Tuneable Liquid Crystal Micro-Lens Array for Image Contrast Enhancement in a Pixelated Thin Film Photo-Transistor Flat Panel Imager

Abstract

:1. Introduction

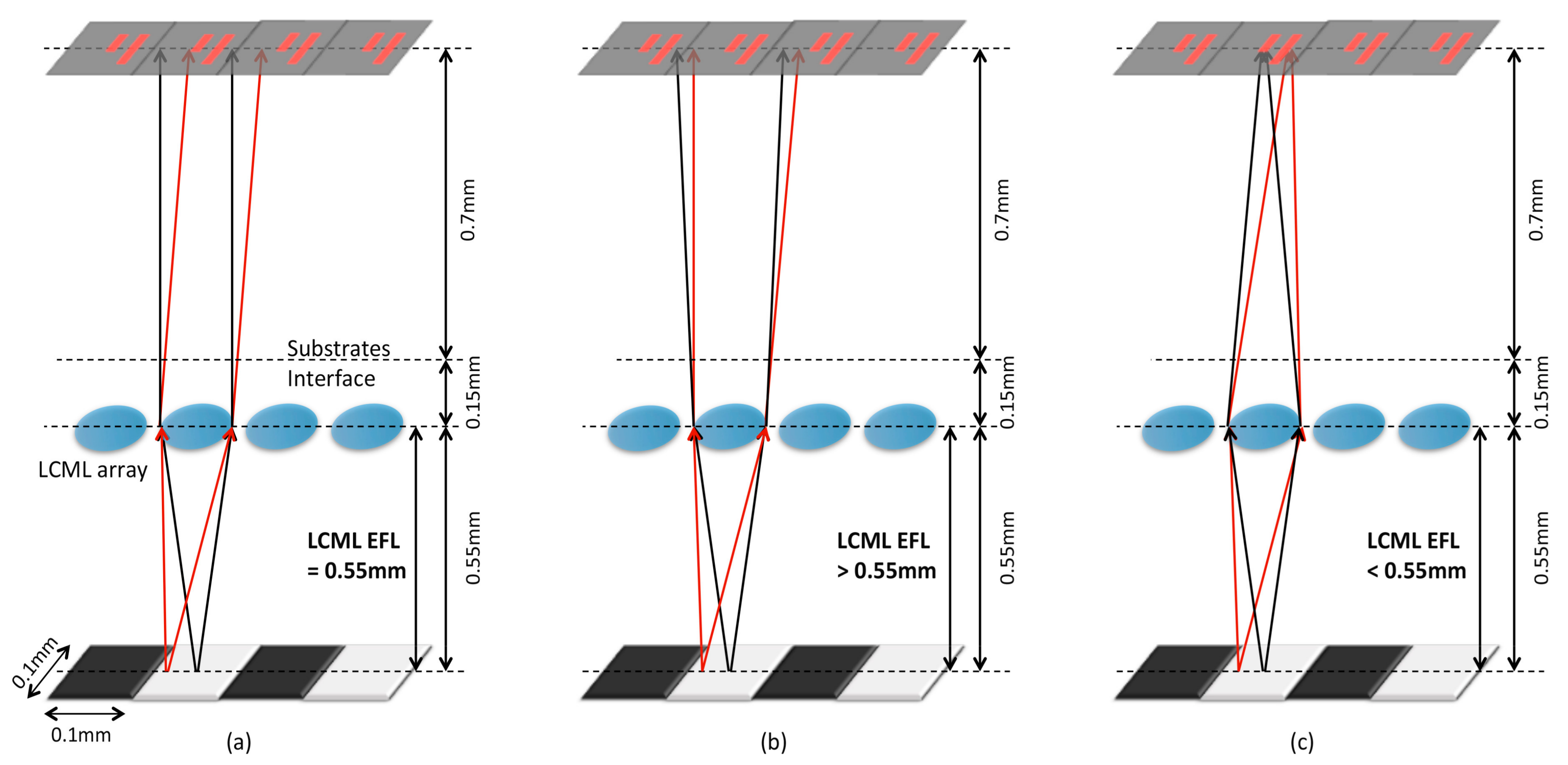

2. Design Considerations

2.1. Consideration of the Practical Implementation and Design of a Micro-Lens Array

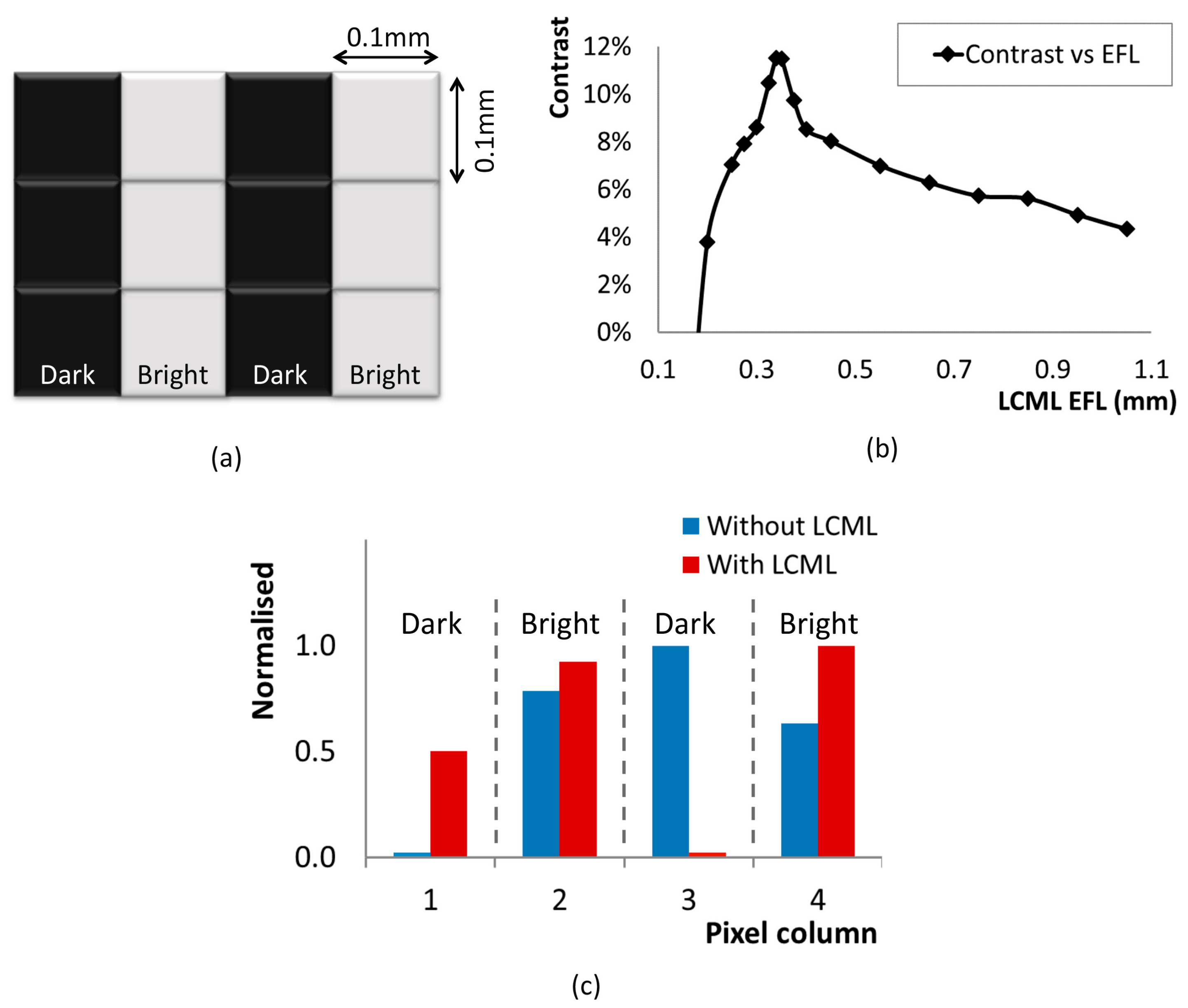

2.2. Simulation Verification

3. Results

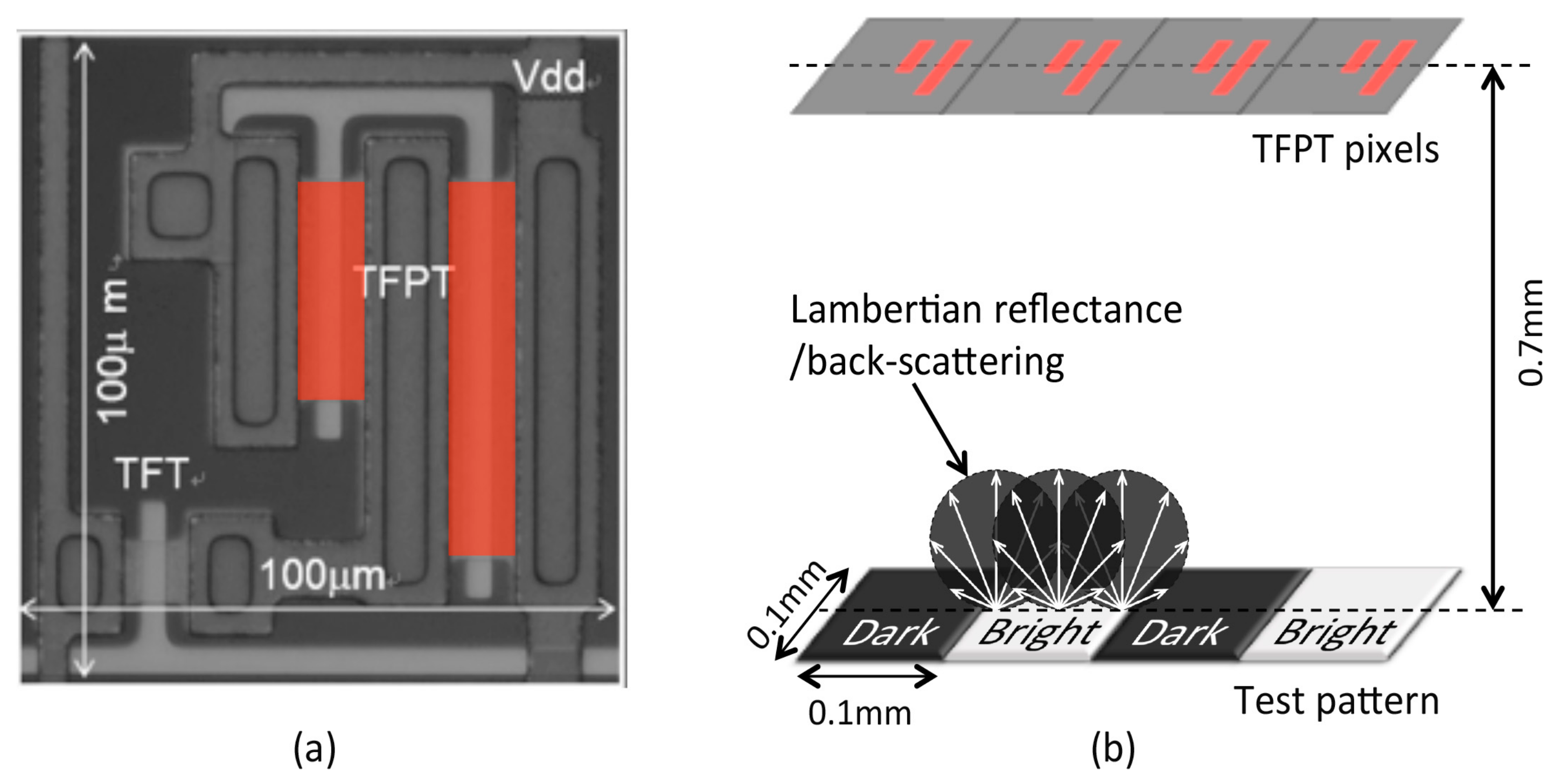

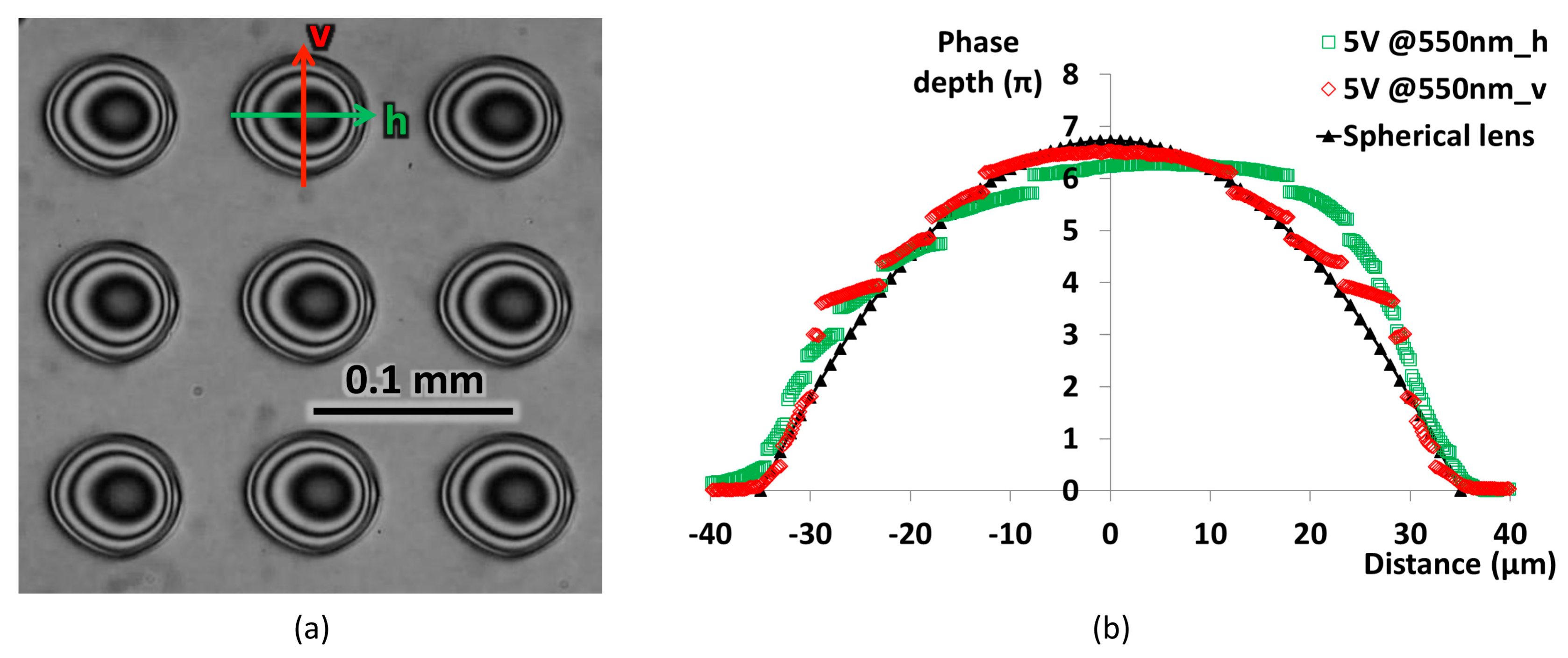

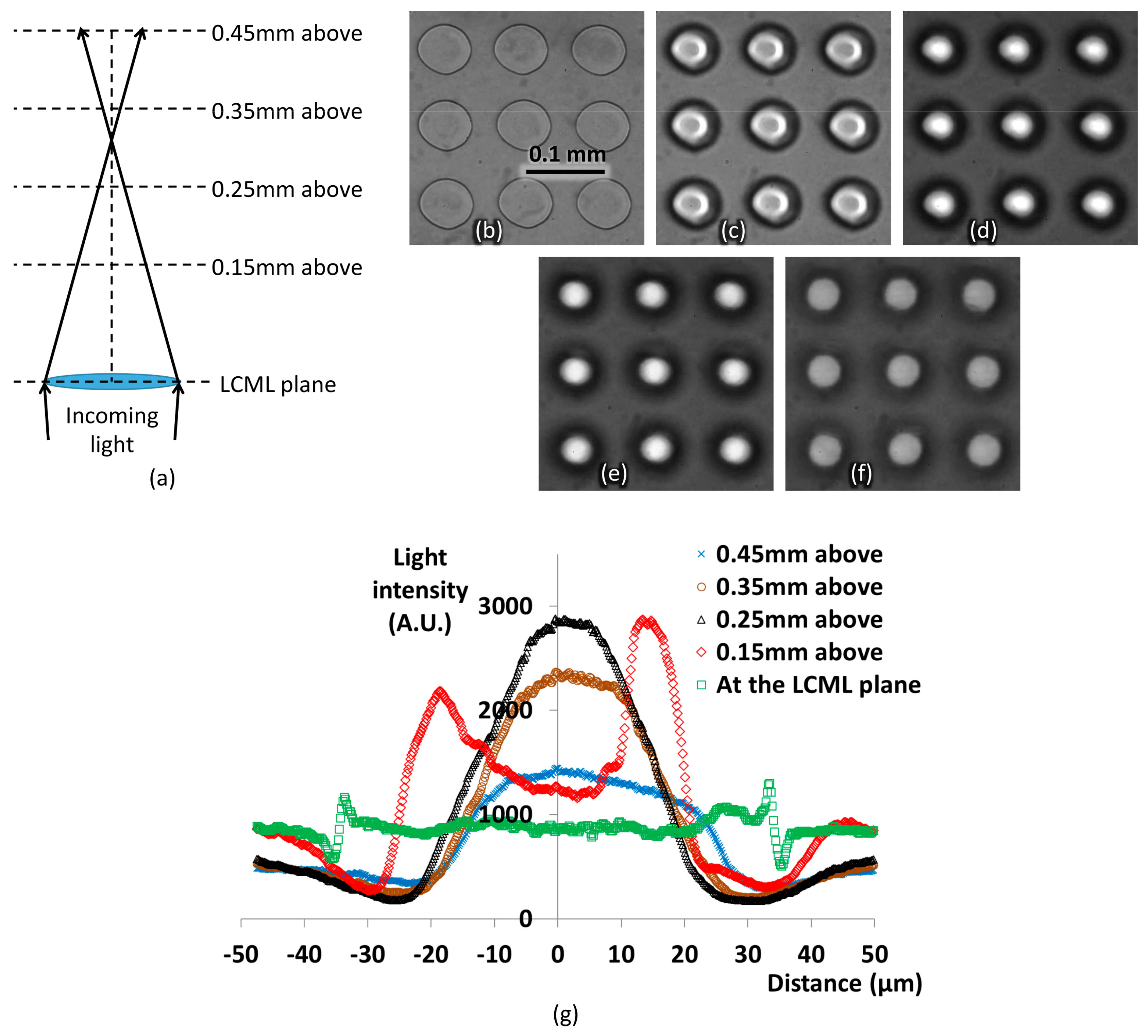

3.1. Device Fabrication and Characterisation

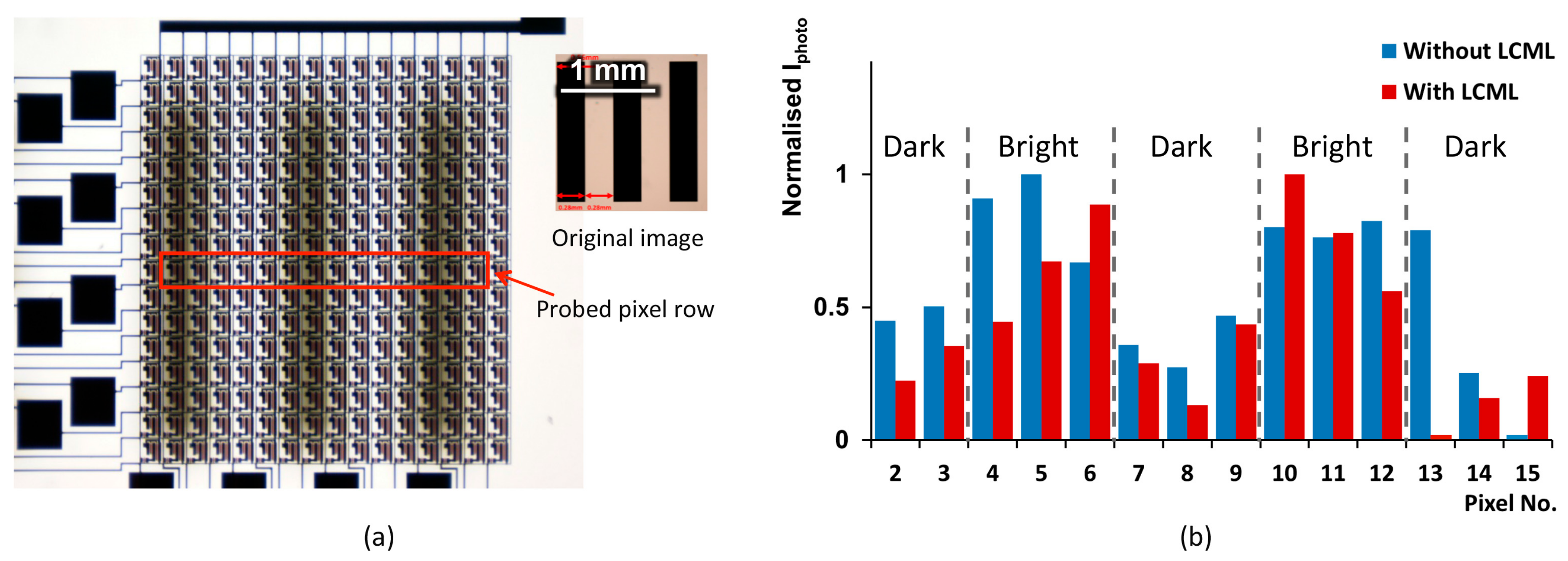

3.2. Test on the TFPT Imager

4. Discussion and Future Work

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Two Sides. Reading from Paper or Reading from Screens. What Do Consumers Prefer? A Survey of UK Consumers Undertaken by Two Sides, May 2015. Available online: http://www.twosides.info/download/Learning-and-literacy-Report-UK.pdf (accessed on 24 June 2017).

- Two Sides. Reading from Paper or Reading from Screens. What Do Consumers Prefer? A Survey of US Consumers Undertaken by Two Sides, May 2015. Available online: http://www.twosidesna.org/download/TS-North-America-Reading-from-paper-or-screens.pdf (accessed on 24 June 2017).

- World Health Organisation Visual Impairment and Blindness—Fact Sheet N°282. Available online: http://www.who.int/mediacentre/factsheets/fs282/en/ (accessed on 20 July 2004).

- Pal, J.; Pradhan, M.; Shah, M.; Babu, R. Assistive technology for vision-impairments: An agenda for the ICTD community. In Proceedings of the 20th International Conference on the World Wide Web, Hyderabad, India, 28 March–1 April 2011; pp. 513–522. [Google Scholar] [CrossRef]

- Haji, S.A.; Sambhav, K.; Grover, S.; Chalam, K.V. Evaluation of the iPad as a low vision aid for improving reading ability. Clin. Ophthalmol. 2015, 9, 17–20. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.J.; Ledge, G.E. Psychophysics of reading-XIII. Predictors of magnifier-aided reading speed in low vision. Vis. Res. 1995, 35, 1931–1938. [Google Scholar] [CrossRef]

- Wolffsohn, J.S.; Peterson, R.C. A review of current knowledge on Electronic Vision Enhancement Systems for the visually impaired. Ophthalmic Physiol. Opt. 2003, 23, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.S.; Jan, H.-A.; Lay, Y.-L.; Huang, C.-C.; Chen, H.-T. Evaluating the image quality of closed circuit television magnification systems versus a head-mounted display for people with low vision. Assist. Technol. 2014, 26, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Bowers, A.; Cheong, A.M.Y.; Lovie-Kitchin, J.E. Reading with optical magnifiers: Page navigation strategies and difficulties. Optom. Vis. Sci. 2007, 84, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Blenkhorn, P.; Evans, G.; King, A.; Kurniawan, S.H.; Sutcliffe, A. Screen magnifiers: Evolution and evaluation. IEEE Comput. Graph. Appl. 2003, 23, 54–61. [Google Scholar] [CrossRef]

- Yamashita, T.; Shima, T.; Nishizaki, Y.; Kimura, M.; Kara, H.; Inoue, S. Evaluation of thin-film photodiodes and development of thin-film phototransistor. Jpn. J. Appl. Phys. 2008, 47, 1924–1929. [Google Scholar] [CrossRef]

- Kimura, M.; Okumura, M.; Matsuda, T.; Noguchi, S. 49.3: High-resolution Active-Matrix Imager using Poly-Si Thin-Film Phototransistors in a Magnifying Viewer Mutsumi using Poly-Si Thin-Film Phototransistors in a Magnifying Viewer. SID 2014 Dig. 2014, 45, 709–712. [Google Scholar] [CrossRef]

- Sato, S. Liquid-Crystal Lens-Cells with Variable Focal Length. Jpn. J. Appl. Phys. 1979, 18, 1679–1684. [Google Scholar] [CrossRef]

- Choi, Y.; Park, J.-H.; Kim, J.-H.; Lee, S.-D. Fabrication of a focal length variable microlens array based on a nematic liquid crystal. Opt. Mater. (Amst.) 2003, 21, 643–646. [Google Scholar] [CrossRef]

- Ren, H.; Fan, Y.-H.; Wu, S.-T. Liquid-crystal microlens arrays using patterned polymer networks. Opt. Lett. 2004, 29, 1608–1610. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, M.; Nakamura, K.; Sato, S. Liquid-crystal micro-lens array with two-divided and tetragonally hole-patterned electrodes. Opt. Express 2013, 21, 26520–26526. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, S.-T. Polarization independent adaptive microlens with a blue-phase liquid crystal. Opt. Express 2011, 19, 8045–8050. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Robertson, B.; Pivnenko, M.; Deng, Y.; Chu, D.; Zhou, J.; Yao, J. High quality micro liquid crystal phase lenses for full resolution image steering in auto-stereoscopic displays. Opt. Express 2014, 22, 21679–21689. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Yöntem, A.Ö.; Deng, Y.; Shrestha, P.; Chu, D.; Zhou, J.; Yao, J. Full resolution auto-stereoscopic mobile display based on large scale uniform switchable liquid crystal micro-lens array. Opt. Express 2017, 25, 9654. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Na, J.; Kim, C.; Lee, S. Design and fabrication of liquid crystal-based lenses. Liq. Cryst. 2017, 1–12. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Chu, D.; Chu, J.; Kitajima, S.; Matsuda, T.; Kimura, M. Tuneable Liquid Crystal Micro-Lens Array for Image Contrast Enhancement in a Pixelated Thin Film Photo-Transistor Flat Panel Imager. Micromachines 2017, 8, 205. https://doi.org/10.3390/mi8070205

Li K, Chu D, Chu J, Kitajima S, Matsuda T, Kimura M. Tuneable Liquid Crystal Micro-Lens Array for Image Contrast Enhancement in a Pixelated Thin Film Photo-Transistor Flat Panel Imager. Micromachines. 2017; 8(7):205. https://doi.org/10.3390/mi8070205

Chicago/Turabian StyleLi, Kun, Daping Chu, Jiaqi Chu, Shuhei Kitajima, Tokiyoshi Matsuda, and Mutsu Kimura. 2017. "Tuneable Liquid Crystal Micro-Lens Array for Image Contrast Enhancement in a Pixelated Thin Film Photo-Transistor Flat Panel Imager" Micromachines 8, no. 7: 205. https://doi.org/10.3390/mi8070205