Light-Powered Micro/Nanomotors

Abstract

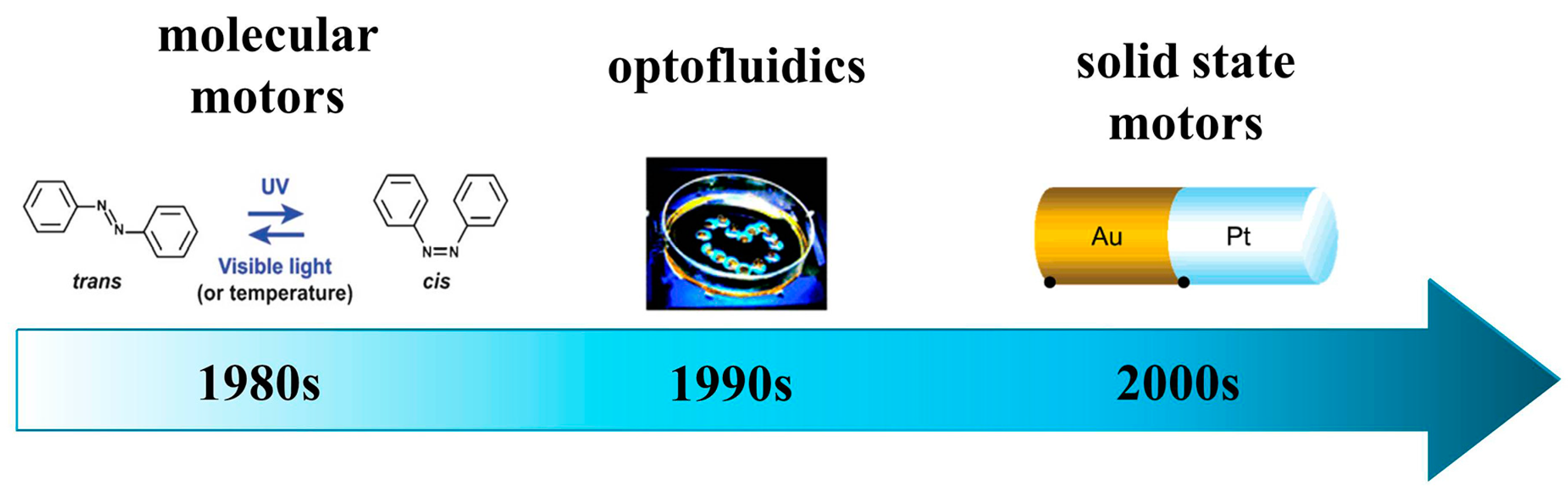

:1. Introduction

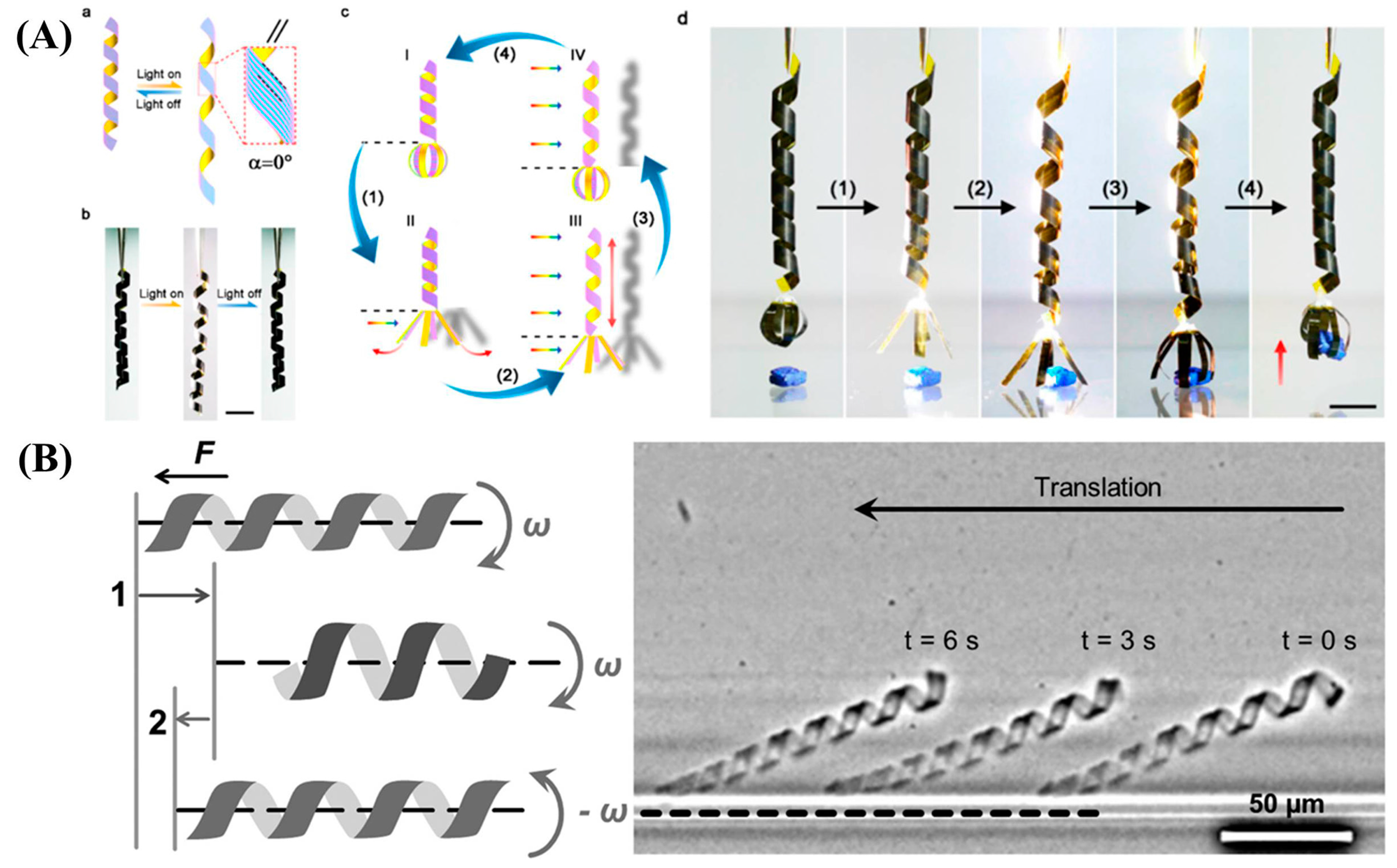

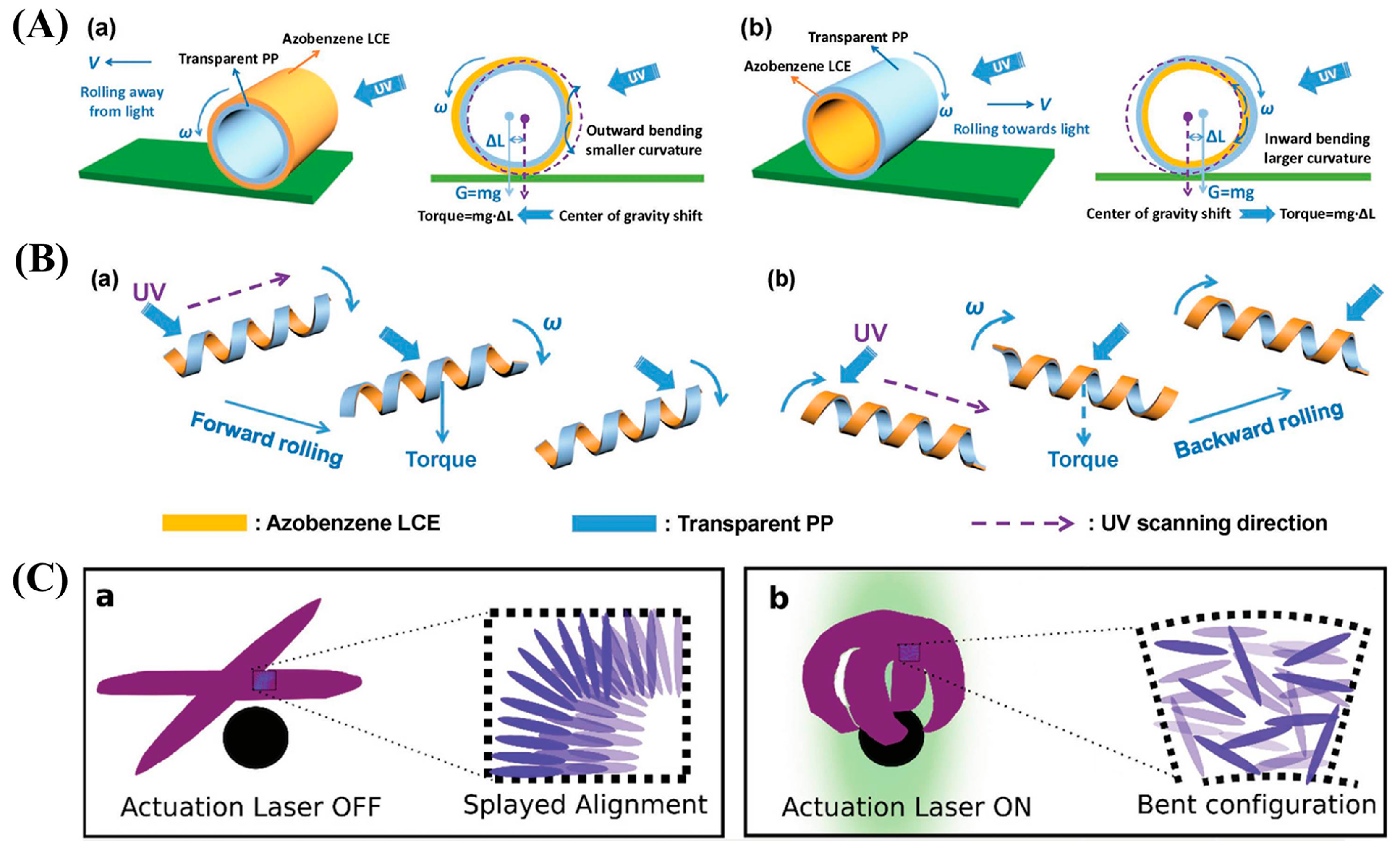

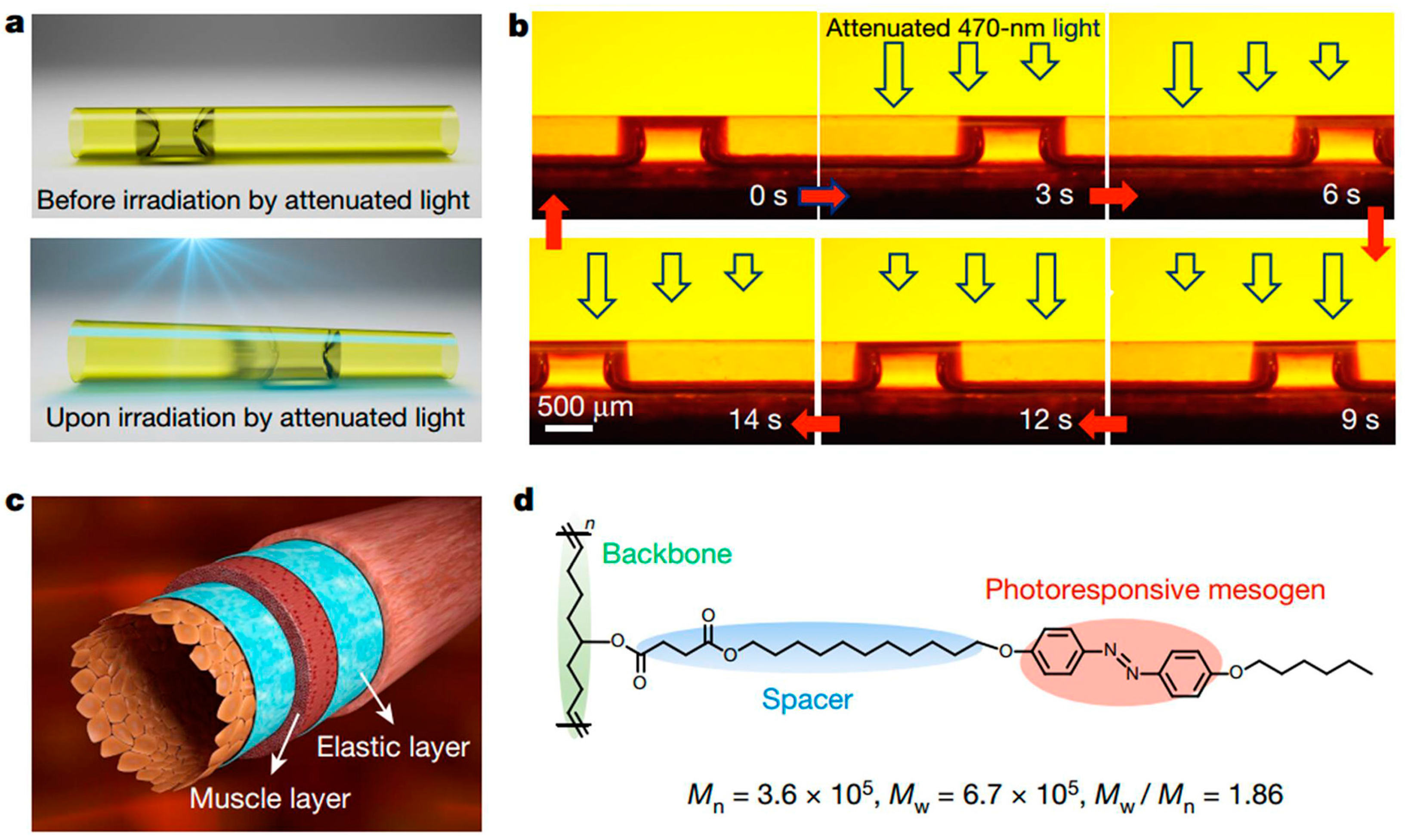

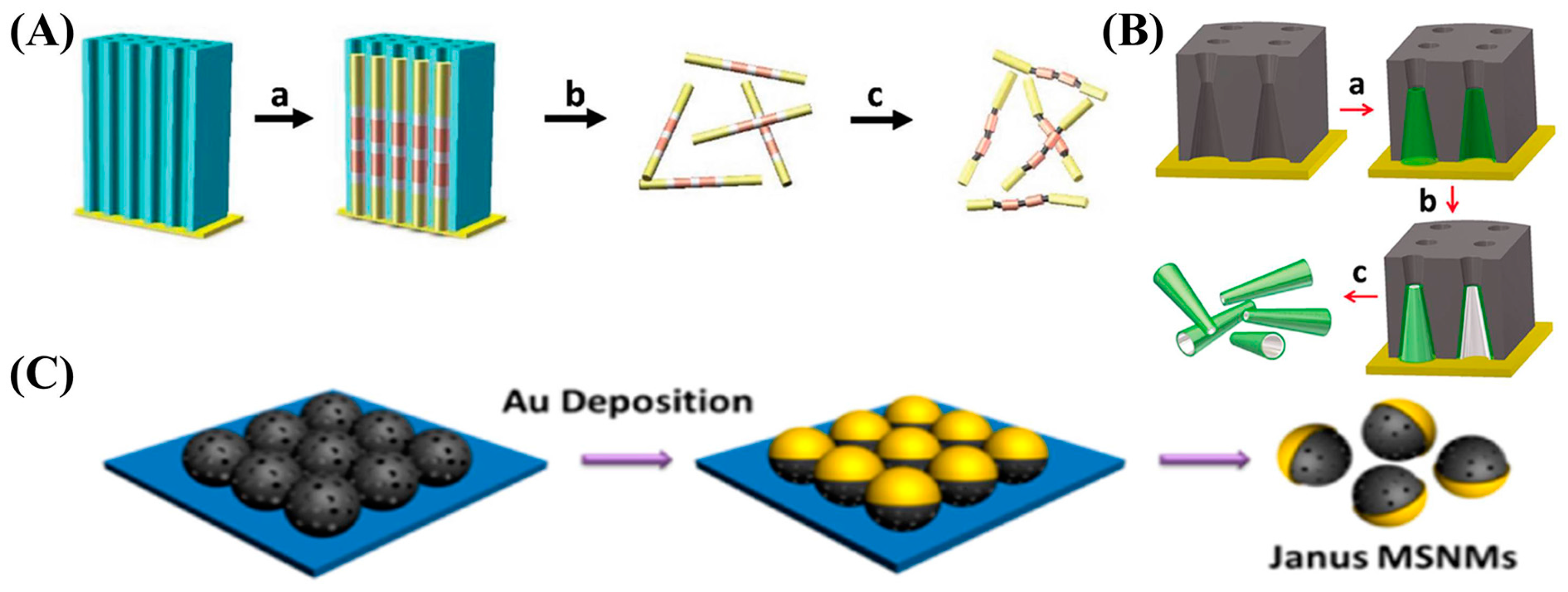

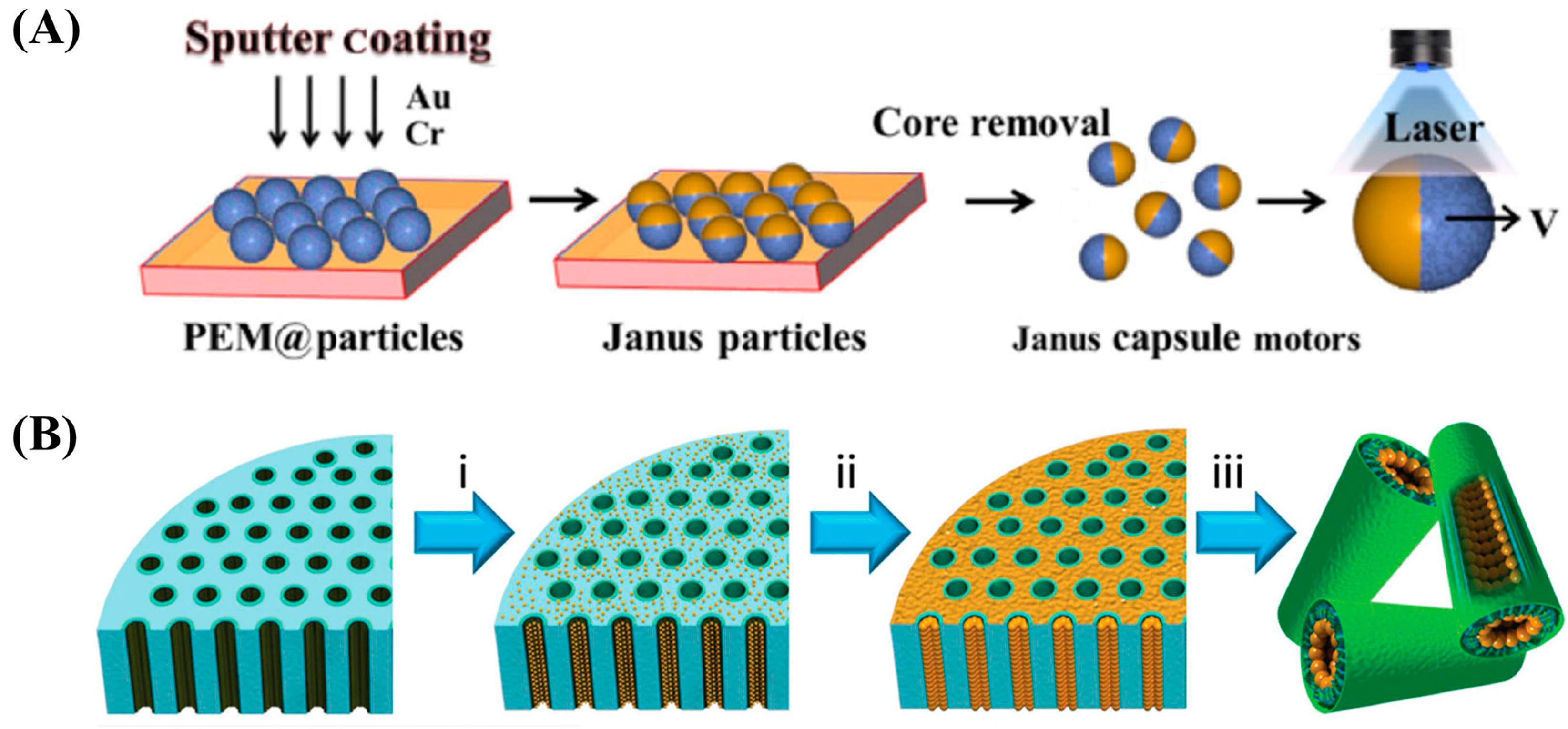

2. Fabrication of Light-Powered MNMs

2.1. Fabrication of Light-Powered MNMs Based on Photoactive Materials

2.2. Fabrication of Light-Powered MNMs with Different Geometries

3. Motion Manipulation of Light-Powered MNMs

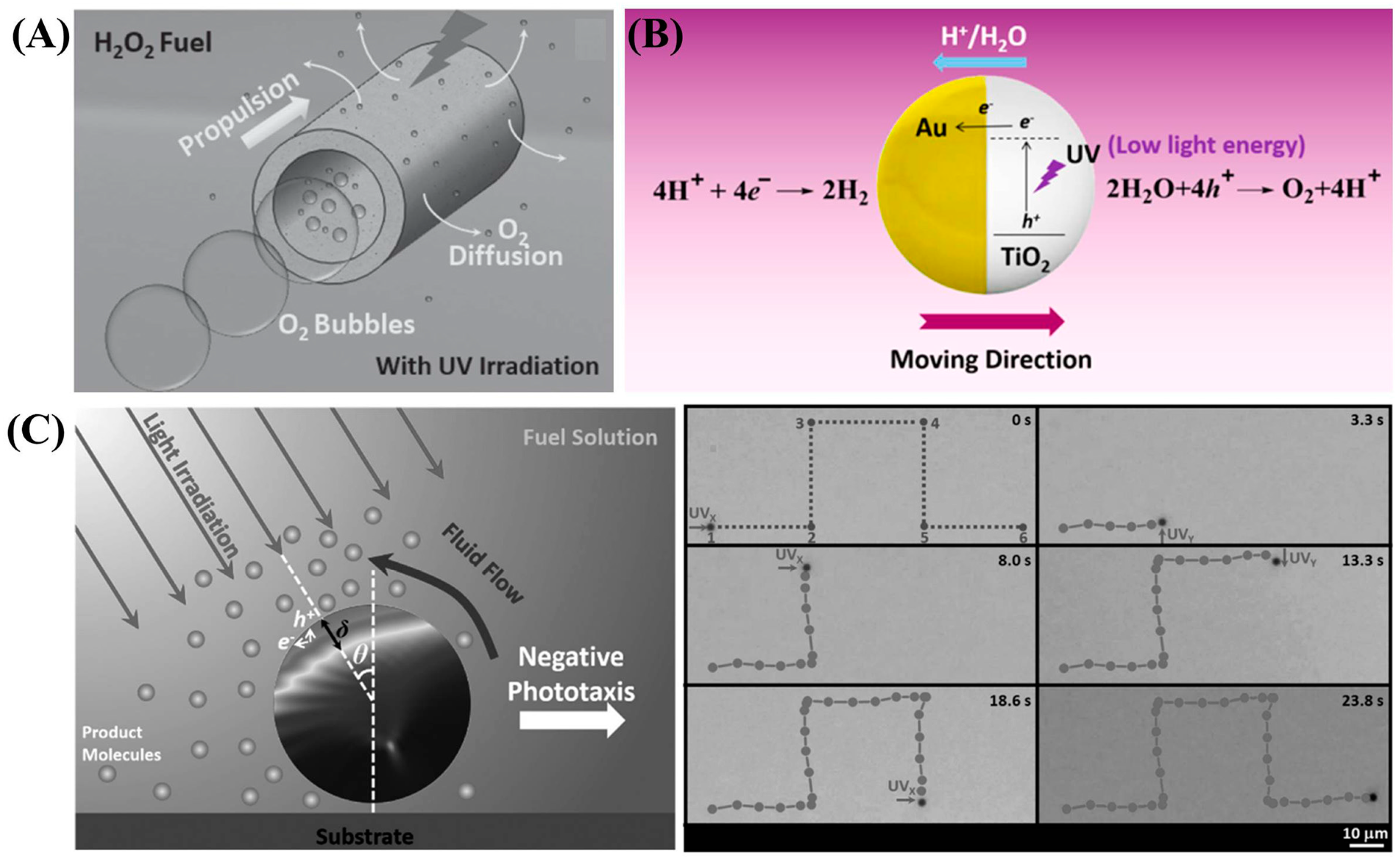

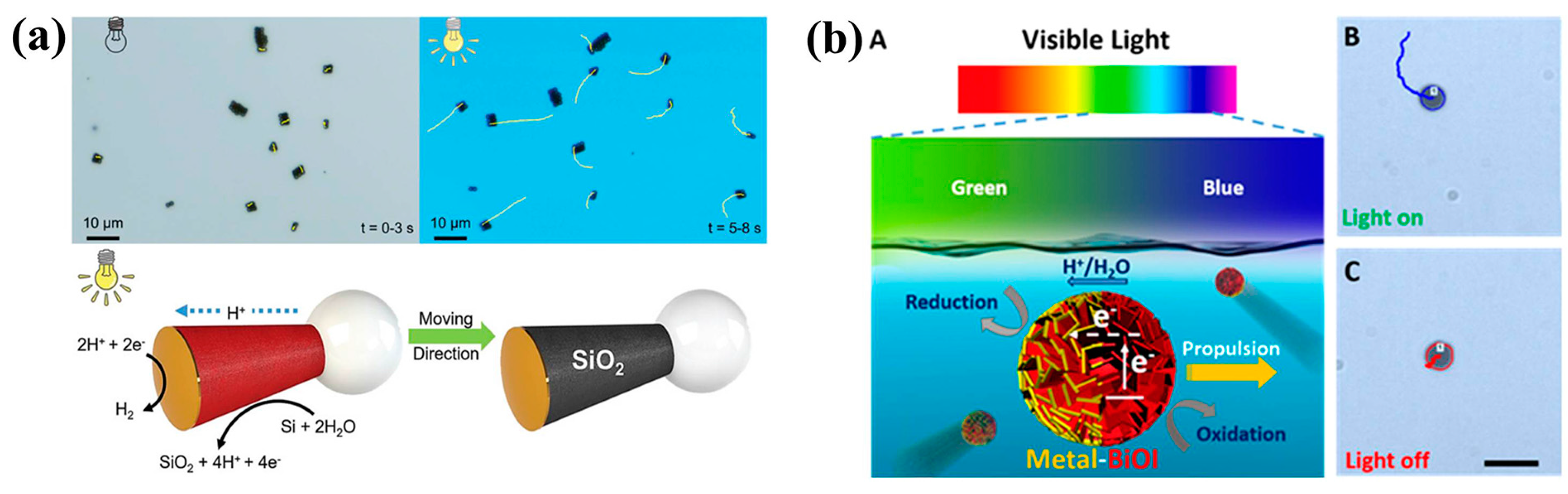

3.1. Motion of MNMs Manipulated by Different Light Sources

3.1.1. UV Light

3.1.2. Visible Light

3.1.3. NIR Light

3.1.4. Multi-Wavelength Light

3.2. Manipulation of Motion Behaviors

4. Application Prospects

5. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hess, H.; Bachand, G.D.; Vogel, V. Powering nanodevices with biomolecular motors. Chem. Eur. J. 2004, 10, 2110–2116. [Google Scholar] [CrossRef] [PubMed]

- Ozin, G.A.; Manners, I.; Fournier-Bidoz, S.; Arsenault, A. Dream nanomachines. Adv. Mater. 2005, 17, 3011–3018. [Google Scholar] [CrossRef]

- Wang, J. Can man-made nanomachines compete with nature biomotors? ACS Nano 2009, 3, 4–9. [Google Scholar] [CrossRef] [PubMed]

- Aranson, I.S. Microrobotics: Swimmers by design. Nature 2016, 531, 312–313. [Google Scholar] [CrossRef] [PubMed]

- Heuvel, M.G.; Dekker, C. Motor proteins at work for nanotechnology. Science 2007, 317, 333–336. [Google Scholar] [CrossRef] [PubMed]

- Palagi, S.; Mark, A.G.; Reigh, S.Y.; Melde, K.; Qiu, T.; Zeng, H.; Parmeggiani, C.; Martella, D.; Sanchez-Castillo, A.; Kapernaum, N.; et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 2016, 15, 647–653. [Google Scholar] [CrossRef] [PubMed]

- Guix, M.; Mayorga-Martinez, C.C.; Merkoci, A. Nano/micromotors in (bio)chemical science applications. Chem. Rev. 2014, 114, 6285–6322. [Google Scholar] [CrossRef] [PubMed]

- Mei, Y.; Solovev, A.A.; Sanchez, S.; Schmidt, O.G. Rolled-up nanotech on polymers: From basic perception to self-propelled catalytic microengines. Chem. Soc. Rev. 2011, 40, 2109–2119. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.T.; Ahmed, S.; Mallouk, T.E.; Sen, A. Small power: Autonomous nano- and micromotors propelled by self-generated gradients. Nano Today 2013, 8, 531–554. [Google Scholar] [CrossRef]

- Kim, K.; Guo, J.; Xu, X.; Fan, D.L. Recent progress on man-made inorganic nanomachines. Small 2015, 11, 4037–4057. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Wu, Z.; Wu, Y.; Xuan, M.; He, Q. Self-propelled micro/nanomotors based on controlled assembled architectures. Adv. Mater. 2016, 28, 1060–1072. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Lin, X.; Si, T.; He, Q. Recent progress on bioinspired self-propelled micro/nanomotors via controlled molecular self-assembly. Small 2016, 12, 3080–3093. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Wang, J. The environmental impact of micro/nanomachines: A review. ACS Nano 2014, 8, 3170–3180. [Google Scholar] [CrossRef] [PubMed]

- Guix, M.; Orozco, J.; Garcia, M.; Gao, W.; Sattayasamitsathit, S.; Merkoci, A.; Escarpa, A.; Wang, J. Superhydrophobic alkanethiol-coated microsubmarines for effective removal of oil. ACS Nano 2012, 6, 4445–4451. [Google Scholar] [CrossRef] [PubMed]

- Soler, L.; Sanchez, S. Catalytic nanomotors for environmental monitoring and water remediation. Nanoscale 2014, 6, 7175–7182. [Google Scholar] [CrossRef] [PubMed]

- Soler, L.; Magdanz, V.; Fomin, V.M.; Sanchez, S.; Schmidt, O.G. Self-propelled micromotors for cleaning polluted water. ACS Nano 2013, 7, 9611–9620. [Google Scholar] [CrossRef] [PubMed]

- Moo, J.G.; Pumera, M. Chemical energy powered nano/micro/macromotors and the environment. Chem. Eur. J. 2015, 21, 58–72. [Google Scholar] [CrossRef] [PubMed]

- Orozco, J.; Vilela, D.; Valdes-Ramirez, G.; Fedorak, Y.; Escarpa, A.; Vazquez-Duhalt, R.; Wang, J. Efficient biocatalytic degradation of pollutants by enzyme-releasing self-propelled motors. Chem. Eur. J. 2014, 20, 2866–2871. [Google Scholar] [CrossRef] [PubMed]

- Kagan, D.; Laocharoensuk, R.; Zimmerman, M.; Clawson, C.; Balasubramanian, S.; Kang, D.; Bishop, D.; Sattayasamitsathit, S.; Zhang, L.; Wang, J. Rapid delivery of drug carriers propelled and navigated by catalytic nanoshuttles. Small 2010, 6, 2741–2747. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Kagan, D.; Pak, O.S.; Clawson, C.; Campuzano, S.; Chuluun-Erdene, E.; Shipton, E.; Fullerton, E.E.; Zhang, L.; Lauga, E.; et al. Cargo-towing fuel-free magnetic nanoswimmers for targeted drug delivery. Small 2012, 8, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Wu, Y.; He, W.; Lin, X.; Sun, J.; He, Q. Self-propelled polymer-based multilayer nanorockets for transportation and drug release. Angew. Chem. Int. Ed. 2013, 52, 7000–7003. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Wang, J. Synthetic micro/nanomotors in drug delivery. Nanoscale 2014, 6, 10486–10494. [Google Scholar] [CrossRef] [PubMed]

- Mhanna, R.; Qiu, F.; Zhang, L.; Ding, Y.; Sugihara, K.; Zenobi-Wong, M.; Nelson, B.J. Artificial bacterial flagella for remote-controlled targeted single-cell drug delivery. Small 2014, 10, 1953–1957. [Google Scholar] [CrossRef] [PubMed]

- Patra, D.; Sengupta, S.; Duan, W.; Zhang, H.; Pavlick, R.; Sen, A. Intelligent, self-powered, drug delivery systems. Nanoscale 2013, 5, 1273–1283. [Google Scholar] [CrossRef] [PubMed]

- Laurell, T.; Petersson, F.; Nilsson, A. Chip integrated strategies for acoustic separation and manipulation of cells and particles. Chem. Soc. Rev. 2007, 36, 492–506. [Google Scholar] [CrossRef] [PubMed]

- Kuralay, F.; Sattayasamitsathit, S.; Gao, W.; Uygun, A.; Katzenberg, A.; Wang, J. Self-propelled carbohydrate-sensitive microtransporters with builtIn boronic acid recognition for isolating sugars and cells. J. Am. Chem. Soc. 2012, 134, 15217–15220. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Qiu, F.; Kim, S.; Ghanbari, A.; Moon, C.; Zhang, L.; Nelson, B.J.; Choi, H. Fabrication and characterization of magnetic microrobots for three-dimensional cell culture and targeted transportation. Adv. Mater. 2013, 25, 5863–5868. [Google Scholar] [CrossRef] [PubMed]

- Marx, V. Biophysics: Using sound to move cells. Nat. Methods 2014, 12, 41–44. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Li, P.; French, J.B.; Mao, Z.; Zhao, H.; Li, S.; Nama, N.; Fick, J.R.; Benkovic, S.J.; Huang, T.J. Controlling cell–cell interactions using surface acoustic waves. Proc. Natl. Acad. Sci. USA 2015, 112, 43–48. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, S.; Kagan, D.; Hu, C.M.; Campuzano, S.; Lobo-Castanon, M.J.; Lim, N.; Kang, D.Y.; Zimmerman, M.; Zhang, L.; Wang, J. Micromachine-enabled capture and isolation of cancer cells in complex media. Angew. Chem. Int. Ed. 2011, 50, 4161–4164. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gao, W. Nano/microscale motors: Biomedical opportunities and challenges. ACS Nano 2012, 6, 5745–5751. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Jannasch, A.; Albrecht, U.-R.; Hahn, K.; MiguelLópez, A.; Schäffer, E.; Sánchez, S. Enzyme-powered hollow mesoporous Janus nanomotors. Nano Lett. 2015, 15, 7043–7050. [Google Scholar] [CrossRef] [PubMed]

- Uygun, M.; Singh, V.V.; Kaufmann, K.; Uygun, D.A.; De Oliveira, S.D.; Wang, J. Micromotor-based biomimetic carbon dioxide sequestration: Towards mobile microscrubbers. Angew. Chem. Int. Ed. 2015, 54, 12900–12904. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.V.; Soto, F.; Kaufmann, K.; Wang, J. Micromotor-based energy generation. Angew. Chem. Int. Ed. 2015, 54, 6896–6899. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, J.; Ávila, B.E.-F.; Li, T.; Gao, W.; He, Q.; Zhang, L.; Wang, J. Water-powered cell-mimicking Janus micromotor. Adv. Funct. Mater. 2015, 26, 7497–7501. [Google Scholar] [CrossRef]

- Wezenberg, S.J.; Chen, K.-Y.; Feringa, B.L. Visible-light-driven photoisomerization and increased rotation speed of a molecular motor acting as a ligand in a ruthenium(II) complex. Angew. Chem. Int. Ed. 2015, 54, 11457–11461. [Google Scholar] [CrossRef] [PubMed]

- Rikken, R.S.; Nolte, R.J.; Maan, J.C.; Hest, J.C.; Wilson, D.A.; Christianen, P.C. Manipulation of micro- and nanostructure motion with magnetic fields. Soft Matter 2014, 10, 1295–1308. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, T.; Xu, T.; Kiristi, M.; Liu, W.; Wu, Z.; Wang, J. Magneto–acoustic hybrid nanomotor. Nano Lett. 2015, 15, 4814–4821. [Google Scholar] [CrossRef] [PubMed]

- Peyer, K.E.; Tottori, S.; Qiu, F.; Zhang, L.; Nelson, B.J. Magnetic helical micromachines. Chem. Eur. J. 2013, 19, 28–38. [Google Scholar] [CrossRef] [PubMed]

- Fischer, P.; Ghosh, A. Magnetically actuated propulsion at low Reynolds numbers: Towards nanoscale control. Nanoscale 2011, 3, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, N.; Hong, Y.; Sen, A.; Velegol, D. Magnetic enhancement of phototaxing catalytic motors. Langmuir 2010, 26, 6308–6313. [Google Scholar] [CrossRef] [PubMed]

- Campuzano, S.; Kagan, D.; Orozco, J.; Wang, J. Motion-driven sensing and biosensing using electrochemically propelled nanomotors. Analyst 2011, 136, 4621–4630. [Google Scholar] [CrossRef] [PubMed]

- Mou, F.; Kong, L.; Chen, C.; Chen, Z.; Xu, L.; Guan, J. Light-controlled propulsion, aggregation and separation of water-fuelled TiO2/Pt Janus submicromotors and their “on-the-fly” photocatalytic activities. Nanoscale 2016, 8, 4976–4983. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Soto, F.; Gao, W.; Garcia-Gradilla, V.; Li, J.; Zhang, X.; Wang, J. Ultrasound-modulated bubble propulsion of chemically powered microengines. J. Am. Chem. Soc. 2014, 136, 8552–8555. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Li, S.; Mair, L.; Ahmed, S.; Huang, T.J.; Mallouk, T.E. Acoustic propulsion of nanorod motors inside living cells. Angew. Chem. Int. Ed. 2014, 53, 3201–3204. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Soto, F.; Gao, W.; Dong, R.; Garcia-Gradilla, V.; Magana, E.; Zhang, X.; Wang, J. Reversible swarming and separation of self-propelled chemically powered nanomotors under acoustic fields. J. Am. Chem. Soc. 2015, 137, 2163–2166. [Google Scholar] [CrossRef] [PubMed]

- Balk, A.L.; Mair, L.O.; Mathai, P.P.; Patrone, P.N.; Wang, W.; Ahmed, S.; Mallouk, T.E.; Liddle, J.A.; Stavis, S.M. Kilohertz rotation of nanorods propelled by ultrasound, traced by microvortex advection of nanoparticles. ACS Nano 2014, 8, 8300–8309. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Gentekos, D.T.; Fink, C.A.; Mallouk, T.E. Self-assembly of nanorod motors into geometrically regular multimers and their propulsion by ultrasound. ACS Nano 2014, 8, 11053–11060. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Gradilla, V.; Sattayasamitsathit, S.; Soto, F.; Kuralay, F.; Yardimci, C.; Wiitala, D.; Galarnyk, M.; Wang, J. Ultrasound-propelled nanoporous gold wire for efficient drug loading and release. Small 2014, 10, 4154–4159. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Chiang, T.-Y.; Velegol, D.; Mallouk, T.E. Understanding the efficiency of autonomous nano- and microscale motors. J. Am. Chem. Soc. 2013, 135, 10557–10565. [Google Scholar] [CrossRef] [PubMed]

- Baraban, L.; Harazim, S.M.; Sanchez, S.; Schmidt, Q.G. Chemotactic behavior of catalytic motors in microfluidic channels. Angew. Chem. Int. Ed. 2013, 52, 5552–5556. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Feng, X.; Hennessy, C.; Wang, J. Organized self-assembly of Janus micromotors with hydrophobic hemispheres. J. Am. Chem. Soc. 2013, 135, 998–1001. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.-C.; Alarcón-Correa, M.; Miksch, C.; Hahn, K.; Gibbs, J.G.; Fischer, P. Self-propelling nanomotors in the presence of strong brownian forces. Nano Lett. 2014, 14, 2407–2412. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Wang, J. Water-driven micromotors. ACS Nano 2012, 6, 8432–8438. [Google Scholar] [CrossRef] [PubMed]

- Mei, Y.; Huang, G.; Solovev, A.A.; Ureña, E.B.; Mönch, I.; Ding, F.; Reindl, T.; Fu, R.K.Y.; Chu, P.K.; Schmidt, O.G. Versatile approach for integrative and functionalized tubes by strain engineering of nanomembranes on polymers. Adv. Mater. 2008, 20, 4085–4090. [Google Scholar] [CrossRef]

- Sanchez, S.; Solovev, A.A.; Mei, Y.; Schmidt, O.G. Dynamics of biocatalytic microengines mediated by variable friction control. J. Am. Chem. Soc. 2010, 132, 13144–13145. [Google Scholar] [CrossRef] [PubMed]

- Orozco, J.; Garcia-Gradilla, V.; D’Agostino, M.; Gao, W.; Cortes, A.; Wang, J. Artificial enzyme-powered microfish for water-quality testing. ACS Nano 2013, 7, 818–824. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Sattayasamitsathit, S.; Orozco, J.; Wang, J. Highly efficient catalytic microengines: Template electrosynthesis of polyaniline/platinum microtubes. J. Am. Chem. Soc. 2011, 133, 11862–11864. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Uygun, A.; Wang, J. Hydrogen-bubble-propelled zinc-based microrockets in strongly acidic media. J. Am. Chem. Soc. 2012, 134, 897–900. [Google Scholar] [CrossRef] [PubMed]

- Campuzano, S.; Orozco, J.; Kagan, D.; Guix, M.; Gao, W.; Sattayasamitsathit, S.; Claussen, J.C.; Merkoci, A.; Wang, J. Bacterial isolation by lectin-modified microengines. Nano Lett. 2012, 12, 396–401. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Dong, R.F. Catalytic iridium-based Janus micromotors powered by ultralow levels of chemical fuels. J. Am. Chem. Soc. 2014, 136, 2276–2279. [Google Scholar] [CrossRef] [PubMed]

- Wong, F.; Sen, A. Progress toward light-harvesting self-electrophoretic motors: Highly efficient bimetallic nanomotors and micropumps in halogen media. ACS Nano 2016, 10, 7172–7179. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, S.; Soler, L.; Katuri, J. Chemically powered micro- and nanomotors. Angew. Chem. Int. Ed. 2015, 54, 1414–1444. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Mou, F.; Gong, H.; Luo, M.; Guan, J. Light-driven micro/nanomotors: From fundamentals to applications. Chem. Soc. Rev. 2017, 46, 6905–6926. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Xu, L.; Zhang, X. Ultrasound propulsion of micro/nanomotors. Appl. Mater. Today 2017, 9, 493–503. [Google Scholar] [CrossRef]

- Xu, T.; Gao, W.; Xu, L.; Zhang, X.; Wang, S. Fuel-free synthetic micro-/nanomachines. Adv. Mater. 2017, 29, 1603250. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Peng, F.; Wilson, D.A. Motion manipulation of micro- and nanomotors. Adv. Mater. 2017, 29, 1701970. [Google Scholar] [CrossRef] [PubMed]

- You, M.; Huang, F.; Chen, Z.; Wang, R.-W.; Tan, W. Building a nanostructure with reversible motions using photonic energy. ACS Nano 2012, 6, 7935–7941. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Sreelatha, S.; Hou, R.; Efremov, A.; Liu, R.; Maarel, J.R.C.; Wang, Z. Bipedal nanowalker by pure physical mechanisms. Phys. Rev. Lett. 2012, 109, 238104. [Google Scholar] [CrossRef] [PubMed]

- Loh, I.Y.; Cheng, J.; Tee, S.R.; Efremov, A.; Wang, Z. From bistate molecular switches to self-directed track-walking nanomotors. ACS Nano 2014, 8, 10293–10304. [Google Scholar] [CrossRef] [PubMed]

- Yeo, Q.Y.; Loh, I.Y.; Tee, S.R.; Chiang, Y.H.; Cheng, J.; Liu, M.H.; Wang, Z.S. A DNA bipedal nanowalker with a piston-like expulsion stroke. Nanoscale 2017, 9, 12142–12149. [Google Scholar] [CrossRef] [PubMed]

- Baigl, D. Photo-actuation of liquids for light-driven microfluidics: State of the art and perspectives. Lab Chip 2012, 12, 3637–3653. [Google Scholar] [CrossRef] [PubMed]

- Diguet, A.; Guillermic, R.-M.; Magome, N.; Saint-Jalmes, A.; Chen, Y.; Yoshikawa, K.; Baigl, D. Photomanipulation of a droplet by the chromocapillary effect. Angew. Chem. Int. Ed. 2009, 48, 9281–9284. [Google Scholar] [CrossRef] [PubMed]

- Paxton, W.F.; Kistler, K.C.; Olmeda, C.C.; Sen, A.; Angelo, S.K.; Cao, Y.; Mallouk, T.E.; Lammert, P.E.; Cresp, V.H. Catalytic nanomotors: Autonomous movement of striped nanorods. J. Am. Chem. Soc. 2004, 126, 13424–13431. [Google Scholar] [CrossRef] [PubMed]

- Ismagilov, R.F.; Schwartz, A.; Bowden, N.; Whitesides, G.M. Autonomous movement and self-assembly. Angew. Chem. Int. Ed. 2002, 41, 652–654. [Google Scholar] [CrossRef]

- Mourran, A.; Zhang, H.; Vinokur, R.; Möller, M. Soft microrobots employing nonequilibrium actuation via plasmonic heating. Adv. Mater. 2017, 29, 1604825. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Guo, S.; Tong, X.; Xia, H.; Zhao, Y. Tunable photocontrolled motions using stored strain energy in malleable azobenzene liquid crystalline polymer actuators. Adv. Mater. 2017, 29, 1606467. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Liu, Y.; Wei, J.; Chen, E.; Qin, L.; Yu, Y. Photocontrol of fluid slugs in liquid crystal polymer microactuators. Nature 2016, 537, 179–184. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Zhang, Q.; Gao, W.; Pei, A.; Ren, B. Highly efficient light-driven TiO2−Au Janus micromotors. ACS Nano 2016, 10, 839–844. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Hu, Y.; Wu, Y.; Gao, W.; Ren, B.; Wang, Q.; Cai, Y. Visible-light-driven BiOI-based Janus micromotor in pure water. J. Am. Chem. Soc. 2017, 139, 1722–1725. [Google Scholar] [CrossRef] [PubMed]

- Xuan, M.; Wu, Z.; Shao, J.; Dai, L.; Si, T.; He, Q. Near infrared light-powered Janus mesoporous silica nanoparticle motors. J. Am. Chem. Soc. 2016, 138, 6492–6497. [Google Scholar] [CrossRef] [PubMed]

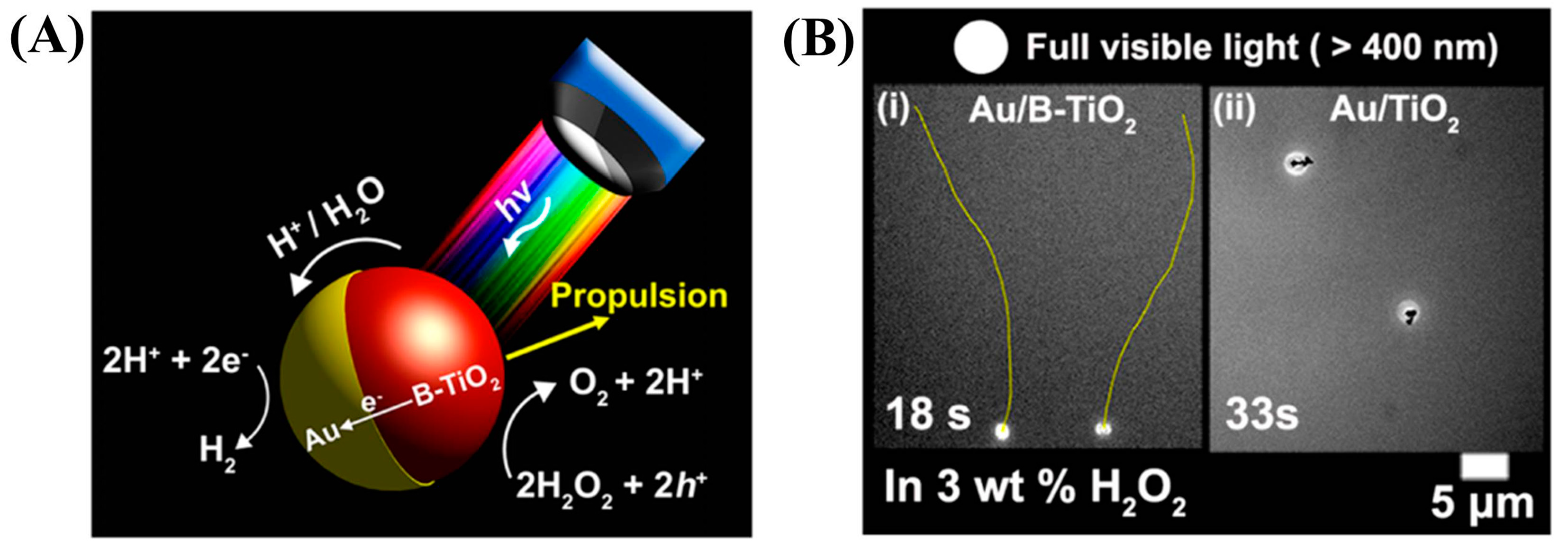

- Jang, B.; Hong, A.; Kang, H.E.; Alcantara, C.; Charreyron, S.; Mushtaq, F.; Pellicer, E.; Büchel, R.; Sort, J.; Lee, S.S.; et al. Multiwavelength light-responsive Au/B-TiO2 Janus micromotors. ACS Nano 2017, 11, 6146–6154. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.; Wang, J.; Xiong, Z.; Zhan, X.; Dai, W.; Li, C.-C.; Feng, S.-P.; Tang, J. Programmable artificial phototactic microswimmer. Nat. Nanotechnol. 2016, 11, 1087–1092. [Google Scholar] [CrossRef] [PubMed]

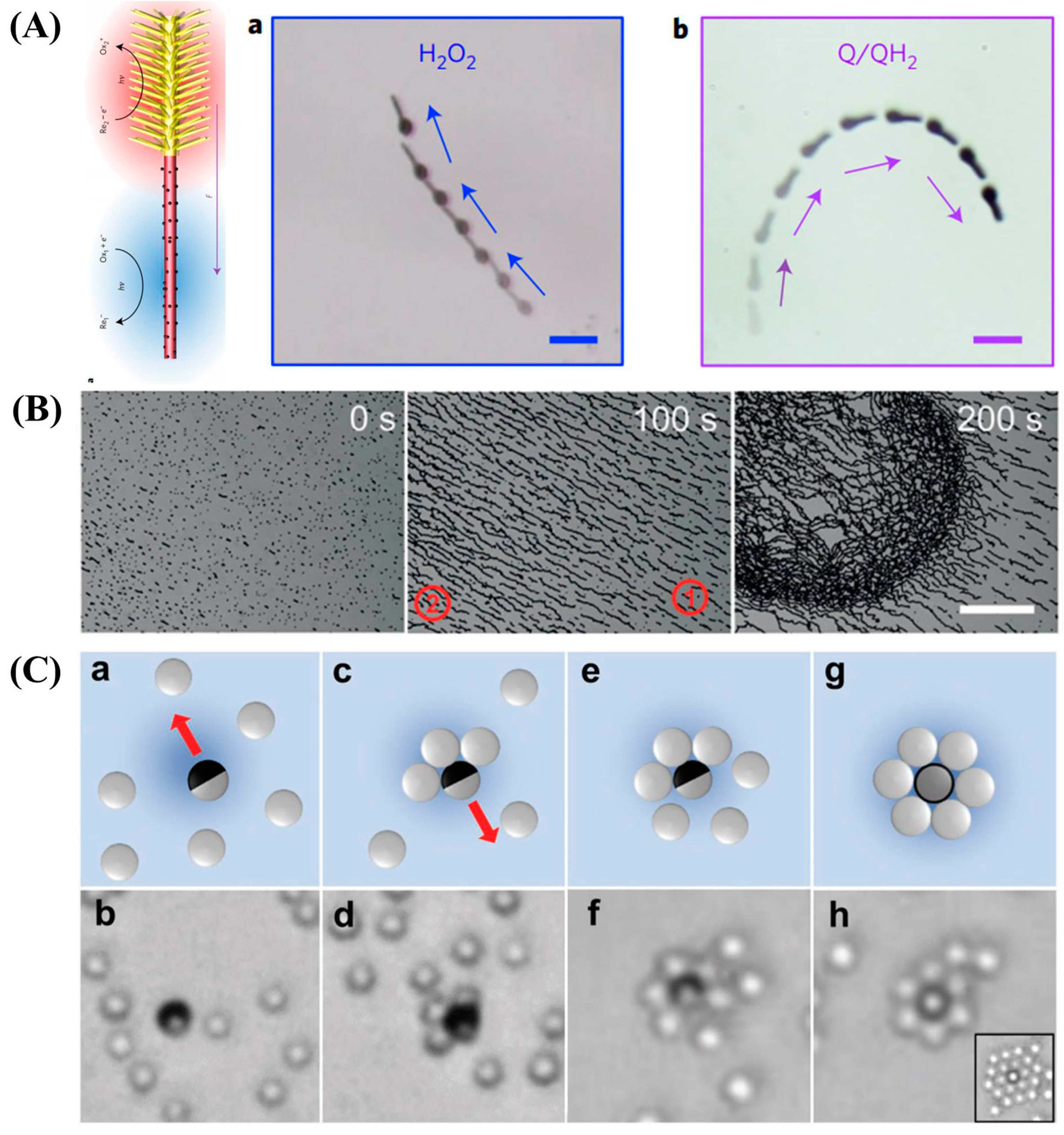

- Lin, Z.; Si, T.; Wu, Z.; Gao, C.; Lin, X.; He, Q. Light-activated active colloid ribbons. Angew. Chem. Int. Ed. 2017, 56, 13517–13520. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Cui, H.; Sun, B.; Wang, J.; Zhao, Q.; Xia, K.; Wu, T.; Humayun, M.S. Photothermally triggered shape-adaptable 3D flexible electronics. Adv. Mater. Technol. 2017, 2, 1700120. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Chen, P.; Fang, X.; Sun, X.; Jiang, Y.; Weng, W.; Wang, B.; Peng, H. Tunable photothermal actuators based on a pre-programmed aligned nanostructure. J. Am. Chem. Soc. 2016, 138, 225–230. [Google Scholar] [CrossRef] [PubMed]

- Martella, D.; Nocentini, S.; Nuzhdin, D.; Parmeggiani, C.; Wiersma, D.S. Photonic microhand with autonomous action. Adv. Mater. 2017, 29, 1704047. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Li, J.; Zhang, H.; Chang, X.; Song, W.; Hu, Y.; Shao, G.; Sandraz, E.; Zhang, G.; Li, L.; et al. Magnetically propelled fish-like nanoswimmers. Small 2016, 12, 6098–6105. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.J.; Lin, X.K.; Wu, Z.G.; Mohwald, H.; He, Q. Self-propelled polymer multilayer Janus capsules for effective drug delivery and light-triggered release. ACS Appl. Mater. Interfaces 2014, 6, 10476–10481. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Si, T.; Shao, J.; Wu, Z.; He, Q. Near-infrared light-driven Janus capsule motors: Fabrication, propulsion, and simulation. Nano Res. 2016, 9, 3747–3756. [Google Scholar] [CrossRef]

- Wu, Z.; Lin, X.; Wu, Y.; Si, T.; Sun, J.; He, Q. Near-infrared light-triggered“on/off” motion of polymer multilayer rockets. ACS Nano 2014, 8, 6097–6105. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Si, T.; Gao, W.; Lin, X.; Wang, J.; He, Q. Superfast near-infrared light-driven polymer multilayer rockets. Small 2016, 12, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.G.; Lin, X.K.; Zou, X.; Sun, J.M.; He, Q. Biodegradable protein-based rockets for drug transportation and light-triggered release. ACS Appl. Mater. Interfaces 2015, 7, 250–255. [Google Scholar] [CrossRef] [PubMed]

- Rao, Q.; Si, T.; Wu, Z.; Xuan, M.; He, Q. A light-activated explosive micropropeller. Sci. Rep. 2017, 7, 4621. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, T.; Shen, H.; Liu, W.; Wang, S.; Liu, K.; Zhang, J.; Yang, B. Ag nanoparticle/polymer composite barcode nanorods. Nano Res. 2015, 8, 2871–2880. [Google Scholar] [CrossRef]

- Chen, H.; Mu, S.; Fang, L.; Shen, H.; Zhang, J.; Yang, B. Polymer-assisted fabrication of gold nanoring arrays. Nano Res. 2017, 10, 3346–3357. [Google Scholar] [CrossRef]

- Gomez-Solano, J.R.; Blokhuis, A.; Bechinger, C. Dynamics of self-propelled Janus particles in viscoelastic fluids. Phys. Rev. Lett. 2016, 116, 138301. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.-R.; Yoshinaga, N.; Sano, M. Active motion of a Janus particle by self-thermophoresis in a defocused laser beam. Phys. Rev.Lett. 2010, 105, 268302. [Google Scholar] [CrossRef] [PubMed]

- Qian, B.; Montiel, D.; Bregulla, A.; Cichosb, F.; Yang, H. Harnessing thermal fluctuations for purposeful activities: The manipulation of single micro-swimmers by adaptive photon nudging. Chem. Sci. 2013, 4, 1420–1429. [Google Scholar] [CrossRef]

- Mou, F.; Li, Y.; Chen, C.; Li, W.; Yin, Y.; Ma, H.; Guan, J. Single-component TiO2 tubular microengines with motion controlled by light-induced bubbles. Small 2015, 11, 2564–2570. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Mou, F.; Xu, L.; Wang, S.; Guan, J.; Feng, Z.; Wang, Q.; Kong, L.; Li, W.; Wang, J.; et al. Light-steered isotropic semiconductor micromotors. Adv. Mater. 2017, 29, 1603374. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Li, Y.C.; Xu, P.; Ren, L.; Zhang, G.; Mallouk, T.E.; Li, L. Visible-light driven Si–Au micromotors in water and organic solvents. Nanoscale 2017, 9, 11434–11438. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiong, Z.; Zhan, X.; Dai, B.; Zheng, J.; Liu, J.; Tang, J. A silicon nanowire as a spectrally tunable light-driven nanomotor. Adv. Mater. 2017, 29, 1701451. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Li, J.; Morozov, K.I.; Wu, Z.; Xu, T.; Rozen, I.; Leshansky, A.M.; Li, L.; Wang, J. Highly efficient freestyle magnetic nanoswimmer. Nano Lett. 2017, 17, 5092–5098. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Li, J.; Leong, Y.J.; Rozen, I.; Qu, X.; Dong, R.; Wu, Z.; Gao, W.; Chung, P.H.; Wang, J.; et al. 3D-printed artificial microfish. Adv. Mater. 2015, 27, 4411–4417. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.P.; Choudhury, U.; Fischer, P.; Mark, A.G. Non-equilibrium assembly of light-activated colloidal mixtures. Adv. Mater. 2017, 29, 1701328. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Wang, J.; Cui, H.; Zhao, Q.; Chen, H.; He, L.; Wang, Y. Breath-taking patterns: Discontinuous hydrophilic regions for photonic crystal beads assembly and patterns revisualization. ACS Appl. Mater. Interfaces 2017, 9, 38117–38124. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Lei, N.-Y.; Hu, P.; Zhang, L.; Ong, D.H.-C.; Ge, X.; Zhang, Z.; Lam, M.H.-W. In vivo imaging of the morphology and changes in pH along the gastrointestinal tract of Japanese medaka by photonic band-gap hydrogel microspheres. Anal. Chim. Acta 2013, 787, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Naumov, P.; Du, X.; Hu, Z.; Wang, J. Vapomechanically responsive motion of microchannel programmed actuators. Adv. Mater. 2017, 29, 1702231. [Google Scholar] [CrossRef] [PubMed]

| Geometries of MNMs | Light Source | Driving Mechanism | Motion Behavior | References | |

|---|---|---|---|---|---|

| 1 | Hydrogel ribbon | Near-Infrared light | Photothermal effect | Translational motion | [76] |

| 2 | Wheel and spring-like ribbon | Ultraviolet light | Photoisomerization of azobenzene and strain energy | Controlled direction and speed | [77] |

| 3 | Tubular liquid crystal polymer | Blue light | Capillary forces arising from photodeformation | Controllable velocity and direction | [78] |

| 4 | TiO2-Au Janus micromotor | Ultraviolet light | Self-electrophoresis | 25 body length/s | [79] |

| 5 | BiOI-metal Janus motor | Visible light | Self-electrophoresis | 1.62 μm/s in pure water | [80] |

| 6 | Polymer multilayer rockets | Near-Infrared light | Thermophoretic force | High speed of 160 μm/s | [81] |

| 7 | Au/B-TiO2 Janus micromotor | Multiple light wavelengths | Self-electrophoresis | Maximus speed in H2O2: 30.1 μm/s | [82] |

| 8 | Nanotree | Ultraviolet light | Self-electrophoresis | Positive and negative phototaxis behaviors | [83] |

| 9 | Peanut-shaped colloid | Blue light | Diffusion-osmotic flow | Phototactic behavior | [84] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Zhao, Q.; Du, X. Light-Powered Micro/Nanomotors. Micromachines 2018, 9, 41. https://doi.org/10.3390/mi9020041

Chen H, Zhao Q, Du X. Light-Powered Micro/Nanomotors. Micromachines. 2018; 9(2):41. https://doi.org/10.3390/mi9020041

Chicago/Turabian StyleChen, Hongxu, Qilong Zhao, and Xuemin Du. 2018. "Light-Powered Micro/Nanomotors" Micromachines 9, no. 2: 41. https://doi.org/10.3390/mi9020041