Effects of Doping Elements on the Friction and Wear of SUJ2 Steel Sliding against Aluminum Alloys

Abstract

:1. Introduction

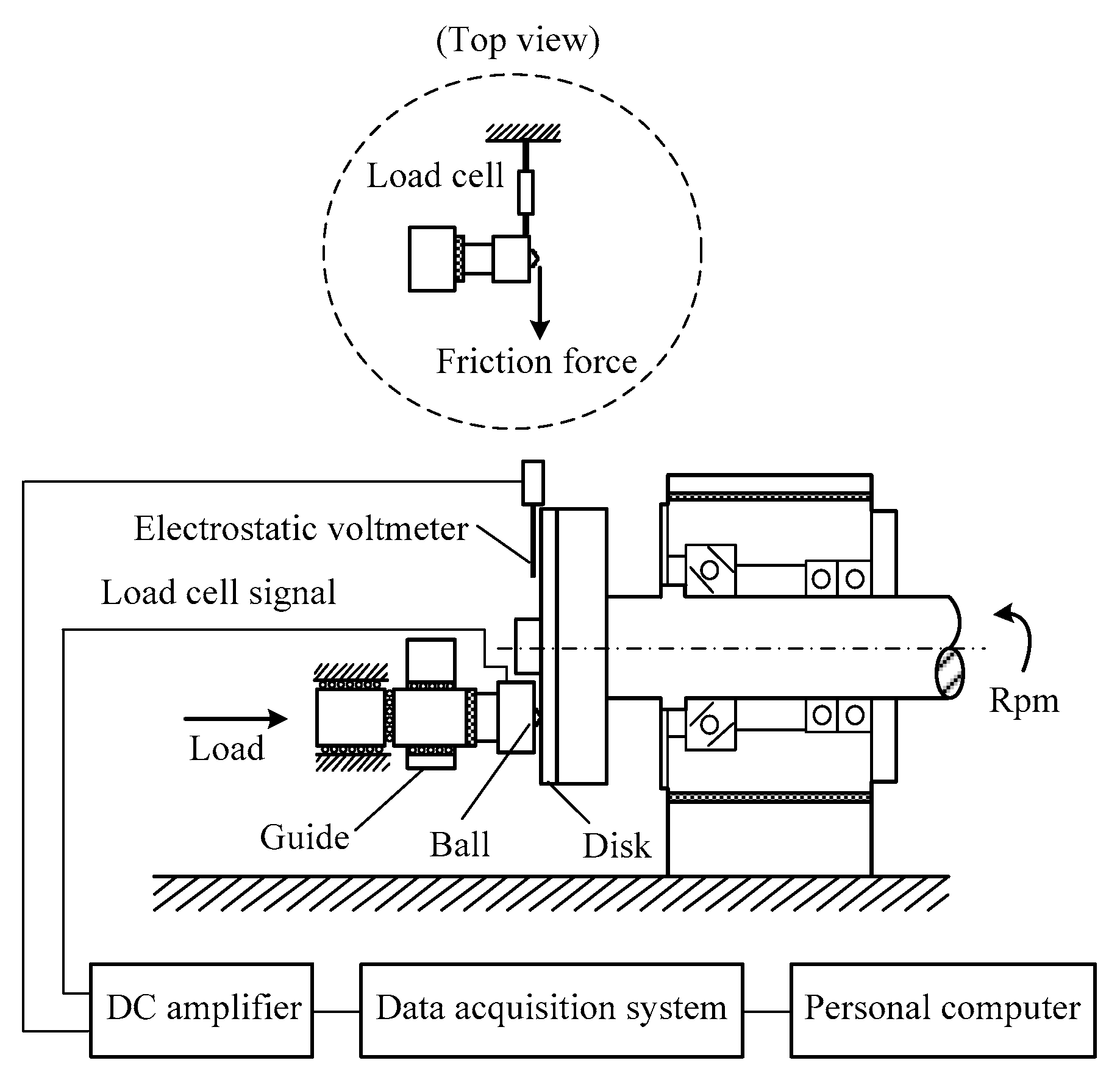

2. Experimental Apparatus and Procedures

3. Results and Discussion

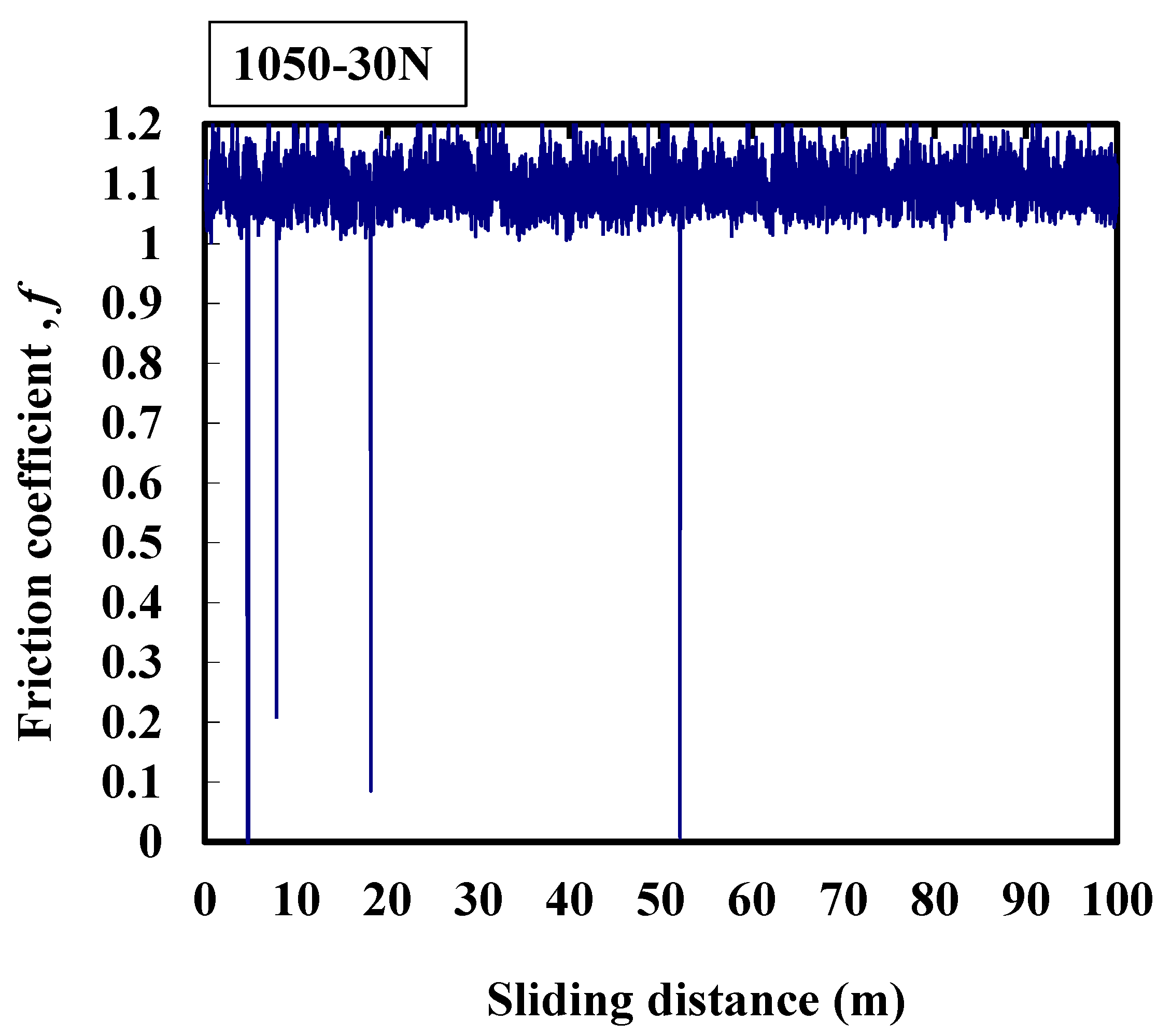

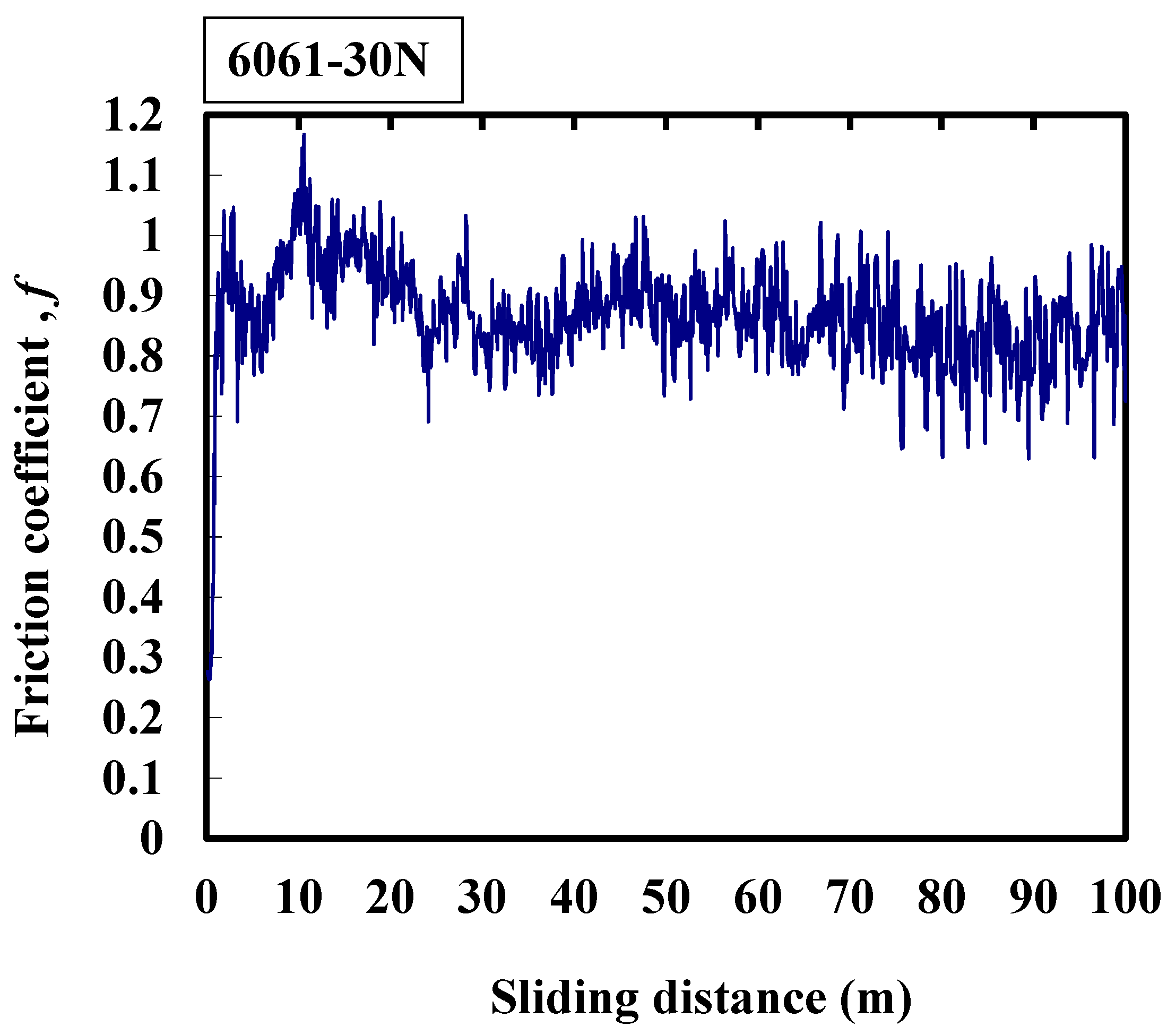

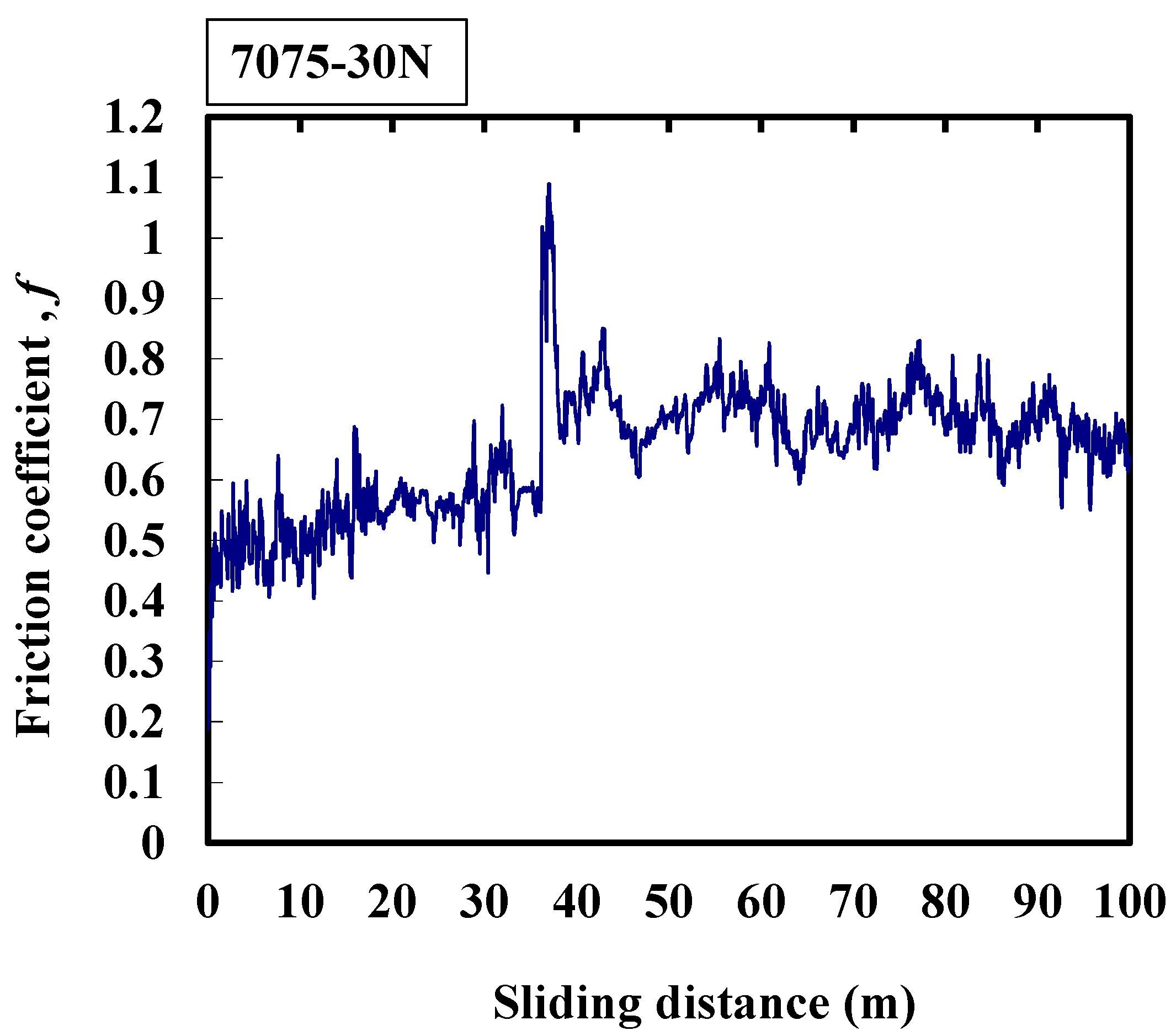

3.1. Friction Coefficient

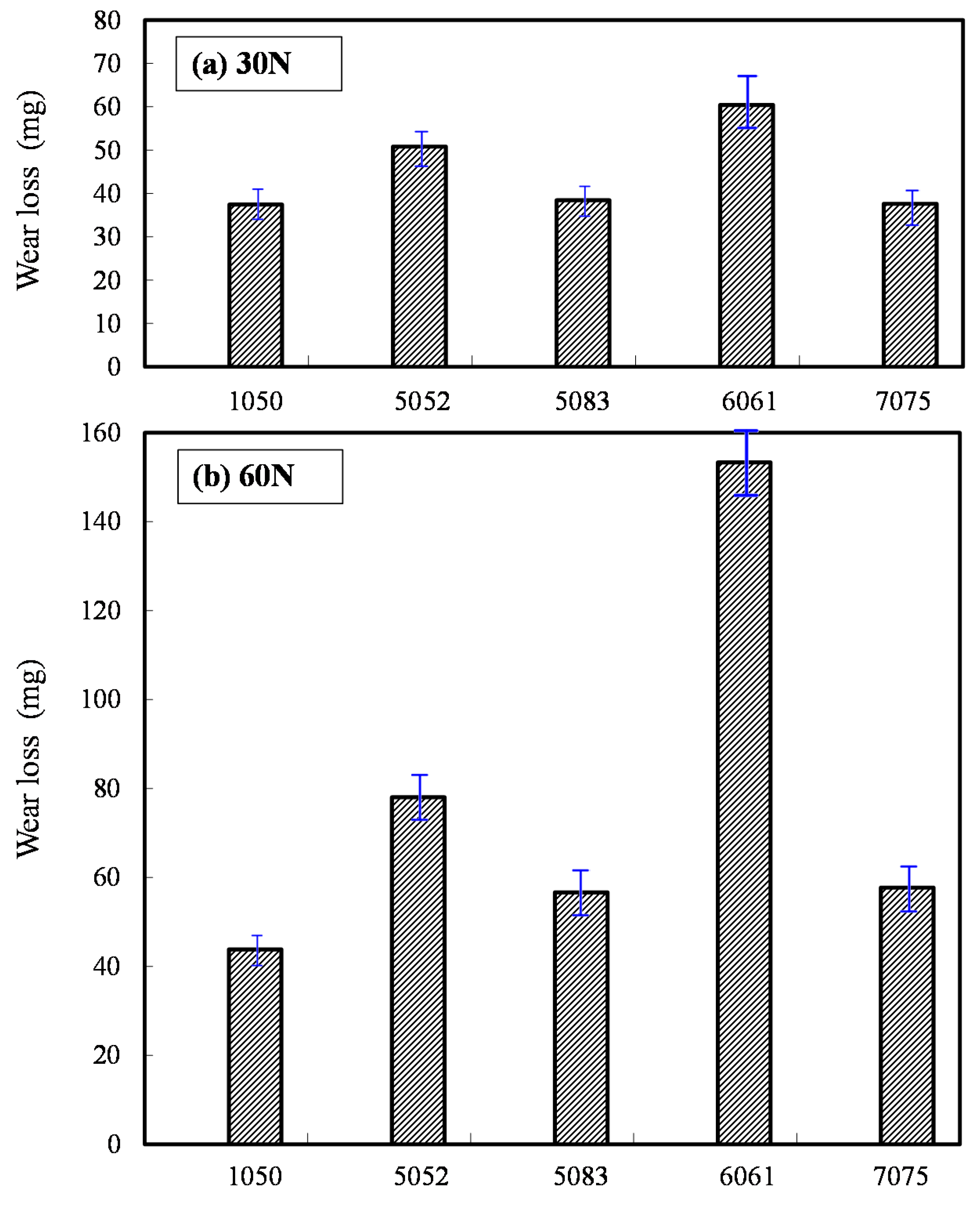

3.2. Wear Loss

3.3. Optical Microscopy of the Wear Track

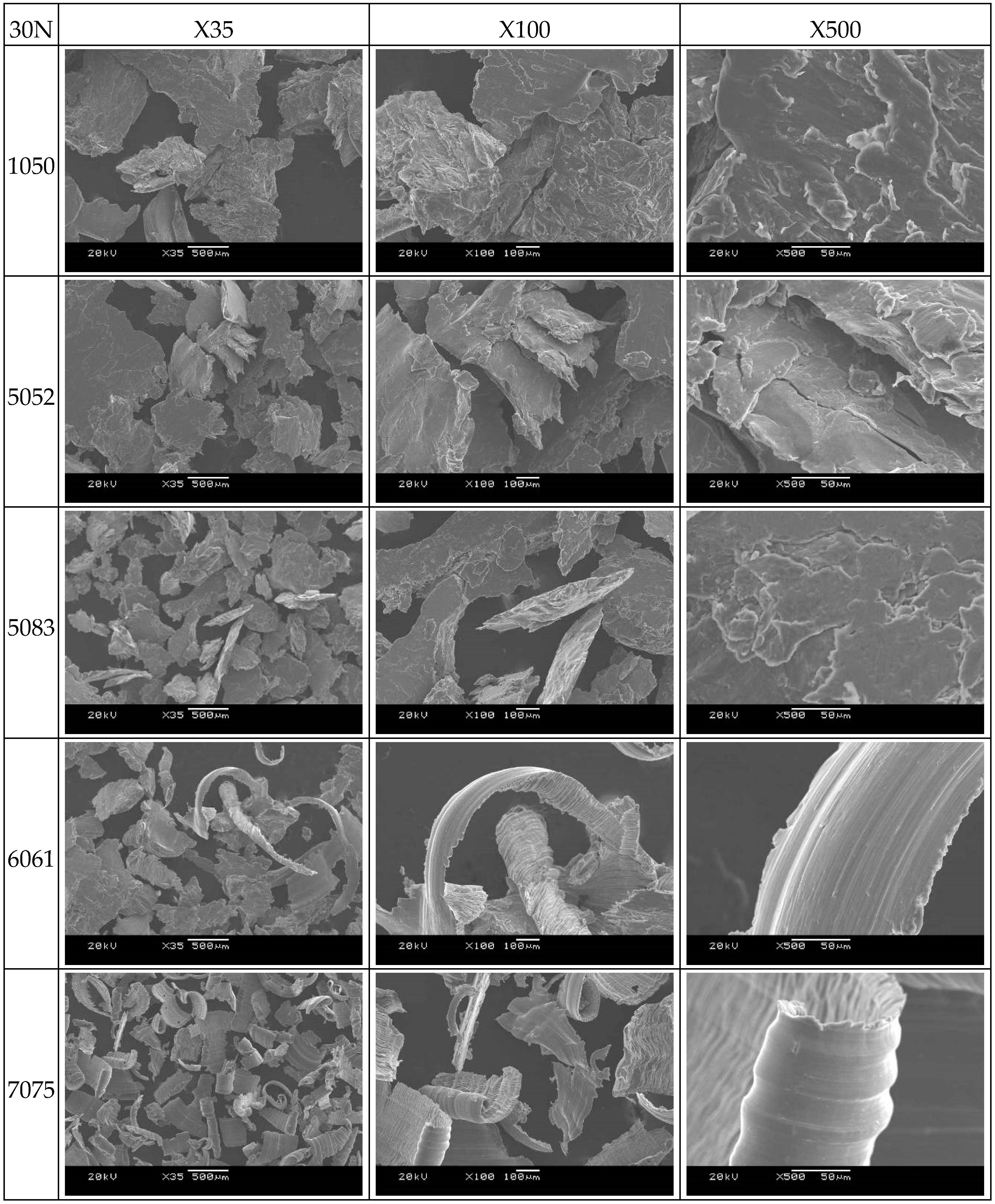

3.4. SEM Observation of Wear Particle

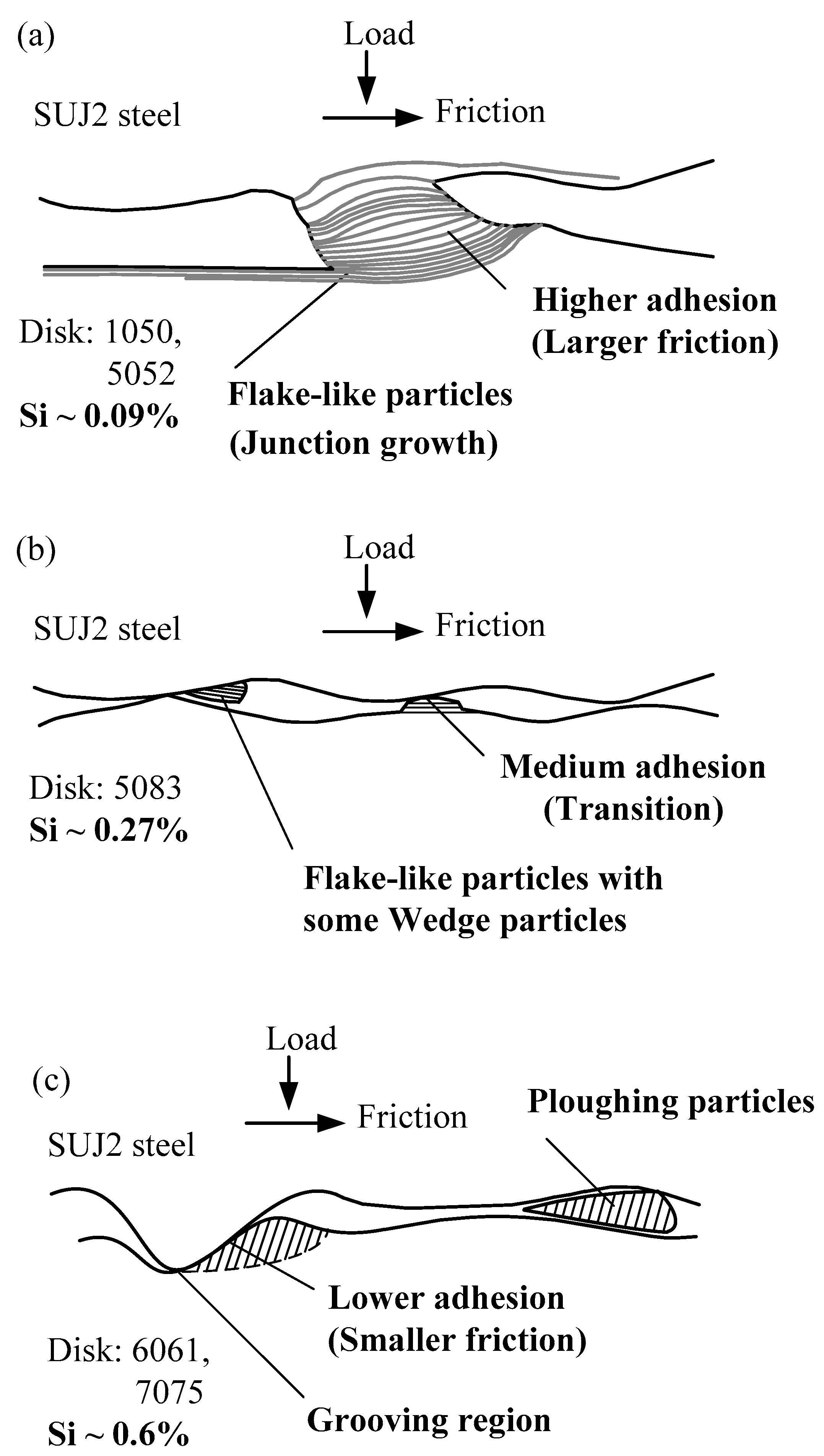

3.5. Frictional Models and Wear Mechanisms

4. Conclusions

- The materials with a higher Si content percentage show lower friction. Generally, the friction coefficient decreases with increases in the Si content, and the variation of the friction coefficient is milder.

- The 6061 aluminum alloy has severe ploughing and wear particles. The wear losses for the compatible doping elements are larger. Therefore, the higher the contents of iron and copper, the more materials are removed, representing better machinability.

- Three frictional models and wear mechanisms that describe the effects of the content of doping elements on the friction and wear of SUJ2 steel sliding against aluminum alloys are proposed. The wear mechanisms change as the silicon content increases, from the junction growth to the wedge and the ploughing particles.

- Based on the above three models, better choices of aluminum alloys with regards to friction and wear can be made. These results have great practical importance for the precision machinery industry.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, J.; Wei, Z.; Chen, Z.; Li, S.; Tang, Y. Numerical investigation of pileup process in metal microdroplet deposition manufacture. Micromachines 2014, 5, 1429–1444. [Google Scholar] [CrossRef]

- Florian, P.; Benedikt, A.; Ralf, H. Micromachining of AlN and Al2O3 using fiber laser. Micromachines 2014, 5, 1051–1060. [Google Scholar]

- Yang, J.; Si, C.; Han, G.; Zhang, M.; Ma, L.; Zhao, Y.; Ning, J. Researching the aluminum nitride etching process for application in MEMS resonators. Micromachines 2015, 6, 281–290. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, J.; Si, C.; Han, G.; Zhao, Y.; Ning, J. Research on the piezoelectric properties of AlN thin films for MEMS applications. Micromachines 2015, 6, 1236–1248. [Google Scholar] [CrossRef]

- Lane, J. Aluminium in Building; Ashgate Publish Ltd.: Hants, UK, 1992. [Google Scholar]

- Krishna Kanth, V.; Pramila Bai, B.N.; Biswas, S.K. Wear mechanisms in a hypereutectic aluminum silicon alloy sliding against steel. Scr. Metall. Mater. 1990, 24, 267–271. [Google Scholar] [CrossRef]

- Torabian, H.; Pathak, J.P.; Tiwari, S.N. Wear characteristics of Al-Si alloys. Wear 1994, 172, 49–58. [Google Scholar] [CrossRef]

- Sarkar, A.D. Wear of aluminium-silcon. Wear 1975, 31, 331–343. [Google Scholar]

- Prasad, B.K.; Venkateswarlu, K.; Modi, O.P.; Jha, A.K.; Das, S.; Dasgupta, R.; Yegneswaran, A.H. Sliding wear behavior of some Al-Si alloys: Role of shape and size of Si particles and test conditions. Metall. Mater. Trans. A 1998, 29, 2747–2752. [Google Scholar] [CrossRef]

- Smith, W.F. Structure and Properties of Engineering Alloys, 2nd ed.; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Saeid, F.; Saeid, M. Effect of material structure machining characteristics of hypereutectic Al-Si alloy. Mech. Adv. Manuf. Technol. 2007, 4–15. [Google Scholar]

- Birol, Y. Cooling slope casting and thixoforming of hypereutectic A390 alloy. J. Mater. Process. Technol. 2008, 207, 200–203. [Google Scholar] [CrossRef]

- Rios, P.R.; Fonseca, G.S. Grain boundary pinning by Al6Mn precipitates in an Al-1wt % Mn alloy. Scr. Mater. 2004, 50, 71–75. [Google Scholar] [CrossRef]

- Reddy, A.S.; Bai, B.N.P.; Murthy, K.S.S.; Biswas, S.K. Wear and seizure of binary Al-Si alloys. Wear 1994, 171, 115–127. [Google Scholar] [CrossRef]

- Reddy, A.S.; Bai, B.N.P.; Murthy, K.S.S.; Biswas, S.K. Mechanism of seizure of aluminium-silicon alloys dry sliding against Steel. Wear 1995, 181–183, 658–667. [Google Scholar] [CrossRef]

- Wert, J.A. Microstructures of friction stir weld joints between an aluminum-base metal matrix composite and a monolithic aluminum alloy. Scr. Mater. 2003, 49, 607–612. [Google Scholar] [CrossRef]

- Yamauch, S.; Shibue, K.; Okubo, Y.; Sano, H.; Inumalu, S. Development of wear-resistant P/M aluminum alloys “PA4XX”. Bull. Jpn. Inst. Met. 1988, 27, 492–494. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1995; pp. 38–39, 84–88. [Google Scholar]

- Alpas, A.T.; Zhang, J. Wear rate transitions in cast aluminum-silicon alloys reinforced with SiC particles. Scr. Metall. Mater. 1992, 26, 505–509. [Google Scholar]

- Zhang, J.; Alpas, A.T. Delamination wear in ductile materials containing second phase particles. Mater. Sci. Eng. A 1993, 160, 25–35. [Google Scholar] [CrossRef]

- Alpas, A.T.; Hu, H.; Zhang, J. Plastic deformation and damage accumulation below the worn surfaces. Wear 1993, 162–164, 188–195. [Google Scholar] [CrossRef]

- Li, X.Y.; Tandon, K.N. Mechanical mixing induced by sliding wear of an Al-Si alloy against M2 steel. Wear 1999, 225–229, 640–648. [Google Scholar]

- Subramanian, C. On mechanical mixing during dry sliding of aluminium-12.3 wt % silicon alloy against copper. Wear 1993, 161, 53–60. [Google Scholar]

- Wang, Y.; Li, X.D.; Feng, Z.C. The relationship between the product of load and sliding speed with friction temperature and sliding wear of a 52100 steel. Scr. Metall. Mater. 1995, 33, 1163–1168. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, M.; Li, X.D.; Lei, T. Frictional temperature field and wear behavior of steel 52100 with different microstructures. J. Tribol. 1994, 116, 255–259. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and grapheme—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.B.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional metal matrix composites: Self-lubricating, self-healing, and nanocomposites—An Outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Omrani, E.; Moghadam, A.D.; Algazzar, M.; Menezes, P.L.; Rohatgi, P.K. Effect of graphite particles on improving tribological properties Al-16Si-5Ni-5Graphite self-lubricating composite under fully flooded and starved lubrication conditions for transportation applications. Int. J. Adv. Manuf. Technol. 2016, 87, 929–939. [Google Scholar] [CrossRef]

- Chiou, Y.C.; Chang, Y.P.; Lee, R.T. Tribo-electrification mechanism for self-mated metals in dry severe wear process, part II: Pure soft metals. Wear 2003, 254, 616–624. [Google Scholar] [CrossRef]

- Chang, Y.P.; Yur, J.P.; Chou, H.M.; Chu, H.M. Tribo-electrification mechanisms for self-mated carbon steels in dry severe wear process. Wear 2006, 260, 1209–1216. [Google Scholar] [CrossRef]

- Chang, Y.P.; Chu, H.M.; Chou, H.M. Effects of mechanical properties on the tribo-electrification mechanisms of iron rubbing with carbon steels. Wear 2007, 262, 112–120. [Google Scholar] [CrossRef]

| Aluminum Alloys | Si | Fe | Cu | Mn | Mg |

|---|---|---|---|---|---|

| 1050 | 0.09 | 0.23 | 0.01 | 0.01 | 0.03 |

| 5052 | 0.09 | 0.26 | 0.02 | 0.05 | 2.50 |

| 5083 | 0.27 | 0.38 | 0.09 | 0.59 | 4.70 |

| 6061 | 0.58 | 0.62 | 0.26 | 0.06 | 1.07 |

| 7075 | 0.60 | 0.20 | 0.16 | 0.07 | 1.00 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-P.; Huang, Z.-W.; Chou, H.-M. Effects of Doping Elements on the Friction and Wear of SUJ2 Steel Sliding against Aluminum Alloys. Micromachines 2017, 8, 96. https://doi.org/10.3390/mi8040096

Chang Y-P, Huang Z-W, Chou H-M. Effects of Doping Elements on the Friction and Wear of SUJ2 Steel Sliding against Aluminum Alloys. Micromachines. 2017; 8(4):96. https://doi.org/10.3390/mi8040096

Chicago/Turabian StyleChang, Yuh-Ping, Zi-Wei Huang, and Huann-Ming Chou. 2017. "Effects of Doping Elements on the Friction and Wear of SUJ2 Steel Sliding against Aluminum Alloys" Micromachines 8, no. 4: 96. https://doi.org/10.3390/mi8040096