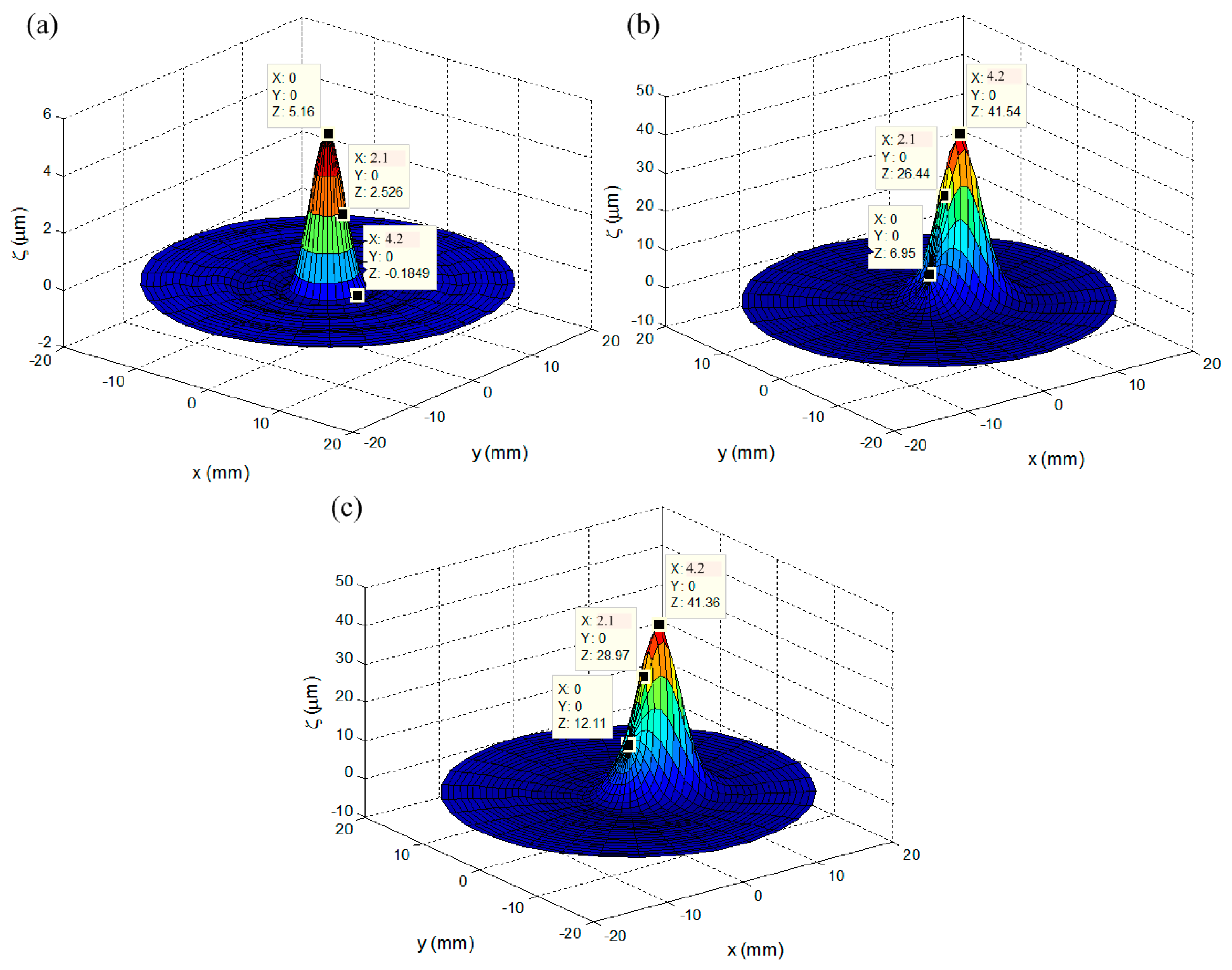

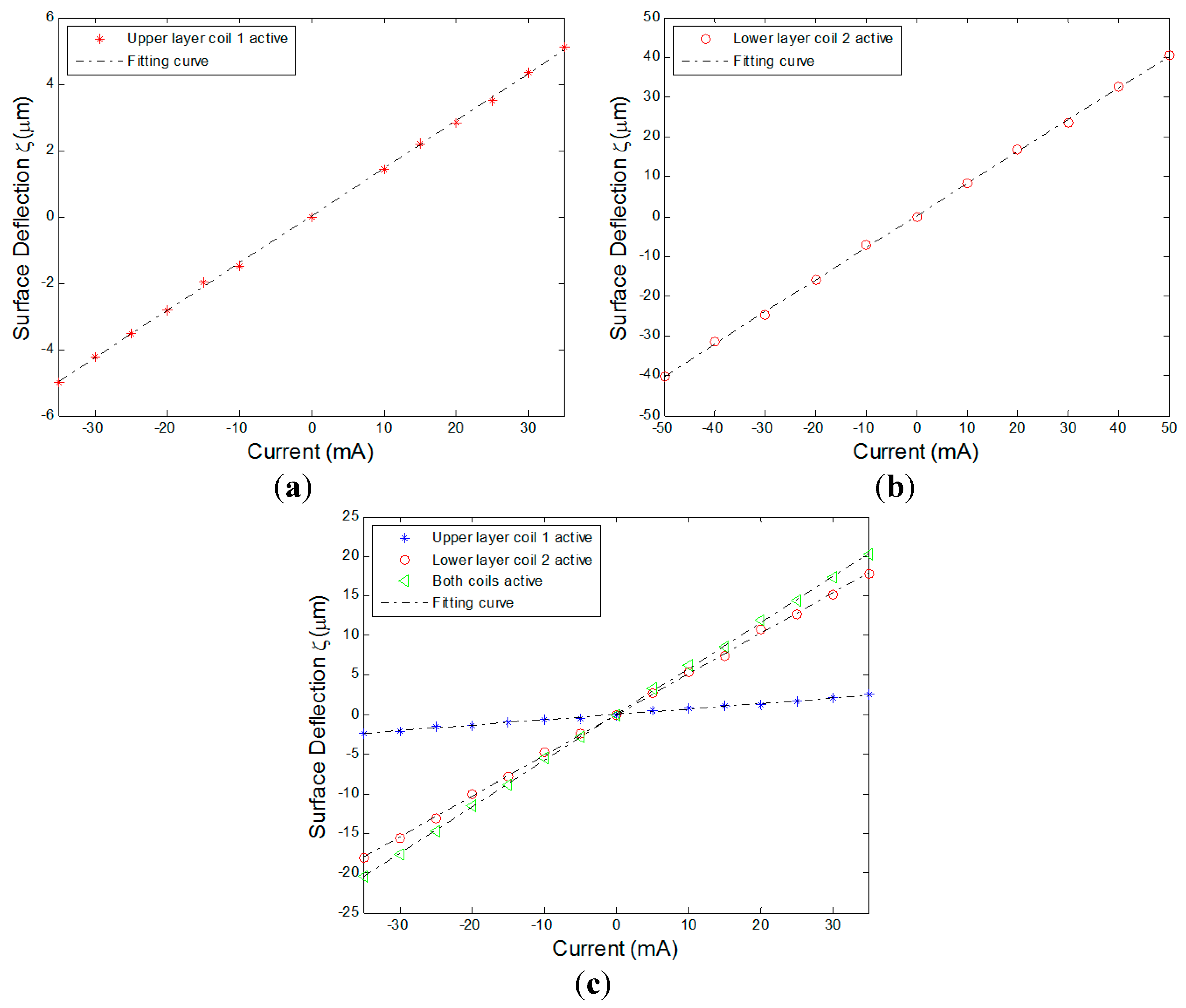

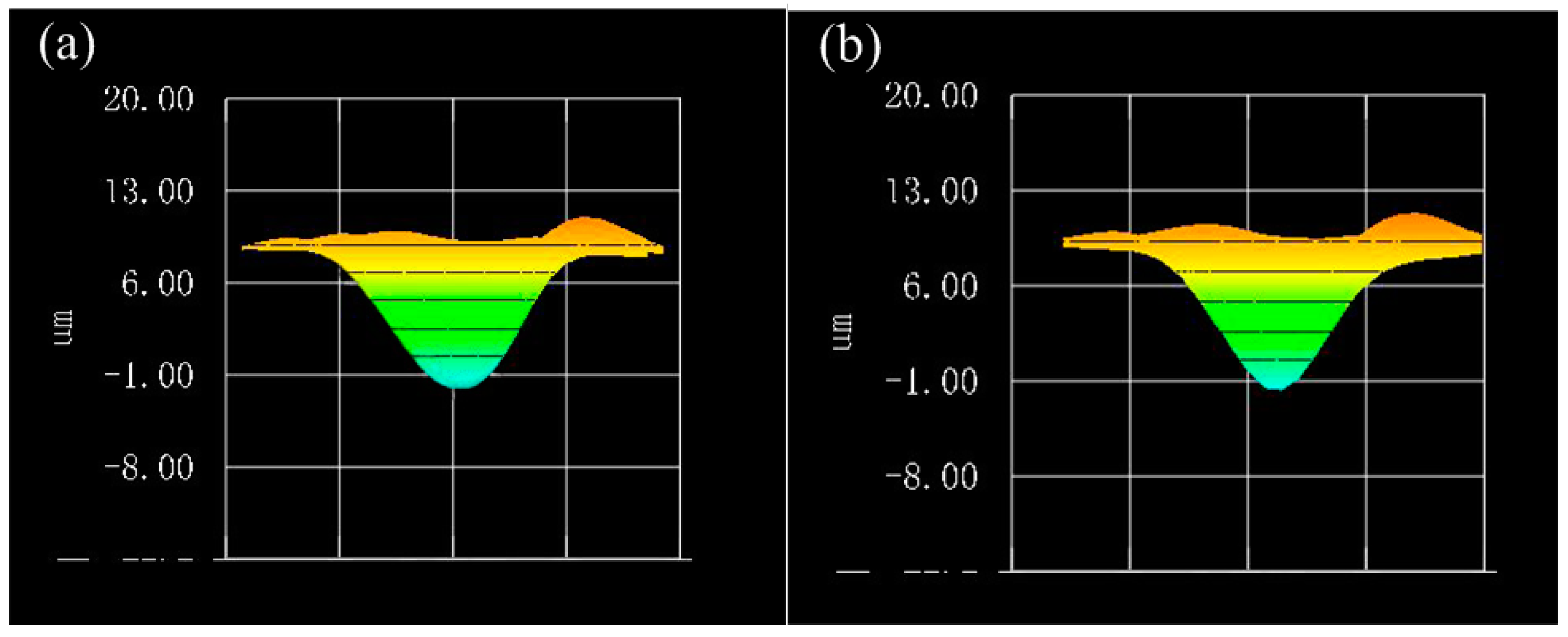

The linear response of the mirror surface deflection is simulated and verified in the COMSOL and MATLAB (version 2011a, Mathworks Inc., Natick, MA, USA) co-simulation environment. The lower-layer coils can provide a large stroke deflection due to the relatively large size of the electromagnetic coils compared with the upper-layer coils. Based on the structure parameters of the coils in each layer, the corresponding magnetic potentials are obtained in COMSOL with the analytical model of the MFDM developed in MATLAB. When the Maxwell coil is turned on with a current of 500 mA, the simulation results of the surface deflection contour are shown in

Figure 6. In

Figure 6a, it can be seen that the maximum deflection magnitude is 5.16 µm at (0,0) when coil 1 in the upper layer (see

Figure 1) is active at 35 mA. In

Figure 6b, the maximum deflection magnitude is 41.54 µm at (4.2,0) when coil 2 in the lower layer (see

Figure 1) is set to 50 mA. When both coils are active,

Figure 6c indicates that the surface deflection of the mirror is the linear sum of the deflections generated by each of the two coils separately.